Page 1

PSS12H2W/E & /F

GENERATOR

INSTALLATION AND

OPERATORS

MANUAL

WINCO INC. 225 S. CORDOVA AVE. LE CENTER, MN 56057 507-357-6821

SERVICE DEPT. 507-357-6831

www.wincogen.com

Page 2

TABLE OF CONTENTS

SAVE THESE INSTRUCTIONS 3

TESTING POLICY 3

SAFETY INFORMATION 4

ANSI SAFETY DEFINITIONS

SPECIFICATIONS 5

GENERATOR

ENGINE

INTRODUCTION 5

PRODUCT DESCRIPTION

PREPARING THE UNIT 6

UNPACKING

INSTALLATION 6

ENGINE-GENERATOR SET MOUNTING

FUEL INSTALLATION 6

LIQUID PROPANE VAPOR (LP)

NATURAL GAS (NG)

FUEL PRESSURE

FUEL PRESSURE TABLES

NG/LP FUEL CONVERSION

INSTALLING THE BATTERY 9

SERVICING BATTERIES

BATTERY CHARGING

CONNECTING THE BATTERY CHARGER

SOLAR CHARGER OPTION 10

AC ELECTRICAL CONNECTIONS 11

GENERATOR CONNECTIONS

WINCO UL ATS (ASCO 185)

DC ELECTRICAL INTERCONNECTION 12

ASCO 185 UL SWITCH

INITIAL START UP 12

START UP PROCEDURE

CUSTOMER CONNECTION AREA

SEQUENCE OF OPERATION 16

DSE 3110 17

FRONT PANEL CONFIGURATION

ACCESSING THE FRONT PANEL

EDITING A PARAMETER

DSE 3110 FAULT CODES

DSE 3110 ENGINE CONTROL

MODULE DISPLAY

PREVENTATIVE MAINTENANCE 18

AUTOMATIC TRANSFER SWITCH

ENGINE-GENERATOR SET

TROUBLE SHOOTING TABLES 19

PAD LAYOUT DRAWING 20

AC AND DC GENERATOR SCHEMATIC 21

AC WIRING SCHEMATIC 21

SOLAR CONTROL PANEL 22

EXTERNAL RECEPTACLE ASSEMBLY 22

SOLAR PANEL ASSEMBLY 23

12 MONTH LIMITED WARRANTY 24

60706-209

2

REV F

Page 3

SAVE THESE INSTRUCTIONS

TESTING POLICY

This manual contains important instructions that should be followed

during installation and maintenance of the generator. Read and

understand all instructions in the manual before starting and operating

the generator.

USING THIS MANUAL

Congratulations on your choice of a WINCO generator. You have

selected a high-quality, precision-engineered generator designed and

tested to give you years of satisfactory service.

To get the best performance from your new generator, it is important

that you carefully read and follow the operating instructions in this

manual.

Should you experience a problem please follow the “Troubleshooting

Tables” near the end of this manual. The warranty listed in the manual

describes what you can expect from WINCO should you need service

assistance in the future.

COPY YOUR MODEL AND SERIAL NUMBER HERE

No other WINCO generator has the same serial number as yours.

If you should ever need to contact us on this unit, it will help us to

respond to your needs faster.

Before any generator is shipped from the factory, it is fully checked

for performance. The generator is loaded to its full capacity, and the

voltage, current, and frequency are carefully checked.

Rated output of generator is based on engineering tests of typical units,

and is subject to, and limited by, the temperature, altitude, fuel, and

other conditions specied by the manufacturer of applicable engines.

MODEL __________________________________________________

SERIAL NUMBER _________________________________________

PURCHASE DATE _________________________________________

DEALER NAME ___________________________________________

DEALER PHONE # ________________________________________

3REV F

60706-209

Page 4

SAFETY INFORMATION

This engine generator set has been designed and manufactured to

allow safe, reliable performance. Poor maintenance, improper or

careless use can result in potentially deadly hazards; from electrical

shock, exhaust gas asphyxiation, or re. Please read all safety

instructions carefully before installation or use. Keep these instructions

handy for future reference. Take special note and follow all warnings on

the unit labels and in the manuals.

D. Keep a re extinguisher nearby and know its proper use.

Fire extinguishers rated ABC by NFPA are appropriate.

E. Store fuel only in an approved container, and only in a well

ventilated area.

F. Follow local codes for closeness to combustible material.

3. DEADLY EXHAUST GAS -

Exhaust fumes from any gasoline engine contain carbon monoxide, an

invisible, odorless and deadly gas that must be mixed with fresh air.

CALIFORNIA PROPOSITION 65

WARNING: This product contains crude oil, gasoline,

diesel fuel and other petroleum products, Antifreeze to

which can expose you to chemicals including toluene

and benzene, Ethylene glycol (ingested) which are

known to the State of California to cause cancer, birth defects or other

reproductive harm and developmental issues.

For more information go to www.P65Warning.ca.gov.

ANSI SAFETY DEFINITIONS

DANGER:

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word is to be

limited to the most extreme situations.

WARNING:

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

A. Operate only in well ventilated areas.

B. Never operate indoors including attached garages

C. Never operate the unit in such a way as to allow exhaust gases

to seep back into closed rooms (i.e. through windows, walls,

oors).

4. NOISE HAZARD -

Excessive noise is not only tiring, but continual exposure can lead to

loss of hearing.

A. Use hearing protection when working around this equipment for

long periods of time.

B. Keep your neighbors in mind when using this equipment.

5. CLEANLINESS -

Keep the generator and surrounding area clean.

A. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

B. Remove any rags or other materials that could create a

potential re hazard.

C. Carefully clean up any gas or oil spills before starting the unit.

1. ELECTRICAL SHOCK -

The output voltage present in this equipment can cause fatal electric

shock. This equipment must be operated by a responsible person.

A. Do not allow anyone to operate the generator without proper

instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Use extreme care if operating this unit in rain or snow.

E. Use only three-pronged grounded receptacles and extension

cords.

F. Be sure the unit is properly grounded to an external ground rod

driven into the earth.

2. FIRE HAZARD -

Gasoline and other fuels present a hazard of possible explosion and/

or re.

A. Do not refuel when the engine is running or hot.

B. Keep fuel containers out of reach of children.

C. Do not smoke or use open ame near the generator set or fuel

tank.

60706-209

6. SERVICING EQUIPMENT -

All service, including the installation or replacement of service parts,

should be performed only by a qualied technician.

A. Use only factory approved repair parts.

B. Do not work on this equipment when fatigued.

C. Never remove the protective guards, covers, or receptacle

panels while the engine is running.

D. Use extreme caution when working on electrical components.

High output voltage from this equipment can cause serious

injury or death.

E. Always avoid hot mufers, exhaust manifolds, and engine parts.

They can cause severe burns instantly.

F. The use of the engine-generator set must comply with all

national, state, and local codes.

