Wind Crest CTI304D User Manual

INSTALLATION INSTRUCTIONS

ELECTRIC COOKTOP MODELS: CTI304D, CTI365D

IMPORTANT: Save these instruction for Local Electrical Inspector’s use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instruction for future reference.

READ AND SAVE THESE INSTRUCTIONS

Before beginning, please read these instruction completely and carefully.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use This Unit Only In The Manner Intended By The Manufacturer. If You Have Any Questions, Contact

The Manufacturer.

2. Before Installing Or Servicing Unit, Switch Power Off At Service Panel And Lock Service Disconnecting

Means To Prevent Power From Being Switched On Accidentally. When The Service Disconnecting Means

Cannot Be Locked, Securely Fasten a Prominent Warning Device, Such As A Tag, To The Service Panel.

POWER SUPPLY – Power supply is dual rated: 240 VAC /208 VAC, 3-wire, 60 Hz, 50Amp circuit breaker

required for CTI365D Models and 30 Amp circuit breaker for CTI304D Models.

JUNCTION BOX – Plan the installation of the unit so that the location of the junction box is within three (3)

feet of the center bottom of the cooktop. The junction box must be accessible from the

front of the unit. See FIG – 4.

CABINET PREPARATION AND CLEARANCE – Be sure your appliance is properly installed and

grounded by a qualified technician.

To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a

range hood that projects horizontally a minimum of 5 inches beyond the bottom of the cabinets.

Page 1 of 8 11067.00 Rev B

COOKTOP INSTALLATION

WARNING – DISCONNECT POWER BEFORE INSTALLING COOKTOP.

FOAM TAPE – A foam tape is provided to seal the cooktop edges to the countertop. Turn the cooktop upside

down (USE A TOWEL OR TABLE CLOTH BETWEEN COOKTOP AND SUPPORT SURFACE) and apply the

tape to bottom side edges of metal frame. The tape should be approximately 1/16 inch from the edge of the Glass

& Rear Extrusion FIG – 2.

Fastening Cooktop – Fasten the two hold down straps with screws supplied see (fig -3). Install the cooktop in the

counter top cutout, Center the cooktop in opening, and secure hold down straps to cabinet side with (2) wood

screws.

ELECTRICAL CONNECTION

Attach flexible conduit, four (4) foot cable, located at center rear of cooktop bottom, to junction box.

Connect cooktop lead wires to junction box supply wires, in proper phase: black to black (L1), red to red (L2),

and green wire to ground. No white wire connection is required. CAUTION: You must shield white power

supply wire if it is installed in the J-Box. This will result in compliance with the National Electrical Code.

Location of Data Plate bottom of cooktop. See FIG – 2.

START UP TEST

Remove all items from cooktop

Clean cooktop with Windex or clean damp cloth.

