Wincor Nixdorf TH250 Programmer's Manual

TH250

Thermal Printer

Programmer’s Guide (January 2016)

Contents

About this Guide ........................................................................................................................... 1

How to use this guide .................................................................................................................... 1

Where to find the basics ................................................................................................................ 1

Where to find advanced technical information .............................................................................. 1

Support ....................................................................................................................................... 1

Diagnostics and Configuration ...................................................................................................... 2

Start-up Diagnostics ................................................................................................................... 2

Runtime Diagnostics ...................................................................................................................... 3

Remote Diagnostics ....................................................................................................................... 3

Accessing the remote diagnostic tallies ...................................................................................... 4

Indicators ...................................................................................................................................... 5

Error conditions and correcting them......................................................................................... 5

Communication of printer status to the host application ........................................................... 5

Printer configuration ..................................................................................................................... 6

Configuring the printer ............................................................................................................... 7

Communication interface settings.............................................................................................. 8

Diagnostics modes ..................................................................................................................... 8

Enable or disable data scope mode ............................................................................................ 9

Enable or disable receipt test mode ........................................................................................... 9

Electronic Journal Datascope Diagnostic .................................................................................. 10

Printer emulations ....................................................................................................................... 10

Printer settings and functions .................................................................................................. 10

Programming the Printer ............................................................................................................ 13

Overview of commands ............................................................................................................... 13

Comparison to A793 .................................................................................................................... 13

Two-color commands (comparison TH210 to TH250) .................................................................. 15

Character appearance ................................................................................................................. 16

Width specifications .................................................................................................................... 16

Print zones................................................................................................................................... 16

Print zones for 80mm paper ..................................................................................................... 16

Emulation modes ......................................................................................................................... 18

Print setup in emulation modes ............................................................................................... 18

Programming Commands ........................................................................................................... 19

Commands listed by function ...................................................................................................... 19

Command conventions ................................................................................................................ 28

Command descriptions ................................................................................................................ 28

Printer actions ......................................................................................................................... 28

Print and paper feed ................................................................................................................ 36

Text characteristics commands ................................................................................................ 45

Double-byte fonts .................................................................................................................... 61

Graphics ................................................................................................................................... 64

Status .......................................................................................................................................... 78

Status command introduction ..................................................................................................... 78

Batch mode.............................................................................................................................. 78

Real time commands................................................................................................................ 81

Rules for using real time commands ........................................................................................ 82

Automatic Status Back ............................................................................................................. 87

Unsolicited status mode........................................................................................................... 89

Bar codes .................................................................................................................................... 93

QR code Overview ....................................................................................................................... 93

Select model for QR code ......................................................................................................... 93

Set size for QR code module .................................................................................................... 93

Set data parsing mode for QR Code ......................................................................................... 94

Select error correction level for QR Code ................................................................................. 94

Store symbol data for QR Code ................................................................................................ 94

Print symbol data for QR code ................................................................................................. 95

Select printing position of HRI characters ................................................................................. 96

Select pitch of HRI characters ................................................................................................... 96

Select bar code height .............................................................................................................. 97

Print bar code .......................................................................................................................... 97

Print multiple barcodes ............................................................................................................ 99

Print GS1 DataBar, null terminated .........................................................................................100

Print GS1 DataBar, data length specified .................................................................................100

Set GS1 DataBar parameters ...................................................................................................101

Select PDF 417 parameters .....................................................................................................101

Select bar code width..............................................................................................................103

Set DataMatrix Parameters .....................................................................................................103

Set DataMatrix Module size ....................................................................................................104

Store DataMatrix data in symbol storage area ........................................................................105

Print DataMatrix symbol data in the symbol storage area .......................................................105

Page mode ................................................................................................................................ 107

Print and return to standard mode ............................................................................................ 107

Cancel print data in page mode ................................................................................................. 107

Print data in page mode ............................................................................................................ 108

Select page mode ...................................................................................................................... 108

Select standard mode ................................................................................................................ 109

Select print direction in page mode ........................................................................................... 109

Select print area in page mode .................................................................................................. 110

Set absolute vertical print position in page mode ...................................................................... 111

Set relative vertical print position in page mode ........................................................................ 112

Macros ...................................................................................................................................... 113

Select or cancel macro definition ............................................................................................... 113

Execute macro ........................................................................................................................... 113

User data storage ...................................................................................................................... 115

Write to user data storage ......................................................................................................... 115

Read from user data storage ..................................................................................................... 115

Select memory type (SRAM/flash) where to save logos or user-defined fonts ........................... 115

Flash memory user sectors allocation ........................................................................................ 116

Flash object area pack ............................................................................................................... 117

Flash object delete .................................................................................................................... 117

Expanded flash memory allocation ............................................................................................ 117

Select flash area for storing logos and user-defined characters ................................................. 118

Return flash area size ................................................................................................................ 118

User storage status .................................................................................................................... 119

Lock permanent font flash area ................................................................................................. 120

Flash download ......................................................................................................................... 120

Switch to flash download mode ................................................................................................. 121

Erase all flash contents except boot sector ................................................................................ 121

Return main program flash CRC ................................................................................................. 121

Download application ................................................................................................................ 121

Reset firmware .......................................................................................................................... 122

Ethernet setup commands ........................................................................................................ 123

Restore default settings ............................................................................................................. 123

Set IP address ............................................................................................................................ 123

Set Net Mask ............................................................................................................................. 123

Set Gateway .............................................................................................................................. 124

Set raw TCP/IP port ................................................................................................................... 124

DHCP (auto-configuration) ......................................................................................................... 124

Inactivity timeout ...................................................................................................................... 124

Keep-alive pings......................................................................................................................... 125

Set HTTP port ............................................................................................................................ 125

Get Ethernet configuration ........................................................................................................ 125

Settings commands ................................................................................................................... 127

Save current settings ................................................................................................................. 127

Restore factory settings .............................................................................................................. 127

Upload current settings .............................................................................................................. 127

Upload factory settings .............................................................................................................. 127

Download settings ..................................................................................................................... 127

Black bar commands ................................................................................................................. 128

Set black bar flags ...................................................................................................................... 128

Enable feed to mark on form feed ............................................................................................. 128

Enable feed to mark on cut ........................................................................................................ 128

Enable black bar paper low detection ........................................................................................ 128

Enable black bar max feed ......................................................................................................... 129

Enable black bar threshold ........................................................................................................ 129

Enable black bar offset .............................................................................................................. 129

Miscellaneous configuration commands .................................................................................. 130

Set diagnostics mode ................................................................................................................. 130

Enable or disable knife ............................................................................................................... 130

Enable or disable paper low sensor ........................................................................................... 130

Set max power ........................................................................................................................... 131

Set printer emulation ................................................................................................................ 131

Reset settings to default values ................................................................................................. 131

Set partial cut distance .............................................................................................................. 132

Set default font.......................................................................................................................... 132

Set font size ............................................................................................................................... 132

Set color density ........................................................................................................................ 132

Enable or disable Code 128 check digit calculation .................................................................... 133

Enable or disable barcode ITF leading zero ................................................................................ 133

Enable or disable barcode string terminator .............................................................................. 133

Set paper low threshold extension ............................................................................................ 134

Enable or disable USM canned status ........................................................................................ 134

Send diagnostic pages to comm port ......................................................................................... 134

Enable or disable EJ action via operator control ......................................................................... 134

Set fine adjustment of partial cut steps ..................................................................................... 135

Set printer ID mode ................................................................................................................... 135

Set default code page at power on ............................................................................................ 135

Set Asian ASCII characters to narrow ......................................................................................... 135

Set vertical white space ............................................................................................................. 136

Set printer tone ......................................................................................................................... 136

Enable or disable shutdown mode ............................................................................................. 136

Set shutdown mode timeout ..................................................................................................... 137

Set print quality level ................................................................................................................. 137

Appendix A: .............................................................................................................................. 138

TH230 Emulation Exceptions ..................................................................................................... 138

Appendix B: ............................................................................................................................... 141

Commands listed by hexadecimal code ..................................................................................... 141

Appendix C: ............................................................................................................................... 147

Resident Character Sets ............................................................................................................. 147

Character sets .........................................................................................................................147

Character code table Page 0 (PC437: USA, Standard Europe): .................................................147

Character code table Page 1 (PC850: Multilingual Latin I): ......................................................148

Character code table Page 2 (PC852: Latin II): .........................................................................149

Character code table Page 3 (PC860: Portuguese): ..................................................................150

Character code table Page 4 (PC863: Canadian French): .........................................................151

Character code table Page 5 (PC865: Nordic): .........................................................................152

Character code table Page 6 (PC858: Multilingual I + Euro): ....................................................153

Character code table Page 7 (PC866: Russian): ........................................................................154

Character code table Page 8 (WPC1252: Latin I): .....................................................................155

Character code table Page 9 (PC862: Hebrew): .......................................................................156

Character code table Page 10 (PC737: Greek): ........................................................................157

Character code table Page 11 (PC874: Thai): ...........................................................................158

Character code table Page 12 (PC857: Turkish): ......................................................................159

Character code table Page 13 (WPC1251: Cyrillic): ..................................................................160

Character code table Page 14 (WPC1255: Hebrew): ................................................................161

Character code table Page 15 ((KZ_1048: Kazakh): ..................................................................162

Character code table Page 16 (WPC1254: Turkish): .................................................................163

Character code table Page 17 (WPC1250: Central Europe): .....................................................164

Character code table Page 18 (WPC28591: Latin 1): ................................................................165

Character code table Page 19 (WPC28592: Latin 2): ................................................................166

Character code table Page 20 (WPC28599: Turkish): ...............................................................167

Character code table Page 21 (WPC28605: Latin 9): ................................................................168

Character code table Page 22 (PC864: Arabic): ........................................................................169

Character code table Page 23 (PC720: Arabic): ........................................................................170

Character code table Page 24 (WPC1256: Arabic): ..................................................................171

Character code table Page 25 (WPC28596: Arabic): ................................................................172

Character code table Page 26 (KATAKANA: Asia): ....................................................................173

Character code table Page 27 (PC775: Baltic): .........................................................................174

Character code table Page 28 (WPC1257: Baltic): ....................................................................175

Character code table Page 29 (WP28594: Baltic): ....................................................................176

TH250 Programmer’s Guide

About this Guide

How to use this guide

This is a supplemental guide providing programming information on Wincor Nixdorf’s TH250

printers. This guide is written for tech-savvy users who are interested in customizing or adjusting

printer functionality and is meant to be used in conjunction with the User Manual.

If you experience any difficulties during the programming process or feel unsure of adjustments

you have made, contact your Wincor Nixdorf representative for further assistance.

Where to find the basics

If you are looking for information on setup or basic operation, refer to the User Guide. The

programming guide assumes that you have the User Guide handy for reference or are already

familiar with the printer.

Where to find advanced technical information

This guide contains the most complete information available on programming the printer. If you

cannot find what you need here or would like further guidance on how to program the printer,

contact a Wincor Nixdorf representative for assistance.

If you are having problems with the physical operation of the printer, the Service Manual provides

in-depth information on diagnostics and service. The Service Manual is available to qualified

service technicians who have been certified by Wincor Nixdorf to perform advanced procedures.

Support

For more advanced procedures and troubleshooting, you may need to refer to the printer’s service

manual or speak to a Wincor Nixdorf technical professional. Your representative is able to provide

you with necessary information.

For online service, refer to the Web site at www.wincor-nixdorf.com.

1

TH250 Programmer’s Guide

Diagnostics and Configuration

The printer performs a number of diagnostics that provide useful information about the operating

status of the printer. The following diagnostic tests are available.

Start-up diagnostics

Perform during the printer’s start-up cycle.

Runtime diagnostics

Perform during normal printer operation.

Remote diagnostics

Maintained during normal operation and reported in the print test.

The printer can be configured with the following settings and functions through the

configuration menu that is printed on the receipt. For more information on configuring the

printer, see “Printer configuration” on page 6.

Communication interfaces:

Diagnostic modes

Printer emulations/software options

Hardware options

Paper Type

Firmware features

Start-up Diagnostics

When the printer receives power or performs a hardware reset, it automatically performs the

startup diagnostics (also known as level 0 diagnostics) during the start-up cycle. The following

diagnostics are performed:

Turn off motors

Perform boot CRC check of the firmware ROM and test main program CRC

Failure causes Start-up Diagnostics to stop; the printer beeps and the LED flashes a set number

of times, indicating the nature of the failure. The table in the “Indicators” section (page 14)

describes the specific tone and LED sequences.

Check if paper is present

Return the knife to the home position

Failure causes a fault condition. The table in the “Indicators” section (page 14) describes the

specific tone and LED sequences.

Check if receipt cover is closed

Failure does not interrupt the start-up cycle.

At power up, if the LED blinks twice, every four seconds, the object storage areas are being

initialized. This process could take up to two minutes. Once the object storage area initialization is

complete the printer will continue with its normal startup procedure and operation. DO NOT

RESET THE PRINTER UNTIL THIS PROCESS IS COMPLETE.

When the start-up diagnostics are complete, the printer makes a two-tone beep (low then high

frequency), the paper feed button is enabled, and the printer is ready for normal operation.

If the printer has not been turned on before, or a new EEPROM has been installed, the default

values for the printer functions will be loaded into the EEPROM during start-up diagnostics, and

the printer will make a quick four-tone beep (high then low frequency, twice).

