Page 1

COMPACT SERIES

TRACTOR DRIVE GENERATOR

W10PTOS/A

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION 3

SPECIFICATIONS 4

UNPACKING 4

INSTALLATION 4

FOUNDATION MOUNTING 4

TRAILER MOUNTING 5

THREE POINT HITCH MOUNTING 5

ELECTRICAL CONNECTIONS 6

LOAD DISCONNECT PLUG INSTALLATION 7

PRE-START CHECKLIST 7

GENERATOR STARTING PROCEDURE 8

PTO ALIGNMENT 8

STORAGE & MAINTENANCE REQUIREMENTS 9

LUBRICATION 9

SERVICE DIAGNOSIS 10

COMPLETE UNIT ASSEMBLY ILLUSTRATION 11

WIRING DIAGRAM 12

RECEPTACLE PANEL ASSEMBLY 14

TWO WHEEL TRANSPORT 15

WINCO LIMITED WARRANTY 16

Copy you model and serial number here.

MODEL ______________________________________

No other Winco generator has the same serial number

as yours. It is important that you record the number

and other vital information here. If you should ever

need to contact us about this unit it will help us to

respond to your needs faster.

SERIAL NUMBER _____________________________

PURCHASE DATE _____________________________

DEALER _____________________________________

CAUTION

FOLLOW THE INSTRUCTIONS IN THE OWNER’S MANUAL SPECIFICALLY WHEN PUTTING THIS PTO GENERATOR INTO

SERVICE.

IMPORTANT

ALL STANDBY POWER PLANTS INCLUDING TRACTOR DRIVEN GENERATORS SHOULD BE PERIODICALLY EXERCISED. FOR PROPER MAINTENANCE OF YOUR TRACTOR DRIVEN GENERATOR, IT SHOULD BE OPERATED FOR ONE

HOUR CARRYING RATED LOAD AT LEAST TWICE A YEAR. THIS WILL ASSURE THAT YOUR PTO GENERATOR IS IN

OPERATING CONDITION AND READY FOR USE WHEN THE NEED ARISES.

PARTS LIST, PARTS DRAWINGS, AND WIRING DIAGRAM PERTAINING TO YOUR UNIT ARE ENCLOSED WITH THIS

MANUAL.

This manual covers the latest compact portable tractor driven Power Take Off (PTO) generator model from Winco.

This 10,000 watt generator is designed to provide120/240V single phase electrical power for standby and utility service when commercial power is interrupted, inaccessible or impractical. This PTO unit has a cast iron gear case with

a 1-3/8” – 6 spline, 540 rpm rated input shaft (unit operating speed is 515 RPM) and brushless, heavy-duty 3600

rpm, 2 pole, low waveform distortion generator.

This compact PTO generator unit is designed to provide reliable electrical power for customers who already have a

compact utility tractor with 20 to 30 horsepower and a 540 rpm rated PTO shaft. The PTO unit is a cost-effective way

of providing needed electrical power without the cost or added maintenance of a dedicated drive engine. Primary applications for these PTOs are for infrequent or medium duty loads where the unit will normally be operated less than

50 to100 hours per year. Typical uses might be for farm, ranch or home standby or portable eld power away from

convenient utility or where running an extension cord is impractical. The compact PTO units are built to last, but are

not intended for prime power (continuous or sole source) applications.

2

3225-0060706-241

Page 3

SAFETY INFORMATION

This generator set has been designed and manufactured to allow

safe, reliable performance. Poor maintenance, improper or careless use can result in potential deadly hazards; from electrical

shock, exhaust gas asphyxiation, or re. Please read all safety

instructions carefully before installation or use. Keep these

instructions handy for future reference. Take special note and

follow all warnings on the unit labels and in the manuals.

ANSI SAFETY DEFINITIONS

__________________________________________________

DANGER:

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This signal word

is to be limited to the most extreme situations.

__________________________________________________

WARNING:

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

___________________________________________________

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

___________________________________________________

NOTE:

CAUTION is also used on the unit labels and in this manual to indicate a situation that could result in serious damage or destruc-

tion of the equipment and possible personal injury.

___________________________________________________

1. ELECTRIC SHOCK- The output voltage present in this

equipment can cause a fatal electric shock. This

equipment must be operated by a responsible person.

a. Do not allow anyone to operate the generator

without proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or

snow.

e. Use only three-prong grounded plugs and

extension cords.

f. Be sure the unit is properly grounded to an external

ground rod driven into the earth.

g. Do not make or break electrical connection under load.

2. FIRE HAZARD- Gasoline, diesel and other fuels always pres-

ent a hazard of possible explosion and/or re.

a. Keep a re extinguisher nearby and know its proper use.

Fire extinguishers rated ABC by NFPA are appropriate.

3. DEADLY EXHAUST GAS - Exhaust fumes from any

engine contain carbon monoxide, an invisible, odorless

and deadly gas that must be mixed with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

4. NOISE HAZARD - Excessive noise is not only tiring, but

continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when working

around this equipment for long periods of time.

b. Keep your neighbors in mind when permanently

installing this equipment.