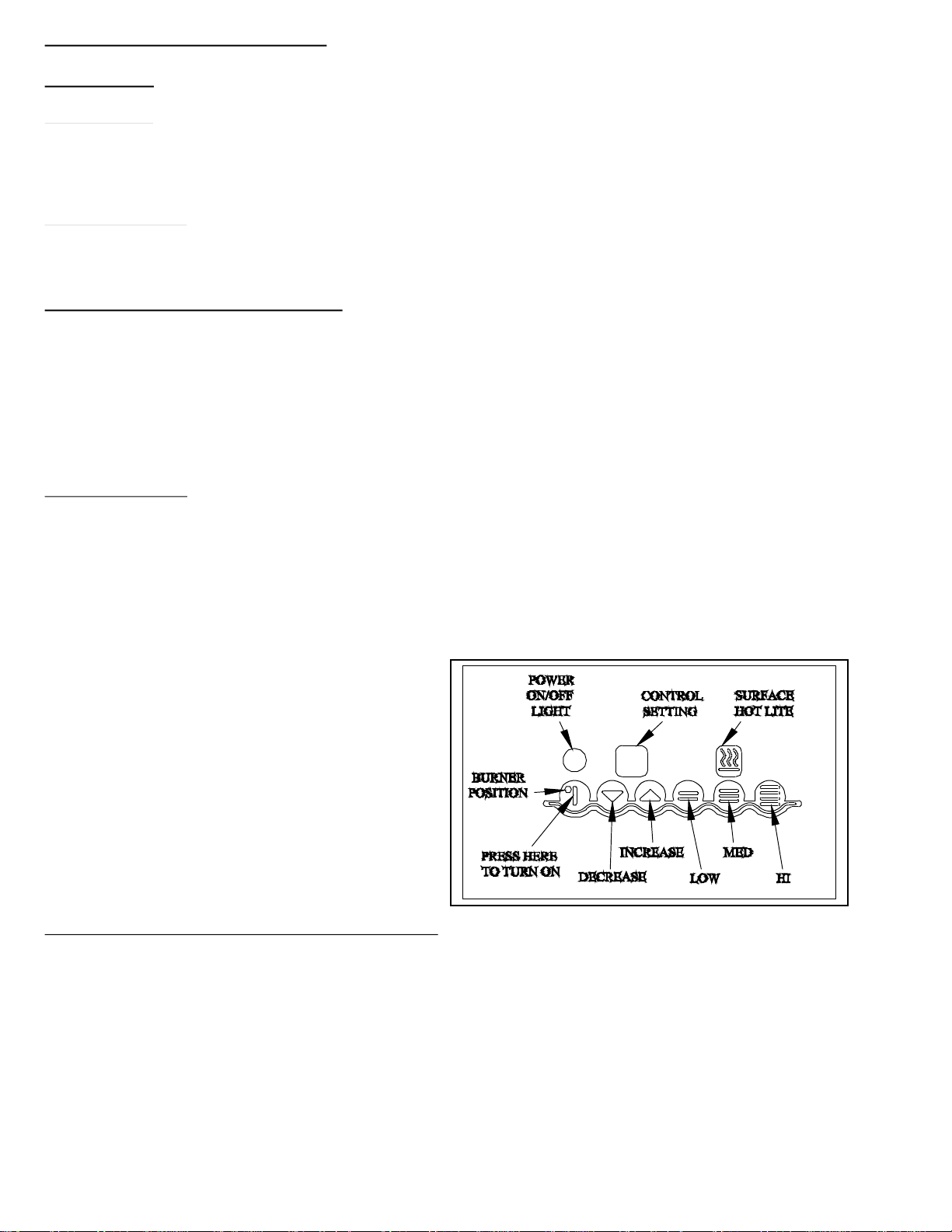

Turn power on at service panel. The controls will automatically cycle on and then turn off.

Turn Element on to check unit operation. Note: You must use a pot that attracts a magnet on pan bottom to

test operation. Put a small amount of water in pot to

prevent damaging the pot.

Press HI, then MED and LOW

Increase setting then Decrease

Turn controls off after checking operation.

CABINET PREPARATION AND CLEARANCE – Be sure your appliance is properly installed and grounded

by a qualified technician.

To eliminate the risk of burns or fire by reaching over heated cooking utensils, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a

range hood that projects horizontally a minimum of 5 inches beyond the bottom of the cabinets.

