Winchester B2332496, B2332493, B2332491, B2332492, B2332490 User Manual

INSTALLATION MANUAL

SINGLE STAGE ECM

RESIDENTIAL GAS FURNACES

MODELS: TM8E, TMLE

(80% Multi-Position/Standard & Low NOx)

LIST OF SECTIONS

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ELECTRICAL POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

LIST OF FIGURES

Duct Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Furnace and Coil Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Combustible Floor Base Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Horizontal Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typical Attic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typical Suspended Furnace / Crawl Space Installation . . . . . . . . . . . 7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Side Return Cutout Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

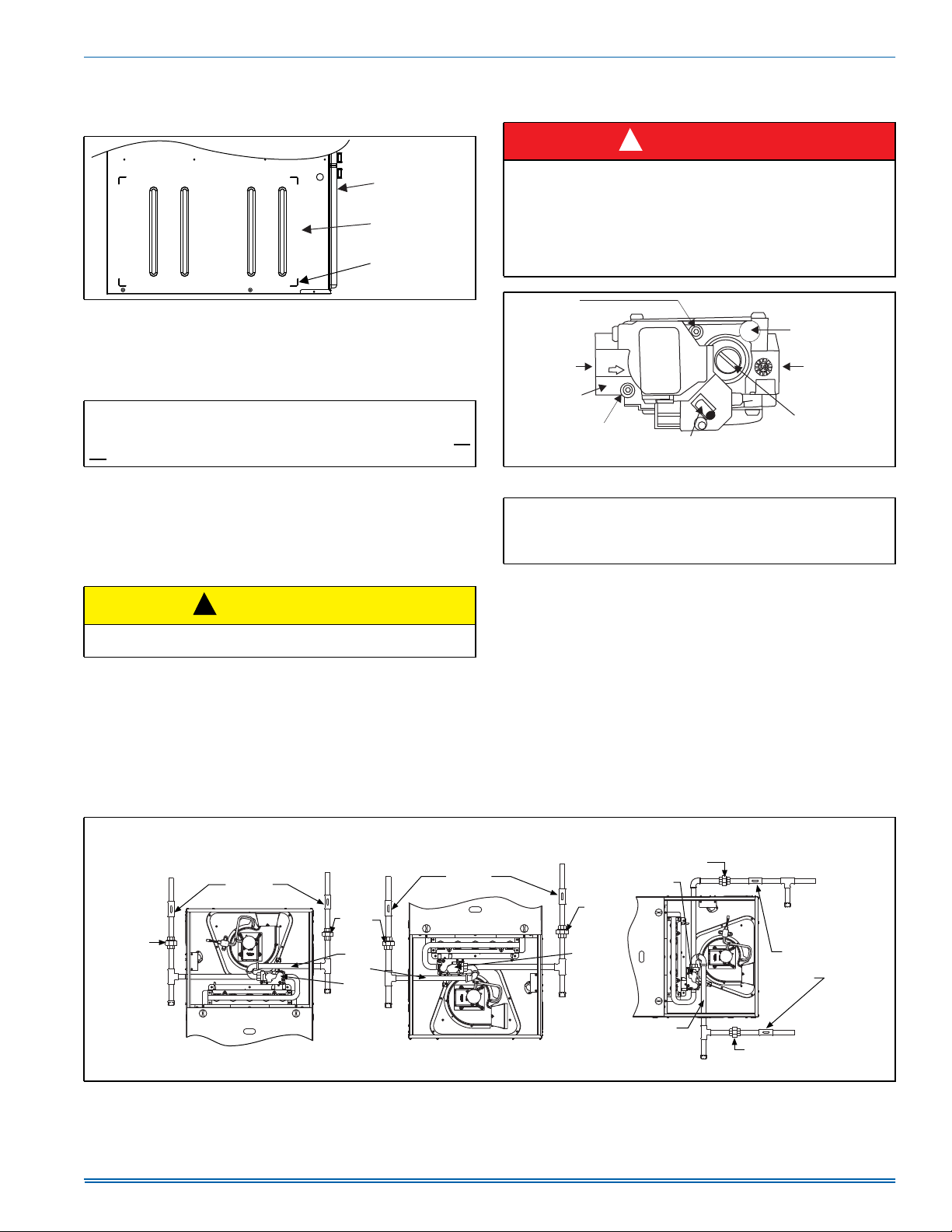

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

START-UP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . 16

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . 25

REPLACEMENT PART CONTACT INFORMATION . . . . . . . . 25

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

START UP SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Thermostat Chart - Single Stage AC with

Single Stage Furnaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Thermostat Chart - Single Stage HP with

Single Stage Furnaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Combustion Air Inducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Combustion Airflow Path Through The Furnace Casing to the Burner

Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Outside and Ambient Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . 15

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Reading Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Furnace Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

LIST OF TABLES

Unit Clearances to Combustibles (All Dimensions in

Inches and cm, and All Surfaces Identified with the

Unit in an Upflow Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cabinet and Duct Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Recommended Filter Sizes (High Velocity 600 FPM) . . . . . . . . . 8

Nominal Manifold Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ratings & Physical / Electrical Data . . . . . . . . . . . . . . . . . . . . . 11

Estimated Free Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

These high efficiency, compact units employ induced combustion, reliable hot surface ignition and high heat transfer aluminized tubular heat

exchangers. The units are factory shipped for installation in upflow or

horizontal applications and may be converted for downflow applications.

These furnaces are designed for residential installation in a basement,

closet, alcove, attic, recreation room or garage and are also ideal for

commercial applications. All units are factory assembled, wired and

tested to assure safe dependable and economical installation and operation.

These units are Category I listed and may be common vented with

another gas appliance as allowed by the National Fuel Gas Code.

SECTION I: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

Unconfined Space Minimum Area . . . . . . . . . . . . . . . . . . . . . . . 14

Free Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Gas Rate (CU FT/HR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inlet Gas Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Nominal Manifold Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Default Blower Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Blower Performance CFM - Any Position (without filter) . . . . . . 21

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury. It is also used to

alert against unsafe practices and hazards involving only property damage.

!

WARNING

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Failure to carefully read and

follow all instructions in this manual can result in furnace malfunction, death, personal injury and/or property damage. Only a

qualified contractor, installer or service agency should install this

product.

Johnson Controls Ducted Systems 5594752-UIM-B-0419

5594752-UIM-B-0419

SPECIFIC SAFETY RULES AND PRECAUTIONS

1. Only Natural gas or Propane (LP) gas are approved for use with

this furnace.

2. Install this furnace only in a location and position as specified in

these instructions.

3. A gas-fired furnace for installation in a residential garage must be

installed as specified in these instructions.

4. Provide adequate combustion and ventilation air to the furnace

space as specified in these instructions.

5. Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in SECTION

VI of these instructions.

6. Test for gas leaks as specified in these instructions.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections. A fire or explosion may result causing property

damage, personal injury or loss of life.

7. Always install the furnace to operate within the furnace’s intended

temperature rise range. Only connect the furnace to a duct system

which has an external static pressure within the allowable range, as

specified on the furnace rating plate.

