TECHNICAL

TECHNICAL

GUIDE

GUIDE

80% SINGLE STAGE ECM

RESIDENTIAL GAS FURNACES

MULTI-POSITION STANDARD & LOW NOx

MODELS: TM8E, TMLE

NATURAL GAS

40 - 130 MBH INPUT

Due to continuous product improvement, specifications are

subject to change without notice.

Visit us on the web at

www.upgnet.com

Additional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY

A 20-year limited warranty on heat exchangers in residential

applications.

A 10-year warranty on the heat exchanger in commercial

applications.

Standard 5-year limited Parts warranty.

Extended lifetime heat exchanger and 10-year limited

parts warranty when product is registered online within

90 days of purchase for replacement or closing for new

home construction.

See Limited Warranty certificate in Users Information Manual for details.

5597959-BTG-A-0119

DESCRIPTION

These compact units employ induced combustion, reliable hot

surface ignition and high heat transfer aluminized tubular heat

exchangers. The units are factory shipped for installation in

upflow applications and may be converted for horizontal or

downflow applications.

These furnaces are designed for residential installation in a

basement, closet, alcove, attic, recreation room, or garage and

are also ideal for commercial applications. All units are factory

assembled, wired, and tested to assure safe, dependable, and

economical installation and operation.

These units are Category I listed and may be common vented

with another gas appliance as allowed by the National Fuel Gas

Code.

FEATURES

• Easily applied in upflow, horizontal left or right, or downflow

installation with minimal conversion necessary.

• Compact, easy to install, ideal height 33" tall cabinet.

• Blower-off delay for cooling SEER improvement.

• Easy access to controls to connect power/control wiring.

• Built-in, high level self diagnostics with fault code displays

standard on integrated control module for reliable operation.

• Low unit amp requirement for easy replacement application.

• All models are convertable to use propane (LP) gas.

• Electronic Hot Surface Ignition saves fuel cost with increased

dependability and reliability.

• 100% shut off main gas valve for extra safety.

• 5 speed direct drive Standard ECM blower motor.

• 24V, 40 VA control transformer and blower relay supplied for

add-on cooling.

• Hi-tech tubular aluminized steel primary heat exchanger.

• Timed on, adjustable off blower capability for maximum

comfort.

• Blower door safety switch.

• Solid removable bottom panel allows easy conversion.

• Low NOx models have been designed to meet specific code

requirements.

• Airflow leakage less than 1% of total airflow at duct performance testing conditions.

• No knockouts to deal with, making installation easier.

• Movable duct connector flanges for application flexibility.

• Quiet inducer operation.

• Inducer rotates for easy conversion of venting options.

• Fully supported blower assembly for easy access and

removal of blower.

• External air filters used for maximum flexibility in meeting

customers’ IAQ needs.

• Venting applications - may be installed as a common vent

with other gas-fired appliances or use a masonry chimney.

• 1/4 turn knobs provided for easy door removal.

• High-efficiency blower motor for lower electrical power usage

and improved A/C SEER ratings.

• Insulated blower compartment for thermal and acoustic

performance.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

5597959-BTG-A-0119

5,*+76,'(

´

´

5(7851(1'

´

´

/()76,'(

´

´

´

%

´

9HQW&RQQHFWLRQ

2XWOHW

(OHFWULFDO

(QWU\

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

´'LDPHWHU

9HQW&RQQHFWLRQ

2XWOHW

&

)5217

$

´

(OHFWULFDO

(QWU\

9HQW

&RQQHFWLRQ

2XWOHW

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

%

6833/<(1'

