Page 1

INSTRUCTION BOOK

1B20

1B30

1B40

43380204-ENG-01.01-2.5

Printed in Germany

Page 2

A new HATZ Diesel engine - working for you

This engine is intended only for the purpose determined by the manufacturer of the equipment in

which it is installed. Using it in any other manner contravenes the intended purpose.

For danger and damage due to this, Motorenfabrik HATZ accepts no warranty. The risk is with the

user only.

Use of this engine in the intended manner presupposes compliance with the maintenance and repair

instructions laid down for it.

Please do not fail to read this operating manual before starting the engine. This will help you to avoid

accidents, ensure that you operate the engine correctly and assist you in complying with the maintenance intervals in order to ensure long-lasting, reliable performance.

Please pass this Instruction Manual on to the next user or to the following engine owner.

The worldwide HATZ Service Network is at your disposal to advise you, supply with spare parts and

undertake servicing work.

You will find the address of your nearest HATZ service station in the enclosed list.

Use only original spare parts from HATZ. Only these parts guarantee a perfect dimensional stability

and quality. The order numbers can be found in the enclosed spare parts list. Please note the spare

part kits shown in Table 1.

We reserve the right to make modifications in the course of technical progress.

MOTORENFABRIK HATZ GMBH & CO KG

1

Page 3

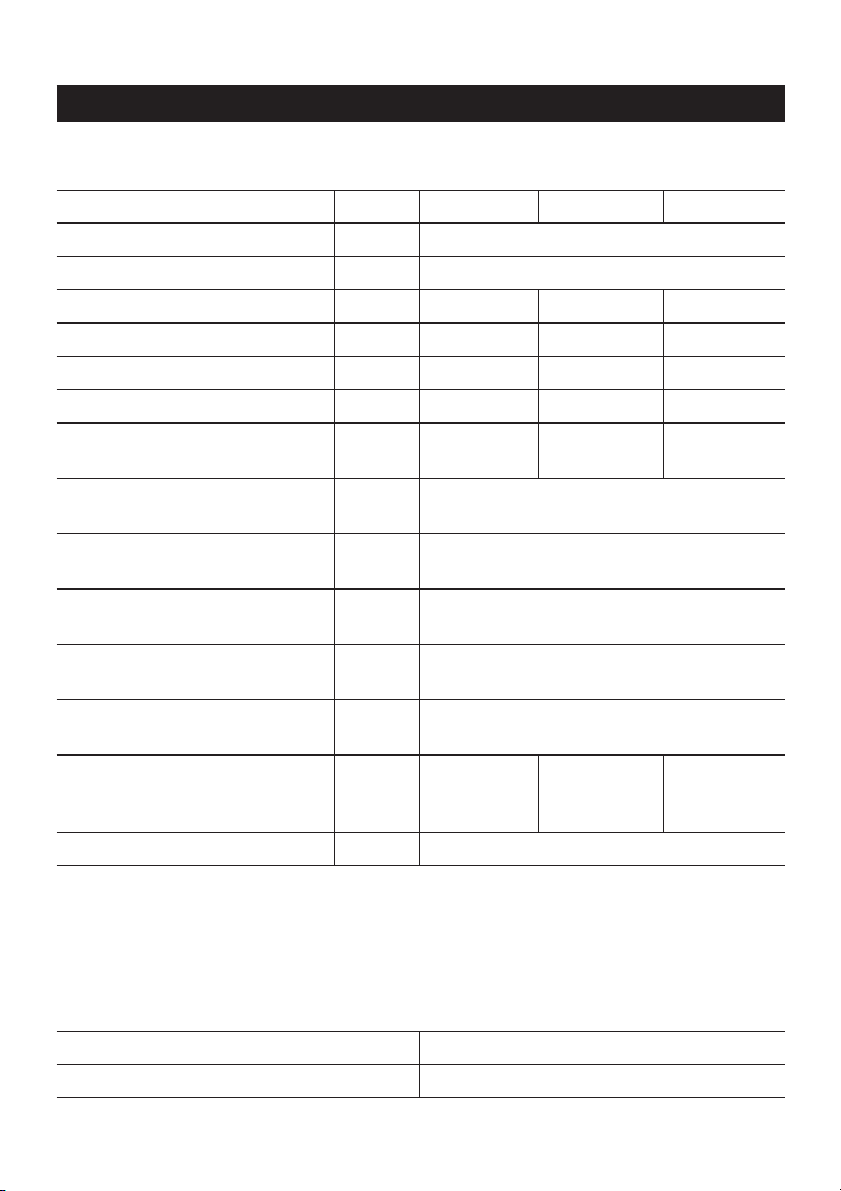

Contents

Page

1. Important safety notes when operating the engine 3

2. Description of the engine 5

3. General notes 6

3.1. Technical data

3.2. Transport

3.3 Notes on installation

3.4. Load on engine

3.5. Type plate

4. Operation 7

4.1. Prior to first-time start-up

4.2. Starting

4.3. Switching off - Stopping

5. Maintenance 12

5.1. Maintenance chart

5.2. Maintenance every 8–15 operating hours

5.3. Maintenance every 250 operating hours

5.4. Maintenance every 500 operating hours

5.5. Maintenance every 1000 operating hours

6. Malfunctions–causes–remedies 19

7. Work on the electrical system 23

8. Storage out of use 23

9. Warranty 23

This symbol identifies important safety precautions.

Please comply with these most carefully in order to avoid any risk of injury to persons or

damage to materials.

General legal requirements and safety regulations issued by the competent authorities or

industrial accident insurers must also be complied with.

2

Page 4

1. Important safety notes when operating the engine

HATZ diesel engines are efficient, strong and durable. For this reason they are frequently installed on

equipment used for commercial purposes.

The manufacturers of such equipment must observe any relevant equipment safety regulations when

the engine forms part of an overall system.

A few general points concerning operating safety should none the less be noted.

Depending on the engine's operating and installation conditions, equipment manufacturers and their

users may have to fit safety or protective devices in order to prevent improper use. Examples:

– Exhaust system components as well as the surface of the engine will naturally be hot and must not

be touched while the engine is running or until it has cooled down after being stopped.

– Incorrect wiring or improper operation of the electrical system may cause sparking and must there-

fore be avoided.

– Provide protection against contact with rotating parts once the engine is connected to the driven

equipment or machine.

HATZ protective guards are available for the belt drive of the cooling fan and alternator drive systems.

– Always observe the start-up information in the operating instructions before starting the engine:

this is particularly important when starting an engine with the recoil starter.

– Mechanical starting devices should not be operated by children or persons deficient in physical

strength.

– Check that all safety devices are in place before starting the engine.

– Ensure that operation, maintenance and repair of the engine are undertaken by suitably trained per-

sonnel only.

– Protect the starter key against unauthorised use.

– Do not run the engine in closed or badly ventilated rooms.

Do not breath in emissions – danger of poisoning!

– Also fuel and lubricants could contain poisonous components. Please follow the instructions of the

mineral oil producer.

3

Page 5

Important safety notes when operating the engine

– The engine must be stopped before performing any maintenance, cleaning- or repair work.

– Stop the engine before refilling the fuel tank.

Never refuel near a naked flame or sparks which could start a fire. Don't smoke. Don't spill fuel.

– Keep explosive materials as well as flammable materials away from the engine because the exhaust

gets very hot during operation.

– Wear close-fitting clothing when working on the engine while it is running.

Please don't wear necklaces, bracelets or any other things which you could get caught with.

– Please pay attention to all advice- and warning stickers placed on the engine and keep them in legi-

ble condition. Contact your next HATZ Servicestation, if a sticker comes off or is illegible and ask

for a new one.

– We accept no liability for damage resulting from improper modifications to the engine.

Regular maintenance in accordance with the details given in these operating instructions is essential

to keep the engine in good working order.

When in doubt, consult your local HATZ service station before starting the engine.

4

Page 6

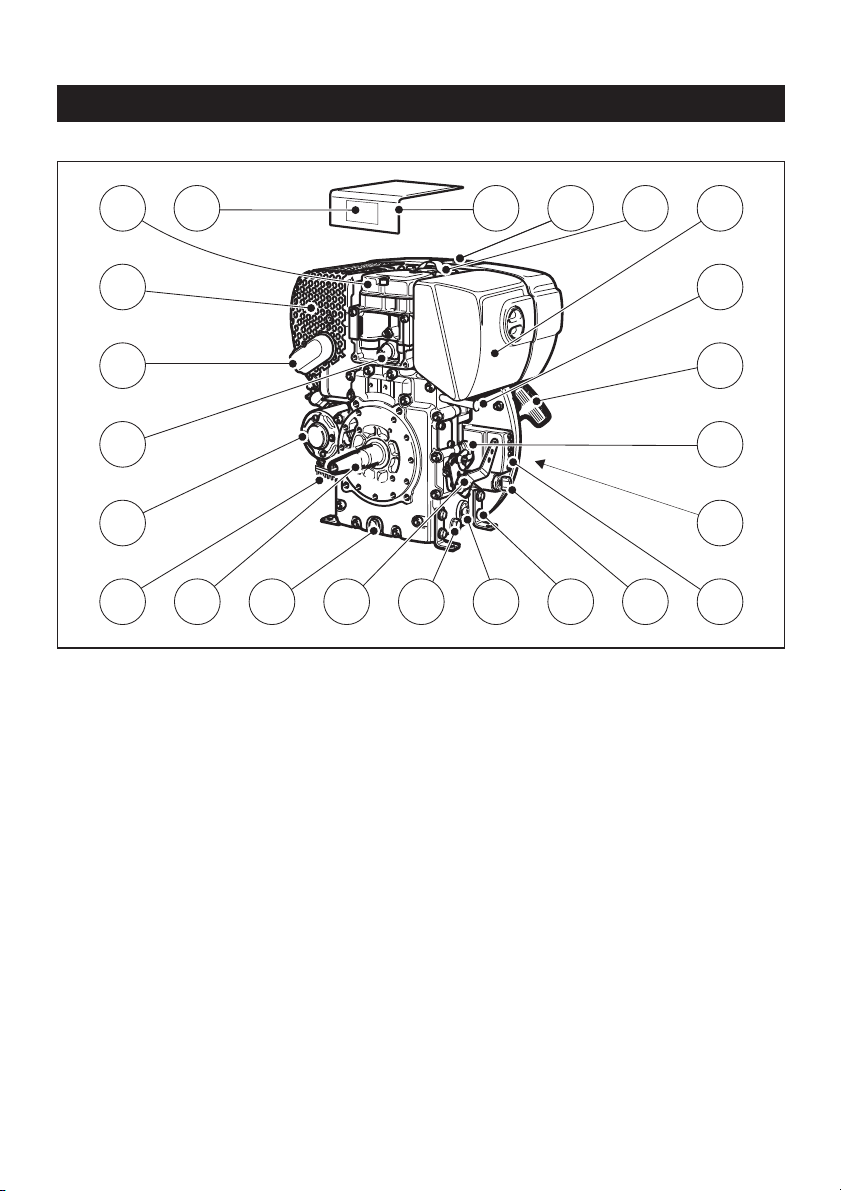

2. Description of the engine

5

Fig. 1

1 Type plate

2 Cylinder head cover

3 Exhaust silencer

4 Exhaust mesh insert

5 Oil pressure switch

6 Starter motor

7 Voltage regulator

8 Crankshaft - power take-off

9 Oil drain plug

10 Speed adjustment lever

11 Oil filter

12 Engine mountings

13 Ignition key

14 LED display

15 Intake opening for cooling and

combustion air

16 Oil filler pipe and dipstick

17 Recoil starter

18 Engine shutdown pin

19 Dry-type air cleaner

20 Lifting lug (see also Fig 32, Pos. 1)

21 Fuel tank cap

22 Noise insulating hood

12

3

4

5

6

7

8910

2122

9

11

12

20

13

19

18

17

16

15

14

Page 7

3. General notes

3.1. Technical data

Type 1B20 1B30 1B40

Design Air-cooled four-stroke diesel engine

Combustion system Direct injection

Number of cylinders 1 1 1

Bore / stroke mm 69 / 62 80 / 69 88 / 76

Displacement cm

3

232 347 462

Lubricating oil capacity l, approx. 0.9* 1.1* 1.5*

Difference between

“max” and “min” levels l, approx. 0.5* 0.5* 0.8*

Lubricating oil consumption

(after running in) approx. 0.5 % of fuel consumption at full load

Lubricating oil pressure

(oil temperature 100 °C) approx. 2.5 bars at 3000 r.p.m.

Direction of rotation,

power take-off end anti-clockwise

Valve clearance 10 - 30 °C

Inlet and exhaust valve mm 0.10

Max. tilt angle in operation, Flywheel 25° down

in direction all other directions 35°

Weight (incl. fuel tank, air-cleaner,

exhaust silencer, recoil starter and kg,

electric starter) approx. 33 38 55

Battery capacity Amp/h max. 12 V / 60 Amp/h

* These values are intended as an approximate guide. The max. marking on the dipstick is the

determining factor, Fig. 7.

Tightening torques

Item Nm

Oil drain plug 50

6

Page 8

3.2. Transport

Standard lifting lug „20“ is to allow

the engine and its auxiliaries to be

transported safely, chap. 2. It is not suitable or

approved for lifting the complete equipment to

which the engine is attached.

3.3. Notes on installation

The „Guide to selecting and installing an engine“

contains all the necessary information on engine

applications if you have an engine which has not

yet been installed in equipment and still has to

be fitted or set up.

This guide is available from your local

HATZ service station.

Do not exceed the forces and torques

indicated on the speed adjustment

lever and the stop pin, otherwise you may

damage the stops and internal governor components. Figure 2.

3.4. Load on engine

Operating the engine for a lengthy period offload or at very low loads can affect its running

quality.

We therefore recommend a minimum engine

load of 15 %. If operated at such low loads, it is

best to operate the engine at a significantly higher load for a short period before switching it off.

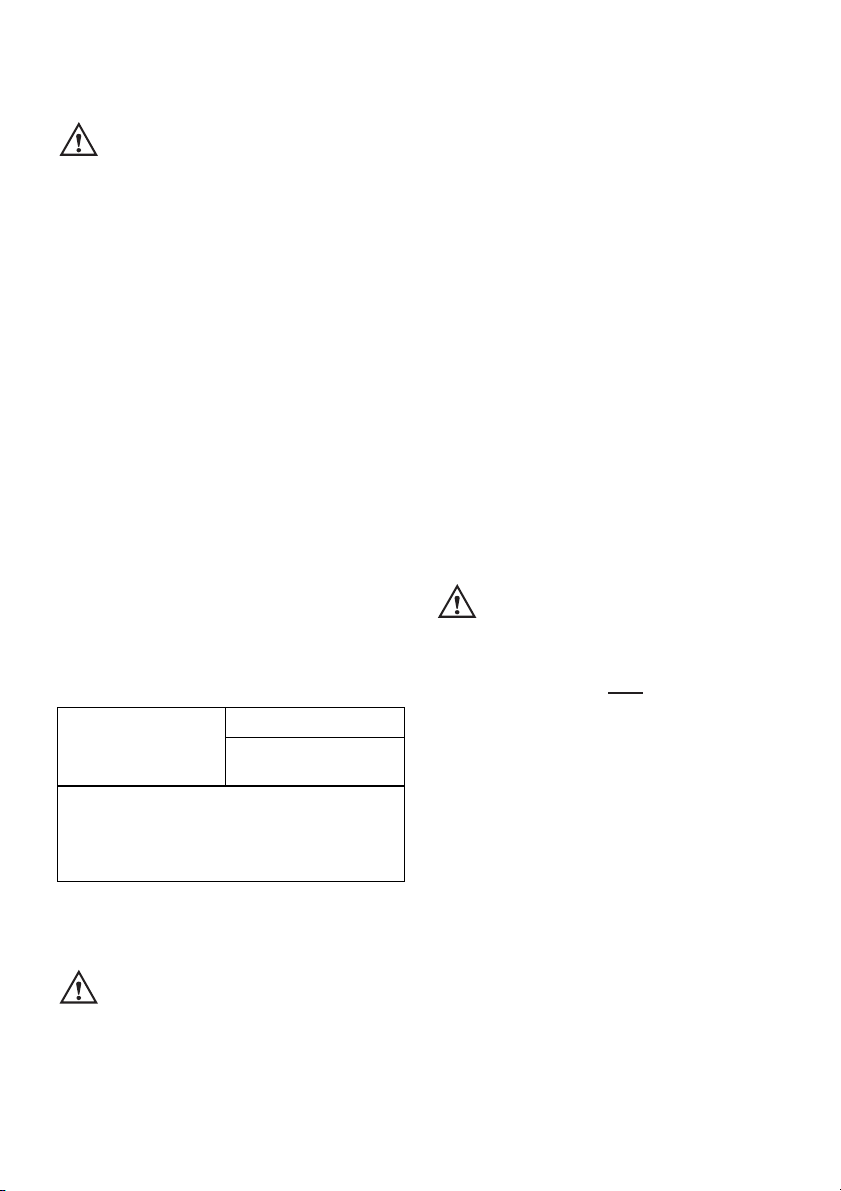

3.5. Type plate

The type plate is placed on the noise insulating

hood (Fig. 1, pos. 1) and includes the following

engine information (Fig. 3):

➀ engine type

➁ code (only for special equipment)

➂ engine number (also stamped on crankcase,

Fig. 4)

➃ max. engine speed

For any offer as well as spare parts orders it is

necessary to mention these data (also see spare

parts list, page 1).

4. Operation

4.1. Before starting up for the first time

Engines are normally supplied dry, i.e. not containing fuel or oil.

4.1.1. Engine oil

Oil quality

CCMC- D4 - D5 - PD2 or

API - CD - CE - CF - CG or

SHPD

If engine oil of a poorer quality is used, reduce

oil change intervals to 150 hours of operation.

Oil viscosity

Select the viscosity class according to the

ambient temperature for cold starts (Fig. 5).

When adding oil or checking the oil level, the

engine must be horizontal.

– Remove oil filler screw and add engine oil,

Fig. 6.

Lubricating oil capacity: see Chapter 3.1.

– To check the oil level, remove the dipstick,

clean it - then screw it back in and finally

remove it again, Fig. 7.

Check the oil level on the dipstick and, if

necessary, top up to the max. level.

4.1.2. Version with oilbath air cleaner

– Take off oil reservoir „1“ and fill with engine oil

as far as the mark, Figs. 8 and 9.

– Insert the filter element into the oil reservoir

with the long end „2“ leading, Fig. 8.

– Attach the oil reservoir, making sure that

sealing ring „3“ is correctly seated and

fasteners „4“ are tight.

7

Page 9

4.1.3. Fuel

Stop the engine before refilling the

fuel tank. Never refuel near a naked

flame or sparks which could start a fire. Don't

smoke. Use only pure fuel and clean filling

equipment. Take care not to spill fuel.

All diesel oils which satisfy the following specifications are suitable:

EN 590 or

DIN 51601 - DK or

BS 2869 A1 / A2 or

ASTM D 975 - 1D / 2D

– Remove fuel tank cap, Fig. 10.

– Fill the fuel tank at least half full with diesel oil,

Fig. 11.

The fuel system does not require to be bled

as this is done automatically.

– Replace fuel tank cap, Fig. 12.

At temperatures below 0 °C, winter-grade fuel

should be used or paraffin added to the fuel well

in advance.

4.2. Starting

Do not run the engine in closed or

badly ventilated rooms – danger of

poisoning! Before starting the engine, ensure

that no-one is in the danger area close to the

engine or equipment, and that all protective

guards are fitted.

4.2.1. Starting procedure

If possible, disengage the engine from any

driven equipment.

The auxiliary equipment should always be placed

in neutral.

– First of all set the speed adjuster to the STOP

position, Figures 13 and 14, then move it to

the starting position.

Speed adjuster, standard version

– Set speed adjustment lever „1“ either to 1/2

START or max. START position, as desired or

necessary (Fig. 13).

Starting at a lower speed will help to prevent

exhaust smoke.

Speed adjuster with pull rod

– Move speed adjuster to the „START/RUN“

position, Figure 14.

Never use starting sprays!

Fig. 15.

4.2.2. Recoil starter with decompression

device (down to –6 °C)

– Starting procedure, see Chapter 4.2.1

The engine has an automatic decompression

system, which allows for a start from any position. However, we would like to recommend the

following procedure:

– Pull the starting cable out by the handle until

you feel a slight resistance, Fig. 16.

– Let the cable run back; in this way the entire

length of the starting cable can be used to

start the engine.

– Devices which are not securely fastened

should be restrained with the foot.

– Grip the handle with both hands, Fig. 17.

8

Lowest ambient

temperature when

starting, in °C

0 up to –10 20 % –

–10 up to –15 30 % –

–15 up to –20 50 % 20 %

–20 up to –30 – 50 %

Paraffin content for:

Summer Winter

fuel fuel

Page 10

– Commence pulling the starting cable vigorous-

ly and at an increasing speed (do not jerk it

violently) until the engine starts, Fig. 18.

On engines with an electric start system the

recoil starter also acts as an emergency-starter.

In this case the automatic decompression

system will switch back to normal compression

at a very low speed.

For this reason, please note that the starting

procedure described previously must be

followed exactly.

Note:

If after several attempts of starting the exhaust

begins to emit white smoke, move the speed adjustment lever to the STOP position and pull the

starting cable out slowly 5 times.

Repeat the starting procedure, Chapter 4.2.1.

4.2.3. Recoil starter without decom-

pression device (special version)

For use in regions with ambient temperatures of

–18 °C or lower, the engines are supplied without a decompression device.

At such low temperatures, only the electric

starter should be used.

The recoil starter serves as an emergency

starting device at higher temperatures (–6°C or

above).

– Prepare the engine for starting;

see Chapter 4.2.1.

– Pull out the handle with the cord slowly until

compression resistance is clearly felt; Fig. 16.

– Continue to pull slowly but with greater force

until the resistance becomes noticeably less

(compression overcome).

– Now let the cord run back - the engine is in

the correct starting position.

In this way the engine can be accelerated

through about one and a half revolutions with

the starting cord, to overcome compression resistance and achieved the required momentum

for starting.

– Support equipment with the foot if it is too

light in weight or liable to tip over.

– Take hold of the handle with both hands;

Fig. 17.

– Pull the starting cord up forcefully and at an

increasing speed (but do not jerk it) - the engine should then start.

4.2.4. Electric starter

– For starting preparations, see Chapter 4.2.1.

– Insert the key and turn it to position I, Fig. 19

and Fig. 20.

Depending upon the model, the battery charge

telltale „2“ and the oil pressure warning light „3“

will come on.

– The engine temperature display „4“ (additional

equipment) lights up if the temperature at the

cylinder head becomes too high.

Switch off the engine and trace and eliminate the cause of the problem, see chapter 6.

– Turn the key to position II.

– Release the key as soon as the engine runs.

The starting key must spring back to position I

and remain there during engine operation.

– The battery charge and oil pressure lights

should extinguish directly after the engine

starts. The display lamp „1“ lights up to show

that the engine is running.

– Prior to starting up again, the key has to be

returned to position 0. When the engine is

running the starter repeat lock in the ignition

switch will prevent the starter from engaging

and suffering damage.

9

Page 11

Preheater system (optional extra)

When starting a cold engine, the preheat indicator „5“ will light, Fig. 19 and Fig. 20.

– Start the engine immediately after the light

goes out.

Fuel shut-off valve, stop solenoid

(additional equipment)

As soon as the starting key is at Position I, fuel

shut-off valve „1“ is electrically released; Fig. 21.

The fuel feed to the injection pump is then open

and the engine is ready to start.

When the engine is running, turning the starting

key to position 0 closes the cut-off valve and interrupts the fuel supply to the injection pump, so

that the engine stops; Chapter 4.3.

This shut-off valve is also used for the automatic

electrical shutdown system.

Emergency start

If the shut-off valve is blocking the fuel supply

as a result of an electrical fault and the engine

therefore cannot be started, an emergency start

can be attempted.

Proceed as follows for this:

– Turn the emergency start lever „1“ approx.

180° counter-clockwise as far as its stop,

using suitable pliers (the lead seal wire will

break off); Fig. 22.

– As soon as the emergency start lever is in the

starting position, the electric starter or recoil

starter can be used; Chapter 4.2.2 and 4.2.3.

The oil level must always be checked before an

emergency start, as insufficient oil pressure

can lead to complete damage of the engine

within a very short time.

After this, the engine can only be

stopped with the starting key in the

emergency operating mode if the emergency

starting lever is first turned back clockwise to

the stop position.

Immediately after a period of emergency running, ascertain the cause of the fault and have it

rectified; Chapter 6.

Have the emergency-starting lever sealed once

again by a HATZ service point.

When the automatic electrical shutdown system

is used, the emergency start described above

means that liability for risks must be accepted

by the operator (not covered by our warranty!)

In case of difficulty contact the nearest HATZ

service point.

Automatic electrical shutdown system

(additional equipment)

Engines with the automatic shutdown system

can be recognised by the externally located instrument box with preheat indicator „5“, Fig. 20.

Important!

If the engine cuts out immediately after starting

or switches off by itself during operation, a

monitoring element in the automatic shutdown

system has tripped. The corresponding indicator

light (Fig. 20, positions 2 - 4) will come on.

After the engine has stopped, the display continues to glow for about 12 seconds.

The electrical device then switches itself off automatically.

The display lights up again after the start key

has been turned back to position 0 and then to

position I again.

Trace and eliminate the cause of the operating

fault before trying to restart the engine

(see chapter 6).

The display light goes out when the engine is

next started.

Even with automatic shutdown monitoring the

oil level must be checked every 8 – 15 operating hours (Chapter 5.2.1.).

10

Page 12

4.3. Stopping the engine

Speed adjuster, standard version

– Move the speed adjustment lever „1“ back

to the STOP position. The engine cuts out,

Fig. 13.

Note:

Engines with a fixed lower idling speed cannot

be switched off using the speed adjustment

lever. See the paragraph entitled „Other ways of

switching off the engine“.

Speed adjuster with pull rod

(optional extra)

– Move the speed adjuster to the „STOP“ posi-

tion and press it until the engine cuts out,

Fig. 14.

Other ways of switching off the engine

1. Fuel shut-off valve, stop solenoid

(optional extra)

– Turn ignition key to the 0 position. The engine

cuts out, Fig. 19 and Fig. 20.

2. Stop pin (optional extra)

– Press the stop pin „2“ until the engine cuts

out, Fig. 13.

– Once the engine has cut out, release the

pin „2“ and ensure that it returns to its initial

position.

Depending upon the model, the battery charge

indicator „2” and oil pressure warning indicator

„3“ will come on again after the engine comes to

a stop, Fig. 19 and Fig. 20.

– Turn the key to position 0 and remove it.

All the indicator lights must go out, Fig. 19

and Fig. 20.

Note:

Failure to return the starter key to position 0

may result in the battery being totally

discharged.

If operation of the engine is inter-

rupted for any reason, or at the end of

the working day, the starter key should be kept

out of reach of unauthorised persons.

11

Page 13

5. Maintenance

Only carry out maintenance work with the engine switched off.

Observe all relevant laws and regulations governing the handling and disposal of used

oil, filters and cleaning agents.

Protect the starting key against unauthorised use.

On engines with an electric starter, disconnect the battery's negative terminal.

When maintenance work has been completed, check that all tools have been removed from

theengine and all protective guards fitted again.

Before starting the engine, ensure that there are no persons in the danger area close to the

engine or equipment.

5.1. Maintenance chart

12

Maintenance interval Maintenance work required

Chap.

Every 8 – 15 operating

hours, or before each

daily start-up

Check oil level.

Examine the lower section of the oilbath air

cleaner to ensure correct oil level and freedom

from contamination; change the oil if it contains

sludge.

On version with cyclone-type dust trap, empty the

dust collector.

Check combustion and cooling air intake zone.

Check air-cleaner maintenance indicator.

Check the water trap.

5.2.1.

4.1.2.

5.3.1.

5.3.1.

5.2.2.

5.2.3.

5.2.4.

Every 250

operating hours

Oilbath air cleaner maintenance.

Change engine oil.

Check and adjust valve clearances.

Clean cooling air area.

Check screw connections.

Clean mesh insert for exhaust.

5.3.1.

5.3.2.

5.3.3.

5.3.4.

5.3.5.

5.3.6.

Every 500

operating hours

Change fuel filter element.

Dry-type air cleaner maintenance.

5.4.1.

5.4.2.

Every 1000

operating hours

Clean the oil filter. 5.5.1.

8-15

250

500

1000

Page 14

The above maintenance chart is supplied with

every engine. This label should be affixed to the

engine or equipment in an easily visible position.

The maintenance chart governs the maintenance

intervals.

On new or reconditioned engines, after the

first 25 operating hours, always

– Change engine oil, Chapter 5.3.2.

–

Check valve clearances and adjust if necessary,

Chapter 5.3.3.

– Check screw connections for tightness,

Chapter 5.3.5.

If the engine is not used frequently, change the

engine oil after 12 months at the latest, regardless of the actual number of hours it has been in

operation.

13

8-15

250

IN 0.1 mm

0.004 "

EX 0.1 mm

0.004 "

°C°F

OIL: SAE...

122

4050104

30

86

20

68

5W/40

10

50

5W/30

10W / 3 0

0

32

10W

-10

14

-20

-4

-30

-22

-40

-40

OIL

OIL

40

30

15W / 4 0

10W / 4 0

500

1000

051 104 02

1B20

Page 15

5.2. Maintenance every 8 - 15

operating hours

5.2.1. Checking engine oil level

To check the oil level, the engine must be

standing level and be switched off.

– Remove any dirt from the oil dipstick area.

– Remove dipstick and clean it.

– To check the oil, screw the dipstick back in

and then remove it again, Fig. 7.

– Check the dipstick oil level and, if necessary,

add oil to the max. mark, Chapter 4.1.1.

5.2.2 Check air intake area for

combustion and cooling

Heavy contamination is an indication that increased dust accumulation necessitates a correspondingly shorter maintenance interval,

Chapter 5.3.1., 5.3.4. and 5.4.2.

– Check air intake points for severe blockage

due to leaves, heavy dust accumulation etc.,

and if necessary clean them, Fig. 23.

On version with oilbath air cleaner, also check

air intake area „2“, Fig. 28.

5.2.3. Check air cleaner maintenance

indicator (optional extra)

Mechanical service indicator

– Increase the speed of the engine briefly to the

maximum.

If the rubber bellows shrinks and covers the

green area „1“, the air cleaner system should

be serviced, Figure 24, Chapter 5.4.2.

Under dusty conditions, check the rubber bellows several times per day.

5.2.4. Checking the water trap

The intervals at which you should check the

water trap depend entirely on the amount of

water in the fuel and the care taken when refuelling. The normal interval is once a week.

– Loosen hexagon screw „1“ with approx.

3-4 rotations; Fig. 25.

– Trap the drops which emerge in a transparent

vessel. Since water has a greater specific gravity than diesel fuel, the water emerges before

the diesel fuel. The two substances separate at

a clearly visible line.

– As soon as diesel only emerges at screw „1“,

this can be tightened again.

If an external water trap is attached, check its

water content every day, when the engine oil

level is checked. The water which has collected

is separated at a clearly visible line from the

diesel fuel above it.

– Open drain plug „1“ and drain the water out

into a suitable vessel; Fig. 26.

– If the drain plug is difficult to reach, an exten-

sion hose can be attached to it.

14

Page 16

5.3. Maintenance every 250

operating hours

5.3.1. Oilbath air cleaner maintenance

– Take off oil reservoir „1“ and clean it, Fig. 27.

– Rinse out filter element „2“ in diesel oil; allow

it to drip thoroughly and wipe it down before

re-assembling the air cleaner.

– If severely contaminated, clean filter

housing „3“.

Never attempt to repair the oilbath air cleaner by

welding, brazing etc., as this could damage the

filter beyond repair and cause engine damage.

– Re-attach parts previously removed from the

air cleaner and add oil so that it is ready for

use, Chapter 4.1.2.

Version with cyclone-type dust trap

– Take off dust collector „1“, empty it and

wipe clean (dust collector must remain dry),

Fig. 28.

– Clean intake aperture „2“ (also keeping it dry).

Important:

Do not add any oil to the dust collector.

– Attach the cyclone-type dust trap and secure

with the wing nut.

5.3.2. Changing engine oil

The engine must be standing level and be

switched off.

Only change the oil when the engine is warm.

Danger of scalding from hot oil!

Trap the old oil and dispose of it in

accordance with local legislation.

– Take out oil drain plug „1“ and allow the oil to

drain out, Fig. 29.

– Clean the oil drain plug „1“, fit a new washer

„2“,

insert and tighten.

Tightening torque: 50 Nm.

– Add engine oil, Chapter 4.1.1.

5.3.3. Checking and adjusting valve

clearances

Only carry out adjustments when the engine is

cold (10 - 30 °C).

– Remove air cleaner cover, fig. 30 and noise-

insulating hood, Fig. 31.

– On version with oilbath air cleaner, remove

screw „2“ and take off cover plate with noiseinsulating hood, Fig. 32.

– Remove any contamination adhering to the

cover for the cylinder head.

– Remove screws „1“ (two screws on 1B20 and

1B30 engines, three screws on 1B40 engines)

and take off the cylinder head cover with gasket „2“, Fig. 33.

– Remove rubber cap from the inspection hole

cover, Fig. 34.

– Turn the engine over in the normal direction of

rotation until the valves are in the overlap position (exhaust valve not yet closed, inlet valve

starts to open).

– Turn the crankshaft through 360° in the

normal direction of rotation and align exactly

to the • • •-marking, Figure 34.

– Check valve clearances with feeler gauge „1“

(0.10 mm), Fig. 35.

– If valve clearances require adjusting, slacken

off screw „2“ and turn hex nut „3“ until feeler

gauge „1“ can be pulled through with just

slight resistance when screw „2“ is retightened.

– Fit cover for cylinder head and tighten evenly,

always using a new gasket.

15

Page 17

– Re-attach parts previously removed from

engine.

Do not forget: replace the rubber cap at the

inspection hole cover.

– Carry out a brief test run, then check the cover

for leaks.

5.3.4. Cleaning the air cleaner zone

The engine must be switched off and

cooled down before cleaning!

– If severely contaminated, clean the cooling fins

on the cylinder and cylinder head, and also the

fan blades in the flywheel. If necessary, contact your local HATZ service station.

5.3.5. Checking screw connections

– Check the engine mounting screws for tight-

ness.

The adjusting screws at the engine

governor and on the injection system

are sealed with lacquer and are not to be tightened or adjusted, Fig. 36.

5.3.6. Cleaning the exhaust mesh inlet

Exhaust system components will natu-

rally be hot and must not be touched

while the engine is running or until it has

cooled down after being stopped.

– Unscrew hex nut and remove the exhaust

mesh insert, Fig. 37.

– Remove any deposits in the mesh insert by

means of a wire brush.

– Check the exhaust mesh insert for cracks or

damage and, if necessary replace with a new

one.

– Screw on hexagon nut „1“ by approx. 1 turn,

Fig. 38.

– Insert exhaust screen with hoop „1“ into hole,

them pull outwards again so that the hoop is

retained, Fig. 39.

– Tighten the hexagon nut fully.

16

Page 18

5.4. Maintenance every 500

operating hours

5.4.1. Renewing fuel filter

The maintenance intervals for the fuel filter are

dependent upon the purity of the diesel oil being

used and, if necessary, may have to be reduced

to 250 hours.

When working on the fuel system, do

not expose it to naked flames; do not

smoke.

Important:

Keep the entire area clean so that no dirt

reaches the fuel.

Model with fuel filter in fuel tank

– Open the tank cover and pull the fuel filter out

of the tank by its cord; Fig. 40.

– Pull fuel supply line „1“ off fuel filter „2“ and

insert a new filter, Fig. 41.

– Fit the fuel filter again and close the tank cap.

Bleeding of the fuel injection system takes

place automatically.

Model with external fuel filter

– Empty the fuel tank by taking out screw „1“,

Fig. 25 or Fig. 26 and allow the fuel to drain

into a clean vessel. This fuel can be re-used

later.

– Unscrew the fuel filter from its mount, Fig. 42.

– Place a suitable vessel under the filter to trap

the residual fuel.

– Pull off fuel supply line „1“ at both ends of fuel

filter „2“ and insert the new filter, Fig. 43.

– Always renew the fuel filter. Note the arrows

indicating the correct direction of flow.

– Secure the filter to its mount.

– Fill the fuel tank with diesel oil; Chapter 4.1.3.

Air is vented from the fuel system automatically.

– Check the fuel filter and lines for leaks after a

short test run.

5.4.2. Air cleaner maintenance

The filter cartridge should only be cleaned when

the maintenance lamp lights at maximum speed,

Chap. 5.2.3.

However, the filter cartridge should always be replaced after 500 operating hours at the latest.

– Remove the air cleaner cover, Fig. 30.

– Unscrew and remove knurled nut „1“ and take

off air cleaner element „2“, Fig. 44.

– Clean the filter compartment and the cover.

Dirt and other foreign bodies must not be

allowed to enter the engine’s air inlet points.

– On versions with a mechanical air cleaner

service indicator, check the condition and

cleanliness of valve plate „1“, Figure 45.

– The filter cartridge should either be renewed

or, depending upon the degree of contamination, cleaned, or checked, as follows:

Cleaning the filter cartridge

Dry contamination

Use compressed air to blow through the filter

cartridge from the inside outwards, until no further dirt emerges, Fig. 46.

Important!

The pressure must not exceed 5 bar.

Moist or oily contamination

Renew the filter cartridge.

17

Page 19

Checking the filter cartridge

– Check filter cartridge's gasket surface „1“ for

damage, Fig. 46.

– Check the filter cartridge for cracks or any

other type of damage to the paper filter by

holding it inclined towards the light or by

shining a light source through it.

Important!

The slightest damage to the paper filter rules

out it being used any longer.

– Re-assemble the filter cartridge in the reverse

order of work.

5.5. Maintenance every 1000

operating hours

5.5.1. Cleaning the oil filter

The oil filter should be cleaned at the same time

as the engine oil is changed, since oil escapes

when the filter is removed.

The engine must be standing horizontally and

switched off.

Danger of scalding from hot oil!

Trap the old oil and dispose of it in

accordance with local legislation.

– Loosen screw „1“ with approx. 5 rotations,

Fig. 47.

– Remove oil filter from housing, Fig. 48.

– Use an air line to blow out oil filter dirt from

the inside outwards, Fig. 49.

– Check joint washer „1“ whether it is damage;

replacement if necessary, Fig. 50.

– Check joint washer „2“ whether it is damage

and correctly fitted, replace oil filter if neces-

sary.

– Lubricate joint washer before fitting.

– Put in oil filter and press until limit stop,

Fig. 51.

– Check whether tension springs sit close to oil

filter with both ends „1“, before tightening

screw.

– Check the oil level and restore to the max.

level if required, Chapter 4.1.1.

18

Page 20

6. Malfunctions – causes and remedies

Malfunctions Possible causes Remedy Chap.

19

6.1.

Engine does not

start, or not immediately, but can be

turned over easily

as usual.

At low

temperatures.

Speed control lever in stop or

idle position.

Engine shutdown pin in STOP

position.

No fuel in the injection pump.

Insufficient compression:

-Incorrect valve clearance.

-Valves worn.

-Cylinders and/or piston rings

worn.

Injector not functioning.

Below starting threshold

temperature.

Equipment not disengaged.

Preheating system faulty

(optional extra).

Fuel has inadequate resistance

to low temperatures.

Move lever to START position.

Move to operating position by

pulling the pin gently.

Add fuel.

Systematically check the entire

fuel supply system:

If still no fault found,

-check engine feed line

-check fuel filter

Check valve clearances, adjust if

necessary.

See workshop manual.

See workshop manual.

See workshop manual.

Operate preheater

(optional extra).

Disengage engine from equipment, if possible.

See workshop manual.

Check whether clear (not turbid)

fuel emerges at the fuel line detached from the injection pump.

If turbid or separated - either

warm up the engine or drain the

complete fuel supply system.

Refill with winter-grade fuel to

which paraffin has been added.

4.2.1.

4.3.

4.1.3.

5.4.1.

5.3.3.

4.2.4.

4.1.3.

Page 21

Malfunctions Possible causes Remedy Chap.

20

At low

temperatures:

If equipped with a

stop solenoid or

automatic electrical shutdown system (additional

equipment)

6.2.

Engine fires but

does not run.

Automatic

electrical shut-off

device

(optional extra)

6.3.

Starter motor does

not operate or engine does not turn

over.

Starting speed below 400 min

-1

-Viscosity of oil too high.

-Battery charge too low.

Solenoid faulty and/or fault in

the electrical system.

Speed control lever not moved

far enough towards „START“.

Equipment not disengaged.

Fuel filter blocked.

One of the automatic shutdown's monitoring elements

has initiated a stop signal.

(See also Chapter 6.4.)

Fault in the electrical system:

-Battery and/or other cables

incorrectly connected up.

-Cable connections loose and/or

oxidised.

-Battery faulty and/or flat.

-Starter motor faulty.

-Faulty relays, monitoring

element.

Change lubricating oil and add

oil of the correct viscosity class.

Check the battery, if necessary

contact a service station.

See workshop manual.

Move lever to „START“ position.

Disengage engine from equipment if possible.

Renew fuel filter.

Localise the monitoring element

responsible and clear the fault,

or contact a

HATZ service station.

Check electrical system and its

component. See also the workshop manual.

5.3.2.

4.1.1.

7.

4.2.1.

5.4.1.

7.

Page 22

Malfunctions Possible causes Remedy Chap.

21

Fuel supply interrupted

-Tank has run empty.

-Fuel filter blocked.

-Tank venting inadequate.

Mechanical faults.

One of the automatic shutdown's

monitoring elements has initiated a stop signal.

Monitoring element for:

-oil pressure too low

-engine temperature too high

-defective alternator.

Fuel supply interrupted:

-Tank has run empty.

-Fuel filter blocked.

-Tank breathing inadequate.

-Speed control lever does not

remain in desired position.

Air cleaner contaminated.

Valve clearances incorrect.

Injector not functioning.

Add fuel.

Change fuel filter.

Ensure adequte tank venting.

Contact a HATZ service station.

Localise the monitoring element

responsible and clear the fault,

or contact a

HATZ service station.

Check oil lubrication.

Check air cooling zone for contamination.

See workshop manual.

Add fuel.

Change fuel filter.

Provide adequate tank breathing.

Lock the lever into position.

Clean or renew the air cleaner.

Adjust valve clearances.

See workshop manual.

4.1.3.

5.4.1.

5.2.1.

5.3.4.

4.1.3.

5.4.1.

5.3.1.

5.4.2.

5.3.3.

6.4.

Engine cuts out of

its own accord

during operation.

Automatic

electrical shut-off

device

(optional extra)

6.5.

Engine output and

speed both drop.

6.6.

Engine output and

speed fall, black

smoke from exhaust.

Page 23

Malfunctions Possible causes Remedy Chap.

22

6.7.

Engine becomes

very hot. Indicator

lamp for cylinder

temperature

(optional extra)

comes on.

6.8.

Moisture condensate emerging

from exhaust.

Too much lubricating oil

in engine.

Inadequate cooling:

-Contamination of entire

cooling air zone.

-Air duct panels not

properly sealed.

Operation off load for a prolonged period.

Drain off lubricating oil as far as

upper mark on dipstick.

Clean cooling air zone.

Check cooling air deflector

plates and shafts for completeness and airtight seal.

Operate the machine at about

70 % load until moisture no

longer emerges from the exhaust.

5.3.2.

5.3.4.

Page 24

7. Work on the electrical

system

Batteries generate explosive gases.

Keep them away from naked flame and

sparks which could cause them to ignite.

Do not smoke.

Protect eyes, skin and cloth against the corrosive battery acid. Pour clear water over acid

splashes immediately. In case of emergency

call doctor.

Do not place any tools on top of the battery.

– Do not confuse the positive (+) and

negative (–) terminals of the battery.

– When fitting the battery, first connect up the

positive lead, then the negative lead.

Negative terminal to earth = engine block.

– When removing, first disconnect the negative

lead, then the positive lead.

– Always take care to avoid short-circuits and

earth (ground) contact of live cables.

– If malfunctions occur, first of all check that

cable connections make good contact.

– Replace a failed indicator light without delay.

– Do not remove the ignition key while the en-

gine is running.

– Do not disconnect the battery while the en-

gine is running.

– Do not spray water on to components of the

electrical system when cleaning the engine.

If this is unavoidable, disconnect the battery

first and carefully blow all components dry

before reconnecting.

– When carrying out welding work on the en-

gine or equipment, fit the earth clip of the

welding equipment as close to the welding

point as possible and disconnect the battery.

The connecting plug for the voltage regulator

must be removed.

The relevant circuit diagrams are enclosed with

the engine if it is equipped with an electrical system. Additional circuit diagrams can be supplied

to order.

Electrical systems that do not comply with HATZ

circuit diagrams are excluded from warranty.

8. Storage out of use

The new engine can normally be stored dry for

up to one year.

In very humid climates or coastal regions, the

protective treatment is sufficient for up to about

6 months.

For longer periods of storage, please contact

your nearest HATZ service station.

9. Warranty

Not applicable for the U.S.A. and Australia.

The right to claim under guarantee lasts for a

period of 12 up to 24 months (according to the

equipment) or for a maximum of 2000 working

hours, depending which criteria are met first.

Warranty is granted according to the terms stated in our warranty agreements, details of which

are available from every HATZ service station.

23

Page 25

F<15 N STOP

2

GMBH

CO

+

3

6

7

4

5

MOTORENFABRIK HATZ KG

D-94099 RUHSTORF

TYP

MOTOR/ FABRIK NO.

KENNZ.

ABE/AUSF.

GMBH

+

CO

<

F 30 N

<

M 2.3 Nm

-1

MIN NH PV CM

3

76.5°

STOP

START

MADE IN GERMANY

°C°F

OIL: SAE...

50

122

40

104

30

86

20

68

10

50

0

32

-10

14

-20

-4

-30

-22

-40

-40

5W/40

5W/30

15W/40

10W/40

10W/30

10 W

30

40

2438 / 1

max.

Page 26

2440 / 10

8

9

12 13

10

11

2444 / 5

2439 / 12

2439 / 16

2439 / 9

Page 27

14

050 145 00

15

18 19

16

17

2438 / 17

2441 / 3

2444 / 17

Page 28

1

20 21

24

25

22

23

2

3

4

5

2438 / 12

1

1

Page 29

26

27

30 31

28

29

1

2444 / 3

2440 / 13

2443 / 12

2445 / 3

Page 30

2442 / 18

32

33

36

37

34

35

2

1

23

1

2

3

2119 / 3

2442 / 6

Page 31

2441 / 12

38 39

42 43

40

41

2441 / 8

Page 32

2442 / 3

44

45

48

49

46 47

2444 / 10

1

2445 / 10

Page 33

50 51

Page 34

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State

of California to cause cancer, birth

defects, and other reproductive harm.

Loading...

Loading...