2

TH250 Programmer’s Guide

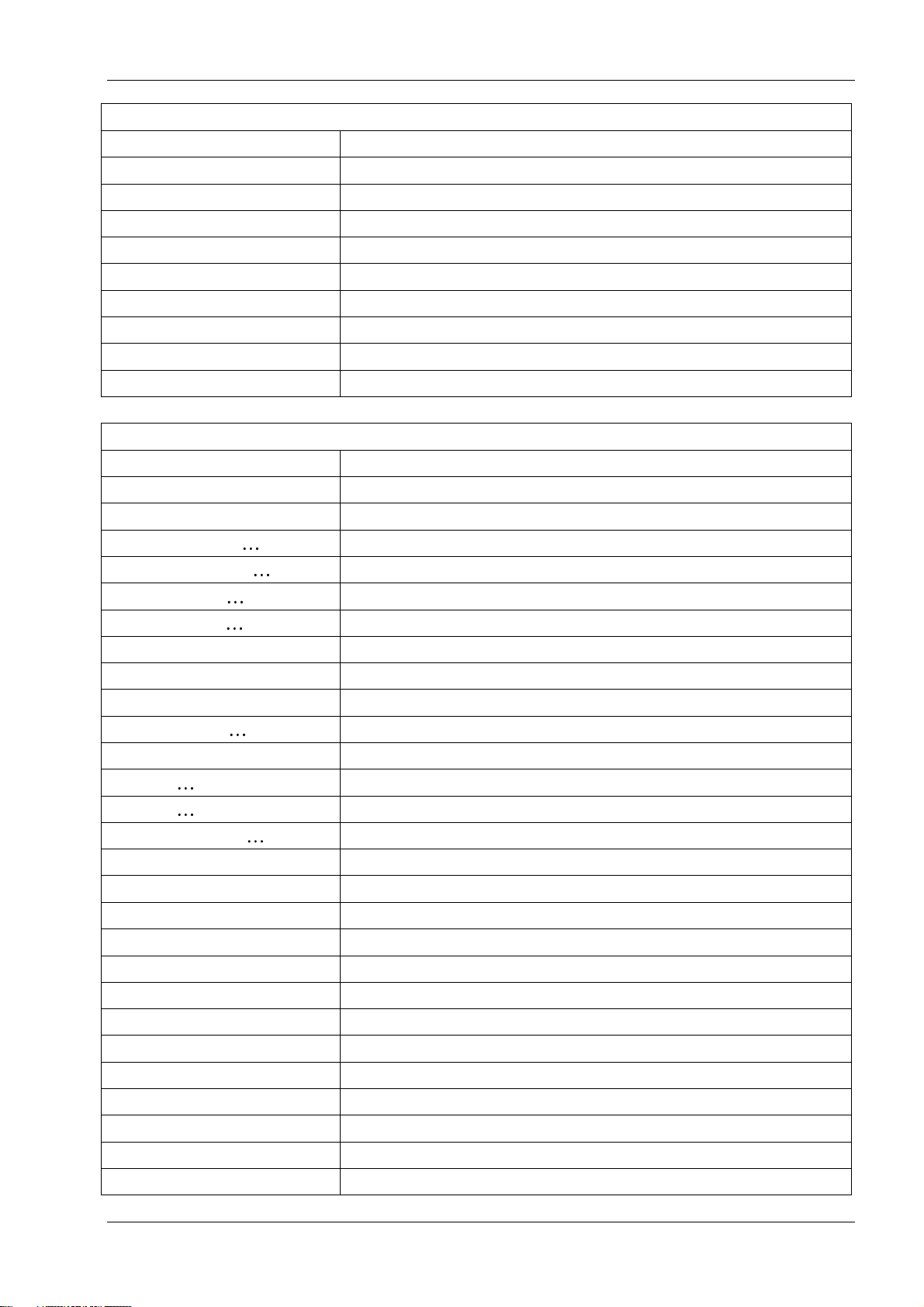

Model number

Serial number

CRC number

Number of lines printed

Number of knife cuts

Number of hours the printer has been on

Number of flash cycles

Number of cutter jams

Number of times the cover is opened

Number of barcodes printed

Number of receipt characters printed

Number of printer faults

Maximum temperature reached

Number of dots printed

Number of dots printed on current printhead

Number of printhead changes

Number of receipt mechanism changes

Number of knife mechanism changes

Number of black mark errors

Number of thermistor errors

Number of low voltage errors

Number of high voltage errors

Number of firmware starts

Number of EEPROM updates

Runtime Diagnostics

Runtime diagnostics (sometimes called level 2 diagnostics) run during normal printer operation.

When the following conditions occur, the printer automatically turns off the appropriate motors

and disables printing to prevent damage to the printer:

Paper out

Receipt cover open

Knife unable to home

Printhead too hot

Voltages out of range

The LED on the operator panel will signal when these conditions occur as well as indicate what

state or mode the printer is in.

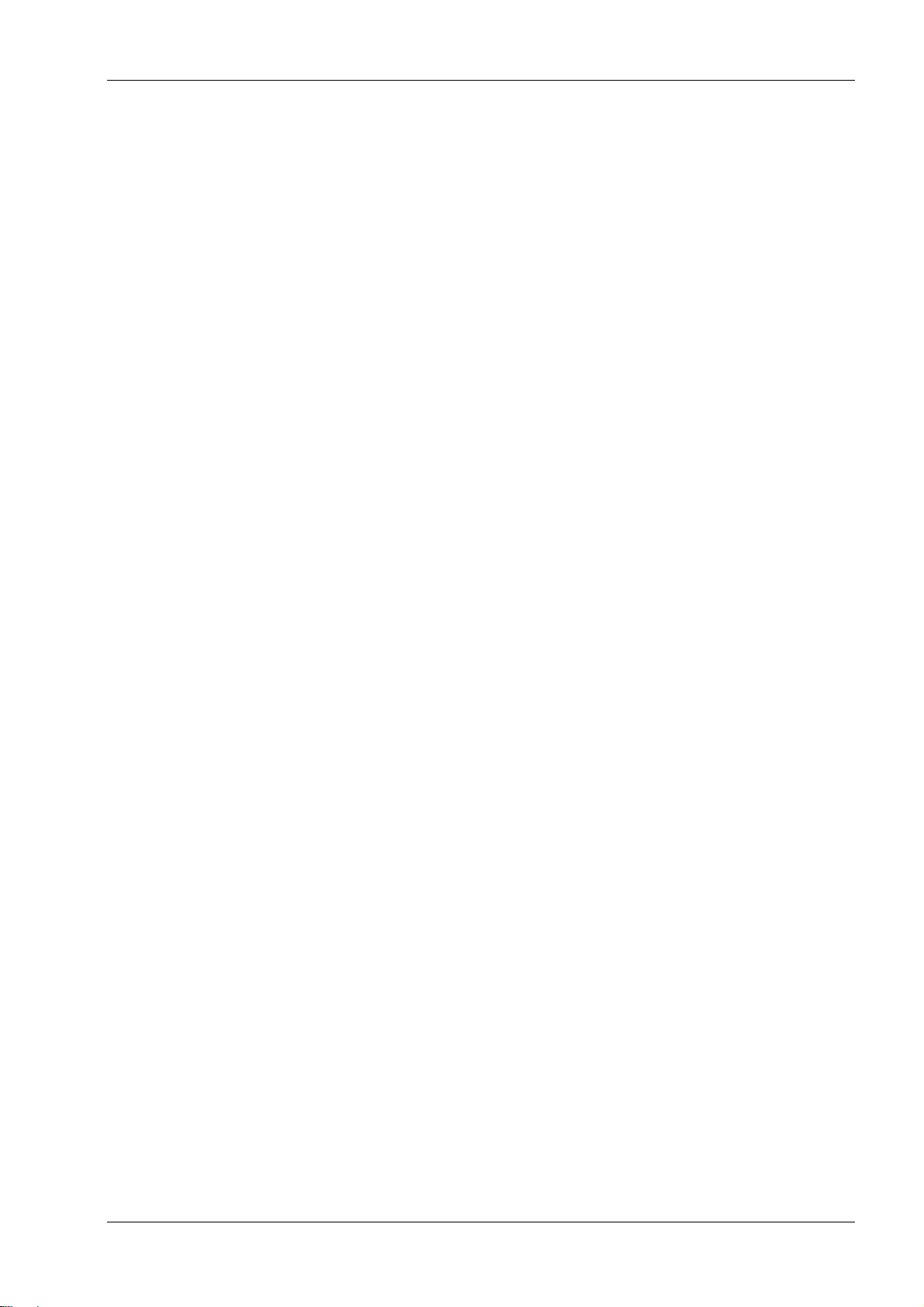

Remote Diagnostics

Remote diagnostics (sometimes called level 3 diagnostics) keeps track of the following tallies and

prints them on the receipt during the print test. See the sample test printout on the next page.

These tallies can be used to determine the printer’s state of health.

3

TH250 Programmer’s Guide

TH250 Diagnostics Form

*** ***

Print test will vary per model or printer configuration.

Accessing the remote diagnostic tallies

Refer to “Command descriptions” in Chapter “Programming commands“

(Status commands: Transmit printer ID, remote diagnostics extension, Hexadecimal 1D 49 40 n)