4

REV F

Page 5

SPECIFICATIONS

INTRODUCTION

GENERATOR

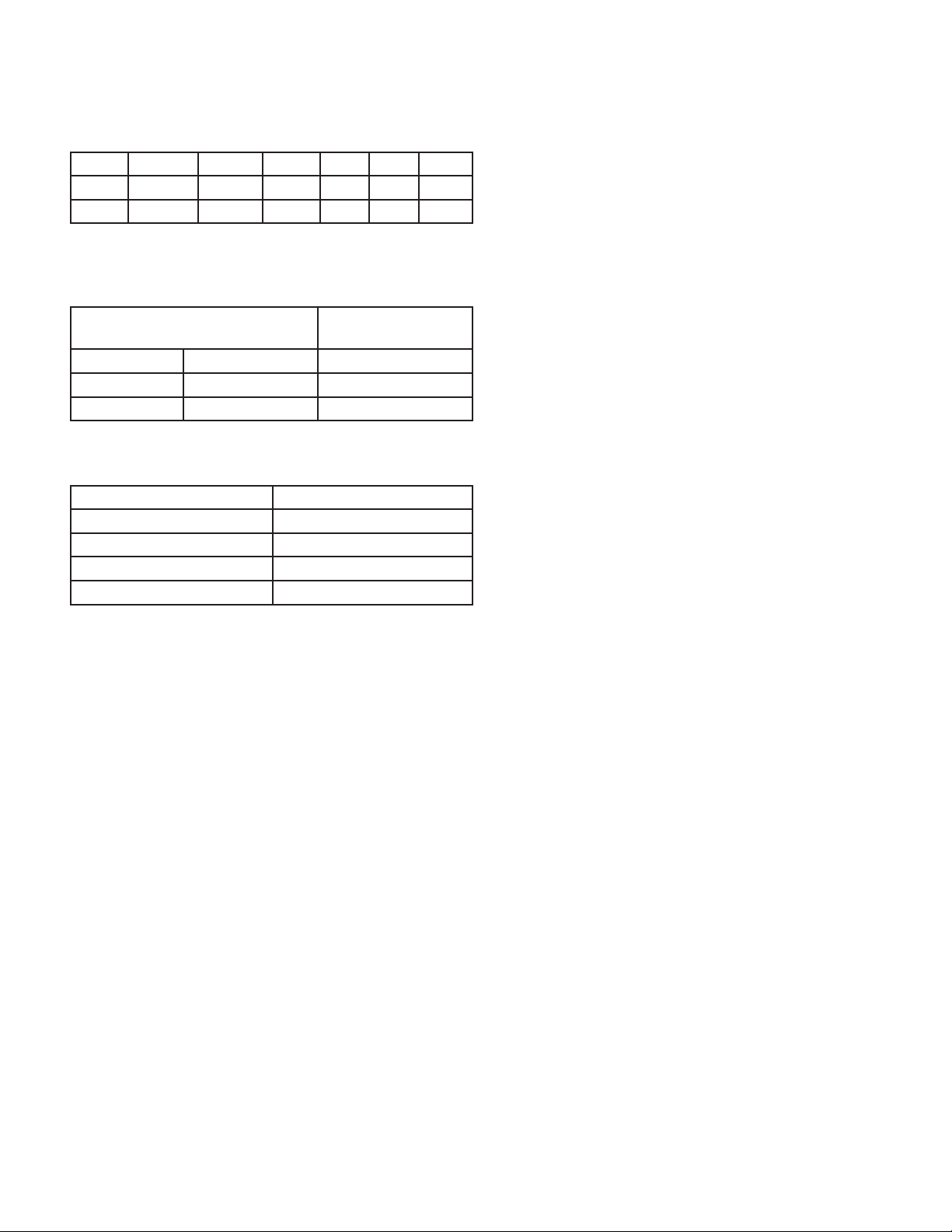

Fuel Watts* Volts Amps HZ PH RPM

LP 12,000 120/240 50 60 1 3600

NG 10,000 120/240 41 60 1 3600

*Continuous rating.

Derate 3.5% per 1000 feet elevation above sea level.

FUEL CONSUMPTION

Natural Gas

1000 BTU/FT³

CF/HR* 194 75.4

BTU/HR* 194,000 190,000

GAL/HR* N/A 2.1

*Based on full load operation.

LP Vapor

2520 BTU/FT³

LP TANK SIZING

Tank Temperature Tank Size

60° F (16° C) 150 Gallons

32° F (0° C) 250 Gallons

0° F (18° C) 500 Gallons

-20° F (-29° C) 1000 Gallons

ENGINE

Make Honda

Model GX690

Displacement 688 CC/OHV

Cylinders/Sleeves V-Twin/Cast Iron

Ignition Electronic

Governor Mechanical

Exhaust Critical Grade, Glass-pack

See engine manual for additional information

PRODUCT DESCRIPTION

The package standby system is designed to automatically provide

standby power to unattended loads during electrical outages. Upon

interruption of normal electrical service, the packaged standby system

electrical control circuits will automatically start the engine. The

generator will produce electrical power and the Automatic Transfer

Switch (ATS) will automatically transfer the electrical loads to the

engine-generator set. Upon restoration of normal electrical service the

emergency transfer switch will sense return of the normal commercial

power. The Automatic Transfer Switch will transfer the load back

to the normal commercial power source. The engine control circuits will

begin a cool-down cycle, after which the fuel supply will be shut off and

the engine ignition system disabled.

AUTOMATIC TRANSFER SWITCH (not included)

A wall mounted ASCO 185 Automatic Transfer Switch (ATS) designed

for inside or outside installation is recommended. The transfer switch is

UL1008 approved. A fourteen day electronic exerciser circuit is installed

in the ATS as standard equipment. The ATS also contains the power

failure sensing circuitry necessary to start and stop the engine

generator set. The transfer switch is also equipped standard with a 3

second start delay, and a 15 second transfer delay to allow the engine

to warm up before transferring the load to the generator. When the line

power is restored the ATS has a 5 minute transfer delay to allow the

incoming utility to stabilize before transferring back to line power and

then an additional 1 minute engine cool down delay before the engine

shuts down. Read and understand the ATS owners manual before

installing, servicing or operating the transfer switch.

UL Automatic Transfer Switch Sizes

UNIT LINE SIDE GENERATOR

CONTACTOR SIDE CONTACTOR

ULPSS12H2W 100-400 AMPS 100-400 AMPS

The ASCO185 100-400 Amp Switches are available in single phase

only.

ENGINE / GENERATOR

The engine generator set consists of a Honda GX690, twin cylinder,

four cycle air cooled engine. The engine is factory equipped to run

on LP or NG fuel. The engine operates at 3600 rpm and frequency

regulation is maintained by the engine governor within 4 cycles

variation (62.5 Hz - 58.5 Hz) from no load to rated load. The generator

is a brushless, single bearing, direct drive, rotating eld design. The

generator is connected to the engine’s tapered (quill) crankshaft

extension. The engine generator is mounted in a drip-proof enclosure

for outside installation. Connection boxes and terminal blocks are

provided for all customer connections (both AC output and DC control).

A customer supplied 12 volt 500 CCA (BCI group 26) battery is required

to complete the installation.

NOTICE:

This unit will automatically transfer if a power outage occurs while

running in an exercise mode.

5REV F

60706-209

Page 6

PREPARING THE UNIT

INSTALLATION

UNPACKING

CAUTION: EQUIPMENT DAMAGE

When you unpack your new generator, be sure to remove all of the

information sheets and manual from the carton.

