TH210

Thermal Printer

Programmer’s Guide (December 2015)

Contents

About this Guide ........................................................................................................................... 1

How to use this guide .................................................................................................................... 1

Where to find the basics ................................................................................................................ 1

Where to find advanced technical information .............................................................................. 1

Support ....................................................................................................................................... 1

Diagnostics and Configuration ...................................................................................................... 2

Start-up Diagnostics ................................................................................................................... 2

Runtime Diagnostics ...................................................................................................................... 3

Remote Diagnostics ....................................................................................................................... 3

Accessing the remote diagnostic tallies ...................................................................................... 4

Indicators ...................................................................................................................................... 5

Error conditions and correcting them......................................................................................... 5

Communication of printer status to the host application ........................................................... 5

Printer configuration ..................................................................................................................... 6

Using the configuration menu to configure the printer .............................................................. 6

Configuring the printer ............................................................................................................... 7

Communication interface settings.............................................................................................. 8

Diagnostics modes ..................................................................................................................... 8

Enable or disable data scope mode ............................................................................................ 9

Enable or disable receipt test mode ........................................................................................... 9

Electronic Journal Datascope Diagnostic .................................................................................. 10

Printer emulations ....................................................................................................................... 10

Printer settings and functions .................................................................................................. 10

Programming the Printer ............................................................................................................ 13

Overview of commands ............................................................................................................... 13

Comparison to A793 .................................................................................................................... 13

Character appearance ................................................................................................................. 14

Width specifications .................................................................................................................... 14

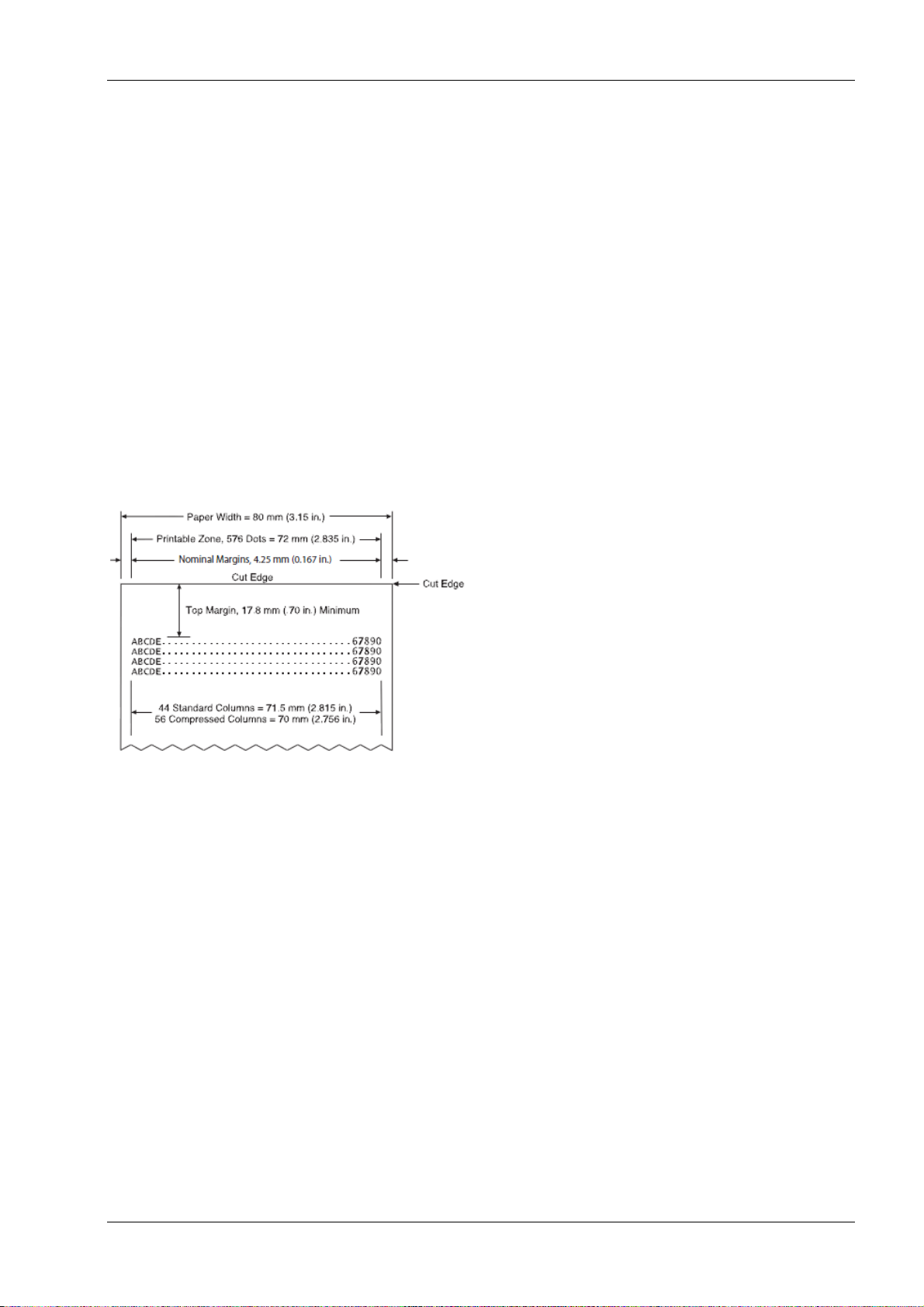

Print zones................................................................................................................................... 15

Print zones for 80mm paper ..................................................................................................... 15

Emulation modes ......................................................................................................................... 16

Print setup in emulation modes ............................................................................................... 16

Programming Commands ........................................................................................................... 17

Commands listed by function ...................................................................................................... 17

Command conventions ................................................................................................................ 24

Command descriptions ................................................................................................................ 24

Printer actions ......................................................................................................................... 24

Print and paper feed ................................................................................................................ 29

Text characteristics commands ................................................................................................ 39

Double-byte fonts .................................................................................................................... 53

Graphics ................................................................................................................................... 56

Status .......................................................................................................................................... 65

Status command introduction ..................................................................................................... 65

Batch mode.............................................................................................................................. 65

Real time commands................................................................................................................ 69

Rules for using real time commands ........................................................................................ 69

Automatic Status Back ............................................................................................................. 74

Unsolicited status mode........................................................................................................... 76

Bar codes 79

QR code Overview ................................................................................................................... 79

Select printing position of HRI characters ................................................................................. 83

Select pitch of HRI characters ................................................................................................... 83

Select bar code height .............................................................................................................. 83

Print multiple barcodes ............................................................................................................ 85

Print GS1 DataBar, null terminated .......................................................................................... 86

Print GS1 DataBar, data length specified .................................................................................. 87

Set GS1 DataBar parameters .................................................................................................... 87

Select PDF 417 parameters ...................................................................................................... 88

Select bar code width............................................................................................................... 89

Set DataMatrix Parameters ...................................................................................................... 90

Set DataMatrix Module size ..................................................................................................... 91

Store DataMatrix data in symbol storage area ......................................................................... 91

Print DataMatrix symbol data in the symbol storage area ........................................................ 92

Page mode ............................................................................................................................... 93

Print and return to standard mode .......................................................................................... 93

Cancel print data in page mode................................................................................................ 94

Print data in page mode ........................................................................................................... 94

Select page mode..................................................................................................................... 94

Select standard mode .............................................................................................................. 95

Select print direction in page mode ......................................................................................... 96

Select print area in page mode................................................................................................. 96

Set absolute vertical print position in page mode..................................................................... 97

Set relative vertical print position in page mode ...................................................................... 98

Macros ..................................................................................................................................... 99

Select or cancel macro definition ............................................................................................. 99

Execute macro ......................................................................................................................... 99

User data storage ....................................................................................................................100

Write to user data storage ......................................................................................................100

Read from user data storage ...................................................................................................100

Select memory type (SRAM/flash) where to save logos or user-defined fonts .........................100

Flash memory user sectors allocation .....................................................................................101

Flash object area pack .............................................................................................................101

Flash object delete ..................................................................................................................102

Expanded flash memory allocation .........................................................................................102

Select flash area for storing logos and user-defined characters ...............................................103

Return flash area size ..............................................................................................................103

Erase user flash sector ............................................................................................................103

Lock permanent font flash area ...............................................................................................104

Flash download .......................................................................................................................104

Settings commands .................................................................................................................106

Miscellaneous configuration commands .................................................................................107

Appendix A: .............................................................................................................................. 113

Commands listed by hexadecimal code ..................................................................................... 113

Appendix B: ............................................................................................................................... 118

Resident Character Sets ............................................................................................................. 118

Character sets .........................................................................................................................118

Character code table Page 0 (PC437: USA, Standard Europe): .................................................118

Character code table Page 1 (PC850: Multilingual Latin I): ......................................................119

Character code table Page 2 (PC852: Latin II): .........................................................................120

Character code table Page 3 (PC860: Portuguese): ..................................................................121

Character code table Page 4 (PC863: Canadian French): .........................................................122

Character code table Page 5 (PC865: Nordic): .........................................................................123

Character code table Page 6 (PC858: Multilingual I + Euro): ....................................................124

Character code table Page 7 (PC866: Russian): ........................................................................125

Character code table Page 8 (WPC1252: Latin I): .....................................................................126

Character code table Page 9 (PC862: Hebrew): .......................................................................127

Character code table Page 10 (PC737: Greek): ........................................................................128

Character code table Page 11 (PC874: Thai): ...........................................................................129

Character code table Page 12 (PC857: Turkish): ......................................................................130

Character code table Page 13 (WPC1251: Cyrillic): ..................................................................131

Character code table Page 14 (WPC1255: Hebrew): ................................................................132

Character code table Page 15 (KZ_1048: Kazakh): ...................................................................133

Character code table Page 16 (WPC1254: Turkish): .................................................................134

Character code table Page 17 (WPC1250: Central Europe): .....................................................135

Character code table Page 18 (WPC28591: Latin 1): ................................................................136

Character code table Page 19 (WPC28592: Latin 2): ................................................................137

Character code table Page 20 (WPC28599: Turkish): ...............................................................138

Character code table Page 21 (WPC28605: Latin 9): ................................................................139

Character code table Page 22 (PC864: Arabic): ........................................................................140

Character code table Page 23 (PC720: Arabic): ........................................................................141

Character code table Page 24 (WPC1256: Arabic): ..................................................................142

Character code table Page 25 (WPC28596: Arabic): ................................................................143

Character code table Page 26 (KATAKANA: Asia): ....................................................................144

Character code table Page 27 (PC775: Baltic): .........................................................................145

Character code table Page 28 (WPC1257: Baltic): ....................................................................146

Character code table Page 29 (WP28594: Baltic): ....................................................................147

TH210 Programmer’s Guide

About this Guide

How to use this guide

This is a supplemental guide providing programming information on Wincor Nixdorf’s TH210

printers. This guide is written for tech-savvy users who are interested in customizing or adjusting

printer functionality and is meant to be used in conjunction with the User Manual.

If you experience any difficulties during the programming process or feel unsure of adjustments

you have made, contact your Wincor Nixdorf representative for further assistance.

Where to find the basics

If you are looking for information on setup or basic operation, refer to the User Manual. The

programmer’s guide assumes that you have the User Manual handy for reference or are already

familiar with the printer.

Where to find advanced technical information

This guide contains the most complete information available on programming the printer. If you

cannot find what you need here or would like further guidance on how to program the printer,

contact a Wincor Nixdorf representative for assistance.

If you are having problems with the physical operation of the printer, the Service Manual provides

in-depth information on diagnostics and service. The Service Manual is available to qualified

service technicians who have been certified by Wincor Nixdorf to perform advanced procedures.

Support

For more advanced procedures and troubleshooting, you may need to refer to the printer’s service

manual or speak to a Wincor Nixdorf technical professional. Your representative is able to provide

you with necessary information.

For on-line service, refer to the Web site at www.wincor-nixdorf.com.

1

TH210 Programmer’s Guide

Diagnostics and Configuration

The printer performs a number of diagnostics that provide useful information about the operating

status of the printer. The following diagnostic tests are available.

Start-up diagnostics

Perform during the printer’s start-up cycle.

Runtime diagnostics

Perform during normal printer operation.

Remote diagnostics

Maintained during normal operation and reported in the print test.

The printer can be configured with the following settings and functions through the

configuration menu that is printed on the receipt. For more information on

configuring the printer, see “Printer configuration” on page xx.

Communication interfaces

Diagnostic modes

Printer emulations/software options

Hardware options

Firmware features

Start-up Diagnostics

When the printer receives power or performs a hardware reset, it automatically performs the

startup diagnostics (also known as level 0 diagnostics) during the start-up cycle. The following

diagnostics are performed:

Turn off motors

Perform boot CRC check of the firmware ROM and test main program CRC

Failure causes Start-up Diagnostics to stop; the printer beeps and the LED flashes a

set number of times, indicating the nature of the failure. The table in the

“Indicators” section (page 14) describes the specific tone and LED sequences.

Check if paper is present

Return the knife to the home position

Failure causes a fault condition. The table in the “Indicators” section (page 14)

describes the specific tone and LED sequences.

Check if receipt cover is closed

Failure does not interrupt the start-up cycle.

At power up, if the LED blinks twice, every four seconds, the object storage areas are being

initialized. This process could take up to two minutes. Once the object storage area initialization is

complete the printer will continue with its normal startup procedure and operation. DO NOT

RESET THE PRINTER UNTIL THIS PROCESS IS COMPLETE.

When the start-up diagnostics are complete, the printer makes a two-tone beep (low then high

frequency), the paper feed button is enabled, and the printer is ready for normal operation.