5. CLEANLINESS- Keep the generator and surrounding area

clean.

a. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

b. Remove any rags or other material that could create

potential re hazards.

6. SERVICING EQUIPMENT- All service, including the

installation or replacement of service parts, should be

performed only by a qualied technician.

a. Use only factory approved repair parts.

b. Do not work on this equipment when fatigued.

c. Use extreme caution when working on electrical

components. High output voltages from this equipment

can cause serious injury or death.

7. INSTALLATION- Installing a PTO generator is not a “do-it-

yourself” project. Consult a qualied, licensed electrician or

contractor. The installation must comply with all national,

state, and local codes.

a. NEVER operate the PTO drive generator without

having it properly mounted to a concrete base or

approved trailer.

b. NEVER connect the PTO generator to an existing

electrical system without installing an isolation

transfer switch.

c. Always insure the drive shaft is straight and level

before operating the generator.

8. OPERATION - PTO drive shafts (Tumbling Bars) have

many inherent dangers, extreme caution must be

exercised when using them.

a. NEVER allow children around a drive shaft when it is in

operation.

b. Keep all safety guards and shields in place and securely

tightened.

c. NEVER operate a drive shaft that has been damaged or

had the safety shield removed.

d. NEVER step over a drive shaft while it is running.

e. NEVER wear a necktie, loose articles of clothing, or

anything else that can be caught in moving parts.

f. NEVER try to stop a turning drive shaft with your hand or

your foot.

g. ALWAYS connect the shield anti-rotation chain to the

tractor safety shield

33225-00

60706-241

Page 4

DESCRIPTION

UNPACKING

The WINCO rotating eld power take-off generators are designed primarily for hobby/small farm use as a standby electrical

power supply, utilizing the power take-off of a tractor or truck

as the prime mover. This PTO drive generator will provide

120/240V single phase, 60Hz electrical service when properly

driven.

NOTE: The prime mover which drives the generator must be

capable of delivering approximately 2 HP per 1000 watts output

from the generator. Observe input RPM specications.

This generator may be mounted in many different fashions. The

three most popular are foundation mounted, trailer mount or 3point hitch mounted, for used as a standby or portable electrical

power source. Your application will dictate how you may want to

mount it.

This generator includes a color coded voltmeter to warn against

high or low voltage, and two output power receptacles with

individual circuit breakers for your protection. To reduce maintenance problems, the coupling between the generator input shaft

and rotor consists of precision helical gearing rather than a chain

link drive. The input shaft is a 1 3/8 in. diameter 6 spline shaft.

The factory thoroughly tests each generator before shipment. All

are continuous duty rated.

IMPORTANT:

THE MANUFACTURER STRONGLY RECOMMENDS RUNNING THE GENERATOR UNDER LOAD AT LEAST ONCE A

MONTH IN ORDER TO EVAPORATE ANY ACCUMULATED

MOISTURE CONDENSATION AND TO KEEP THE UNIT IN

GOOD WORKING ORDER.

CAUTION: Equipment Damage

DO NOT invert generator during unpacking. The Gearcase contains oil which will leak out if inverted during unpacking.

Unpack the generator as follows:

1. Remove the carton.

2. Examine the unit for damage.

3. Find the small subpack carton packed in the large carton. Be careful not to throw away the subpack carton

with the large carton.

4. Open the subpack carton and make sure it contains:

a. Generator instruction manual

b. Load disconnect plug (disassembled, in bag)

5. Remove the four bolts which hold the generator feet to

the pallet.

6. Lift the generator from the pallet by means of the lifting

eye on the top of the generator.

7. Inspect the generator carefully for freight loss or damage. If loss or damage is noted at time of delivery,

require that the person making the delivery make note

of the loss or damage on the freight bill, or sign the

consignee’s memo of the loss or damage. Contact the

carrier for claim procedures.

When loss or damage is noted after delivery, segregate the damaged material, and contact the carrier for claim procedures.

SPECIFICATIONS

Model Number W10PTOS/

Wattage 10000

Amperage 42

Input Speed 515 RPM

Generator Speed 3600 RPM

Input Shaft 1 3/8” - 6 spline

Tractor PTO Hp Required 20

Gear Lube

Volume 16 ounces

Type 85/90W-140

Features

* Brushless, low harmonic design with skewed rotor and

damper windings for minimal load noise

* Capacitor Excitation

* Dual voltage - 120/240 volt output

* 4 wire Load connection plug for convenient full load 120/

240 volt output cord set

* 15 Amp duplex convenience receptacle

* Large face Voltmeter for proper speed setting and

adjustment

“Concealed damage” means damage to the contents of a package which is not evident when the package is delivered by the

carrier, but which is discovered later. The carrier or carriers are

responsible for merchandise lost or damaged in transit. The

title to the goods rests with the consignee when the goods are

shipped FOB factory, and only the consignee can legally le

claims. Two years are allowed in which to le suit after a claim is

disallowed in writing by the carrier.