1. As you receive your unit, it is critical to check it for any damage. If

any damage is noted, it is always easiest to refuse the shipment and

let WINCO take care of the freight claim. If you sign for the unit, the

transfer of the ownership requires that you le the freight claim

2. Before proceeding with the preparations of your new generator

for operation, take a couple of minutes to ensure the unit you have

received is the correct model and review the specication pages in this

manual to ensure that this unit meets your job requirements.

CAUTION:

These units are shipped with oil. Be sure to check oil levels before

operating. See engine manufacturer’s instruction manual for

recommended oil requirements before initial starting.

WARNING:

Before proceeding with installation, be sure the operation selector

switch is in the stop position.

These engine generator sets are designed to be mounted on a pad

outdoors only. The transfer switch is mounted next to your electrical

entrance or distribution panel inside or outside the building. Consult

a qualied, licensed electrician or contractor to install and wire the

transfer switch. The installation must comply with all national, state and

local codes. Before beginning the installation process check the rating

of the generator set and its transfer switch rating. Be certain they can

handle the intended load and are compatible with the entrance voltage,

phase and current ratings. Plans for installation should be prepared

with proper attention to mechanical and electrical engineering detail to

assure a satisfactory system installation. The information in this manual

is offered only as a guide to nalizing your installation plans.

ENGINE-GENERATOR SET MOUNTING

WARNING: PERSONAL INJURY:

The enclosures on these units can become very hot adjacent to the

exhaust areas. Special care must be taken when installing these units

to insure that the risk of contact by people is minimized.

The unit’s main frame should be bolted to a pad that meets local code.

Various materials, including concrete and composites, are acceptable

as long as they are structurally sound supporting the weight of the

unit and preventing movement during operation. The mounting holes

on the base of this unit is 0.563” in diameter. The engine-generator is

mounted on a sub-frame which is isolated with special shock mounts

on the main frame. This allows the engine-generator to vibrate without

affecting the control panel on the main frame.

Do not install any shock mounts between the base frame and the

pad. Engine vibration will be transmitted to the control panel causing

erroneous start/stop cycles and premature control failure.

These units should be mounted a minimum of 24” from a structure. This

will allow for ample room to maintain and work on the generator set.

Units must be installed in accordance with all local, state, and national

codes. Consult your local agency for specic requirements.

FUEL INSTALLATION

The fuel supply should be as close as possible to the engine. This will

reduce the installation cost of fuel runs. The information in this manual

is offered to assist you in providing the proper fuel for your engine.

However, this information is only provided to inform you of the engine’s

requirements and assist in making you aware of the decisions you

must make. In no case should the instructions and information provided

be interpreted to conict with any local, state or national codes. If in

doubt, always consult your local re marshal, gas supplier or building

inspector.

60706-209

6

REV F

Page 7

WARNING: FIRE HAZARD:

All fuel runs should be installed by a licensed fuel supplier.

To connect the fuel line to the generator set you will connect your

incoming fuel line to the 3/4 inch NPT tting located on the left side

of the engine-generator set. This tting is shipped with a plastic plug

installed to insure the fuel system stays clean. For all vapor fuel

systems the delivery pressure of the fuel to the fuel solenoid on the unit

must be four to six ounces psi (per square inch) or 7 to 11 inches

W.C. (water column). These fuel pressures are critical; failure to

provide the proper pressure can cause many problems ranging from a

unit that will not start to causing damage to the fuel system.

These units are normally tested on Natural Gas and will have a

tag hanging on the fuel hose indicating on what fuel your unit was

factory tested. If you are running on LP or have to change fuel types

at any time, see information on page 8 on NG/LP CONVERSION.

INSTALLING THE FUEL LINE

NOTICE: The engine generator sets are properly adjusted before they

leave the factory. A tag is attached to the unit that species the fuel,

natural gas (NG) or propane vapor (LP) that the unit was set up and

tested on.

NATURAL GAS or LP VAPOR PIPE SIZE

Size of pipe normally required for generators operating on natural gas

or LP vapor. Unit location will determine the size of fuel line that is

required to supply the engine with a constant fuel pressure and volume.

LIQUID PROPANE VAPOR (LP)

Refer to the tables on the following pages for fuel line size and

recommended tank size. For distances of 100 feet or over, a two

regulator fuel system is recommended. This is accomplished by

installing a primary regulator at the tank which will reduce the tank

pressure down to 10 to 15 lbs. A low pressure regulator is installed to

further reduce the fuel pressure to the required four (4) to six (6) oz.

operating pressure. This low pressure regulator must be at least 10

feet from the engine generator set; any closer installation will require

a larger line be installed to provide a fuel reservoir. This is also true

for the single low pressure regulator, it should also be a minimum of

10 feet from the unit. If this is not done, the demand regulator on the

unit and the pressure regulator in the fuel line will interfere with each

other. When the two (2) regulator system is used on LP, a fuel line size

of 1/2 to 5/8 inch is generally adequate for distances up to 300 feet

from the primary to the low pressure regulator. Consult your local fuel

supplier for your exact requirements . The appropriate line size from

the following table is then installed from the low pressure regulator to

the generator set.

Feet* Size of pipe

Up to 25 ft ¾” pipe

25 - 100 ft 1” pipe

Over 100 ft Use a two regulator system

*Allow an additional 3 feet for each standard elbow. DO NOT use

‘street ells’ (restrictive).

LP TANK SIZING

Tank Temperature Tank Size

60° F (16° C) 150 Gallons

32° F (0° C) 250 Gallons

0° F (18° C) 500 Gallons

-20° F (-29° C) 1000 Gallons

NATURAL GAS (NG)

The primary regulator (fuel meter) on the building should deliver the

correct volume and pressure to the generator set. This regulator must

be sized to deliver the required BTU’s to the generator set and all other

appliances in the building. If the primary regulator (fuel meter) is a high

pressure regulator, then a low pressure regulator must be installed

to bring the pressure down to 4-6 oz. (7-11 inches water column) of

pressure. This low pressure regulator must be at least 10 feet from the

engine generator set; any closer installation will require a larger line

be installed to provide a fuel reservoir. If this is not done, the demand

regulator on the unit and the pressure regulator in the fuel line will

interfere with each other. This regulator must be sized to accommodate

the demand of the generator set and any other appliance connected to

it. See the following table for the correct size of pipe to be installed.

Feet* Size of pipe

Up to 25 ft ¾” pipe

25 - 100 ft 1” pipe

Over 100 ft Use a two regulator system

*Allow an additional 3 feet for each standard elbow. DO NOT use

‘street ells’ (restrictive).

WARNING: PERSONAL DANGER:

Do not use galvanized pipe in fuel line runs. The galvanized coating

can become eroded and ake off, causing possible obstructions in the

regulator or fuel valve. The results could range from inoperative engine

to hazardous fuel leaks.

CAUTION:

Be careful when sealing gas joints. Excessive sealing compound can

be drawn into the solenoid, regulator or carburetor causing an engine

malfunction.

FUEL PRESSURE

Correct fuel pressure cannot be stressed enough. The most common

cause for inoperative systems is an inadequate or incorrect fuel

pressure. Performance of the engine is in direct relation to the

correctness of the fuel system. Shown below is a diagram of a typical

LP vapor fuel installation. Notice the following tables give two different

units of measuring fuel pressure. The rst and most accurate is the

use of a simple water manometer. A manometer is calibrated in inches

of water column . The second is with a pressure gauge calibrated in

ounces per square inch.

7REV F

60706-209

Page 8

FUEL PRESSURE TABLES

The following tables are the fuel pressure readings at each reference in

the system.

Single low pressure regulator (LP vapor only)

Ref# 1 3 4

Unit off Line PSI 7-11 in

4-6 oz

Starting Line PSI 7-11 in

4-6 oz

No load Line PSI 7-11 in

4-6 oz

Full load Line PSI 7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

Reference numbers 1 through 3 in the diagram above are system parts

supplied by the customer. Reference number 4 is on the generator.

The following diagram is of a natural gas (NG) installation.

Two regulator system (LP vapor only)

Ref# 1 2 3 4

Unit off Line PSI 10-15 lbs 7-11 in

4-6 oz

Starting Line PSI 10-15 lbs 7-11 in

4-6 oz

No load Line PSI 10-15 lbs 7-11 in

4-6 oz

Full load Line PSI 10-15 lbs 7-11 in

4-6 oz

Natural gas

Ref# 2 3 4

Unit off 2 PSI 7-11 in

4-6 oz

Starting 2 PSI 7-11 in

4-6 oz

No load 2 PSI 7-11 in

4-6 oz

Full load 2 PSI 7-11 in

4-6 oz

NG/LP FUEL CONVERSION

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

7-11 in

4-6 oz

Reference numbers 2 through 4 in the previous diagram are system

parts supplied by the customer. Reference number 4 is on the

generator.

60706-209

These generator sets are factory tested on NG and will require no

modications for normal operation on NG. The carburetion system

has been preset and anti-tamper plugs have been installed in the

carburetor as required by the EPA.

If you are going to operate on LP, you will need to move the fuel line

from the NG port to the LP port on the fuel outlet tee. These two ports

have different orice inserts installed on them, which provide proper

operation with no further adjustments.

NOTE: When moving the fuel

line from one port to the other,

be sure not to kink or bend

the line. Use a large sweeping

curve as possible and never

shorten the fuel line. For proper

operation, the fuel line must

stay the same length as it was shipped.

8

REV F

Page 9

INSTALLING THE BATTERY

CAUTION:

In the following battery installation procedure, check to be sure the

selector switch remains in the ‘off’ position. This should be your last

step before initial start-up.

A customer supplied twelve-volt battery is required to complete

the installation. Installation of the highest CCA rated battery, within

the correct BCI group (size), will increase cold weather starting

performance. Gel batteries should not be used with the battery

tender installed in the generator enclosure.

bicarbonate of soda (baking soda) to one gallon of water. The

bicarbonate of soda is to be added until the evidence of reaction,

foaming, has ceased the resulting liquid is to be ushed with water

and the area dried.

DANGER: EXPLOSIVE FIRE RISK:

Never smoke near batteries

Do not cause a ame or spark in the battery area.

Always discharge static electricity from your body before touching

batteries by rst touching a ground metal surface.

SERVICING BATTERIES

Voltage BCI Group MIN. CCA Rating

12 26 500

Installation and servicing of batteries must be performed or supervised

only by persons knowledgeable of batteries and the required

precautions. Keep unauthorized persons away from batteries. When

installing or replacing batteries, use the proper group/size starting

battery. The battery should be a maintenance free lead acid design.

Deep cycle batteries will not work for this application.

CAUTION: PERSONAL DANGER:

NEVER dispose of a battery in a re. The battery is capable of

exploding.

DO NOT open or mutilate the battery. Released electrolyte is known to

be harmful to the skin and eyes and to be very toxic.

These generator sets are all NEGATIVE ground. Be very careful not

to connect the battery in reverse polarity, as this may short circuit the

battery charging system on the engine.

CAUTION:

A battery presents a risk of electrical shock and high short circuit

current. The following precautions must be observed when working

with batteries.

1. Remove watches, rings, and other metal objects.

2. Use tools with insulated handles.

3. Check both the battery cable ends and the battery posts to be sure

they are free of corrosion.

4. Always connect the battery positive cable rst and then connect the

battery negative cable. When removing the battery cables from the

battery, reverse the procedure and disconnect the negative cable

rst and then the positive cable.

5. Be sure all connections are tight and coat the terminals and cable

ends with dielectric grease.

WARNING:

The electrolyte is a diluted sulfuric acid that is harmful to the skin

and eyes. It is electrically conductive and corrosive, The following

precautions must always be taken.

1. Always wear full eye protection and protective clothing.

2. Where electrolyte contacts skin, wash off immediately with water.

3. If electrolyte contacts the eyes, ush immediately and thoroughly

with water. Seek immediate medical attention.

4. Spilled electrolyte is to be washed down with an acid neutralizing

agent. A common practice is to use a solution of one pound of

Batteries used on these units may over time lose water. This is

especially true if you are using a trickle charger to maintain your battery.

When relling the battery with water, use only distilled water. Tap water

will shorten the service life of the battery.

Never ll the battery above the ll line. Over lling above the upper

level line may cause electrolyte to overow, resulting in corrosion to

the engine or nearby parts. Immediately wash off any spilled electrolyte

following the procedure above.

BATTERY CHARGING

Units equipped with electric start have a small ywheel charge built into

the engine ywheel assembly for recharging the starting battery. This

ywheel charger generates a small AC current that passes through a

rectier/regulator assembly on the engine to produce a DC charging

current. This circuit is not designed to be used as a battery charging

circuit to recharge dead batteries.

CAUTION: EQUIPMENT DAMAGE:

Always connect the positive cable rst and the negative cable last.

When disconnecting, remove the negative cable rst and the positive

cable last. Failure to connect and disconnect in the proper sequence

can cause equipment damage.

Observe polarities: connect the positive (+) battery terminal to the

(+) cable from the engine starter; the negative (-) battery terminal is

connected to the negative cable (ground) from the engine generator

assembly. All connections must be clean and tight. Check the

electrolyte (uid) in the battery periodically to be sure it is above the

plates. Never allow the battery to remain in a discharge condition.

CAUTION: EQUIPMENT DAMAGE:

NEVER JUMP START these units. Doing so will destroy the engine

control module, rendering the unit non-operational. Remove and fully

recharge the battery before attempting to start.

CONNECTING THE BATTERY CHARGER

A two-stage battery tender is provided on all PSS series generators.

This battery tender charges at a rate of 750 mA until the battery is fully

charged and then automatically switches to a 13.2 VDC oat charger.

The charger has an indicator light on it. Red indicates it is charging,

and green indicates it is in storage mode (oat charge). This charger is

9REV F

60706-209

Page 10

mounted on the generator set which is located behind an access cover

in the rear of the unit.

The battery tender receptacle is to be powered by a GFCI circuit and

installed in accordance with the United States National Electric Code.

These AC wires can be run in the same conduit as the other AC leads

from the generator. It is suggested that this circuit be fused for 15

Amps. Terminal block connections have been provided in the customer

connection area of the engine-generator set. See following diagram.

NOTICE:

The battery tender is not intended to recharge a battery which has

become completely discharged. It is designed to produce enough

current to recharge a slightly low battery and maintain a fully charged

battery.

SOLAR CHARGER OPTION

(If equipped)

The WINCO solar option consists of two parts; one, the solar panel

and two, the Sun Guard charge controller. The solar panel collects the

energy while the Sun Guard controls the charging process acting as

a switch to prevent the solar panel from discharging or overcharging

the battery. If you are experience problems with solar charging system

contact WINCO service for trouble shooting instructions.

This package also included external receptacles, a 14-50 50 Amp and

a 5-20 20 Amp duplex.

Note: this option has a 50 Amp circuit breaker.

60706-209

10

REV F

Page 11

AC ELECTRICAL CONNECTIONS

NOTICE:

CLASS 1 WIRING METHODS ARE TO BE USED FOR ALL FIELD

WIRING CONNECTIONS TO TERMINAL OF A CLASS 2 CIRCUIT.

The load terminals in the ATS are marked “LOAD - L3 & L7”. The leads

to the load distribution panel are connected to terminals L3 & L7.The

neutral leads from all three locations are connected to the isolated

terminal lugs on the sidewall of the cabinet. This terminal block is

labeled “NEUTRAL” and the terminal lugs are mounted on red isolation

standoffs.

WARNING:

A mainline circuit breaker has been provided inside the generator

housing. During all wiring installation, make sure the breaker is in the

off position and the generator operators switch is in the off position.

Note: This symbol always indicates ground where used.

GENERATOR CONNECTIONS

WIRE TEMPERATURE RATING

CU Connector AL Connector

75° C #2 AWG #1/0 AWG

90° C #3 AWG #2 AWG

The previous table shows the minimum conductor sizes between the

generator and the ATS, based on wire type and temperature rating.

Wire has been derated 40° C ambient temperatures.

To gain access to the customer connections, remove the end door

panel opposite the mufer. All AC and DC connections to the ATS, 120

Volt power connection for battery charger, and battery installation are

made behind this panel. See drawings for generator set and pad layout

featured within this manual.

Two hot leads, one neutral, and one ground lead are required between

the generator and the ATS or distribution panel. The two power leads

from the generator are marked G1 and G3. Next install the two leads,

one neutral, and one ground from the generator set to the ATS or

distribution panel.

In addition to the power leads, install a three wire 120 Volt, 15 Amp

circuit from your distribution panel to the generator. This circuit will be

used to power the battery charger, optional block heater and optional

battery heater.

The last four wires you will install are the DC control leads (14 or

16 gauge) for the start circuit in the ATS. These connections will be

discussed later in more detail.

WINCO UL ATS (ASCO 185)

See the ASCO installation manual for additional details on proper

wiring of the Automatic Transfer Switch.

The ground leads from all locations are connected to the grounded

terminal lugs also located on the side wall. This set of terminals is

labeled “GROUND”.

INSTALLATION NOTES:

The load current carrying wires (L) and (T) must be sized to handle the

maximum load current without excessive voltage drop. By code, the

wire must be heavy enough to handle the full current rating of the main

line circuit breaker (or fuse) in the entrance (or sub-panel) protecting

the contactor switch. All wires should be installed in rigid or exible

conduit. Because of the many different types of service, feeder, and

distribution equipment, no specic wiring instructions can be provided.

It is, however, recommended that copper wire be used. In all cases it

is essential that while the load is connected to the generator, there can

be absolutely no feedback from the generator to the power line or the

power line to the generator. When properly installed, the normal ATS

control and safety systems will eliminate all paths for feedback. Check

with your local electrical inspector on applicable local, state and federal

codes.

WARNING:

A service disconnect must be installed in front of the ATS panel as

the ATS is not service entrance rated. This will allow you to test the

generator under load. Should you ever have to work on the switch,

you will be able to disconnect the power and work on the switch cold

without having the power company pull your meter.

To wire the automatic transfer switch into the existing wiring, rst

determine which circuits will be on the emergency load circuit. If the

entire load is to be transferred, the transfer switch can be wired in

directly after the watt-hour meter and the service entrance, providing

the service entrance ampere rating is within the transfer switch’s rated

capability.

If only specic circuits are to be powered under emergency power

failure conditions, an additional distribution panel designated

“emergency distribution panel” must be installed.

All selected emergency circuits are removed from main distribution

panels and reinstalled in the emergency distribution panel. Suggested

circuits: freezer, refrigerator, furnace, emergency lights, sump pump,

emergency outlet circuits, etc. Total running load must not exceed

generator rating.

The standby generator terminals in the ATS are marked “ALTERNATE

L2 & L6”. The “hot” leads G1 and G3 from the generator are connected

to the terminals L2 & L6. The normal line power terminals in the ATS

are marked “PREFERRED - L1 & L5”. The “hot” line power leads

are L1 and L3 from the utility power supply. They are connected to

terminals L1 and L5.

11REV F

60706-209

Page 12

INITIAL START UP

WARNING:

DO NOT jump start these engine generator sets. Starting these units

on a low battery of jump starting them will cause damage to the engine

control module.

Use the following checklist to verify correct installation before starting

the engine:

Ƒ(QJLQHRLO&KHFNOHYHO¿OODVUHTXLUHGZLWKSURSHU

grade/quantity.

Ƒ8QLWPRXQWLQJEDVHSURSHUO\EROWHGGRZQ

Ƒ&OHDUDQFHIRUVHUYLFHDQGPDLQWHQDQFHRQDOOVLGHV

Ƒ3URSHUIXHOOLQHPDWHULDODQGVL]H

Ƒ$OOIXHOOLQHFRQQHFWLRQVWLJKW

Ƒ)XHOOLQHSURWHFWHGDQGDPRLVWXUHWUDSLQVWDOOHGPD\EH

required for NG).

Ƒ/31*SUHVVXUH2.R]LQ:&

Ƒ%DWWHU\FRQQHFWLRQVFOHDQDQGWLJKW

Ƒ%DWWHU\IXOO\FKDUJHG

Ƒ$OO$&DQG'&ZLULQJLQVWDOOHGDQGSURSHUO\SURWHFWHG

* Refer to engine owners manual for proper levels and types.

After completing the above checklist, the engine generator set is ready

for the initial start-up test.

START UP PROCEDURE

ENGINE-GENERATOR SET ONLY

The engine control module (ECM) is manufactured by Deep Sea

Electronics. Model 3110 is used on this generator set.

See following picture and look for more information stated within this

manual.

MANUAL OPERATION

Press and release the red Stop/Reset button. Then press and release

the green Start Engine button. The engine-generator will crank and

start automatically. If the engine fails to start, reference the fault codes

to correct the problem before proceeding.

DC ELECTRICAL INTERCONNECTION

INITIAL START UP

CAUTION:

Never run the AC and DC wiring on the same conduit.

ASCO 185 UL SWITCH

Your DC connection points in the ASCO 185 UL ATS are on the

terminal block on the bottom of the controller in the lower left hand

corner of the ATS panel. The terminal block (TB7) is numbered 1

through 9. These terminals will accept # 22 - # 14 AWG stranded wire.

It is recommended that you use # 16 AWG for distances up to 200

feet. You need to run two (2) wires from the engine generator set to the

transfer switch. You will be using terminals 4 and 5, wire Start # 23 will

connect to terminal # 5 and wire Battery Negative # 1 will connect to

terminal # 4. See the following table and illustration.

Wire # Purpose Recommended Color

#23 Start Black

#1 Battery negative White

WARNING:

DO NOT jump start these engine generator sets. Starting these units

on a low battery of jump starting them will cause damage to the engine

control module.

Use the following checklist to verify correct installation before starting

the engine:

□ Engine oil.* Check level & ll as required with proper

grade/quantity.

□ Unit mounting base properly bolted down.

□ Clearance for service and maintenance on all sides.

□ Proper fuel line material and size.

□ All fuel line connections tight.

□ Fuel line protected and a moisture trap installed (may be

required for NG).

□ LP/NG pressure OK. 4-6 oz. (7-11 in. WC).

□ Battery connections clean and tight.

□ Battery fully charged.

□ All AC and DC wiring installed and properly protected.

* Refer to engine owners manual for proper levels and types.

After completing the above checklist, the engine generator set is ready

for the initial start-up test.

START UP PROCEDURE

ENGINE-GENERATOR SET ONLY

The engine control module (ECM) is manufactured by Deep Sea

Electronics. Model 3110 is used on this generator set.

See following picture and look for more information stated within this

manual.

MANUAL OPERATION

Press and release the red Stop/Reset button. Then press and release

the green Start Engine button. The engine-generator will crank and

start automatically. If the engine fails to start, reference the fault codes

to correct the problem before proceeding.

60706-209

12

REV F

Page 13

STOP/RESET (red button) - This button places the

module into its Stop/Reset mode. This will clear any

alarm conditions for which the triggering criteria have

been removed. The fuel supply de-energizes and the

engine comes to a standstill. Should a remote start

signal be present while operating in this mode, a

remote start WILL NOT occur.

AUTO (white button) - This button places the module

into its Automatic mode. This mode allows the module

to control the function of the generator automatically.

The module will monitor the remote start input

and once a start request is made, the set will be

automatically started and placed on load. The module

will then wait until the next start event.

START (green button) - Pressing this button from

STOP/RESET will start the engine and run the load.

TRANSFER SWITCH & ENGINE-GENERATOR

Automatic (remote) Operation

This procedure checks the electrical operation of the automatic transfer

switch. If the actual operation does not follow procedure, consult the

trouble-shooting section in the transfer switch manual.

1. Turn on the preferred source (utility) circuit breaker. The Utility

Acceptable Light should now come on, as well as the Load on

Utility Light. If those lights fail to come on, recheck your incoming

power to ensure you have 240 Volts nominal. If not, troubleshoot

your utility source before continuing.

2. Press and release the Auto button on the engine control module

(ECM). The auto mode icon will appear on the screen. The unit is

now ready to be operated from the Automatic Transfer Switch.

3. Turn on the alternate source (generator) circuit breaker.

PAGE - Pressing this button scrolls the display to show

the various instruments.

With the engine running soothly, check the no load voltage and

frequency wire #1 and #4 on the generator terminal block in the ATS

(L2 and L6 in the ASCO ATS). The voltage should be 240 Volts plus

or minus nominal. The frequency should be between 61.5 to 62 Hertz

(Hz). The Voltage should also be checked between the hot terminals

(L2 and L6) and the neutral connection. The Voltage should be about

one half of the line to line Voltage.

OPERATING SPEED

The engine-generator must be run at the correct speed in order to

produce the proper electrical voltage and frequency.

The speed of the engine was carefully adjusted at the factory so that

the generator produces the proper voltage and frequency. For normal

usage, the speed setting should not be charged. If the generator is

being run continuously on a very light load, it is often advisable to lower

the operating speed slightly.

WARNING: PERSONAL INJURY HAZARD:

Install front cover in transfer switch before operation. An electrical

system fault could cause a ash and severe personal injury.

CAUTION: EQUIPMENT DAMAGE

SPEED ADJUSTMENTS SHOULD ONLY BE MADE BY A QUALIFIED

SERVICE TECH.

NOTICE:

If for any reason during the check out procedures the Voltage and

frequency are not correct, press the red Stop/Reset button and correct

the trouble before proceeding.

After verifying the Voltage and frequency are not correct, press the

Stop/Reset button. This will shut off the engine immediately.

The digital controller provides sensing, timing, and control functions for

the ATS. This micro-processor-based controller includes built-in control

buttons and status lights for control of the ATS and the generator.

PUSH BUTTONS

On the front control display are the three push buttons that control the

operation of the generator and the ATS.

CAUTION:

Before using the transfer test button, be sure that conditions are safe

for running the generator and for load tester.

TRANSFER TEST

Use this button to test the system. This operation starts the generator

and transfers the load. The controller is shipped with a load transfer set

13REV F

60706-209

Page 14

by default. Changing the exercise without a load will be discussed later.

Be sure that conditions are safe to do this operation.

BYPASS TIME DELAY

Use this button to cancel the active time delay or exercise period (stops

the generator after cool-down).

SET ENGINE EXERCISER

Use this button to set the automatic exerciser.

Function Factory

Setting

Clock Battery Off S2 10 On (up)

Exerciser Off S1 7 On (up)

With load or

without load

Without

Load

Dip

Switch

S1 8 With (up)

Dip

Actuator

Actuator Position

Off (down)

Off (down)

Without (down)

INDICATOR LIGHTS

On the front control display are ve lights that indicate the status of the

sources and the ATS.

UTILITY ACCEPTABLE

This light indicates that the utility voltage is acceptable for connection

to the loads.

GENERATOR ACCEPTABLE

This light indicates that the generator voltage and frequency is

acceptable for connection to the load.

LOAD ON UTILITY

This light indicates that the generator voltage is acceptable for

connection to the load.

AUTOMATIC GENERATOR EXERCISER

This light indicates the status of the generator exerciser:

• Blinks during the exercise period (including cool down)

• Stays on when the exerciser has been set.

• Is off when the exerciser has not been set.

GENERATOR STARTING CONTACTS

Disconnect the generator battery. Connect the generator starting wires

#1 (battery -) to terminal 4; wire #23 (start) to terminal 5 of the TB7

terminal block. This is removable for convenient connections.

SETTING THE EXERCISER

Press and hold (5 seconds) the Set Engine Exerciser button. The

exercise period occurs immediately and at the same time weekly

thereafter. The status light below the button blinks during the exercise

period (including cool down). The light stays on to indicate that the

exerciser has been set. If the light is off, the exerciser has not been set.

CANCELING AN ACTIVE EXERCISE PERIOD

Press the Bypass Time Delay button to stop an exercising generator. If

exercise with load is set, the ATS retransfers the load to the utility, then

stops the generator after cooldown.

WARNING:

With a total power failure (utility power fails and the generator fails to

start and run), the exerciser must be reset after the power is restored.

The ASCO 185 has settings that can be changed for various

applications. The dipswitch options are explained in the ASCO 185

Operator’s Manual.

This completes your installation and unit testing. ALWAYS leave the

system in automatic mode unless servicing the unit. For automatic

operation, the auto mode icon must be displayed on the engine control

module display.

GENERATOR EXERCISER CIRCUIT

The automatic generator exerciser is congured to automatically

exercise the generator for 20 minutes once every week.

In order to set and test the exercise circuit the AUTO button on the

generator control panel must be on.

EXERCISE WITH OR WITHOUT LOAD

The transfer switch can be set up to exercise the generator with or

without a load transfer. Normally, WINCO generators exercise without

a load transfer. This is because you may not with to have a momentary

interruption of power. Turn the exerciser dip switch on. Then set the

“with load” or “without load”. See the following table.

60706-209

14

REV F

Page 15

CUSTOMER CONNECTION AREA

ENGINE

CONTROL

MODULE

ASSEMBLY

CUSTOMER DC

CONNECTIONS

TO 2-WIRE

AUTOMATIC

TRANSFER

SWITCH 1 & 22/23

TORQUE

SCREWS TO 9.6

IN LBS. 14 TO 16

AWG COPPER

WITH LUGS

CUSTOMER TO

CONNECT TO

120V UTILITY

LINE TO POWER

BATTERY

TENDER AND

OPTIONAL

ENGINE HEATER

START &

FUEL RELAYS

LOCATED IN

BACK

EMERGENCY

STOP CONTACTS

PROVIDED

FOR REMOTE

EMERGENCY

STOP SWITCH

UNIT WILL NOT

RUN IF JUMPER

IS REMOVED

CUSTOMER

GENERATOR OUTPUT

CONNECTIONS

TO EMERGENCY

TRANSFER SWITCH

TORQUE TO 16 IN LBS

RATED FOR 4 TO 10

AWG WIRE - 85 AMPS

BATTERY

TENDER

CUSTOMER EARTH

GROUND CONNECTED

HERE AS REQUIRED

15REV F

60706-209

Page 16

SEQUENCE OF OPERATION

UTILITY FAILURE

60706-209

16

REV F

Page 17

DSE 3110

DSE 3110 FAULT CODES

FRONT PANEL CONFIGURATION

ACCEPT BUTTON DECREASE VALUE/

NEXT ITEM BUTTON

NEXT PAGE BUTTON INCREASE VALUE/

NEXT ITEM BUTTON

This conguration mode allows the operator limited customizing of

the way the module operates. Use the module’s navigation buttons to

traverse the menu and make value changes to the parameters.

ACCESSING THE FRONT PANEL

Press and simultaneously. This display shows the

conguration icon: The rst parameter is also displayed.

EDITING A PARAMETER

1. Press to select the required ‘page’ as detailed below.

2. Press to select the next parameter or to select the

previous parameter within the current page.

3. When viewing the parameter to be changed, press . The value

begins to ash.

4. Press or to adjust the value to the requested setting.

5. Press to save the current value. The value stops ashing.

6. Press and hold the button to exit the editor, the is removed

from the display.

Auxiliary inputs can be user congured and will display

he message as written by the user.

Fail to Start. The engine has not red after the preset

number of start attempts.

Fail to Stop. The module has detected a condition that

indicates that the engine is running when it has been

instructed to stop.

NOTE:- ‘Fail to Stop’ could indicate a faulty oil pressure

sensor - If engine is at rest, check oil sensor wiring and

conguration.

Low Oil Level. The module detects that the engine oil

level has fallen below the low oil level pre-alarm setting

level after the Safety On timer has expired.

Engine High Oil Temperature. The module detects that

the engine oil temperature has exceeded the high engine

temperature pre-alarm setting level after the Safety On

timer has expired.

Underspeed - The engine speed has fallen below the

underspeed pre-alarm setting.

Overspeed - The engine speed has risen above the

overspeed pre-alarm setting.

Battery Under/Over Voltage. The DC supply has fallen

below or risen above the low/high Volts setting level.

Generator Under Voltage - The generator output voltage

has fallen below the pre-set pre-alarm setting level.

Generator Over Voltage - The generator output voltage

has risen above the pre-set pre-alarm setting after the

Safety On timer has expired.

Generator Under Frequency - The generator frequency

has fallen below the pre-set pre-alarm setting after the

Safety On timer has expired.

Generator Over Frequency - The generator output

frequency has risen above the pre-set pre-alarm setting

NOTE:

Values representing pressure will be displayed in Bar. Values

representing temperature are displayed in degrees Celsius.

When adjusting values in the front panel editor, a “press and hold” of

the increment button will cover the full range of the item being adjusted

(min to max) in under 20 seconds.

When the editor is visible, it will exit after 5 minutes of inactivity for

security.

17REV F

60706-209

Page 18

DSE 3110 ENGINE CONTROL

PREVENTATIVE MAINTENANCE

PROTECTIONS

When an alarm is present, the Common alarm LED (if congured) will

illuminate. The LCD display will show an icon to indicate the failure.

WARNINGS

Warnings are non-critical alarm conditions and do not affect the

operation of the generator system; they serve to draw the operator’s

attention to an undesirable condition. Warning alarms are self-resetting

when the fault condition is removed. The icon will appear steady in the

display.

SHUTDOWNS

Shutdowns are critical alarm conditions that stop the engine and draw

the operator’s attention to an undesirable condition. Shutdown alarms

are latching. The fault must be removed and the Stop/Reset button

pressed to reset the module. The icon will appear ashing in the

display.

MODULE DISPLAY

TIMER ICON

When the module is controlling the engine (starting and stopping),

an animated timer icon will be displayed in the icon area to indicate

that a timer is active. For example, cranking time, crank test, etc.

STOPPED ICON

Reasonable care in preventative maintenance will ensure high

reliability and a long life for the engine-generator set and Automatic

Transfer Switch.

WARNING:

When performing any type of maintenance on this equipment, make

sure the selector switch on the engine-generator is in the off position.

If you are working in the Automatic Transfer Switch, conrm with a

reliable meter that all power has been disconnected.

AUTOMATIC TRANSFER SWITCH

Clean and inspect the switch once a year. De-energize all power

sources, both line and engine-generator set, then brush and vacuum

away any excessive dust or dirt accumulation. At this time, with the

conductor de-energized, you can remove the contact covers and check

the contacts. Make sure contacts are clean and not burned or pitted.

ENGINE-GENERATOR SET

Service the engine in accordance with the engine manufacturer’s

manual provided with your new equipment. Routinely remove debris

and dirt from around the inside generator enclosure. Ensure that the air

intakes are free from leaves and other debris at all times.

When there are no alarms present, an icon will be

displayed to indicate the engine is stopped and what mode the unit is

in Stop mode, Auto mode, or Manual mode.

RUNNING ICON

When there are no alarms present, an animated icon is displayed

to indicate the engine is running.

USB CONNECTION

When a USB connection is made to the module, the USB

icon is displayed.

MEMORY CORRUPTION

If either the cong le or engine le becomes corrupted, the unit

will display the memory corruption icon.

Clean and inspect battery terminals at least twice a year. Also check

the battery water level at least twice a year.

Other than keeping the generator clean and free of debris, there is

no other routine or preventative maintenance required as long as the

generator is run bi-weekly to keep it dry and in good working order.

COLD WEATHER OPERATION

Extreme cold weather operation requires special considerations.

Higher CCA batteries are required for cold weather starting; 650 CCA

or larger are recommended. In addition, you should consider installing

an oil heater kit and a battery warmer for reliable starting during cold

weather.

60706-209

18

REV F

Page 19

TROUBLE SHOOTING TABLES

WARNING:

Never jump start these units. Jump starting these units with low or bad

batteries will cause permanent damage to the engine control module.

UNIT WILL NOT CRANK WHEN THE POWER FAILS

1. Engine module not in the “Auto” mode.

2. Transfer switch control board not closing the contacts,

3. Low or dead battery, must hold 12 Volts during cranking.

4. Incorrect wiring between transfer switch and generator.

5. Loose or dirty battery terminals.

6. Defective engine control module (ECM).

7. Defective starter.

8. Defective start solenoid.

9. Defective start/stop control in the transfer switch.

10. ATS panel in fault from previous run cycle.

11. Blown 2 Amp fuse on generator control panel.

12. Blown 10 Amp fuse on generator control panel.

13. Defective starter/fuel solenoid relay(s).

ENGINE WILL NOT CRANK USING START BUTTON ON THE

GENERATOR

1.Low or dead battery, must hold 12 Volts during cranking.

2. Blown 2 Amp fuse on generator control panel.

3. Blown 10 Amp fuse on generator control panel.

4. Loose or dirty battery terminals.

5. Defective engine control module (ECM).

6. Defective starter.

7. Defective start solenoid.

8. Locked up engine generator set.

9. Defective starter/fuel solenoid relays.

ENGINE CRANKS BUT WILL NOT START

1. Improper fuel pressure being delivered to unit.

2. Fuel supply shut-off.

3. Fuel supply empty.

4. Defective spark plug.

5. Defective engine ignition module.

6. Dirty air cleaner lter

7. Defective fuel solenoid valve.

8. Low Voltage from battery to fuel solenoid, must hold 12 Volts

during cranking.

9. Oil in the bottom of the air cleaner from crankcase breather.

10. Defective starter/fuel solenoid relay(s).

ENGINE START AND THEN STOPS - Fault icon comes on

1. Engine is low on oil

2. No AC output from generator to engine stop crank circuit.

ENGINE WILL NOT COME UP TO SPEED AFTER IT STARTS

1. Insufcient fuel volume getting to the unit.

a. Fuel line too small.

b. Low fuel pressure.

2. AC short circuit.

3. Wiring to the ATS panel crossed and shorted.

4. Unit is overloaded. Check load amperage.

ATS PANEL WILL NOT TRANSFER TO EMERGENCY SUPPLY

1. No AC generator out put from generator.

2. See Automatic Transfer Switch Manual.

ATS PANEL WILL NOT PULL IN ON NORMAL POWER

1. See Automatic Transfer Switch Manual.

NO AC OUTPUT FROM GENERATOR

1. Defective diodes.

2, Defective voltage regulator.

3. Defective rotor.

4. Defective stator.

5. Defective exciter rotor.

6. Defective exciter stator.

7. AC short in the input leads.

8. Defective/Open breaker.

9. Wiring error.

19REV F

60706-209

Page 20

PAD LAYOUT DRAWING

ENGINE GENERATOR SET

PAD LAYOUT

60706-209

20

REV F

Page 21

AC AND DC GENERATOR SCHEMATIC

10A

2 4

AC AND DC GENERATOR SCHEMATIC

ENGINE CONTROLLER

ES+

N

G1

9

8

4

3

2

1

2A

DEEP SEA

3110

12

13

14

15

1 24

37

84

ES-

24

23

5

1

214

1

22

24

CR 1

22

ASCO 165 SERIES

TRANSFER SWITCH

TB7

23

CONTROL TOWER

96

4

1

CR 2

MLCB

GND

1

L1

N

GND

G3

N

G1

(L2)

9

8

7

6

5

4

3

2

1

9 POSITION

CONNECTOR

(L6)

NEUTRAL T/B

GROUND T/B

TO

RECEPTACLE

ON

CONTROL

TOWER

9852

SC

FSS

BC

+-

EC

OTS

SEE NOTE

SC

BATTERY

SM

3

1

6

7

OLS

4

FS

3

4

GENERATOR

EXCITATION CAPACITOR

1

2

AL ALARM LAMP (SYSTEM OFF)

BC BATTERY FLOAT CHARGER

CB CIRCUIT BREAKER

CR CONTROL RELAY

EC ENGINE COIL

FS FUEL SOLENOID

FSS FUEL SOURCE SELECT (LP or NG)

OLS OIL LEVEL SWITCH

OTS OIL TEMPERATURE SWITCH

RTM RUNNING TIME METER

SC START CONTACTOR

LEGEND

SM STARTER MOTOR

NOTE:

ENGINE COIL WIRES REMOVED FOR 2-WIRE APPLICATION.

TVS TRANSIENT VOLTAGE SUPPRESSOR

AC WIRING SCHEMATIC

POWER

CONNECTIONS

21REV F

60706-209

Page 22

SOLAR CONTROL PANEL

N

N

GND

GND

G1

G1

G3

G3

G3

G3

(IF EQUIPPED)

EXTERNAL RECEPTACLE ASSEMBLY

(IF EQUIPPED)

60706-209

22

REV F

Page 23

SOLAR PANEL ASSEMBLY

(IF EQUIPPED)

23REV F

60706-209

Page 24

12 MONTH LIMITED WARRANTY

WINCO, Incorporated warrants to the original purchaser for 12 months or 1000 hours which ever occurs rst, that goods

manufactured or supplied by it will be free from defects in workmanship and material, provided such goods are installed,

operated and maintained in accordance with WINCO written instructions.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be limited to the repair of the

product. At WINCO’s option, material found to be defective in material or workmanship under normal use and service

will be repaired or replaced. For warranty service, return the product within 12 months or 1000 hours which ever occurs

rst from the date of purchase, transportation charges prepaid, to your nearest WINCO Authorized Service Center or to

WINCO, Inc. at Le Center Minnesota.

THERE IS NO OTHER EXPRESS WARRANTY.

To the extent permitted by law, any and all warranties, including those of merchantability and tness for a particular

purpose, are limited to 12 months or 1000 hours which ever occurs rst, from date of purchase. In no event is WINCO

liable for incidental or consequential damages.

Note: Some states do not allow limitation on the duration of implied warranty and some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitations may not apply in every instance. This

warranty gives you specic legal rights which may vary from state to state.

WINCO reserves the right to change or improve its products without incurring any obligations to make such changes or

improvement on products purchased previously.

EXCLUSIONS:

WINCO does not warrant Engines. Engines are covered exclusively by the warranties of their respective manufacturers,

see enclosed warranties.

WINCO does not warrant Component Parts that are warranted by their respective manufacturers.

WINCO does not warrant modications or alterations which were not made by WINCO, Inc.

WINCO does not warrant products which have been subjected to misuse and/or negligence or have been involved in an

accident.

This warranty does not include travel time, mileage, or labor for removal or re-installation of WINCO product from its

application.

WINCO INC. • 225 S. CORDOVA AVE. • LE CENTER, MN 56057 • 507-357-6821

60706-209

24

REV F

Loading...

Loading...