2

TH210 Programmer’s Guide

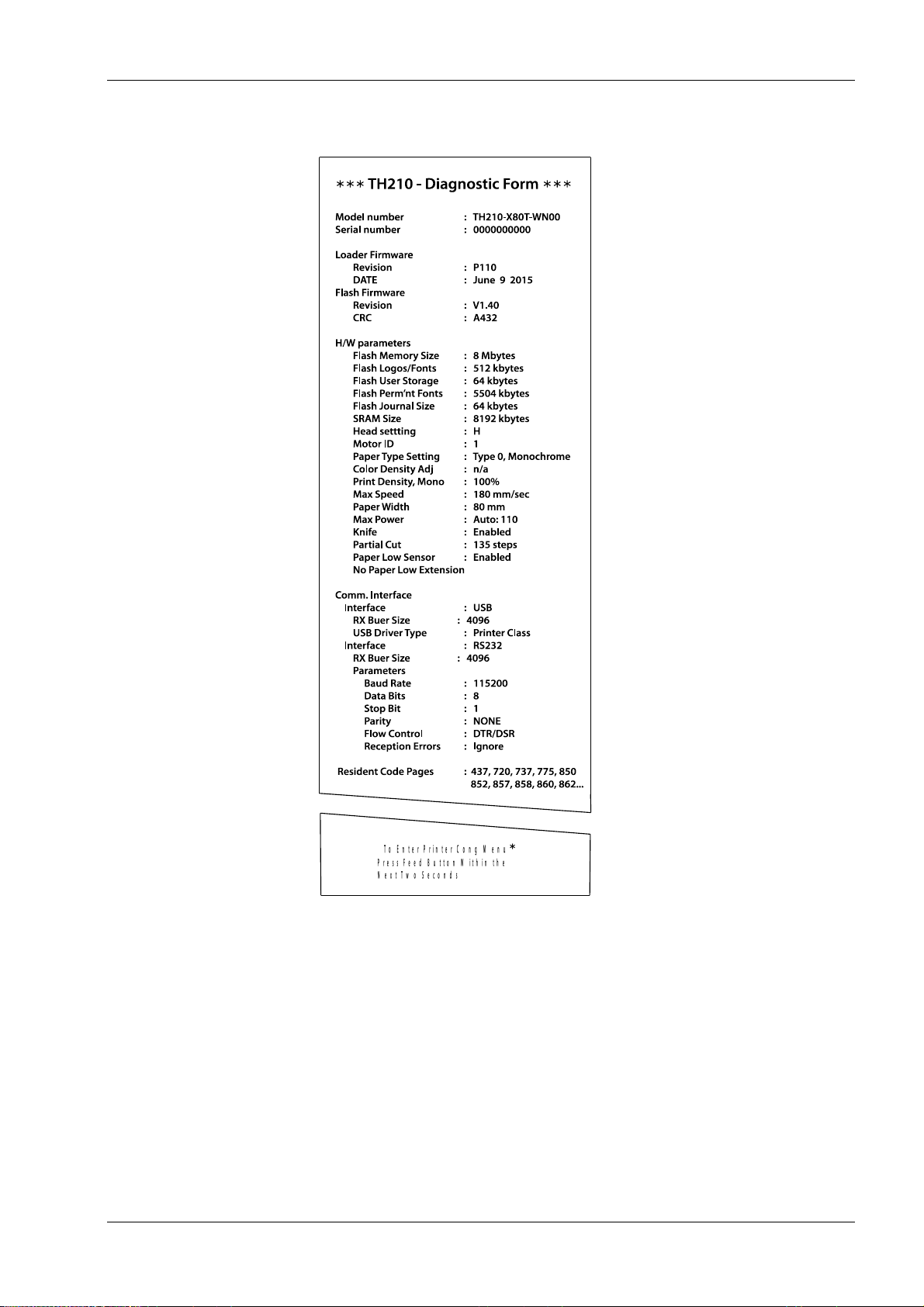

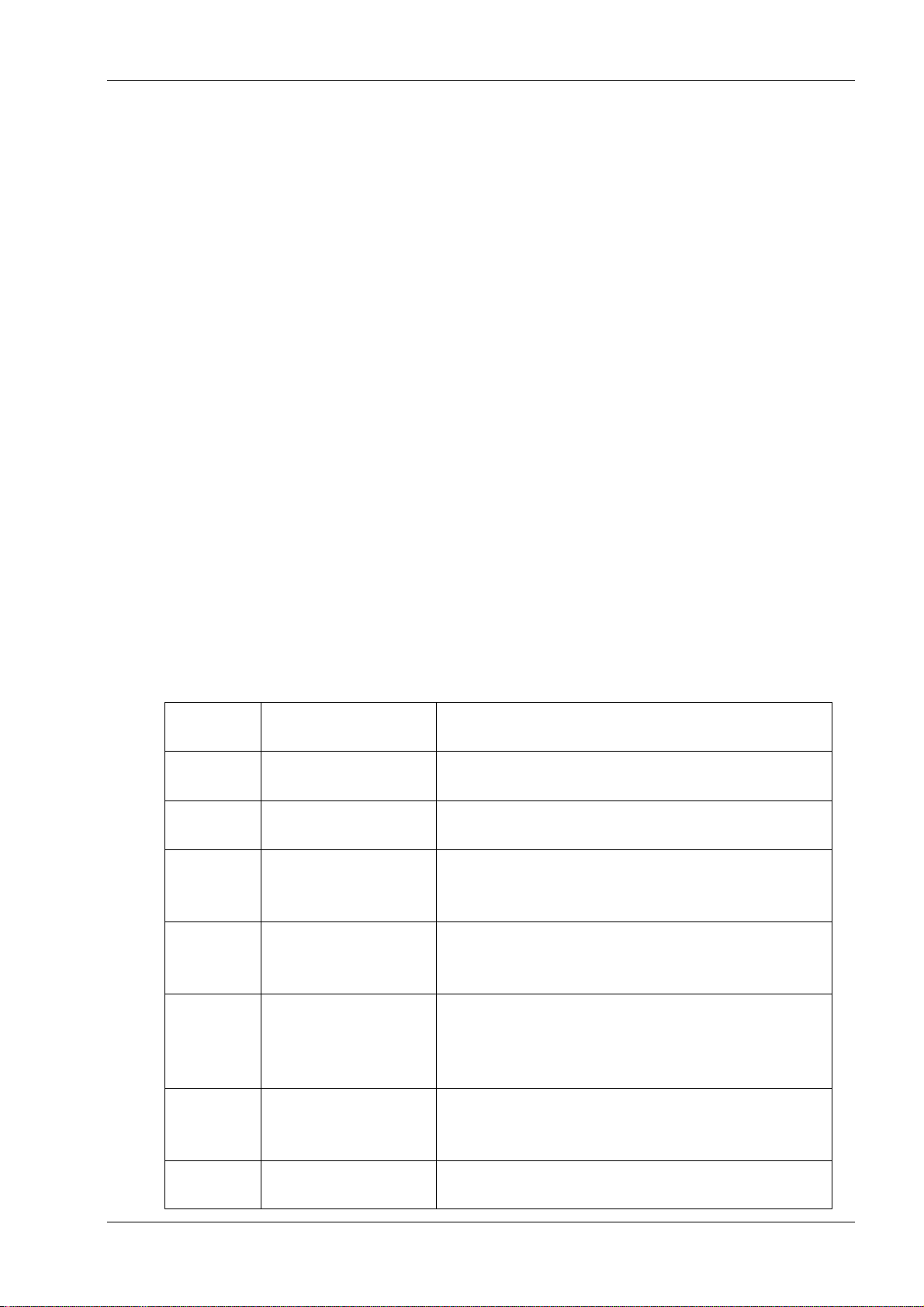

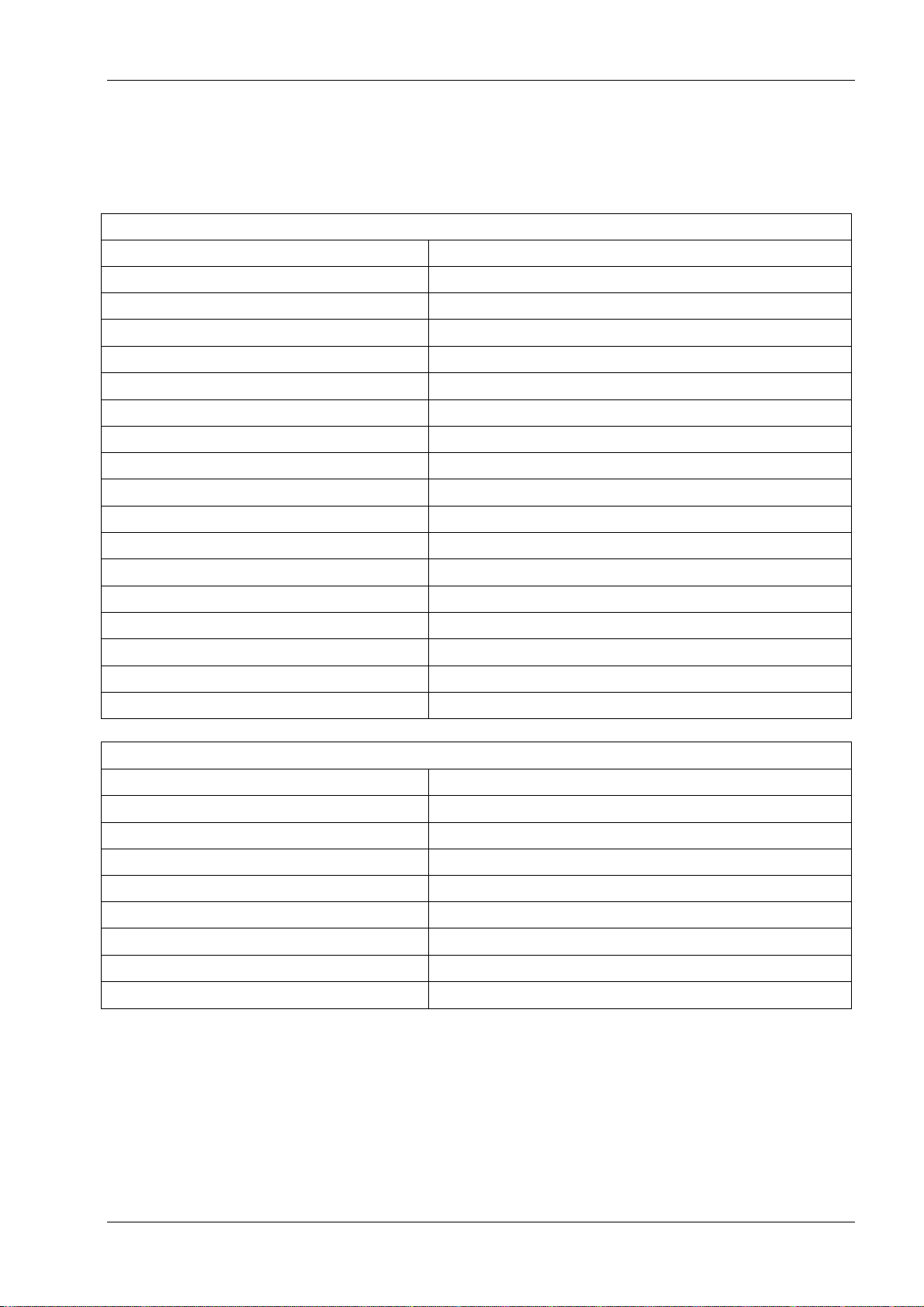

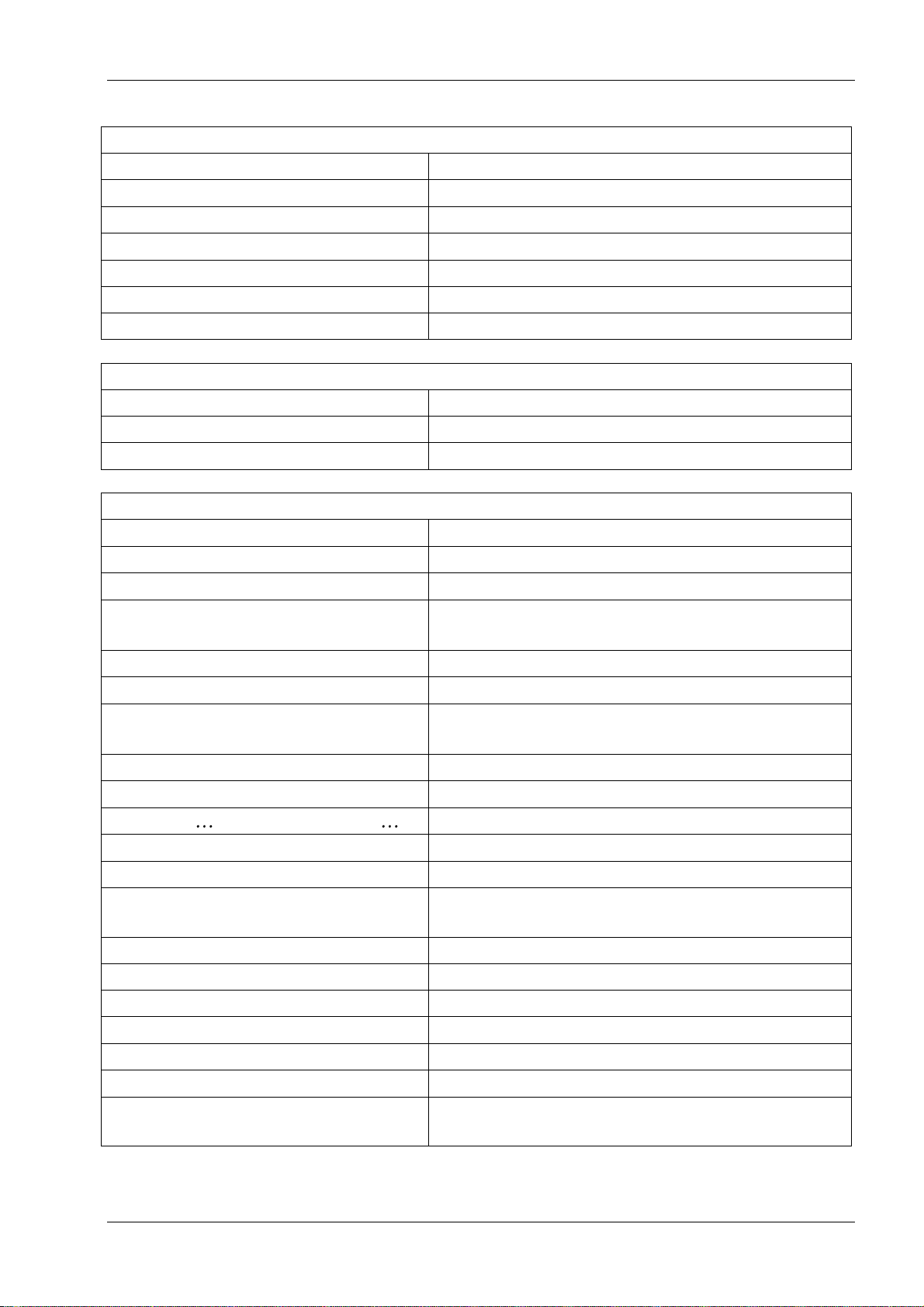

Model number

Serial number

CRC number

Number of lines printed

Number of knife cuts

Number of hours the printer

has been on

Number of flash cycles

Number of cutter jams

Number of times the cover is

opened

Number of barcodes printed

Number of receipt characters

printed

Number of printer faults

Maximum temperature reached

Number of dots printed

Number of dots printed on current

printhead

Number of printhead changes

Number of receipt mechanism

changes

Number of knife mechanism

changes

Number of black mark errors

Number of thermistor errors

Number of low voltage errors

Number of high voltage errors

Number of firmware starts

Number of EEPROM updates

If the printer has not been turned on before, or a new EEPROM has been installed, the default

values for the printer functions will be loaded into the EEPROM during start-up diagnostics, and

the printer will make a quick four-tone beep (high then low frequency, twice).