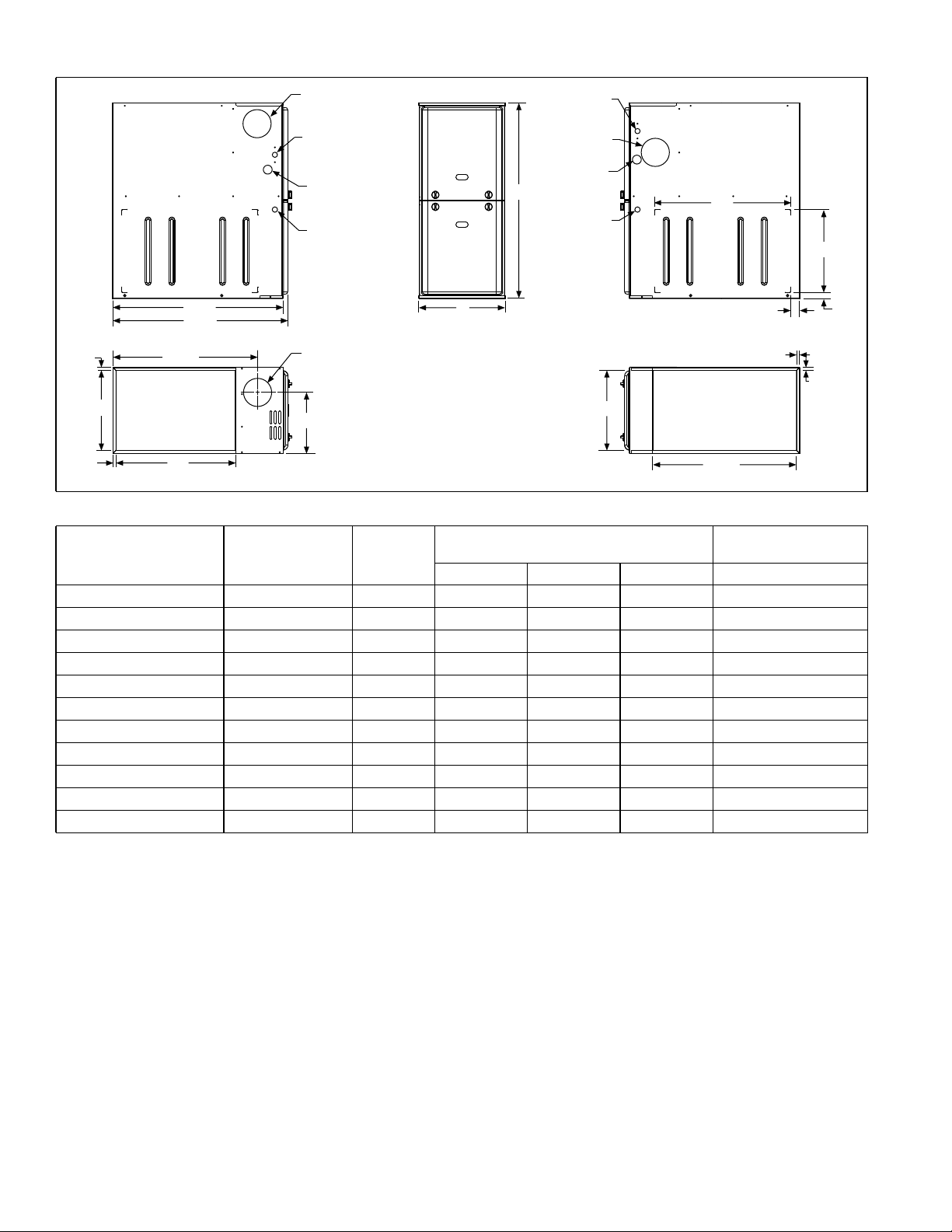

Cabinet & Duct Dimensions

Models

Nominal

CFM (m

3

/min)

Cabinet

Size

TM(8,L)E040A12MP11 1200 A 14 1/2 13 3/8 10.3 89

TM(8,L)E060A12MP11 1200 A 14 1/2 13 3/8 10.3 94

TM(8,L)E080B12MP11 1200 B 17 1/2 16 3/8 11.8 103

TM(8,L)E080C16MP11 1600 C 21 19 7/8 13.6 116

TM(8,L)E080C20MP11 2000 C 21 19 7/8 13.6 121

TM(8,L)E100B12MP11 1200 B 17 1/2 16 3/8 11.8 108

TM(8,L)E100C16MP11 1600 C 21 19 7/8 13.6 120

TM(8,L)E100C20MP11 2000 C 21 19 7/8 13.6 124

TM(8,L)E120C16MP11 1600 C 21 19 7/8 13.6 125

TM(8,L)E120C20MP11 2000 C 21 19 7/8 15.8 131

TM(8,L)E130D20MP11 2000 D 24 1/2 23 3/8 17.5 137

Cabinet Dimensions (Inches)

