Winchester Super X3 Owner's Manual

Winchester®Super X®3 Autoloading Shotgun Owner’s Manual

Licensee

Important instructions for

Winchester®Super X®3

Autoloading Shotgun

Winchester Rifles and Shotguns

Customer Service Department (United States)

BACO, Inc.

275 Winchester Avenue

Morgan, Utah 84050-9333

Phone: (800) 945-5237

If you have any questions or comments regarding your

new firearm, please feel free to write or call us. Use the

space below to record information about your new firearm.

Model _________________________________________

Serial Number __________________________________

Purchased From _________________________________

Date of Purchase ________________________________

Winchester and associated trademarks are registered trademarks of

Olin Corporation. Invector-Plus, Perma-Cote and Dura-Touch are

trademarks of Browning.

NEU06101.5/06013

Contents Page

Gun Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terminology and Descriptions . . . . . . . . . . . . . . . . . . . .4

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Initial Cleaning and Oiling . . . . . . . . . . . . . . . . . . . . . . .4

Ammunition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operation of the Safety . . . . . . . . . . . . . . . . . . . . . . . . . .8

Initial Assembly and Takedown . . . . . . . . . . . . . . . . . .10

Magazine Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

In the Case of a Misfire . . . . . . . . . . . . . . . . . . . . . . . . .16

Invector-Plus

Magazine Three Shot Adapter (Plug) . . . . . . . . . . . . .19

Stock Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Use of Extra Barrels . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Mounting a Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Trigger Group Maintenance . . . . . . . . . . . . . . . . . . . . .28

Bolt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Cleaning and Maintenance Suggestions . . . . . . . . . . . .34

Parts, Service, Repair and Questions . . . . . . . . . . . . . .37

Website Information . . . . . . . . . . . . . . . . . . . . . . . . . . .38

™

Choke Tube System . . . . . . . . . . . . . . .17

GUN SAFETY WARNINGS

IT IS ESSENTIAL THAT THESE OPERATING

INSTRUCTIONS BE THOROUGHLY STUDIED BEFORE USING

THIS FIREARM TO ASSURE PROPER AND SAFE FIREARM

HANDLING. FAILURE TO FOLLOW THESE

INSTRUCTIONS OR FAILURE TO OBEY ANY SAFETY

WARNING MAY RESULT IN INJURY TO YOURSELF OR

OTHERS, OR CAUSE DAMAGE TO YOUR FIREARM.

As a firearm owner, you accept a set of demanding

responsibilities. How seriously you take these

responsibilities can be the difference between life and

death. There is no excuse for careless or abusive handling

of any firearm. At all times handle your shotgun and any

other firearm with intense respect for its power and

potential danger.

PLEASE READ AND UNDERSTAND ALL OF THE

CAUTIONS, PROPER HANDLING PROCEDURES AND

INSTRUCTIONS OUTLINED IN THIS OWNER’S MANUAL

BEFORE USING YOUR NEW FIREARM.

1. Do not carry a loaded firearm with a live shell in the

chamber while running, climbing a tree, crossing a

fence or anywhere you might slip or fall, drop the

firearm or otherwise bump or jar the firearm. A firearm

that is dropped, bumped or jarred with a chambered

shell might accidentally discharge even with the safety

on, causing serious injury to you or someone else.

When you are ready to shoot and a shell is chambered,

keep the safety in the “on safe” position until shooting

is imminent.

2. Do not rely on the safety to prevent accidental

discharge. Many safeties merely block the trigger

and prevent firing by pulling the trigger. The safety

may not prevent an accidental discharge due to

dropping, jarring or bumping a firearm.

3. Use only ammunition for which the firearm is

chambered, as indicated on the barrel, to prevent

excessive pressure and possible serious personal injury.

4. Incorrectly reloaded ammunition can cause serious

personal injury and damage to the firearm due to

excessive pressure. Reload only after proper instruction

and in strict compliance with instructions and data

contained in current reloading manuals.

5. Never point a firearm at anything you do not intend to

shoot. Always keep it pointed in a safe direction in

case of accidental discharge.

6. Always check to ensure that the barrel is free of

obstructions before loading and using the firearm. If

you experience light recoil or off sound, check the

barrel for an obstruction.

1

7. Before firing, clean any grease or oil out of the barrel

with a cleaning rod and patch. Grease or heavy

accumulation of oil can cause excessive pressures

and result in serious personal injury.

8. Keep barrel, chamber and action free of rust. Rust in

the barrel and chamber can cause excessive pressures

resulting in serious injury. A rusted, pitted or eroded

barrel should be replaced.

9. Use hearing protection to prevent ear damage

from repeated exposure to gunfire.

10. Always use proper shooting glasses to prevent

eye injury from flying particles.