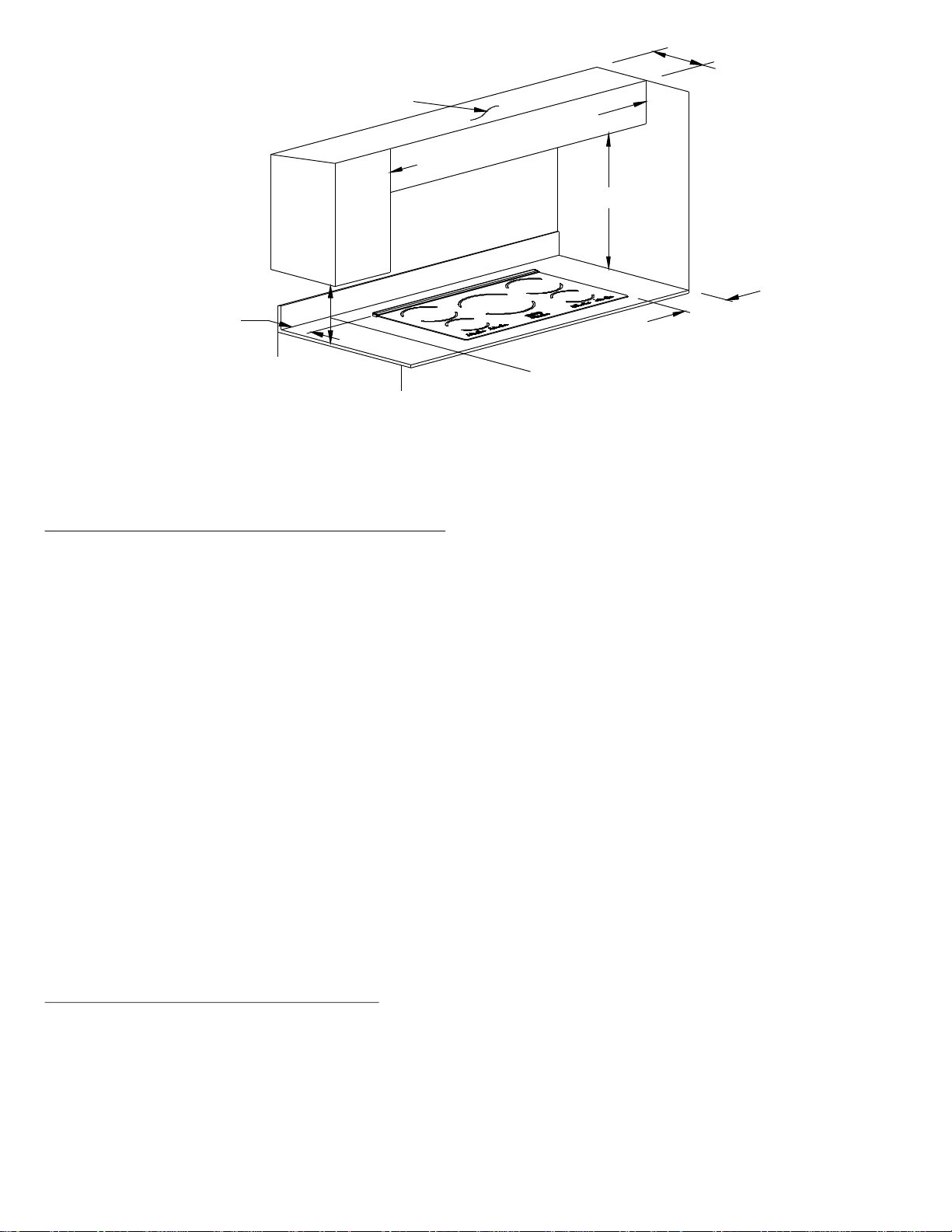

NOTE: Plan the installation so that the electrical connection is accessible from the front of the cabinet (see FIG-4),

and all of the following minimum dimensions are provided.

Page 2 of 8 11067.00 Rev B

CABINET

MINIMUM CABINET WIDTH

= COOKTOP WIDTH

MAXIMUM

DEPTH = 13"

MINIMUM CLEARANCE

FROM BACK OF EXTRUSION

TO BACKSPLASH = 2"

18" MINIMUM

FROM COUNTER

TOP FOR

COMBUSTIBLE

SURFACES

EXTENDING

BEYOUND WIDTH

OF COOKTOP

A

MINIMUM

SIDE WALL

CLEARANCE

= 1"

CLEARANCE TO COMBUSTIBLE SURFACES – A=30 inches minimum clearance between the countertop

and the bottom of an unprotected wood or metal cabinet.

A = 30 inches minimum clearance between the top of the cooking surface and the bottom of an unprotected wood

or metal cabinet or A = 24 inches minimum when the bottom of wood or metal cabinet is protected by not less than

1/4 inch thick flame retardant material covered with not less than #28 gage sheet steel, .015 inch thick stainless

steel, .024 inch thick aluminum, or .020 inch thick copper.

Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED

MINERAL AND FIBER BOARDS.

SURFACE BURNING CHARACTERISTICS

This mark is followed by the flame spread and smoke ratings. These designations are shown as “FHC (Flame

Spread)/(Smoke Developed)”. Material with “0” flame spread rating are flame retardant. Local codes may allow

other flame spread ratings.

The minimum horizontal clearance from the sides and back of the cooktop to the adjacent vertical combustible

walls is 1 inch on sides and 2 inches on back.

COUNTERTOP CUTOUT DIMENSION – Always consult the countertop manufacturer for specific installation

instruction or requirements. Note: Counter top opening must

accept square corners of cooktop.

Page 3 of 8 11067.00 Rev B

Loading...

Loading...