Operating Weights

A B C Lbs

´

´

´

$

Approximate

´

´

2 Johnson Controls Unitary Products

Ratings & Physical / Electrical Data

5597959-BTG-A-0119

Models

TM(8,L)E040A12MP11 40 32 80.0 20-50 190 1/2 6.4 11 x 8 15 8.2 1/2"

TM(8,L)E060A12MP11 60 48 80.0 30-60 190 1/2 6.4 11 x 8 15 8.2 1/2"

TM(8,L)E080B12MP11 80 64 80.0 35-65 190 1/2 6.4 11 x 8 15 8.7 1/2"

TM(8,L)E080C16MP11 80 64 80.0 30-60 190 1/2 6.4 11 x 10 15 8.7 1/2"

TM(8,L)E080C20MP11 80 64 80.0 25-55 190 1 11.5 11 x 11 20 13.8 1/2"

TM(8,L)E100B12MP11 100 80 80.0 40-70 190 1/2 6.4 11 x 8 15 8.7 1/2"

TM(8,L)E100C16MP11 100 80 80.0 40-70 190 3/4 8.8 11 x 10 15 11.1 1/2"

TM(8,L)E100C20MP11 100 80 80.0 25-55 190 1 11.5 11 x 11 20 13.8 1/2"

TM(8,L)E120C16MP11 120 96 80.0 40-70 190 3/4 8.8 11 x 10 15 11.1 1/2"

TM(8,L)E120C20MP11 120 96 80.0 35-65 190 1 11.5 11 x 11 20 13.7 1/2"

TM(8,L)E130D20MP11 130 104 80.0 35-65 190 1 11.5 11 x 11 20 13.7 1/2"

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

Input Output

MBH MBH °F °F HP Amps

AFUE

Air Temp.

Rise

Max. Outlet

Air Temp

Blower

Blower

Size

Recommended

Fuse or Circuit

Breaker Amps

Total Unit

Amps

Gas Pipe

Connection,

NPT

HORIZONTAL SIDEWALL VENTING

For applications where vertical venting is not possible, the only

approved method of horizontal venting is the use of an auxiliary

power vent. Auxiliary power venters must be approved by CSA,

UL, or other recognized safety agencies. Follow all application

and installation details provided by the manufacturer of the

power vent.

Single side return above 1800 CFM is approved as long as

the filter velocity does not exceed filter manufacturer’s recommendation and a transition is used to allow use on a

20x25 filter.

Recommended Filter Sizes

NOTICE

FILTER PERFORMANCE

Cabinet

Size

!

CAUTION

In downflow furnace arrangement, the filter must be located

a minimum of 12” from the return air inlet of furnace.

The airflow capacity data published in the “Blower Performance” table shown represents blower performance WITHOUT

filters.

All applications of these furnaces require the use of field

installed air filters. All filter media and mounting hardware or

provisions must be field installed external to the furnace cabinet. DO NOT attempt to install any filters inside the furnace.

3

CFM (m

1. Air velocity through throwaway type filters may not exceed 300 feet per min-

2. Do not exceed 1800 CFM using a single side return and a 16x25 filter. For

/min)

1200 (34.0) A 16 x 25 14 x 25

1200 (34.0) B 16 x 25 16 x 25

1600 (45.3) C 16 x 25 20 x 25

2000 (56.6) C (2) 16 x 25 20 x 25

2000 (56.6) D (2) 16 x 25 22 x 25

ute (91.4 m/min). All velocities over this require the use of high velocity filters.

CFM greater than 1800, you may use two side returns or one side and the

bottom or one return with a transition to allow use of a 20x25 filter.