Runtime Diagnostics

Runtime diagnostics (sometimes called level 2 diagnostics) run during normal printer operation.

When the following conditions occur, the printer automatically turns off the appropriate motors

and disables printing to prevent damage to the printer:

Paper out

Receipt cover open

Knife unable to home

Printhead too hot

Voltages out of range

The LED on the operator panel will signal when these conditions occur as well as indicate what

state or mode the printer is in.

Remote Diagnostics

Remote diagnostics (sometimes called level 3 diagnostics) keeps track of the following tallies and

prints them on the receipt during the print test. See the sample test printout on the next page.

These tallies can be used to determine the printer’s state of health.

3

TH210 Programmer’s Guide

TH210 Diagnostics Form

*** ***

Print test will vary per model or printer configuration.

Accessing the remote diagnostic tallies

Refer to “Command descriptions” in Chapter “Programming commands“

(Status commands: Transmit printer ID, remote diagnostics extension, Hexadecimal 1D 49 40 n)

4

TH210 Programmer’s Guide

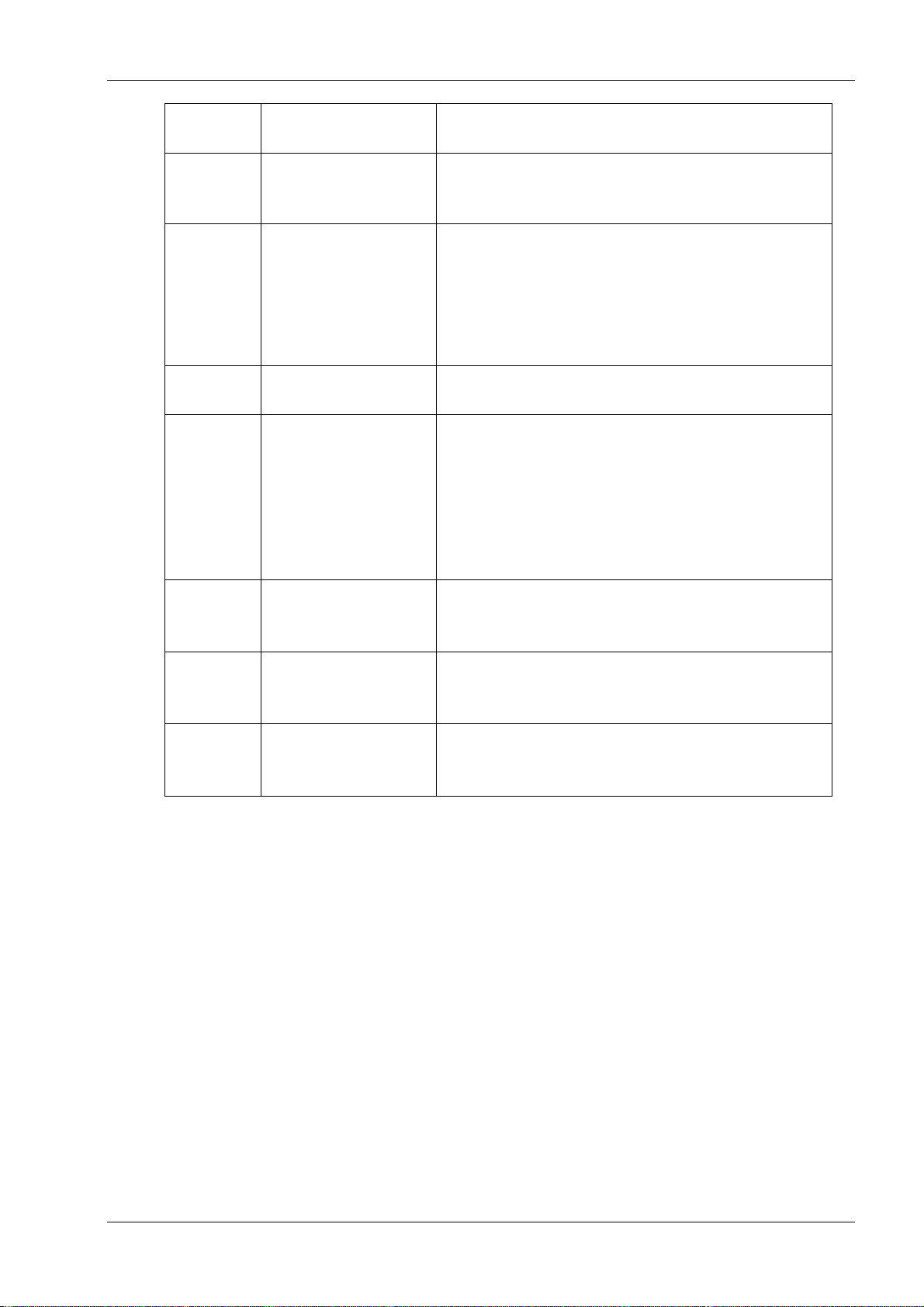

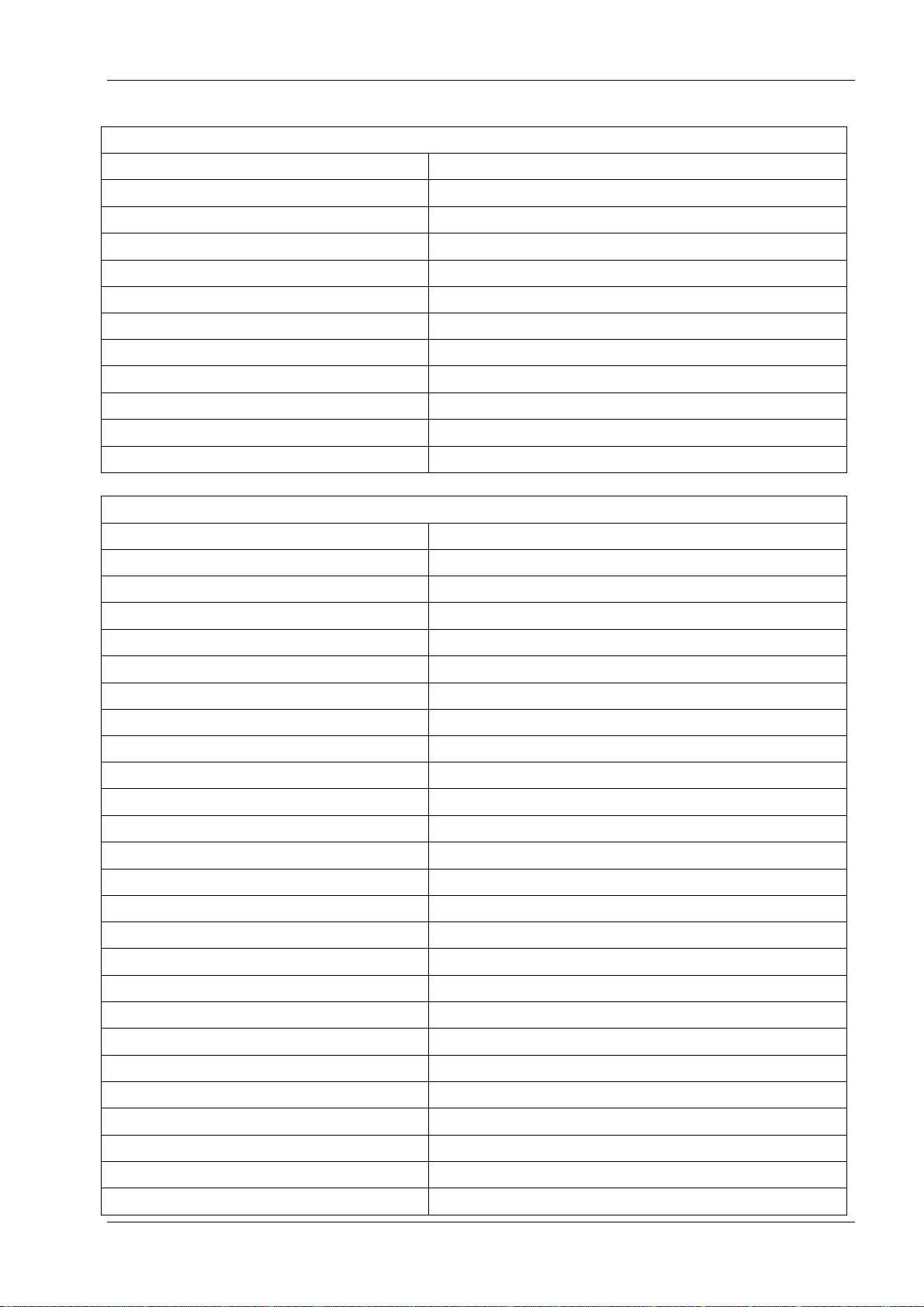

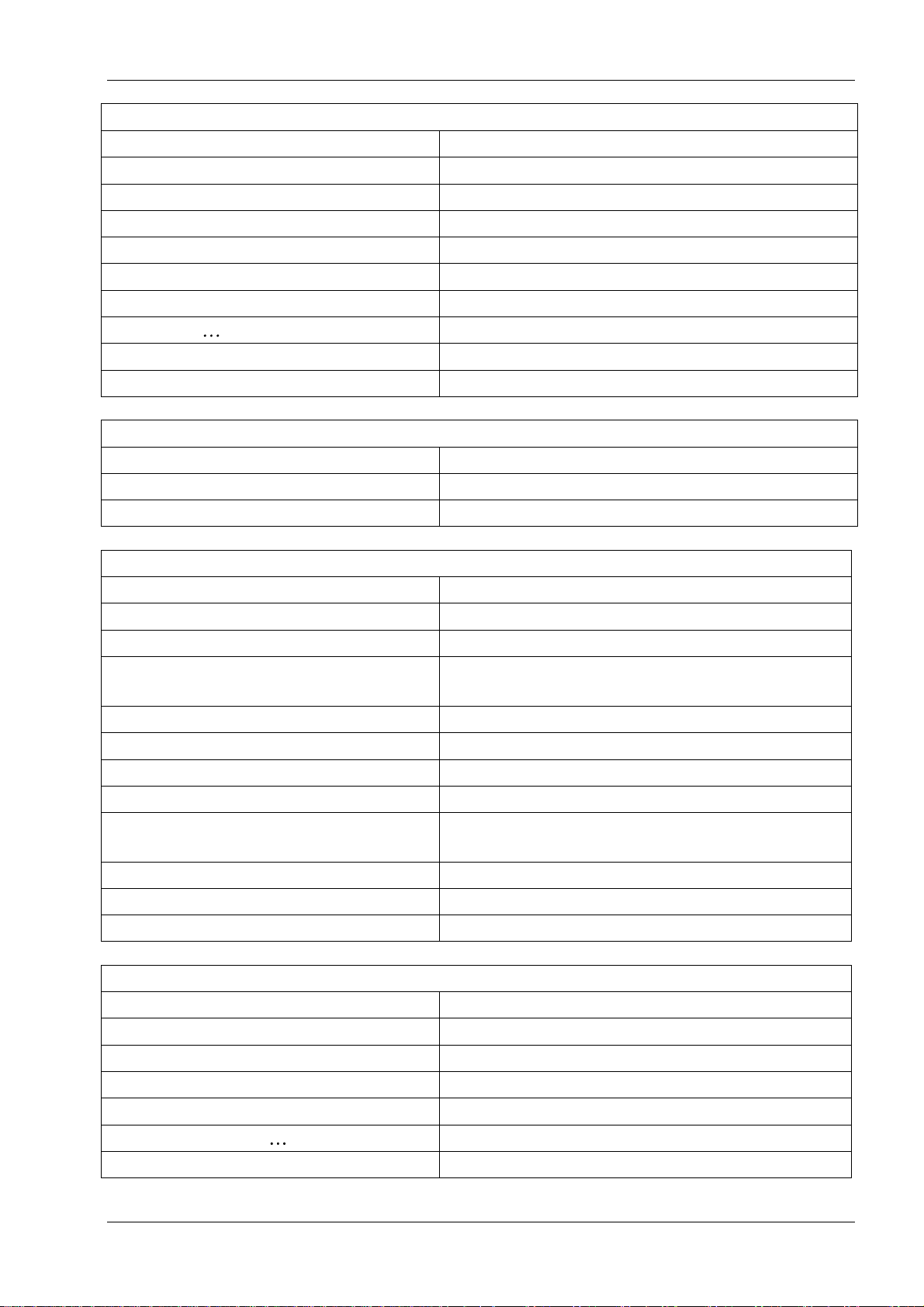

Indicator

Sequence

Condition

LED

Continuous, blinking on

Paper out

Cover open

Black dot sensor error

Knife unable to home

LED

Continuous, blinking off

Paper is low

Printhead too hot

Voltages low/high

LED

Continuous, double LED flash

Write to permanent memory in progress

LED

Blinks once every five seconds

Printer in sleep mode

LED

Continuous, quick blinking (on

power up)

Invalid firmware

LED

Continuous, slow blinking

Power supply and max power setting

don’t match

Tone

Two-tone beep (low frequency,

high frequency)

Start-up diagnostics completed

successfully

LED and

Tone

Two-tone beep (low frequency,

high frequency)

Continuous, quick blinking of LED

When entering flash download mode*

*Note: The printer enters flash download mode when a download command

is sent to the printer.