4

TH250 Programmer’s Guide

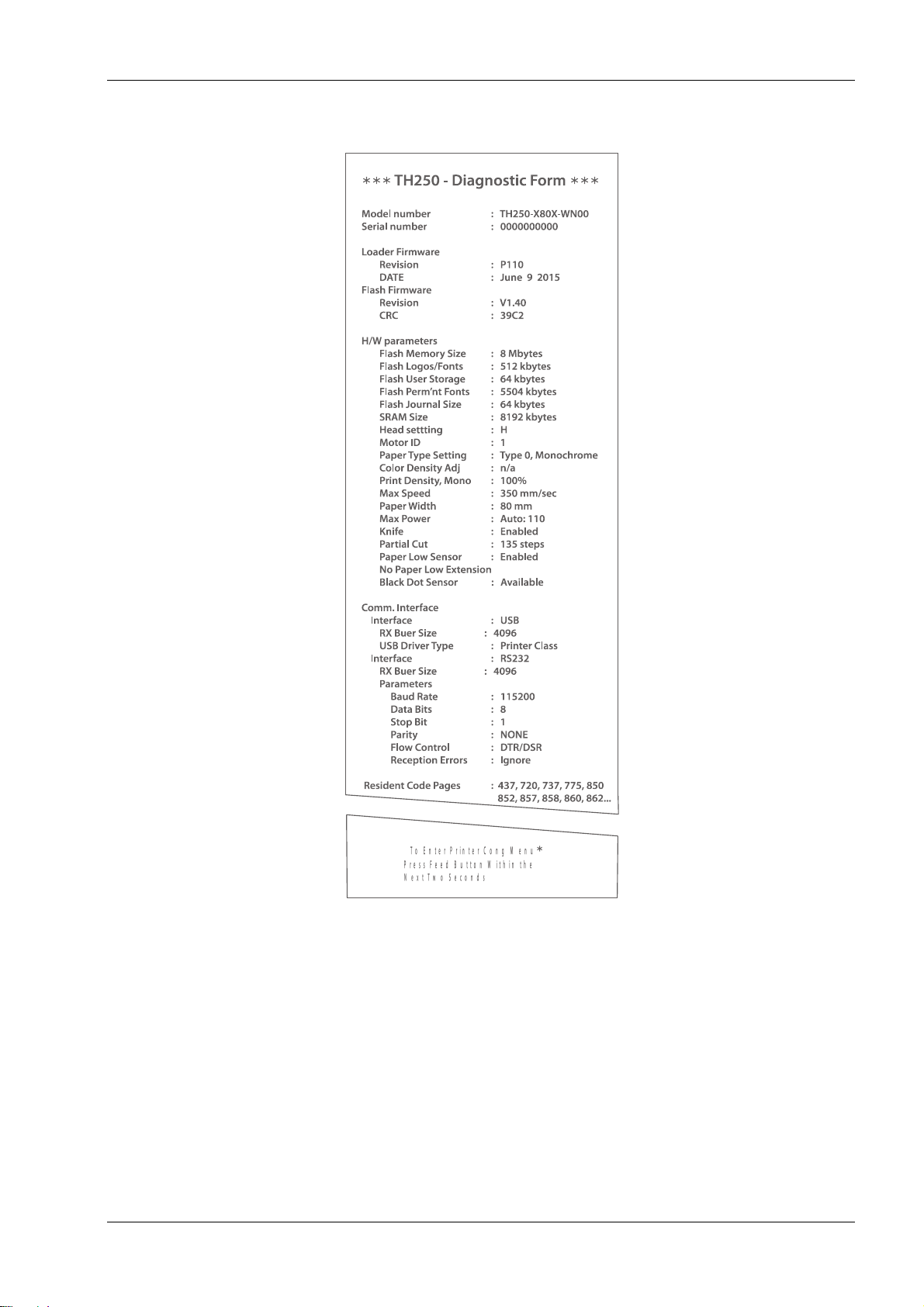

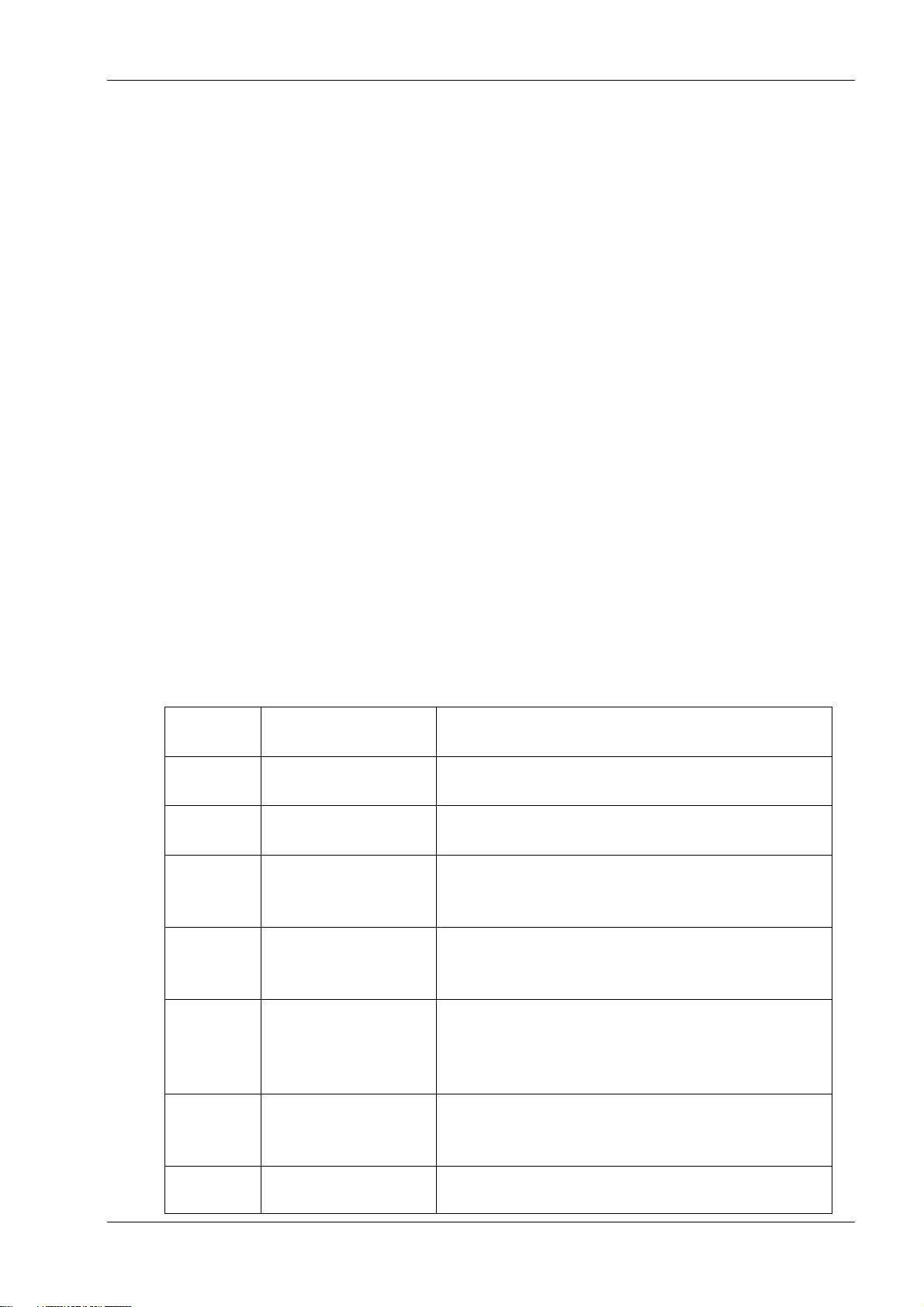

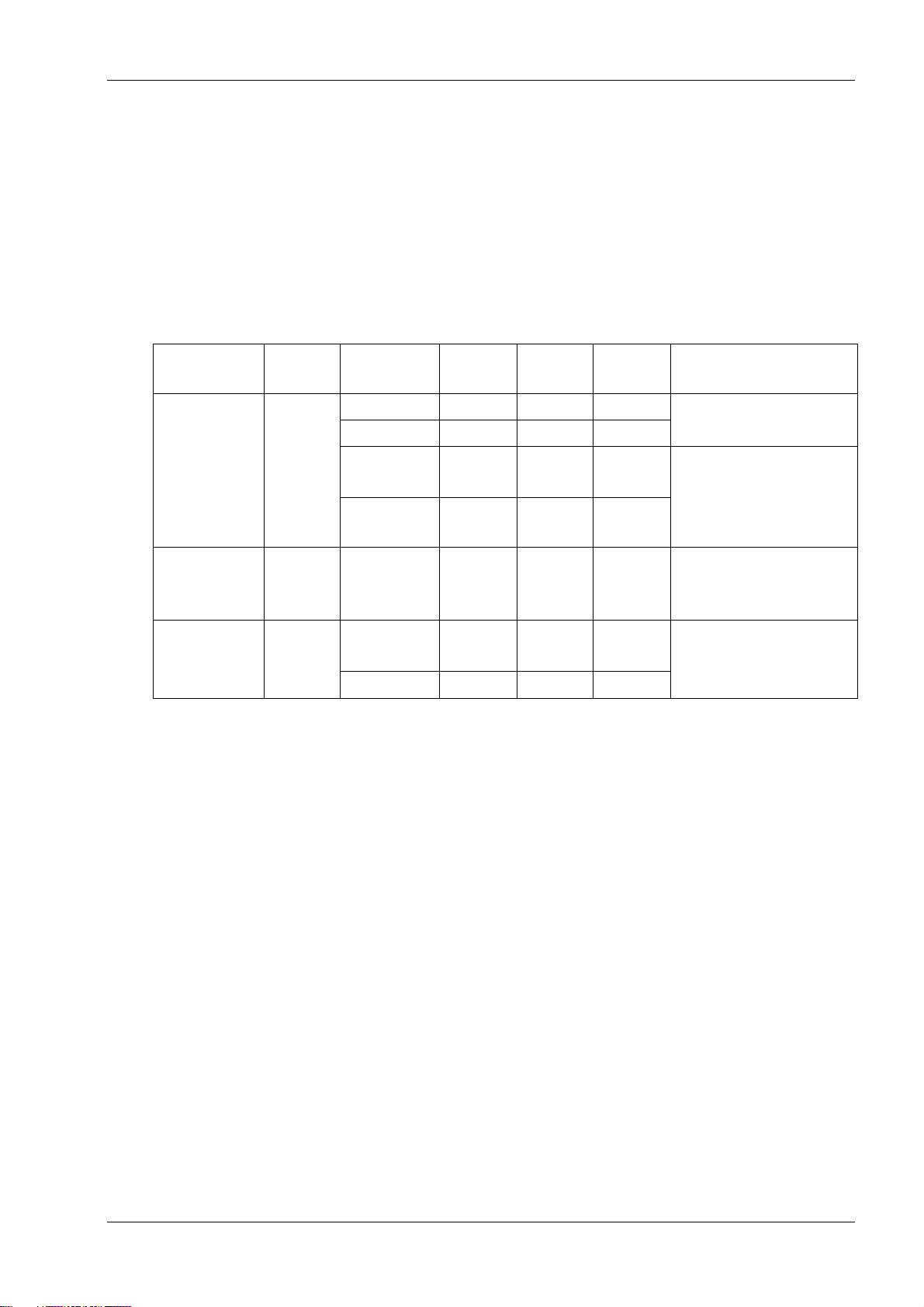

Indicator

Sequence

Condition

LED

Continuous, blinking on

Paper out

Cover open

Black dot sensor error

Knife unable to home

LED

Continuous, blinking off

Paper is low

Printhead too hot

Voltages low/high

LED

Continuous, double LED flash

Write to permanent memory in progress

LED

Blinks once every five seconds

Printer in sleep mode

LED

Continuous, quick blinking (on

power up)

Invalid firmware

LED

Continuous, slow blinking

Power supply and max power setting

don’t match

Tone

Two-tone beep (low frequency,

high frequency)

Start-up diagnostics completed

successfully

LED and

Tone

Two-tone beep (low frequency,

high frequency)

Continuous, quick blinking of LED

When entering flash download mode*

*Note: The printer enters flash download mode when a download command

is sent to the printer.

Indicators

The printer communicates various conditions both visually, with the green LED or audibly, with a

series of tones or beeps.

The following table lists these indicators.

The printer is also able to communicate its status to the host application if the application has been

programmed to receive this information.

Error conditions and correcting them

Refer to section “Troubleshooting the printer” in chapter “Using the printer” in the User Manual.

Communication of printer status to the host application

Refer to section “Command descriptions” in chapter “Programming commands, Status” sections.

5

TH250 Programmer’s Guide

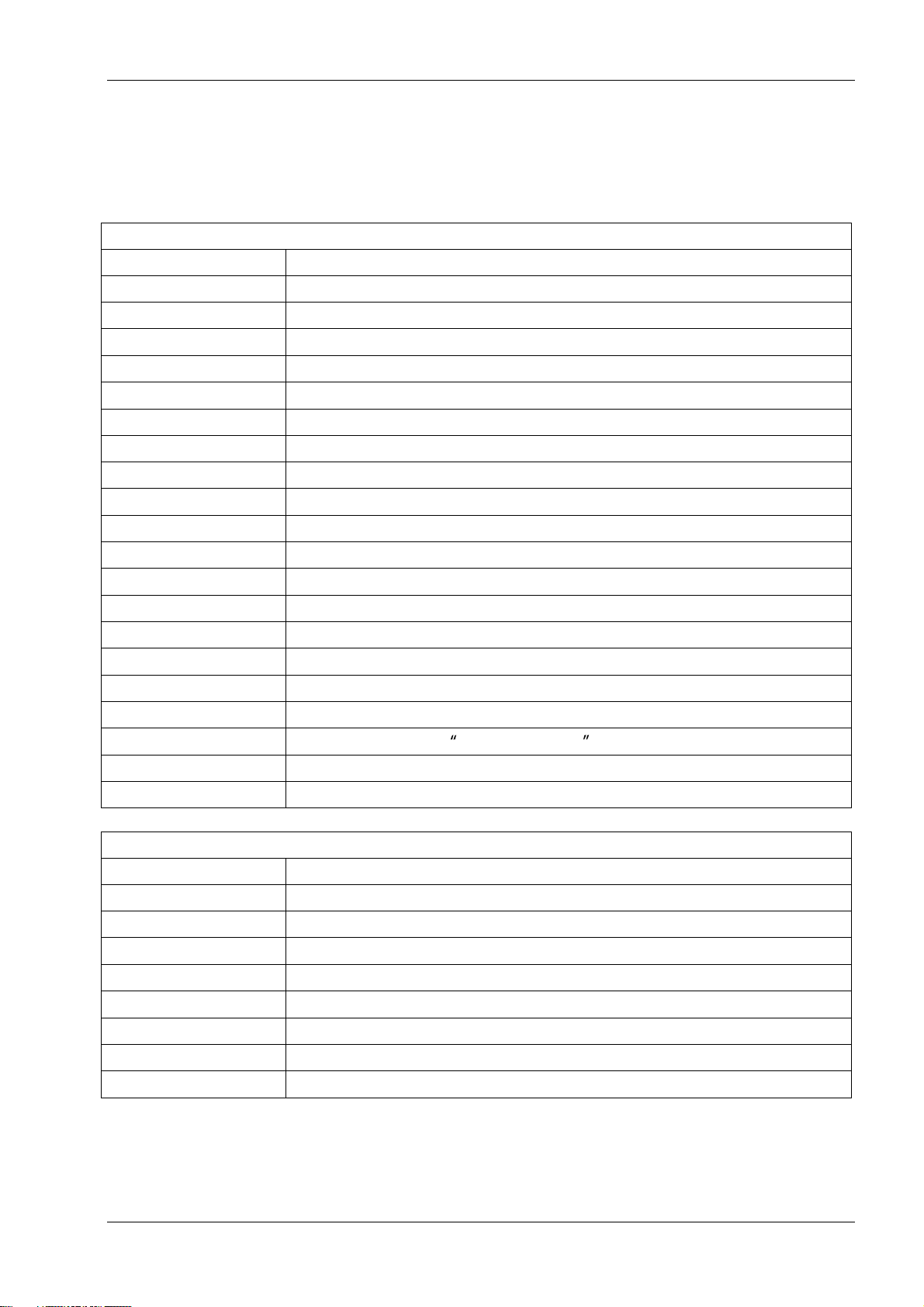

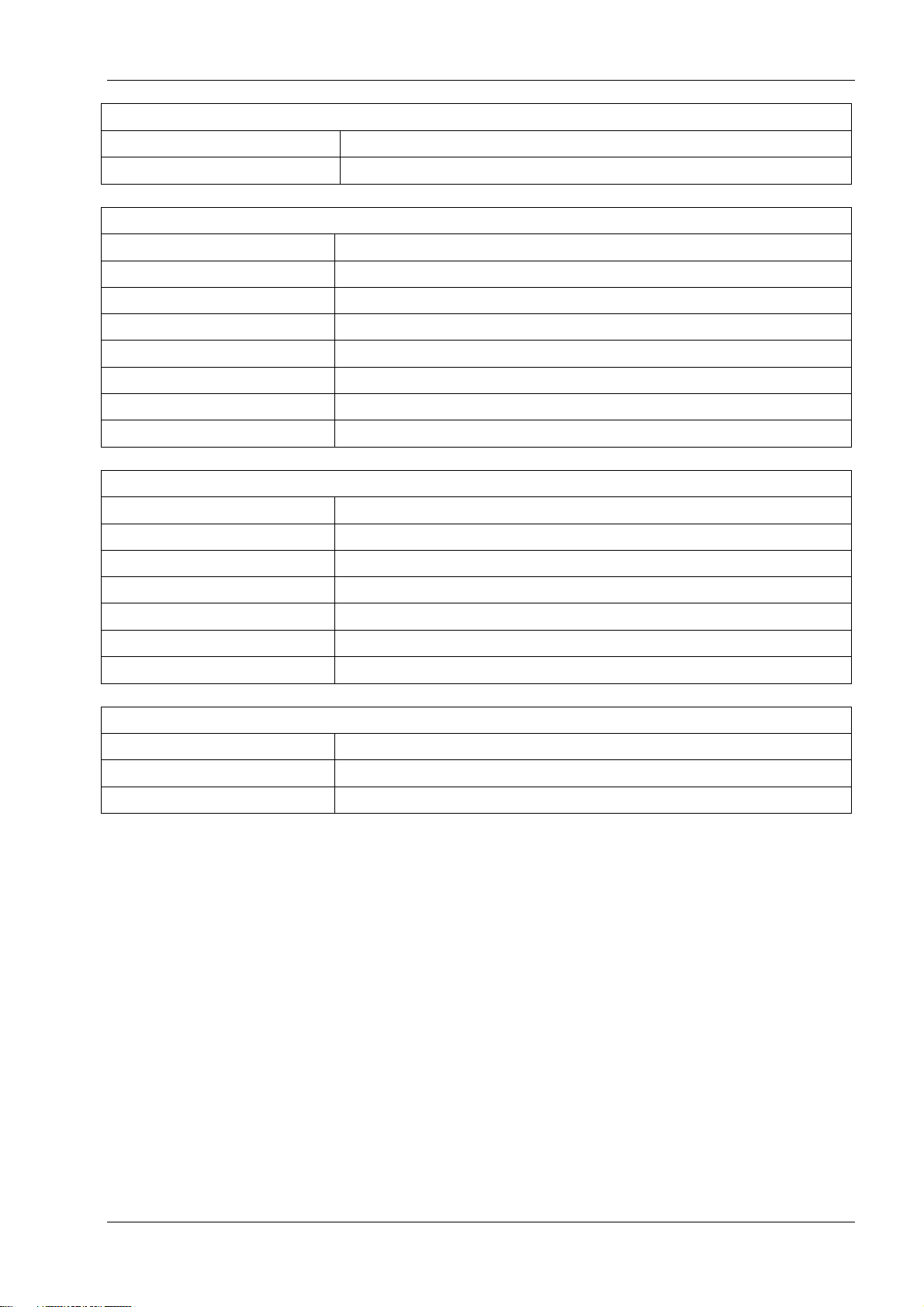

Communication Interfaces

Baud rate

Parity

Hardware (DTR/DSR) or software

(XON/XOFF) flow control

Data reception errors

Alternate DTR/DSR

USB Driver

USB NAK

Diagnostics Modes Normal

Datascope (with or without graphics)

Receipt test

Printer Emulations

Native mode

TH210/TH210-2/TH210/TH210-2/A794

emulation

A793 emulation

LEGACY emulation

TH230 emulation

Emulation/Software options

Printer ID mode

Default lines per inch

Carriage return usage

Code 128 Check Digit

Default font

Font size

Journal Print

Hardware options

Color density

Monochrome print density

Max Power

Partial cut distance

Fine partial cut steps

Paper low sensor

Paper low threshold extension

Printhead setting (cannot change)

Paper type

Firmware features

Paper selection lockout

Beep after knife cut

Cash drawer open after knife cut

Energy-savings timeout value

Print quality level

Printer configuration

Printers are shipped with all the functions and parameters preset at the factory. Settings for various

printer parameters can be changed. This menu is printed on the receipt and scrolls through

instructions for selecting and changing any of the functions or parameters.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

The following functions and parameters can be changed in the scrolling configuration menu

(except as noted):

Using the configuration menu to configure the printer

Refer to the next section “Configuring the printer”.