Unit Clearances to Combustibles (All dimensions in inches, and all surfaces identified with the unit in an upflow configuration)

Side

(in)

Bottom

(in)

Application Top Front Rear

Upflow 1 6 0 0 3 6 Combustible Yes Yes Yes No

Upflow B-Vent 1 3 0 0 0 1 Combustible Yes Yes Yes No

Downflow 1 6 0 0 3 6

Downflow B-Vent 1 3 0 0 0 1

Horizontal 1 6 0 0 3 6 Combustible No Yes Yes

Horizontal B-Vent 1 3 0 0 0 1 Combustible No Yes Yes

1. Special floor base or air conditioning coil required for use on combustible floor.

2. Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position) of the furnace jacket and building

joists, studs, or framing.

Left

Side

Right

Side

Flue

Floor/

Bottom

1

1

1

1

Closet Alcove Attic

Yes Yes Yes No

Yes Yes Yes No

Contact

Line

Yes

Yes

2

2

Johnson Controls Unitary Products 3

5597959-BTG-A-0119

ACCESSORIES

Propane (LP) Conversion Kit - This accessory conversion kit

may be used to convert natural gas units for LP operation.

S1-1NP0347 - All Models except 130,000 BTU input

S1-1NP0501 - 130,000 BTU input only

LP Stainless Steel Burner Kit - This accessory conversion kit

may be used to convert existing burners to stainless steel burners for LP use only.

S1-32926889000 - All LP Models

Natural (NAT) Gas Stainless Steel Burner Kit - This acces-

sory kit may be used to replace existing burners with stainless

steel burners for NAT gas use only.

S1-32924441000 - All NAT gas Models

Side Return Filter Racks - The S1-1SR0200 Kit accommo-

dates a 1", 2", or 4" filter. The S1-1SR0402 Kit accommodates a

1" filter only.

S1-1SR0200 - All Models

S1-1SR0402 - All Models

Bottom Return Filter Racks - The S1-1BR05* series are galvanized steel filter racks. The S1-1BR06* series are pre-painted

steel filter racks to match the appearance of the furnace cabinet. The S1-1BR05* and S1-1BR06* series filter racks accommodate a 1", 2", or 4" filter.

S1-1BR0514 or S1-1BR0614 - For 14-1/2" cabinets

S1-1BR0517 or S1-1BR0617 - For 17-1/2" cabinets

S1-1BR0521 or S1-1BR0621 - For 21" cabinets

S1-1BR0524 or S1-1BR0624 - for 24-1/2" cabinets

Masonry Chimney Kit - This accessory kit allows upflow 80%

models to be vented into a tile-lined masonry chimney.

S1-1CK0604 - All 80% Non-modulating Models

Combustible Floor Base Kit - These kits are required to pre-

vent potential overheating situations when the furnaces are

installed in downflow applications directly onto combustible

flooring material. These kits are also required in any applications where the furnace is installed in a downflow configuration

without an indoor coil and where the combustible floor base kit

provides access for combustible airflow.

S1-1CB0514 - For 14-1/2" cabinets

S1-1CB0517 - For 17-1/2" cabinets

S1-1CB0521 - For 21" cabinets

S1-1CB0524 - for 24-1/2" cabinets

High Altitude Pressure Switches - For installation where the

altitude is less than 5,000 feet, it is not required that the pressure switch be changed. For altitudes above 5,000 feet, see kits

below.

S1-1PS3301 - 040, 060, 080, 120

S1-1PS3302 - 100, 130

Thermostats - Compatible thermostat controls are available

through accessory sourcing. For optimum performance, these

outdoor units are fully compatible with our residential Hx™

Touchscreen Thermostats available through Source1. For more

information, see the thermostat section of the Product Equipment Catalog.

4 Johnson Controls Unitary Products

Blower Performance CFM - Any Position (without filter)

Models Speed

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

High 1408 1358 1313 1275 1227 1180 1133 1088

Medium High 1195 1153 1093 1043 1005 957 904 850

TM(8,L)E040A12MP11

TM(8,L)E060A12MP11

TM(8,L)E080B12MP11

TM(8,L)E080C16MP11

TM(8,L)E080C20MP11

TM(8,L)E100B12MP11

TM(8,L)E100C16MP11

TM(8,L)E100C20MP11

TM(8,L)E120C16MP11

TM(8,L)E120C20MP11

For notes, see Page 6.