8. When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace,

the return air shall also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing the furnace.

9. It is permitted to use the furnace for heating of buildings or structures under construction where the application and use must comply with all manufacturer’s installation instructions including:

• Proper vent installation;

• Furnace operating under thermostatic control;

• Return air duct sealed to the furnace;

• Air filters in place;

• Set furnace input rate and temperature rise per rating plate mark-

ing;

• Means for providing outdoor air required for combustion;

• Return air temperature maintained between 55ºF (13ºC) and

80ºF (27ºC);

• The air filter must be replaced upon substantial completion of

the construction process;

• Clean furnace, duct work and components upon substantial com-

pletion of the construction process, and verify furnace-operating

conditions including ignition, input rate, temperature rise and

venting, according to the manufacturer’s instructions.

10. When installed in a non-HUD-Approved Modular Home or building

constructed on-site, combustion air shall not be supplied from occupied spaces.

11. The size of the unit should be based on an acceptable heat loss

calculation for the structure. ACCA, Manual J or other approved

methods may be used.

12. When moving or handling this furnace prior to installation it is recommended to leave the doors on the furnace to provide support

and to prevent damage or warping of the cabinet. When lifting the

furnace by the cabinet, support the ends of the furnace rather than

lifting by the cabinet flanges at the return air openings (bottom or

sides) or supply air opening.

13. When lifting the furnace, it is acceptable to use the primary heat

exchanger tubes as a lifting point provided that the tubes are lifted

at the front of the heat exchangers where attached to the vestibule

panel. Do not use the top return bend of the heat exchangers as lifting points as the tubes may shift out of position or their location

brackets/baffles.

IMPORTANT: During installation, doors should remain on the

furnace when moving or lifting.

SAFETY REQUIREMENTS

!

CAUTION

This product must be installed in strict compliance with the installation

instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical codes.

• Refer to the unit rating plate for the furnace model number, and

then see the dimensions page of this instruction for return air plenum dimensions in Figure 7. The plenum must be installed

according to the instructions.

• Provide clearances from combustible materials as listed under

Clearances to Combustibles.

• Provide clearances for servicing ensuring that service access is

allowed for both the burners and blower.

• These models ARE NOT CSA listed or approved for installation

into a HUD Approved Modular Home or a Manufactured

(Mobile) Home.

• This furnace is not approved for installation in trailers or recreational vehicles.

• Furnaces for installation on combustible flooring shall not be

installed directly on carpeting, tile or other combustible material

other than wood flooring.

• Check the rating plate and power supply to be sure that the electrical characteristics match. All models use nominal 115 VAC, 1

Phase, 60 Hz power supply. DO NOT CONNECT THIS APPLIANCE TO A 50 Hz POWER SUPPLY OR A VOLTAGE ABOVE

130 VOLTS.

• Furnace shall be installed so the electrical components are protected from water.

• Installing and servicing heating equipment can be hazardous due

to the electrical components and the gas fired components. Only

trained and qualified personnel should install, repair, or service

gas heating equipment. Untrained service personnel can perform

basic maintenance functions such as cleaning and replacing the

air filters. When working on heating equipment, observe precautions in the manuals and on the labels attached to the unit and

other safety precautions that may apply.

2 Johnson Controls Ducted Systems

5594752-UIM-B-0419

COMBUSTION AIR QUALITY

(LIST OF CONTAMINANTS)

The furnace requires OUTDOOR AIR for combustion when the furnace

is located in any of the following environments.

• Restricted Environments

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft rooms

• Furnaces installed near chemical storage areas

• Chemical exposure

The furnace requires OUTDOOR AIR for combustion when the furnace

is located in an area where the furnace is being exposed to the following substances and / or chemicals.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

When outdoor air is used for combustion, the combustion air intake duct

system termination must be located external to the building and in an

area where there will be no exposure to the substances listed above.

!

WARNING

The furnace area must not be used as a broom closet or for any other

storage purposes, as a fire hazard may be created. Never store items

such as the following on, near or in contact with the furnace.

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum cleaners or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning compounds;

plastic items or containers; gasoline, kerosene, cigarette lighter

fluid, dry cleaning fluids or other volatile fluid.

3. Paint thinners and other painting compounds.

4. Paper bags, boxes or other paper products

Never operate the furnace with the blower door removed. To do

so could result in serious personal injury and/or equipment

damage.

CODES AND STANDARDS

Follow all national, local codes and standards in addition to this installation manual. The installation must comply with regulations of the serving gas supplier, local building, heating, plumbing, and other codes. In

absence of local codes, the installation must comply with the national

codes listed below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and standards for the

following, using the latest edition available:

STEP 1 -Safety

• US: National Fuel Gas Code (NFGC) NFPA 54/ANSI Z223.1 and

the Installation Standards, Warm Air Heating and Air Conditioning

Systems ANSI/NFPA 90B

• CANADA: CAN/CGA-B149.1 National Standard of Canada. Natural Gas and Propane Installation Codes (NSCNGPIC)

STEP 2 -General Installation

• US: Current edition of the NFGC and NFPA 90B. For copies, contact the

National Fire Protection Association Inc.

Batterymarch Park

Quincy, MA 02269

or for only the NFGC, contact the

American Gas Association,

400 N. Capital, N.W.

Washington DC 20001

or www.NFPA.org

• CANADA: NSCNGPIC. For a copy contact:

Standard Sales, CSA International

178 Rexdale Boulevard

Etobicoke, (Toronto) Ontario Canada M9W 1RS

STEP 3 -Combustion and Ventilation Air

• US: Section 5.3 of the NFGC, air for Combustion and Ventilation

• CANADA: Part 7 of NSCNGPIC, Venting Systems and Air Supply

for Appliances

STEP 4 -Duct Systems

• US and CANADA: Air Conditioning Contractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning Contractors

Association National Association (SMACNA), or American Society of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) 1997 Fundamentals Handbook Chapter 32.

STEP 5 -Acoustical Lining and Fibrous Glass Duct

• US and CANADA: Current edition of SMACNA and NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air Ducts

STEP 6 -Gas Piping and Gas Pipe Pressure Testing

• US: NFGC; chapters 2, 3, 4, & 9 and National Plumbing Codes

• CANADA: NSCNGPIC Part 5

STEP 7 -Electrical Connections

• US: National Electrical Code (NEC) ANSI/NFPA 70

• CANADA: Canadian Electrical Code CSA C22.1

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances these

instructions exceed certain local codes and ordinances, especially

those who have not kept up with changing residential and non-HUD

modular home construction practices. These instructions are required

as a minimum for a safe installation.