6

TH250 Programmer’s Guide

Configuring the printer

The configuration menu allows you to select functions or change various settings for the printer.

Instructions printed on the receipt guide you through the processes.

Caution: Be extremely careful changing any of the printer settings to avoid changing other settings

that might affect the performance of the printer.

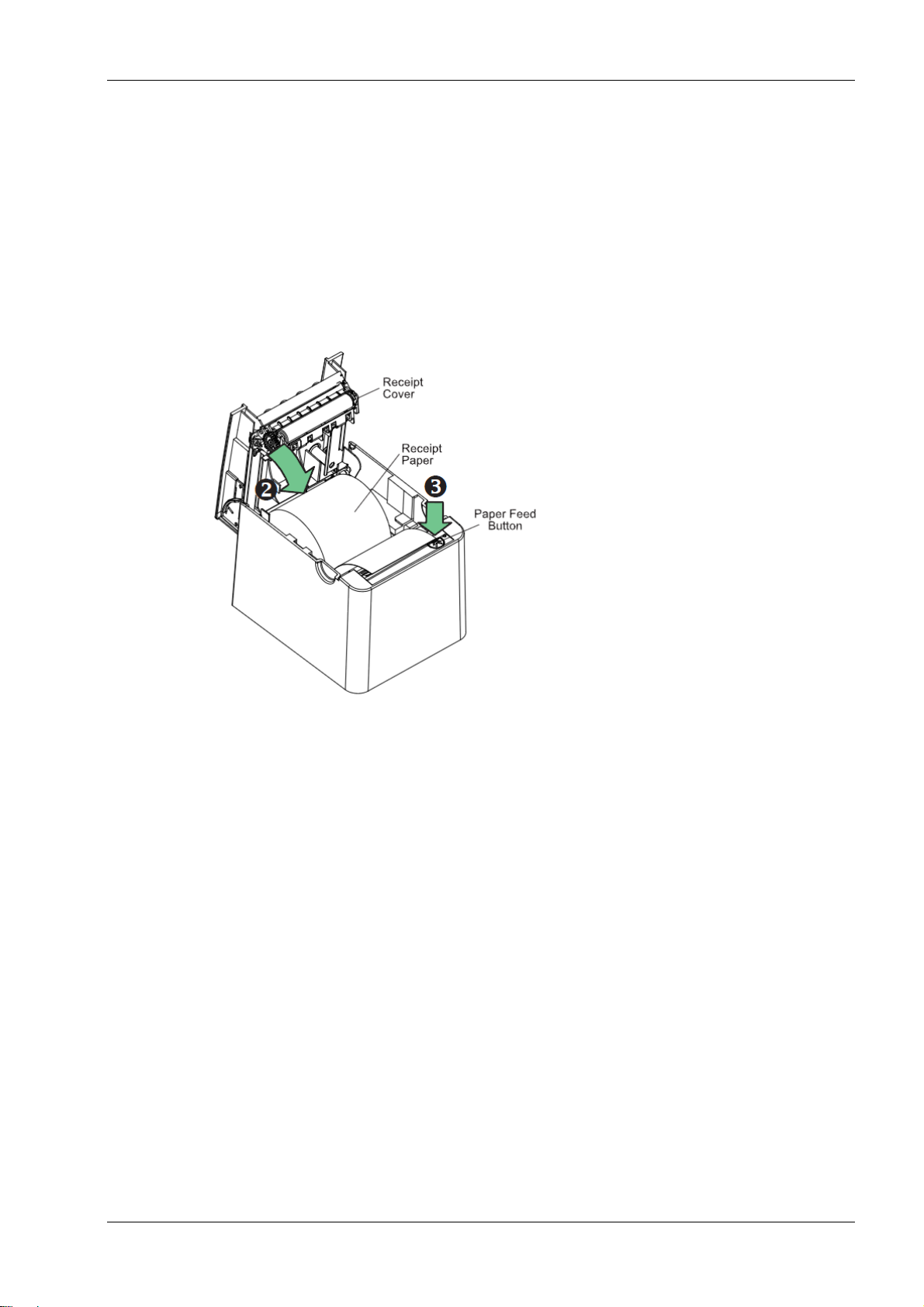

1. Turn power off to printer.

2. Make sure receipt paper is loaded in the rpinter before proceeding. Make sure cover is

closed.

3. Apply power to printer and immediately press and hold the paper feed button until the

configuration printout begins.

The printer beeps, then prints Diagnostics Form I.

Press the paper feed button within two seconds to enter the configuration main menu

The printer prints Diagnostics Form II, followed by the Printer Configuration Menu, and

waits for a main menu selection to be made (see sample printout on page 13; short

clicks are used, except when answering “yes” or validating selection).

4. To communicate with the printer, you will press the paper feed button using either

short or long clicks. Use a long click for “yes” (more than one second) and a short click

for “no.” Follow the printed instructions to make selections.

5. Continue through your menu selections until you are asked, “Save New Parameters?”

Select “Yes.”

Reset the Printer.

Open the receipt cover.

Press and hold the paper feed button while closing the receipt cover.

The diagnostic printout verifies your new settings.

7

TH250 Programmer’s Guide

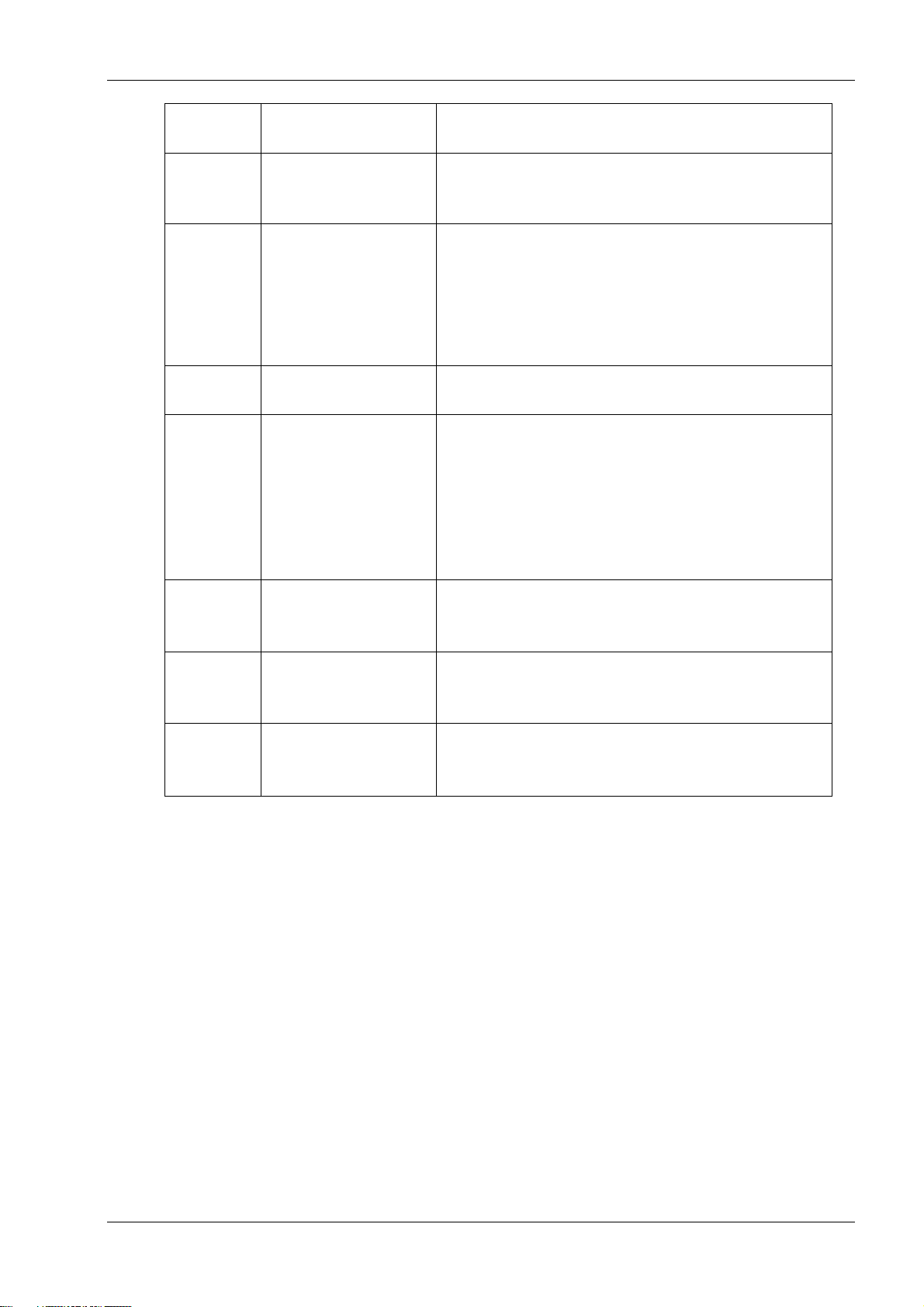

Baud rate

115200 baud

57600 baud

38400 baud

19200 baud

9600 baud

4800 baud

2400 baud

1200 baud

Parity

No Parity

Even Parity

Odd Parity

Flow control methd

Software (XON/XOFF)

Hardware (DTR/DSR)

Data reception errors

Ignore errors

Print “?”

Alternate DTR/DSR

Enabled

Disabled

USB Driver

Printer Cass

Comm Class

USB NAK

Reject Packets When Error

Accept Packets When Error

Communication interface settings

To change the communication interface settings, enter the configuration menu, select “Set

Communication Interface” from the main menu.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed on the configuration menu to select the settings you

want to change.

Note: Press the paper feed button for at least one second to validate the selection.

Setting the RS-232C Serial interface settings

Refer to the section “Configuring the printer”.

Diagnostics modes

To change the the diagnostic modes enter the configuration menu, select “Set Diagnostics Modes”

from the main menu and select one of the following modes:

Normal: normal operating mode of the printer.

Datascope: the receipt printer prints incoming commands and data in hexadecimal format to

help troubleshoot communication problems. There are DataScope modes for both with and

without graphics.

Receipt test: the receipt printer prints all code pages to verify proper printing of the receipt.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Refer to the section “Configuring the printer,” for instructions on how to enter the configuration

menu.