INSTALLATION

FOUNDATION MOUNTING

Mount the generator on a foundation if it is to be used as a

permanent or standby power source. See “TRAILER MOUNTING” or “THREE POINT HITCH MOUNTING” if generator will be

used as a portable power source. When planning a foundation

consider the following points:

A. The foundation location should enable aligning the drive

shaft (tumbling bar) in a straight or nearly straight line between

the power take-off and the generator input shaft. Misalignment

must be less than 5 degrees during generator operation, even

though the mechanical design of the tumbling bar would allow

greater misalignment.

4

3225-0060706-241

Page 5

C. The trailer height and mounting position of the generator on

the trailer should enable aligning the drive shaft (tumbling bar)

in a straight or nearly straight line between the power take-off

and generator input shafts. Misalignment must be less than 10

degrees during generator operation, even though the mechani-

cal design of the tumbling bar would allow greater misalign-

ment.

D. The generator mounting area of the trailer bed should be

flat.

the trailer should enable aligning the drive shaft (tumbling bar)

in a straight or nearly straight line between the power take-off

and generator input shafts. Misalignment must be less than 10

degrees during generator operation, even though the mechani-

cal design of the tumbling bar would allow greater misalign-

ment.

D. The generator mounting area of the trailer bed should be

flat.

All four generator mounting pads must rest firmly on the trailer

bed. Install shims if necessary to even out the bed under the

mounting pads, then bolt the generator firmly in place.