Johnson Controls Ducted Systems 3

5594752-UIM-B-0419

FOR FURNACES INSTALLED IN THE COMMONWEALTH OF MASSACHUSETTS ONLY

For all side wall horizontally vented gas fueled equipment installed in

every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less

than seven (7) feet above finished grade in the area of the venting,

including but not limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At

the time of installation of the side wall horizontal vented gas

fueled equipment, the installing plumber or gasfitter shall

observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor level where the

gas equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated or hard

wired carbon monoxide detector with an alarm is installed on

each additional level of the dwelling, building or structure served

by the side wall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure the services

of qualified licensed professionals for the installation of hard

wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery backup may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not

be met at the time of completion of installation, the owner shall

have a period of thirty (30) days to comply with the above

requirements; provided, however, that during said thirty (30)

day period, a battery operated carbon monoxide detector with

an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon

monoxide detector as required in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed

and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be perma-

nently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the

exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no

less than one-half (1/2) inch in size, "GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance

with the provisions of 248 CMR 5.08(2)(a)1 through 4.

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s freight bill. A separate request for

inspection by the carrier’s agent should be made in writing. Also, before

installation, the unit should be checked for screws or bolts which may

have loosened in transit. There are no shipping or spacer brackets

which need to be removed from the interior of this unit.

FURNACE LOCATION AND CLEARANCES

The furnace shall be located using the following guidelines:

1. Where a minimum amount of air intake/vent piping and elbows will

be required.

2. As centralized with the air distribution as possible.

3. Where adequate combustion air will be available (particularly when

the appliance is not using outdoor combustion air).

4. Where it will not interfere with proper air circulation in the confined

space.

Installation in freezing temperatures:

1. Furnace shall be installed in an area where ventilation facilities provide for safe limits of ambient temperature under normal operating

conditions.

!

WARNING

Improper installation in an ambient below 32ºF (0ºC) could create a

hazard, resulting in damage, injury or death.

2. Do not allow return air temperature to be below 55ºF (13ºC) for

extended periods. To do so may cause condensation to occur in the

main heat exchanger, leading to premature heat exchanger failure.

Clearances for access/service:

Ample clearances should be provided to permit easy access to the unit.

The following minimum clearances are recommended:

1. Twenty-four (24) inches (61 cm) between the front of the furnace

and an adjacent wall or another appliance, when access is required

for servicing and cleaning.

2. Eighteen (18) inches (46 cm) at the side where access is required

for passage to the front when servicing or for inspection or replacement of flue/vent connections.

In all cases, accessibility clearances shall take precedence over clearances for combustible materials where accessibility clearances are

greater.

Installation in a residential garage:

A gas-fired furnace for installation in a residential garage must be

installed so the burner(s) and the ignition source are located not less

than 18” (46 cm) above the floor, and the furnace must be located or

protected to avoid physical damage by vehicles.

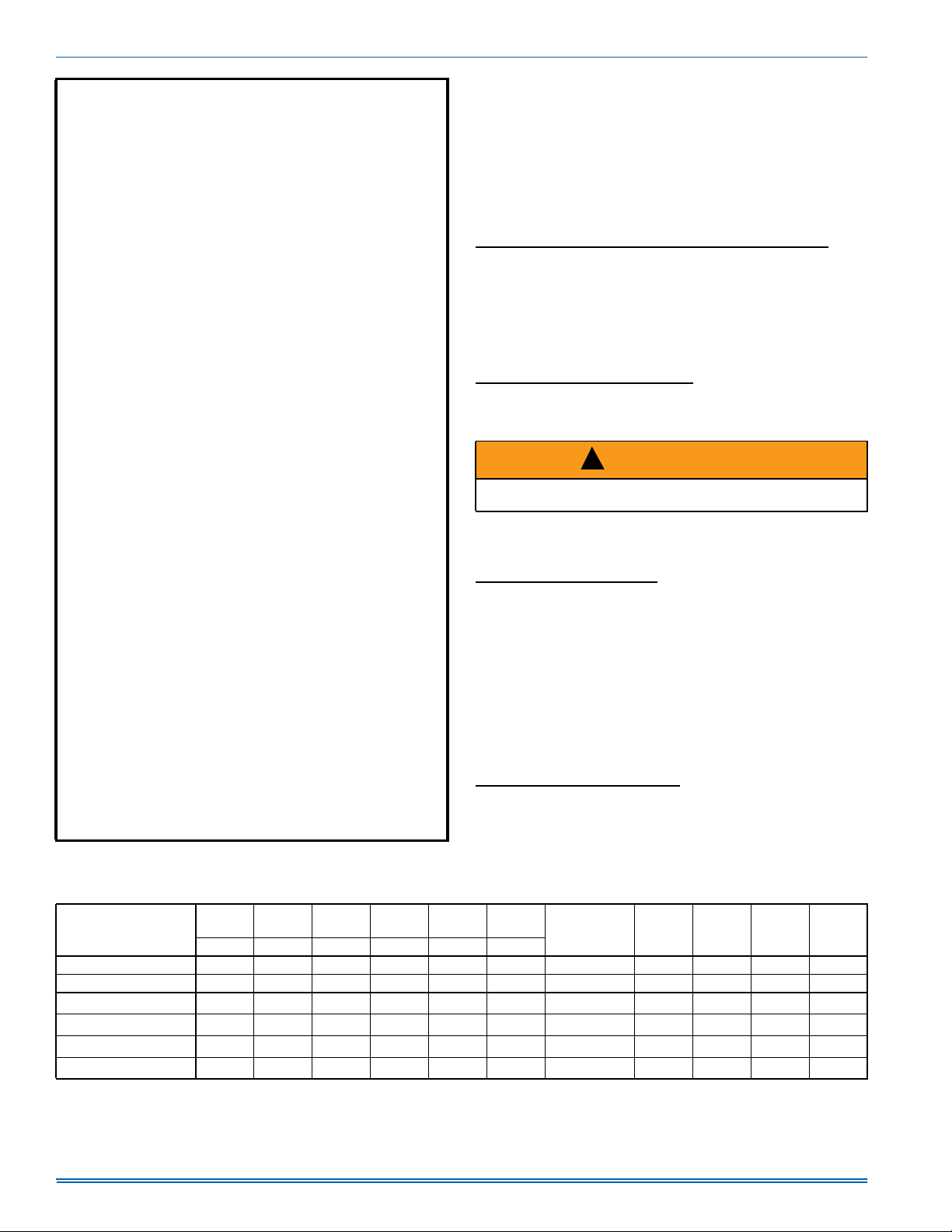

Table 1: Unit Clearances to Combustibles (All Dimensions in Inches and cm, and All Surfaces Identified with the Unit in an Upflow Configuration)

Application

Upflow 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 6 (15.2) Combustible Yes Yes Yes No

Upflow B-Vent 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 1 (2.5) Combustible Yes Yes Yes No

Downflow 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 6 (15.2)

Downflow B-Vent 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 1 (2.5)

Horizontal 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 6 (15.2) Combustible No Yes Yes

Horizontal B-Vent 1 (2.5) 1 (2.5) 0 (0.0) 0 (0.0) 0 (0.0) 1 (2.5) Combustible No Yes Yes

1. Special floor base or air conditioning coil required for use on combustible floor.

2. Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position) of the furnace jacket and building

joists, studs or framing.