8

TH250 Programmer’s Guide

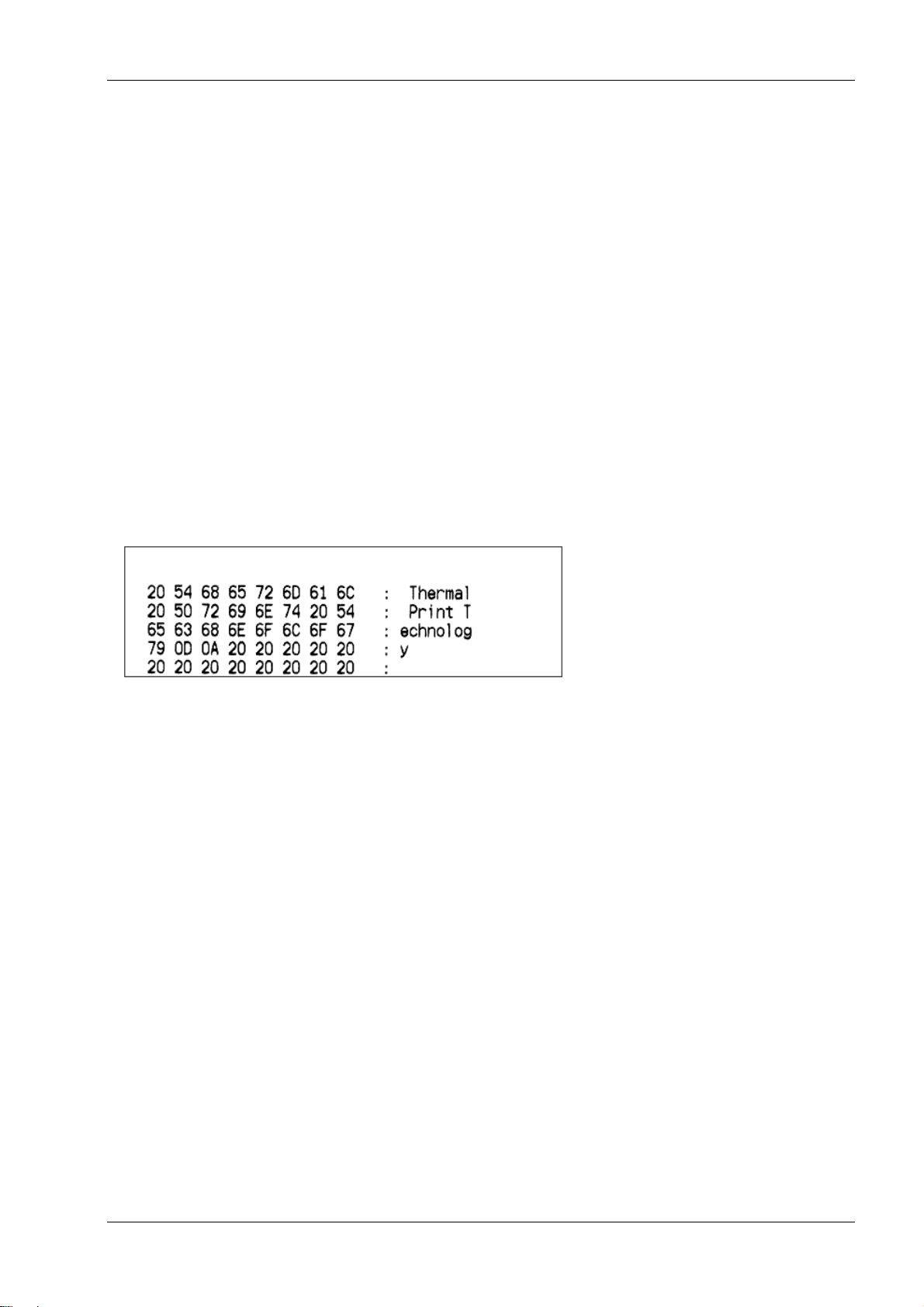

Enable or disable data scope mode

The data scope mode test prints a hexadecimal dump of all data sent to the printer: “1” prints as

hexadecimal 31, “A” as hexadecimal 41 and so on. This helps troubleshoot communication

problems and runs during a normal application (after being enabled through printer configuration).

Note: Data scope mode is usually considered a level 1 diagnostic test.

Data scope mode is enabled and disabled by selecting the “Diagnostics Modes” sub-menu of the

configuration menu. Press the paper feed button as instructed on the “Diagnostics Modes Menu”

to enable or disable the data scope mode test.

Off, normal mode (Data scope mode disabled)

Data scope mode with or without graphics (enabled)

Note: Press the paper feed button for at least one second to validate the selection.

To run the data scope mode:

1. After you have enabled the data scope mode, exit the configuration menu.

2. Run a transaction from the host computer.

All commands and data sent from the host computer will be printed as hexadecimal characters as

shown in the illustration.

To exit the data scope mode:

1. Enter the configuration menu again.

2. Disable the data scope mode.

3. Exit the configuration menu.

The printer is on-line and can communicate normally with the host computer.

Enabling the data scope mode

Refer to the section “Configuring the printer”.

Enable or disable receipt test mode

The receipt test mode verifies proper receipt printing. Receipt test is enabled and disabled by

selecting the “Diagnostics Modes” sub-menu of the configuration menu. See “Configuring the

printer”, for instructions on how to enter the configuration menu.

To run the receipt test mode:

1. Enable the receipt test mode in the configuration menu.

3. Exit the configuration menu.

4. Push the paper feed button. The receipt station prints all code pages and cuts the

receipt.

5. To repeat this test, push the paper feed button again.

9

TH250 Programmer’s Guide

To exit the receipt test mode:

1. Enter the configuration menu again.

2. Disable the receipt test mode.

3. Exit the configuration menu.

The printer is on-line and can again communicate normally with the host computer.

Electronic Journal Datascope Diagnostic

1F 03 18 02 n=1, turn on electronic journal datascope, run time only

1F 03 18 02 n=0, n>1, turn off electronic journal datascope, run time only

1F 03 18 03 n=1, turn on electronic journal datascope, configuration saved over power cycle

1F 03 18 03 n=0, n>1, turn off electronic journal datascope, configuration saved over power cycle

When enabled, “Auto Journal : Datascope” prints on the second diagnostic page.

This diagnostic is for debugging purposes, and should be used only under the direction of customer

support.

Printer emulations

To change the printer emulations settings, enter the configuration menu, select

“Emulation/Software Options” from the main menu and answer “Yes” to “Set printer mode?”

printed on the receipt. This will take you to the instructions for setting the printer emulation.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the printer emulation you want.

Native mode

TH210/TH210-2/TH210/TH210-2/A794 emulation

A793 emulation

LEGACY emulation

TH230 emulation

Note: Press the paper feed button for at least one second to validate the selection.

Setting the printer emulation

Refer to the section “Configuring the printer”.

Printer settings and functions

To change the printer settings and functions, enter the configuration menu, select the sub-menu

from the main menu and answer the questions printed on the receipt until you come to the

instructions for selecting the printer settings.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the printer settings you want.

Select the emulation/software options sub-menu to set:

Printer Mode

This function is used to set the printer emulation to Native, TH230, TH210/TH210-2/A794, A793 or

Legacy emulation.

10

TH250 Programmer’s Guide

Printer ID mode

This function is used to determine what printer ID value is returned in response to a Transmit

printer ID command (1D 49 n) when the printer is in TH210/TH210-2/A794 emulation mode. The

printer can be configured to send back the ID of the TH250, TH210/TH210-2/A794, A793 or

Application Compatible Escape Command systems.

Default lines per inch

This function allows you to set the default for lines per inch to:

8.13 lines per inch

7.52 lines per inch

6.77 lines per inch

6.00 lines per inch

Carriage return usage

This function allows the printer to ignore or use the carriage return (hexadecimal 0D) command

depending on the application. Some applications expect the command to be ignored while others

use the command as a print command.

Code 128 Check Digit

Enables or disables the calculation of the check digit.

Default font

Sets the default for monochrome, two-color, and LEGACY emulations.

Font size

Allows user to set font size for the emulation being used.

Journal Print

Enables or disables operator action.

Select the hardware options sub-menu to set:

Color density

Adjusts printhead energy level to darken color printing or adjust for paper variations. When printer

prints high-density color print lines (text or graphics), it automatically slows down. Factory setting

is 100%.

WARNING: Choose a color density setting no higher than necessary to achieve acceptable color

print density. Failure to observe this rule may result in a printer service call and may void the

printer warranty. Running at a higher energy level will reduce the printhead life. Consult your

Wincor Nixdorf technical support specialist if you have questions.

Print density (monochrome papers only)

Adjusts printhead energy level to darken printout or adjust for paper variations. When printer

prints high-density print lines (text or graphics), it automatically slows down. Factory setting for

the TH250 is 100%.

Note: when printer is set to color paper, Print Density adjusts the overall darkness for both color

and monochrome.

WARNING: Choose a print density setting no higher than necessary to achieve acceptable print

density. Failure to observe this rule may result in a printer service call and may void the printer

warranty. Running at a higher energy level will reduce the printhead life. Consult your Wincor

Nixdorf technical support specialist if you have questions.

Power supply level (Max power)

You can choose from these power settings to match the power supply:

Auto (for Wincor Nixdorf power supplies)

55W

75W

11

TH250 Programmer’s Guide

90W

Partial cut distance

Allows the user to set the distance that the knife will cut across a receipt in 5 step increments

between 110-160.

Fine partial cut steps

Allows the user to set the amount of extra steps the knife will cut across a receipt, between 0 and

4.

Paper low sensor

Senses when the paper roll is getting low on paper.

See troubleshooting section: “Receipt paper is low” in the User Manual.

Paper low threshold extension

Allows the user to set the amount of footage for the extension in 5-foot (1.5 meters) increments

between -10 and 20 feet (-3 meters and 6 meters).

Setting the printer functions and settings

Refer to the section “Configuring the printer”.

Select the paper type sub-menu to set:

Paper Type Name

Sets the printer to optimum performance for paper being used. This can also be done through the

command 1D 81 m n. See the following chapter for command usage.

Available paper types may vary. Refer to our website, www.wincor-nixdorf.com, for an up-to-date

list of qualified paper manufacturers. Currently there are 3 types:

0 = monochrome

4 = two-color (blue/black)

5 = two-color, (red/black or green/black)

Select the firmware features sub-menu to set:

Paper selection lockout

Beep after knife cut

Cash drawer open after knife cut

Energy-savings timeout value

Allows the user to enable and set the time-out value to 15, 30, 60, 120, or 240 minutes, or to

disable the feature.

Print quality level

Allows the user to set the print quality to speed (350mm/s), balanced (300mm/s), or quality

(250mm/s).

12

TH250 Programmer’s Guide

Command

Description

Difference between previous product and new

product emulation mode

15n

Feed n dot rows

This command will move the paper on the receipt

in n/203 inch steps instead of n/152 inch steps.

16 n

Add n extra dot rows

The dot rows will be measured in n/203 inches

versus n/152 inches.

1B 20 n

Set right-side

character spacing

This command sets the right side spacing to “n”

horizontal motion units. By default, these units

are in terms of 1/203 inches versus 1/152 inches.

1B 24 n1

n2

Set absolute starting

position

For graphics commands, the position is scaled to

best match A793. In text mode, the equivalent

character position is calculated.

1B 26 s c1

c2 n1 d1

...nn dn]

Define user-defined

character set

Since the dots on the TH250 printhead are

smaller, user defined characters that were used

on the previous printers will appear smaller on

the TH250 printer.

1B 2A m

n1 n2

d1...dn

Select bit image

mode

In A793 emulation mode, graphics are scaled to

best match the size of the graphic in the A793

printer.

1B 33 n

Set line spacing

This command uses n in terms of n/360 inches.

Since the A793 had a fundamental step of 1/152

Programming the Printer

Overview of commands

Commands control all operations and functions of the printer. This includes selecting the size and

placement of characters and graphics on the receipt to feeding and cutting the paper. The

programming commands have been organized, in order of hexadecimal code within functional

groups. For this reason, “related” commands may not be listed adjacent to one another.

The operation of various printers may be emulated by the commands, including the following:

Native

A793/TH210/TH210-2/A794

TH230

LEGACY

Any of the commands may be used in any combination to program a host computer to

communicate with the printer (unless otherwise noted).

Some commands listed and described here may not be implemented and are identified as “not

implemented.” If received, they are ignored and not sent to the print buffer as data.

Any nonlegal commands have their parameter sent to the print buffer as data.