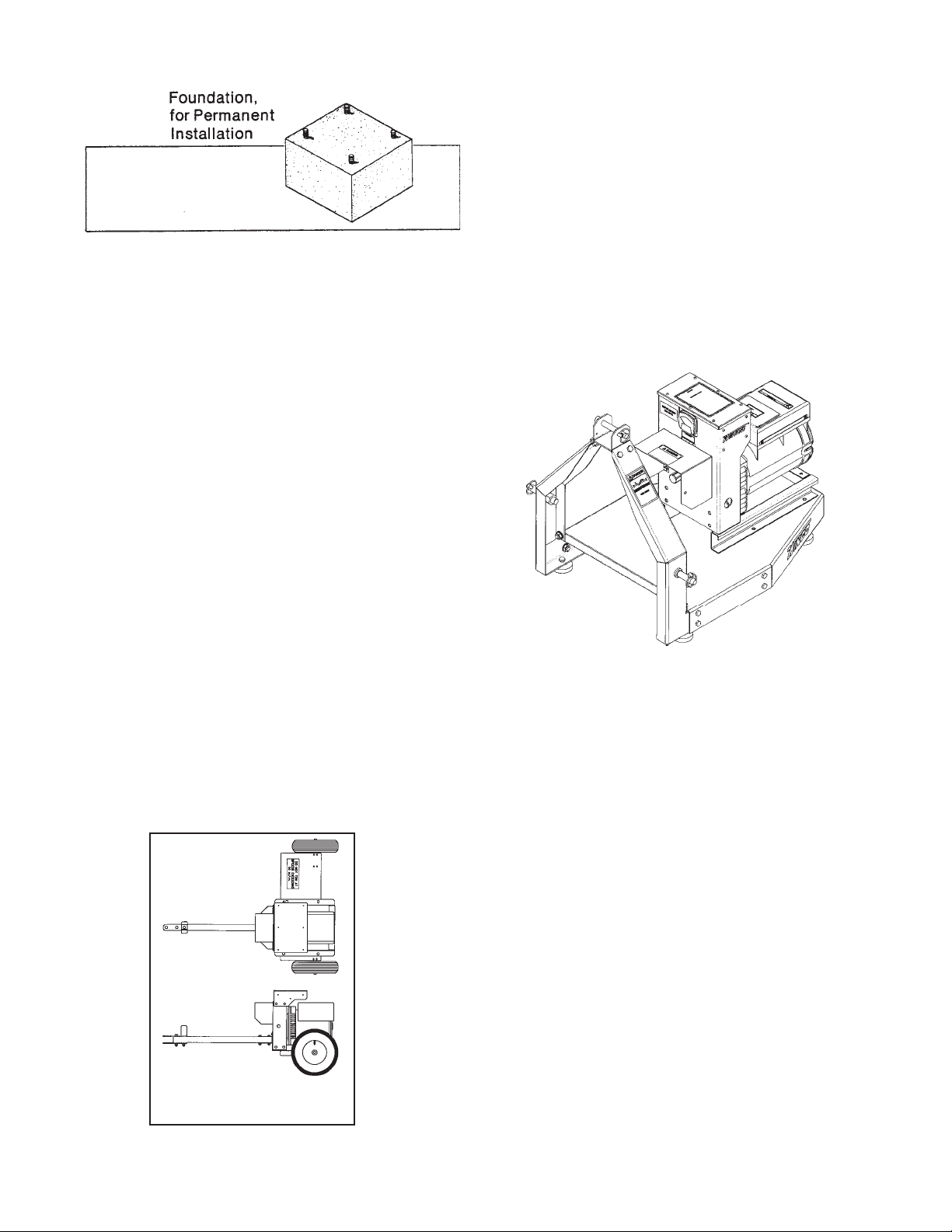

WINCO THREE POINT HITCH

Optional 3-Point Hitch Part Number TPH240

WARNING: Personal Injury & Equipment Damage

WHEN USING THE 3-POINT HITCH ASSEMBLY ALL THREE

POINTS MUST BE ATTACHED TO THE TRACTOR. FAIL-

URE TO DO SO WILL CAUSE THE GENERATOR TO TIP

WHEN LIFTING IT DAMAGING BOTH THE T-BAR AND THE

GENERATOR.

A. The three point hitch must be attached to the tractor at all

times during operation.

B. When operating the generator the three point hitch and

generator must be sitting on flat level ground. All four deck

pads must be in constant contact with the ground at all

times. This will reduce the vibration in both the generator

and the tumbling bar.

C. For safety the generator must be bolted to the three point

hitch deck using all four mounting bolts

the trailer should enable aligning the drive shaft (tumbling bar)

in a straight or nearly straight line between the power take-off

and generator input shafts. Misalignment must be less than 5

degrees during generator operation, even though the mechanical

design of the tumbling bar would allow greater misalignment.

D. The generator mounting area of the trailer bed should be at.

B. The foundation must be solid enough to absorb generator

starting and reected load torque during operation.

C. The foundation surface should be at.

D. Space is required around the generator for mounting switching devices, making connections, and for servicing.

E. The generator mounting bracket must rest evenly and rmly

on the foundation. Install shims if necessary to even out the foun-

dation under the mounting pads then bolt the generator rmly in

place.

TRAILER MOUNTING

Optional Trailer Part Number TDM76

Mount the generator on a trailer if you plan to use it as a portable

power source. When selecting or building a trailer to mount the

generator, consider the following points:

A. The trailer construction must be strong enough to support

the generator.

B. The design of the trailer must enable the trailer to remain

stable during operation, and to resist tipping caused by generator

starting and reected load torque.

WARNING: Personal Injury & Equipment Damage

TRAILER MAY TIP OVER AND CAUSE INJURIES IF WHEELS

ARE NOT SPACED FAR ENOUGH APART.

All four generator mounting pads must rest rmly on the trailer

bed. Install shims if necessary to even out the bed under the

mounting pads, then bolt the generator rmly in place.

WINCO THREE POINT HITCH

Optional 3-Point Hitch Part Number TPH240

WARNING: Personal Injury & Equipment Damage

WHEN USING THE 3-POINT HITCH ASSEMBLY ALL THREE

POINTS MUST BE ATTACHED TO THE TRACTOR. FAILURE

TO DO SO WILL CAUSE THE GENERATOR TO TIP WHEN

LIFTING IT DAMAGING BOTH THE T-BAR AND THE GENERATOR.

A. The three point hitch must be attached to the tractor at all

times during operation.

B. When operating the generator the three point hitch and

generator must be sitting on at level ground. All four deck pads

must be in constant contact with the ground at all times. This will

reduce the vibration in both the generator and the tumbling bar.

C. For safety the generator must be bolted to the three point

hitch deck using all four mounting bolts

53225-00

60706-241

Page 6

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

CAUTION:

Only qualified electricians should install electrical wiring.

Wiring must conform to all applicable national, state, and

local codes. (Reference: National Fire Protection Associa-

tion Manual No. 70, National Electrical Code.)

DANGER: PERSONAL INJURY

IF THE GENERATOR IS TO BE USED AS A STANDBY

POWER SOURCE, A MANUAL TRANSFER SWITCH

MUST BE INSTALLED TO SEPARATE THE GENERATOR

AND THE COMMERCIAL POWER LINES. THE SWITCH

MUST ISOLATE THE GENERATOR FROM THE COM-

MERCIAL POWER LINES AND THE LOAD WHEN THE

GENERATOR IS ON STANDBY, AND MUST ISOLATE

THE COMMERCIAL POWER LINES FROM THE LOAD

AND THE GENERATOR WHEN THE GENERATOR IS

SUPPLYING POWER. SEE FIGURE 6

CAUTION:

Only qualied electricians should install electrical wiring.

Wiring must conform to all applicable national, state, and local codes. (Reference: National Fire Protection Association

Manual No. 70, National Electrical Code.)

DANGER: PERSONAL INJURY

IF THE GENERATOR IS TO BE USED AS A STANDBY

POWER SOURCE, A MANUAL TRANSFER SWITCH MUST

BE INSTALLED TO SEPARATE THE GENERATOR AND THE

COMMERCIAL POWER LINES. THE SWITCH MUST ISOLATE

THE GENERATOR FROM THE COMMERCIAL POWER LINES

AND THE LOAD WHEN THE GENERATOR IS ON STANDBY,

AND MUST ISOLATE THE COMMERCIAL POWER LINES

FROM THE LOAD AND THE GENERATOR WHEN THE GENERATOR IS SUPPLYING POWER. SEE FIGURE 6

FIGURE 6

6

3225-0060706-241

Page 7

A properly rated and installed double throw manual power isola-

Make sure blades

tion transfer switch must be used with a standby generator. The

transfer switch isolates the load from the power line and allows

you to safely operate your loads without endangering the power

line repair crew. See page 6.

The load, connected to the normal terminals of the transfer

switch, is energized by the normal power line when the switch is

in the normal position. The generator, connected to the emergency terminals of the switch, furnishes power when the switch

is in the emergency mode position.

There are two ways to install a manual transfer switch. The rst

shown on the left side of page 6 is to install the switch between

the watt-hour meter and the normal distribution panel. As with

any system you must install an entrance rated breaker before the

manual transfer switch. The manual transfer switch must in all

cases be equal to or greater than the rating of the entrance rated

breaker.

The second way to install the system is to purchase and install

an emergency distribution panel and move the circuits you wish

to back up to the new distribution panel. In this case the manual

transfer switch only has to be sized to the amperage of the circuit

breaker in the main distribution panel that is feeding it. See the

right hand drawing on page 6.

Before deciding which system to install, rst determine which

loads you can safely run on your PTO generator and the cost

of buying a large manual transfer switch versus the cost of a

smaller switch and the additional distribution panel.

To assemble and wire the load disconnect plug, proceed as follows:

1. Strip outer jacket 2-3/4”.

2. Cut and strip leads to lengths specied for the

particular plug.

3. Disassemble cable clamp and top cover.

4. Remove one blade at a time, insert the stripped end

of the appropriate colored wire designated above,

and tighten the set screw.

5. Fit blades through slots in bottom cover and push

down until home. Please note: Make sure blades

are in correct slots and oriented in accordance with

the diagram above or you will not be able to close

the top cover fully.

6. Place top plastic cover over assembly and partially

tighten the bakelite assembly screw. Realign

blades straight (so they t into the top bakelite

housing properly) and tighten the assembly screw.

7. Assemble cable clamp over the outer jacket of the

wire and tighten the two clamp screws. Special Note:

For small size round (less than 3/4”) and at cables, the

wire clamp may be inverted.

WARNING - Personal Injury:

Failure to wire as instructed may cause personal injury or

damage to device or equipment. To be installed or checked

by an electrician or qualied person only.

PRE-START CHECKS

The nal item that you are going to have to assemble/wire is the

plug that will be used to connect the generator to the manual

transfer switch. You should have found this load plug in a small

box when you unpacked the PTO generator. If you need additional plugs for multiple sites you can order additional plugs from

your Winco dealer, the part number is “300137”.

WARNING: Personal Injury

DISCONNECT POWER BEFORE WIRING

IMPORTANT: Use copper wire only. Do not use tinned con-

ductors. Sizing cable - see NEC 400-5.

CORD SIZE: #4/4 conductor cord SO, 1.25 inch dia. max.

WARNING: Personal Injury

When working on or around these generators, do not wear

loose tting clothing or any articles that may get caught in

moving parts.

1. Visually inspect the generator. Check for:

a Correct mounting

b. Physical damage

c. Debris in cooling vents and screens (could

cause generator to overheat).

IMPORTANT:

The manufacturer recommends that, if the generator has

been stored for any length of time, before using it, the operator remove the control box cover and cooling fan screen,

then inspect the generator for rodent nests or other objects

that could cause generator binding and/or overheating. See

“Cleaning” portion of Maintenance section.

2. Check gear case oil

level. (See Figure 4.)

Case should be lled with

oil to plug marked “OIL

LEVEL.” Fill or remove oil

as required.

NOTE: EITHER TOO LITTLE

OR TOO MUCH OIL CAN HARM

THE EQUIPMENT

See “Lubrication” portion of Main-

tenance for oil specications.

73225-00

60706-241

Page 8

3. Make sure the drive shaft (tumbling bar) is assembled

to warm it up before proceeding, so that it will run smoothly

and achieve full power under generator load.

3. With engine idling, engage the power take-off drive.

4. Watch the voltmeter on the generator and slowly increase

engine speed until the output reaches approximately 240 to

245 volts, in green portion of voltmeter scale.

5. Plug 4 wire load cord set into receptacle. Place transfer

switch in the emergency position.

6. Place the load circuit breaker in the “on” position. If the

breaker trips, move manual transfer switch to “off” or

normal position. Check for short circuit or grounded

connection in the load cable to the double throw switch and

repair. A breaker that trips from overload or short circuit

must be reset by moving to “off” before reclosing.

7. With engine and generator running smoothly, switch on the

electrical load while watching the voltmeter. Readjust en-

gine throttle to keep generator output under load at 240V

(in green portion of voltmeter scale). If engine is equipped

with its universal joint knuckles “synchronized,” as illustrated in Figure 7. If knuckles are not synchronized,

the bar will chatter when rotating, which will cause the

generator output voltage to icker. Drive shafts shipped

new from Winco are always synchronized and tethered

so they can not be taken apart.

DANGER: Personal Injury

POWER TAKE-OFF MUST BE DISENGAGED AT THIS TIME.

4. Couple the tractor to the generator with the drive shaft

(tumbling bar). Couple the tumbling bar to the genera-

tor input shaft rst, then to the power take-off shaft.

Check alignment, tractor, power take-off shaft (tumbling

bar), and generator input shaft should form a straight

(or nearly straight) line, with less than 5° misalignment

between the shafts. Misalignment will cause generator

output voltage to icker.

WARNING - Personal Injury

Make sure that all tumbling bar lock pins are engaged and

that all safety shields are in place before operating the PTO

generator.

5. Make sure no binding exists in generator or gear box. If

binding is found, locate the cause and correct it before

proceeding.

6. Make sure that the electrical loads to be driven by the

generator will not draw more current than the ratings of

the generator receptacle or cord set which will supply

the current.

7. Check all electrical connections in the system to be

energized by the generator. Make sure the connections

are correct and are tight.

8. Make sure all loads are turned off. Do not start the generator under load.

GENERATOR STARTING

PROCEDURE

1. Set the manual transfer to mid or normal (up)

position.

2. With the power take-off drive disengaged, start the engine which will drive the generator. Run the engine long

enough to warm it up before proceeding, so that it will

run smoothly and achieve full power under generator

load.

3. With engine idling, engage the power take-off drive.

4. Watch the voltmeter on the generator and slowly

increase engine speed until the output reaches approximately 240 to 245 volts, in green portion of voltmeter

scale.

CAUTION: Equipment Damage

Most electrical equipment in North America operates satisfactorily at frequencies between 59 and 61 Hz (cycles per

second). Operating the generator at frequencies outside

that range may cause damage to the generator and/or to

electrical equipment driven by the generator.

5. Plug 4 wire load cord set into receptacle. Place

transfer switch in the emergency position.

6. Place the load circuit breaker in the “on” position. If

the breaker trips, move manual transfer switch to “off”

or normal position. Check for short circuit or grounded

connection in the load cable to the double throw switch

and repair. A breaker that trips from overload or short

circuit must be reset by moving to “off” before reclosing.

7. With engine and generator running smoothly, switch on

the electrical load while watching the voltmeter. Readjust engine throttle to keep generator output under load

at 240V (in green portion of voltmeter scale). If engine

is equipped with speed governor, it may automatically

readjust the throttle as the load changes and keep the

generator output at the proper level. However, some

governors are not sensitive enough to maintain proper

output under changing load, and in such cases the

throttle will have to be manually readjusted.

NOTE: Equipment Damage

If the load includes motors turn them on one at a time, highest starting current motor rst, next highest second, etc

8. The return of normal power will be indicated by the

lamp on the front of transfer switch; (applicable only

when the transfer switch is equipped with indicating

lamps or your electrician has installed them). After sufcient time to assure that power restoration isn’t temporary, return the transfer switch to normal power (10 - 20

minutes).

9. Place the alternator circuit breaker in “off” position. Do

not remove plug before opening the breaker.

8

3225-0060706-241

Page 9

10. Slowly reduce power take-off speed to a minimum and

CLEANING

1. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end,

circuit breakers, and receptacles.

2. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indica-

tion of the entrance of mice or insects into the generator.

The inlet and outlet openings are louvered, but possible

damage to the louvers could occur. Mice can destroy the

generator winding.

WARNING: Equipment Damage

the generator. See Figure 4. Maintain the oil level before

each use of the generator. Maintain the oil level at oil level

plug height. The generator is shipped with lubricant in the

gear case. Specifications for gear case lubricant are: API

Service: GL-5 EP Rated, Grade: SAE 85W-90-140,

Amount: 1 pint. The following kinds of oil are recom-

mended for use in the generator gear case:

Mobil SAE 85W90-140 API Service GL-5

Sunoco/DX XL80W90-140

Kendal Three Star 85W-140

Amoco 85W140 or equivalent

and require no further lubrication.

lubricated with a thin film of grease before and after each

use of the generator. See Figure 6 for lubrication sched-

ule.

universal joints in the coupling shaft free from grease and

dirt buildup.

over lubricate

the universal joints.

CLEANING

1. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end,

circuit breakers, and receptacles.

2. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indica-

tion of the entrance of mice or insects into the generator.

The inlet and outlet openings are louvered, but possible

damage to the louvers could occur. Mice can destroy the

generator winding.

WARNING: Equipment Damage

DO NOT CLEAN THE GENERATOR WHILE IT IS RUNNING.

CAUTION: Equipment Damage

Most electrical equipment in North America operates

satisfactorily at frequencies between 59 and 61 Hz (cycles

per second). Operating the generator at frequencies

outside that range may cause damage to the generator

and/or to electrical equipment driven by the generator.

disengage the power take-off. Some tractors have a

brake on the power take-off that stops the shaft instantly. Stopping the alternator rotor instantly from rated

speed may result in a broken shaft or other drive line

failures.

WARNING: Personal Injury

Never try to manually stop the generator. Always let it coast

until it stops

.

11. Shut off the engine.

12. Disconnect drive shaft (tumbling bar)

power take-off end rst, then generator end.

13. Exercise PTO alternator for one hour under load at least

twice a year.

STORAGE & MAINTENANCE

If the generator is mounted on an off-highway trailer, such as the Winco trailer, it

should be stored in a garage, barn or machine shed in a dry and clean location. The

generator should be covered with a tarpaulin

to prevent the entrance of dust, chaff, and/or

moisture.

The generator may be stored on end,

provided the generator is on a clean, dry elevated surface such as a board. Do not have

it resting on a dirt surface. (Figure 3)

MAINTENANCE REQUIREMENTS

LUBRICATION

A. Check the generator gear case oil level before each use

of the generator. See Figure 4. Maintain the oil level before

each use of the generator. Maintain the oil level at oil level plug

height. The generator is shipped with lubricant in the gear case.

Specications for gear case lubricant are: API Service: GL-5 EP

Rated, Grade: SAE 85W-90-140, Amount: 1 pint. The following

kinds of oil are recommended for use in the generator gear case:

Mobil SAE 85W90-140 API Service GL-5

Sunoco/DX XL80W90-140

Kendal Three Star 85W-140

Amoco 85W140 or equivalent

CAUTION: Equipment Damage

Do not overll generator gear case. Overlling causes overheating and oil seal failure.

C. The splined generator input shaft should be cleaned and

lubricated with a thin lm of grease before and after each use of

the generator. See Figure 6 for lubrication schedule.

D. The drive shaft (tumbling bar) requires greasing. Keep the

universal joints in the coupling shaft free from grease and dirt

buildup.

NOTE: Do not over lubricate

the universal joints.

CLEANING

A. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end, circuit

breakers, and receptacles.

B. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indication of

the entrance of mice or insects into the generator. The inlet and

outlet openings are louvered, but possible damage to the louvers

could occur. Mice can destroy the generator winding.

WARNING: Equipment Damage

DO NOT CLEAN THE GENERATOR WHILE IT IS RUNNING.

B. The generator bearings are factory lubricated and sealed,

and require no further lubrication.

93225-00

60706-241

Page 10

Increase size of line wiring. Might also be the result of loose

connection indicated by excessive heating at the loose

connection terminal.

Check for overload on the tractor or undersized.

Check tractor governor. Tight or defective throttle levers

and joints.

Worn or defective tractor engine

(see engine manufacturers

check list.)

REMEDY

Back flash the 120 volt circuit with 12 volts DC

Replace grounded rotor assembly.

Repair or replace stator assembly.

Replace defective diode(s).

Clean and tighten generator and receptacle connections.

Clean screens, make sure interior of generator is unobstructed.

Readjust or Replace as required

Test and replace if defective.

Resync drive line halves.

Realign within 10 degrees.

Replace stator. (Include generator model and serial number

on the order.)

Same as above.

Same as above.

Repair or replace as required

Test and replace if defective.

Low Speed

High line loss. Indicated by lower voltage at load than at

generator terminals.

1. Undersized/overloaded.

2. Defective governor.

3. Low power - worn engine.

LOW OUTPUT VOLTAGE

POSSIBLE CAUSE

Loss of residual magnetism. Usually occurs only after

disassembly of field frame or severe mechanical stress/abuse.

Grounded or shorted rotor winding.

Open excitor circuit in stator

Defective diode(s) on rotor.

Broken or corroded connection.

NO OUTPUT VOLTAGE

Clogged ventilating inlet and/or outlet.

EXCESSIVE HEATING

Generator is spinning too fast, slow tractor down.

HIGH OUTPUT VOLTAGE

Shorted or grounded rotor coil.

VOLTAGE UNSTEADY/ LIGHTS FLICKERING

Drive line knuckles out of sync. (See Figure 5.)

PTO drive line alignment.

Shorted stator winding. This can be identified by the use of an

internal “growler” at a competent rewinding shop.

Grounded stator. Check winding by test lamp or high potential

tester from stator leads to lamination.

Open stator circuit. Measure circuit between leads with an

ohmmeter. Should have a circuit between any pair of leads.

Defective stator

Defective Capacitors

10

3225-0060706-241

Page 11

ILLUSTRATED

PARTS LIST

COMPLETE ASSEMBLY

113225-00

60706-241

Page 12

REF # PART NUMBER QTY DESCRIPTION

H H

N

GND

G1

G3

H

N

1

2

3

4

GND

Generator

Voltmeter

40A

240V

Breaker

20A

Breaker

20

Amp

Rcpt

60

Amp

Rcpt

Ground

Lug

G3 G3

G1 G1

Nuetral

to

Ground

Bond

1 16406-007 1 Formed Base

2 99839-002 1 Generator with Gear Case

Mecc Alte Model:

S20W-1302 M5

3 15209-003 1 Decal Electrical Shock

4 Z2553 1 Decal Operators Instructions

5 300137 1 NEMA 14-60P Plug

6 21698-001 9 Torx Screw

7 300080-3 1 Top Cover

8 Z2568 1 Decal Danger PTO

9 300086-2 1 Drive Shaft Guard

10 98479-000 1 Decal Winco #1

11 53113-002 2 Decal Winco

12 63966-009 1 Nameplete

13 99841-003 1 Gear Case Support

14 16335-015 1 Generator Support

NI Z9941 1 Decal Oil Fill Hole

NI 91369-003 1 Decal 515 RPM

NI Not Illustrated

WIRING DIAGRAM

12

3225-0060706-241

Page 13

GENERATOR END ASSEMBLY

REF # PART NUMBER QTY DESCRIPTION

99839-002 1 Complete Generator End

with Gear Case

19 54665-000 1 6205-2RS Bearing

26 300323-208 2 Varistor

27 300323-207 2 Diode

65 99839-112 1 45 mf Capacitor

GENERATOR SPECIFICATIONS:

STATOR: 0.145 Ohms

ROTOR: 5.67 Ohms

CAPACITOR LEADS 1.31 Ohms

133225-00

60706-241

Page 14

RECEPTACLE PANEL

ON OFF

H H

N

GND

G1

G3

H

N

2

3

4

5

6

7

8

1

ASSEMBLY

REF # PART NUMBER QTY DESCRIPTION

1 300080-3 1 Top Cover

2 91286-001 1 20 Amp 1-Pole Circuit Breaker

3 63708-000 1 Ground Lug

4 57030-007 1 45 Amp 240 VAC Circuit Breaker

5 91370-000 1 Voltmeter

6 300079-5 1 Control Box

7 50766-000 1 NEMA 5-20R Receptacle

8 300136 1 NEMA 14-60R Receptacle

14

3225-0060706-241

Page 15

TWO WHEEL TRANSPORT

DESCRIPTION PART NO.

1 SUPPORT, TONGUE (QTY. 2) 300081

2 HITCH, TONGUE (QTY. 2) 300082

3 TONGUE 300083

4 AXLE (QTY. 2) 300085

5 SUPPORT, AXLE 300164

6 SUPPORT, PTO SHAFT 300161-1

7 SUPPORT, PTO SHAFT 300161-2

8 TIRE/RIM, PNEUMATIC (QTY. 2) 43657-000

153225-00

60706-241

Page 16

PTO GENERATOR

12 MONTH LIMITED WARRANTY

WINCO, Inc., warrants for twelve months from date of shipment, that it will repair or replace at

its option, for the original user, the whole or any part of the product found upon examination, by

WINCO at its factory at 225 South Cordova Avenue, Le Center, Minnesota, or by any factoryauthorized service station, to be defective in material or workmanship under normal standby use.

For warranty service, return the product within 12 months from the date of purchase,

transportation charges prepaid, to your nearest factory-authorized service station or the WINCO

factory.

There is no other express warranty. To the extent permitted by law, any and all warranties,

including those of merchantability and fitness for a particular purpose, are limited to 12 months

from date of shipment, and liability for incidental or consequential damages or expenses is

excluded. Some states do not allow limitations on the duration of an implied warranty, and some

states do not allow the exclusion or limitation of incidental or consequential damages, so that

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights;

you may have other rights which vary from state to state.

This warranty is limited to bench labor and parts only, no allowance will be made for travel time,

or removal and reinstallation of the PTO unit.

WINCO does not warrant drive lines, trailer tires, receptacles, or certain other component parts

of the product installed by others, since such items are warranted by their manufacturers.

WINCO does not warrant modifications or alterations which were not made or authorized by the

WINCO factory and which affect the stability or reliability of the product.

WINCO does not warrant products which have been exposed to misuse and/or negligence or

have been involved in an accident.

WINCO does not warrant products which have been installed in such a manner as not to protect

them from the adverse environmental conditions (water, mud, insects, etc.) or have not been

kept clean.

WINCO reserves the right to change or improve its products without incurring any obligations

to make such changes or improvements on products purchased previously.

16

WINCO INC.

225 S. CORDOVA AVE.

LE CENTER, MN 56057

SERVICE DEPT.

(507) 357-6831

wincogen.com

3225-0060706-241

Loading...

Loading...