Page 1

OWNERS MANUAL

INSTALLATION AND OPERATION MANUAL

60706-201

Page 2

SAVE THESE INSTRUCTION

This manual contains important instructions that

should be followed during installation and maintenance of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

USING THIS MANUAL

Congratulations on your choice of a Winco generator set.

You have selected a high-quality, precision-engineered

generator set designed and tested to give you years of

satisfactory portable service.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The

warranty listed in this manual describes what you can

expect from WINCO should you need service assistance

in the future.

PROPER USE AND INSTALLATION

You must be sure your new engine generator set is:

* Properly serviced before starting

* Operated in a well ventilated area

* Exhaust gases are dispersed safely

* Wired by a qualified electrician

* Operated only for its designed purposes

* Used only by operators who understand its operation

* Properly maintained

TABLE OF CONTENTS

PRODUCT SAFETY 1

SPECIFICATIONS 2

PREPARATION

UNPACKING 2

OIL REQUIREMENTS 2

FUEL REQUIREMENTS 3

COOLANT REQUIREMENTS 3

BATTERY CONNECTIONS 3

CONTROL PANEL LAYOUT & DESCRIPTION

DGC-2020 ENGINE CONTROL 4

FRONT PANEL DESCRIPTION 6

RECEPTACLE AND BREAKERS 6

FULL POWER CONNECTIONS 8

OPERATIONS

SELECTING THE CORRECT

VOLTAGE 8

START-UP CHECKLIST 9

ELECTRIC STARTING 9

REMOTE STARTING 9

CONNECTING THE LOADS 10

UNIT STORAGE 11

50 CYCLE OPERATION 11

MAINTENANCE 11

PREVENTIVE MAINTENANCE 11

WIRING DIAGRAMS

DC ELECTRICAL SCHEMATIC 12

SHORE POWER 13

GENERATOR WIRING 14

SELECTOR SWITCH WIRING 15

CIRCUIT BREAKER WIRING 16

RECEPTACLE PANEL 17

WARRANTY 18

COPY YOUR MODEL AND SERIAL NUMBER

BELOW FOR FUTURE REFERENCE.

No other WINCO generator has the same serial number

as yours. It is important that you record the number and

other vital information here, if you should ever need to

contact us on this unit it will help us to respond to your

needs faster.

MODEL____________________________________

SERIAL NUMBER____________________________

PURCHASE DATE____________________________

DEALER___________________________________

Page i

Page 3

GUIDE TO PRODUCT SAFETY

This engine generator set has been designed and manufactured to insure your personal safety. Improper use can

result in potential deadly hazards, from electrical shock,

exhaust gas asphyxiation, or fire. Please read all safety

instructions carefully before installation or use. Keep

these instructions handy for future reference. Take

special note and follow all warnings on the unit and in the

manuals.

************************************************************

CAUTION: Possible Damage to Equipment.

CAUTION notes indicate any condition or practice, which

if not strictly observed or remedied, could result in damage or destruction of the equipment.

************************************************************

************************************************************

WARNING: Personal Danger.

WARNING notes indicate any condition or practice, which

if not strictly observed, could result in personal injury or

possible loss of life.

***********************************************************

1. ELECTRIC SHOCK - The output voltage present in

this equipment can cause a fatal electric shock. This

equipment must be operated by a responsible person.

A. Do not allow anyone to operate the generator without

proper instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Use extreme care if operating this unit in rain or snow.

E. Use only three-prong grounded receptacles and

extension cords.

F. Be sure the unit is properly grounded to an external

ground rod driven into the earth.

2. FIRE HAZARD - Diesel fuel and other fuels always

present a hazard of possible explosion and/or fire.

A. Do not refuel when the engine is running or hot. Allow

the engine to cool at least two minutes before refueling.

B. Keep fuel containers out of reach of children.

C. Do not smoke or use open flame near the generator

set or fuel tank.

D. Keep a fire extinguisher nearby and know its proper

use. Fire extinguishers rated ABC by NFPA are appropriate.

E. Store fuel only in an approved container, and only in a

well-ventilated area.

4. NOISE HAZARD - Excessive noise is not only tiring,

but continual exposure can lead to loss of hearing.

A. Use hearing protection equipment when working

around this equipment for long periods of time.

B. Always operate with the housing doors closed to

reduce the operational noise level.

5. CLEANLINESS - Keep the generator and surrounding

area clean.

A. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

B. Remove any rags or other material that could create

potential fire hazards.

C. Carefully wipe up any gas or oil spills before starting

the unit.

D. Never allow leaves or other flammable material to build

up around the engine exhaust area.

6. SERVICING EQUIPMENT - All service, including the

installation or replacement of service parts, should be

performed only by a qualified technician.

A. Use only factory approved repair parts.

B. Do not work on this equipment when fatigued.

C. Never remove the protective guards, cover or receptacle panels while the engine is running. Keep hands

away from all moving parts.

D. Never wear neckties or other loose clothing that can be

caught in moving parts while you are servicing or operating this equipment.

E. Use extreme caution when working on electrical

components. High output voltages from this equipment

can cause serious injury or death.

F. When servicing this unit always avoid hot mufflers,

exhaust manifolds, and engine parts. They all can cause

severe burns instantly.

G. Installing and wiring a standby generator is not a “do it

yourself” project. Consult a qualified, licensed electrician

or contractor. The installation must comply with all

national, state, and local codes.

7. LIFTING THE EQUIPMENT - When lifting always

make sure that the area under the equipment is kept

clear.

A. Be certain rigging is designed to lift unit safely.

B. Never attempt to lift the equipment unless you are

certain the lifting device has sufficient capacity.

C. Never allow the equipment to swing while suspended.

D. Be certain the supporting structure is adequate to

handle the load.

3. DEADLY EXHAUST GAS - Exhaust fumes from any

internal combustion engine contain carbon monoxide, an

odorless and deadly gas that must be mixed with fresh

air.