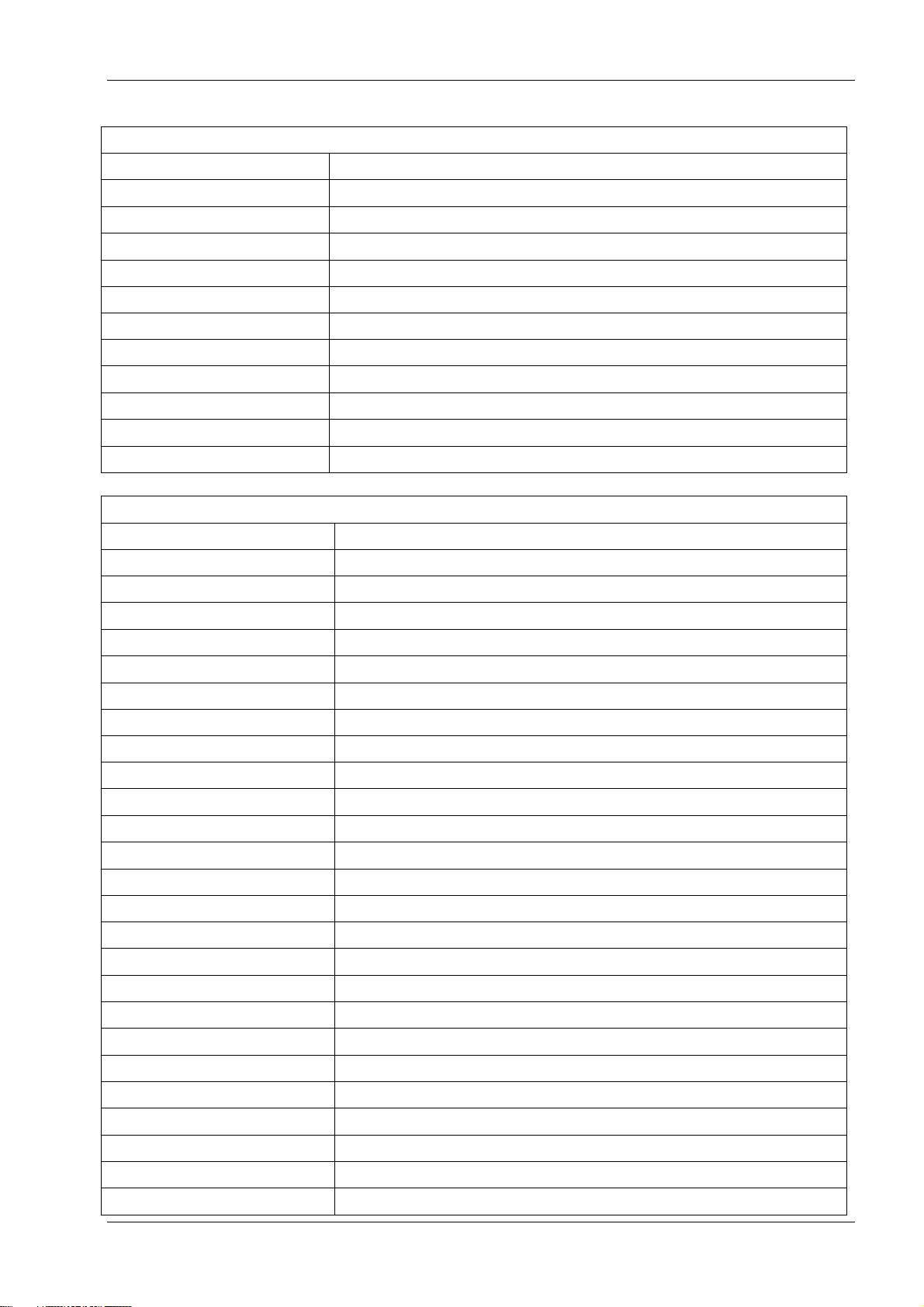

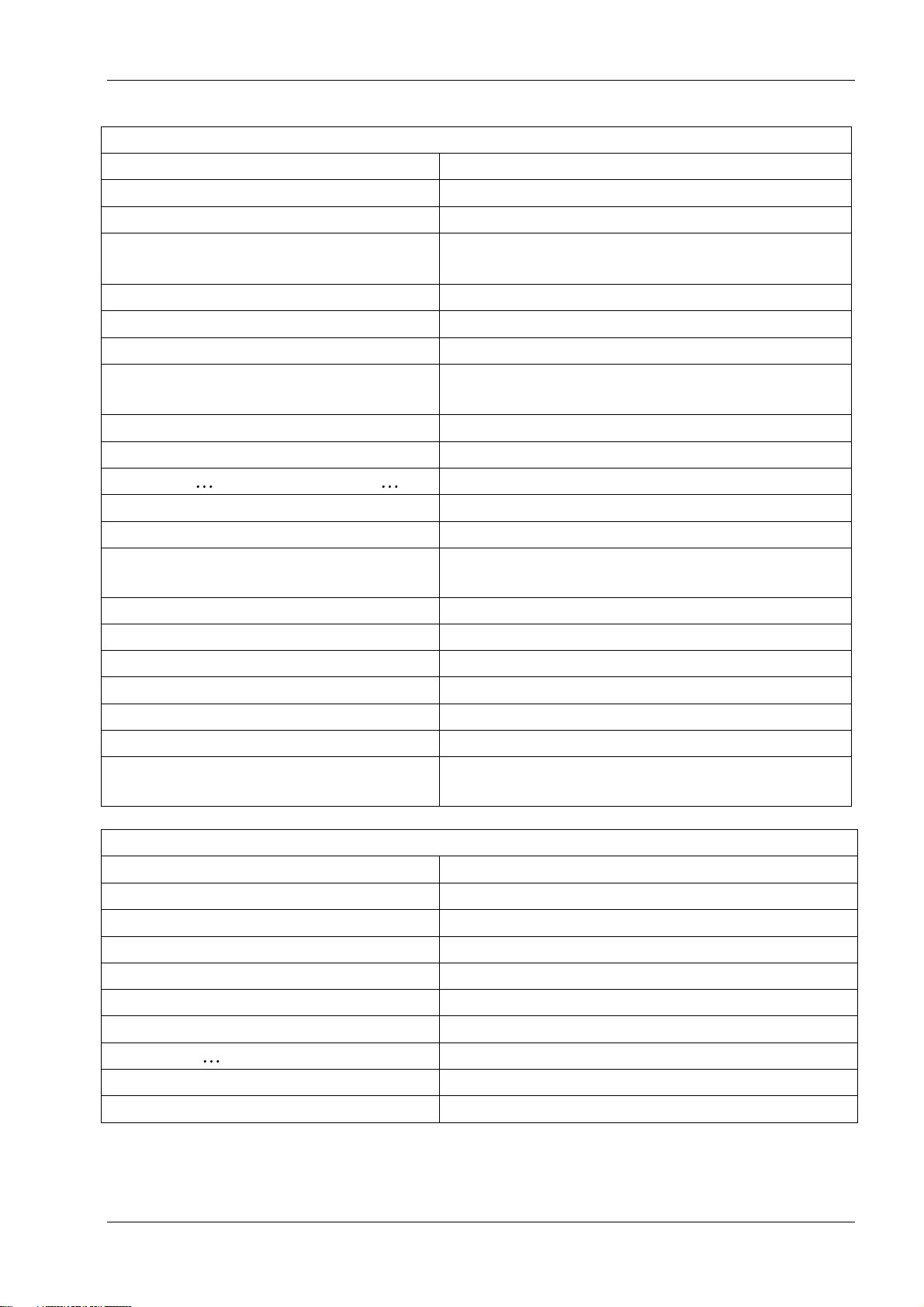

Comparison to A793

The following table details the list of commands whose behavior differs between the A793,

TH210/TH210-2/A794, and TH250 because of the physical differences of a 6 dots/mm head (A793)

versus an 8 dots/mm head (TH210/TH210-2/A794 and TH250).

13

TH250 Programmer’s Guide

Command

Description

Difference between previous product and new

product emulation mode

inch and the TH250 has a fundamental step of

1/203 inch, the actual line spacing will not exactly

match the requested spacing.

1B 4A n

Print and feed paper

This command uses n in terms of n/360 inches.

Since the A793 had a fundamental step of 1/152

inch and the TH250 has a fundamental step of

1/203 inch, the actual line spacing will not exactly

match the requested spacing.

1B 59 n1

n2 d1...dn

Select doubledensity graphics

In A793 emulation mode, the printer scales the

graphics to provide the best match.

1B 5C n1

n2

Set relative print

position

The parameter to this command is in units of

dots.

However, the command moves and aligns to

character positions. In A793 emulation mode, this

command calculates how many character

positions to move based on the A793 character

width in dots (10) versus the TH250 (13).

1B 61 n

Select justification

This command does true dot resolution

alignment for centering versus character-aligned

centering.

1D 2A n1

n2

d1...dn]

Define downloaded

bit image

In A793 emulation mode, this command scales

the incoming data to provide a best match to the

size of the image as it printed on A793.

1D 2F m

Print downloaded

bit image

In A793 emulation mode, this command scales

the incoming data to provide a best match to the

size of the image as it printed on A793.

14

TH250 Programmer’s Guide

Color interpreted commands

Hexadecimal

ASCII

Description

1B 72 m

ESC r m

Set current color

1D A0 nl nh

1D GS

Set temporary maximum target speed

1D 23 n

GS # n

Select current logo

1D 42 n

GS B n

Select or cancel white/black reverse print

mode

1D 2A n1 n2 d1 dm

GS * n1 n2 d1 – dm

Define downloaded bit image

1D 2F m

GS / m

Print downloaded bit image

1D 81 m n

GS 0x81 m n

Set paper type

1D 82 n1 n72

GS 0x82 n1– n72

Print raster monochrome graphics

1D 83 n1 n144

GS 0x83 n1– n144

Print raster color graphics

1D 84 n m n1 n2 d1 dx

GS 0x84 n m n1 n2

d1 dx

Download logo image

1D 85 m n

GS 0x85 m n

Reverse color text mode (two-color)

1D 86 m

GS 0x86 m

Monochrome shade mode

1D 87 m

GS 0x87 m

Color shade mode

1D 89 n m

GS 0x89 n m

Logo print with color plane swap

1D 8B n m o

GS 0x8B n m o

Apply shading to logo

1D 8C n m

GS 0x8C n m

Merge watermark mode

1D 8D n m

GS 0x8D n m

Text strike through mode

1D 90 m x y o p q

GS 0x8A m x y o p

q

Form and print real time surround

graphic

1D 91 n

GS 0x91 n

Save graphics buffer as logo

1D 92 n

GS 0x92 n

Background logo print mode

1D 97 m n

GS 0x87 m n

User storage status

1D 99 l m n o

US

Apply margin message mode

1D 9A n m o

GS 0x9A n m o

Shade and store logo

1D 9B m n

GS

Logo print with knife cut

1F 03 16 05 n

US

Set interpretation of “Set current color”

command

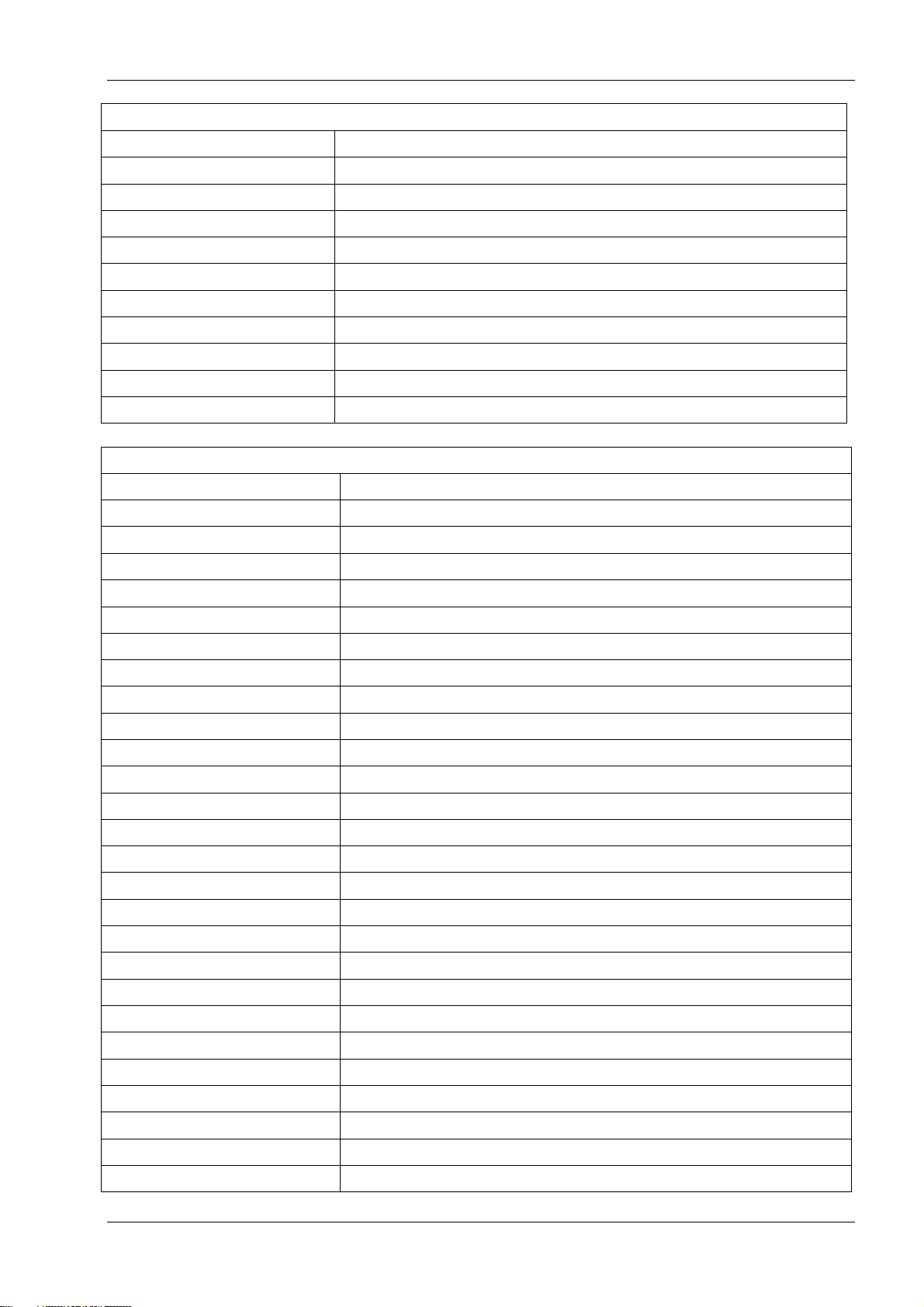

Two-color commands (comparison TH210 to TH250)

The following table details the list of commands that have been added for two-color functionality

or existing commands that have been altered by the addition of two-color capacity.

15

TH250 Programmer’s Guide

Standard

Rotated

Italic

Compressed

Underlined

Strike-through

Double-high

Bold

Scaled

Double-wide

Reverse

Shading

Upside-down

Rotated

Italic

Standard

Compressed

Characters per inch: 15.6

Characters per inch: 20.3

Characters per line: 44

Characters per line: 56

Cell size:

13 x 24 dots (default font)

13 x 27 dots (Tall fonts)

13 x 18 dots (paper-saving font)

Cell size:

10 x 24 dots (default font)

10 x 27 dots (Tall fonts)

10 x 18 dots (paper-saving font)

576 dots (addressable) @ 8

dots/mm, centered on 80mm

Top margin to manual tear-off:

17.8mm (0.70 inches)

Standard mode: minimum

margins: 2.0mm (.079 inches)

Top margin to knife cut: 19.0mm

(0.75 inches)