Medium 1053 1008 954 897 851 797 755 702

Medium Low 947 892 838 783 738 684 626 582

Low 649 697 682 630 575 518 471 422

High 1343 1309 1279 1238 1193 1163 1123 1075

Medium High 1149 1107 1074 1031 993 942 900 857

Medium 997 959 911 877 825 777 737 697

Medium Low 921 878 831 782 731 696 651 599

Low 838 784 742 695 648 601 551 518

High 1457 1421 1387 1358 1325 1289 1256 1220

Medium High 1336 1302 1269 1233 1198 1163 1124 1083

Medium 1118 1088 1052 1016 973 945 885 841

Medium Low 994 957 926 880 839 786 734 686

Low 811 770 725 673 625 572 521 467

High 1784 1746 1704 1660 1607 1556 1504 1466

Medium High 1444 1405 1354 1304 1252 1210 1157 1114

Medium 1253 1211 1157 1111 1064 1015 969 908

Medium Low 1083 1033 979 924 872 816 755 693

Low 902 849 787 724 659 593 538 475

High 2200 2162 2110 2061 2021 1981 1931 1970

Medium High 1980 1939 1892 1846 1804 1758 1701 1652

Medium 1734 1687 1645 1592 1547 1504 1456 1408

Medium Low 1597 1547 1504 1457 1410 1357 1310 1256

Low 1413 1362 1304 1247 1195 1148 1095 1046

High 1360 1321 1288 1259 1223 1182 1146 1105

Medium High 1197 1154 1127 1085 1046 1005 957 912

Medium 1016 981 945 899 859 805 761 710

Medium Low 916 878 839 794 743 691 643 595

Low 781 741 696 643 594 535 482 433

High 1795 1755 1715 1673 1631 1587 1533 1479

Medium High 1464 1417 1364 1325 1290 1227 1188 1138

Medium 1217 1171 1120 1072 1021 978 924 869

Medium Low 1062 1011 956 910 858 801 738 669

Low 905 847 784 732 668 601 540 465

High 2219 2179 2136 2095 2044 2001 1952 1912

Medium High 1994 1951 1911 1872 1820 1774 1733 1678

Medium 1727 1687 1648 1595 1558 1502 1456 1406

Medium Low 1618 1574 1528 1480 1432 1383 1337 1288

Low 1410 1364 1316 1255 1206 1164 1109 1042

High 1765 1721 1684 1635 1606 1542 1503 1442

Medium High 1429 1384 1340 1292 1256 1209 1164 1114

Medium 1207 1169 1119 1077 1028 977 930 888

Medium Low 1055 1018 955 907 862 810 761 705

Low 885 834 783 733 675 618 544 500

High 2235 2199 2148 2108 2066 2034 1984 1932

Medium High 1960 1901 1860 1819 1776 1723 1682 1642

Medium 1693 1640 1593 1557 1504 1455 1413 1365

Medium Low 1580 1533 1488 1444 1394 1342 1296 1244

Low 1417 1362 1313 1269 1223 1169 1120 1079

Airflow Data (SCFM)

Ext. Static Pressure (in. H2O)

1, 2

5597959-BTG-A-0119

Johnson Controls Unitary Products 5

Blower Performance CFM - Any Position (without filter) (Continued)

Models Speed

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

High 2229 2182 2133 2088 2047 1996 1946 1893

TM(8,L)E130D20MP11

NOTES:

1. Airflow expressed in standard cubic feet per minute (SCFM).

2. Motor voltage at 115 V.

3. Not all speeds are recommended for use as heating speeds.

Medium High 2009 1968 1925 1881 1829 1778 1737 1679

Medium 1818 1765 1729 1675 1616 1580 1540 1480

Medium Low 1569 1520 1472 1427 1376 1329 1281 1237

Low 1448 1394 1341 1275 1221 1183 1131 1085

Airflow Data (SCFM)

Ext. Static Pressure (in. H2O)

1, 2

Subject to change without notice. Published in U.S.A. 5597959-BTG-A-0119

Copyright © 2019 by Johnson Controls, Inc. All rights reserved. Supersedes: Nothing

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...