Indicators

The printer communicates various conditions both visually, with the green LED or audibly, with a

series of tones or beeps.

The following table lists these indicators.

The printer is also able to communicate its status to the host application if the application has been

programmed to receive this information.

Error conditions and correcting them

Refer to section “Troubleshooting the printer” in chapter “Using the printer” in the User Manual.

Communication of printer status to the host application

Refer to section “Command descriptions” in chapter “Programming commands, Status” sections.

5

TH210 Programmer’s Guide

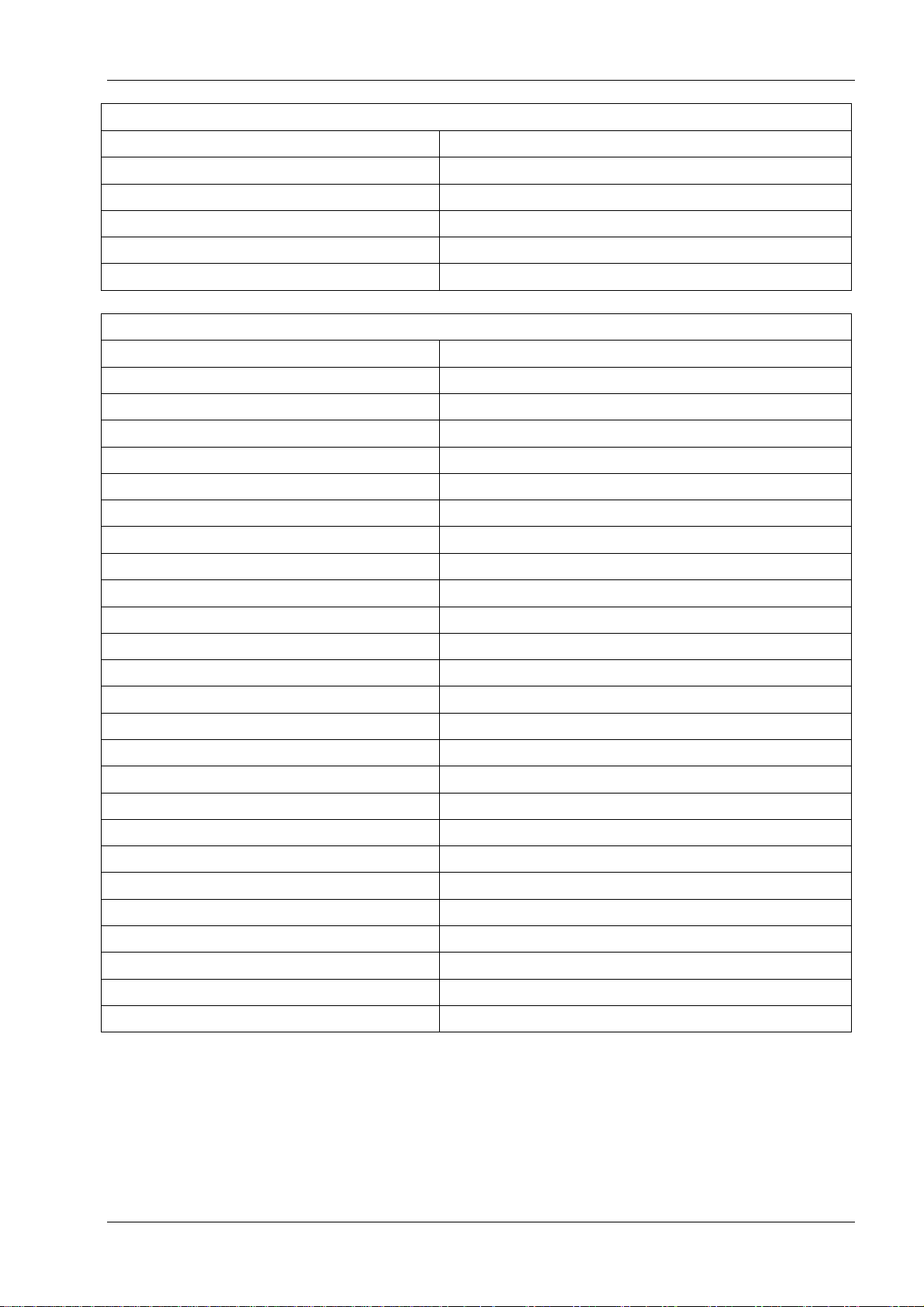

Communication Interfaces

Baud rate

Parity

Hardware (DTR/DSR) or software

(XON/XOFF) flow control

Data reception errors

Alternate DTR/DSR

USB Driver

USB NAK

Diagnostics Modes Normal

Datascope (with or without graphics)

Receipt test

Printer Emulations

Native mode

A794 emulation

A793 emulation

LEGACY emulation

Emulation/Software options

Printer ID mode

Default lines per inch

Carriage return usage

Code 128 Check Digit

Default font

Font size

Journal Print

Hardware options

Color density

Monochrome print density

Max Power

Partial cut distance

Fine partial cut steps

Paper low sensor

Paper low threshold

extension

Printhead setting (cannot

change)

Firmware features

Paper selection lockout

Beep after knife cut

Cash drawer open after

knife cut

Energy-savings timeout

value

Printer configuration

Printers are shipped with all the functions and parameters preset at the factory. Settings for various

printer parameters can be changed. This menu is printed on the receipt and scrolls through

instructions for selecting and changing any of the functions or parameters.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

The following functions and parameters can be changed in the scrolling configuration menu

(except as noted):

Using the configuration menu to configure the printer

Refer to the next section “Configuring the printer”.

6

TH210 Programmer’s Guide

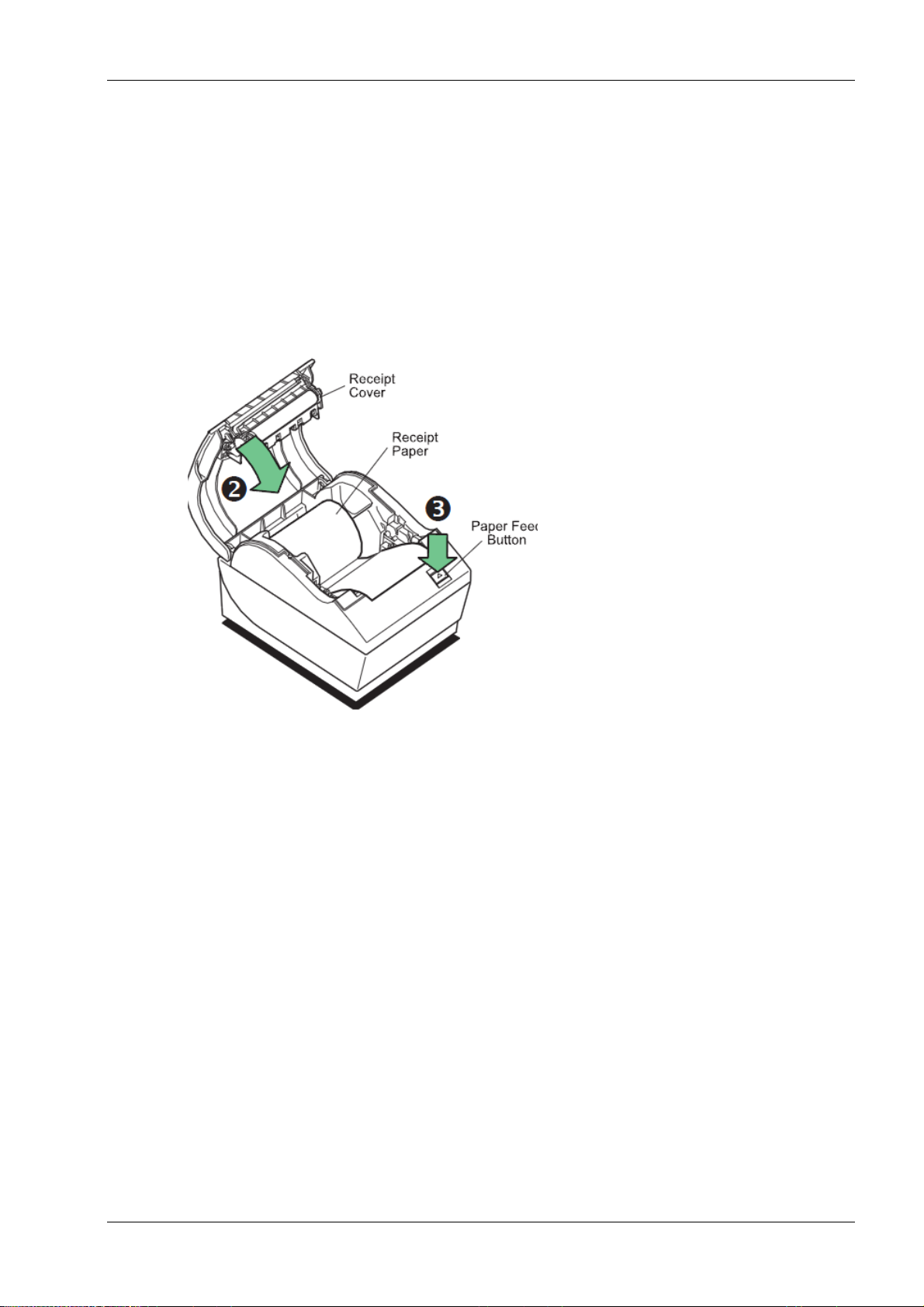

Configuring the printer

The configuration menu allows you to select functions or change various settings for the printer.

Instructions printed on the receipt guide you through the processes.

Caution: Be extremely careful changing any of the printer settings to avoid changing other settings

that might affect the performance of the printer.

1. Turn power off to printer.

2. Make sure receipt paper is loaded in the rpinter before proceeding. Make sure cover is

closed.

3. Apply power to printer and immediately press and hold the paper feed button until the

configuration printout begins.

The printer beeps, then prints Diagnostics Form I.

Press the paper feed button within two seconds to enter the configuration main menu

The printer prints Diagnostics Form II, followed by the Printer Configuration Menu, and

waits for a main menu selection to be made (see sample printout on page 13; short

clicks are used, except when answering “yes” or validating selection).

4. To communicate with the printer, you will press the paper feed button using either

short or long clicks. Use a long click for “yes” (more than one second) and a short click

for “no.” Follow the printed instructions to make selections.

5. Continue through your menu selections until you are asked, “Save New Parameters?”

Select “Yes.”

Reset the Printer.

Open the receipt cover.

Press and hold the paper feed button while closing the receipt cover.

The diagnostic printout verifies your new settings.

7

TH210 Programmer’s Guide

Baud rate

115200 baud

57600 baud

38400 baud

19200 baud

9600 baud

4800 baud

2400 baud

1200 baud

Parity

No Parity

Even Parity

Odd Parity

Flow control methd

Software (XON/XOFF)

Hardware (DTR/DSR)

Data reception errors

Ignore errors

Print “?”

Alternate DTR/DSR

Enabled

Disabled

USB Driver

Printer Cass

Comm Class

USB NAK

Reject Packets When Error

Accept Packets When Error

Communication interface settings

To change the communication interface settings, enter the configuration menu, select “Set

Communication Interface” from the main menu.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed on the configuration menu to select the settings you

want to change.

Note: Press the paper feed button for at least one second to validate the selection.

Setting the RS-232C Serial interface settings

Refer to the section “Configuring the printer”.

Diagnostics modes

To change the the diagnostic modes enter the configuration menu, select “Set Diagnostics Modes”

from the main menu and select one of the following modes:

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Refer to the section “Configuring the printer,” for instructions on how to enter the configuration

menu.

8

Normal: normal operating mode of the printer.

Datascope: the receipt printer prints incoming commands and data in hexadecimal

format to help troubleshoot communication problems. There are DataScope modes

for both with and without graphics.

Receipt test: the receipt printer prints all code pages to verify proper printing of the

receipt.