Top Front Rear

In. (cm) In. (cm) In. (cm) In. (cm) In. (cm) In. (cm)

Left

Side

Right

Side

Flue

Floor/

Bottom

1 (25.4)

1 (25.4)

Closet Alcove Attic

1

Yes Ye s Ye s No

1

Yes Ye s Ye s No

Line

Contact

2

Yes

2

Yes

4 Johnson Controls Ducted Systems

5594752-UIM-B-0419

SECTION II: DUCTWORK

DUCTWORK GENERAL INFORMATION

The duct system’s design and installation must:

1. Handle an air volume appropriate for the served space and within

the operating parameters of the furnace specifications.

2. Be installed in accordance of National Fire Protection Association

as outlined in NFPA standard 90B (latest editions) or applicable

national, provincial, state, and local fire and safety codes.

3. Create a closed duct system. For residential and non-HUD Modular

Home installations, when a furnace is installed so that the supply

ducts carry air circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled by a

duct(s) sealed to the furnace casing and terminating outside the

space containing the furnace.

4. Complete a path for heated or cooled air to circulate through the air

conditioning and heating equipment and to and from the conditioned space.

!

CAUTION

The indoor coil must be installed in the supply air duct, downstream of

the furnace. Cooled air may not be passed over the heat exchanger.

When the furnace is used with an indoor coil, the coil must be installed

parallel with, or in the supply air side of the furnace to avoid condensation in the primary heat exchanger. When a parallel flow arrangement is

used, dampers or other means used to control airflow must be adequate to prevent chilled air from entering the furnace. If manually operated, the damper must be equipped with means to prevent the furnace

or the air conditioner from operating unless the damper is in full heat or

cool position.

When replacing an existing furnace, if the existing plenum is not the

same size as the new furnace then the existing plenum must be

removed and a new plenum installed that is the proper size for the new

furnace. If the plenum is shorter than 12” (30.5 cm) the turbulent air flow

may cause the limit controls not to operate as designed, or the limit controls may not operate at all.

The duct system is a very important part of the installation. If the duct

system is improperly sized the furnace will not operate properly.

The ducts attached to the furnace plenum, should be of sufficient size

so that the furnace operates at the specified external static pressure

and within the air temperature rise specified on the nameplate.

IMPORTANT: The minimum plenum height is 12” (30.5 cm). The furnace will not operate properly on a shorter plenum height. The minimum recommended rectangular duct height is 4” (10.1 cm) attached

to the plenum.

!

WARNING

The duct system must be properly sized to obtain the correct airflow

for the furnace size that is being installed.

Refer to Table 5 or the furnace rating plate for the correct rise range

and static pressures.

If the ducts are undersized, the result will be high duct static pressures and/or high temperature rises which can result in a heat

exchanger OVERHEATING CONDITION. This condition can result in

premature heat exchanger failure, which can result in personal injury,

property damage, or death.

If a matching cased indoor coil is used, it may be placed directly on the

furnace outlet and sealed to prevent leakage. If an uncased indoor coil

with a thermoplastic drain pan is to be installed in the upflow/horizontalconfiguration, then extra 2” minimum spacing may be needed to ensure

against drain pan distortion.

On all installations without an indoor coil, a removable access panel is

recommended in the outlet duct such that smoke or reflected light

would be observable inside the casing to indicate the presence of leaks

in the heat exchanger. This access cover shall be attached in such a

manner as to prevent leaks.

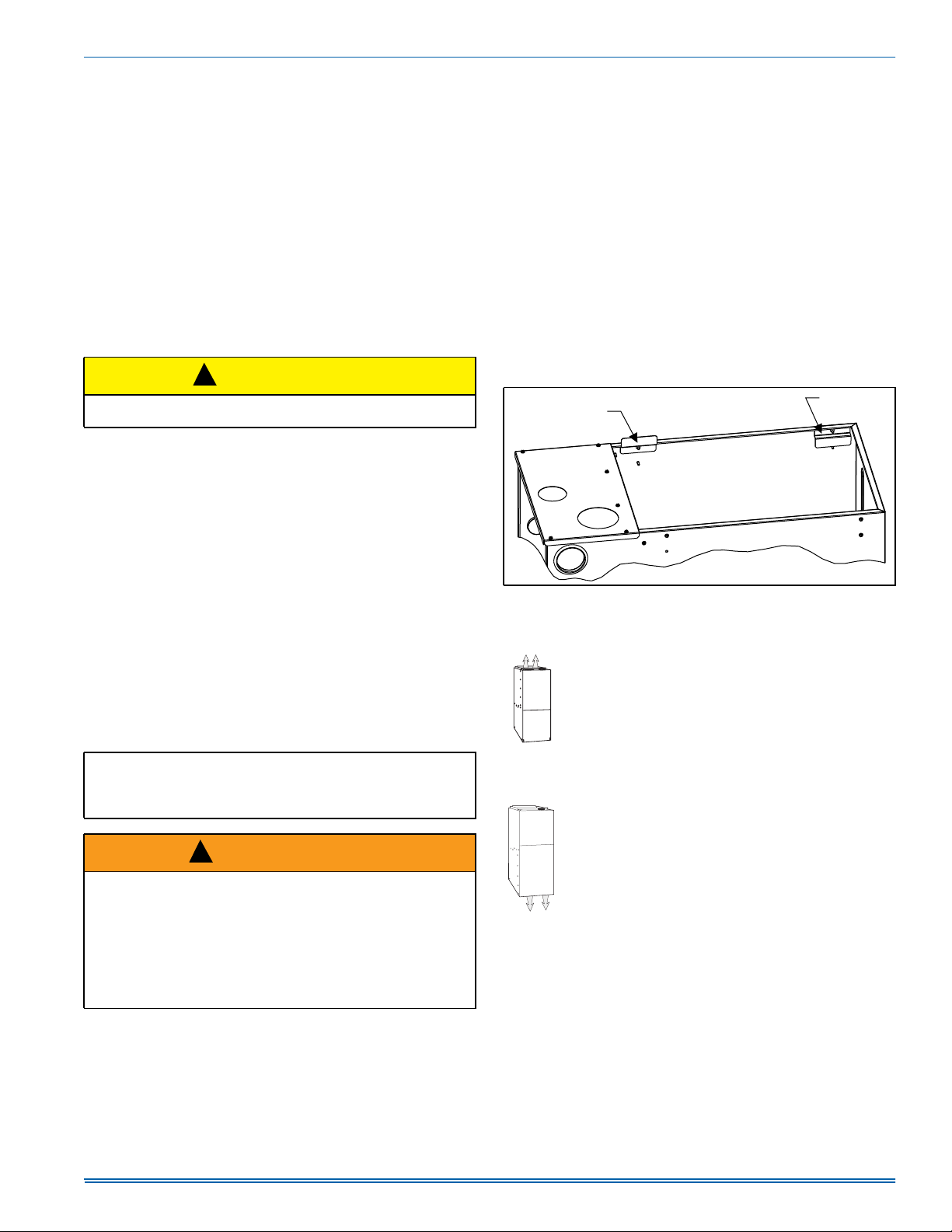

DUCT FLANGES

Four flanges are provided to attach ductwork to the furnace. These

flanges are rotated down for shipment. In order to use the flanges,

remove the screw holding an individual flange, rotate the flange so it is

in the upward position and reinstall the screw then repeat this for all 4

flanges.

If the flanges are not used, they must remain in the rotated down position as shipped.

)RUGXFWDWWDFKPHQW

LIQHHGHG

FIGURE 1: Duct Attachment

)DFWRU\

LQVWDOOHG

$

DUCTWORK INSTALLATION AND SUPPLY PLENUM

CONNECTION - UPFLOW/HORIZONTAL

Attach the supply plenum to the furnace outlet. The use of

an approved flexible duct connector is recommended on all

installations. This connection should be sealed to prevent

air leakage. The sheet metal should be crosshatched to

eliminate any popping of the sheet metal when the indoor

fan is energized.

FLOOR BASE AND DUCTWORK INSTALLATION DOWNFLOW

Installations on combustible material or directly on any

floors must use a combustible floor base shown in Figure 3.

Follow the instructions supplied with the combustible floor

base accessory. This combustible floor base can be

replaced with a matching indoor coil, properly sealed to prevent leaks. Follow the instructions supplied with the indoor

coil cabinet for installing the cabinet to the duct connector.

Plug intake and vent pipe holes in bottom panel and move

grommet to desired vent side exit.

Downflow Air Conditioning Coil Cabinet

The furnace should be installed with coil cabinet part number specifically intended for downflow application. If a matching indoor coil is

used, it may be placed directly on the furnace outlet and sealed to prevent leakage. For details of the coil cabinet dimensions and installation

requirements, refer to the installation instructions supplied with the coil

cabinet.

Attach the indoor coil cabinet to the duct connector, and then position

the furnace on top of the coil cabinet. The connection to the furnace,

indoor coil cabinet, duct connector, and supply air duct must be sealed

to prevent air leakage.

Johnson Controls Ducted Systems 5

5594752-UIM-B-0419

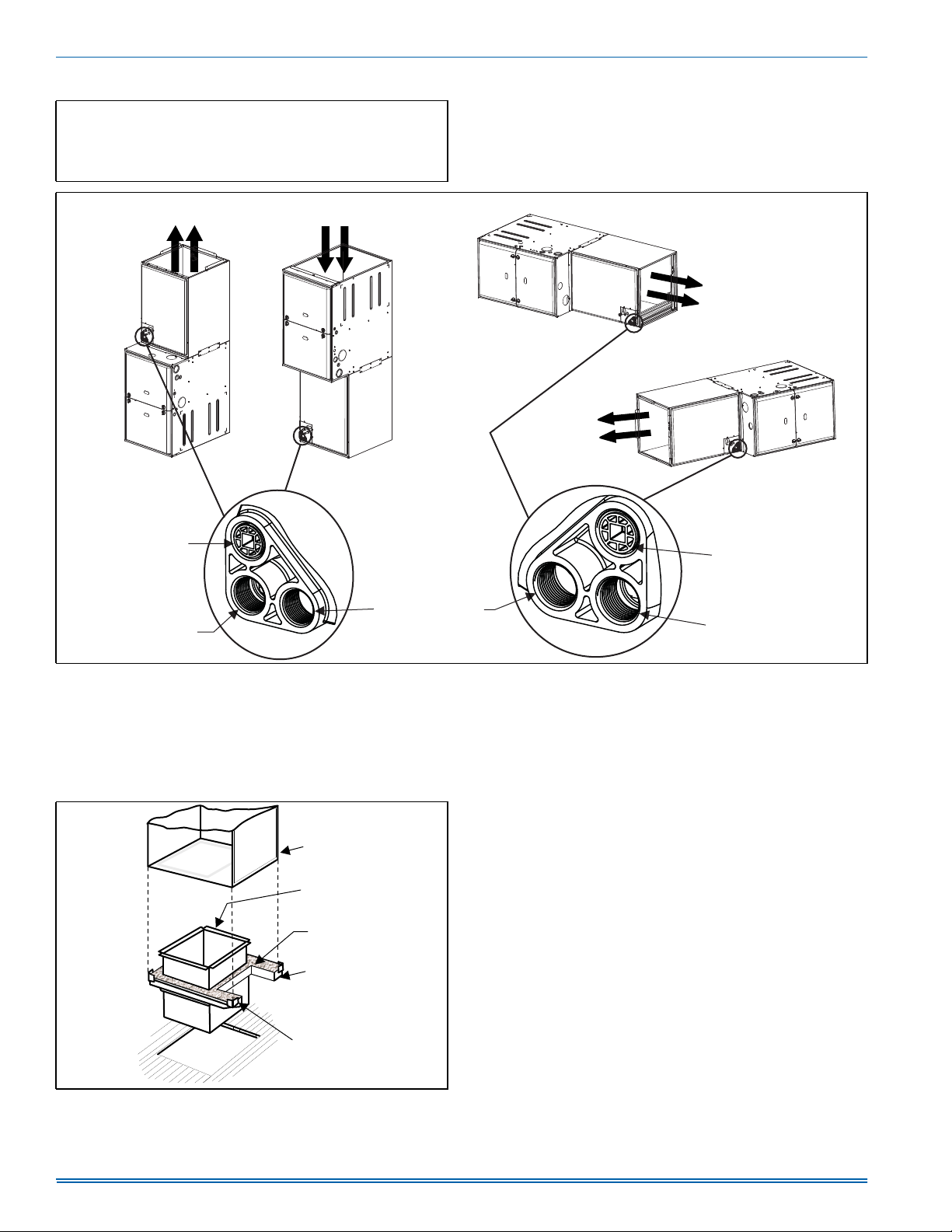

COIL INSTALLATION

IMPORTANT: On all installations without a coil, a removable access

panel is recommended in the outlet duct such that smoke or reflected

light would be observable inside the casing to indicate the presence

of leaks in the heat exchanger. This access cover shall be attached in

such a manner as to prevent leaks.

'2:1)/2:

$33/,&$7,21

127(

9HULI\WKDWDOOGUDLQV

DUHWUDSSHGRUSOXJJHG

)851$&(

&2,/

&2,/

)851$&(

'5$,13/8*

)25+25,=217$/

6(&21'$5<'5$,1

83)/2:

$33/,&$7,21

The indoor coil must be mounted on the supply side of the furnace as

shown in Figure 2. Refer to the Installation Instructions provided with

each indoor coil.