A. Operate only in well ventilated areas.

B. Never operate indoors.

C. Never operate the unit in such a way as to allow

exhaust gases to seep back into closed rooms (i.e.

through windows, walls or floors).

8190-00

8. TOWING THE EQUIPMENT - When towing this

equipment always use a vehicle large enough for safe

operation.

A. Never tow without the safety chains secured.

B. Always use the proper size hitch ball on the vehicle.

C. Never attempt to tow with a vehicle that does not have

side mirrors installed.

Page 1

60706-201

Page 4

SPECIFICATIONS

GENERATOR SPECIFICATIONS

RP25

KILOWATT 20 kW

KILOVOLT-AMPS (.8 PF)25 kVA

AMPERAGE 277/480 VOLT 3 PHASE 30 AMPS*

120/240 VOLT 3 PHASE 60 AMPS*

120/208 VOLT 3 PHASE 69 AMPS*

120/240 VOLT 1 PHASE 70 AMPS**

*Based on .8 power factor

**Single Phase is limited by the circuit breaker to 150

Amps on the full power terminal block - The additional

amperage is available through receptacles.

Derate 3% per 1000 feet (305 meters) between 300 feet

(90 meters) and 7,500 feet (2,286 meters) above sea

level. Contact the factory for rating data for operation in

altitudes above 7,500 feet (2,286 meters).

For prime power application (24/7) derate all output rating

by 10%

GENERATOR RESISTANCE

RP25

Generator Make Stamford

Generator Model BCI184F

Generator Winding #311

Voltage Regulator SX460

for specific maintenance and care information regarding

the engine. Read ALL instructions in the manuals provided before attempting to operate the generator set.

UNPACKING

When receiving the unit, be sure to inspect it carefully for

freight loss or damage. Check the nameplate to be sure it

is what you ordered (proper kW, voltage, fuel, etc.). If you

have questions, contact your local authorized dealer. If

you see evidence of loss or damage at the time of delivery, have the driver sign and describe the loss or damage

in the “memo of loss or damage” section on the freight

bill. Then contact the carrier to get instructions on filing a

claim.

When loss or damage is discovered after the equipment

is delivered, but not seen at the time of delivery, it is

referred to as “concealed damage.” Separate any damaged material and contact the carrier for proper procedures to file a “concealed damage” claim.

OIL REQUIREMENTS

This engine was filled at the factory. Before starting

check the oil level and ensure it is full. If not, refill to the

proper level. See engine manual for proper grade of oil.

OIL QUANTITY US Qt. Liters

RP55 7 6.6

Main Stator 0.13 ohms

Main Rotor 0.74 ohms

Exciter Stator 22 ohms

Exciter Rotor 0.23 ohms

ENGINE SPECIFICATIONS

See Iveco Operation and Maintenance Manual for complete engine specifications.

TRAILER/HOUSING

RP25

Capacity 3500 lb.

Fuel Capacity 45 Gallons

Axles Single

Hitch Height Adjustable

Tires P225/75R-15

Tire Pressure 35 psi

Sound Attenuated ULTRA QUIET

Housing Housing Standard

PREPARATION

NOTE: This booklet covers the entire unit, EXCEPT THE

ENGINE. See the engine manufacturer’s operator manual

60706-201

Page 2

FUEL REQUIREMENTS

See your engine operator's manual for complete type and

fuel grade information.

WARNING -NO BIODIESEL

Filling the Fuel Tank

Standard Trailer - The standard trailer is equipped with a

single 45 gallon fuel tank. Use caution when filling the

tank so as not to overflow the tank into the trailer.

WARNING PERSONAL DANGER

Never refuel a running engine. Always stop the engine

and allow to cool before refueling.

Never allow the fuel tank to run completely empty, as air

may enter the fuel system making it necessary to bleed

the engine when restarting.

COOLANT REQUIREMENTS

The cooling system of this engine has been filled at the

factory with a 50% water and 50% ethylene-glycol

antifreeze and the proper amount of supplemental coolant

additives. This mixture provides engine protection to -37

degrees F.

8190-00

Page 5

When replenishing coolant or changing coolant refer to

your Isuzu engine manual for the proper type and mixture

of water, antifreeze and supplemental coolant additives.

CAUTION – A battery presents a risk of electrical shock and

high short circuit current. The following precautions must be

observed when working with batteries:

WARNING: EQUIPMENT DAMAGE

Failure to properly follow Isuzu requirements for antifreeze and supplemental coolant additives can lead to

permanent damage to your engine cylinder liner walls.

BATTERY CONNECTION INSTRUCTIONS

WARNING! EQUIPMENT DAMAGE

FAILURE TO PUT THE ENGINE CONTROL SWITCH IN

THE ‘OFF’ POSITION PRIOR TO CONNECTING THE

BATTERY CABLE(S) MAY RESULT IN DAMAGE TO

THE ECM. (SOLID STATE ENGINE CONTROL MODULE).

INSTALLING THE BATTERY

A customer supplied twelve-volt battery is required to

complete the installation. Installation of the highest CCA

rated battery, within the correct BCI group, will increase

cold weather starting performance. Gel batteries should

not be used with the battery tender installed in the generator enclosure.

MINIMUM

Model Voltage BCI Group CCA Rating

RP25 12 24 650

Installation and servicing of batteries must be performed

or supervised only by personnel knowledgeable of

batteries and the required precautions. Keep unauthorized personnel away from batteries.

When installing or replacing batteries, use the proper

group/size starting battery. The battery should be a

Maintenance Free lead acid design. Deep cycle batteries

will not work for this application.

CAUTION – PERSONAL DANGER

NEVER dispose of a battery in a fire. The battery is capable of

exploding.

DO NOT open or mutilate the battery. Released electrolyte is

known to be harmful to the skin and eyes and to be very toxic.