11. Never carry a loaded firearm in a motor vehicle or

carry one into a dwelling. Always carefully unload the

firearm before entering a motor vehicle, a dwelling or

an area such as a camp. Always point your firearm in a

safe direction while loading or unloading to prevent

serious injury in case of an accidental discharge.

Never load your firearm in a house or in a vehicle.

12. Never shoot at a hard, flat surface or at the surface

of water to avoid a ricochet and possible serious

personal injury to yourself or a bystander.

13. Store firearms in a clean, dry place out of reach of

children and separated from stored ammunition.

14. Never alter any parts of your firearm. Any alterations

or adjustments that may become necessary to the

operating mechanism should be performed by a

qualified gunsmith.

15. Hunting from elevated surfaces, such as tree stands, is

dangerous. Doing so may increase the risk of handling

any firearm. Always make certain that the stand being

used is safe, sturdy and stable. Always make certain

your firearm is unloaded when it is being taken up and

down from the stand. Always make certain that your

firearm is not dropped from the stand or dropped

while it is being taken up or down from the stand.

16. Discharging firearms in poorly ventilated areas,

cleaning firearms or handling ammunition may result

in exposure to lead and other substances known to

cause birth defects, reproductive harm and other

serious physical injury. Have adequate ventilation at

all times. Wash hands thoroughly after exposure.

GENERAL DESCRIPTION

The Super X®3 is a world-class shotgun with world-class

origins. Every aspect of the design points toward unmatched

reliability and superb handling. It is clear that this shotgun

has the performance features demanded by serious hunters

and shooters. A few things to take notice of are:

2

• The remarkably simple, self-adjusting Active Valve

gas piston system.

• The alloy receiver balances weight between the hands with

just enough barrel weight for a smooth swing.

™

• The acclaimed Invector-Plus

choke system incorporates

long choke tapers and a back-bored barrel for superior

shot patterns.

As you learn about your new shotgun and begin shooting

it, we’re sure you’ll agree its design sets new standards for

reliability and handling.

Your new shotgun is one of several different versions

and configurations offered. The basic operating

procedures are the same for all models. Where there

are differences, they are pointed out in this owner’s

manual for your convenience.

GENERAL OPERATION

This shotgun is an autoloading design that allows you to

fire follow-up shots by merely pulling the trigger. When

you fire a shell, the Active Valve gas system moves a shell

from the magazine to the chamber where it is fired with a

pull of the trigger. This can be repeated until the

magazine is empty. A single shell can also be inserted into

the chamber manually or moved from the loaded

magazine by cycling the action with the operating handle.

With the magazine three-shot adapter (plug) removed

from the magazine and using 2

3

⁄4" loads, the shotgun is

capable of shooting five shots in rapid succession, one

shot with each pull of the trigger. The short stroke of the

gas piston along with the snug, gas sealing fit of the gas

piston rings and tight fit of the piston sleeve push rod

limit the amount of combustion gases blown past the

piston sleeve and into the receiver, keeping the inside of

the receiver cleaner. This is an exceptionally advanced

design that offers reliable function from the gas system

and easy disassembly for maintenance and cleaning.

However, in order to keep your new shotgun in top

condition and operating at its peak performance, you

must read, understand and follow all of the instructions in

this owner’s manual.

Prior to using live ammunition, familiarize yourself

thoroughly with these operating instructions. Get

accustomed to the feel of your new firearm. Know the

forces required to operate the action. Learn how to pull

the trigger, and above all, know the location and

operation of the safety. Procedures for disassembly and

operation of various components are outlined later in this

owner’s manual. Please read and study them thoroughly.

In addition, always remember:

WARNING: ALWAYS KEEP THE MUZZLE POINTED IN A

SAFE DIRECTION. USE THE CORRECT AMMUNITION AS

REFERENCED BY THE INSCRIPTION ON THE BARREL.

