Winco 1800-12, 1800-13, 700-13, 1800-14, 1800-15 Owner's Manual

...

I

OWNER'S MANUAL

..

ILMSBRUCTIOFIIS

A.

C.

GENERATORS

8

Model

700

Series

Model

1800

Series

I

Model

3030

Series

:.-

I

MODEL

1800

MODEL

700

I

I

If

any correspondence is required regarding these generators, always be sure to

furnish the model number and serial number

stqmped on the generator nameplate.

I

WINCHARGER CORPORATION

1

SIOUX CITY

2,

IOWA,

U.

S.

A.

Form

SR214,

Part

No.

20757

I

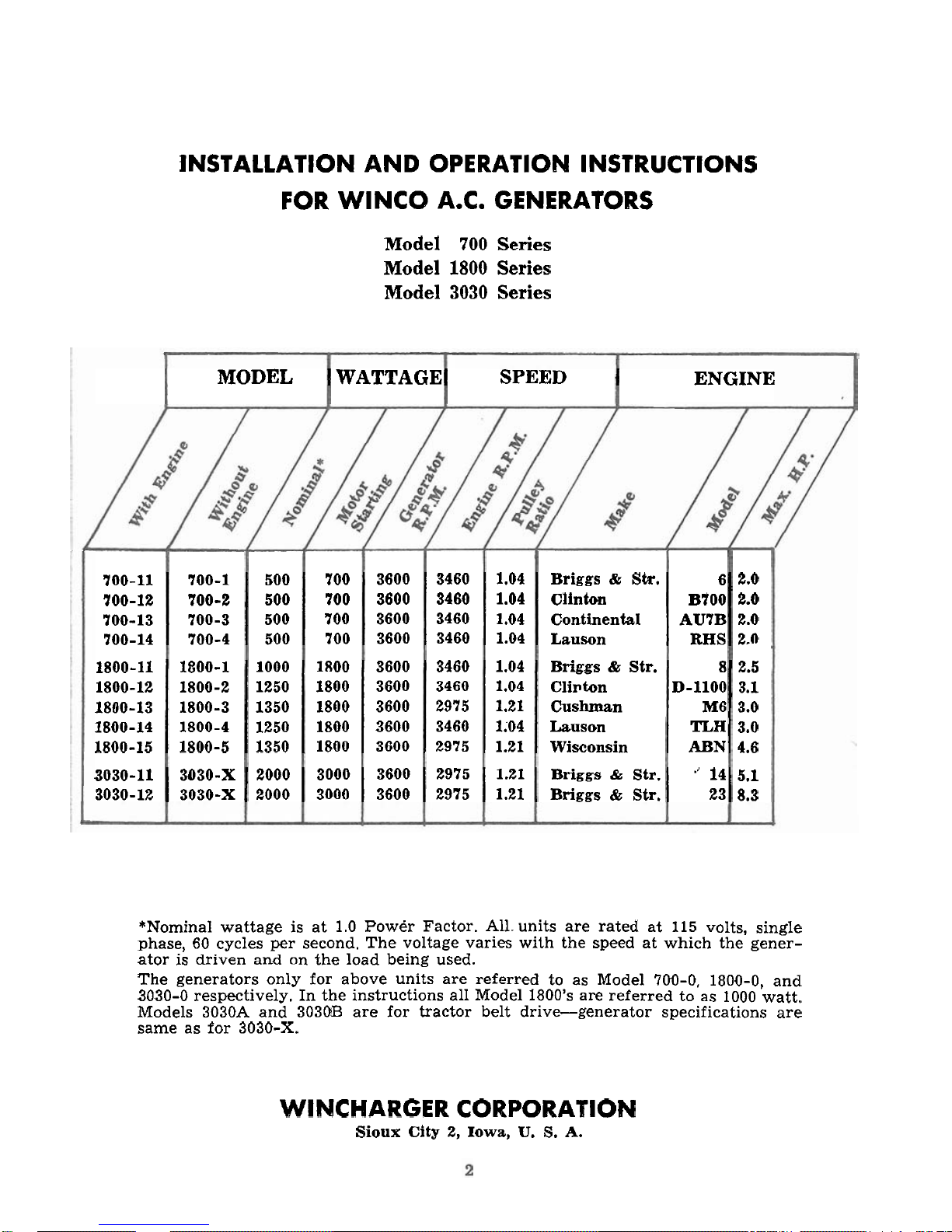

INSTALLATION AND OPERATION INSTRUCTIONS

FOR

WlNCO

A.C.

GENERATORS

Model 700 Series

Model 1800 Series

Model 3030 Series

MODEL WATTAGE SPEED ENGINE

700-11 700-1

500

700 3600

3460 1.04

Briggs

&

Sir. 6 2.0

700-12

700-2

500

700 3600

3460 1.04

Clinton

B700

2.0

700-13 700-3 500 700 3600 3460 1.04 Continental

AU7B

2.0

700-14 700-4 500 700 3600 3460 1.04

Lauson

RHS

2.n

1800-11

1800-1

1000 1800

3600 3460 1.04

Briggs&Str. 8 2.5

1800-12 1800-2 1250

1800

3600 3460 1.04

Clipton D-1100 3.1

1800-13 1800-3

1350

1800 3600

2975 1.21

Cushman M6 3.0

1800-14 1800-4

1250 1800

3600 3460 1.04

Lauson

TLW

3.0

1800-15

1800-5

1350 1800 3600

2975 1.21

Wisconsin

ABN

4.6

3030-11

3030-X

2000 3000

3600 2975 1.21

Briggs& Str.

"

14 5.1

3030-12

3030-X 2000 3000 3600

2975

1.21

Briggs&Str. 23 8.3

*Nominal wattage is at

1.0

Power Factor. All. units are rated at

115

volts, single

phase,

60

cycles per second. The voltage varies with the speed at which the gener-

ator

is

driven and on the load being used.

The generators only for above units are referred to as Model

700-0, 1800-0,

and

3030-0

respectively. In the instructions all Model

1800's

are referred to as

1000

watt.

Models

3030A

and

303OB

are for tractor belt drive-generator specifications are

same as for

3030-X.

WINCHARGER CORPORATION

Sioux City 2, Iowa,

U.

S.

A.

TABLE OF CONTENTS

I. INTRODUCTION

4

A.

Testing

B. Unpacking

C. Guarantee

11. INSTALLATION

--------------

........................

4

A.

Portable Use

B. Transfer Switch

C. Flexible Cord

111. FRAMES----------------------------------------

5

A.

500-1000 Watt Models

1.

Engine Base Holes

2.

Mounting

3.

Belt Tightening

4.

Checking Lineup

B. 2000 Watt Models

1.

Pulleys

2.

Mounting

3.

Belt Tightening

4.

Checking Lineup

IV. GENERATORS

........................................

6

A.

Design

B. Performance characteristics

C. Speed

D. Overload Protection

V.

ENGINES----------------------------------------

7

A.

Lubrication

B. Manuals

VI. POWER REQUIREMENTS

..............................

7

A.

Engine Size

B. Altitude-Temperature

VII. USE OF A.C. MOTORS

.................................

7

VIII. MAINTENANCE

.......................................

8

X.

PARTS LIST

...........................................

10

XI. TRACTOR DRIVEN UNITS

.............................

10

XII. ACCESSORIES 12

Models

700, 1800,3030

8.

INTRODUCTION

Each generator is carefully inspected at

the factory and "run-in" until the brushes

are satisfactorily seated. The unit is then

carefully checked for correct output under

average operating conditions. NO GENERATOR IS SHIPPED UNLESS IT PRODUCES ITS FULL RA'IYCD CAPACITY,

NOR UNTIL IT HAS PASSED RIGID INSPECTION TESTS. If uwon installation a

new generator does noi work properly,

check all of the electrical connections and

the generator speed before concluding that

the generator is not performing satisfactorily.

when unpacking the machine, be sure to

inspect it carefully to see that no damages

occilrred in transit. If damages are noted,

notify the transportation company immediately and have them write the

nature of the damages on the freight

bill, so that a claim can be filed if necessary.

Each

AC generator is guaranteed to be

free from defects in workmanship and

material arising in connection with normal

usage for a period of one year, provided

that the owner returns his guarantee registration card within

10 days after purchasing the unit. Fill in the information

requested on the registration- card and

return it,

so

the guarantee can be issued

to

you.

etc. directly into the outlet terminals. The

outlet box is equipped with lock-type receptacles which prevent the plugs from

working loose.

To operate permanently

connecte~

motors, etc. on a standby basis, provision

must be made to

prevent the generated

current from "feeding back" into the power

line where it could be a hazard to linemen

and other users.

ALL WIRING

IS

TO BE DONE IN CON-

FORMANCE

WITH

-NATIONAL

ELEC-

TRICAL CODE AND WITH STATE AND

LOCAL REGULATIONS.

The conductor from the transfer switch

to the generator can be made of No.

14

type

S

cord for distance up to 25 feet. Always

use the twist-lock plug for making these

connections permanently.

When starting the generator, turn off the

load or reduce it. If too many light bulbs

are left on, the generator may fail to build

up voltage.

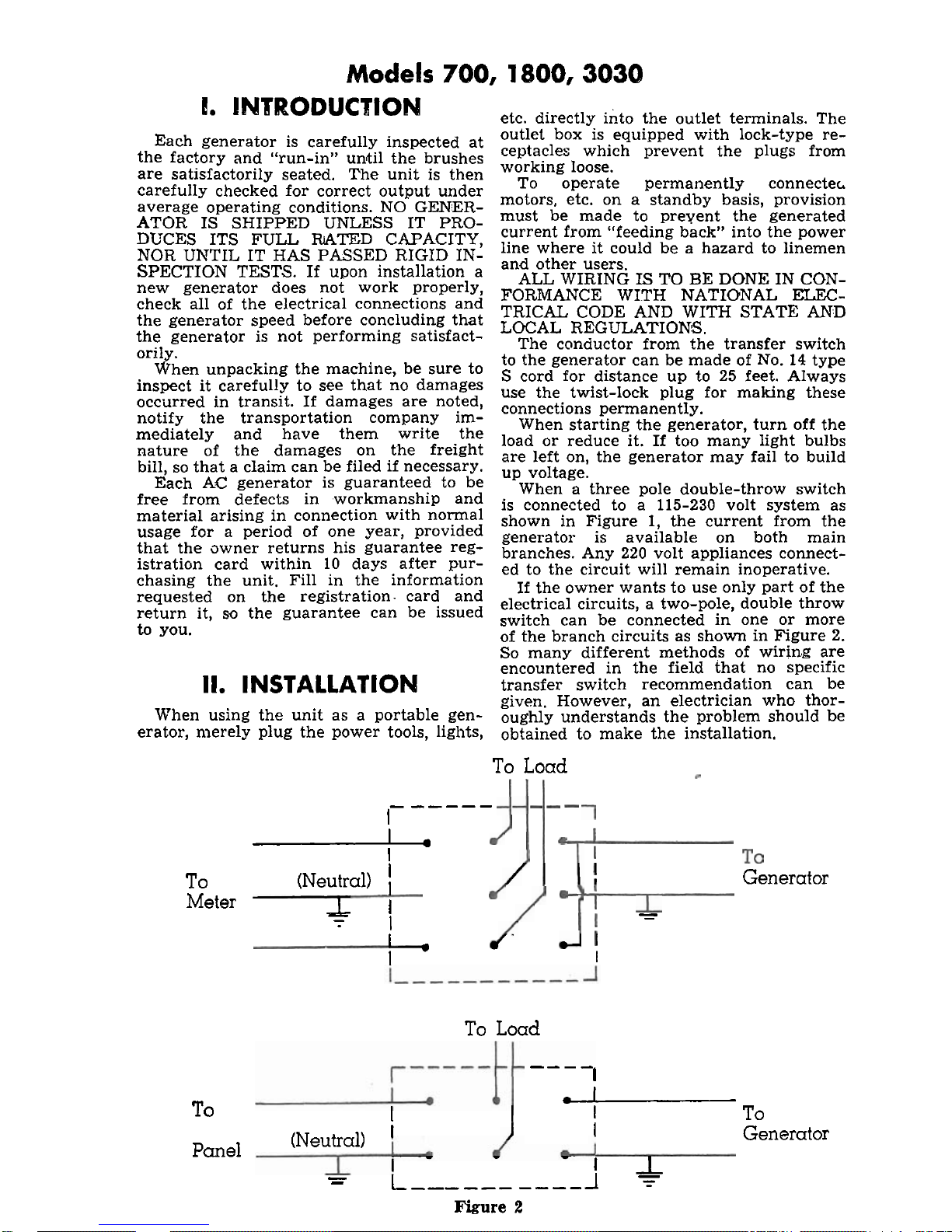

When a three pole double-throw switch

is connected to a

115-230 volt system as

shown in Figure

1,

the current from the

generator is available on both main

branches. Any

220 volt appliances connect-

ed to the circuit will remain inoperative.

If the owner wants to use only part of the

electrical circuits, a two-pole, double throw

switch can be connected in one or more

of the branch circuits as shown in Figure 2.

So

many different methods of wiring are

encountered in the field that no specific

II.

INSTALLATION

transfer switch recommendation can be

given. However, an electrician who thor-

when using the unit as a portable gen- oughly understands the problem should be

erator, merely plug the power tools, lights, obtained to make the installation.

To

Load

I-

-----

I

To

-

(Neutral)

I

I

Generator

Meter

I_

-

I

-

-

7

I

I.

I

I

To

Load

----

I

To

i

I

I

To

(Neutral)

I

I

Generator

Panel

-

I

-

-

L

----------

1

+

Figure

2

Loading...

Loading...