These engine generator sets are all NEGATIVE ground.

Be very careful not to connect the battery in reverse

polarity, as this may short circuit the battery charging

system on the engine.

1. Remove watches, rings and other metal objects.

2. Use tools with insulated handles.

3. Check both the battery cable ends and the battery

posts to be sure they are free of corrosion.

3. Always connect the battery positive cable first and

then connect the battery negative cable. When removing

the battery cables from the battery reverse the procedure,

disconnect the negative cable first and then the positive

cable.

4. Be sure all connections are tight and coat the terminals and cable end with dialectic grease.

WARNING – The electrolyte is a diluted sulfuric acid that is

harmful to the skin and eyes. It is electrically conductive and

corrosive. The following precautions must always be taken:

* Always wear full eye protection and protective clothing.

* Where electrolyte contacts the skin, wash off immediately with water.

* If electrolyte contacts the eyes, flush thoroughly and

immediately with water and seek immediate medical

attention.

* Spilled electrolyte is to be washed down with an acid

neutralizing agent. A common practice is to use a

solution of one pound of bicarbonate of soda (baking

soda) to one gallon of water. The bicarbonate of soda

solution is to be added until the evidence of reaction,

foaming, has ceased. The resulting liquid is to be flushed

with water and the area dried.

DANGER – Explosive Fire Risk

* Never smoke when near batteries

* Do not cause a flame or spark in the battery area

* Always discharge static electricity from your body

before touching batteries by first touching a grounded

metal surface.

SERVICING BATTERIES

Batteries used on these units may over time lose water.

This is especially true if you are using a trickle charger to

maintain your battery. When refilling the battery with

water use only distilled water. Tap water will shorten the

service life of the battery.

Never fill the battery above the fill line. Over filling above

the upper level line may cause the electrolyte to overflow,

resulting in corrosion to the engine or nearby parts.

Immediately wash off any spilled electrolyte following the

procedure above..

8190-00

Page 3

60706-201

Page 6

CAUTION - NEVER ATTEMPT TO JUMP START THIS

ENGINE. If the battery should accidentally become

discharged disconnect the battery cables and recharge

the battery before attempting to start the unit. Boost/jump

starting this unit improperly will result in PERMANENT

DAMAGE TO THE ENGINE CONTROL MODULE (ECM).

• Integrated RS485

• Auto Synchronizing

FUNCTIONS

DGC-2020 Digital Genset Controllers perform the following

functions:

DESCRIPTION AND IDENTIFICATION

1. ENGINE CONTROL MODULE (DGC-2020)

The DGC-2020 Digital Genset Controller provides integrated engine-genset control, protection, and metering in a

single package. Microprocessor based technology allows

for exact measurement, set point adjustment, and timing

functions. Front panel controls and indicators enable quick

and simple DGC-2020 operation. Basler Electric communication software (BESTCOMSPlus) allows units to be easily

customized for each application. A wide temperature-range

liquid crystal display (LCD) with backlighting can be viewed

under a wide range of ambient light and temperature conditions.

FEATURES

DGC-2020 Digital Genset Controllers have the following

features:

• Local and Remote Generator Control

• Engine and Generator Protection

• Programmable Analog Engine Senders

• ECU Communications via SAE J1939

• Programmable Logic

• Automatic Transfer Switch Control (Mains Failure)

Generator Protection and Metering

Generator protection guards against over voltage, under

voltage, under frequency, and over frequency. Over current

and phase imbalance protection is available as an option at

the time of manufacture. Each generator protection function

has an adjustable pickup and time delay setting. Metered

generator parameters include voltage, current, real power

(watts), apparent power (VA), and power factor (PF).

Engine Protection and Metering

Engine protection features include oil pressure and coolant

temperature monitoring, over crank protection, ECU specific

protection elements, and diagnostic reporting.

Metered engine parameters include, oil pressure, coolant

temperature, battery voltage, speed, fuel level, engine

load, coolant level (from ECU), ECU specific parameters,

and run-time statistics.

All metering functions are displayed on the liquid crystal

display. The front panel display begins with the SUMMARY SCREEN. Pressing the Right arrow key will open

the MAIN MENU screen. The MAIN MENU screen

consists of METERING and SETTINGS

ENGINE CONTROL

MODULE

DGC-2020

60706-201

Page 4

8190-00

Page 7

Summary Screen

Summary screen can be set to standard or scrolling. When

set to standard, only the following are displayed:

• Generator Voltage

• Generator Amperage

• Generator Phase

• Generator Frequency

• Engine Oil Pressure

• Engine Coolant Temperature

• Engine Battery Voltage

up-arrow button moves to items higher in the list. During a

settings editing session, the up- and down-arrow buttons are

used to raise and lower the value of the selected setting.

L - Edit Push-button. Pressing this button starts an editing

session and enables changes to DGC-2020 settings. At the

conclusion of an editing session, the Edit push-button is

pressed again to save the setting changes.

DISPLAY OPERATION

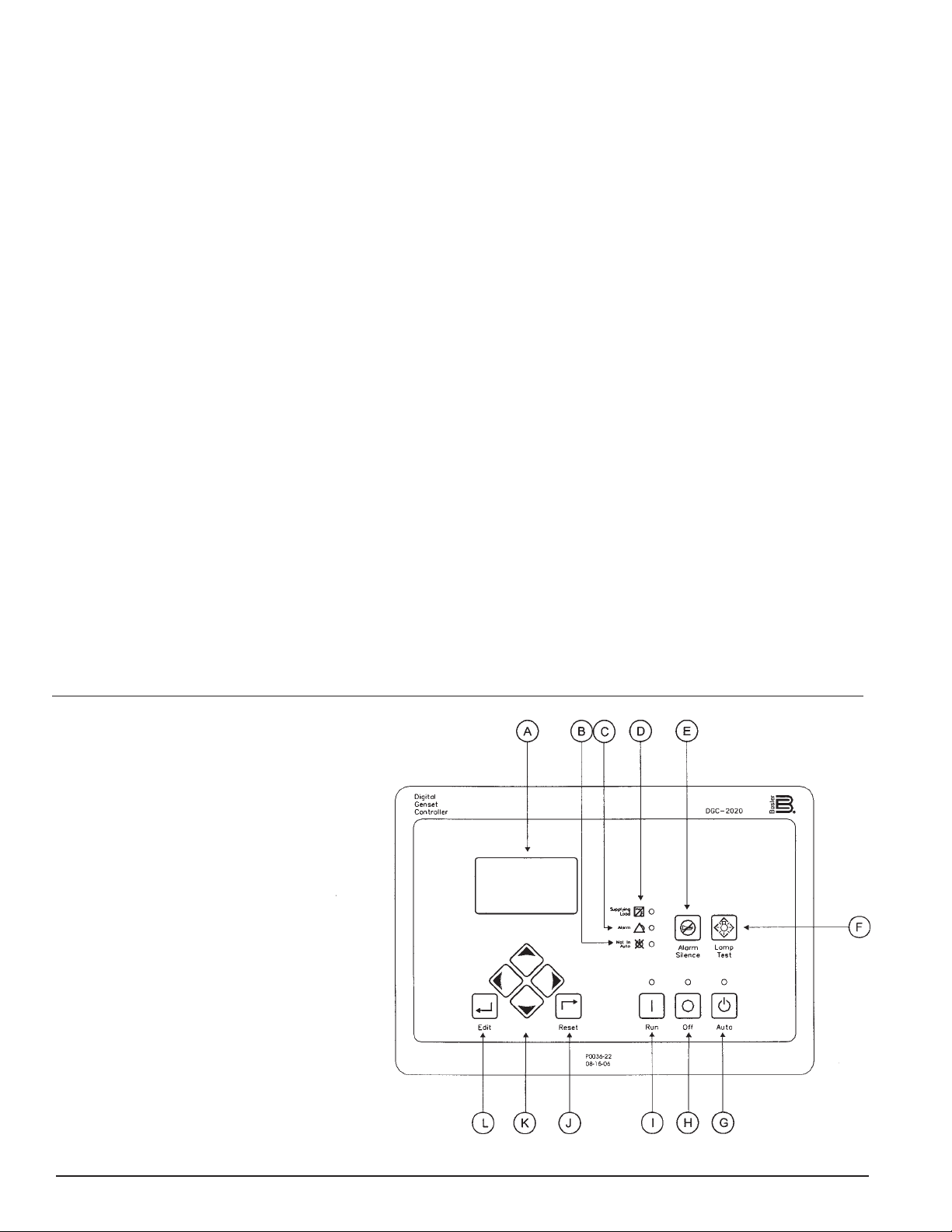

A - Liquid Crystal Display. The backlit, 64 by 128 pixel LCD

serves as the local information source for metering, alarms,

pre-alarms, and protective functions. Display operation is

maintained at -20°C. An optional LCD heater maintains

display operation at -40°C.

B - Not in Auto Indicator. This red LED lights when the

DGC-2020 is not operating in Auto mode.

C - Alarm Indicator. This red LED lights continuously during

alarm conditions and flashes during pre-alarm conditions.

D - Supplying Load Indicator. This green LED lights when

the generator current is greater than EPS threshold current.

E - Alarm Silence Push-button. Pressing this button opens

the relay output programmed as the horn output.

F - Lamp Test Push-button. Pressing this button tests the

DGC-2020 indicators by exercising all LCD pixels and

lighting all LEDs.

G - Auto Push-button and Mode Indicator. Pressing the

Auto button places the DGC-2020 in Auto mode. The green

Auto mode LED lights when Auto mode is active.

H - Off Push-button and Mode Indicator. Pressing this

button places the DGC-2020 in Off mode. The red Off mode

LED lights when the DGC-2020 is in Off mode.

I - Run Push-button and Mode Indicator. Pressing this

button places the DGC-2020 in Run mode. The green Run

mode LED lights when Run mode is active.

J - Reset Push-button. This button is pressed to cancel

a settings editing session and discard any settings

changes. When pressed, this button also resets the

Breaker Management Pre-Alarms

K - Arrow Push-buttons. These four buttons are used to

navigate through the front panel display menus and modify

settings. The left- and right-arrow buttons are used to

navigate through the menu levels. The right arrow button is

pressed to move downward through the menu levels and the

left-arrow button is pressed to move upward. Within a level,

the up-arrow and down-arrow buttons are used to move

among items within the menu level. Pressing the downarrow button moves to items lower in the list. Pressing the

The front panel display is used to make settings changes

and display metering values. Refer to call-outs J, K, and L in

text and illustration for information on changing settings

through the front panel and navigating through the Metering

screens. When the unit is first powered up, the clock may

need to be reset. Editing the clock provides familiarity with

the edit process. All programming changes from the front

panel are accessed through the edit key to begin and exit the

internal microprocessor program.

Login and Permissions

To login, navigate to the SETTINGS, ENTER PASSWORD

screen and press the Edit key. Use the Up/Down arrow keys

to scroll through the characters. Use the Left/Right arrow

keys to enter more characters. The Owner operator password is OP. Once the password has been entered, press the

Edit key to login. See the key stroke sequence listed below

to access the control and enter the edit mode. A LOGOUT

selection now appears in the list of SETTINGS. To logout,

navigate to SETTINGS, LOGOUT and press the Edit key.

The LOGOUT selection is removed from the SETTINGS list.

Sequence for setting (or resetting) the system clock -

1) Press ‘K’ (right key) for initial set or ‘K’ (left to

back up, up / down) to choose menu item and

time/date element to be changed.

2) Press ‘L’ (Edit) to access change mode to enter

Password - OP as follows:

2a -Press K (up) to select O

2b -Press K (right) to move cursor

2c -Press K (up) to select P

2d -Press L (Edit) to begin change mode

3) Press ‘K’ (up or down) to choose year

4) Press ‘L’ (Edit) to enter year

5) Press ‘K’ (down) to select month mode

6) Press ‘L’ (Edit) to access month change

7) Press ‘K’ (up or down) to choose month

8) Press ‘L’ (Edit) to enter month

9) Repeat sequence 5 through 8 for day, minute,

second and DST (Daylight Saving Time.

To finish clock setting, process - Press ‘K’ (left).

The microprocessor is still in the General Settings Edit

mode. Pressing ‘K’ (left) a second time exits the Edit

mode and allows full access to the View Only mode for all

control settings and current status. Any items to be

changed are accessed by pressing ‘K’ (up/down/right or

left) to select, ‘L’ (Edit) to change and ‘K’ (left) to exit.

8190-00

Page 5

60706-201

Page 8

FRONT PANEL LAYOUT

2. FRONT PANEL LAYOUT

A - DGC-2020 Digital Gen-Set Control. See Explana-

tion on page 4.

H - Voltage Selector Switch. This heavy duty four

position switch allows the operator to quickly and safely

reconnect the 12 lead generator to any one of four output

voltages. Once the output voltage is selected, the switch

will lock to prevent it from accidentally being changed

during operation. (See "H" below)

J - Selector Switch Safety Release. This safety button

must be depressed before you can change the selector

switch. Depressing this will also kill the engine, this is to

ensure the unit is not running when the selector switch is

changed.

3. RECEPTACLES and CIRCUIT

BREAKERS

NOTICE - CLASS 1 WIRING METHODS ARE TO BE

USED FOR ALL FIELD WIRING CONNECTIONS TO

TERMINALS OF A CLASS 2 CIRCUIT. ALL WIRING

MUST BE DONE IN ACCORDANCE WITH

NATIONAL ELECTRIC CODE NFPA 70

B - Voltage Adjust Rheostat. Controls the output

voltage of the generator by varying voltage regulators

reference voltage. This trim pot is used to adjust the

voltage when you switch between the different voltages

on the Selector Switch.

C -DC Control Circuit Fuse. The 10 amp DC Circuit

Fuse protects the 12 volt circuits and engine wiring

harness against faults in wiring or control equipment.

The fuse also prevents a discharge of the battery due to

a circuit fault. (Replacement AGC-10A-250V)

D -DGC-2020 Fuse. This 1 amp DC fuse protects the

DGC-2020 printed circuit board.

(Replacement AGC-1A-250V)

E -Emergency Stop Switch (3)- When depressed this

switch will disconnect all the 12 volt power to the DGC2020 shutting the engine down. The lamp in the emergency stop switch will light up when the switch is depressed showing that the power to the panel has been

disconnected.

F- Panel Light Switch- Two panel lights are provided for

your convenience. It is activated by this panel light

switch.

G -Panel Light - 12 Volt DC

A - 120 VOLT 20 AMP 3 WIRE RECESSED SHORE

POWER PLUG, NEMA Spec 6-20. This panel mounted

plug is designed to plug directly in a standard 20 amp

receptacle on a extension cord. The plug when connected will provide power to the block heater and the

battery trickle charger mounted inside the generator

enclosure. This can be used when the set is used in a

standby application to keep the engine warm and the

battery charged or in your rental yard to keep the battery

charged up. This receptacle is to be powered by a GFCI

circuit and installed in accordance with the United States

National Electric Code.

B - TWO - 120 VOLT 20 AMP GROUND FAULT

INTERRUPTER DUPLEX. These duplex receptacles are

protected by 20 Amp circuit breakers mounted just above

the duplexes. With the “T” slot design both 15 and 20 amp

120 volt cords can be plugged in.

60706-201

Page 6

8190-00

Page 9

RECEPTACLES and CIRCUIT BREAKERS

C - TWO 120/240 VOLT 50 AMP 4 WIRE TWISTLOCK.

These receptacles are rated for dual voltage, 120 or 240

volt use. It is a four wire receptacle, with a center grounding pin. Four wire drop cords plugged into this receptacle

may be split into 120 volt receptacles at a distribution box.

Each receptacle is protected by a two pole 50 amp circuit

breaker mounted just above it.

THIS RECEPTACLE UTILIZES A HUBBELL PLUG PART

NUMBER “CS 6365”.

D - 120 VOLT 20 AMP CIRCUIT BREAKERS. These

two push button 20 amp circuit breakers protect the two

GFCI receptacles (Ref B) mounted below. If you are not

able to reset these breakers, check the load plugged into

the GFCI receptacle or the receptacle itself for a fault.

E - 250 VOLT 50 AMP CIRCUIT BREAKERS. These

circuit breakers protect the two 50 amp twistlock receptacles (Ref C) mounted in the panel below.

F - DOOR SAFETY SWITCH. This safety switch is

connected to the DGC-2020 engine control and will shut

the unit down any time door is opened with the unit

running. This prevents someone from accidently getting

their hands by the main power connection with the unit

running. This unit will not start if the door is not closed

and latched.

H - CIRCUIT BREAKER LOCKING BAR. Select and

turn on either the high voltage breaker (480 V) or the low

voltage breaker (208 or 240 Volt) depending on which

position you have the selector switch in.

J - 480 VOLT MAINLINE CIRCUIT BREAKER. This is

the high voltage mainline circuit breaker feeding the full

output terminal block (Ref M) below. This is the circuit

breaker that is used when the selector switch in the 277/

480 volt three phase position.

K - NEUTRAL TERMINAL BLOCK. This is the neutral

connection point for the customers full power output

connections. This terminal block also has the neutral to

ground bond attached to it. If you need to operate an

isolated ground system this jumper must be removed.

