Page 1

PACKAGE

PSS60/D

STANDBY

SYSTEMS

PSS90/D

DSE7310

INSTALLATION AND

OPERATORS MANUAL

Page 2

SAVE THESE INSTRUCTIONS

This manual contains important instructions

that should be followed during installation and

maintenance of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

USING THIS MANUAL

Congratulations on your choice of a Winco generator set.

You have selected a high-quality, precision-engineered

generator set designed and tested to give you years of

satisfactory standby service.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The

warranty listed in this manual describes what you can

expect from WINCO should you need service assistance

in the future.

COPY YOUR MODEL AND SERIAL NUMBER

HERE

No other WINCO generator has the same serial number

as yours. It is important that you record the number and

other vital information here. If you should ever need to

contact us on this unit it will help us to respond to your

needs faster.

MODEL_____________________________________

SERIAL NUMBER____________________________

PURCHASE DATE____________________________

DEALER____________________________________

TABLE OF CONTENTS

INTRODUCTION 2

GUIDE TO PRODUCT SAFETY 3

BASIC INFORMATION 4

Description 4

DSE 7310 Engine Control 5

Specication Table 5

PREPARING THE UNIT

Unpacking the unit 6

ENGINE GENERATOR INSTALLATION

Installation 6

Fuel Line Installation 7

Fuel Pressure Tables 7

LP Liquid Withdrawal 8

Lubrication 8

Coolant 8

Battery Installation 9

Battery Charger/Block Heater Wiring 9

AC Electrical Connections 10

DC Electrical Connections 11

ENGINE CONTROL PANEL LAYOUT 13

DSE 7310 CONTROLLER 13

INITIAL START-UP 14

START-UP PROCEDURE 14

EXERCISER CLOCK 15

TROUBLESHOOTING INFORMATION 15

CHANGING THE FUEL TYPE 16

GENERATOR END SPECIFICATION 16

ENGINE SPECIFICATIONS 17

ENGINE MAINTENANCE SCHEDULE 18

VOLTAGE REGULATOR WIRING 19

AC WIRING - THREE PHASE

277/480 Volt 20

120/208 Volt 20

120/240 Volt 21

AC WIRING - SINGLE PHASE

120/240 Volt 21

DC SCHEMATIC - WIRING DIAGRAM 22

OUTLINE DRAWING 23

12 MONTH WARRANTY 24

PROPER USE AND INSTALLATION

You must be sure your new engine generator set is:

* Properly serviced before starting

* Operated in a well ventilated area

* Properly exhausted and gases safely dispersed

* Wired by a qualied electrician

* Operated only for its designed purposes

* Used only by operators who understand its

operation

* Properly maintained

2

4228-0060706-251

Page 3

IMPORTANT SAFETY

INSTRUCTIONS

SAVE THESE INSTRUCTION

This manual contains important instructions

that should be followed during installation and

maintenance of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

This engine generator set has been designed and manufactured

to allow safe, reliable performance. Poor maintenance, improper

or careless use can result in potential deadly hazards; from

electrical shock, exhaust gas asphyxiation, or re. Please read

all safety instructions carefully before installation or use. Keep

these instructions handy for future reference. Take special note

and follow all warnings on the unit labels and in the manuals.

ANSI SAFETY DEFINITIONS

************************************************************

DANGER:

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury. This signal

word is to be limited to the most extreme situations.

************************************************************

************************************************************

WARNING:

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

************************************************************

************************************************************

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

************************************************************

NOTE:

CAUTION is also used on the unit labels and in this manual

to indicate a situation that could result in serious damage or

destruction of the equipment and possible personal injury.

1. ELECTRIC SHOCK - The output voltage present in this

equipment can cause a fatal electric shock. This equipment

must be operated by a responsible person.

a. Do not allow anyone to operate the generator without

proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or snow.

e. Use only three-prong grounded receptacles and

extension cords.

f. Be sure the unit is properly grounded to an external

ground rod driven into the earth.

2. FIRE HAZARD - Natural gas and L.P. present a hazard of

possible explosion and/or re.

a. Do not smoke or use open ame near the generator

set.

b. Keep a re extinguisher nearby and know its proper use.

Fire extinguishers rated ABC by NFPA are appropriate.

3. DEADLY EXHAUST GAS - Exhaust fumes from any gaso-

line engine contain carbon monoxide, an invisible, odorless

and deadly gas that must be mixed with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

c. Never operate the unit in such a way as to allow exhaust

gases to seep back into closed rooms (i.e. through

windows, walls or oors).

4. NOISE HAZARD - Excessive noise is not only tiring, but

continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when working

around this equipment for long periods of time.

b. Keep your neighbors in mind when permanently install ing this equipment.

5. CLEANLINESS - Keep the generator and surrounding area

clean.

a. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

b. Remove any rags or other material that could create

potential re hazards.

c. Carefully wipe up any gas or oil spills before starting the

unit.

d. Never allow leaves or other ammable material to build

up around the engine exhaust area.

6. SERVICING EQUIPMENT - All service, including the

installation or replacement of service parts, should be

performedonlybyaqualiedtechnician.

a. Use only factory approved repair parts.

b. Do not work on this equipment when fatigued.

c. Never remove the protective guards, cover, or recep tacle panels while the engine is running.

d. Use extreme caution when working on electrical compo nents. High output voltages from this equipment can

cause serious injury or death.

e. Always avoid hot mufers, exhaust manifolds, and

engine parts. They all can cause severe burns instantly.

f. Installing a generator set is not a “do-it-yourself” project.

Consult a qualied, licensed electrician or contractor.

The installation must comply with all national, state, and

local codes.

g. Always make sure unit is disabled before placing your

hands anywhere near the fan, belts, alternator or water

hoses.

34228-00

60706-251

Page 4

TESTING POLICY:

Before any generator is shipped from the factory, it is fully

checked for performance. The generator is loaded to its full

capacity, and the voltage, current, and frequency are carefully

checked.

Rated output of generators is based on engineering tests of

typical units, and is subject to, and limited by, the temperature,

altitude, fuel, and other conditions specied by the manufacturer

of the applicable engines.

INTRODUCTION AND

DESCRIPTION

With the addition of an Automatic Transfer Switch this packaged

standby system includes all items necessary for a completely

automatic standby power system.

DESCRIPTION

This package power system is designed to automatically provide

standby power to unattended loads during electrical outages.

Upon an interruption of normal electrical service this package

power system’s electrical control circuits will automatically start

the engine. The generator will produce electrical power and the

Automatic Transfer Switch (A.T.S.) will automatically transfer the

electrical loads to the engine-generator set. Upon restoration

of normal electrical service the A.T.S. will sense return of the

normal commercial power and retransfer the load back to normal

commercial power source. The engine control circuits shut off the

run signal to the engine generator set.

2) ENGINE/GENERATOR

PSS60- The engine generator set consists of a GM 5.7L, V-8

industrial, liquid-cooled engine equipped to run on L.P./N.G. fuel.

The engine operates at 1800 rpm and frequency regulation is

maintained by the electronic governor within .5 cycles variation,

from no load to rated load. The 60,000 watt (60kW) generator is

a single bearing, direct drive, rotating eld design. The generator

is connected to the engine ywheel via exible drive disks.

The engine generator is mounted in a weather proof enclosure

for outside installation. Connection boxes are provided to all

customer connections (both AC output and DC control). A

customer supplied 12 Volt, 650 CCA (BCI group 24) battery

is required to complete the installation. Engine operation is

controlled by a Deep Sea (DSE) engine control mounted in the

engine generator enclosure.

PSS90 - The engine generator set consists of a GM 5.7L,

Turbocharged/Aftercooled V-8 industrial, liquid-cooled engine

equipped to run on L.P./N.G. fuel. The engine operates at

1800 rpm and frequency regulation is maintained by the engine

governor within .5 cycles variation, no load to rated load. The

90,000 watt (90kW) generator is a single bearing, direct drive,

rotating eld design. The generator is connected to the engine

ywheel via exible drive disks. The engine generator is

mounted in a weather proof enclosure for outside installation.

Connection boxes are provided to all customer connections

(both AC output and DC control). A customer supplied 12 Volt,

650 CCA (BCI group 24) battery is required to complete the

installation. Engine operation is controlled by a Deep Sea (DSE)

engine control mounted in the engine generator enclosure.

** NOTICE **

These units will automatically transfer if a power outage occurs

while running in an exercise mode.

These package power systems consist of two major

components:

1) AUTOMATIC TRANSFER SWITCH (UL LISTED)

The Automatic Transfer Switches (A.T.S.) is a wall mount switch

designed for inside installation. An electronic exerciser circuit

is installed in the A.T.S. as standard equipment. The A.T.S. also

contains the power failure sensing circuitry necessary to send

a start/stop signal to the engine generator set. The following

is a list of recommended A.T.S. sizes for each model. Outside

switches as well as additional sizes are available, consult your

sales rep for additional information.