3

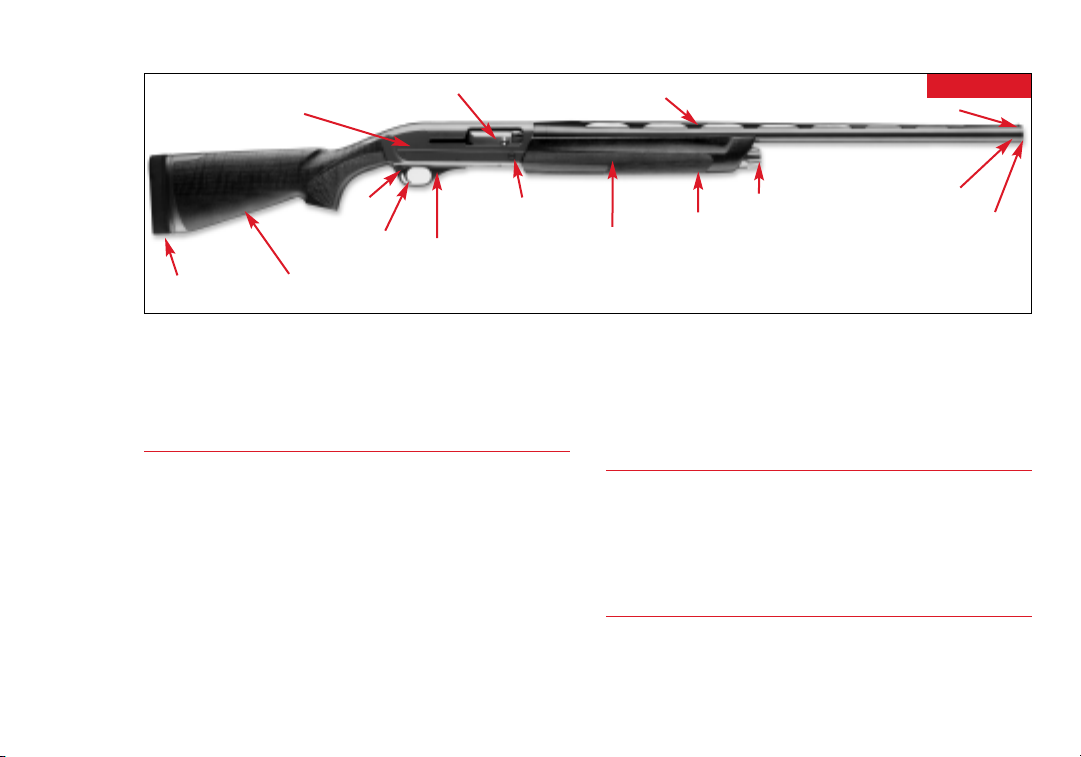

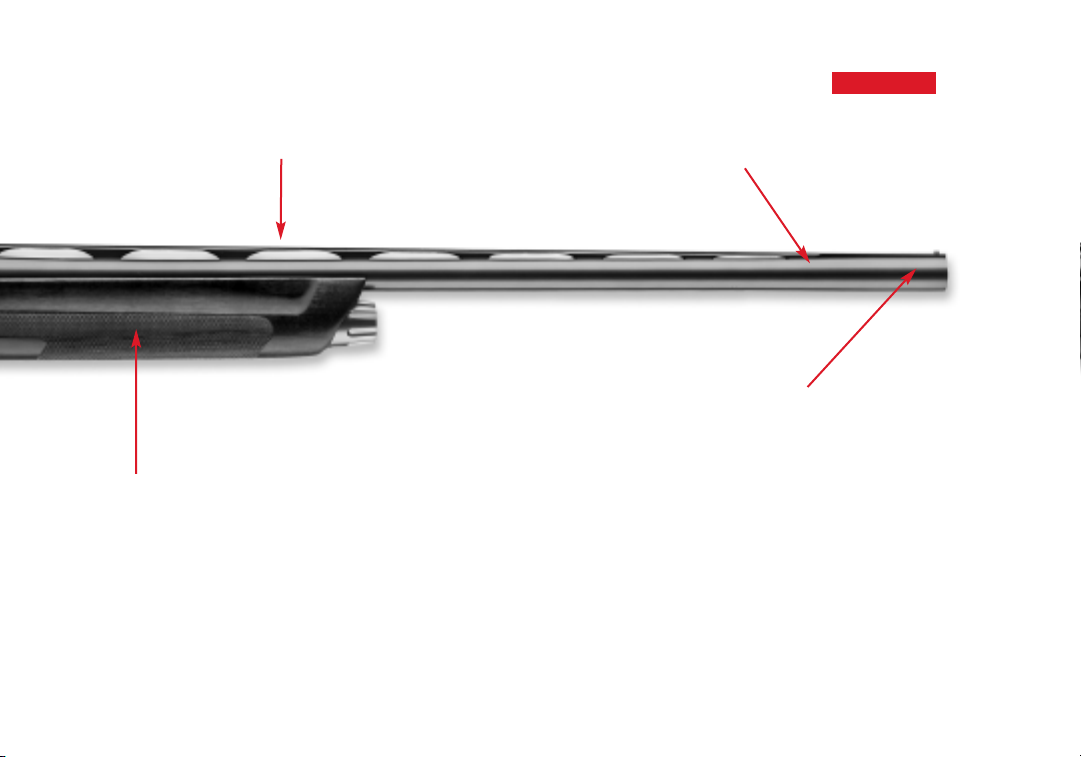

Receiver

Ejection Port

Ventilated Rib

FIGURE 1

Sight

Recoil Pad

Safety

Trigger

Buttstock

Carrier Release Button

Trigger Guard

BEFORE LOADING YOUR FIREARM BE SURE ALL GREASE

AND OIL HAVE BEEN REMOVED FROM THE BARREL AND

CHAMBER, AND THERE ARE NO OBSTRUCTIONS.

TERMINOLOGY AND DESCRIPTIONS

Descriptions in this owner’s manual generally refer to the

firearm in the horizontal position; that is, in the normal

firing position. For example, the muzzle is forward or front;

the butt stock is rearward or rear; the trigger is downward

or underneath; the sight is upward or on top. For general

parts terminology refer to Figure 1.

The shotgun is also shown disassembled to the extent

necessary in order to follow instructions contained in this

book (Figure 20, page 27). Figure 3 (page 6) covers the

™

Magazine Tube

(Inside Forearm)

Forearm

Magazine Cap

Invector-Plus

Choke Tube System

general features and benefits of the shotgun’s design.

Throughout this owner’s manual the term “action” refers

to the mechanism of this shotgun which loads and secures

the shell in the chamber.

SERIAL NUMBER

The serial number is located on the left side of the

receiver, just above the trigger guard. Record the

serial number at the front of this owner’s manual for

future reference.

INITIAL CLEANING AND OILING

Some metal parts of your new shotgun have been coated

at the factory with a rust preventative compound. Before

4

Muzzle

using your shotgun, clean the anti-rust compound from

the inside of the barrel, receiver, bolt mechanism and the

action/chamber areas. A high quality, lightweight gun oil

should be used to remove this compound and to give your

new firearm its first lubrication. Clean the barrel using a

cleaning rod and patch as explained under “Cleaning and

Maintenance Suggestions” found on page 33 in this

owner’s manual.

If your new shotgun is to be stored for an extended period

of time, it is permissible to leave the rust preventative

compound in place and keep your shotgun in its box for

maximum protection during long-term storage.

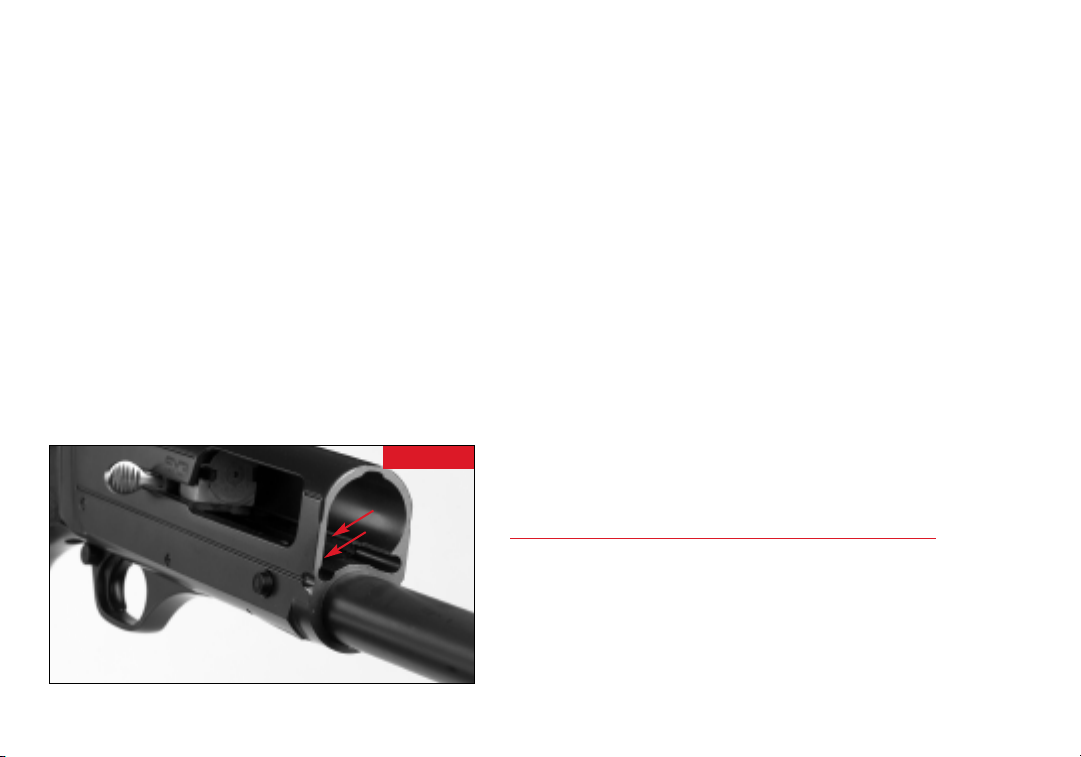

Before beginning assembly of your shotgun, you should first

wipe the mechanism clean and apply a few drops of quality

oil to the rails on which the bolt slides. These are found

inside the receiver (Figure 2). Avoid applying too much oil.

FIGURE 2

Be sure you lightly oil the bolt rails inside

the receiver at these points.

Only a light film is necessary. Excessive oil should be wiped

off, especially in cold weather.

CLEANING PARTS WITH SPECIAL FINISHES —

Be especially careful when cleaning firearms with

camouflage, Dura-Touch

®

Armor Coating and other

special finishes. Always prevent these surfaces from

coming in contact with cleaning solvents, barrel

scrubbers and other strong chemicals. It is preferable to

clean these surfaces with a light gun oil containing no

solvents or with a damp cloth and mild dish soap (be sure

to keep water out of the action). When cleaning your

firearm’s bore and action, protect the external finishes

from any contact with chemicals used. Also, avoid any

contact between external finishes and other strong

chemicals like those found in DEET-containing insect

repellents, sunscreens, etc. Damage to camouflage,

Dura-Touch and other finishes caused by chemicals is

irreversible and unrepairable.

AMMUNITION

There are two basic versions of this shotgun, those with a

31⁄2" chamber and those with a 3" chamber. This

information can be found inscribed on the barrel.

5

(Continued on page 8.)

SHOTGUN FEATURES

Several stock materials are available. Choose from

black or camouflage composite models with grip

enhancing Dura-Touch

traditional walnut models.

®

Armor Coating, or

The advanced aluminum alloy receiver offers the

strength of steel and exceptional between-the-hands

balance. Camo and Perma-Cote

™

UT finishes are both

durable and good looking, with minimal glare.

The entire bolt assembly removes easily for

thorough cleaning. This is a firearm designed for

extreme reliability under real-world, adverse

hunting conditions.

A deluxe next generation Pachmayr

®

Decelerator®recoil pad provides maximum

comfort. The hard heel prevents snagging

on clothing when shouldering.

The large safety button offers excellent

convenience with both gloved and

ungloved fingers. Plus, it is reversible

for left-handed shooters.

6

The trigger assembly quickly

removes with a durable two-pin

system for easy maintenance

and cleaning.

Lightweight, machined ventilated rib.

The advanced Active Valve gas system uses just the right amount

of gas needed to cycle the action. The 3

12 gauge field loads from 2

The 3" model shoots factory 12 gauge field loads from 2

1

3

⁄2" models shoot factory

⁄4" to 31⁄2" (11⁄8 oz. to 21⁄4 oz.) loads.

3

⁄4" to 3"

(1 oz. field to 2 oz.) loads.

FIGURE 3

.742" Back-Bored Technology creates the ideal

bore diameter, providing improved pattern

performance and shot velocity.

The longer Invector-Plus choke tubes have special tapers for optimum patterning, and

they are specially designed for back-bored barrels. It allows you to change choke

constrictions to meet the demands of the game being hunted or target presentation.

Extra-full choke tubes are available for hunting turkey or other game requiring extremely

tight patterns with lead shot loads.

7

• 31⁄2" — These models have a 31⁄2" chamber designed to

shoot factory 12 gauge loads including 2

(11⁄8 oz. to 21⁄4 oz.) field loads. (

They are

3

⁄4", 3" and 31⁄2"

NOT designed

to shoot the lightest factory 7⁄8 oz. and 1 oz. loads.)

3" — These models have a 3" chamber designed to

•

shoot factory 12 gauge loads including 23⁄4" and 3"

(1 oz. to 2 oz.) field loads. (

They are

NOT designed

to shoot the lightest factory 7⁄8 oz. and 1 oz. target

loads or any 31⁄2" shells.)

Winchester ammunition is always an excellent choice for

your new Winchester firearm, delivering the unmatched

performance and dependability you want.

USE ONLY THE EXACT AMMUNITION/GAUGE AS LISTED

ON THE LEFT SIDE OF THE BARREL. WINCHESTER

FIREARMS CAN ASSUME NO RESPONSIBILITY FOR

INCIDENTS WHICH OCCUR THROUGH THE USE OF

CARTRIDGES OF NONSTANDARD DIMENSION OR THOSE

THAT, WHEN SHOT, DEVELOP PRESSURES IN EXCESS OF

INDUSTRY STANDARDS ESTABLISHED BY THE SPORTING

ARMS AND AMMUNITION MANUFACTURERS’ INSTITUTE

(SAAMI). DISCHARGING FIREARMS IN POORLY

VENTILATED AREAS, CLEANING FIREARMS, OR

HANDLING AMMUNITION MAY RESULT IN EXPOSURE

TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE

BIRTH DEFECTS, REPRODUCTIVE HARM AND OTHER

SERIOUS PHYSICAL INJURY. HAVE ADEQUATE

VENTILATION AT ALL TIMES. WASH HANDS

THOROUGHLY AFTER EXPOSURE.

Incorrectly reloaded ammunition can cause serious

personal injury and damage to the firearm due to

excessive pressure. Reload only after proper instruction

and in strict compliance with instructions and data

contained in current reloading manuals.

OPERATION OF THE SAFETY

This shotgun is designed with a cross-bolt-type safety. It is

located just rearward of the trigger on the trigger guard,

and is convenient for gloved or ungloved fingers. It is

essential that you become very familiar with the feel, look

and operation of the safety on this shotgun before

attempting to load and shoot.

The cross-bolt safety prevents the trigger from being

pulled when in the “on safe” position. In the “off safe”

position, if your firearm is loaded with a shell in the

chamber, the chambered shell can be fired by simply

pulling the trigger.

The safety on this shotgun is reversible for right- or

left-handed operation. It comes from the factory in the

right-handed position. Verify the installation of your

firearm’s safety. Instructions in this owner’s manual are

for the safety installed in the right-handed position.

8

• “On Safe” — The safety button is pushed fully to

the right. The red band on the left side is not showing

(Figure 4). Always maintain the safety in the

“on safe” position (fully on) when a cartridge is in

the chamber and until shooting is imminent.

•

“Off Safe” — The safety button is pushed fully to the

left. A large red band is exposed on the button as it

protrudes on the left side of the trigger guard. The red

band is an added aid to safe gun handling (Figure 5).

CAUTION: THE RED WARNING BAND ON THE SAFETY

BUTTON IS FOR CONVENIENCE ONLY. DO NOT DEPEND

ON THE RED COLOR ALONE TO INDICATE YOUR

FIREARM’S SAFETY STATUS, AS TIME, EXPOSURE TO

THE ELEMENTS, AND THE ABRASIVE ACTION OF

CLEANING AGENTS CAN ERASE IT.

Never rely totally on your firearm’s safety button. It is

merely an aid to safe gun handling. Like any mechanical

device the safety can possibly fail; it can be jarred or

inadvertently manipulated into an unsafe condition.

Always keep your shotgun pointed in a safe direction.

At all times in the field keep the safety in the “on safe”

position and the barrel pointed in a safe direction. It is

a good idea never to load your shotgun until you are in

the field and shooting is imminent or until you are at

your station and it is your turn to shoot when you are

shooting at a range. For extra safety, and as a courtesy

to others, fully unload and place the action in the open

position at all times other than when shooting is

immediately imminent.

“On Safe” position

FIGURE 4

FIGURE 5

“Off Safe” position.

Red Band showing.

9

IT IS ESSENTIAL THAT YOU BECOME VERY FAMILIAR

WITH THE FEEL, LOOK AND OPERATION OF THE SAFETY

ON THIS SHOTGUN BEFORE ATTEMPTING TO LOAD AND

SHOOT IT.

IMPORTANT: THE SAFETY ON THIS SHOTGUN CAN BE

REVERSED FROM RIGHT- TO LEFT-HANDED BY A

QUALIFIED GUNSMITH. WHEN REVERSED TO

LEFT-HANDED, THE SAFETY BUTTON’S RED WARNING

BAND WILL SHOW ON THE RIGHT SIDE OF THE

TRIGGER GUARD WHEN THE SAFETY IS IN THE

“OFF SAFE” POSITION.

INITIAL ASSEMBLY AND TAKEDOWN

ASSEMBLY —

Remove the barrel assembly and receiver/stock section

from the carton. The shotgun usually comes from the

factory with the barrel removed and the forearm still

attached to the magazine tube. Wipe them clean and

lightly oil component parts as explained under “Initial

Cleaning and Oiling” on page 4. It is important to

carefully follow the assembly instructions below —

especially steps 1, 2 and 3 — to assure the proper

assembly of your shotgun.

ALWAYS PLACE THE SAFETY IN THE “ON SAFE” POSITION

BEFORE BEGINNING ASSEMBLY PROCEDURES. VISUALLY

INSPECT THE CHAMBER, FEED MECHANISM AND

MAGAZINE TO BE ABSOLUTELY CERTAIN THE SHOTGUN

IS COMPLETELY UNLOADED. POINT THE BARREL IN

A SAFE DIRECTION.

1. Lock the bolt rearward by pulling the operating handle

fully to the rear. If it will not pull rearward it usually

indicates that the bolt slide link has fallen out of the

end of the socket on the return spring plunger while

your firearm was being shipped. This is not a problem.

Refer to the section titled “Bolt Maintenance” on page

30 in this owner’s manual for special instructions on

how to perform this alignment procedure.

Align the piston sleeve push rod with the slot on

the left side of the receiver.

FIGURE 6

10

2. Carefully remove the forearm from the magazine tube

by unscrewing the magazine cap and sliding the forearm

forward off the magazine tube. DO NOT SQUEEZE HARD

ON THE OPEN REAR END OF WOOD FOREARMS. TOO

MUCH PRESSURE COULD CAUSE THE WOOD TO SPLIT.

The magazine spring is held in place by a friction-type

magazine spring retainer. ALWAYS KEEP THE MAGAZINE

POINTED AWAY FROM YOU AND OTHERS WHEN

REMOVING THE MAGAZINE CAP.

3. Leave the components of the gas system (the piston

sleeve, piston sleeve spring and gas piston) in place on

the magazine tube. They do not need to be removed,

except for cleaning. In the event that components of the

gas system have been removed, it is easy to reinstall

them as explained below.

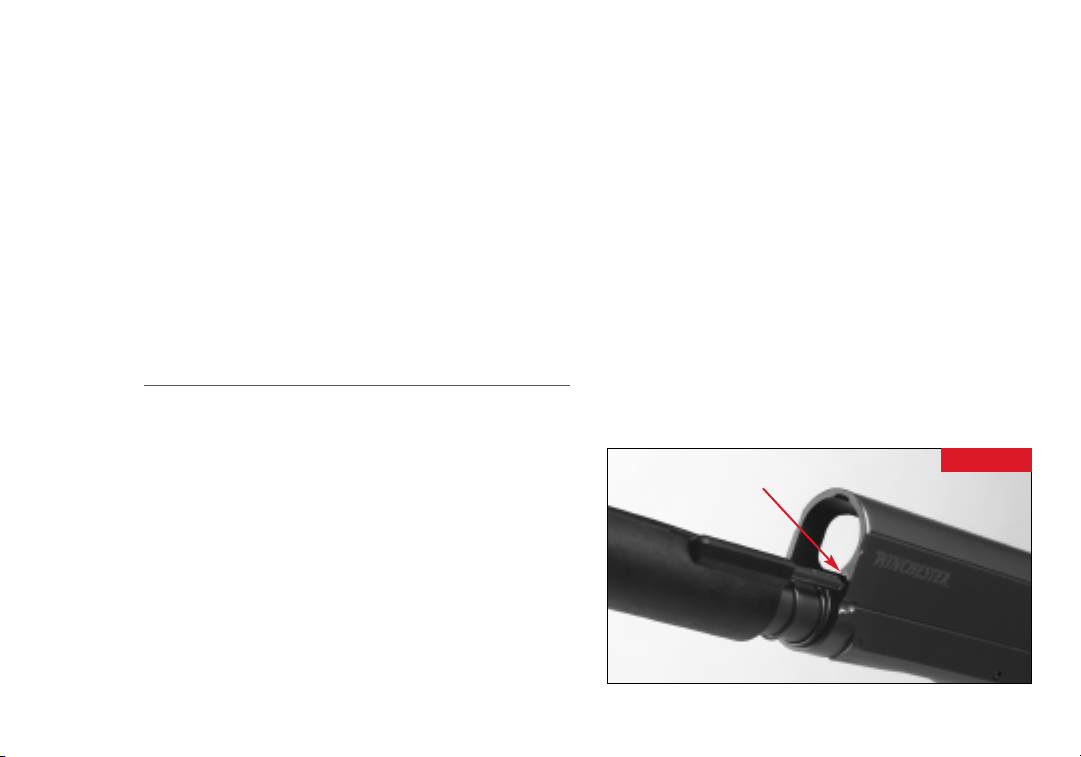

FIGURE 7

Position the gas piston in the gas bracket on the bottom of the barrel.

4. If the gas piston, piston sleeve and piston sleeve spring

have been removed, first slide the piston sleeve spring

over the magazine tube. Then slide the piston sleeve

onto the magazine tube, piston sleeve push rod end first.

Check the piston sleeve push rod to make sure it is

aligned with the slot on the left side of the receiver

(Figure 6), as viewed from the normal shooting position.

5. Slide the gas piston into the rear of the gas bracket on

the barrel, smaller end first (Figure 7).

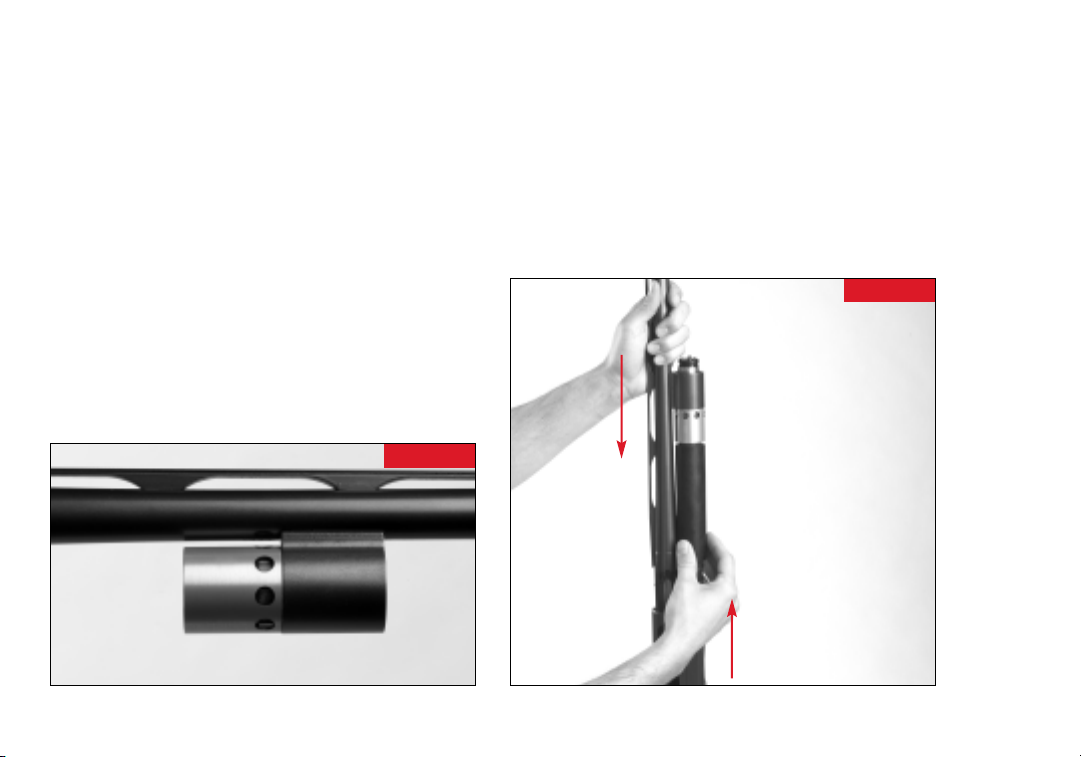

FIGURE 8

Insert the gas piston and gas

bracket over the magazine

tube. Start the barrel

extension into the receiver.

You may have to lift

up slightly on the

piston sleeve.

11

6. Hold the firearm in the vertical position. Slide the gas

bracket and gas piston over the magazine tube (Figure 8).

The barrel extension should slip solidly down into the

receiver. Make sure the piston sleeve push rod on the

piston sleeve moves freely in its slot in the left side of

the receiver. On a new firearm with very tight

tolerances, it may be necessary to lift up slightly on the

piston sleeve to allow the barrel extension to drop into

the receiver. After you do this, always check piston

sleeve push rod alignment as explained previously.

7. Replace the forearm by sliding it onto the magazine

tube and over the gas bracket so it seats securely. Install

the magazine cap. Make sure the magazine cap is fully

tightened down. Open and close the action several

times and then retighten the magazine cap. This will

help ensure a proper seal.

TAKEDOWN —

ALWAYS PLACE THE SAFETY IN THE “ON SAFE”

POSITION BEFORE BEGINNING DISASSEMBLY

PROCEDURES. VISUALLY INSPECT THE CHAMBER, FEED

MECHANISM AND MAGAZINE TO BE ABSOLUTELY

CERTAIN THE SHOTGUN IS COMPLETELY UNLOADED.

POINT THE BARREL IN A SAFE DIRECTION.

Disassembly for storage is essentially the reverse of the

assembly procedures. The action should be left open if

disassembly of the rest of the firearm will not be

performed. If you intend to fully disassemble your firearm,

you may start with the action closed.

1. Unscrew the magazine cap and remove it. Because the

magazine spring is held in place by a friction-type

magazine spring retainer, always be careful which

direction the end of the magazine is pointed.

ALWAYS KEEP THE MAGAZINE POINTED AWAY

FROM YOU AND OTHERS WHEN REMOVING THE

MAGAZINE CAP.

2. Remove the forearm by sliding it forward off the

magazine tube.

3. If you are disassembling your shotgun for cleaning

remove the barrel, gas piston, piston sleeve and piston

sleeve spring by sliding them forward off the magazine

tube. See “Cleaning and Maintenance Suggestions” on

page 33 in this owner’s manual for cleaning procedures.

If you are disassembling for storage, lock the action

open. Leave the gas piston, piston sleeve and piston

sleeve spring on the magazine tube as explained

previously. Reinstall them if they have been removed.

Install the forearm over the magazine tube and screw on

the magazine cap. You will then have two compact

units: (1) the barrel, and (2) the action with forearm

and stock.

12

Loading...

Loading...