Generally this is only required when the generator is

being used as backup or being wired into an existing

wiring system that already has one neutral to ground

bond in it. Lugs will handle up to 2/0 wire. Torque

lugs to 150 in. lbs. using #1 & #2 wire and 180 in. lbs.

for 1/0 & 2/0 wire.

L - REMOTE START/E-STOP TERMINAL BLOCK. This

terminal block provides the customer two different connections. Torque Screws to 9.6 in. lb. using 14 to 16

awg copper wire with lugs.

G - 208/240 VOLT MAINLINE CIRCUIT BREAKER. This

is the low voltage mainline circuit breaker feeding the full

output terminal block (Ref M) below. This is the circuit

breaker that is used when the selector switch in the 120/

208 volt or 120/240 volt three phase position as well as

the 120/240 volt single phase position.

8190-00

Page 7

1. Emergency stop connection for installing a remote

emergency stop switch. This emergency stop switch

connection point must be closed during normal operation,

this is done at the factory by installing a jumper lead

between the two connection points. If you have an

application (i.e.. gas station) that requires a remote stop

60706-201

Page 10

switch be installed, remove the jumper and install a

normally closed emergency stop switch between the two

terminals. When the emergency stop switch is opened

the generator will instantly shut down, requiring the

switch to be reclosed before the generator can be

restarted.

2. Remote start contact connections for starting the

unit from a remote location. This can be either an

automatic transfer switch or just a remote switch in a job

trailer. This feature requires a relay closure between the

two connections on the terminal block to put the unit into

an auto-start mode. This Auto start mode does have

both a start delay and a cooldown delay built into the

DGC-2020. In addition the DGC-2020 will ensure the

unit is no longer carrying any load before it shuts the

engine down even after the remote start contacts have

been opened.

M - FULL POWER OUTPUT TERMINAL BLOCK.

The full power terminal block is capable of handling full

generator output at any of the selected voltages. Be very

careful when using 240 volt three phase that you properly

account for the wild leg (208 Volt) coming from the

generator. This unit has it in the G3 position . For

single phase 120/240 use G1 and G3, the third leg G2 is

not powered or used. Lugs will handle up to 2/0 wire.

Torque lugs to 150 in. lbs. using #1 & #2 wire and 180

in. lbs. for 1/0 & 2/0 wire.

N - WIRE ENTRANCE HOLES. These hole have been

specifically provided for you to route your full power leads

through to the output lugs. The routing holes were

provided to insure that no small child or curious adult

could reach up inside and come in contact with the main

output lugs with the unit running.

DANGER: PERSONAL INJURY

This unit will start as soon as the door is closed if the

start switch is in the run position. Do not use the switch

on this door to shutdown a unit to connect to the full load

terminal block , this is a safety switch only.

OPERATING THE UNIT

A. SETTING THE JACKS

1. Move the two rear jacks from the transport position to

the run position.

2. Rotate the front jack from the transport position to the

run position.

3. Level the unit using the three jacks before proceeding.

WARNING - POTENTIAL EQUIPMENT DAMAGE

Besure to return the jacks to the transport position before

trying to move the unit. If you don't the jacks maybe

damaged, rendering them useless.

B. SELECTING THE CORRECT VOLTAGE

A variety of voltages are available from the four position

selector switch. The four basic connection patterns are,

Delta (120/240), Low or Parallel WYE (120/208), High

WYE (277/480) and Single phase 120/240.

Before starting this unit be sure you have the selector

switch set for the right voltage. You must depress the

safety switch below the selector switch to change the

position of the voltage selector switch. If the unit is

running depressing this switch will kill the engine generator set.

If you have any doubts as to the voltage in your area

compare your incoming power or load name plates to the

voltage table below.

1. 120/240 Single Phase* This configuration will

produce the following line-to-line and line-to-neutral

voltage. In this selector switch position, all of the receptacles on the front panel are powered.

G1 - G3 240 Volts single phase

G1 - N 120 Volts

G2 - N Dead

G3 - N 120 Volts

2. 120/240 Three Phase* (Delta/Series configuration) This configuration will produce the following line-to-line

and line-to-neutral voltage. In this selector switch position,

all of the receptacles on the front panel are powered.

G1 - G2 - G3 240 Volts three phase

G1 - G2 240 Volts single phase

G2 - G3 240 Volts single phase

G1 - G3 240 Volts single phase

G1 - N 120 Volts

G2 - N 208 Volts

G3 - N 120 Volts

60706-201

Page 8

8190-00

Page 11

WARNING - POTENTIAL EQUIPMENT DAMAGE

THIS DELTA CONFIGURATION HAS A WILD LEG

THAT PRODUCES 208 VOLTS LINE TO NEUTRAL ON

G2. BE SURE WHEN CONNECTING TO YOUR PANEL

OR LOAD THAT YOU MATCH THE WILD PHASE ON

THE GENERATOR TO THE WILD PHASE IN YOUR

PANEL OR LOAD. FAILURE TO DO SO WILL RESULT

IN 12O VOLT DEVICES RECEIVING 208 VOLTS. YOU

MUST ALSO MATCH YOUR ROTATION.

3. 120/208 Three Phase (Low/Parallel WYE configuration) This configuration will produce the following line-toline and line-to-neutral voltage. Use of this selector switch

position allows utilization of the 120 volt receptacle only.

The 240 volt receptacles cannot be used as the voltage at

them will be 208 volts, the line to line voltage.

G1 - G2 - G3 208 Volts three phase

G1 - G2 208 Volts single phase

G2 - G3 208 Volts single phase

G1 - G3 208 Volts single phase

G1 - N 120 Volts

G2 - N 120 Volts

G3 - N 120 Volts

4. 277/480 Three Phase (High/Series WYE configuration) This configuration will produce the following line-toline and line-to-neutral outputs.

NOTE - CONVENIENCE RECEPTACLES

THE 120 OR 240 VOLT RECEPTACLES ARE DISCONNECTED WITH THE SELECTOR SWITCH IN THIS

POSITION

G1 - G2 - G3 480 Volts three phase

G1 - G2 480 Volts single phase

G2 - G3 480 Volts single phase

G1 - G3 480 Volts single phase

G1 - N 277 Volts

G2 - N 277 Volts

G3 - N 277 Volts

CIRCUIT BREAKER SELECTION

After you have selected the correct voltage for your

application and locked the selector switch, do the same

with the main line circuit breakers.

C. STARTUP CHECKLIST

4. Check tire pressure. (35 psi)

5. Trailer level to within 15 degrees.

6. Battery securely fastened, connection clean and

tight, and proper fluid level.

7. Fuel tank filled with the proper grade of diesel

fuel.

8. Check the fan belt for tightness and excessive

wear.

9. Check hoses and clamps for leakage.

10. Check the air cleaner indicator. Service only

when indicated. Do not over-service.

11. Clean out dust cup on the air cleaner.

D. ELECTRIC STARTING (Normal portable use)

CAUTION: EQUIPMENT DAMAGE

DO NOT ATTEMPT TO JUMP/BOOST START THIS

UNIT. TO DO SO MAY DAMAGE THE ELECTRONIC

MICROPROCESSOR IN THE ENGINE CONTROL.

TURN THE DC BREAKER “OFF” AND RECHARGE THE

BATTERY WITH A BATTERY CHARGER.

1. Select the desired voltage on the voltage selector

switch.

2. Turn off both main line circuit breakers.

3. Depress the run button on the front of the control

panel.

4. After the engine is running at proper speed, adjust the

voltage to the desired level using the external voltage trim

rheostat.

5. Turn on the proper main line breaker (either high or

low voltage) and padlock the lock bar to prevent the

incorrect breaker from being turned on.

E. REMOTE STARTING AND CONNECTION

(Standby applications)

1. Complete the manual starting procedure above to

insure the system is set up properly.

2. Insure the engine control is in the “off” position during

installation of the remote start connections.

3. Locate the remote start terminal block. This terminal

block is located next to the full power connections, behind

the access door on the control panel.

4. Locate the remote start terminals in your remote

automatic transfer switch (ATS). The ATS terminal block

and wire numbers will vary with each ATS manufacturer.

The RP25 require a contact closure for start.

Before initial start up and each subsequent start complete

the following checklist:

1. Check oil level, refill with proper grade oil.

2. Check coolant level, refill with proper mixture of

coolant. See engine manual.

3. Check for loose bolts or hardware.

8190-00

Page 9

WARNING: EQUIPMENT DAMAGE

THE REMOTE “SIGNAL” MUST BE A “DRY” (NONPOWERED) CONTACT CLOSURE. USING A POWER

CONTACT WILL CAUSE PERMANENT DAMAGE TO

THE ENGINE CONTROL MODULE.

60706-201

Page 12

5. For most installations 16-gauge wire is sufficient to

handle the control signal. On extremely long runs increase wire size to minimize voltage drop.

19. Compare the amperage reading from each leg on the

generator and insure that none of the legs is exceeding

the nameplate rating on the generator.

6. Locate the neutral and full power output load connection terminal on the generator.

7. Locate and identify the “neutral” and “generator”

connections in the automatic transfer switch.

8. Connect the load block to the transfer switch using

the proper wire sizes. Refer to the National Electric Code

Handbook (NFPA 70) for proper wire type and sizing.

Use Table 310-16 for wiring run through conduit and table

310-17 for free air wiring.

Use extreme caution when installing the delta voltage

pattern. One power leg of this 3 phase pattern produces

208 volts measured from line to neutral. Be sure to match

the location of the generator wild leg to the location of the

wild leg on the incoming power service. Failure to do so

will cause equipment damage to any 120 volt load

incorrectly connected to this line.

9. Connect the neutral to the transfer switch using the

same wire size.

10. For isolated neutral operation remove the jumper wire

between the ground lug and neutral connection block.

Then route a ground lead back to system ground.

11. Ground the Mobile Diesel Generator set using an 8 ft.

copper ground rod or other approved grounding system.

Connect #4 Awg Copper cable from the ground lug on the

generator to the ground rod.

12. Depress the "RUN" button on the RP25 control panel

to start the generator set.

13. Check the voltage at the transfer switch. Verify that it

matches the incoming power line voltage line-to-line and

line-to-neutral on each leg.

16. Check the three phase rotation pattern. Insure that

you have the same rotation, with both the generator and

the normal power source.

17. Depress the “STOP” button on the front of the engine

control. Let the unit stop and then depress the “AUTO”

button. The unit is now in automatic start mode. Also be

sure the "AUTO" light is lighted on the control, this light

tells you it is in automatic mode. See control panel layout

for additional information.

20. Upon completion of the test, leave all control mode

switches in the “AUTO” position.

21. The system is now ready to start and power the loads

should the power fail.

F. CONNECTING THE LOADS

WARNING -ALL WIRING MUST BE DONE IN ACCORDANCE WITH NATIONAL ELECTRIC CODE NFPA 70

There are two ways the loads may be connected to a

Mobile Diesel Generator.

1. FRONT PANEL - A variety of receptacles have been

provided for your convenience on the front panel. The 120

volt receptacles are powered when the voltage selector

switch is in the 120/240 single and three phase and 120/

208 three phase volt position. The 240 volt receptacles

are only usable in the 120/240 volt single and three phase

position. In the 120/208 volt three phase position the 240

volt receptacles have only 208 volts at them.

2. FULL POWER LOAD CONNECTION TERMINAL

BLOCK - For remote connections and connecting load

distribution boxes, heavy duty terminal blocks have been

provided. These terminal blocks are located on the rear of

the unit just below the main line circuit breakers. The

neutral and ground are connected together at this panel.

For use with an isolated neutral, remove the jumper strap

between the neutral connection block and the ground lug.

This will isolate the neutral from the ground and allow you

single point grounding at a distribution panel. When using

these terminal blocks be sure to use wire rated large

enough to carry your full load or the full rated load of the

generator.

3. GROUNDING THE UNIT - To comply with current

safety standards this generator set must be properly

grounded. Ground the Mobile Diesel Generator set by

driving an 8 ft. copper ground rod into the earth. Then

connect a #4 AWG ground cable from the grounding lug

on the generator to the ground rod.

18. If the transfer switch has a test button use it to test

the complete system. The unit should start up and the

transfer switch should transfer the load to the generator.

60706-201

Page 10

8190-00

Page 13

G. UNIT STORAGE

Certain precautions must be taken if a Mobile Diesel

Generator set is to be stored for a long period of time.

The unit must be stored in a dry location to prevent the

generator winding from drawing moisture. The unit should

also be thoroughly cleaned prior to storage.

For engine storage procedures consult your local Iveco

engine dealer. They have certain procedures that must be

followed in order to prevent engine damage, i.e. cylinder

rust and injector deterioration.

50 CYCLE (HZ) OPERATION

With a couple of minor changes these Mobile Diesel

Generators are capable of producing 50 Hz power. Two

changes must be made:

A. New equipment must be carefully monitored until

extended operation has demonstrated that it is performing

satisfactorily.

B. Old equipment requires more frequent inspection

(and possibly servicing) than similar equipment that has

seen less service.

C. Time spent in cleaning, inspecting and correcting

minor defects before they become major troubles means

time saved in overhaul and repair.

PREVENTIVE MAINTENANCE

A. Daily Maintenance Checklist

** Oil level is between the “L” low mark and the “H” high

mark on the dipstick

** Fuel tank full of proper grade of diesel fuel

A. The engine must be reduced to 1500 RPM governed

speed. Consult your local Iveco Service Center for the

proper procedure for reducing the engine speed and

setting up the governor to operate at 1500 RPM.

B. The automatic volt/hertz regulator must also be reset to

operate at 50 HZ instead of the standard 60 HZ. Refer to

the generator manual for proper procedures.

MAINTENANCE

The ultimate aim of a preventive maintenance program is

to maintain the equipment in optimum condition, either in

service or ready for service, for the maximum amount of

time during the useful life of the equipment. The detection

of faults before they develop into major sources of

difficulty will decrease the incidence of repair. To this end,

a regular schedule of cleaning and inspection will go far

toward assuring trouble-free operation. Personnel responsible for maintenance should set up a schedule for

inspection, and cleaning at intervals calculated to keep

the equipment in good condition. In making up a schedule, keep the following in mind:

** Water and sediment drained from water separator

** Radiator filled with the proper coolant mixture

** Check air cleaner service indicator. Change the filter

element when the red indicator flag is at the raised

position

** Inspect for any fluid leaks

** Look for any loose or damaged parts

** Check belts for cracks or frays

** Check trailer hitch and safety chains for fitness

** Check tires for proper pressure

** Check battery for proper fluid level

** Check the generator control panel for loose or dam-

aged parts

** Check the unit for general appearance and cleanliness

8190-00

Page 11

60706-201

Page 14

DC ELECTRICAL SCHEMATIC

60706-201

Page 12

AC INTERFACE

CONNECTOR

TO GENERATOR

8190-00

Page 15

DC ELECTRICAL SCHEMATIC LEGEND

8190-00

Page 13

60706-201

Page 16

GENERATOR WIRING

AC INTERFACE

CONNECTOR

TO DGC-2020

GENERATOR

WIRING

VOLTAGE

REGULATOR

DIAGRAM

60706-201

Page 14

8190-00

Page 17

VOLTAGE SELECTOR SWITCH WIRING

8190-00

Page 15

60706-201

Page 18

CIRCUIT BREAKER/FULL POWER

TERMINAL BLOCK WIRING

60706-201

Page 16

8190-00

Page 19

RECEPTACLE WIRING

8190-00

Page 17

60706-201

Page 20

WINCO, INC.

12 Month Limited Warranty

WINCO, Incorporated warrants to the original purchaser for 12 months that goods manufactured or supplied by it will be free from defects in workmanship and material, provided such

goods are installed, operated and maintained in accordance with WINCO written instructions.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be

limited to the repair of the product. At WINCO’s option, material found to be defective in

material or workmanship under normal use and service will be repaired or replaced. For

warranty service, return the product within 12 months from the date of purchase, transportation charges prepaid, to your nearest WINCO Authorized Service Center or to WINCO, Inc.

at Le Center Minnesota.

THERE IS NO OTHER EXPRESS WARRANTY.

To the extent permitted by law, any and all warranties, including those of merchantability and

fitness for a particular purpose, are limited to 12 months from date of purchase. In no event

is WINCO liable for incidental or consequential damages.

Note: Some states do not allow limitation on the duration of implied warranty and some

states do no allow the exclusion or limitation of incidental or consequential damages, so the

above limitations may not apply in every instance. This warranty gives you specific legal

rights which may vary from state to state.

WINCO reserves the right to change or improve its products without incurring any obligations

to make such changes or improvement on products purchased previously.

EXCLUSIONS:

WINCO does not warrant Engines. Engines are covered exclusively by the warranties of their

respective manufacturers, see enclosed warranties.

WINCO does not warrant engines, batteries, or other component parts that are warranted by

their respective manufacturers.

WINCO does not warrant modifications or alterations which were not made by the WINCO,

Inc.

WINCO does not warrant products which have been subjected to misuse and/or negligence

or have been involved in an accident.

60706-201 - 8190-00

225 South Cordova Avenue

Le Center, Minnesota 56057

1-507-357-6821

Loading...

Loading...