)851$&(

/()7)/2:

$33/,&$7,21

&2,/

&2,/

5,*+7)/2:

$33/,&$7,21

'5$,13/8*

)259(57,&$/

6(&21'$5<'5$,1

)851$&(

35,0$5<'5$,1

75$3&211(&7,21

6(&21'$5<'5$,1

75$3&211(&7,21

FIGURE 2: Furnace and Coil Attachment

DOWNFLOW DUCT CONNECTORS

All downflow installations must use a suitable duct connector approved

by the furnace manufacturer for use with this furnace. The duct connectors are designed to be connected to the rectangular duct under the

floor and sealed. Refer to the instructions supplied with the duct connector for proper installation.

)851$&(

&20%867,%/()/225

%$6($&&(6625<

FIGURE 3: Combustible Floor Base Accessory

:$50$,53/(180

:,7+´)/$1*(6

),%(5*/$66

,168/$7,21

),%(5*/$667$3(

81'(5)/$1*(

$

35,0$5<'5$,1

75$3&211(&7,21

$

RESIDENTIAL AND MODULAR HOME UPFLOW

RETURN PLENUM CONNECTION

Return air may enter the furnace through the side(s) or bottom depending on the type of application. Return air may not be connected into the

rear panel of the unit.

SIDE RETURN APPLICATION

Side return applications pull return air through an opening cut in the

side of the furnace casing. This furnace is supplied with a bottom blockoff panel that should be left in place if a side return is to be used. If the

furnace is to be installed on a flat, solid surface, this bottom panel will

provide an adequate seal to prevent air leakage through the unused

bottom opening. However, if the furnace is to be installed on a surface

that is uneven, or if it is to be installed on blocks or otherwise raised off

the floor, it will be necessary to seal the edges of the bottom panel

to the casing using tape or other appropriate gasket material to

prevent air leakage.

BOTTOM RETURN AND ATTIC INSTALLATIONS

Bottom return applications normally pull return air through a base platform or return air plenum. Be sure the return platform structure or return

air plenum is suitable to support the weight of the furnace.

The internal bottom panel must be removed for this application.

Attic installations must meet all minimum clearances to combustibles

and have floor support with required service accessibility.

6 Johnson Controls Ducted Systems

5594752-UIM-B-0419

DOWNFLOW APPLICATION

For downflow applications, the furnace must be turned upside-down so

that the circulating air enters at the top and exits the furnace at the bottom. The combustion air inducer must be rotated 90° as shown in Figure 14. DO NOT BLOCK COMBUSTION AIR INLET OPENINGS.

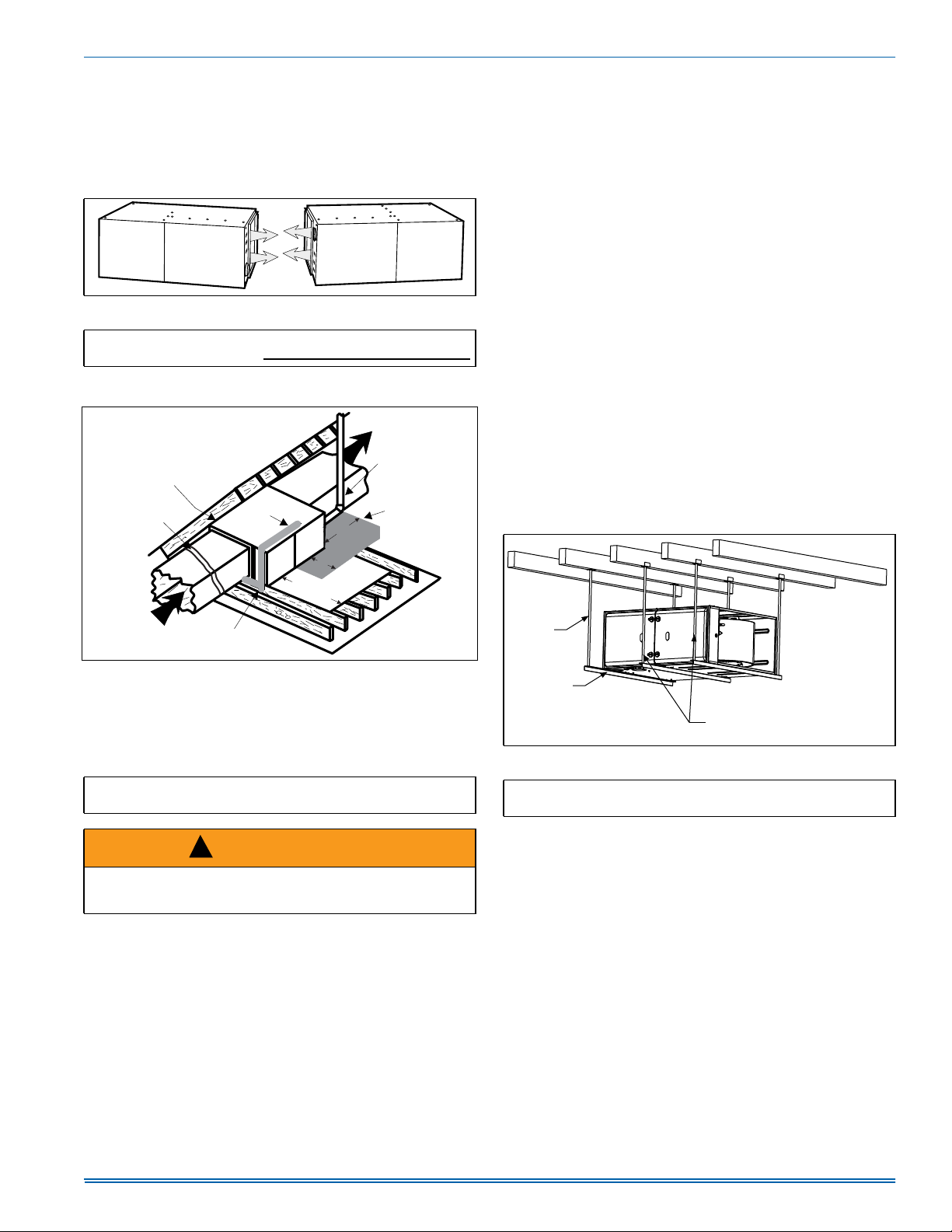

HORIZONTAL APPLICATION

$

FIGURE 4: Horizontal Application

IMPORTANT: This furnace may be installed in a horizontal position

on either side as shown above. It must not be installed on its back.

ATTIC INSTALLATION

´

6833/<$,5

9(170DLQWDLQ

UHTXLUHGFOHDUDQFHV

WRFRPEXVWLEOHV

6+((70(7$/

,1)52172)

)851$&(

&20%867,21$,5

23(1,1*6,6

5(&200(1'('

$

/,1(&217$&721/<3(50,66,%/(

%(7:((1/,1(6)250('%<7+(

,17(56(&7,212))851$&(723

$1'7:26,'(6$1'%8,/',1*

-2,676678'625)5$0,1*

),/7(55$&.

0867%($0,1,080

',67$1&(

2)´FP

)5207+(

)851$&(

5(7851$,5

*$63,3,1*

6(',0(17

75$3

´

´0,1

:25.$5($

FIGURE 5: Typical Attic Installation

This appliance is certified for line contact when the furnace is installed

in the horizontal left or right position. The line contact is only permissible

between lines that are formed by the intersection of the top and two

sides of the furnace and the building joists, studs or framing. This line

may be in contact with combustible material. Refer to Figure 5.

When moving or handling this furnace prior to installation, always leave

the doors on the furnace to provide support and to prevent damage or

warping of the cabinet. When lifting the furnace, support the ends of the

furnace rather than lifting by the cabinet flanges at the return air openings (bottom or sides) or supply air opening.

It is acceptable to use the primary heat exchanger tubes as a lifting

point provided that the tubes are lifted at the front of the heat exchangers where attached to the vestibule panel. Do not use the top return

bend of the heat exchangers as lifting points as the tubes may shift out

of position or their location brackets/baffles.

SUSPENDED FURNACE / CRAWL SPACE

INSTALLATION

The furnace can be hung from floor joists or installed on suitable blocks

or pads. Blocks or pad installations shall provide adequate height to

ensure that the unit will not be subject to water damage.

Units may also be suspended from rafters or floor joists using rods, pipe

angle supports or straps. In all cases, the furnace should be supported

with rods, straps, or angle supports at three locations to properly support the furnace. Place one support at the supply end of the furnace,

one support located approximately in the center of the furnace near the

blower shelf, and the third support should be at the return end of the furnace. Maintain a 6” (15.2 cm) minimum clearance between the front of

the furnace and the support rods or straps.

All six suspension points must be level to ensure proper and quiet furnace operation. When suspending the furnace, use a secure platform

constructed of plywood or other building materials secured to the floor

or ceiling joists. Refer to Figure 6 for details and additional information.

6XSSRUW

5RG

6XSSRUW

$QJOH[

$

FIGURE 6: Typical Suspended Furnace / Crawl Space Installation

0DLQWDLQ´PLQLPXP

FOHDUDQFHEHWZHHQVXSSRUW

URGVDQGIURQWRIIXUQDFH

IMPORTANT: During installation, doors should remain on the

furnace when moving or lifting.

IMPORTANT: During installation, doors should remain on the

furnace when moving or lifting.

When moving or handling this furnace prior to installation it is recom-

!

WARNING

When a furnace is installed in an attic or other insulated space, keep

all insulating materials at least 12 inches (30.5 cm) away from furnace

and burner combustion air openings.

mended to leave the doors on the furnace to provide support and to

prevent damage or warping of the cabinet. When lifting the furnace,

support the ends of the furnace rather than lifting by the cabinet flanges

at the return air openings (bottom or sides) or supply air opening.

It is acceptable to use the primary heat exchanger tubes as a lifting

point provided that the tubes are lifted at the front of the heat exchangers where attached to the vestibule panel. Do not use the top return

bend of the heat exchangers as lifting points as the tubes may shift out

of position or their location brackets/baffles.

Johnson Controls Ducted Systems 7

5594752-UIM-B-0419

5,*+76,'(

´

´

5(7851(1'

´

´

/()76,'(

´

´

´

%

´

9HQW&RQQHFWLRQ

2XWOHW

(OHFWULFDO

(QWU\

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

´'LDPHWHU

9HQW&RQQHFWLRQ

2XWOHW

&

)5217

$

´

(OHFWULFDO

(QWU\

9HQW

&RQQHFWLRQ

2XWOHW

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

%

6833/<(1'

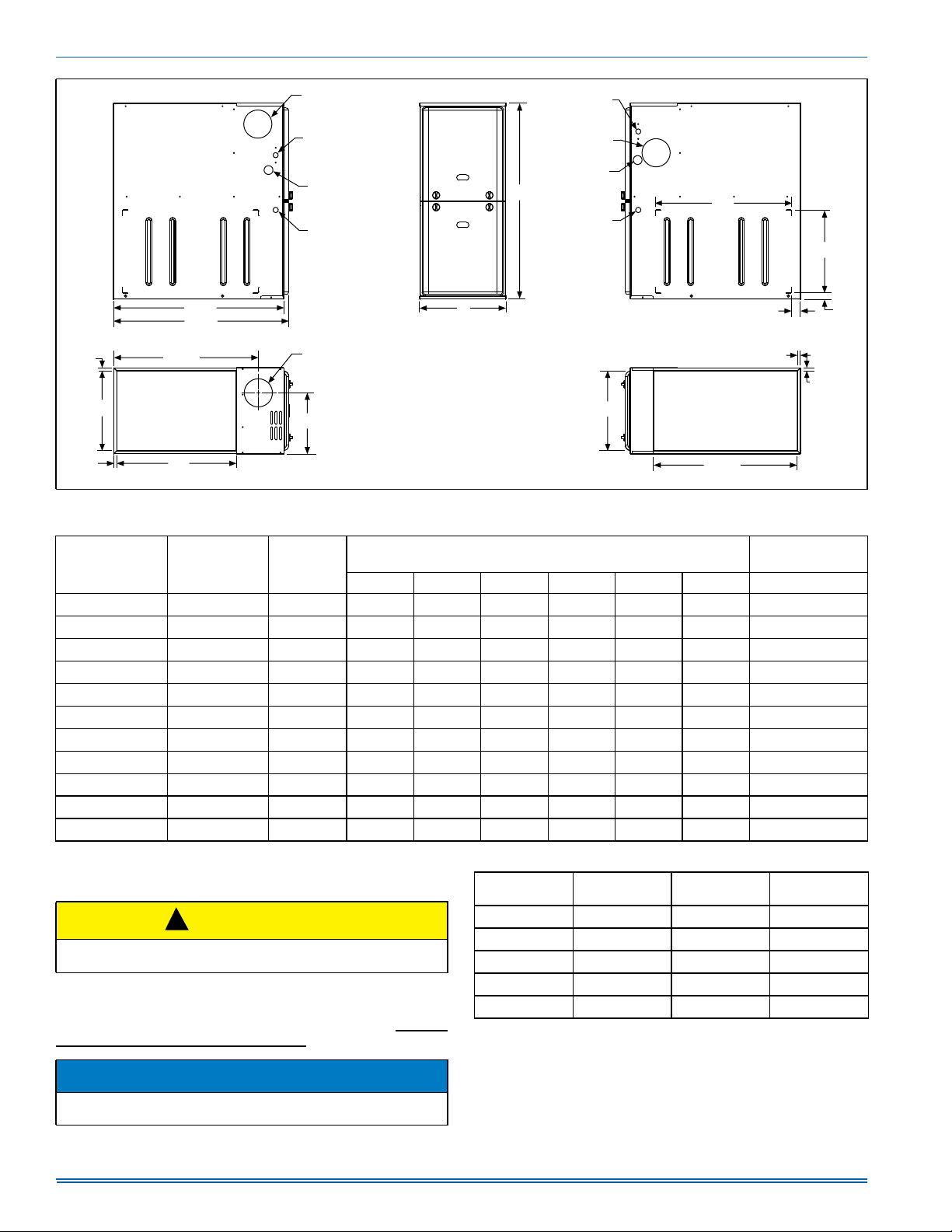

FIGURE 7: Dimensions

Table 2: Cabinet and Duct Dimensions

BTUH (kW)

Input

Nominal

CFM (m

3

/min)

Cabinet

Size

A A (cm) B B (cm) C C (cm) Lbs

Cabinet Dimensions (Inches)

40 (11.7) 1200 (34.0) A 14 1/2 36.8 13 3/8 34.0 10.3 26.2 89

60 (17.6) 1200 (34.0) A 14 1/2 36.8 13 3/8 34.0 10.3 26.2 94

80 (23.4) 1200 (34.0) B 17 1/2 44.4 16 3/8 41.6 11.8 29.9 103

80 (23.4) 1600 (45.3) C 21 53.3 19 7/8 50.5 13.6 34.5 116

80 (23.4) 2000 (56.6) C 21 53.3 19 7/8 50.5 13.6 34.5 121

100 (29.3) 1200 (34.0) B 17 1/2 44.4 16 3/8 41.6 11.8 29.9 108

100 (29.3) 1600 (45.3) C 21 53.3 19 7/8 50.5 13.6 34.5 120

100 (29.3) 2000 (56.6) C 21 53.3 19 7/8 50.5 13.6 34.5 124

120 (35.1) 1600 (45.3) C 21 53.3 19 7/8 50.5 15.8 40.1 125

120 (35.1) 2000 (56.6) C 21 53.3 19 7/8 50.5 15.8 40.1 131

130 (38.1) 2000 (56.6) D 24.5 62.2 23 3/8 59.4 17.5 44.4 137

´

´

´

´

´

$

Approximate

Operating Weights

SECTION III: FILTERS

FILTER INSTALLATION

!

CAUTION

All filters and mounting provision must be field supplied. All installations must have a filter installed.

All applications require the use of a field installed filter. All filters and

mounting provision must be field supplied.

Filters must be installed external to the furnace cabinet. DO NOT

attempt to install filters inside the furnace.

NOTICE

Single side return above 1800 CFM is approved as long as the filter

Table 3: Recommended Filter Sizes (High Velocity 600 FPM)

CFM

(m³/min)

Cabinet

Size

Side

(in)

Bottom

(in)

1200 (34.0) A 16 x 25 14 x 25

1200 (34.0) B 16 x 25 16 x 25

1600 (45.3) C 16 x 25 20 x 25

2000 (56.6) C (2) 16 x 25 20 x 25

2000 (56.6) D (2) 16 x 25 22 x 25

1. Air velocity through throwaway type filters may not exceed 300 feet per

minute (91.4 m/min). All velocities over this require the use of high velocity

filters.

2. Do not exceed 1800 CFM using a single side return and a 16x25 filter. For

CFM greater than 1800, you may use two side returns or one side and the

bottom or one return with a transition to allow use of a 20x25 filter.

velocity does not exceed filter manufacturer’s recommendation.

8 Johnson Controls Ducted Systems

5594752-UIM-B-0419

SIDE RETURN

Locate the “L” shaped corner locators. These indicate the size of the cutout to be made in the furnace side panel. Refer to Figure 8.

)52172)

)851$&(

6,'(2)

)851$&(

&251(5

0$5.,1*6

$

FIGURE 8: Side Return Cutout Markings

Install the side filter rack following the instructions provided with that

accessory. If a filter(s) is provided at another location in the return air

system, the ductwork may be directly attached to the furnace side

panel.

IMPORTANT: Some accessories such as electronic air cleaners and

pleated media may require a larger side opening. Follow the instructions supplied with that accessory for side opening requirements. Do

not cut the opening larger than the dimensions shown in Figure 7.

HORIZONTAL FILTERS

Any branch duct (rectangular or round duct) attached to the plenum

must attach to the vertical plenum before the filter. Use of straps and/or

supports is required to support the weight of the external filter box.

DOWNFLOW FILTERS

!

CAUTION

In downflow furnace arrangement, the filter must be located a minimum of 12” from the return air inlet of furnace.

Downflow furnaces typically are installed with the filters located above

the furnace, extending into the return air plenum or duct. Any branch

duct (rectangular or round duct) attached to the plenum must attach to

the vertical plenum above the filter height.

Filter(s) may be located in the duct system external to the furnace using

an external duct filter box attached to the furnace plenum or at the end

of the duct in a return filter grille(s). The use of straps and/or supports is

required to support the weight of the external filter box.

SECTION IV: GAS PIPING

GAS SAFETY

!

DANGER

An overpressure protection device, such as a pressure regulator,

must be installed in the gas piping system upstream of the furnace

and must act to limit the downstream pressure to the gas valve so it

does not exceed 0.5 PSI (14" w.c., 3.48 kPa). Pressures exceeding

0.5 PSI (14” w.c., 3.48 kPa) at the gas valve will cause damage to the

gas valve, resulting in a fire or explosion or cause damage to the furnace or some of its components that will result in property damage

and loss of life.

OUTLET

PRESSURE

PORT

INLET

WRENCH

BOSS

INLET

PRESSURE

PORT

ON/OFF SWITCH

(Shown in ON position)

OFF

ON

FIGURE 9: Gas Valve

IMPORTANT: Plan your gas supply before determining the correct

gas pipe entry. Use 90-degree service elbow(s), or short nipples and

conventional 90-degree elbow(s) to enter through the cabinet access

holes.

GAS PIPING INSTALLATION

Properly sized wrought iron, approved flexible or steel pipe must be

used when making gas connections to the unit. If local codes allow the

use of a flexible gas appliance connection, always use a new listed connector. Do not use a connector that has previously serviced another gas

appliance.

Some utility companies or local codes require pipe sizes larger than the

minimum sizes listed in these instructions and in the codes. The furnace

rating plate and the instructions in this section specify the type of gas

approved for this furnace - only use those approved gases. The installation of a drip leg and ground union is required. Refer to Figure 10.

VENT PORT

OUTLET

MAIN REGULATOR

ADJUSTMENT

A0226-001

NOTE: Ground Union maybe installed inside or outside unit.

Ground

Union

To Gas

Supply

Drip

Leg

External

Manual

Shut-off

Valve

Upflow

Configuration

To Gas

Supply

Drip

Leg

Ground

Union

Gas

Pipe

Gas

Valve

To Gas

Supply

Drip

Leg

External

Manual

Shut-off

Valve

Downflow

Configuration

To Gas

Supply

Drip

Leg

Ground

Union

Gas

Valve

Horizontal

Configuration

Gas Pipe

Gas

Valve

Ground

Union

Drip Leg

Drip Leg

Ground

Union

External

Manual

Shut-off

Valve

To Gas

Supp

To Gas

Supply

ly

FIGURE 10: Gas Piping

Johnson Controls Ducted Systems 9

Loading...

Loading...