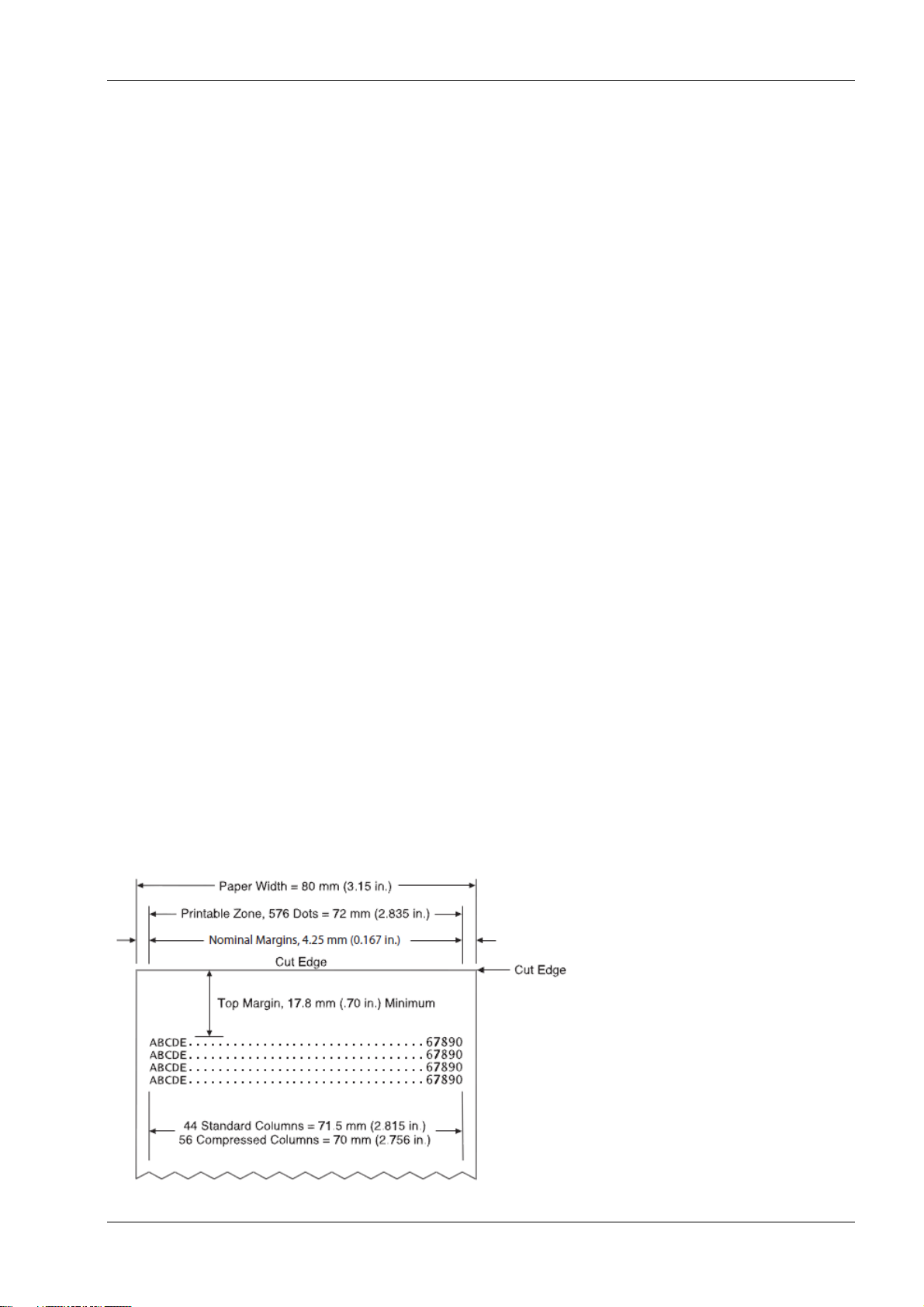

Character appearance

The appearance of text can be changed using the following print modes:

Width specifications

Print zones

Print zones for 80mm paper

Specifications of print zone for 80mm paper:

16

TH250 Programmer’s Guide

Upside down (1B 7B n)

Rotated CW (1B 56 n)

Rotated CCW (1B 12)

Resulting

output

Canceled

Canceled

Cleared

Canceled

Set

X

Set

Canceled

X

Set

Set

X

X X Set

Note: The application centers 44 standard character cells (13 X 24 dots), or 56 compressed

character cells (10 X 24 dots), or 576 addressable bits of graphics across an 80mm wide receipt.

Minimum print line height is 24 dots for text or graphics. Standard print line spacing is 27 dots (i.e.,

3 extra row dots).

The TH250 Series adds a 27 dot high font, so standard print spacing is 30 dots.

The TH250 Series paper-saving feature adds a 18 dot high font and reduces extra dot rows to 2, so

standard print spacing is 20 dots.

Rotated printing commands

Three commands control the rotation of printing. The table shows the combinations of set/cancel

upside down print, set/ cancel rotated print (clockwise), and rotated print (counterclockwise).

Rotated clockwise and rotated counterclockwise print commands are mutually exclusive: the

setting of the last received command is effective. Unintended consequences may result when

rotated clockwise is mixed with other commands

The samples of the print show only the normal-size characters. Double-wide and double-high

characters are printed in the same orientation. They may also be mixed on the same line.

Note: The following print modes cannot be mixed on the same line:

Right-side up and upside-down

17

TH250 Programmer’s Guide

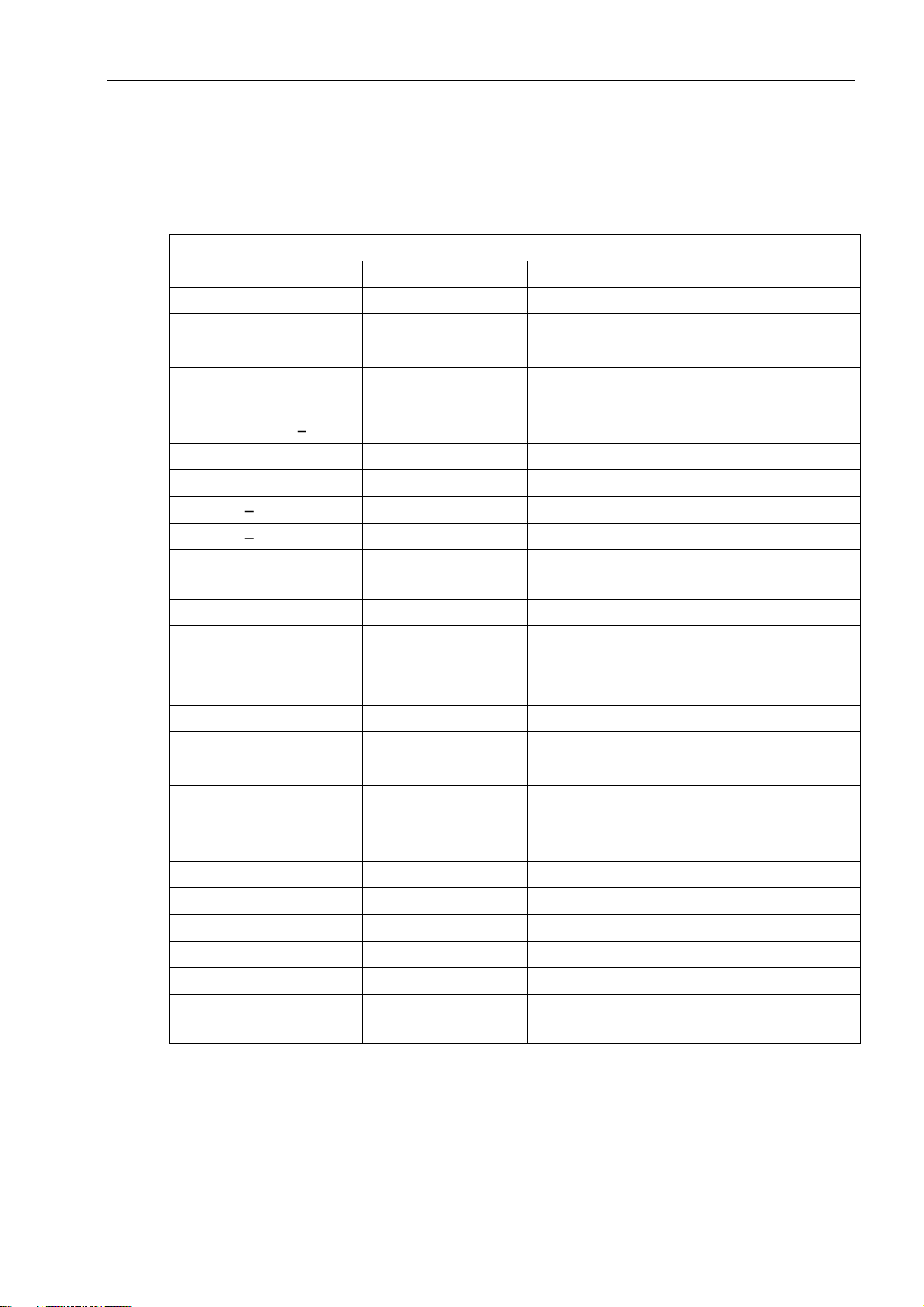

Emulation

mode

LPI

options

Font(s)

options

Font

size

Default

LPI

Default

EDR

Comments

Native,

6.00,

6.77,

7.52,

8.13

Standard

13X24

7.52

3

Default setup for

monochrome paper

TH230

Tall

13X27

6.77

3

Emulation

2-color

13X27

6.77

3

Default setup for twocolor paper

Papersaving

13X18

10.15

3

TH210/

A793/A794

emulation

6.00,

7.52,

8.13

Standard

13X24

7.52

3

LEGACY

emulation

6.00

Tall 13X27

6.00

7

Default setup for

Escape Commands

Standard

13X24

6.00

10

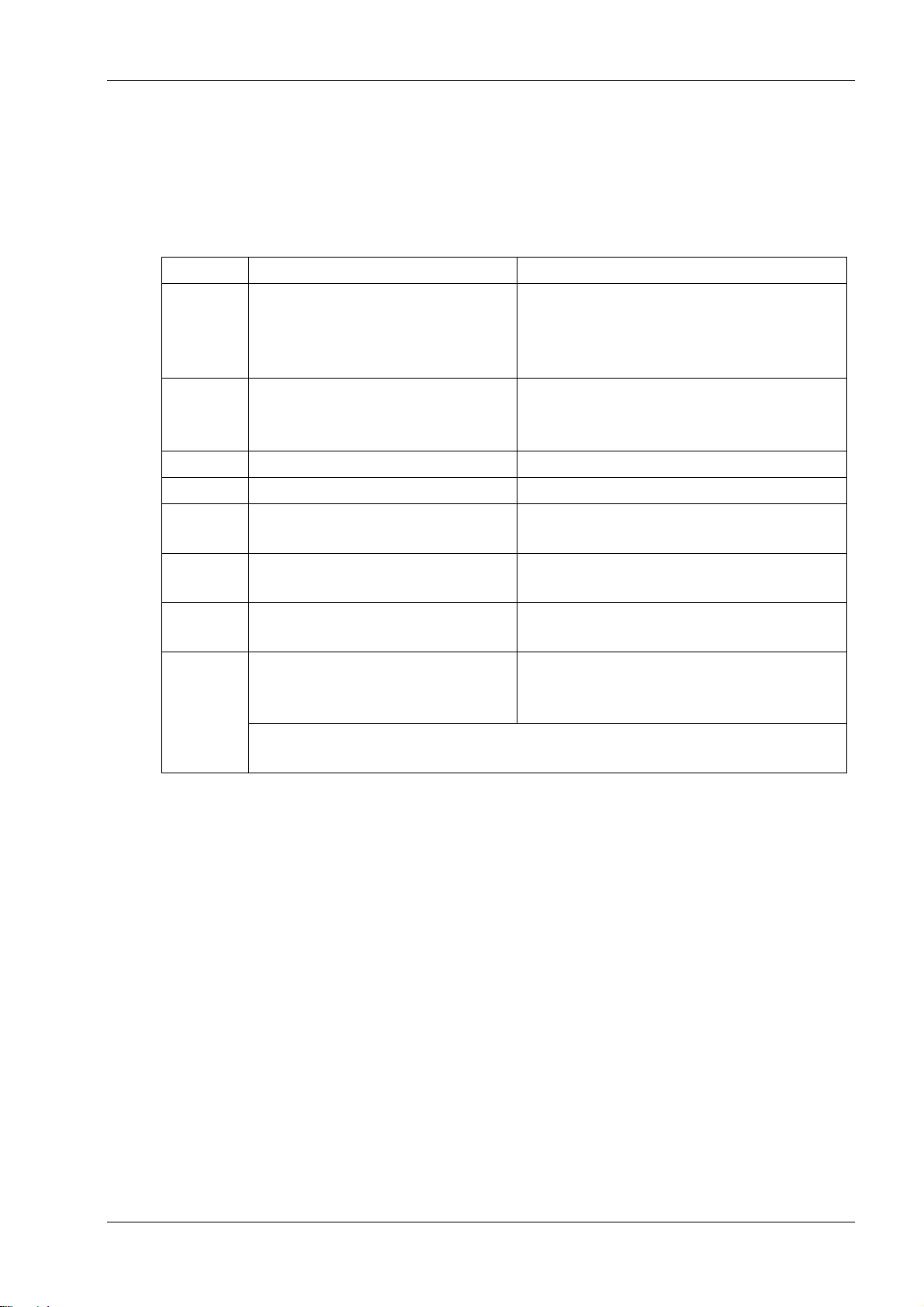

Emulation modes

The Wincor Nixdorf TH250 Series printer may be operated in a number of different emulation

modes. However, printing characteristics and defaults may differ, depending on the desired mode.

For instance, two-color paper commands and features are available only in TH250 native mode.

Print setup in emulation modes

Refer to the chart below for defaults and allowed printing options in each emulation mode.

The following list clarifies how the TH250 printer will behave in each emulation mode:

Two-color paper commands and features are supported only in native mode.

If the paper type is changed using the 0x1D 0x81 command, the font and default lines per inch

(LPI) will be setup as in the table above.

If only the font is changed, the default LPI will automatically be changed as in the table above.

If emulation is switched to LEGACY, Native, TH230, TH210/TH210-2/A794 or A793

emulation(s), the paper type will automatically be changed to monochrome paper, and the

font and LPI will be changed as in the table above.

If emulation is switched from any emulation to native or TH230, the font and LPI will remain

unchanged because the Native and TH230 modes supports all font and LPI options offered in

the emulation modes.

The “Set Default LPI” option in the configuration menu is not offered in LEGACY emulation

mode. The LPI is set at 6.00.

18

TH250 Programmer’s Guide

Printer actions

Code (hexadecimal)

Command

10

Clear printer

19

Perform full knife cut (or code 1B 69)

1A

Perform partial knife cut (or code 1B 6D)

1B 07

Generate tone

1B 3D n

Select peripheral device (for multi-drop)

1B 40

Initialize printer

1B 63 34 n

Select sensors to stop printing

1B 63 35 n

Enable or disable panel button

1B 69

Perform full knife cut (or code 19)

1B 6D

Perform partial knife cut (or code 1A)

1B 70 n p1 p2

Generate pulse to open cash drawer

1B 72 m

Set current color

1F 03 3C ll hh

Set timeout value for low-power idle state

1F 70

Set printer into low-power idle state

1D 56 m

Select cut mode and cut paper (or code 1D 56 m n)

1D 56 m n

Select cut mode and cut paper (or code 1D 56 m)

1D 81 m n

Set paper type (for two-color printing)

1F 03 16 05 n

Set interpretation of Set current color command

1F 03 4E n1 n2

Port Idle Timeout

1F 74

Print test form

Print and paper feed

Code (hexadecimal)

Command

0A

Print and feed paper one line

0D

Print and carriage return

14n

Feed n print lines

15 n

Feed n dot rows

16 n

Add n extra dot rows

17

Print

1B 4A n

Print and feed paper

1B 64 n

Print and feed n lines

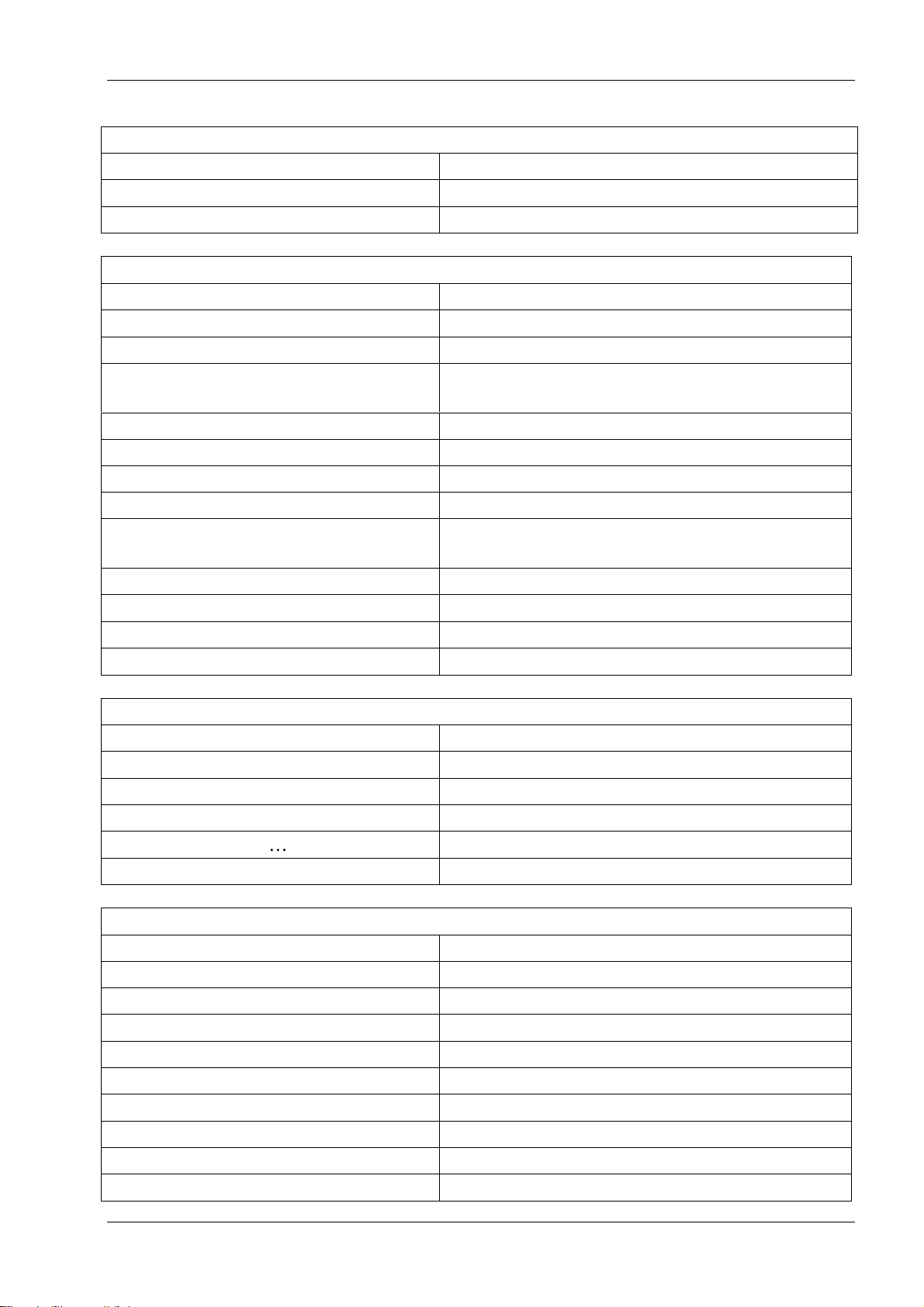

Programming Commands

Commands listed by function

19

TH250 Programmer’s Guide

Vertical and horizontal positioning

Code (hexadecimal)

Command

09

Horizontal tab

1B 14 n

Set column

1B 24 nL nH

Set absolute starting position

1B 32

Set vertical line spacing to 1/6 inch

1B 33 n

Set vertical line spacing

1B 44 n1...nk 00

Set horizontal tab positions

1B 5C n1 n2

Set relative print position

1B 61 n

Select justification

1D 4C nL nH

Set left margin

1D 50 x y

Set horizontal and vertical minimum motion units

1D 57 nL nH

Set printing area width

Text characteristics

Code (hexadecimal)

Command

12

Select double-wide characters

13

Select single-wide characters

1B 12

Select 90 degree counter-clockwise rotated print

1B 16 n

Select pitch (column width)

1B 20 n

Set right-side character spacing

1B 21 n

Select print mode

1B 25 n

Select or cancel user-defined character set

1B 26 s c1 c2

Define user-defined character set

1B 2D n

Select or cancel underline mode

1B 3A 30 30 30

Copy character set from ROM to RAM

1B 3F n

Cancel user-defined character

1B 45 n

Select or cancel emphasized mode

1B 47 n

Select or cancel double-strike

1B 49 n

Select or cancel italic print

1B 52 n

Select international character code

1B 56 n

Select or cancel 90 degree clockwise rotated print

1B 74 n

Select international character set

1B 7B n

Select or cancel upside-down print mode

1D 21 n

Select character size

1D 42 n

Select or cancel white/black reverse print mode

1D 62 n

Set smoothing

1D 85 m n

Reverse color text mode (two-color)

1D 8D n m

Text strike-through mode

1D F0 01 n

Select font ID number

1D F0 02 ns

Select font tyle number

20

TH250 Programmer’s Guide

Text characteristics

Code (hexadecimal)

Command

1D F0 03

Save font ID number as default font at power up

1D F0 80

Download font

1D F0 C0 02

Download font list

1F 03 45 FSID

Configure use of font set over power cycles

1F 03 46 n

Configure line spacing

1F 05 n

Select superscript or subscript modes

1F 26 s c1 c2

Define extended user-defined character set

1F 69 n

Select active user-defined character set

1D F0 20 nn

Get double-byte font CRC (font ID)

1D F0 21 nn mm

Get double-byte font CRC (font ID and font style)

Text characteristics

Code (hexadecimal)

Command

12

Select double-wide characters

13

Select single-wide characters

1B 12

Select 90 degree counter-clockwise rotated print

1B 16 n

Select pitch (column width)

1B 20 n

Set right-side character spacing

1B 21 n

Select print mode

1B 25 n

Select or cancel user-defined character set

1B 26 s c1 c2

Define user-defined character set

1B 2D n

Select or cancel underline mode

1B 3A 30 30 30

Copy character set from ROM to RAM

1B 3F n

Cancel user-defined character

1B 45 n

Select or cancel emphasized mode

1B 47 n

Select or cancel double-strike

1B 49 n

Select or cancel italic print

1B 52 n

Select international character code

1B 56 n

Select or cancel 90 degree clockwise rotated print

1B 74 n

Select international character set

1B 7B n

Select or cancel upside-down print mode

1D 21 n

Select character size

1D 42 n

Select or cancel white/black reverse print mode

1D 62 n

Set smoothing

1D 85 m n

Reverse color text mode (two-color)

1D 8D n m

Text strike-through mode

1D F0 01 n

Select font ID number

1D F0 02 n

Select font style number

1D F0 03

Save font ID number as default font at power up

21

TH250 Programmer’s Guide

Text characteristics

Code (hexadecimal)

Command

1D F0 80

Download font

1D F0 C0 02

Download font list

1F 03 45 FSID

Configure use of font set over power cycles

1F 03 46 n

Configure line spacing

1F 05 n

Select superscript or subscript modes

1F 26 s c1 c2

Define extended user-defined character set

1F 69 n

Select active user-defined character set

1D F0 20 nn

Get double-byte font CRC (font ID)

1D F0 21 nn mm

Get double-byte font CRC (font ID and font style)

Graphics

Code (hexadecimal)

Command

11 n1 . . . n72

Print raster graphics

1B (+*.BMP file)

Download BMP logo

1B 2A m n1 n2 d1 dn

Select bit image mode

1B 2E m n rL rH d1 dn

Print advanced raster graphics

1B 4B n1 n2 d1 dn

Select single-density graphics

1B 59 n1 n2 d1 dn

Select double-density graphics

1C 70 n m

Print flash logo

1C 71 n . . . .

Define flash logos

1D 23 n

Select the current logo (downloaded bit image)

1D 2A n1 n2 d1 dn

Define downloaded bit image

1D 2F m

Print downloaded bit image

1D 82 n1 n72

Print raster monochrome graphics

1D 83 n1 n144

Print raster color graphics

1D 84 m n1 n2 d1 dx

Download logo image

1D 8B n m o

Apply shading to logo

1D 86 m

Monochrome shade mode

1D 87 m

Color shade mode

1D 89 n m

Logo print with color plane swap

1D 8C n m

Merge watermark mode

1D 90 m x y o p q

Form and merge real time surround graphic

1D 91 n

Save graphics buffer as logo

1D 92 n

Background logo print mode

1D 99 l m n o

Apply margin message mode

1D 9A n m o

Shade and store logo

1D 9B m n

Logo print with knife cut

1D A0 nl nh

Set temporary max target speed

1F 04 n

Convert 6-dots/mm bitmap to 8 dots/mm bitmap

22

TH250 Programmer’s Guide

Graphics

Code (hexadecimal)

Command

1F 7B n

Enable constant speed logos

Status

Batch mode

Code (hexadecimal)

Command

1B 75 0

Transmit peripheral device status (RS-232C printers only)

1B 76

Transmit paper sensor status

1D 49 n

Transmit printer ID

1D 49 40 27

Transmit printer model number

1D 72 n

Transmit status

1F 56

Send printer software version

Real time

Code (hexadecimal)

Command

10 04 n

Real time status transmission (DLE sequence)

10 05 n

Real time request to printer (DLE sequence)

1D 03 n

Real time request to printer (GS sequence)

1D 04 n

Real time status transmission (GS sequence)

1D 05

Real time printer status transmission

1F 7A

Real time commands disabled

Automatic status back / Unsolicited status mode

Code (hexadecimal)

Command

1D 61 n

Enable/disable Automatic Status Back (ASB)

1D 61 n

Select or cancel unsolicited status mode

23

TH250 Programmer’s Guide

Bar codes

Code (hexadecimal)

Command

1D 48 n

Select printing position for HRI characters

1D 66 n

Select pitch for HRI characters

1D 28 6B 04 00

00 31 41 n1 n2

Select model for QR Code

1D 28 6B 03 00 31 43 n

Set size of module for QR Code

1D 28 6B 03 00 31 44 m

Set data parsing mode for QR Code

1D 28 6B 03 00 31 45 n

Select error correction level for QR Code

1D 28 6B qL qH

31 50 30 f1 ... fk

Store symbol data for QR Code

1D 28 6B 03 00 31 51 30

Print symbol data for QR Code

1D 68 n

Select bar code height

1D 6B m d1 dk 00 or 1D 6B m n d1 dn

Print bar code

1D 6B FF n

Print Multiple Barcodes

1D 6B n d1... 00

Print GSI Databar (formerly RSS), null terminated

1D 6B m n L n H d1... dn

Print GSI Databar (formerly RSS), data length

specified

1D 70 a b c d e f

Select PDF 417 parameters

1D 71 a b c d e f L f H

Set GSI Databar (formerly RSS) parameters

1D 77 n

Select bar code width

1D 28 6B 05 00 36 42 m d1 d1

Set DataMatrix parameters

1D 28 6B 05 00 36 43 n

Set DataMatrix module size

1D 28 6B pL pH 36 50 30 d1...dk

Store DataMatrix data in symbol storage area

1D 28 6B 03 00 36 54 30

Print DataMatrix symbol data in the symbol storage

area

Page mode

Code (hexadecimal)

Command

0C

Print and return to standard mode

18

Cancel print data in page mode

1B 0C

Print data in page mode

1B 4C

Select page mode

1B 53

Select standard mode

1B 54 n

Select print direction in page mode

1B 57 n1, n2 n8

Set print area in page mode

1D 24 nL nH

Set absolute vertical print position in page mode

1D 5C nL nH

Set relative vertical print position in page mode

24

TH250 Programmer’s Guide

Macros

Code (hexadecimal)

Command

1D 3A

Select or cancel macro definition

1D 5E r t m

Execute macro

User data storage

Code (hexadecimal)

Command

1B 27 m a0 a1 a2 d1…dm

Write to user data storage

1B 34 m a0 a1 a2

Read from user data storage

1D 22 n

Select memory type (SRAM/flash) where to save

logos or user-defined fonts

1D 22 55 n1 n2

Flash memory user sectors allocation

1D 22 60 n1

Flash object area pack

1D 22 61 n1 n2 (n3)

Flash object delete

1D 22 80

Expanded flash memory allocation

1D 22 81 n

Select flash area for storing logos and user-defined

characters

1D 22 90 n

Return flash area size

1D 40 n

Erase user flash sector

1D 97 m n

User storage status

1D F0 10 n

Lock permanent flash area

Flash download

Code (hexadecimal)

Command

1B 5B 7D

Switch to flash download mode

1D 0E

Erase all flash contents except boot sector

1D 0F

Return main program flash CRC

1D 11 00 00 00 00 d1 dn

Download Application

1D FF

Reset firmware

Ethernet setup commands

Code (hexadecimal)

Command

1B 5B 7D

Switch to flash download (boot mode)

1F 08 00

Restore default settings

1F 08 01 n1 n2 n3 n4

Set IP address

1F 08 02 n1 n2 n3 n4

Set net mask

1F 08 03 n1 n2 n3 n4

Set gateway

1F 08 04 n1 n2

Set raw TCPIP port

1F 08 08 n1

DHCP

1F 08 09 n1

Inactivity timeout

1F 08 0A n1

Keep-alive pings (arps)

25

Loading...

Loading...