Page 1

Operator Manual

Auto St art Generator Controller

Mechanical Diesel or Gaseous Engines

Part Number: GM100 14 (102-2003)

Version 1.0

______________________________________________________________________________________________________________________________________

Copyright © Controls, Inc.

P.O. Box 368 • Sharon Center, OH 44274

Phone 330.239.4345 • Fax 330.239.2845 • www.controlsinc.com

Page 2

Basic Controller Operation

1) Manual Start

a. Place selector switch in the RUN position.

b. Controller will begin start sequence.

• Preheat (if programmed).

• Crank and fuel systems are energized.

• Control will crank disconnect

automatically once the engine has

been started.

2) Manual Stop

a. Place selector switch in the OFF position.

• Power to fuel solenoid will be turned

off.

3) Automatic Operation

a. Place selector switch in the AUTO position.

b. Close the “REMOTE START” circuit to ground

for engine start.

• Preheat (if programmed).

• Crank and Fuel energized.

• Control will crank disconnect

automatically once the engine has

been started.

c. Open the “REMOTE START” circuit to stop the

engine.

1

Page 3

1. Introduction

The GM100 is a microprocessor-based controller for industrial engines. It is

based on the Controls, Inc. 1100-000 series controller platform.

• The product is housed in an 14”W x 10”H x 10”D

metal enclosure.

• The controller is designed to accept generic wiring

harnesses using circuit board mounted Molex

connectors.

• Color-coded engine and AC wiring harnesses are

available from Controls, Inc. for simple installations.

• The backlit digital display is 1”H x 4”W with two rows

of 16 characters. Character height is approximately

½”. Operating temperature is –20C to +70C.

Extreme temperature ranges available.

Model

• Operating voltage is 12 or 24 VDC.

• AC Voltages can range from single or three phase

systems up to 600 VAC. Controller automatically

senses.

• Current transformers can be used up to 2000:5

amps.

• Engine pre alarm and alarm parameters are

monitored with corresponding amber or red LED

illuminations above the digital display.

• Optional Remote Annunciation or Remote Relay

modules available for expansion.

PART NUMBER BREAKDOWN

GM100 14 252 K

Enclosure

14X10X10

CT Size (250:5)

And Qty (2)

“Kit” Includes

Harness

Press / Temp Senders

(2) Diodes, Fuse

2

Page 4

2. Interface

• LCD Display – The backlit digital display is 1”H x

4”W with two rows of 16 characters. Character

height is approximately ½”.

• Eight full-time display parameter are:

· Water Temp (Degrees F) · Batter Volts

· Oil Pressure (PSI) · Fuel Level

· AC Current · AC Voltage

· Frequency (Hertz) · Phase

• Panel Operation Toggle Switch – Auto / Off / Run

• Running Time / Scroll Lock Toggle Switch

• Amber (Pre Alarm) LED and Red (Alarm) LED

located above the digital display.

3

Page 5

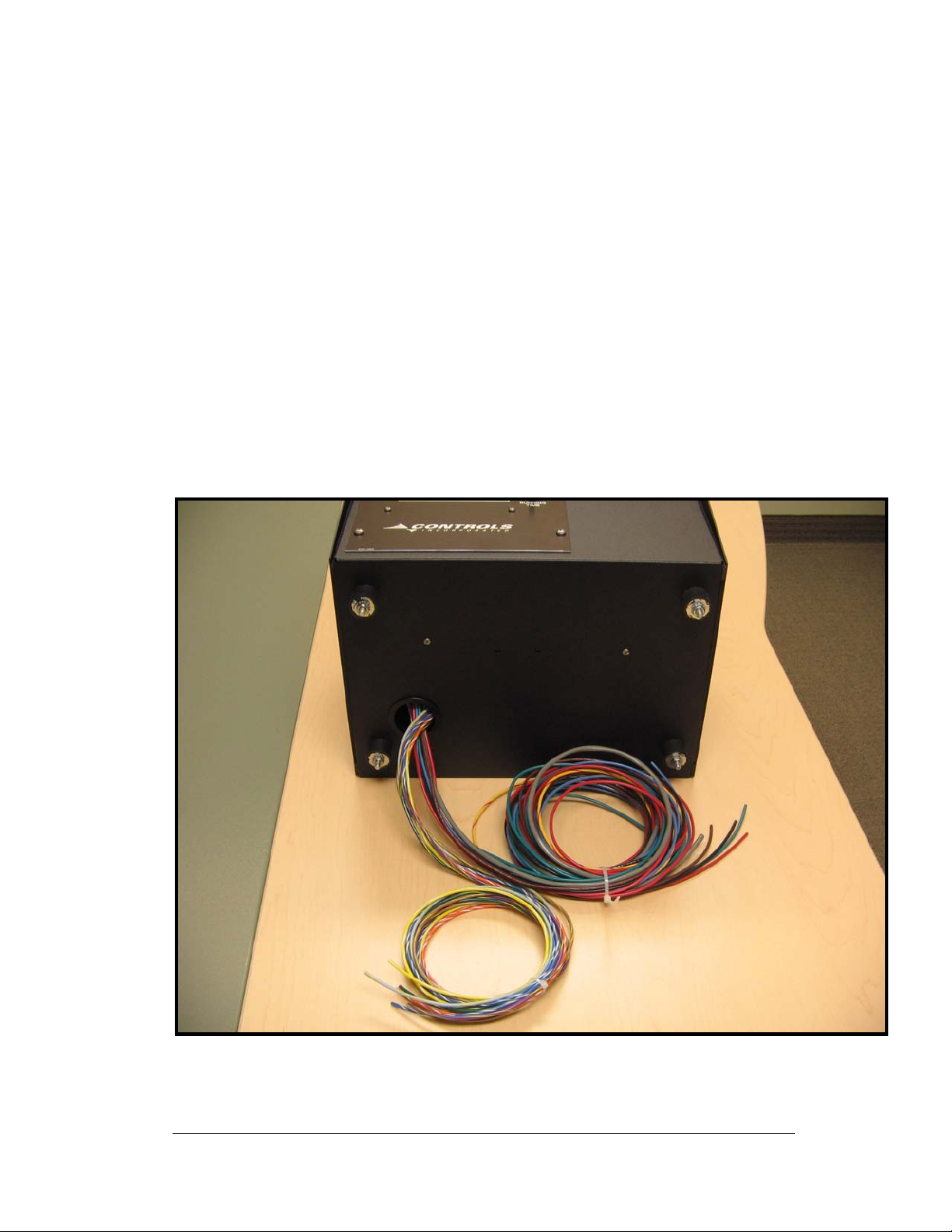

3. Enclosure

• The product is housed in an 14”W x 10”H x 10”D

metal enclosure and supplied with four vibration

isolators to mount the unit to a horizontal surface.

• Removing the eight sheet metal screws holding the

wrapping lid in place can access the inside of the

enclosure.

• Wiring harness exits out a guarded hole in the

bottom of the enclosure.

Wire Harness Exit

AC Harness

GM-H-5-AC

(Sold Separately)

Vibration Isolators

X 4

Engine Harness

GM100-H-10-E

(Sold Separately)

4

Page 6

4. Engine Start & Stop

4.1 The controller is manual and auto start capable.

4.1.1 Manual Operation

4.1.1.1 Turn the panel selector switch to RUN.

4.1.1.2 A message of “Starting Engine” will appear on the display.

4.1.1.3 The controller will engage the starter and fuel systems.

4.1.1.4 The controller automatically crank disconnects when the unit

detects 450 RPM from the engine’s speed sensor or 100+

VAC from the generator output.

4.1.1.5 To stop the engine, move the toggle switch back to the OFF

position.

4.1.1.6 Once the engine has started the controller will begin

monitoring and displaying the engine and generator

parameters.

4.1.1.7 If a fault occurs while the engine is running, the control panel

will open the run circuit to the engine’s fuel system.

4.1.1.8 To clear a fault, the panel selector switch must be cycled to the

OFF position.

4.1.2 Automatic Operation

4.1.2.1 Set the panel selector switch to AUTO.

4.1.2.2 A message of “Unit in Auto” will appear on the display.

4.1.2.3 Closing the remote start circuit to ground will initiate an engine

start sequence.

4.1.2.4 The controller has a cycle crank routine programmed for 5

crank attempts of 10 seconds each.

4.1.2.5 Opening the circuit will initiate an engine shutdown.

4.1.2.6 Note: Ground must be common to the engine battery negative

for reliable remote start signals.

5

Page 7

5. Engine Speed (Frequency) Calibration

5.1 Panel must be calibrated to engine flywheel for proper

frequency display.

5.2 Controller default is 180 pulses per revolution (180 fly wheel

teeth)

5.3 Start engine by placing the toggle switch in the RUN

position.

5.4 Move the Running Time toggle to the Scroll Lock position.

5.5 Adjust engine speed to 1800 RPM. Verify with a hand held

tachometer.

5.6 Locate the hole in the front panel above the LCD. Using

the wooden dowel supplied, press the pcb mounted button

behind the faceplate for 1 second and release.

5.7 Upon release, the Hertz will display 60.0. The control is

now calibrated to the engine flywheel.

6

Page 8

6. Engine Pre Alarms & Alarms

The controller monitors engine oil pressure, engine temperature and engine

speed directly using sensors. If measured parameters become out of

tolerance, the controller will begin to prealarm the specific condition. If the

parameter exceeds the fault values, the controller will open the run signal

causing the engine to shutdown.

6.1 Engine Pre Alarms

6.1.1 In the case of an engine pre alarm, the yellow LED will illuminate.

6.1.2 The engine will continue to run.

6.1.3 If the out of tolerance value is one of the full time display items, the

number will flash every second on the display. (Defaults shown

below)

• Low Fuel Level < 20%

7

Page 9

6.2 Engine Faults

6.2.1 In the case of an engine alarm, the red LED will illuminate.

6.2.2 The controller will open the run circuit causing the engine to stop.

6.2.3 A fault message will be displayed indicating which parameter

caused the controller to stop the engine. (Defaults shown below)

• Low Oil Pressure > 15 PSI for 5 Seconds

• High Engine Temp < 225 F for 5 Seconds

• Low Fuel Level < 1% for 5 Seconds

• Over Speed < 67.0 for 1 Second

• Over Crank

6.2.4 The control panel will keep this message displayed unit a manual

reset done by placing the Auto / Off / Run toggle switch back in the

OFF position.

6.2.5 A fault will also be cleared if a power cycle occurs.

8

Page 10

7. Auxiliary Input / Output Connections

7.1 Aux Inputs

7.1.1 Fuel Level

terminal strip inside the controller. Plug 1 Pin 12 (Light Blue Wire)

7.1.1.1 When a Stewart Warner sender type (240 – 33 ohm) is

connected, fuel level will be displayed in percentage on the LCD.

7.2 Aux Outputs

7.2.1 None

- An analog fuel level sender input is located on the

9

Page 11

8. Engine Sender Types

• Oil Pressure – Stewart Warner 240 – 33 ohm, 0-100

PSI (SD0006 Including with K part numbers)

• Engine Temperature – Stewart Warner 280-EA

Type, 100-255 F (TS4042 Including with K part

numbers)

• Engine Speed – Magnetic Pick Up, 3 VAC minimum

• Fuel Level – Stewart Warner 240 – 33 ohm, 0-100%

TS4042

½” NPT

Temp Sensor

11410-097

5/8”

MPU

SD0006

1/8”

Press Sensor

10

Page 12

9. Generator Sensing

• AC Voltage – Directly from generator output, Up to

600 VAC

• AC Current – Current transformers, 5 Amp output

(XXX: 5). Two required for single phase operation.

Three required for three phase operation. (CTs

Including with K part numbers)

Current

Transformers

11

Page 13

oard

10. Control AC / DC Adjustments

AC Volts

Adjust

AC Circuit

B

CT Input

AC Amps

Adjust

AC Voltage

485 Port

Battery

Adjust

Input

10.1 AC Voltage Adjustment – Using the pcb mounted calibration pots, the

displayed voltage can be adjusted to match

the output of the generator.

10.2 AC Amps Adjustment

– Using the pcb mounted calibration pots, the

displayed current can be adjusted to match the

output of the generator. The adjustment is

limited to the pre-programmed range of the

current transformer inputs. The size of CT’s to

be used must be known at the time of ordering.

12

Page 14

11. Product Warranty

CONTROLS, INC. is herein called “Seller”. The person, firm or corporation to whom

or which the sale is made is herein called “Buyer”. Seller warrants to the Buyer that

all products furnished under this order will conform to Seller’s specification, drawings

as described in its current catalog or quotation and will be free from defects in

materials and workmanship. Seller must approve other special requirements asked

for by the Buyer in its purchase order in writing. Parts replaced or repaired in the

warranty period shall carry the unexpired portion of the original warranty. The

foregoing is subject to the provisions that in no case will the total warranty period

extend beyond twelve (12) months from date seller ships equipment from point of

sale.

The Liability of Seller thereunder is limited to replacing or repairing at Seller’s factory

any part or parts which have been returned to the Seller and which are proved by

buyer as defective or not conforming to Seller’s specifications, drawings or other

written descriptions, accepted by Seller, provided that such part or parts are returned

by the buyer within thirty (30) days after such defect is discovered. All items

returned to Seller for repair or replacement must be sent freight prepaid to its factory.

Buyer must obtain Seller’s Return Goods Authorization prior to returning items. The

above conditions must be met if warranty is valid. Seller will not be liable for any

damage done by unauthorized repair work, unauthorized misapplication in nonsuitable environment.

In no event shall the Seller be liable for loss, damage, or expense directly or

indirectly arising from the use of the units, or from any other cause, except as

expressly stated in the warranty. Seller makes no warranties, express or implied,

including any warranty as to merchantability of fitness for a particular purpose or use.

Seller is not liable for and buyer waives any right or action it has or may have against

seller for any consequential or special damages arising out of any breach of

warranty, and for any damages buyer may claim for damage to any property or injury

or death to any person arising out of its purchase or the use, operation or

maintenance of the product. Seller will not be liable for any labor subcontracted or

performed by buyer for preparation of warranted item for return to Seller’s factory or

for preparation work for field repair or replacement. The Seller will not consider

invoicing of Seller for labor either performed or subcontracted by buyer as a liability.

This warranty shall be exclusive of any and all other warranties express or implied

and may be modified only by a writing signed by an officer of the Seller. With

respect to accessories supplied by Seller, but manufactured by others, there is no

warranty of any kind, express or implied, and specifically there is no warranty of

merchantability or fitness, except as may be set forth in any warranty the

manufactures have made to Seller and which can be passed to the Buyer.

13

Loading...

Loading...