TH210 Programmer’s Guide

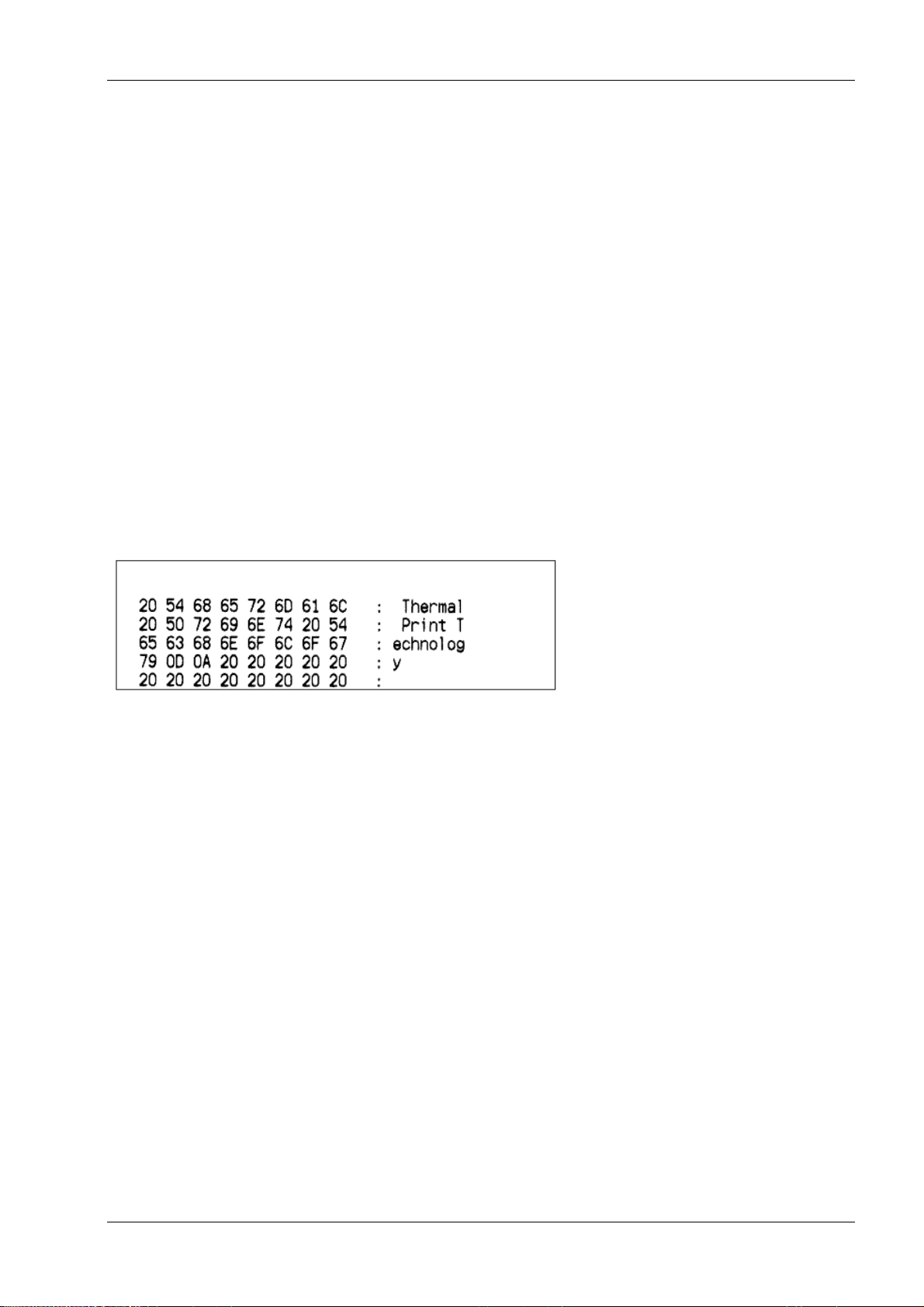

Enable or disable data scope mode

The data scope mode test prints a hexadecimal dump of all data sent to the printer: “1” prints as

hexadecimal 31, “A” as hexadecimal 41 and so on. This helps troubleshoot communication

problems and runs during a normal application (after being enabled through printer configuration).

Note: Data scope mode is usually considered a level 1 diagnostic test.

Data scope mode is enabled and disabled by selecting the “Diagnostics Modes” sub-menu of the

configuration menu. Press the paper feed button as instructed on the “Diagnostics Modes Menu”

to enable or disable the data scope mode test.

Off, normal mode (Data scope mode disabled)

Data scope mode with or without graphics (enabled)

Note: Press the paper feed button for at least one second to validate the selection.

To run the data scope mode:

1. After you have enabled the data scope mode, exit the configuration menu.

2. Run a transaction from the host computer.

All commands and data sent from the host computer will be printed as hexadecimal characters as

shown in the illustration.

To exit the data scope mode:

1. Enter the configuration menu again.

2. Disable the data scope mode.

3. Exit the configuration menu.

The printer is on-line and can communicate normally with the host computer.

Enabling the data scope mode

Refer to the section “Configuring the printer”.

Enable or disable receipt test mode

The receipt test mode verifies proper receipt printing. Receipt test is enabled and disabled by

selecting the “Diagnostics Modes” sub-menu of the configuration menu. See “Configuring the

printer”, for instructions on how to enter the configuration menu.

To run the receipt test mode:

1. Enable the receipt test mode in the configuration menu.

2. Exit the configuration menu.

9

TH210 Programmer’s Guide

3. Push the paper feed button. The receipt station prints all code pages and cuts the

receipt.

4. To repeat this test, push the paper feed button again.

To exit the receipt test mode:

1. Enter the configuration menu again.

2. Disable the receipt test mode.

3. Exit the configuration menu.

The printer is on-line and can again communicate normally with the host computer.

Electronic Journal Datascope Diagnostic

1F 03 18 02 n=1, turn on electronic journal datascope, run time only

1F 03 18 02 n=0, n>1, turn off electronic journal datascope, run time only

1F 03 18 03 n=1, turn on electronic journal datascope, configuration saved over power cycle

1F 03 18 03 n=0, n>1, turn off electronic journal datascope, configuration saved over power cycle

When enabled, “Auto Journal : Datascope” prints on the second diagnostic page.

This diagnostic is for debugging purposes, and should be used only under the direction of customer

support.

Printer emulations

To change the printer emulations settings, enter the configuration menu, select

“Emulation/Software Options” from the main menu and answer “Yes” to “Set printer mode?”

printed on the receipt. This will take you to the instructions for setting the printer emulation.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the printer emulation you want.

Native mode

A794 emulation

A793 emulation

LEGACY emulation

Note: Press the paper feed button for at least one second to validate the selection.

Setting the printer emulation

Refer to the section “Configuring the printer”.

Printer settings and functions

To change the printer settings and functions, enter the configuration menu, select the sub-menu

from the main menu and answer the questions printed on the receipt until you come to the

instructions for selecting the printer settings.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the printer settings you want.

10

TH210 Programmer’s Guide

Select the emulation/software options sub-menu to set:

Printer Mode

This function is used to set the printer emulation to Native, A794, A793 or Legacy emulation.

Printer ID mode

This function is used to determine what printer ID value is returned in response to a Transmit

printer ID command (1D 49 n) when the printer is in A794 emulation mode. The printer can be

configured to send back the ID of the TH210, A794, A793 or Application Compatible Escape

Command systems.

Default lines per inch

This function allows you to set the default for lines per inch to:

8.13 lines per inch

7.52 lines per inch

6.77 lines per inch

6.00 lines per inch

Carriage return usage

This function allows the printer to ignore or use the carriage return (hexadecimal 0D) command

depending on the application. Some applications expect the command to be ignored while others

use the command as a print command.

Code 128 Check Digit

Enables or disables the calculation of the check digit.

Default font

Sets the default for monochrome, two-color, and LEGACY emulations.

Font size

Allows user to set font size for the emulation being used.

Journal Print

Enables or disables operator action.

Select the hardware options sub-menu to set:

Print density (monochrome papers only)

Adjusts printhead energy level to darken printout or adjust for paper variations. When printer

prints high-density print lines (text or graphics), it automatically slows down. Factory setting for

the TH210 is 100%.

WARNING: Choose a print density setting no higher than necessary to achieve acceptable print

density. Failure to observe this rule may result in a printer service call and may void the printer

warranty. Running at a higher energy level will reduce the printhead life. Consult your Wincor

Nixdorf technical support specialist if you have questions.

Power supply level (Max power)

You can choose from these power settings to match the power supply:

Auto (for Wincor Nixdorf power supplies)

11

TH210 Programmer’s Guide

55W

75W

90W

Partial cut distance

Allows the user to set the distance that the knife will cut across a receipt in 5 step increments

between 110-160.

Fine partial cut steps

Allows the user to set the amount of extra steps the knife will cut across a receipt, between 0 and

4.

Paper low sensor

Senses when the paper roll is getting low on paper.

See troubleshooting section: “Receipt paper is low” in the User Manual.

Paper low threshold extension

Allows the user to set the amount of footage for the extension in 5 foot increments between -10

and 20 feet.

Setting the printer functions and settings

Refer to the section “Configuring the printer”.

Select the firmware features sub-menu to set:

Paper selection lockout

Beep after knife cut

Cash drawer open after knife cut

Energy-savings timeout value

Allows the user to enable and set the time-out value to 15, 30, 60, 120, or 240 minutes, or to

disable the feature.

12

TH210 Programmer’s Guide

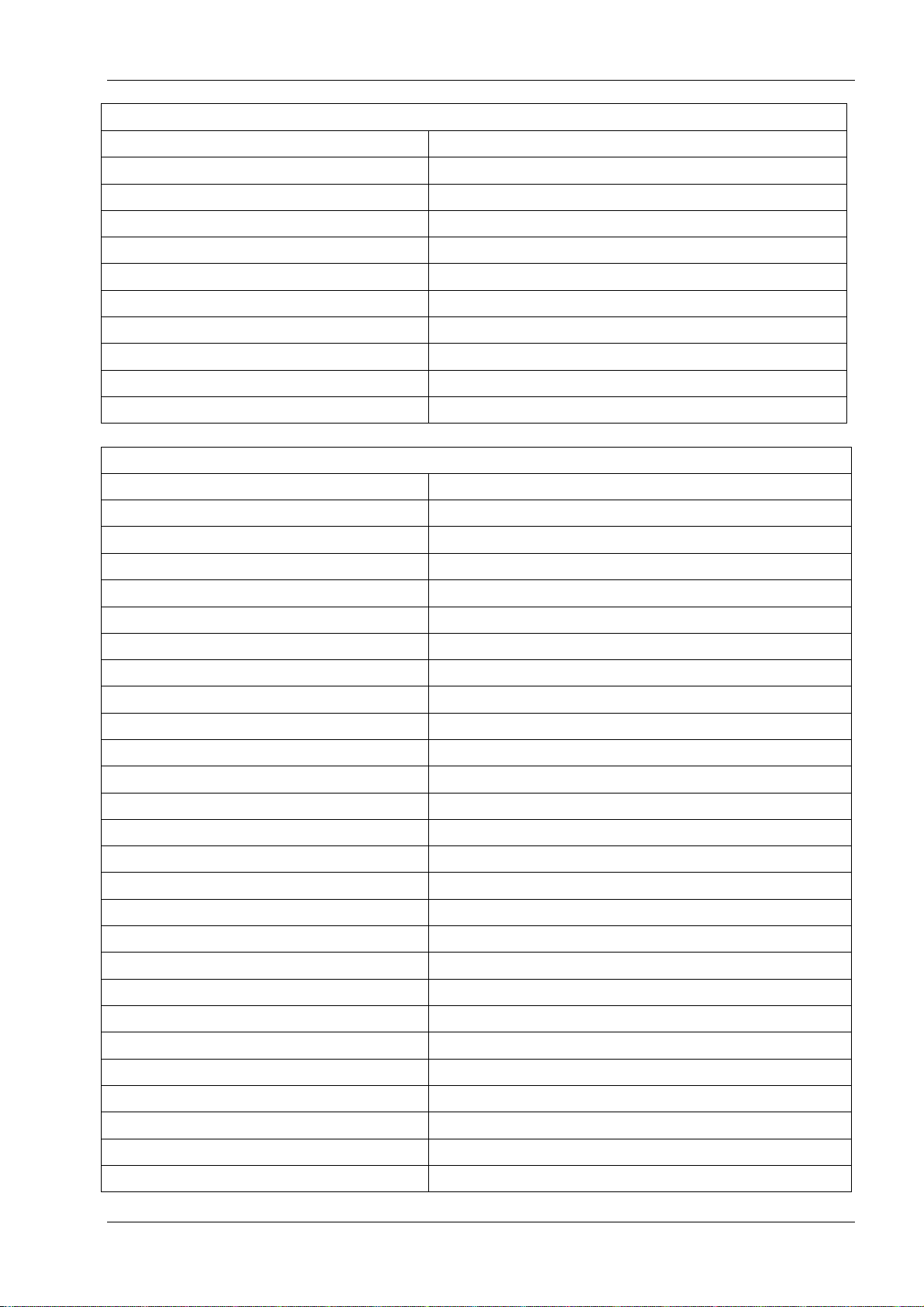

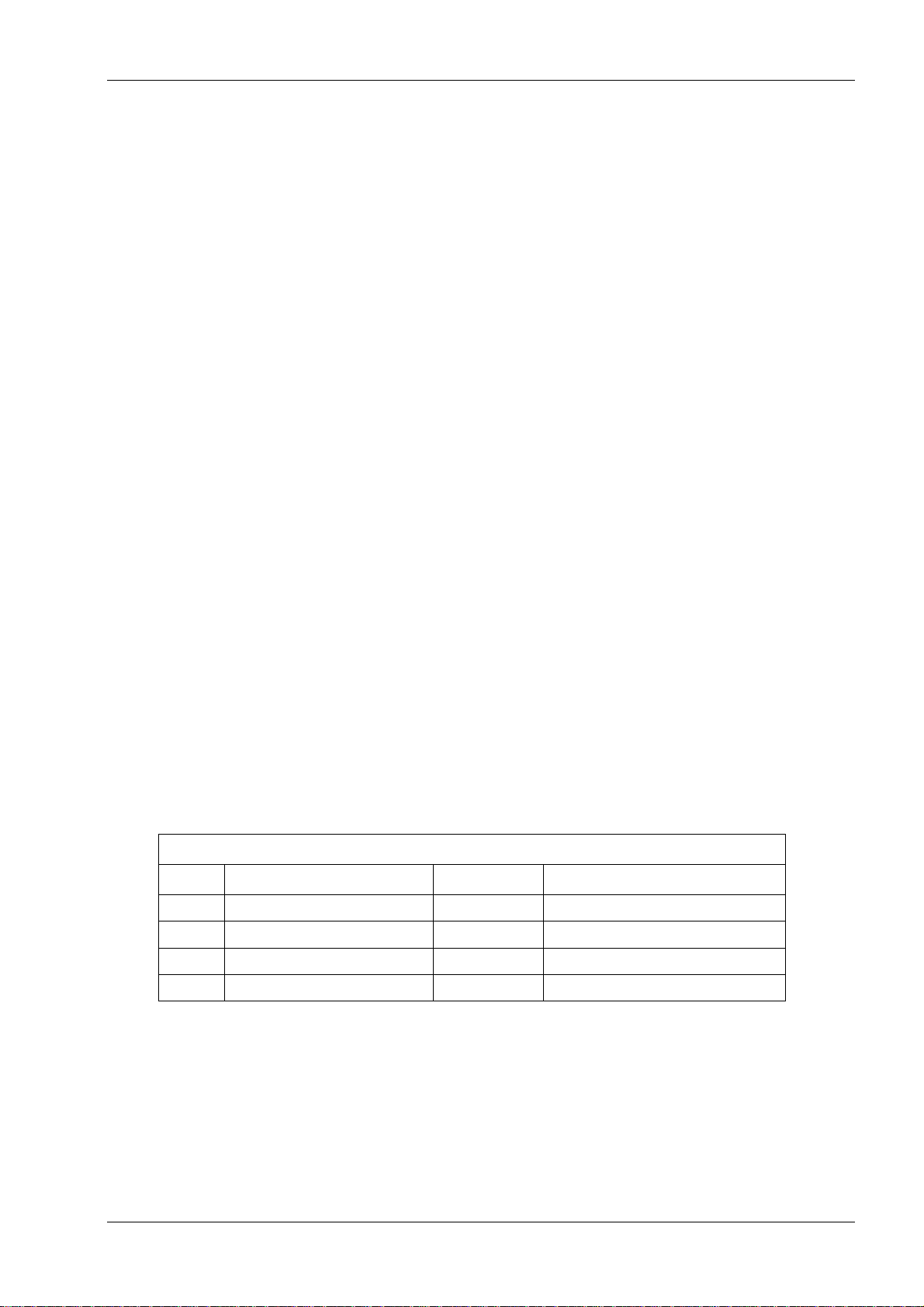

Command

Description

Difference between previous product and new

product emulation mode

15n

Feed n dot rows

This command will move the paper on the receipt

in n/203 inch steps instead of n/152 inch steps.