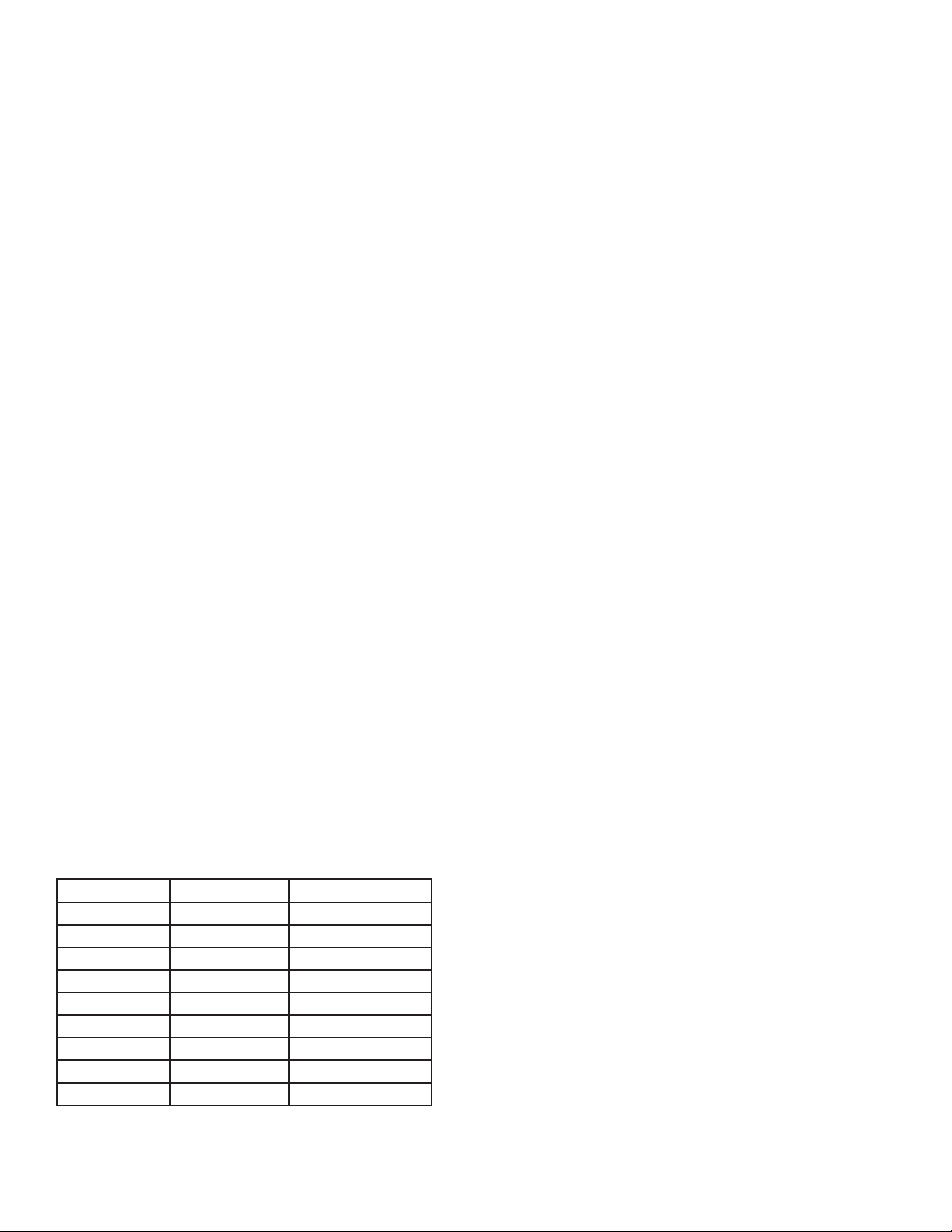

RECOMMENDED

MODEL VOLTAGE ATS AMPERAGE

PSS60-3 120/240 400

PSS60-4 120/208 400

PSS60-17 120/240 200

PSS60-18 277/480 100

PSS90-3 120/240 400

PSS90-4 120/208 400

PSS90-17 120/240 400

PSS90-18 277/480 200

ENGINE CONTROL MODULE (DSE 7310 Series)

The DSE 7310 Series control modules provide integrated engine

and generator set control, protection and metering in a single

package. Microprocessor based technology allows for exact

measurement, set point adjustment, and timing functions. Front

panel controls and indicators enable quick and simple operation.

Fully congurable via PC software, allows units to be easily

customized for each application. Includes selected front panel

programming for on site changes. A wide temperature-range

liquid crystal display (132 x 64) with backlighting can be viewed

under a wide range of ambient light and temperature conditions.

FEATURES

DSE 7310 Control Modules have the following features:

Local and Remote Generator Control

Engine and Generator Protection

CAN Bus Compatible

Programmable Logic

Five-key Menu Navigation

Engine Exercise Mode

Automatic Transfer Switch Control (Mains Failure)

User Selectable RS232 & RS485 (Remote Operation)

Additional optional A.T.S. sizes are available to meet specic

needs. Contact your local WINCO dealer or the WINCO Sales

Department for a quote.

4

4228-0060706-251

Page 5

FUNCTIONS

DSE 7310 Series Control Modules perform the following

protection and metering functions:

Generator Protection and Metering

Generator protection includes over voltage, under voltage,

under frequency, over frequency and overload protection. Each

generator protection function has an adjustable pickup and time

delay setting. Metered generator parameters include voltage,

current, real power (watts), power factor (PF)

Engine Protection and Metering

Engine protection features include oil pressure and coolant

temperature monitoring, over crank protection, ECU specic

protection elements, and diagnostic reporting.

FUEL CONSUMPTION

NG LP VAPOR

(1,000 BTU/CU FT) (2,520 BTU/CU FT)

MODEL CF/HRBTU/HR #/HR GAL/

PSS60 799 799,000 39.4 9.29 334 850,964

PSS90 1230 1,230,000 52.6 12.4 446 1,149,00

CF/HRBTU/HR

HR

L.P. TANK SIZING

Minimum required L.P. Tank size for L.P. Vapor withdrawal

operating at various outside temperatures given in degrees

Fahrenheit (Celsius)

Metered engine parameters include, oil pressure, coolant

temperature, battery voltage, speed, engine load, coolant level

(from ECU), ECU specic parameters, and run-time statistics.

** NOTICE **

These units will automatically transfer if a power outage occurs

while running in an exercise mode.

SPECIFICATIONS

LP RATING

MODEL WATTS VOLTS AMP HZ PH RPM

PSS60-3 56,000 120/240 233* 60 1 1800

PSS60-4 60,000 120/208 208** 60 3 1800

PSS60-17 60,000 120/240 180** 60 3 1800

PSS60-18 60,000 277/480 90** 60 3 1800

PSS90-3 80,000 120/240 333* 60 1 1800

PSS90-4 80,000 120/208 278** 60 3 1800

PSS90-17 80,000 120/240 240** 60 3 1800

PSS90-18 80,000 277/480 120** 60 3 1800

TANK TEMPERATURE

MODEL 60 F(16 C) 30 F(0 C) 0 F(-18 C) -20 F(-29 C)

PSS60 500 Gal 1000 Gal 2000 Gal* 5000 Gal*

PSS90 500 Gal 1000 Gal 2000 Gal* 5000 Gal*

*Recommend liquid withdrawal at these temperatures.

ENGINE SPECIFICATIONS:

** NOTICE **

Regarding Engines - This manual covers the generator portion

of these units. See the separate engine instruction manual

for engine-related problems, detailed engine information and

engine warranty. Refer to engine operating and maintenance

instructions

** CAUTION **

EQUIPMENT DAMAGE - Be sure to check the engine oil level

frequently as specied in the engine manual.

The engine manufacturer has established an excellent worldwide

engine service organization; engine service is available from a

nearby authorized dealer or distributor. Go to the WINCO web

site for a list of engine dealers. (http://www.wincogen.com/

Engine_Support/ )

NG RATING

MODEL WATTS VOLTS AMP HZ PH RPM

PSS60-3 55,000 120/240 229* 60 1 1800

PSS60-4 58,000 120/208 201** 60 3 1800

PSS60-17 58,000 120/240 174** 60 3 1800

PSS60-18 58,000 277/480 87** 60 3 1800

PSS90-3 90,000 120/240 375* 60 1 1800

PSS90-4 90,000 120/208 312** 60 3 1800

PSS90-17 90,000 120/240 270** 60 3 1800

PSS90-18 90,000 277/480 135** 60 3 1800

*Unity Power Factor - Derate 3.5% per 1000 feet elevation above

sea level.

**Power Factor .8 - Derate 3.5% per 1000 feet elevation above

sea level.

The rated power of each engine-generator is limited by the

temperature, altitude and all other ambient conditions specied

by the engine manufacturer. Engine power will decrease 3-1/2%

for each 1000 ft. above sea level, and will decrease an additional

1% for each 10o Fahrenheit above 60o Fahrenheit. Units should

not be operated in ambient temperature greater than 104o F.

54228-00

60706-251

Page 6

UNPACKING INSTRUCTIONS

** NOTICE **

When unpacking the generator set, be sure to inspect it carefully

for freight loss or damage. If loss or damage is noted at the

time of delivery, require that the person making the delivery

make note of the loss or damage on the freight bill, or afx his

signature under the consignees’s memo of the loss or damage.

Contact the carrier for claim procedures.

INSTALLATION

****************

***** WARNING *****

****************

PERSONAL INJURY - Before proceeding with the installation,

be sure the operation selector switch is in the “stop” position.

General Information

When loss or damage is noted after delivery, segregate the

damaged material, and contact the carrier for claim procedures.

“Concealed Damage” is understood to mean damage to the

contents of a package which is not in evidence at the time of

delivery by the carrier, but which is discovered later. The carrier

or carriers are responsible for merchandise lost or damaged

in transit. The title to goods rests with the consignee when

generators are shipped FOB factory, and only the consignee can

legally le a claim.

**** CAUTION ****

EQUIPMENT DAMAGE - These units are shipped with oil, and

a 50/50 mix of coolant. Be sure to check all uid levels before

operating. See engine manufacturer’s instruction manual for

recommended oil requirements before initial starting.

UNPACKING:

1. Carefully remove the carton.

2. After inspecting the engine-generator for external physical

damage, check for the following items packed inside the

carton:

a. Owner’s manual and wiring diagram.

b. Engine manufacturer’s instruction manual.

3. Remove main frame hold down bolts, (6).

4. Unit can now be lifted from shipping rails.

Note:Roofaccesspanelshavebeenprovidetocheck/ll

the engine oil and the coolant. Side panels are equipped

with door latches for their removal. All the door latches are

keyed with a common key.

These engine generator sets are for outdoor installation. These

units must be bolted solidly to a concrete pad. The transfer

switch is mounted next to your distribution panel inside the

building. Consult a qualied, licensed electrician or contractor to

install and wire the transfer switch. The installation must always

comply with all national, state, and local codes.

***** CAUTION *****

EQUIPMENT DAMAGE - These units must be mounted on a

solid concrete pad to prevent air from exiting under the unit.

Allowing air to exit under the unit may cause the unit to overheat

from lack of proper air ow.

Before beginning the installation process recheck the rating

of the generator set and its transfer switch rating. Be certain

they can handle the intended load and are compatible with

the entrance voltage, phase and current ratings. Plans

for installation should be prepared with proper attention to

mechanical and electrical engineering detail to assure a

satisfactory system installation. The information in this manual

is offered only as a guide to nalizing your installation plans. For

full service switching the A.T.S. must have a fusible disconnect

(circuit breaker) installed before the switch to protect the

contacts.

ENGINE GENERATOR SET MOUNTING

The unit’s main frame should be bolted solidly to a 4 to 6 inch

thick cement pad. The engine-generator is mounted on a subframe which is attached with special shock mounts to the main

frame. This allows the engine-generator free movement without

affecting the control panel which is mounted on the main frame.

Do not shock mount the main frame. Engine vibration will be

transmitted to the control panel causing erroneous start/stop

cycles and premature control failure.

These units should be mounted a minimum of 24” from a

structure. This will allow for ample room to maintain and work

on the generator set. Units must be installed in accordance with

all local, state, and national codes. Consult your local agency

having jurisdiction for specic requirements.

6

4228-0060706-251

Page 7

FUEL INSTALLATION

The fuel supply should be as close as possible to the engine.

This will reduce the installation cost of fuel runs. The information

in this manual is offered to assist you in providing the proper fuel

for your engine. However, this information is only provided to

inform you of the engine’s requirements and assist in making you

aware of the decisions you must make. In no case should the

instructions or information provided be interpreted to conict with

any local, state or national codes. If in doubt, always consult

your local re marshal or gas supplier.

****************

***** WARNING *****

****************

FIRE HAZARD - All fuel runs should be installed by a licensed

fuel supplier.

Connect the fuel supply to the inlet of the fuel solenoid (see

table for recommended line size). The pressure at the demand

regulator must be four to six ounces per square inch or 7 to 11

inches W.C. (Water column) on vapor withdrawal units. On units

equipped with liquid withdrawal fuel systems full tank pressure

is plumbed to the fuellock strainer mounted on the generator

rails. The fuel converter mounted on the unit will handle both

vaporization of the fuel and pressure reduction.

****************

***** WARNING *****

****************

PERSONAL DANGER - Do not use galvanized pipe in fuel line

runs. The galvanized coating can become eroded and ake off,

causing possible obstructions in the regulator or fuel valve. The

results could range from inoperative engine start to hazardous

fuel leaks.

Size of pipe normally required for generators operating on NG/

LP:

UP TO

25 FEET*

PSS60 1.25” pipe NOT

PSS90 1.25” pipe NOT

* Allow an additional 3 feet for each standard elbow.

Do not use ‘street ells’ (restrictive).

** USE THE TWO REGULATOR SYSTEM SHOWN BELOW.

OVER

25 FEET

RECOMMENDED**

RECOMMENDED**

**** CAUTION ****

EQUIPMENT DAMAGE - Be careful when sealing gas line joints.

Excessive sealing compound can be drawn into the solenoid,

regulator or carburetor causing an engine malfunction.

INSTALLING THE FUEL LINE

** NOTICE **

The engine generator sets are properly adjusted before they

leave the factory for a specic fuel, either NG (natural gas), LP

(liquid propane vapor) or LPG (liquid withdrawal propane). This

fuel type is noted in your model number. If it becomes necessary

to change the fuel type in the eld see information on page 16.

Line Size (vapor system)

Unit location will determine the size of fuel line that is required

to supply the engine with a constant fuel pressure. Refer

to the tables below for fuel line size, fuel consumption and

recommended tank size. For distances of 25 feet and over, a

two regulator fuel system is recommended. This is accomplished

by installing a primary regulator at the tank which will reduce the

tank pressure down to 10 to 15 lbs. A secondary regulator is

installed to further reduce the fuel pressure to the required six (6)

oz operating pressure. This secondary regulator must be at least

10 feet from the engine generator set. Any closer installation

will require a larger line be installed to provide a fuel reservoir.

If this is not done, the demand regulator on the unit and the

pressure regulator in the fuel line will interfere with each other.

When this two (2) stage regulator system is used, a fuel line size

of 3/4 to 1 inch is generally adequate for distances up to 300 feet

from the primary to the secondary regulator. (Consult your local

fuel supplier for your exact requirements). The appropriate line

size from the table below is then installed from the secondary

regulator to the generator set.

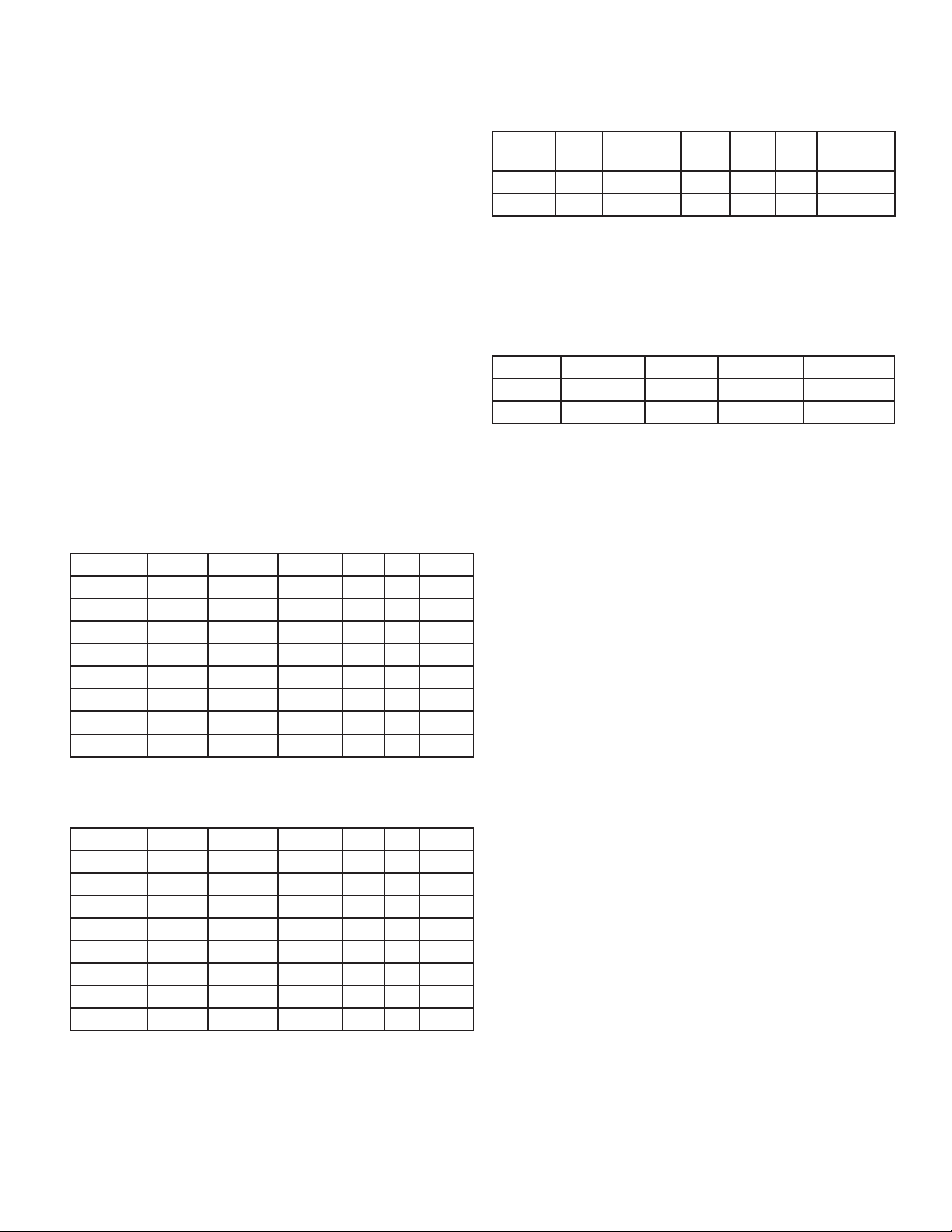

FUEL PRESSURE (vapor system)

Correct fuel pressure cannot be stressed enough. The most

common cause for inoperative systems is an inadequate or

incorrect fuel pressure. Power and performance of the engine

is in direct relation to the correctness of the fuel system. Shown

below is a diagram of a typical L.P. or N.G. installation.

Reference numbers 1 through 3 in the diagrams below are

system parts supplied by customer.

Reference number 4 is the engine generator set.

Below is a table of the fuel pressure reading at each reference in

the system.

Fuel Pressure Table

74228-00

60706-251

Page 8

Single Regulator (L.P. Vapor only)

1 3 4

UNIT OFF TANK PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING TANK PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD TANK PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD TANK PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

Natural Gas

2 3 4

UNIT OFF LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

Notice the preceding tables give two (2) different units of

measuring fuel pressure. The rst is with a pressure gauge

calibrated in ounces per square inch. The second and most

accurate is the use of a simple water manometer. A manometer

is calibrated in inches of water column.

Remember that whichever fuel delivery system or type of vapor

fuel used, the fuel pressure at the demand regulator installed on

the engine generator must be between 4 and 6 oz. (7-11 inches

of water column). Any lower pressure and the unit will starve

for fuel under load. Any higher and the unit may ‘ood’ when

attempting to start.

Two (2) Regulator System (L.P. Vapor only)

1 2 3 4

UNIT OFF TANK PSI 10-15 lbs 7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING TANK PSI 10-15 lbs 7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD TANK PSI 10-15 lbs 7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD TANK PSI 10-15 lbs 7-11 in 7-11 in

4-6 oz 4-6 oz

LP LIQUID WITHDRAWAL SYSTEMS

When installing a unit equipped the LP liquid withdrawal a

primary regulator is not required on the supply tank. The supply

line is connected to a liquid withdrawal valve on the supply

tank and runs directly to the fuellock strainer mounted on the

engine generator set. Normally a 3/8 to 1/2 inch copper line is

acceptable for this type of fuel installation. You must be sure

that the valve you have connected to on the supply tank is in

fact a liquid supply valve and has a drop tube inside the tank

that is pulling fuel from the bottom of the supply tank. Before

starting the unit you must conrm that you have a good liquid

supply at the unit. Engine generator sets equipped for liquid

withdrawal will not run properly when supplied with high

pressure vapor fuel.

LUBRICATION

Before starting the engine, check the oil level in the crankcase.

If it is low, rell to the full mark with the proper weight/grade of

oil as recommended by the engine manufacturer’s maintenance

instructions. The necessity of using the correct oil, and keeping

the crankcase full cannot be over emphasized. Failure to use

the proper oil and keep the crankcase properly lled will cause

excessive engine wear and shorten its useful life.

COOLANT

Before starting the engine, check the coolant level in radiator.

If it is low, rell as specied in the engine manufacturer’s

maintenance instructions. The radiator should be lled to about

1 inch below the ller neck. For additional information on engine

coolant requirements see engine manufacturer’s maintenance

instructions.

8

4228-0060706-251

Page 9

INSTALLING THE BATTERY

**** CAUTION ****

In the following battery installation procedure, check to be sure

the selector switch remains in the “stop” position. This should be

your last step before initial start-up.

A customer supplied twelve-volt battery is required to complete

the installation. Installation of the highest CCA rated battery,

within the correct BCI group, will increase cold weather starting

performance. Gel batteries should not be used with the battery

tender installed in the generator enclosure.

Model Voltage BCI

Group

PSS60 12 24 650

PSS90 12 24 650

Installation and servicing of batteries must only be performed

or supervised by personnel knowledgeable of batteries and the

required precautions. Keep unauthorized personnel away from

batteries.

MINIMUM

CCA Rating

WARNING – The electrolyte is a diluted sulfuric acid that is

harmful to the skin and eyes. It is electrically conductive and

corrosive. The following precautions must always be taken.

* Always wear full eye protection and protective clothing.

* Where electrolyte contacts the skin, wash off immediately

with water.

* If electrolyte contacts the eyes, ush thoroughly and immedi

ately with water and seek immediate medical attention.

* Spilled electrolyte is to be washed down with an acid

neutralizing agent. A common practice is to use a solution

of one pound of bicarbonate of soda (baking soda) to one

gallon of water. The bicarbonate of soda solution is to be

added until the evidence of reaction, foaming, has ceased.

The resulting liquid is to be ushed with water and the area

dried.

DANGER – Explosive Fire Risk

* Never smoke when near batteries.

* Do not cause a ame or spark in the battery area.

* Always discharge static electricity from your body before

touching batteries by rst touching a grounded metal surface.

When installing or replacing batteries, use the proper group/size

starting battery. The battery should be a Maintenance Free

lead acid design. Deep cycle batteries will not work for this

application.

CAUTION – PERSONAL DANGER

CAUTION - NEVER dispose of a battery in a re. The battery is

capable of exploding.

CAUTION - DO NOT open or mutilate the battery. Released

electrolyte is known to be harmful to the skin and eyes and to be

very toxic.

These engine generator sets are all NEGATIVE ground. Be very

careful not to connect the battery in reverse polarity, as this may

short circuit the battery charging system on the engine.

CAUTION – A battery presents a risk of electrical shock and high

short circuit current. The following precautions must be observed

when working with batteries.

1. Remove watches, rings and other metal objects.

2. Use tools with insulated handles.

3. Check both the battery cable ends and the battery posts to

be sure they are free of corrosion.

4. Always connect the battery positive cable rst and then

connect the battery negative cable. When removing the

battery cables from the battery reverse the procedure,

disconnect the negative cable rst and then the positive

cable.

5. Be sure all connections are tight and coat the terminals and

cable end with dialectic grease.

SERVICING BATTERIES

Batteries used on these units may over time lose water. This is

especially true if you are using a trickle charger to maintain your

battery. When relling the battery with water use only distilled

water. Tap water will shorten the service life of the battery.

Never ll the battery above the ll line. Over lling above the

upper level line may cause the electrolyte to overow, resulting in

corrosion to the engine or nearby parts. Immediately wash off

any spilled electrolyte following the procedure above.

NOTE: Always make sure that a new battery is fully charged

before installing it on a generator set. Failure to do so can cause

damage to the engine control module in the generator set.

All connections must be clean and tight. Check the electrolyte

(uid) in the battery periodically to be sure it is above the plates.

Never allow the battery to remain in a discharged condition.

CONNECTING THE BATTERY CHARGER &

BLOCKHEATER

A three-stage battery charger is provided standard for all 12 volt

standby systems. The standard charger is an Automatic Battery

Charger & Maintainer. This Charger has three rates of charging.

During the rst stage, know as BULK Charging, the charging

current is limited to 2 Amps at a voltage of up to 14.5 volts. The

green LED will blink during this stage. During stage two, know

as ABSORPTION Charging, the charging voltage is held at

14.5 volts and the charging rate gradually reduces the amount

of current (amps) owing to the battery. The green LED will also

blink during this stage. Stage three is called MAINTENANCE

Charging. During this stage the voltage will drop to 13.3 volts and

the charge rate will drop to as low at .1 amps. This keeps your

batteries in a fully charged condition without over charging them.

During this stage the green LED is constantly lit. There are

optional 5 and 10 amp chargers available that may be installed

on some units

94228-00

60706-251

Page 10

** NOTICE **

The trickle charger is not intended to recharge a battery which

has become completely discharged. It is designed to produce

just enough current to maintain a fully charged battery.

The battery tender receptacle is to be powered by a GFCI circuit

and installed in accordance with the United States National

Electric Code. These AC wires can be run in the same conduit

as the other AC leads from the generator. It is suggested that

this circuit be fused for 15 amps, then both the battery charger

and the block heater can be connected to the same circuit. A

120 volt duplex receptacle is mounted on the generator along

side circuit breaker panel, the battery tender is shipped already

plugged into the receptacle.

The engine blockheater installed on this unit should also be

plugged in this receptacle. The block heater is thermostatically

controlled and when plugged in will maintain the engine coolant

temperature between 100 and 120 degrees F.

MOUNTING THE AUTOMATIC

TRANSFER SWITCH (A.T.S.)

****************

***** WARNING *****

****************

FIRE HAZARD - All wiring must be done by a licensed

electrician, and must conform to the national electrical code and

comply with all state and local codes and regulations. Check

with the local authorities before proceeding!

A.C. ELECTRICAL

CONNECTIONS

NOTICE - CLASS 1 WIRING METHODS ARE TO BE USED

FOR ALL FIELD WIRING CONNECTIONS TO TERMINALS

OF A CLASS 2 CIRCUIT

INSTALLERS NOTE: To access the AC and DC

interconnections on this unit, open the single door

on the right hand side of the units. Then remove the

safety panel covering the mainline circuit breaker. All

connection are behind this panel.

INSTALLATION NOTES

Because of the many different types of service, feeder, and

distribution equipment, no specic wiring instructions can be

provided. It is recommended that only copper wire be used.

In all cases it is essential that while the load is connected to

the generator, there can be absolutely no feedback from the

generator to the power line or the power line to the generator.

When properly installed, the normal A.T.S. Control and safety

systems will eliminate all paths for feedback.

To wire the automatic transfer switch into the existing wiring, rst

determine which circuits will be on the emergency load circuit.

If the entire load is to be transferred, the transfer switch can

be wired in directly after the watt-hour meter and the service

entrance, providing the service entrance ampere rating is within

the transfer switch’s rated capability.

If only specic circuits are to be powered under emergency

power failure conditions, an additional distribution panel

designated “emergency distribution panel” must be installed.

All selected emergency circuits are removed from main

distribution panels and installed in the emergency distribution

panel. The A.T.S. is then installed between the main panel and

the emergency distribution panel. Suggested circuits: freezer,

refrigerator, furnace, emergency lights, sump pump, emergency

outlet circuits, etc. Total running load must not exceed generator

rating.

A- Neutral Lugs, These neutral lugs are isolated from ground

and provided for you to connect your neutral wire from the

transfer switch to. The lugs on the 90 kW will handle wire sizes

#1 AWG to 600 MCM and should be torqued to 300 in. lbs. The

lugs on the 60 kW will accommodate #4 AWG to 300 MCM and

should be torqued to 250 in. lbs.

B - Generator Circuit Breaker, This circuit breaker provides

overload protection for the generator. Your power feeds from

the transfer switch will connect to the bottom lugs on the circuit

breaker. The generator power feeds have already been wired

into the upper lugs.

The table below gives you the circuit breaker size, lug wire sizes

and torque specication. (see the actual breaker for additional

information and restrictions)

kW Voltage PH Amp Wire Capability Lug Torque

90 120/240 1 350 #1 AWG - 600 MCM 375 in lbs

90 120/208 3 300 #1 AWG - 600 MCM 375 in lbs

90 120/240 3 250 #1 AWG - 600 MCM 375 in lbs

90 277/480 3 150 #4 AWG - 300 MCM 250 in lbs

60 120/240 1 250 #1 AWG - 600 MCM 375 in lbs

60 120/208 3 200 #4 AWG - 300 MCM 250 in lbs

60 120/240 3 175 #4 AWG - 300 MCM 250 in lbs

60 277/480 3 90 #14 - #3/0 AWG 120 in lbs

10

4228-0060706-251

Page 11

Minimum Conductor Sizes between the Generator and the ATS.

Based on wire type and temperature rating. Wire has been

derated for 40o C ambient temperatures.

Cu Conductor Al Conductor

C/B Wire Temperature Rating

kW Voltage PH Amp 750C 900C 750C 900C

90 120/240 1 350 600 MCM 500 MCM (NOTE 1) 600 MCM

90 120/208 3 300 500 MCM 350 MCM 600 MCM 500 MCM

90 120/240 3 250 300 MCM 250 MCM 500 MCM 350 MCM

90 277/480 3 150 2/0 AWG 1/0 AWG 4/0 AWG 3/0 AWG

60 120/240 1 250 300 MCM 250 MCM 500 MCM 350 MCM

60 120/208 3 200 4/0 AWG 3/0 AWG 300 MCM 250 MCM

60 120/240 3 175 3/0 AWG 2/0 AWG 250 MCM 4/0 AWG

60 277/480 3 90 #2 AWG #3 AWG 1/0 AWG #2 AWG

NOTE 1 TWO 250 MCM MAY BE USED.

For additional information on wire sizing refer to table 310-15 (B)

(16) of the National Electrical Code ANSI/NFPA 70.

C - Ground Lug, These ground lugs are bonded to ground

and are provided for you to connect your ground wire from the

transfer switch to. The lugs on the 90 kW will handle wire sizes

#1 AWG to 300 MCM and should be torqued to 250 in. lbs. The

lugs on the 60 kW will accommodate #1 AWG to 250 MCM and

should be torqued to 250 in. lbs..

D. 120 Volt Terminal Block, This terminal block is provide for

the 120 volt/ 15 amp feed from customers distrubution panel for

the block heater and the trickle charger.

D.C. ELECTRICAL

CONNECTIONS

NOTE:

There are various DC connectors on the engine that have

nothing connected to them. This was done intentionally,

these connectors are for END OF LINE TESTING and

other diagnostic tests. They are not used during normal

operations and can just be ignored.

All DC connections are completed on the terminal strip just below

the engine control cabinet.

****************

***** WARNING *****

****************

A main line circuit breaker has been provided inside the

generator housing. During all wiring installations make sure the

breaker is in the off position and the generator operation switch

is in the off position.

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - When installing a Three Phase 240

volt system be sure you know which lead is the high voltage

“wild” leg (208 Volt line to neutral). The generator normally

carries the high voltage on the G2 lead.

The load current carrying wires (L) and (T) must be sized to

handle the maximum load current without excessive voltage

drop. By code, the wire must be heavy enough to handle the

full current rating of the main line circuit-breaker (or fuse) in the

entrance (or sub-panel) protecting the contactor switch.

See the manual shipped with the Automatic Transfer Switch for

connection locations in the switch. Connections in each switch

will vary depending on the type of switch and the manufacturer.

GROUNDING

A grounding lug has been provided on the engine generator set

to grounded to earth ground if required. Check with your local

codes. Generally a 8 foot copper rod driven into the earth will

provide a proper earth ground.

A - Customer Remote Start CONNECTIONS TERMINALS.

The two remote start leads from the Automatic Transfer Switch

are connected to the two terminals marked 1 & 23. The wire

in terminal labeled #1 is Battery Negative and the wire in the

terminal labeled #23 is your Remote Start lead. Closing these

two leads together will signal the DSE 7310 to go into an autostart mode and start up the engine generator.

Depending on the distance, 14 to 16 gauge stranded wire should

be used. It is suggested that these wires be labeled S1 and S23.

The terminal blocks are designed to use terminal lugs on all

wires and the screws should be torqued to 9.6 in. lbs.

Note: Any relay closure can be used to start and stop this

generator. As long as the contact stays closed the engine

generator set will continue to run. Once the relay is opened

the unit will shut down and remain in the standby mode until

the remote start relay is closed again.

114228-00

60706-251

Page 12

B - ESTOP- & ESTOP+. Remote Emergency Stop terminals.

CONTROLLER

Series 185(continued)

3 --- Generator Starting Contacts

The generator starting contacts connections are on the

controller. Refer to the generator manual. Disconnect

the generator battery and verify that the ignition switch is

in the OFF position. Connect the generator starting

wires to the appropriate terminals on terminal block TB7

as shown on the wiring diagram. For wiring convenience

terminal block TB7 has a removable plug. See Figure 4

and Table A.

TB7

removable

terminal block

TB7–4, TB7–5, TB7–6

1 2 3 4 5 6 7 8 9

5 --- Automatic Generator Exerciser

The built–in automatic generator exerciser can be set to

exercise the generator for 20 minutes once every week.

Clock Battery

Be sure a fresh battery is installed and turned on. It will

maintain the exerciser clock for about 24 hours in case of

a power outage.

Recommended 9 volt alkaline batteries are (see Figure

5): Duracell MN 1404, Everready 522, Panas onic 6AM6

Turn on battery by putting S2 DIP switch actuator 10 in

the on position (up). See Table B and Figure 6.

Exercise with or without Load

The generator should be exercised under load or follow

the recommendations of the generator manufacturer. Be

sure the exerciser is turned on. Then select either

exercise with or without load. The ATS will transfer the

load to the generator when the exercise with load is

These two terminals are shipped with a jumper installed. If your

application requires the installation of a Remote Emergency

Stop switch, remove the jumper and wire your switch to these

terminals. This unit will not start and run without either the

jumper installed or a remote N/C switch installed..

C - Battery Charger Failure. Battery charger failure relay input

from remote battery charger to DSE7310 controller.

D - Remote Display Panel Interface Terminals. These

interface terminals are prewired to allow for the connection of a

remote display. This display allows for the remote annunciation

of alarms at a location such as a nurses station or a control

room.

*******CAUTION******

Never run the AC and DC wiring in the same conduit.

NOTE: The right hand half of the customer connection

terminal block is for programmable inputs and outputs.

Although these terminals are wired into the DSE7310,

they are not normally programed. This terminal block has

connections for four programmable inputs and four putputs

alongwithoneexinputandaground.Consultthefactory

at 507-357-6831 before attempting to program these inputs/

outputs.

DC Interconnections to the Automatic Transfer Switch

ASCO 185 UL SWITCH

Your DC connection points in the ASCO 185 ATS are

terminals “4” and “5 on the interface terminal block. As this is a

“DRY” unpowered contract set it make no difference which lead

(battery negative #1 or start #23) connect to which terminal.

ASCO 300 UL SWITCH

Your DC connection points in the ASCO 300 ATS are terminals

“14” and “15”. Depending on the size of the switch they are

located in different locations. As this is a “DRY” unpowered

contact set it make no difference which lead (battery negative #1

or start #23) connect to which terminal.

Two control wires are required between the A.T.S. panel and the

generator control terminal box. Depending on the distance, 14 to

16 gauge stranded wire should be used. These wires should be

labeled S1 and S23.

****************

***** WARNING *****

****************

Be sure Engine Generator is in the “OFF” position before you

make any DC interconnections.

12

4228-0060706-251

Page 13

ENGINE CONTROL PANEL

A

B

C

D

F

E

G

H

J

1

2

3

4

LAYOUT

A. USB PROGRAMMING PORT - USB port for computer

interface. Used for programming the DSE7310 controller.

L. FUEL SELECTOR SWITCH - This switch changes the

engine operating fuel from NG (with the switch open ) to LP (with

the switch closed) This selector switch tells the engine ECU

what fuel you are supplying. The engine ECU then makes the

appropriate changes in the engine electronics to handle the fuel

of your choice.

M. CUSTOMER REMOTE CONNECTIONS - See detail on

pervious page.

N. CUSTOMER EXPANDED INTERFACE CONNECTIONS -

Provides connection for programmable inputs and output for the

DSE7310

DSE 7310 Series CONTROLLER

B. DSE7310 CONTROLLER - See controller explanation.

C. Emergency Stop Switch - When depressed this switch

will disconnect all the 12 volt power to the DSE7310 shutting

the engine down. The display on the controller will annunciate

“Emergency Stop”.

D. AC INTERFACE CONNECTOR - This connector is used to

interface with the AC generator end. It provides the controller

with the voltage, amperage and frequency reading for the

display.

E. DC INTERFACE CONNECTOR - This connector provides

all the interface connections for the engine. Including the DC

power supply to operate the DSE7310 controller. Engine ECU

connections are also made through this connector providing the

controller with the engine operational reading.

F. 10 AMP FUSE This fuse supplies the DSE7310 controller 12

Volt DC for all controller functions. (Replacement ATO-ATC 10A-

250V)

G. 3 AMP FUSE -This fuse is in the power supply for the

DSE7310 controller circuitry on the board. (Replacement ATO-

ATC 3A-250V)

H, J, K. 2 AMP FUSE- These fuses are in the AC input line from

the generator. These are the feeds that provide the AC voltage

reading on the display. If one of these is blown the controller will

not show the proper voltage on one leg and may shutdown for

low voltage. (Replacement ATO-ATC 2A-250V)

A. MENU NAVIGATION BUTTONS – Left and Right buttons

select different grouping (i.e. Engine reading, Generator reading,

etc) Up and down buttons scroll through the different reading for

each group.

B. STOP/RESET – This button places the module into its

STOP/RESET mode. This will clear an alarm conditions for

which the triggering criteria have been removed. If the engine is

running and this button is pushed the module will shut off the fuel

solenoid and the engine will come to a stop. If a remote start

signal is received while this switch is activated, the unit will not

start.

C. MANUAL - This mode allows manual control of the generator

functions. Once in the MANUAL mode the module will allow you

to start the unit using the START button. The unit will continue to

run until either the STOP/RESET or AUTO button is pressed. If

the unit receives a remote start signal during manual operation,

the generator will remain running even after the remote start

signal has been lost. You must use the STOP/RESET or AUTO

button to stop the unit once you have started it in manual mode.

**** CAUTION ****

IF THE POWER FAILS WHILE RUNNING IN THE MANUAL

MODE THE TRANSFER SWITCH WILL TRANSFER THE LOAD

TO THE GENERATOR. TO PREVENT THIS THE MAINLINE

CIRCUIT BREAKER ON THE GENERATOR MUST BE

OPENED.

134228-00

60706-251

Page 14

D. AUTO – This button places the module into its AUTOMATIC

mode. This module will monitor the remote start input for a relay

closure. When the remote start signal is received it will time out

the start delay (5 Seconds) and then start the engine generator

set. When the remote start signal is lost (relay opened up) the

module will shut the engine generator set down after the cool

down timer has time out. The module will return to the auto start

mode and await the next start signal.

E. LAMP TEST/HORN RESET - This button silences the

audible alarm if it is sounding and illuminates all of the LEDs as

a lamp test feature. When congured and tted to a compatible

engine ECU, pressing this button in STOP/RESET mode after

pressing the START button (to power the ECU) will cancel any

“passive) alarms on the engine ECU.

1. Engine oil. Fill as required with proper grade/qty.

2. Engine coolant. Fill as required with proper

mixture.

3. Unit mounting base properly bolted down.

4. Clearance for service and maintenance on all

sides.

5. Proper fuel line material and size.

6. All fuel line connections tight.

7. Fuel line protected and a moisture trap installed

(may be required for N.G.).

8. Correct LP/NG pressure 4-6 Oz. (7-11” Wc).

9. Battery connections clean and tight.

10. Battery fully charged.

11. All AC and DC wiring installed and properly

protected.

F. START – This button is active only in the MANUAL or STOP/

RESET mode. Pressing this button in the MANUAL mode will

start the engine locally for testing. The engine will continue to

run until either the STOP/RESET or the AUTO button is pressed.

Pressing this button with the control in the STOP/RESET mode

will turn on the engine ECU (when correctly congured and tted

to a compatible engine ECU)

G. CLOSE GEN-SET – NOT USED IN THIS APPLICATION

H. OPEN GEN-SET – NOT USED IN THIS APPLICATION

J. USER CONFIGURABLE INDICATORS –

1. Remote Start.

2. Fuel Selection on for LP - off for NG.

3. Generator Available

4. Emergency Stop

NOTE: STOP/RESET, MANUAL mode and AUTO mode buttons

all have indicator lamps next to them to tell you what mode you

are in. Pressing buttons out of sequence will cause the engine

not to function properly.. See button operation sequencing

above.

INITIAL START UP

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - DO NOT jump start these engine

generator sets. Starting these units on a low battery or jump

starting them will cause damage to the engine control module.

After completing the above checklist, the engine-generator set is

ready for the initial start-up test.

STARTING PROCEDURE

MANUAL MODE

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - BEFORE ATTEMPTING TO START

THIS UNIT COMPLETE YOUR PRESTART CHECKLIST AND

INSURE THE GENERATOR MAINLINE CIRCUIT BREAKER

IS IN THE PROPER POSITION PRIOR TO STARTING.

STARTING THIS UNIT WITHOUT IT PROPERLY CONNECTED

CAN CAUSE SERIOUS PERSONAL INJURY OR EQUIPMENT

DAMAGE.

1. Depress the manual mode button on the control panel. The

small LED light next to it should come on.

2. Press the start button- The DSE7310 will send a start signal

to the ECU on the engine. The engine ECU will then energize

the fuel solenoid and start the cranking cycle (10 seconds on and

10 seconds off).

NOTE: There is no start delay in this mode of operation.

If the engine fails to start during this cranking period the starter

motor is disengaged and goes into a rest mode after which

a second attempt is made to start the engine. Should this

sequence continue through 3 cranking cycles the start sequence

will be stopped and the display will show ‘FAILED TO START’.

Use the following check list to verify correct installation before

starting the engine:

Note:Roofaccesspanelshavebeenprovidetocheck/ll

the engine oil and the coolant. Side panels are equipped

with door latches for there removal. All the door latches are

keyed with a common key.

3. All engine functions are controlled by the ECU on the engine.

The ECU on the engine will send information signals to the

DSE7310 via the CAN connections to indicate oil pressure, water

temperature, etc for the display on the engine control.

All shutdown functions are also controlled by the ECU on the

engine, what you see displayed on the DSE7310 display is what

is happening inside the ECU on the engine.

The AC output readings displayed on the DSE7310 are collected

through the AC interface harness wired in the generator control

box. An shutdowns related to the AC output are not a function

of the engine ECU but are based on information collected in the

DSE7310 via this AC harness.

14

4228-0060706-251

Page 15

4. During manual operation the load will not normally be applied

to the generator. But caution must be used, if the line power

should fail or be turned off to the transfer switch during manual

operation the load may be applied to the generator.

With the engine running smoothly check the no load voltage

and frequency on the digital display. The voltage should be

208/240/480 AC depending on which model you have and a

frequency of 59.5 To 60.5 hertz (Hz).

If you have the proper voltage at the generator the next step is

to check the voltage at the generator terminals in the Automatic

Transfer Switch. The voltage between the G1 and the G3

terminals should be the same as it was on the generator front

panel. The voltage should also be checked between the hot

terminals (G1 and G3) and the G-N to be certain of a balanced

voltage output and a solid neutral connection. The voltage

between G1 and G-N should be about 120 volts AC (277 on 480

units). The same approximate voltage should be found between

terminals G3 and G-N (120 volts AC).

On three phase panels the G2 voltage level should also be

checked. ON 240 VOLT (DELTA) SYSTEMS BE SURE YOU

KNOW WHERE THE HIGH VOLTAGE “WILD” LEG IS. IT MUST

BE IN THE SAME LOCATION ON THE LINE SIDE AS IT IS ON

THE GENERATOR SIDE. (i.e. if it’s on L-3 on the line side it

must be on G-3 on the generator side.

TROUBLESHOOTING TABLES

UNIT WILL NOT CRANK WHEN THE POWER FAILS

1. Digital Genset Controller not in “AUTO”.

2. Transfer control switch not in “AUTOMATIC”

position.

3. Incorrect wiring between transfer switch and

generator.

4. Blown fuses on Digital Genset Controller.

5. Defective Digital Genset Controller.

6. Loose or dirty battery terminals.

7. Defective auto start controller in the

transfer switch.

8. Defective starter.

9. Defective start solenoid.

ENGINE WILL NOT CRANK WITH GENERATOR

RUN PUSH-BUTTON DEPRESSED

1. Battery dead.

2. Blown fuses Digital Genset Controller.

3. Defective Digital Genset Controller.

4. Loose or dirty battery terminals.

5. Defective starter.

6. Defective start solenoid.

7. Locked up engine genset.

** Notice **

If for any reason during the check out procedure the voltage and

frequency are not correct, depress the STOP/RESET button and

correct the trouble before proceeding.

5. Stopping – There are two ways to stop the unit when it is in

the manual mode. Pressing the STOP/RESET button will stop

the unit immediately. Pressing the AUTO mode button will stop

the unit but only after the cool down timers have timed out and

there is no remote start signal being sent to the unit.

AUTO MODE

To activate the automatic start mode you will just need to

depress the AUTO button, the LED indicator beside the button

conrms that the unit is in automatic start mode.

To test the automatic start Transfer Switches follow the

instruction in the operator’s manual you received with your

transfer switch. If you get a fault light during the initial start up

or prior to start up it is most likely a false warning light. Simply

reset the ATS and start over.

Once you have completed testing of the ATS, be sure you

ALWAYS leave the system in standby mode unless servicing the

unit. For standby operation, press the AUTO button on the front

of the engine control. The green light should light up next the

AUTO button.

SETTING THE EXERCISER CIRCUIT

For all ATS see the instruction manual shipped with the ATS for

instruction on setting the exercise circuit in your ATS

ENGINE CRANKS BUT WILL NOT START

1. Improper fuel pressure being delivered to

unit.

2. Fuel supply shut off.

3. Fuel tank empty.

4. Defective spark plug.

5. Defective engine ignition module.

6. Dirty air cleaner lter.

7. Defective fuel solenoid valve.

8. Low battery.

9. Defective fuel regulator.

10. Defective ECU on the engine.

ENGINE STARTS AND THEN STOPS AND ALARM

LIGHT COMES ON

1. Engine is low on oil.

2. Engine has high water temperature.

3. Engine has overspeed.

4. Engine has gone into overcrank.

5. No output from engine alternator to engage

stop crank circuit.

6. Generator is not aoperating at the correct speed.

7. Defective ECU on the engine

ENGINE WILL NOT COME UP TO SPEED AFTER IT STARTS

1. Insufcient fuel volume getting to the unit.

a. Too small of fuel line.

b. Fuel pressure too low/high.

2. Defective ECU on the engine.

3. Governor is defective.

4. AC short in generator components.

154228-00

60706-251

Page 16

ATS PANEL WILL NOT TRANSFER TO EMERGENCY SUPPLY

(GENERATOR)

1. No AC generator output from generator.

2. Defective transfer switch controller.

3. Incorrect voltage or frequency from the generator.

4. Wiring error between generator and transfer

switch.

5. Defective mechanically switching solenoid in

Automatic Transfer Switch.

6. Improper phase rotating.

7. Main line breaker on generator open/defective.

ATS PANEL WILL NOT RETRANSFER TO NORMAL POWER

1. Proper normal line power not available at line

terminals in ATS panel.

2. Defective transfer switch controller.

3. Defective mechanically switching solenoid in

Automatic Transfer Switch.

4. Retransfer delay still timing out.

NO AC OUTPUT FROM GENERATOR

1. Defective diode.

2. Defective voltage regulator.

3. Defective rotor.

4. Defective stator.

5. Defective exciter rotor.

6. Defective exciter stator.

7. AC short in the output leads.

8. Defective eld circuit breaker.

CHANGING THE FUEL TYPE

**** CAUTION ****

EQUIPMENT DAMAGE - Do not make any fuel adjustments

or governor adjustments until all pressure readings are in

compliance with specication. See fuel pressure charts (tables

1, 2, and 3).

These engine/generator sets are very easy to convert between

LP or NG. As the engine timing is controlled by the ECU on the

engine you only need to tell it what fuel you want to operate on.

A small rocker switch has been provide on the underside of the

engine control cabinet (see ref L on Page 13) for this purpose.

Opening the rocker switch will tell the ECU mounted on the

engine that you are operating on NG Fuel. Closing the rocker

switch will tell the ECU that the fuel being supplied is LP. The

Advance Power Controller has an idicator light for LP. When this

light is lite the engine is set-up for LP, when the LP light is out the

engine is set up for NG. The ECU will then reprogram the engine

to operate on the proper fuel.

GENERATOR SPECIFICATIONS

PSS60-3

Stanford Newage Model# UCI224F1J

06 Winding (Single phase 4 lead generator)

Winco Part Number 351928-41

Voltage Regulator AS440

Rotor Resistance 0.83 ohm

Stator Resistance 0.012 ohm

Excitor Stator Resistance 20.0 ohm

Excitor Rotor Resistance 0.156 ohm

PSS60-4/-17/18

Stanford Newage Model# UCI224F1L

311 Winding (Three phase 12 lead reconnectable)

Winco Part Number 351928-4

Voltage Regulator AS440

Rotor Resistance 0.83 ohm

Stator Resistance 0.033 ohm

Excitor Stator Resistance 20.0 ohm

Excitor Rotor Resistance 0.156 ohm

GENERATOR REPLACEMENT PARTS

The following list of replacemnt parts apply to all four generator

models listed for these generators:

Description Stanford Part #

Automaic Voltage Regulator E000-24403

Winco Part # 350818-2

PSS90-3

Stanford Newage Model# UCI274C1J

06 Winding (Single phase 4 lead generator)

Winco Part Number 352013-1

Voltage Regulator AS440

Rotor Resistance 1.12 ohm

Stator Resistance 0.011 ohm

Excitor Stator Resistance 20.0 ohm

Excitor Rotor Resistance 0.182 ohm

PSS90-4/-17/18

Stanford Newage Model# UCI274C1L

311 Winding (Three phase 12 lead reconnectable)

Winco Part Number 352013-2

Voltage Regulator AS440

Rotor Resistance 1.12 ohm

Stator Resistance 0.03 ohm

Excitor Stator Resistance 20.0 ohm

Excitor Rotor Resistance 0.182 ohm

Bearing UCI224 051-01032

UCI227 051-01049

Rectier Service Kit RSK-2001

Comprises of

6 Diodes with Surge Suppressor

16

4228-0060706-251

Page 17

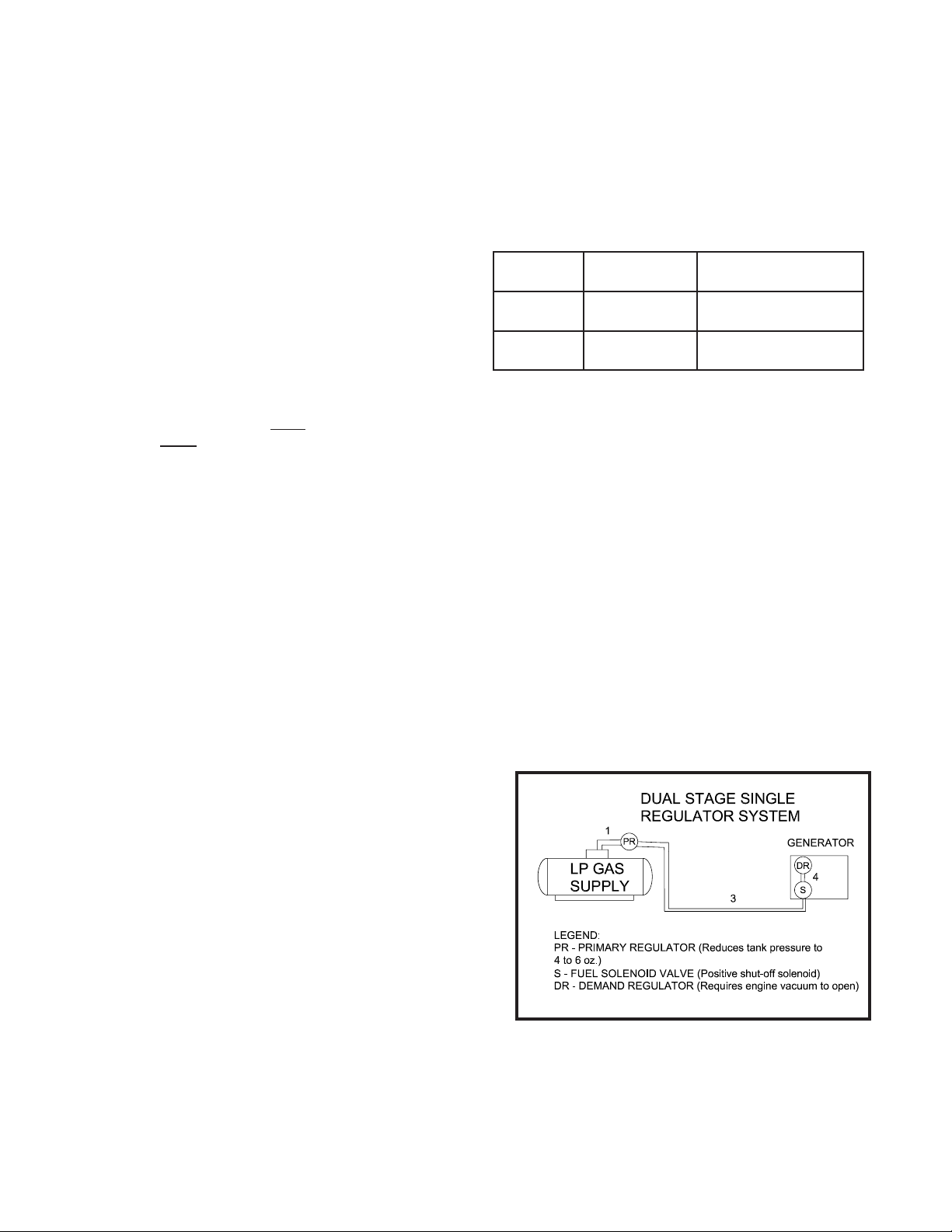

ENGINE SPECIFICATIONS

GENERAL SPECIFICATIONS

Power Solutions, Inc.

GM

Powertrain

Industrial Engines

Engine

1.6L 3.0L 4.3L

5.0L/

5.7L

8.1L/8.1L

Turbo

Type

1.6-2V

3.0L L4

4.3L V

-6

5.7L V-8 GEN-1E

8.1L V

-8

Displacement cc (c.i.d.)

1600 (98)

2966 (181)

4294 (262) 5735 (350) 8127 (496)

Compression Ratio

9.5:1

10.5:1

9.4:1 9.4:1 9.1:1

Valve Configuration

Overhead Cam

Push R

od Actuated

Overhead Valve

Push Rod Actuated

Overhead Valve

Push Rod Actuated

Overhead Valve

Push Rod Actuated

Overhead Valve

Valve Lifters

Hydraulic

Flat Follower

Hydraulic Roller Hydraulic Roller Hydraulic Roller

Bore x Stroke mm (inches)

79.0x81.5 (3.

11x3.21)

101.60x91.44 (4.00x3.60) 101.60x88.39 (4.00x3.48) 101.60x88.39 (4.00x3.48)

107.95x111

(4.25x4.37)

Main Bearing Caps

2 Bolt 2 Bolt 2 Bolt 2 Bolt 4 Bolt

Balance Method

External External

Internal Balance Shaft

External External

Intake Manifold

Mix

er

Mixer Mixer Mixer Mixer

Firing Order

1-3-4-2 1-3-4-2 1-6-5-4-3-2 1-8-4-3-6-5-7-2 1-8-7-2-6-5-4-3

Oil Capacity

With Oil Filter

3.4 qts. (3.2L)

3.7 qts. (3.5L)

4 qts. (3.8L)

5 qts. (4.7L)

4.5 qts. (4.3L)

5 qts. (4.7L)

4.5 qts. (4.3L)

5 qts. (4.7L)

8 qts

. (7.6L)

9 qts (8.5L)

Oil Filter

PF-25 or Equivalent

PF-47/PF-52 or

Equivalent

PF-1218 or Equivalent

PF-454 or Equivalent

Minimum Oil Pressure

(Hot)

21 psi @ idle

6 psi @ 1000 rpm

18 psi @ 2000 rpm

6 psi @1000 rpm

18 psi @ 2000 rpm

6 psi @ 1000 rpm

18 p

si @ 2000 rpm

5 psi @ 1000 rpm

15 psi @ 2000 rpm

Coolant Capacity (Engine)

3.5 qts.

4 qts. (3.78L)

7.75 qts. (7.3L)

8.1 qts (7.8L)

14.5 qts (13.7L)

Coolant Capacity (W/PSI

Rad)

10 qts

12 qts. (11.4L)

17 qts. (16L)

17.5 qts. (16.6L)

28 qts (26.5L)

Fuel Type

NG, LPG LPG, NG LPG, NG LPG, NG LPG, NG

Engine Rotation (Flywheel

End)

CCW CCW CCW CCW CCW

Ignition System

Distributor-less

Electronic (ECU)

High Voltage Switch

(HVS)

High Voltage Switch

(HVS)

High Voltage Switch

(HVS)

Distributor-less

Electron

ic (ECU)

Ignition Timing

ECM Controlled

Not Adjustable

ECM Controlled

Not Adjustable

ECM Controlled

Not Adjustable

ECM Controlled

Not Adjustable

ECM Controlled

Not Adjustable

Spark Plugs

AC Delco 93206675

AC Delco R42LTS

or

R44LTS

AC Delco R42LTS or

R44LTS

AC Delco R42LTS or

R44LTS

AC Delco R42LTS or

R44LTS

Spark Plug Gap

0.035” 0.035” 0.035” 0.035” 0.035”

Valve Clearance (Lash)

Intake

Exhaust

No Adjustment

OHC Engine

½ to 1 Turn Down From

0 Lash

Net Lash

No Adjustment

1 Turn Down From

0 Las

h

Net Lash

No Adjustment

Manufactured

Toluca, Mexico Toluca, Mexico

Tonawanda, NY

Toluca, Mexico

Tonawanda, NY

Revised 12/2008

PSS60 - All voltages

Engine GM/PSI 5.7LN V8 350 CID

LP/NG

PSS90- All Voltages

Engine GM/PSI 5.7LTCAC V8 350 CID

LP/NG

174228-00

60706-251

Page 18

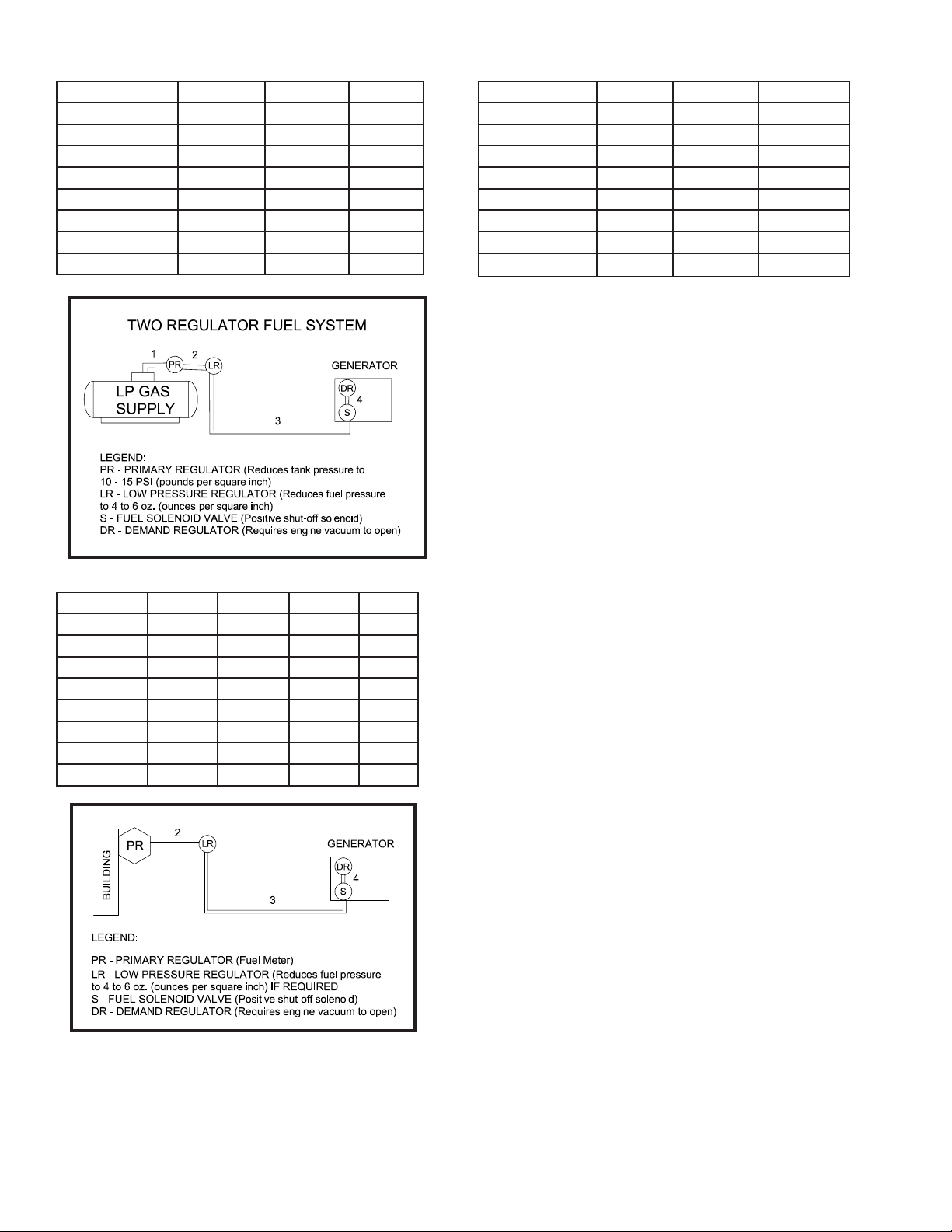

Daily

1000

1500 2000

2500

3000

3500

4000

4500

5000

General Maintenance Section

Visual check for fluid leaks

X

Check engine oil level

X

Check coolant level

X

Change engine oil and filter

Check LPG system for leaks

Inspect accessory drive belts for cracks, breaks, splits or glazing X X X X X

Inspect electrical system wiring for cuts, abrasions or corrosion

X X

Inspect all vacuum lines and fittings for cracks, breaks or hardening

X X

Engine Coolant Section

Clean debris from radiator core

Change coolant

X X X X X

Inspect coolant hoses for cracks, swelling or deterioration

X X X X X

Base Engine – Prime Engines

Compression Test

X X

X

Replace/Rebuild Cylinder Heads

X

X

Base Engine – Turbo Charged Emergency Engines

Replace/Rebuild Cylinder Heads

X X

Replace Turbo Charger

Engine Ignition System

X X X X X

Replace spark plugs

X X

Clean secondary ignition coil tower

X X X X X

Check spark plug wires for cuts abrasions or hardening

X

Replace distributor cap and rotor

X X

Replace spark plug wires

X X

Fuel System Maintenance

Inspect air cleaner

Replace filter element

Replace fuel filter

X X X X X

Inspect Shut-off Valve for leaks and closing

X X

Leak check fuel lines

X X

Check air induction for leaks

X X

X

X

X

Check manifold for vacuum leaks

X X

X

X

X

Drain Vaporizer oil build up

Engine Exhaust System

Inspect exhaust manifold for leaks

X

X

Inspect exhaust piping for leaks

X

X

Check HEGO sensor(s) connector and wires for burns, cuts or damage

X

X

Inspect catalyst for mechanical damage

X

X

Annually, or as required in dusty environments

Every 2500 hrs

Every 200 hours, or every 100 hours in dusty environment

Prior to any service or maintenance activity

Every 100 hours or 60 days of operation

CERTIFIED STATIONARY ENGINE MAINTENANCE REQUIREMENTS

Perform the following maintenance on the engine at the hours indicated and at equivalent hour intervals thereafter.

Interval Hours

Every 150 hours or 120 days of operation

18

4228-0060706-251

Page 19

ENGINE MAINTENANCE NOTES:

FITTING AND OPERATING

SUMMARY OF AVR CONTROLS

CONTROL FUNCTION DIRECTION

VOLTS TO ADJUST GENERATOR OUTPUT VOLTAGE CLOCKWISE INCREASES OUTPUT VOLTAGE

STABILITY TO PREVENT VOLTAGE HUNTING CLOCKWISE INCREASE THE DAMPING EFFECT

STAB SWITCH TO OPTIMISE TRANSIENT PERFORMANCE SEE TABLE ABOVE

UFRO TO SET THE UFRO KNEE POINT CLOCKWISE REDUCES THE KNEE POINT FREQUENCY

DROOP TO SET THE GENERATOR DROOP TO 5% AT 0PF CLOCKWISE INCREASES THE DROOP

VTRIM TO OPTIMISE ANALOGUE INPUT SENSITIVITY CLOCKWISE INCREASES THE GAIN OR SENSITIVITY

EXC TRIP TO SET OVER EXCITATION TRIP CUT OFF LEVEL CLOCKWISE INCREASES THE CUT OFF LEVEL

REFER TO GENERATOR WIRING DIAGRAM

FOR CONNECTION DETAILS

F2 F1 7 8 8 Z2

S1

S2

A1

A2

A

S440

Trim

Droop

Volts

Stability

Selection

UFRO

Frequency

Selection

Indicator LED

Stab

60Hz

50Hz

1

2

3

Lb

La

ABCD

Stability Selection Table

No. Power range Response

B-D < 100kW Slow

A-C < 100kW Fast

B-C 100-550kW Fast

A-B > 550kW Fast

Hand trimmer terminals. Remove

link before fitting hand trimmer.

Link must be fitted when hand

trimmer is not required.

Exc

Trip

8 and Z2 – linked for

normal operation

Oil Filter: Both units use PF-35 or PF-454

Engine oil: Use only engine oils displaying the API Certication

Mark “ FOR GASOLINE ENGINES” on the container. Gasoline

engines that are converted for LPG or NG fuels MUST use oils

Coolant System: Check the coolant daily or after each use, and

only when the engine is cool. Maintain the coolant level 3/4 to 1

1/2 inches below the ller neck seat when the coolant is cold.

labeled “FOR GASOLINE ENGINES”. Do not use oils that are

specically formulated for Diesel Engines only. CC or CD classication oils, even when labeled Heavy Duty or for Natural Gas

Engines, ARE NOT ACCEPTABLE.

Multi-viscosity oils are recommended. SAE 10W-30 is recom-

mended for your engine from 0 degrees F (-18 degrees C)

or above. If ambient temperatures are consistently below 0

degrees F. SAE 5W-30 oil can be used Synthetic oils are not

recommended for Industrial or Stationary engine.

Air Filter: Both the PSS60 and the PSS90 use the same air

lter, the IMPCO F1-15.

Spark Plugs: Both units use R42LTS or R44LTS

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - Never remove the radiator cap when

the engine is hot and never add coolant to any engine that

has become overheated. Either can cause personal injury

and damage to the engine.

The cooling system must be lled with a 50/50 mixture of

antifreeze and water The use of DexCool “Long Life” (typical

orange in color) type coolant is required.

SEE THE ENGINE OPERATORS MANUAL FOR ADDITIONAL

SERVICE INFORMATION

VOLTAGE REGULATOR

The automatic voltage regulator used standard on all models of the PSS60 and PSS90 is the AS440. The regulator is

preset at the factory and should never need adjustment. If you should ever need to adjust the regulator (i.e. you recon-

nect the generator for a different voltage) the only adjustment that should need to be made is the voltage pot. Below is a

description of the AS440, not all function are use on these models. Special order units may use different regulators.

194228-00

60706-251

Page 20

THREE PHASE AC WIRING

HIGH AND LOW WYE

THREE PHASE-LOW WYE

120/208 VOLTS

THREE PHASE-HIGH WYE

277/480 VOLTS

20

4228-0060706-251

Page 21

THREE PHASE AC WIRING - DELTA

SINGLE PHASE AC WIRING

SINGLE PHASE

120/240 VOLTS

THREE PHASE -DELTA

120/240 VOLTS

214228-00

60706-251

Page 22

ENGINE

CONTROL

SCHEMATIC

22

4228-0060706-251

Page 23

PSS60/D OUTLINE DRAWING

THE PAGE

INTENTIONALLY

LEFT BLANK

PSS90/D OUTLINE DRAWING

234228-00

60706-251

Page 24

12 MONTH LIMITED WARRANTY

WINCO, Incorporated warrants to the original purchaser for 12 months or 1000 hours which ever

occurs rst, that goods manufactured or supplied by it will be free from defects in workmanship and

material, provided such goods are installed, operated and maintained in accordance with WINCO

written instructions.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be

limited to the repair of the product. At WINCO’s option, material found to be defective in material

or workmanship under normal use and service will be repaired or replaced. For warranty service,

return the product within 12 months or 1000 hours which ever occurs rst from the date of purchase,

transportation charges prepaid, to your nearest WINCO Authorized Service Center or to WINCO,

Inc. at Le Center Minnesota.

THERE IS NO OTHER EXPRESS WARRANTY.

To the extent permitted by law, any and all warranties, including those of merchantability and tness

for a particular purpose, are limited to 12 months or 1000 hours which ever occurs rst, from date of

purchase. In no event is WINCO liable for incidental or consequential damages.

Note: Some states do not allow limitation on the duration of implied warranty and some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitations