Page 1

TB2400/E

TB4800/A

TB7200/C

TWO BEARING

GENERATORS

TB7200

INSTALLATION AND

OPERATORS

MANUAL

WINCO INC. • 225 S. CORDOVA AVE. • LE CENTER, MN 56057 • 507-357-6821

SERVICE DEPT. 507-357-6831

wincogen.com

Page 2

TABLE OF CONTENTS

TESTING POLICY 2

SPECIFICATIONS 3

TB2400/E

TB4800/A

TB7200/C

INTRODUCTION 3

SAFETY 4

IMPORTANT SAFETY INSTRUCTIONS

ANSI SAFETY DEFINITIONS

CALIFORNIA PROPOSITION 65

UNIT CAPABILITIES 5

GENERATOR CONNECTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed

during installation and maintenance of the generator. Read and

understand all instructions in the manual before starting and operating

the generator.

USING THIS MANUAL

Congratulations on your choice of a WINCO generator. You have

selected a high-quality, precision-engineered generator designed and

tested to give you years of satisfactory service.

To get the best performance from your new generator, it is important

that you carefully read and follow the operating instructions in this

manual.

STARTING ELECTRIC MOTORS 5

PREPARING THE UNIT 6

UNPACKING

CONNECTING THE LOADS 6

APPLYING THE LOAD

UNIT INSTALLATION 7

PLAN THE INSTALLATION

MOUNTING

TROUBLESHOOTING 8

WIRING SCHEMATICS 9

TB2400

TB4800

TB7200

12 MONTH LIMITED WARRANTY 12

Should you experience a problem please follow the “Troubleshooting

Tables” near the end of this manual. The warranty listed in the manual

describes what you can expect from WINCO should you need service

assistance in the future.

COPY YOUR MODEL AND SERIAL NUMBER HERE

No other WINCO generator has the same serial number as yours. It

is important that your record the number and other vital information

here. If you should ever need to contact us on this unit, it will help us to

respond to your needs faster.

MODEL __________________________________________________

SERIAL NUMBER _________________________________________

PURCHASE DATE _________________________________________

DEALER NAME ___________________________________________

DEALER PHONE # ________________________________________

REV C

TESTING POLICY

Before any generator is shipped from the factory, it is fully checked

for performance. The generator is loaded to its full capacity, and the

voltage, current, and frequency are carefully checked.

Rated output of generator is based on engineering tests of typical units,

and is subject to, and limited by, the temperature, altitude, fuel, and

other conditions specied by the manufacturer of applicable engines.

2

OPM-122

Page 3

SPECIFICATIONS

INTRODUCTION

TB2400/E

Watts 2,400

Volts 120

Amps 20

Receptacles (1) NEMA 5-20 Duplex

Moisture Protection IP 23

Generator End

Manufacturer Mecc Alte

Model S15W-85

Capacitor 16 µF

Capacitor Part Number 16346-802

TB4800/A

Watts 4,800

Volts 120/240

Amps 40/20

Receptacles (1) NEMA 5-20 Duplex

(1) NEMA L14-30R

Moisture Protection IP 23

Generator End

Manufacturer Mecc Alte

Model S16W-130/2

Capacitor 25 µF

Capacitor Part Number 16346-612

These generators are a 3600 RPM two-bearing, belt-driven, brushless,

rotating eld design. The generators are self excited and inherently

regulated to +/- (plus or minus) 5% - no load to full rated load. It can be

operated under any load within its rating without being damaged. The

frequency regulation is determined by the sensitivity of the customer

supplied prime mover’s governor. It is desirable to maintain this speed

to within 3 cycles variation (61.5 Hz - 58.5 Hz) no load to full rated load

(3690 RPM - 3510 RPM)

TB7200/C

Watts 7,200

Volts 120/240

Amps 60/30

Receptacles (1) NEMA L14-30R

Moisture Protection IP 23

Generator End

Manufacturer Mecc Alte

Model S20W-110/2

Capacitor 35 µF

Capacitor Part Number 16346-312

3OPM-122

REV C

Page 4

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important information that should be understood

and followed before the installation, operation and maintenance of the

generator. Failure to follow the safety instructions in this manual could

result in serious injury or death. Keep this manual available for future

reference.

ANSI SAFETY DEFINITIONS

DANGER:

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word is to be

limited to the most extreme situations.

WARNING:

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

4. CLEANLINESS -

Keep the generator and surrounding area clean.

A. Remove all grease, ice, snow or materials that create slippery

conditions around the unit.

B. Remove any rags or other materials that could create a

potential re hazard.

C. Carefully clean up any gas or oil spills before starting the unit.

5.SERVICING EQUIPMENT -

All service, including the installation or replacement of service parts,

should be performed only by a qualied technician.

A. Use only factory approved repair parts.

B. Do not work on this equipment fatigued.

C. Use extreme caution when working on electrical components.

High output voltages from this equipment can cause serious

injury or death.

D. Installing a generator is not a “do-it-yourself” project. Consult

a qualied, licensed electrician or contractor. The installation

must comply with all national, state, and local codes.

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may be used to alert

against unsafe practices.

NOTE: CAUTION is also used on the unit labels and in this manual to

indicate a situation that could result in serious damage or destruction of

the equipment and possible personal injury.

1. ELECTRIC SHOCK -

The output voltage present in this equipment can cause a fatal electric

shock. This equipment must be operated by a responsible person.

A. Do not allow anyone to operate the generator without proper

instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Use extreme care if operating this unit in rain or snow.

E. Use only three-prong grounded plugs and extension cords.

F. Be sure the unit is properly grounded to an external ground rod

driven into the earth.

2. FIRE HAZARD -

A. Keep a re extinguisher nearby and know its proper use. Fire

extinguishers rated ABC by NFPA are appropriate.

CALIFORNIA PROPOSITION 65

WARNING: This product contains crude oil, gasoline,

diesel fuel and other petroleum products, Antifreeze to

which can expose you to chemicals including toluene

and benzene, Ethylene glycol (ingested) which are

known to the State of California to cause cancer, birth defects or other

reproductive harm and developmental issues.

For more information go to www.P65Warning.ca.gov.

3. NOISE HAZARD -

Excessive noise is not only tiring, but continual exposure can lead to

loss of hearing.

A. Use hearing protection when working around this

equipment for long periods of time.

B. Keep your neighbors in mind when permanently installing this

equipment.

REV C

4

OPM-122

Page 5

UNIT CAPABILITIES

STARTING ELECTRIC MOTORS

GENERATOR CONNECTIONS

The TB2400 is designed for 120 Volt alternating current (AC) and has

circuit breaker protected receptacles. Generator full output can be

drawn from the 120 Volt GFCI NEMA 5-20 receptacles, mounted on the

end of the generator.

The TB4800 and TB7200 generators are designed for 120/240 Volt

alternating current (AC) and have circuit breaker protected receptacles.

All three generators can be spun in either direction.

FULL POWER 120 VOLT ONLY

TheTB4800 and TB7200 generators can be converted to full power 120

Volt only. Replacement of the circuit breaker and receptacle is required.

The TB4800, has a 40 Amp 1-Pole circuit breaker. On the TB7200, a 60

Amp 1-pole circuit breaker and a 3-wire 60 Amp twist-lock receptacle is

recommended for full power applications. See wiring schematic below:

240 Volt

Electric motors require much more current (Amps) to start than to run.

Some motors, particularly low-cost split-phase motors, are very hard

to start and require 5 to 7 times as much current to start them than to

run them. Capacitor motors are easier to start and usually require 2

to 4 times as much current to start them than to run them. Repulsion

Induction motors are the easiest to start and require 1 1/2 to 2 1/2

times as much current to start them than to run them.

Most fractional horsepower motors take about the same amount

of current to run them whether they are Repulsion Induction (RI),

Capacitor (C), or Split-Phase (SP) type. The chart below shows the

approximate current required to start and run various types and sizes of

120 Volt, 60 cycle electric motors under average conditions.

HP AMPS

RUNNING

SP CAP RI

1/6 3.2 16 TO 22 6 TO 13 5 TO 8

1/4 4.5 22 TO 32 9 TO 8 7 TO 12

1/3 5.2 26 TO 35 10 TO 21 8 TO 17

1/2 7.2 NOT MADE 14 TO 29 11 TO 18

1 13.0 NOT MADE 26 TO 52 20 TO 33

STARTING

AMPS

120 Volt

Check the appliance or tool nameplates for the current and voltage to

ensure compatibility. Although a circuit breaker is provided, damage

due to overloading constitutes abuse and will not be warranted. Refer

to the generator nameplate for unit’s capabilities.

TB4800 - Only 2,400 Watts at 120 Volt (20 Amps) can be taken from

the generator at receptacle A and up to 2,400 Watts at 120 Volts from

receptacle C.

TB7200 - Only 3,600 Watts at 120 Volt (30 Amps) can be taken from

the generator at receptacle A and up to 3,600 Watts at 120 Volts from

receptacle C.

The following diagram represents both the TB4800 and TB7200

generators.

The gures given above are for average load such as a blower or fan.

If the electric motor is connected to a hard starting load such as an air

compressor, it will require more starting current. If it is connected to a

light load, or no load such as a power saw, it will require less starting

current. The exact requirement will also vary with the brand or design

of the motor.

Self- exciting generators respond to severe overloading differently

that utility power. When over loaded, the engine is not able to supply

enough power to bring electric motor up to operating speed. The

generator responds with high initial starting current, but the engine

speed drops sharply. The overload may stall the engine. If allowed to

operate at very low speeds, the electric motor starting winding will burn

out in a short time. The generator winding may also be damaged.

5OPM-122

REV C

Page 6

PREPARING THE UNIT

CONNECTING THE LOADS

UNPACKING

CAUTION: EQUIPMENT DAMAGE

When you unpack your new generator, be sure to remove all of the

information sheets and manual from the carton.

1. As you receive your unit, it is critical to check it for any damage. If

any damage is noted, it is always easiest to refuse the shipment and

let WINCO take care of the freight claim. If you sign for the unit, the

transfer of the ownership requires that you le the freight claim

2. Before proceeding with the preparations of your new generator

for operation, take a couple of minutes to ensure the unit you have

received is the correct model and review the specication pages in this

manual to ensure that this unit meets your job requirements.

APPLYING THE LOAD

A short warm-up time will permit the engine to work more efciently

when the load is applied and will reduce the wear and extend its life.

CAUTION: EQUIPMENT DAMAGE:

Keep the generator load within the generator and receptacle nameplate

ratings. Overloading may cause damage to the generator and/or loads.

Most electric tools and appliances will have the voltage and amperage

requirements on their individual nameplates. When in doubt, consult

the manufacturer or a local electrician. The nameplate’s amperage

rating for electric motors can be misleading. See “Starting Electric

Motors” in specication section.

The generator is a limited source of electrical power, therefore

pay special attention to the receptacle and generator ratings. The

nameplate rating can be obtained through combination of receptacles

or a single receptacle as long as the receptacle amperage rating is not

exceeded. Both the 120 and 240 Volt output can be utilized at the same

time. See specication section for proper load separation. Overloading

a specic receptacle or winding group can result in damage to the

equipment.

Plug your tools such as drills, saws, blowers, sump pump, and other

items to be powered directly into the generator receptacles. Before

plugging in all of the tools and cord sets, recheck the rating of the

generator. Be sure it can handle the intended load and is compatible

with voltage, phase, and current ratings.

‘Hard Wiring’ this unit directly into a temporary construction site

electrical system is NOT A SIMPLE DO-IT-YOURSELF JOB. For

your safety, all wiring must be done by a qualied electrician and

conform to the National Electric Code and all state and local codes and

regulations. Check with local authorities before proceeding.

WARNING: PERSONAL DANGER

A fully isolated, double pole throw manual transfer switch must be

installed any time a generator is being connected to an existing

distribution system.

CAUTION: EQUIPMENT DAMAGE

Failure to properly limit and balance the load applied to the generator

will cause the generator to produce low voltage and may damage the

generator. It may also cause severe damage to the loads connected to

the generator at that time. Improper loading of the generator constitutes

abuse and will not be covered by warranty.

CAUTION: EQUIPMENT DAMAGE

Low voltage may damage any motors or appliances connected to it.

Running the generator at excessively high speeds result in high voltage

which will also damage electrical devices connected to it. Excessively

high speed may also cause damage to the generator armature

windings.

REV C

6

OPM-122

Page 7

UNIT INSTALLATION

Plans for installation should be prepared with proper attention to

mechanical and electrical engineering detail to assure a satisfactory

system installation. The information in this manual is offered as a

guide to nalizing your installation plans. The installation sequence is

summarized below.

The drive belt system must be of adequate size and must be tight

enough to power the generator without slippage. Be careful not to

over-tighten to the extent that it puts excessive strain on the bearings.

Doing so can cause bearing failure and other possible damage to the

generator.

Alignment of the generator to the prime mover is important.

Misalignment of the pulleys will cause excessive belt and pulley wear

and unnecessary stress on the prime mover.

PLAN THE INSTALLATION

Generally, two-bearing generators are used on portable equipment. For

best service consider the following:

1. All electrical equipment should be protected from excessive

moisture. Failure to do so will result in deterioration of the insulation

and short circuits and grounds.

2. The generator should be installed in a sheltered area. If the unit must

be left in the open, it should always be protected with a weather cover

such as a tarp or large piece of canvas after each use to keep out

water and dust.

CAUTION: EQUIPMENT DAMAGE

Always allow the generator and prime mover to cool before covering

with a ammable weather covering.

MOUNTING

CAUTION: EQUIPMENT DAMAGE

The generator must be mounted with the engine to a common rigid

base to prevent stress on the engine and generator shafts and

bearings do to vibration displacement. For permanent installations,

the engine-generator is usually mounted on a sub-frame which can be

shock mounted with neoprene pads on the main frame.

Before proceeding with installation, be sure that you have completely

read and understood the assembly and installation instructions.

The following table shows the effect if carious operating speeds and

electrical loads on a typical generator when matched and mounted to

an adequate prime mover.

LOAD VS. OUTPUT

Generator

Load

None 3690 61.5 129V

Half 3600 60.0 120V

Full 3510 58.5 115V

*Note: Required generator speed must be at 3600 +/- 90 RPM under all

load conditions.

Although individual units and models may vary slightly, the normal

voltage and frequency of typical 60 cycle engine-driven generators

described in this manual are approximately as follows when powered

by a typical prime mover (engine) run rst with no load applied, then at

half capacity as rated on the nameplate.

All engines have a tendency to slow down when a load is applied.

The governor on the engine is designed to hold engine speed nearly

constant. When the electrical load connected to the generator is

increased, the engine is more heavily loaded and as a result, the

speed drops slightly. This slight decrease in speed together with the

natural “voltage drop” within the generator itself due to load current and

heating of the windings, results in a slightly lower voltage than when

the generator is running idle.

Speed

(RPM)

FREQUENCY

(Hz)

Voltage

An engine with adequate horsepower and a close regulated (xed

speed) governor is required for satisfactory operation of this generator.

About 1.4 horsepower is required to produce 1,000 Watts of generator

output power assuming 100% efciency of both the engine and the

generator. However, due to engine and generator efciencies of 80

to 90%, the loss of power due to engine driving accessories such as

cooling fans, battery charging alternators, etc., friction losses and

slippage in the drive pulleys and belts, the general conservative rule

of thumb allowing approximately two (2) horsepower for every 1,000

Watts of generator output is much more realistic. For example, the

7,200 Watt generator output will require a 14.4 horsepower engine

for full output, good speed/voltage regulation, and satisfactory load

performance. When determining the prime mover/generator pulley

ratio to drive the generator at the correct operating speed, bear in mind

the power rating of most prime movers (usually an engine) varies with

speed. It produces more power at higher speeds, less when slowed.

The prime mover must be fast enough to reach desired horsepower for

good generator operation.

The normal slight variations on speed also directly affect the frequency

of the output current. This frequency variation has no appreciable effect

in the operation of most loads (such as motors, lights, and most small

appliances). However, timing devices and clocks will not keep perfect

time unless the engine can keep the generator at exactly 3600 RPM at

all times. Since this is not usually possible, minor time errors in clock

occur.

The speed of the engine is usually adjusted so that the generator

produces proper voltage. If the adjustment is made “cold”, set the

voltage a little higher than normal since it will drop a few Volts as the

generator warms up.

NOTE: When operating continuously at full load, the generator shell

becomes very warm. It will be uncomfortable to the touch. This is

normal for any high performance inherently regulated generator. Output

voltage should be checked periodically to ensure proper operation of

the generator and appliances.

7OPM-122

REV C

Page 8

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S)

Low voltage 1. Generator operating below correct RPM

2. Generator overloaded

3. Defective stator

4. Defective rotor

Output voltage too high Engine speed too high

Generator overheating 1. Generator overloaded

2. Poor ventilation

No output voltage 1. Short in load

2. Broken or loose wire

3. Defective receptacles

4. Defective capacitor

5. Defective diodes

6. No residual magnetism in generator

7. Defective stator

8. Defective rotor

REV C

8

OPM-122

Page 9

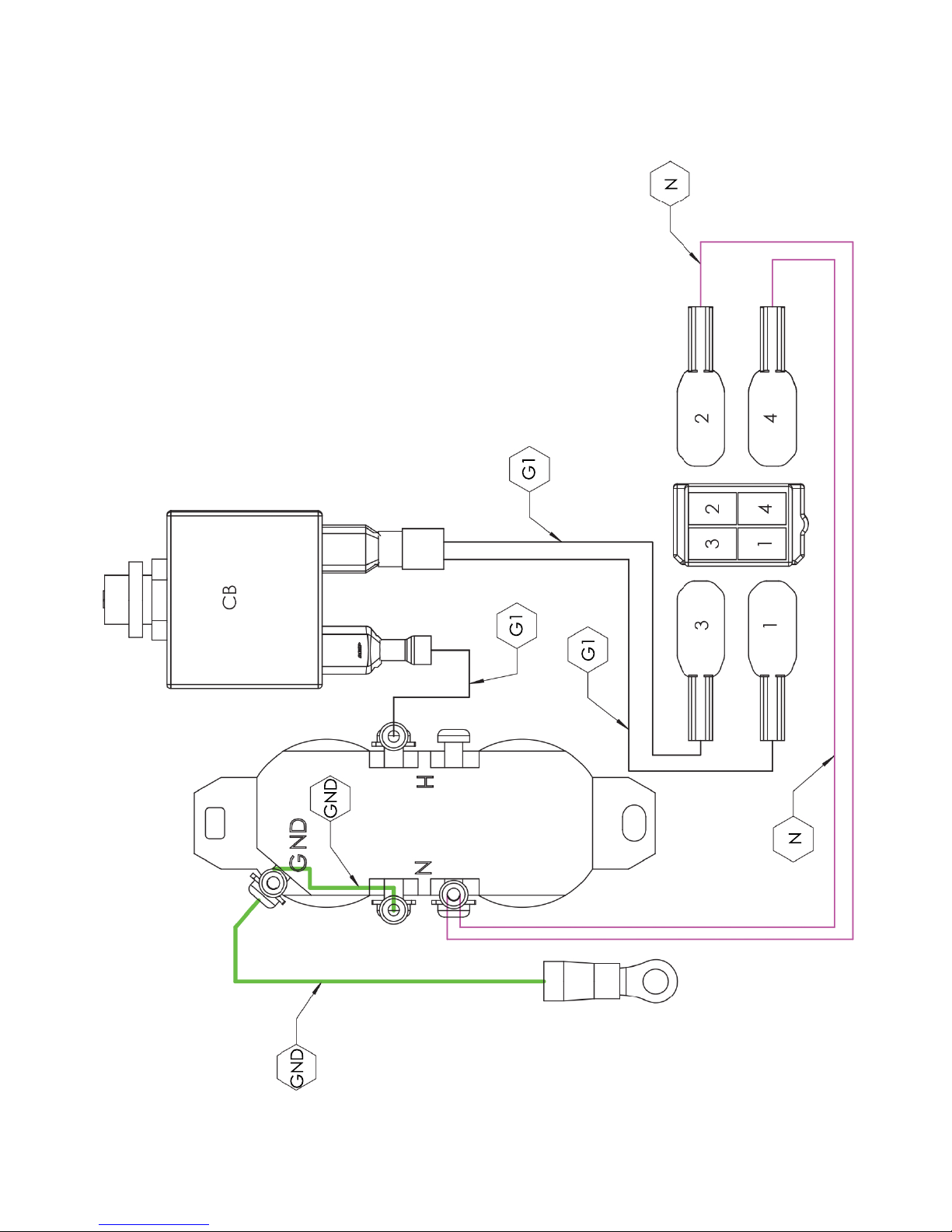

WIRING SCHEMATICS

GND

GND

G1

G1

G1

N

N

TB2400

9OPM-122

REV C

Page 10

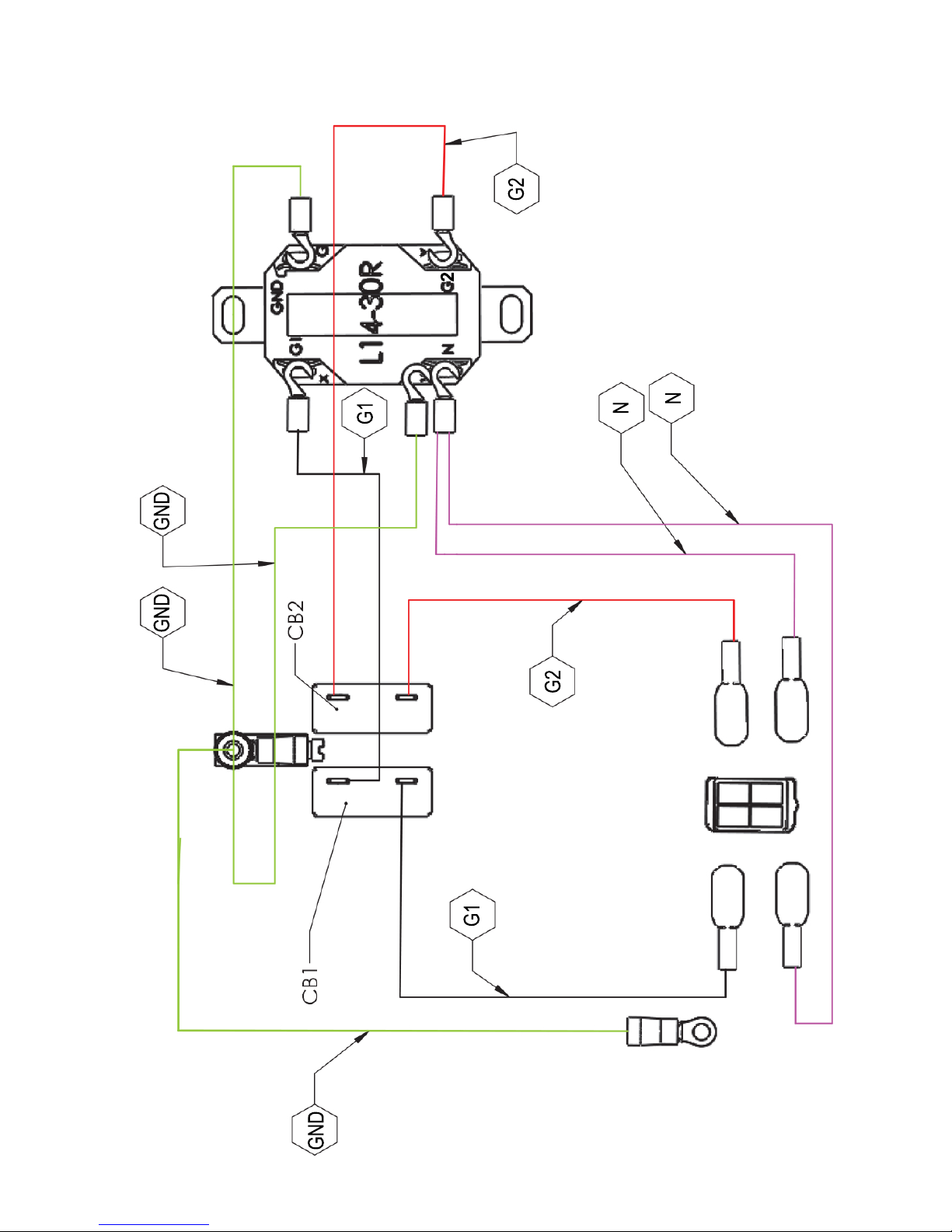

TB4800

2

N

N

N

G1

G1

G1

G2

G2G2

GND GND

GND

GND

REV C

10

OPM-122

Page 11

2

G1

G1

G2

G2

N

N

GND

GND GND

TB7200

11OPM-122

REV C

Page 12

12 MONTH LIMITED WARRANTY

WINCO warrants to the original purchaser for 12 months, that goods manufactured or supplied by it will be free from defects in workmanship and

material, provided such goods are installed, operated and maintained in accordance with WINCO written instructions and applicable codes.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be limited to the repair of the product. At WINCO’s

option, material found to be defective in material or workmanship under normal use and service will be repaired or replaced. For warranty service,

return the product within the warranty period, to your nearest WINCO Authorized Service Center or to WINCO in Le Center Minnesota.

Duration Consumer, Commercial and Rental

Parts & Labor: 12 Months

EXCLUSIONS:

• Normal maintenance consumables or labor.

• This warranty does not cover travel time, mileage or labor for removal or re-installation of WINCO product from its application.

• Normal wear and tear.

• Costs of rental equipment.

• WINCO does not warrant engines. Engines are covered exclusively by the warranties of their respective manufacturers.

• WINCO does not warrant component parts that are warranted by their respective manufacturers.

• WINCO does not warrant modications or alterations which were not made by WINCO.

• WINCO does not warrant products which have been subjected to misuse and/or negligence or have been involved in an accident.

Proof of proper maintenance must be furnished upon request.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE DESCRIBED HEREIN. THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, OR OTHERWISE CREATED, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY, OR

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE.

WINCO is liable for the repair or replacement of the product only and is not liable for incidental or consequential damages as permitted by your

state. This warranty gives you specic legal rights which may vary from state to state.

WINCO INC. • 225 S. CORDOVA AVE. • LE CENTER, MN 56057 • 507-357-6821

REV C

12

OPM-122

Loading...

Loading...