16 n

Add n extra dot rows

The dot rows will be measured in n/203 inches

versus n/152 inches.

1B 20 n

Set right-side

character spacing

This command sets the right side spacing to “n”

horizontal motion units. By default, these units

are in terms of 1/203 inches versus 1/152 inches.

1B 24 n1

n2

Set absolute starting

position

For graphics commands, the position is scaled to

best match A793. In text mode, the equivalent

character position is calculated.

1B 26 s c1

c2 n1 d1

...nn dn]

Define user-defined

character set

Since the dots on the TH210 printhead are

smaller, user defined characters that were used

on the previous printers will appear smaller on

the TH210 printer.

1B 2A m

n1 n2

d1...dn

Select bit image

mode

In A793 emulation mode, graphics are scaled to

best match the size of the graphic in the A793

printer.

1B 33 n

Set line spacing

This command uses n in terms of n/360 inches.

Since the A793 had a fundamental step of 1/152

Programming the Printer

Overview of commands

Commands control all operations and functions of the printer. This includes selecting the size and

placement of characters and graphics on the receipt to feeding and cutting the paper. The

programming commands have been organized, in order of hexadecimal code within functional

groups. For this reason, “related” commands may not be listed adjacent to one another.

The operation of various printers may be emulated by the commands, including the following:

Native

A793/A794

LEGACY

Any of the commands may be used in any combination to program a host computer to

communicate with the printer (unless otherwise noted).

Some commands listed and described here may not be implemented and are identified as “not

implemented.” If received, they are ignored and not sent to the print buffer as data.

Any nonlegal commands have their parameter sent to the print buffer as data.

Comparison to A793

The following table details the list of commands whose behavior differs between the A793, A794,

and TH210 because of the physical differences of a 6 dots/mm head (A793) versus an 8 dots/mm

head (A794 and TH210).

13

TH210 Programmer’s Guide

Command

Description

Difference between previous product and new

product emulation mode

inch and the TH210 has a fundamental step of

1/203 inch, the actual line spacing will not exactly

match the requested spacing.

1B 4A n

Print and feed paper

This command uses n in terms of n/360 inches.

Since the A793 had a fundamental step of 1/152

inch and the TH210 has a fundamental step of

1/203 inch, the actual line spacing will not exactly

match the requested spacing.

1B 59 n1

n2 d1...dn

Select doubledensity graphics

In A793 emulation mode, the printer scales the

graphics to provide the best match.

1B 5C n1

n2

Set relative print

position

The parameter to this command is in units of

dots.

However, the command moves and aligns to

character positions. In A793 emulation mode, this

command calculates how many character

positions to move based on the A793 character

width in dots (10) versus the TH210 (13).

1B 61 n

Select justification

This command does true dot resolution

alignment for centering versus character-aligned

centering.

1D 2A n1

n2

d1...dn]

Define downloaded

bit image

In A793 emulation mode, this command scales

the incoming data to provide a best match to the

size of the image as it printed on A793.

1D 2F m

Print downloaded

bit image

In A793 emulation mode, this command scales

the incoming data to provide a best match to the

size of the image as it printed on A793.

Standard

Rotated

Italic

Compressed

Underlined

Strike-through

Double-high

Bold

Scaled

Double-wide

Reverse

Shading

Upside-down

Rotated

Italic

Standard

Compressed

Characters per inch: 15.6

Characters per inch: 20.3

Characters per line: 44

Characters per line: 56

Character appearance

The appearance of text can be changed using the following print modes:

Width specifications

14

TH210 Programmer’s Guide

Cell size:

13 x 24 dots (default font)

13 x 27 dots (Tall and ColorPOS

fonts)

13 x 18 dots (paper-saving font)

Cell size:

10 x 24 dots (default font)

10 x 27 dots (Tall and ColorPOS

fonts)

10 x 18 dots (paper-saving font)

576 dots (addressable) @ 8

dots/mm, centered on 80mm

Top margin to manual tear-off:

17.8mm (0.70 inches)

Standard mode: minimum

margins: 2.0mm (.079 inches)

Top margin to knife cut: 19.0mm

(0.75 inches)

Print zones

Print zones for 80mm paper

Specifications of print zone for 80mm paper:

Note: The application centers 44 standard character cells (13 X 24 dots), or 56 compressed

character cells (10 X 24 dots), or 576 addressable bits of graphics across an 80mm wide receipt.

Minimum print line height is 24 dots for text or graphics. Standard print line spacing is 27 dots (i.e.,

3 extra row dots).

The TH210 Series adds a 27 dot high font, so standard print spacing is 30 dots.

The TH210 Series paper-saving feature adds a 18 dot high font and reduces extra dot rows to 2, so

standard print spacing is 20 dots.

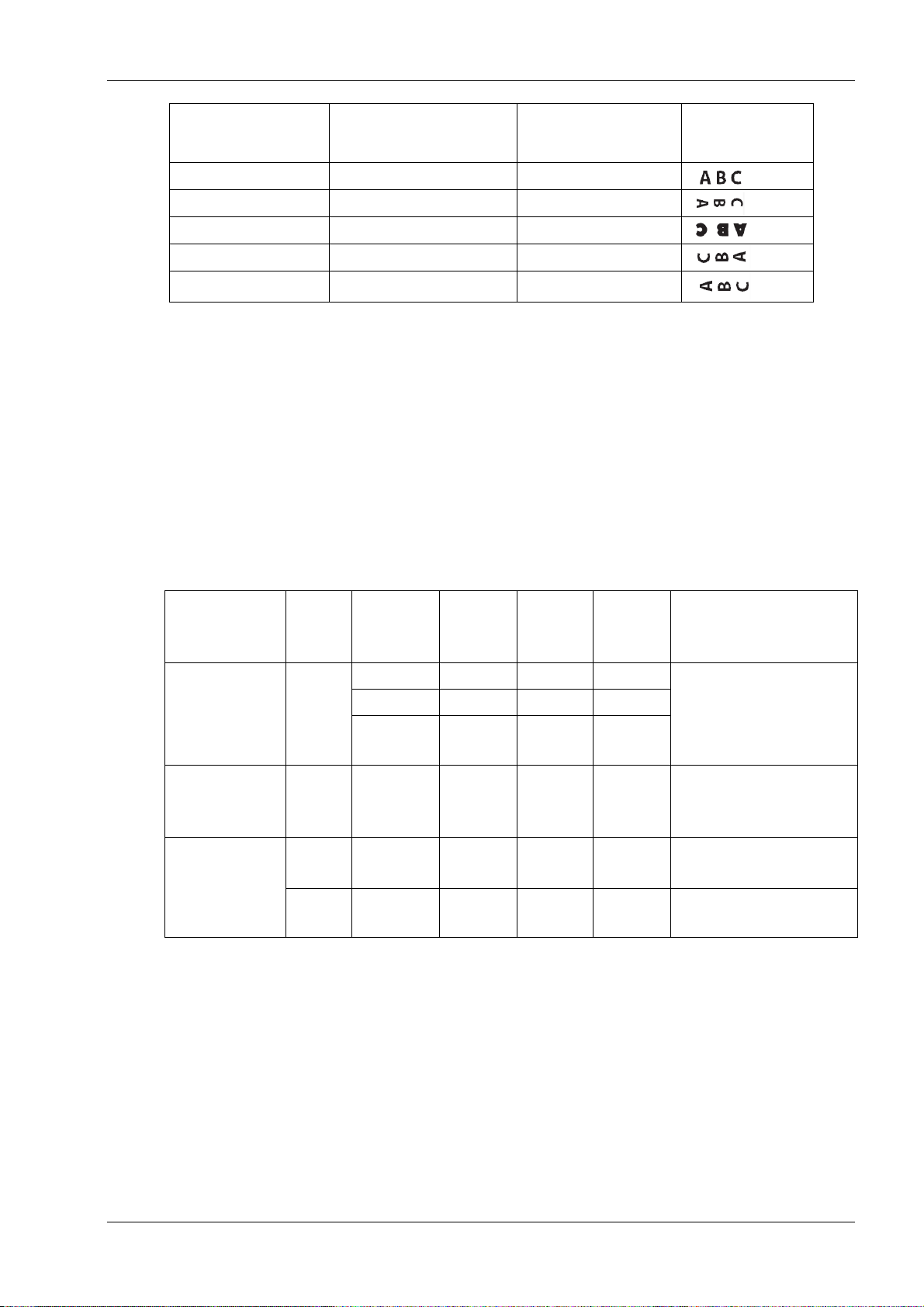

Rotated printing commands

Three commands control the rotation of printing. The table shows the combinations of set/cancel

upside down print, set/ cancel rotated print (clockwise), and rotated print (counterclockwise).

Rotated clockwise and rotated counterclockwise print commands are mutually exclusive: the

setting of the last received command is effective. Unintended consequences may result when

rotated clockwise is mixed with other commands

The samples of the print show only the normal-size characters. Double-wide and double-high

characters are printed in the same orientation. They may also be mixed on the same line.

15

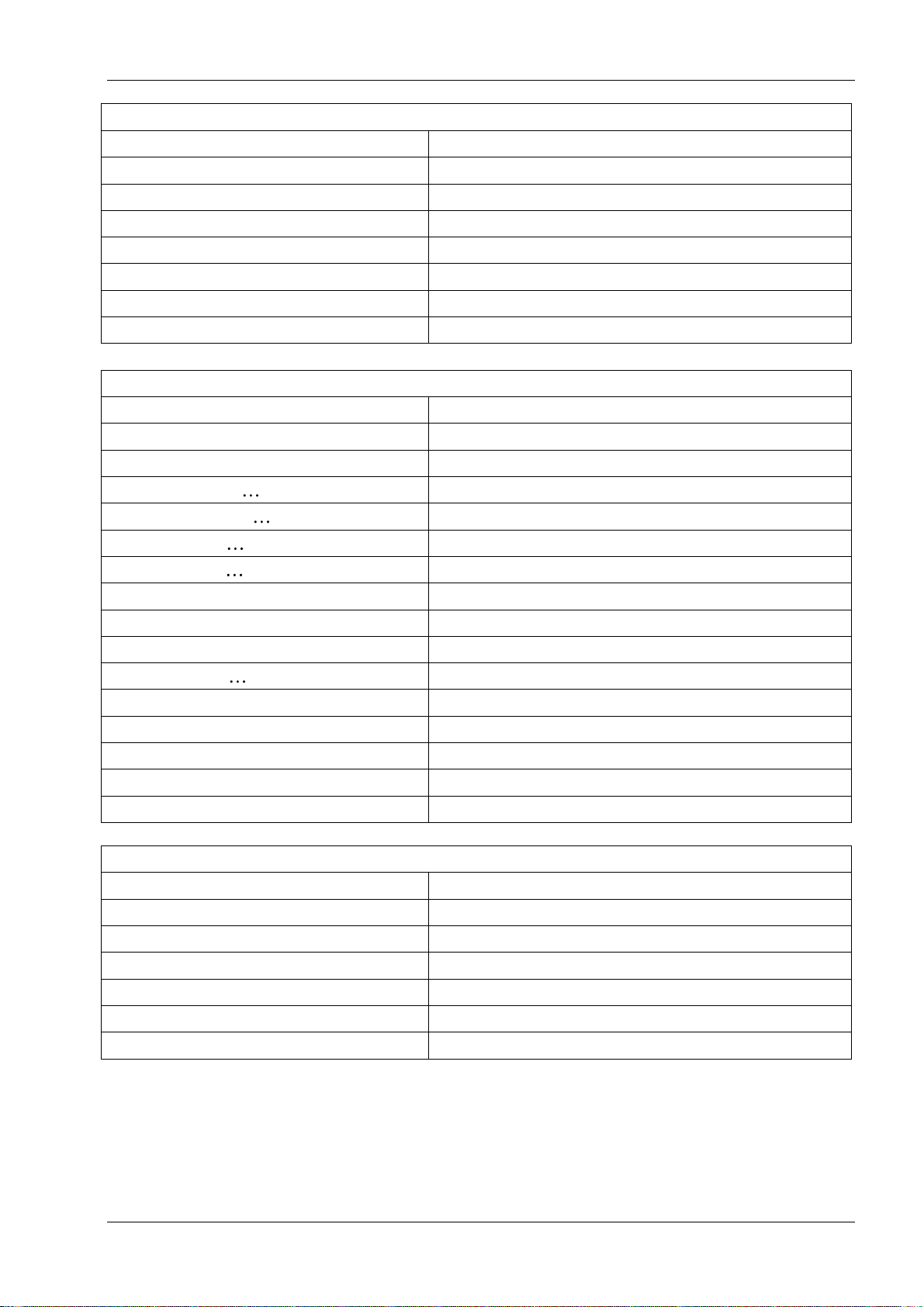

TH210 Programmer’s Guide

Upside down

(1B 7B n)

Rotated CW

(1B 56 n)

Rotated CCW

(1B 12)

Resulting

output

Canceled

Canceled

Cleared

Canceled

Set

X

Set

Canceled

X

Set

Set

X

X X Set

Emulation

mode

LPI

optio

ns

Font(s)

options

Font

size

Default

LPI

Default

EDR

Comments

Native

6.00,

6.77,

7.52,

8.13

Standard

13X24

7.52

3

Default setup

Tall

13X27

6.77

3

Papersaving

13X18

10.15

3

A793/A794

emulation

6.00,

7.52,

8.13

Standard

13X24

7.52

3

LEGACY

emulation

6.00

Tall 13X27

6.00

7

Standard

13X24

6.00

10

Default setup for

Escape Commands

Note: The following print modes cannot be mixed on the same line:

Right-side up and upside-down

Single-high (normal) and double-high

Emulation modes

The Wincor Nixdorf TH210 Series printer may be operated in a number of different emulation

modes. However, printing characteristics and defaults may differ, depending on the desired mode.

Print setup in emulation modes

Refer to the chart below for defaults and allowed printing options in each emulation mode.

The following list clarifies how the TH210 printer will behave in each emulation mode:

If only the font is changed, the default LPI will automatically be changed as in the

table above.

If emulation is switched to LEGACY, Native, A794 or A793 emulation(s), the font and

LPI will be automatically changed as in the table above.

If emulation is switched from any emulation to native, the font and LPI will remain

unchanged because the Native mode supports all font and LPI options offered in

the emulation modes.

The “Set Default LPI” option in the configuration menu is not offered in LEGACY

emulation mode. The LPI is set at 6.00.

16

TH210 Programmer’s Guide

Printer actions

Code (hexadecimal)

Command

10

Clear printer

19

Perform full knife cut (or code 1B 69)

1A

Perform partial knife cut (or code 1B 6D)

1B 07

Generate tone

1B 3D n

Select peripheral device (for multi-drop)

1B 40

Initialize printer

1B 63 34 n

Select sensors to stop printing

1B 63 35 n

Enable or disable panel button

1B 69

Perform full knife cut (or code 19)

1B 6D

Perform partial knife cut (or code 1A)

1B 70 n p1 p2

Generate pulse to open cash drawer

1F 03 3C ll hh

Set timeout value for low-power idle state

1F 70

Set printer into low-power idle state

1D 56 m

Select cut mode and cut paper (or code 1D 56 m n)

1D 56 m n

Select cut mode and cut paper (or code 1D 56 m)

1F 03 4E n1 n2

Port Idle Timeout

1F 74

Print test form

Print and paper feed

Code (hexadecimal)

Command

0A

Print and feed paper one line

0D

Print and carriage return

14n

Feed n print lines

15 n

Feed n dot rows

16 n

Add n extra dot rows

17

Print

1B 4A n

Print and feed paper

1B 64 n

Print and feed n lines

Programming Commands

Commands listed by function

17

TH210 Programmer’s Guide

Vertical and horizontal positioning

Code (hexadecimal)

Command

09

Horizontal tab

1B 14 n

Set column

1B 24 nL nH

Set absolute starting position

1B 32

Set vertical line spacing to 1/6 inch

1B 33 n

Set vertical line spacing

1B 44 n1...nk 00

Set horizontal tab positions

1B 5C n1 n2

Set relative print position

1B 61 n

Select justification

1D 4C nL nH

Set left margin

1D 50 x y

Set horizontal and vertical minimum motion units

1D 57 nL nH

Set printing area width

Text characteristics

Code (hexadecimal)

Command

12

Select double-wide characters

13

Select single-wide characters

1B 12

Select 90 degree counter-clockwise rotated print

1B 16 n

Select pitch (column width)

1B 20 n

Set right-side character spacing

1B 21 n

Select print mode

1B 25 n

Select or cancel user-defined character set

1B 26 s c1 c2

Define user-defined character set

1B 2D n

Select or cancel underline mode

1B 3A 30 30 30

Copy character set from ROM to RAM

1B 3F n

Cancel user-defined character

1B 45 n

Select or cancel emphasized mode

1B 47 n

Select or cancel double-strike

1B 49 n

Select or cancel italic print

1B 52 n

Select international character code

1B 56 n

Select or cancel 90 degree clockwise rotated print

1B 74 n

Select international character set

1B 7B n

Select or cancel upside-down print mode

1D 21 n

Select character size

1D 42 n

Select or cancel white/black reverse print mode

1D 62 n

Set smoothing

1D 85 m n

Reverse color text mode (two-color)

1D 8D n m

Text strike-through mode

1D F0 01 n

Select font ID number

1D F0 02 ns

Select font style number

18

TH210 Programmer’s Guide

Text characteristics

Code (hexadecimal)

Command

1D F0 03

Save font ID number as default font at power up

1D F0 80

Download font

1D F0 C0 02

Download font list

1F 03 45 FSID

Configure use of font set over power cycles

1F 03 46 n

Configure line spacing

1F 05 n

Select superscript or subscript modes

1F 26 s c1 c2

Define extended user-defined character set

1F 69 n

Select active user-defined character set

1D F0 20 nn

Get double-byte font CRC (font ID)

1D F0 21 nn mm

Get double-byte font CRC (font ID and font style)

Text characteristics

Code (hexadecimal)

Command

12

Select double-wide characters

13

Select single-wide characters

1B 12

Select 90 degree counter-clockwise rotated print

1B 16 n

Select pitch (column width)

1B 20 n

Set right-side character spacing

1B 21 n

Select print mode

1B 25 n

Select or cancel user-defined character set

1B 26 s c1 c2

Define user-defined character set

1B 2D n

Select or cancel underline mode

1B 3A 30 30 30

Copy character set from ROM to RAM

1B 3F n

Cancel user-defined character

1B 45 n

Select or cancel emphasized mode

1B 47 n

Select or cancel double-strike

1B 49 n

Select or cancel italic print

1B 52 n

Select international character code

1B 56 n

Select or cancel 90 degree clockwise rotated print

1B 74 n

Select international character set

1B 7B n

Select or cancel upside-down print mode

1D 21 n

Select character size

1D 42 n

Select or cancel white/black reverse print mode

1D 62 n

Set smoothing

1D F0 01 n

Select font ID number

1D F0 02 n

Select font style number

1D F0 03

Save font ID number as default font at power up

1D F0 80

Download font

1D F0 C0 02

Download font list

19

TH210 Programmer’s Guide

Text characteristics

Code (hexadecimal)

Command

1F 03 45 FSID

Configure use of font set over power cycles

1F 03 46 n

Configure line spacing

1F 05 n

Select superscript or subscript modes

1F 26 s c1 c2

Define extended user-defined character set

1F 69 n

Select active user-defined character set

1D F0 20 nn

Get double-byte font CRC (font ID)

1D F0 21 nn mm

Get double-byte font CRC (font ID and font style)

Graphics

Code (hexadecimal)

Command

11 n1 . . . n72

Print raster graphics

1B (+*.BMP file)

Download BMP logo

1B 2A m n1 n2 d1 dn

Select bit image mode

1B 2E m n rL rH d1 dn

Print advanced raster graphics

1B 4B n1 n2 d1 dn

Select single-density graphics

1B 59 n1 n2 d1 dn

Select double-density graphics

1C 70 n m

Print flash logo

1C 71 n . . . .

Define flash logos

1D 23 n

Select the current logo (downloaded bit image)

1D 2A n1 n2 d1 dn

Define downloaded bit image

1D 2F m

Print downloaded bit image

1D 9B m n

Logo print with knife cut

1D A0 nl nh

Set temporary max target speed

1F 04 n

Convert 6-dots/mm bitmap to 8 dots/mm bitmap

1F 7B n

Enable constant speed logos

Status

Batch mode

Code (hexadecimal)

Command

1B 75 0

Transmit peripheral device status (RS-232C only)

1B 76

Transmit paper sensor status

1D 49 n

Transmit printer ID

1D 72 n

Transmit status

1F 56

Send printer software version

20

TH210 Programmer’s Guide

Real time

Code (hexadecimal)

Command

10 04 n

Real time status transmission (DLE sequence)

10 05 n

Real time request to printer (DLE sequence)

1D 03 n

Real time request to printer (GS sequence)

1D 04 n

Real time status transmission (GS sequence)

1D 05

Real time printer status transmission

1F 7A

Real time commands disabled

Automatic status back / Unsolicited status mode

Code (hexadecimal)

Command

1D 61 n

Enable/disable Automatic Status Back (ASB)

1D 61 n

Select or cancel unsolicited status mode

Bar codes

Code (hexadecimal)

Command

1D 48 n

Select printing position for HRI characters

1D 66 n

Select pitch for HRI characters

1D 28 6B 04 00

00 31 41 n1 n2

Select model for QR Code

1D 28 6B 03 00 31 43 n

Set size of module for QR Code

1D 28 6B 03 00 31 44 m

Set data parsing mode for QR Code

1D 28 6B qL qH

31 50 30 f1 ... fk

Store symbol data for QR Code

1D 28 6B 03 00 31 51 30

Print symbol data for QR Code

1D 68 n

Select bar code height

1D 6B m d1 dk 00 or 1D 6B m n d1 dn

Print bar code

1D 6B FF n

Print Multiple Barcodes

1D 6B n d1... 00

Print GSI Databar (formerly RSS), null terminated

1D 6B m n L n H d1... dn

Print GSI Databar (formerly RSS), data length

specified

1D 70 a b c d e f

Select PDF 417 parameters

1D 71 a b c d e f L f H

Set GSI Databar (formerly RSS) parameters

1D 77 n

Select bar code width

1D 28 6B 05 00 36 42 m d1 d1

Set DataMatrix parameters

1D 28 6B 05 00 36 43 n

Set DataMatrix module size

1D 28 6B pL pH 36 50 30 d1...dk

Store DataMatrix data in symbol storage area

1D 28 6B 03 00 36 54 30

Print DataMatrix symbol data in the symbol storage

area

21

TH210 Programmer’s Guide

Page mode

Code (hexadecimal)

Command

0C

Print and return to standard mode

18

Cancel print data in page mode

1B 0C

Print data in page mode

1B 4C

Select page mode

1B 53

Select standard mode

1B 54 n

Select print direction in page mode

1B 57 n1, n2 n8

Set print area in page mode

1D 24 nL nH

Set absolute vertical print position in page mode

1D 5C nL nH

Set relative vertical print position in page mode

Macros

Code (hexadecimal)

Command

1D 3A

Select or cancel macro definition

1D 5E r t m

Execute macro

User data storage

Code (hexadecimal)

Command

1B 27 m a0 a1 a2 d1…dm

Write to user data storage

1B 34 m a0 a1 a2

Read from user data storage

1D 22 n

Select memory type (SRAM/flash) where to save

logos or user-defined fonts

1D 22 55 n1 n2

Flash memory user sectors allocation

1D 22 60 n1

Flash object area pack

1D 22 61 n1 n2 (n3)

Flash object delete

1D 22 80

Expanded flash memory allocation

1D 22 81 n

Select flash area for storing logos and user-defined

characters

1D 22 90 n

Return flash area size

1D 40 n

Erase user flash sector

1D F0 10 n

Lock permanent flash area

Flash download

Code (hexadecimal)

Command

1B 5B 7D

Switch to flash download mode

1D 06

Get firmware CRC

1D 0E

Erase all flash contents except boot sector

1D 0F

Return main program flash CRC

1D 11 00 00 00 00 d1 dn

Download Application

1D FF

Reset firmware

22

TH210 Programmer’s Guide

Settings commands

Code (hexadecimal)

Command

1F 09 01 06

Save current settings as factory settings

1F 09 01 07

Clear active settings and restore factory settings

1F 09 01 08

Upload current settings

1F 09 01 09

Upload factory settings

1F 09 01 0A

Download settings

Miscellaneous configuration commands

Code (hexadecimal)

Command

1F 03 00 n

Set diagnostics mode

1F 03 02 n

Enable or disable knife

1F 03 03 n

Enable or disable paper low sensor

1F 03 04 n

Set max power

1F 03 07 n

Set printer emulation

1F 03 09

Reset settings to default values

1F 03 0A n

Set partial cut distance

1F 03 0F n

Set default font

1F 03 10 n

Set font size

1F 03 1B n

Enable or disable Code 128 check digit calculation

1F 03 1D n

Enable or disable barcode ITF leading zero

1F 03 1E n

Enable or disable barcode string terminator

1F 03 1F n

Set paper low threshold extension

1F 03 28 n

Enable or disable USM canned status

1F 03 2C n

Send diagnostic page to comm port

1F 03 2E n

Enable or disable EJ action via operator control

1F 03 31 n

Set fine adjustment of partial cut steps

1F 03 32 n

Set printer ID mode

1F 03 33 n

Set default code page at power on

1F 03 3D n

Set Asian ASCII characters to narrow

1F 03 3F n1 n2

Set black dot offset

1F 03 47 n

Set vertical white space

1F 03 52 n fL fH dL dH

Set printer tone

1F 03 54 00 n

Enable or disable shutdown mode

1F 03 54 01 ll hh

Set shutdown mode timeout

23

TH210 Programmer’s Guide

Name:

Name of command.

ASCII:

The ASCII control code.

Hexadecimal:

The hexadecimal control code.

Decimal:

The decimal control code.

Value:

A description of the command operands.

Range:

The upper and lower limits of the command operand.

Default:

The command operand default after printer reset.

Description:

Brief description and summary of the command.

Formulas:

Any formulas used for this command.

Exceptions:

Describes any exceptions to this command; for example, incompatible

commands.

Relate

information:

Describes related information for this command; for example, bit

information.

ASCII

DLE

Hexadecimal

10

Decimal

16

Command conventions

The following information describes how each command is organized:

Command descriptions

Printer actions

The printer function commands control the following basic printer functions and are described in

order of their hexadecimal codes:

Resetting the printer

Cutting the paper

Opening the cash drawers

Clear printer

Clears the print line buffer without printing and sets the printer to the following condition:

Double-wide command (0x12) is cancelled

Line spacing, pitch, and user-defined character sets are maintained at current

selections (RAM is not affected)

Single-wide, single-high, non-rotated, and left-aligned characters are set

Printing position is set to column one

Related Information

This command followed by a 04 or 05 is interpreted as a “Real Time Command”.

This command is recognized in A793 emulation and Native mode, ignored in LEGACY emulation.

24

TH210 Programmer’s Guide

ASCII

EM

ESC i

Hexadecimal

19

1B 69

Decimal

25

27 105

ASCII

SUB

ESC m

Hexadecimal

1A

1B 6D

Decimal

26

27 109

ASCII

ESC BEL

Hexadecimal

1B 07

Decimal

27 7

ASCII

ESC = n

Hexadecimal

1B 3D n

Decimal

27 61 n

Value of n:

0 (bit 0), device not selected

1 (bit 0), device selected

Default:

1 (bit 0), device selected

Perform full knife cut

Cuts the receipt.

There are two codes (Hex 19 or 1B 69) for this command and both perform the same function.

Exceptions

The full cut is replaced by a partial cut in the A793 emulation. ASCII EM, (0x19) is ignored in

LEGACY emulation. Line feed is executed first, if the buffer is not empty.

Perform partial knife cut

Partially cuts the receipt. The default setting leaves 5mm (0.20 inch) of paper on the left edge. (See

setting partial cut distance in diagnostics.)

There are two codes (Hex 1A or 1B 6D) for this command and both codes perform the same

function.

Formulas

The cut edge is 144 dot rows or 18 mm (0.71 inch) above the print station.

Exceptions

The command is valid only at the beginning of a line. ASCII SUB, (0x1A), is ignored in LEGACY

emulation. Line feed is executed first, if the buffer is not empty.

Generate tone

Generates an audible tone. Perform by the printer to signal certain conditions.

Related information

This command is ignored in LEGACY emulation.

Select peripheral device (for multi-drop)

Selects the device to which the host computer sends data

25

TH210 Programmer’s Guide

ASCII

ESC @

Hexadecimal

1B 40

Decimal

27 64

Default:

Character pitch:

15.6 CPI

Column width:

44 characters

Extra dot rows:

3 Character set:

Code Page 437

Printing position:

Column One

ASCII

ESC c 4 n

Hexadecimal

1B 63 34 n

Decimal

27 99 52 n

Value of n:

Sensor status

Sensor Status

Bit

Sensor

0

1

0

Receipt paper near-end

Disabled

Enabled

1

Receipt paper near-end

Disabled

Enabled

2-4

Undefined

6

Undefined

Default:

0

Related information

Other bits of n (1–7) are undefined and ignored.

When the printer is disabled by this command, it ignores transmitted data until the printer is reenabled by the same command.

Initialize printer

Clears the print line buffer and resets the printer to the default settings for the start-up

configuration (refer to Default settings above). Data in the receive buffer is not cleared, and

printing position moves to the beginning of the line.

Single-wide, single-high, non-rotated, and left-aligned characters are set, and user-defined

characters or logo graphics are cleared. (Flash memory and macros are not affected.) Tabs reset to

default. Receipt selection state is selected. Barcode settings reset. Page mode settings are cleared

and printer is set to standard mode. ASB is switched off.

Select sensors to stop printing

Bits 5 and & are not used.

Determines which sensor stops printing on the respective station. The command does not affect

the paper out status on the receipt station, which will automatically stop the printer when the

paper is depleted.

26

TH210 Programmer’s Guide

ASCII

ESC c 5 n

Hexadecimal

1B 63 35 n

Decimal

27 99 53 n

Value of n:

0 = Enable

1 = Disable

Default:

0 (Enable)

ASCII

ESC p n p1 p2

Hexadecimal

1B 70 n p1 p2

Decimal

27 112 n p1 p2

Value of n:

00, 48 (Decimal) =

Drawer 1;

01, 49 (Decimal) =

Drawer

Value of p1:

0–255

Value of p2:

0–255

ASCII

GS V m

GS V m n

Hexadecimal

1D 56 m

1D 56 m n

Decimal

29 86 m

29 86 m n

Value of m:

Selects the mode as shown in the table.

Value of n:

Determines cutting position only if m is 65 or 66.

Enable or disable panel button

Enables or disables the paper feed button. If the last bit is 0, the paper feed button is enabled. If

the last bit is 1, the paper feed button is disabled.

Exceptions

Functions that require the paper feed button (except for the execute macro [1D 5E] command)

cannot be used when it has been disabled with this command.

Generate pulse to open cash drawer

Sends a pulse to open the cash drawer.

Formulas

The value for either p1 or p2 is the hexadecimal number multiplied by 2 msec to equal the total

time.

On-time = p1 (Hex) x 2 msec

Off-time = p2 (Hex) x 2 msec

Related information

Off-time is the delay before the printer performs the next operation. Refer to cash drawer

specifications for required on and off-time. If p2 < p1, the off-time is equal to the on-time.

Select cut mode and cut paper

27

TH210 Programmer’s Guide

m

Feed and cut mode

0, 48

Full cut (no extra feed)

1, 49

Partial cut (no extra feed)

65

Feeds paper to cutting position + (n times vertical motion unit), and

cuts the paper completely

66

Feeds paper to cutting position + (n times vertical motion unit), and

performs a partial cut

Range of m:

0, 48; 1. 49

65, 66 (when used with n)

Value of n:

0 - 255

Default of m, n:

0

ASCII

US ETX ‘ ll hh

Hexadecimal

1F 03 3C ll hh

Decimal

31 03 60 ll hh

Value of ll:

low byte of time in seconds

Value of hh:

high byte of time in seconds

ASCII

US p

Hexadecimal

1F 70

Decimal

31 112

Selects a mode for cutting paper and cuts the paper. There are two formats for this command, one

requiring one parameter m, the other requiring two parameters m and n. The format is indicated

by the parameter m.

Formulas

n times the vertical motion unit is used to determine the cutting position to which the paper is fed.

Set n to 0 to cut below the last printed line.

Set timeout value for low-power idle state

This command sets the timeout value in seconds. If the printer has not received data for that

amount of seconds, it will shut down to the low-power (1 watt) state. A value of ll hh = 0 disables

this feature. To bring the printer out of the low-power idle state, press the paper feed button.

Note: shutdown mode (1F 03 54 00 n) must be enabled for this to work.

Set printer into low-power idle state

This command puts the printer in the low-power (1 watt) state immediately. To bring the printer

out of the low-power idle state, press the paper feed button. Note: shutdown mode (1F 03 54 00

n) must be enabled for this to work.

28

TH210 Programmer’s Guide

ASCII

US t

Hexadecimal

1F 74

Decimal

31 116

ASCII

US ETX 0x4E n1 n2

Hexadecimal

1F 03 4E n1 n2

Decimal

31 03 78 n1 n2

Value of n:

n1: low order byte of seconds

n2: high order byte of seconds

Default:

disabled

ASCII

LF

Hexadecimal

0A

Decimal

10

ASCII

CR

Hexadecimal

0D

Decimal

13

Print test form

Prints the current printer configuration settings on the receipt.

Disabled in page mode.

Port Idle Timeout

Sets an idle time after which switching between communication ports can be done without a

power cycle. Setting seconds to 0 disables port idle timeout.

Print and paper feed

The print and feed commands control printing on the receipt and paper feed by the printer.

Print and feed paper one line

Prints one line from the buffer and feeds paper one line.

Carriage return/line feed pair prints and feeds only one line.

Print and carriage return

Prints one line from the buffer and feeds paper one line. The printer can be set through the

configuration menu to ignore or use this command. Some applications expect the command to be

ignored while others use it as print command.

Related information

See ignoring/using the carriage return in Diagnostics for more information.

This command is ignored in LEGACY emulation.

Carriage return/line feed pair prints and feeds only one line.

29

TH210 Programmer’s Guide

ASCII

DC4 n

Hexadecimal

14 n

Decimal

20 n

Value of n:

The number of lines to feed at current line

height setting.

Range of n:

0–255 in Native mode

0–127 in A793 emulation

ASCII

NAK n

Hexadecimal

15 n

Decimal

21 n

Value of n:

n/203 inch

Range of n:

0–255 in Native mode

0–127 in A793 emulation

ASCII

SYN n

Hexadecimal

16 n

Decimal

22 n

Value of n:

Number of extra dot rows

Range of n:

0–16

Default:

3 extra dot rows

Feed n print lines

Feeds the paper n lines at the current line height without printing. Ignored on receipt if current line

is not empty.

Related information

This is ignored in LEGACY emulation and the parameter byte goes into the print buffer.

Feed n dot rows

Feeds the paper n dot rows (n/8 mm, n/203 inch), without printing. Receipt moves n rows if the

print buffer is empty.

Related information

This is ignored in LEGACY emulation and the parameter byte goes into the print buffer.

Add n extra dot rows

Adds n extra dot rows (n/8 mm, n/203 inch) to the character height to increase space between

print lines or decrease the number of lines per inch.

Formulas

The following table shows the relationship between the number of lines per inch and each extra

dot row added:

30

TH210 Programmer’s Guide

Extra

rows

Lines per

inch

Dot rows

Extra

rows

Lines per

inch

Dot rows

0

8.5

24 10

6.0

34

1

8.1

25 11

5.8

35

2

7.8

26 12

5.6

36

3

7.5

27 13

5.5

37

4

7.2

28 14

5.3

38

5

7.0

29 15

5.2

39

6

6.77

30 16

5.1

40 7 6.5

31 8 6.3

32

9

6.1

33

ASCII

ETB

Hexadecimal

17

Decimal

23

ASCII

ESC J n

Hexadecimal

1B 4A n

Decimal

22 n

Value of n:

n/203 inch in Native mode and Application

Compatible Escape Commands emulation

mode;

n/360 inch in A793 emulation mode

Range of n:

0–255

Related information

This is ignored in LEGACY emulation and the parameter byte goes into the print buffer.

Print

Prints one line from the buffer and feeds paper one line. Executes LF on receipt.

Related information

This command is ignored in LEGACY emulation.

Print and feed paper

Prints one line from the buffer and feeds the paper n/8 mm (n/203 inch). The line height equals

the character height when n is too small.

If the set horizontal and vertical minimum motion units command (1D 50) is used to change the

horizontal and vertical minimum motion units, the parameters of this command (print and feed

paper) will be interpreted accordingly.

Related information

For more information, see the description of the set horizontal and vertical minimum motion units

command in this document.

31

TH210 Programmer’s Guide

ASCII

ESC d n

Hexadecimal

1B 64 n

Decimal

27 100n

Range of n:

0–255 (0 is interpreted as 1)

ASCII

HT

Hexadecimal

09

Decimal

9

ASCII

GS P x y

Hexadecimal

1D 50 x y

Decimal

29 80 x y

Value of x:

Horizontal

Value of y:

Vertical

Range of x:

0 - 255

Range of y:

0 - 255

Default of x:

203

Default of y:

203

Print and feed n lines

Prints one line from the buffer and feeds paper n lines at the current line height.

Vertical and horizontal positioning

The horizontal positioning commands control the horizontal print positions of characters on the

receipt.

The commands describe operation for 80mm paper.

Horizontal tab

Moves the print position to the next tab position set by the set horizontal tab positions (1B 44 n1

n2 ... 00) command. The print position is reset to column one after each line.

Tab treats the left margin as column one, therefore changes to the left margin will move the tab

positions.

When no tabs are defined to the right of the current position, or if the next tab is past the right

margin, line feed is executed. HT has no effect in page mode. If underline is set, tab spaces skipped

by this command are not underlined.

Print initialization sets 32 tabs at column 8, 16, 24…

Set horizontal and vertical minimum motion units

Sets the horizontal and vertical motion units to 1/x inch and 1/y inch respectively, until the printer

is initialized, reset, or powered off.

When x or y is set to 0, the default setting for that motion unit is used. When combined with other

commands, the calculated result is truncated to the minimum value of the mechanical pitch.

32

TH210 Programmer’s Guide

Mode

Commands using x

Commands using y

Standard

1B 20, 1B 24, 1B 5C, 1D 4C,

1D 57

1B 33, 1B 4A, 1B 4B, 1D 56

Page (upper left or lower

right)

1B 20, 1B 24, 1B 57, 1B 5C,

[1C 53]

1B 33, 1B 4A, 1B 4B, 1B 57, 1D

24, 1D 56, 1D 5C

Page (upper right or lower

left)

1B 33, 1B 4A, 1B 4B, 1B 57,

1D 24, 1D 5C

1B 20, 1B 24, 1B 57, 1B 5C, [1C

53], 1D 56

ASCII

ESC DC4n

Hexadecimal

1B 14n

Decimal

27 20n

Value of n:

1 – 44 = Standard pitch

1 – 56 = Compressed pitch

Default of n:

1

ASCII

ESC $ nL nH

Hexadecimal

1B 24 nL nH

Decimal

27 36 nL nH

Value of n:

n = Number of dots to be moved from the

beginning of the line.

nL = Remainder after dividing n by 256.

nH = Integer after dividing n by 256.

Set column

Prints the first character of the next print line in column n. It must be sent for each line not printed

at column one. The value of n is set to one after each line.

Exceptions

This command cannot be used with single- or double-density graphics.

Related information

This is ignored in LEGACY emulation and the parameter byte goes into the print buffer.

Set absolute starting position

The values for nL and nH are two bytes in low byte, high byte word orientation.

Sets the print starting position to the specified number of dots (up to the right margin) from the

beginning of the line. The print starting position is reset to the first column after each line.

Formulas

The example shows how to calculate 280 dots as the absolute starting position.

28 x 10 = 280 dots (beginning of column 29)

280/256 = 1, remainder of 24

nL = 24 nH = 1

Related information

If the set horizontal and vertical motion units command (1D 50) is used to change the horizontal

and vertical minimum motion unit, the parameters of the set relative print position command will

33

TH210 Programmer’s Guide

ASCII

ESC 2

Hexadecimal

1B 32

Decimal

27 50

Range of n:

3.33 mm (0.13 inch)

ASCII

ESC 3n

Hexadecimal

1B 33n

Decimal

27 51n

Value of n: