Winchester B2332518, B2332517, B2332480, B2332479 User Manual

A

V

A

TECHNICAL

®

TECHNICAL

GUIDE

GUIDE

MODULAR STANDARD ECM

IR HANDLERS

5493749-BTG-B-0619

DESCRIPTION

This unique modular system allows the flexibility to handle any

application. These versatile ME blowers may be used for

upflow, downflow, or horizontal left or right applications. They

may be combined with cased coils to function as a cooling only

unit or with a heat pump including electric heat for 1 and 3

phase applications. The ME blower and 6HK electric heat kits

can be used as stand alone electric furnaces. Using Standard

ECM motors, system matches provide higher SEER/HSPF

ratings than standard blower models at attractive price points.

FOR USE WITH SPLIT-SYSTEM

COOLING AND HEAT PUMPS

MODELS: ME SERIES - 208/230 V -

1 PHASE

1

Due to continuous product improvement, specifications

are subject to change without notice.

isit us on the web at

www.simplygettingthejobdone.com

FEATURES

COMMON ME AIR HANDLER AND MATCH-UP CM COIL

FEATURES

Rigid Case Construction - An interior endoskeleton for

structural support, smooth sides, and locks in insulation.

Powder-painted - G30 galvanized steel case provide a coated

edge that resists corrosion and rust creep.

Quality Construction - Structural components are made of

Aluminum or G90 galvanized steel to prevent corrosion.

Improved Insulation Design - Single piece with no external

screws to reduce thermal transmission paths to prevent

sweating. Foil faced insulation for ease of cleaning.

Case Depth - These models have 20.5” casing which provide

ease of attic access and tight applications.

ME AIR HANDLERS

Factory Sealed - Achieves 2% or less total airflow leakage rate

at duct leakage test conditions in positive and negative

pressure for system airflow verification.

Electric Heat Kits - 6HK series of field installed electric heat

kits are available for installation-friendly and easy service

applications.

Blowers - All models use direct-drive, standard ECM motors.

CM COILS

MaxAlloy

lasting performance, efficiency, and reliability.

Thermostatic Expansion Valve - The TXV is installed using

Chatleff mechanical fittings and is easy to install on any

MaxAlloy coil without brazing to create an appropriate system

match. Some models are available with a factory installed TXV.

Thermoset Drain Pan - Low retention and positive slope for

drainage to reduce potential mold or contaminants.

Accessories - A full line of matching accessories available for

use with the blower and coils to provide for any type of

application.

TM

Coil - Long life aluminum coils built to deliver

dditional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY

Standard 5-year limited parts warranty.

Extended 10-year limited parts warranty when product is

registered online within 90 days of purchase for replacement

or closing for new home construction.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

5493749-BTG-B-0619

LIST OF SECTIONS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND DUCT CONNECTION DIMENSIONS . . . . . . . . 3

DIMENSIONS - ME MODULAR AIR HANDLERS AND CM

MULTI-POSITION FULL CASED COILS . . . . . . . . . . . . . . . . . . . . . 3

COOLING CAPACITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PHYSICAL AND ELECTRICAL DATA - COOLING ONLY . . . . . . . . 5

kW AND MBH CONVERSIONS - FOR TOTAL

POWER INPUT REQUIREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

APPLICATION FACTORS - RATED CFM VS. ACTUAL CFM . . . . . 6

ELECTRICAL DATA - COOLING ONLY . . . . . . . . . . . . . . . . . . . . . . 6

MINIMUM FAN SPEED - ELECTRICAL HEAT

WITH HEAT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DEFAULT BLOWER SPEEDS FOR FER

COMPLIANCE - ELECTRICAL HEAT ONLY . . . . . . . . . . . . . . . . . . 6

ELECTRIC HEAT PERFORMANCE DATA: 208/230-1-60 AND

208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ELECTRICAL DATA FOR SINGLE SOURCE

POWER SUPPLY: 208/230-1-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ELECTRICAL DATA FOR MULTI-SOURCE

POWER SUPPLY: 208/230-1-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ELECTRICAL DATA FOR SINGLE SOURCE

POWER SUPPLY: 208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ELECTRICAL DATA FOR MULTI-SOURCE

POWER SUPPLY: 208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

POWER WIRING - LINE CONNECTIONS . . . . . . . . . . . . . . . . . . . 10

BLOWER SPEED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 10

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FILTER RACK DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COMBUSTIBLE FLOOR BASE ACCESSORY . . . . . . . . . . . . . . . . 12

TYPICAL THERMOSTAT CONNECTION . . . . . . . . . . . . . . . . . . . . 13

AIRFLOW DATA - CFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

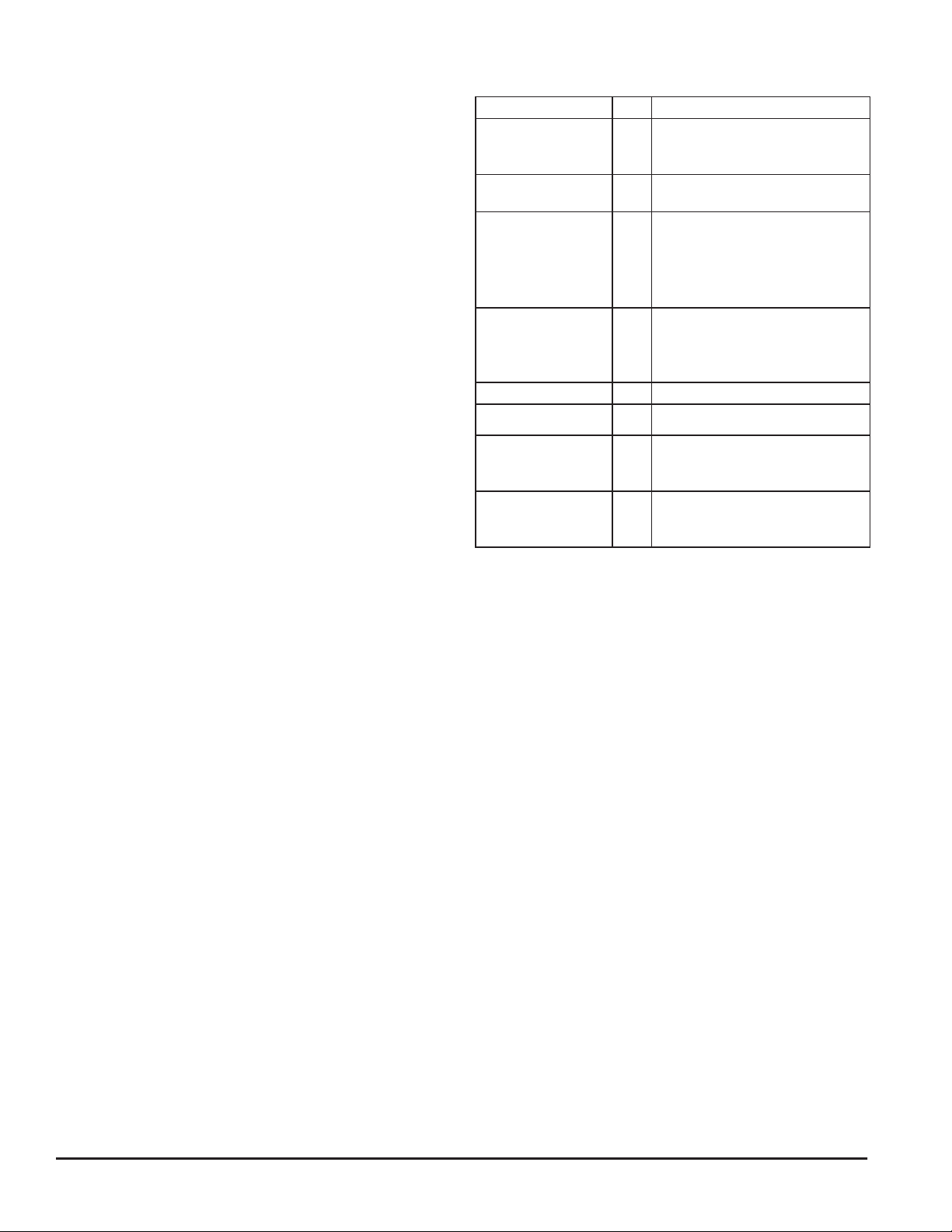

NOMENCLATURE

PRODUCT TYPE

POSITION

MOTOR TYPE

OPTIONS

NOMINAL

AIRFLOW

CABINET WIDTH

OPTIONS

VOLTAGE

(Voltage-Phase-Hertz)

GENERATION

(MAJOR REVISION)

STYLE LETTER

(MINOR REVISION)

NOT USED FOR

ORDERING

M = Modular Blower

M

P = Multi PSC

E = Multi Std ECM

E

V = Multi VS ECM

C = Communications Ready

-

- (No Designator) = Standard (No Options)

08 = 800 CFM

12 = 1,200 CFM

12

14 = 1,400 CFM

16 = 1,600 CFM

20 = 2,000 CFM

A = 14.5"

B = 17.5"

B

C = 21.0"

D = 24.5"

N = No options

N

2 = 208/230-1-60

2

1 = 1st Gen

2 = 2nd Gen

1

etc.

A = Style A

B = Style B

A

etc.

2 Johnson Controls Ducted Systems

5493749-BTG-B-0619

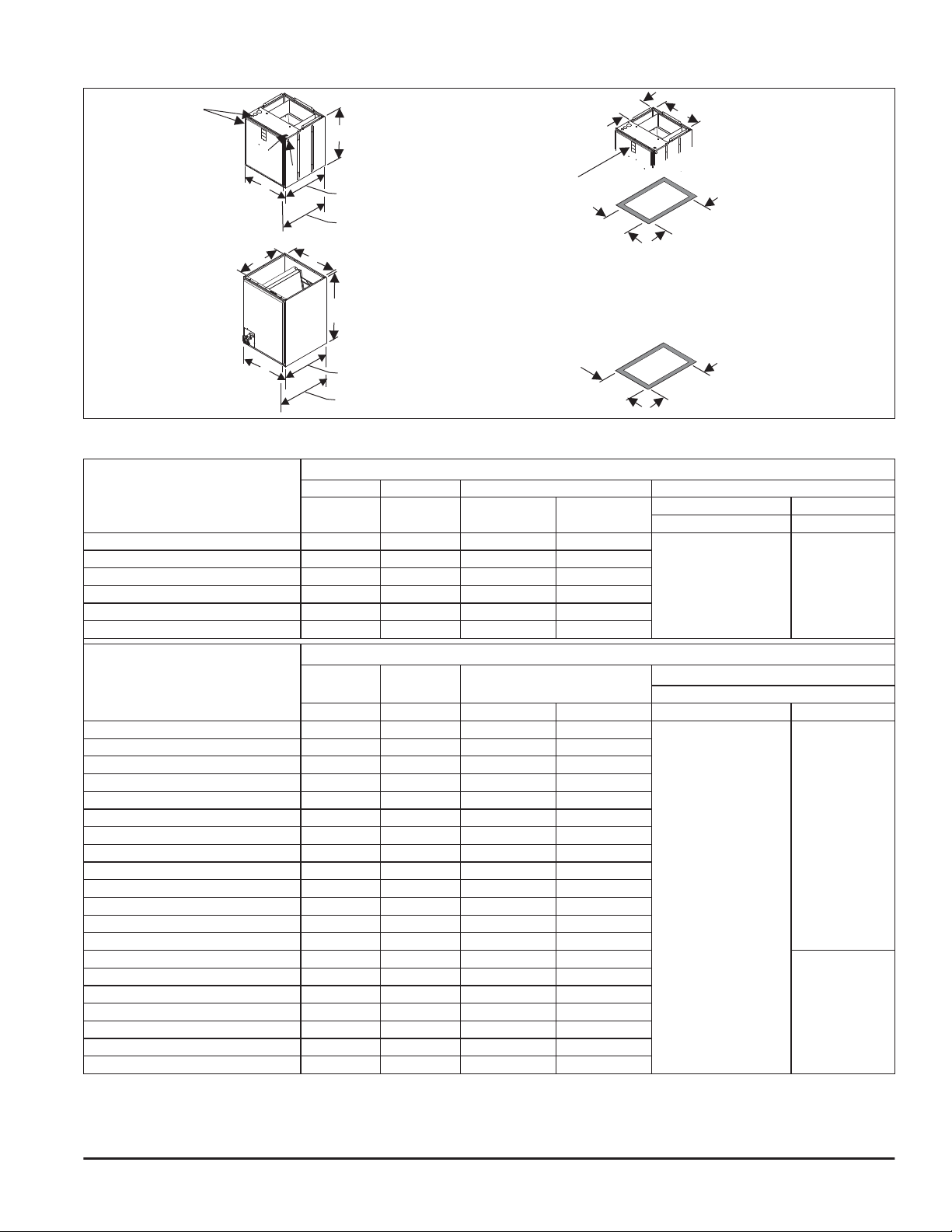

DIMENSIONS AND DUCT CONNECTION DIMENSIONS

E

AIR HANDLER

(OPENING)

COIL

19-1/8”

A

F

F

B

B

20-1/2”

21-1/2”

C (OPENING)

A

20-1/2”

21-1/2”

SERVICE DISCONNECT

PANEL

12-3/16”

C (OPENING)

BOTTOM OPENING

D (OPENING)

D

BOTTOM INLET

19-1/8”

DIMENSIONS

19-1/8”

TOP OUTLET

DIMENSIONS

DIMENSIONS

DIMENSIONS - ME MODULAR AIR HANDLERS AND CM MULTI-POSITION FULL CASED COILS

Dimensions

Models

Height Width Opening Widths Wiring Knockouts

AB C D

ME08BN21 21-1/2 17-1/2 16-1/2 16-1/2

ME12BN21 21-1/2 17-1/2 16-1/2 16-1/2

ME12CN21 22-1/2 21 20 20

ME14DN21 22-1/2 24-1/2 23-1/2 23-1/2

ME16CN21 22-1/2 21 20 20

ME20DN21 22-1/2 24-1/2 23-1/2 23-1/2

Dimensions

Models

2

Height Width Opening Widths

A B C D Liquid Vapor

CM18A* 19-1/2 14-1/2 13-1/2 13-1/2

CM18B 19 17-1/2 16-1/2 16-1/2

CM24A* 19-1/2 14-1/2 13-1/2 13-1/2

CM24B* 19 17-1/2 16-1/2 16-1/2

CM24C 21 21 20 20

CM30A* 25-1/2 14-1/2 13-1/2 13-1/2

CM30B* 23 17-1/2 16-1/2 16-1/2

CM30C 23 21 20 20

CM30D 25 24/1/2 23-1/2 23-1/2

CM36A 25-1/2 14-1/2 13-1/2 13-1/2

CM36B* 25-5/8 17-1/2 16-1/2 16-1/2

CM36C* 25 21 20 20

CM36D 25 24-1/2 23-1/2 23-1/2

CM42C* 27 21 20 20

CM42D 27 24-1/2 23-1/2 23-1/2

CM48C* 33 21 20 20

CM48D* 32-3/4 24-1/2 23-1/2 23-1/2

CM60C* 33 21 20 20

CM60D* 32-3/4 24-1/2 23-1/2 23-1/2

CM64D 32-3/4 24-1/2 23-1/2 23-1/2

1. All dimensions are in inches.

2. Asterisk denotes coils available with Factory installed TXV.

3. Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

4. Adapter fitting must be field installed for other line set size.

5. See outdoor unit technical guide for proper line set size.

1

EF

Power Control

7/8 (1/2),

1-3/8 (1),

1-23/32 (1-1/4)

1

Refrigerant Connections

Line Size

3/8

A0452-002

7/8 (1/2)

3,4,5

3/4

7/8

Johnson Controls Ducted Systems 3

5493749-BTG-B-0619

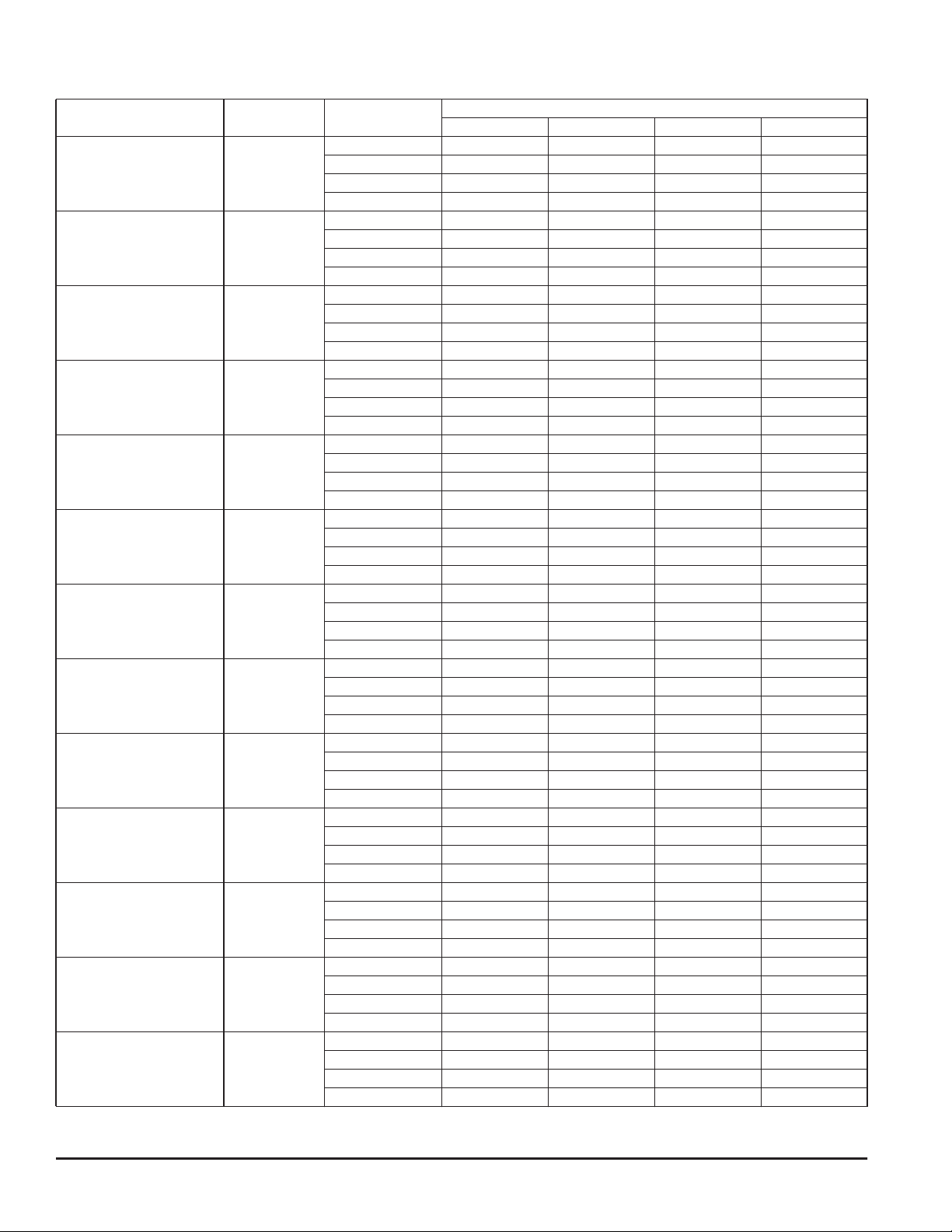

COOLING CAPACITY1

Models

CM18B 600

CM24B 800

CM24C 800

CM30B 1000

CM30C 1000

CM30D 1000

CM36B 1000

CM36B 1200

CM42C 1200

CM36C 1200

CM36D 1200

CM42C 1400

CM42D 1400

Continued on next page

Rated CFM

Entering Air

2

Dry/Wet Bulb (°F)

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

85/72 45.7 41.6 36.8 30.5

80/67 38.5 33.9 28.5 22.3

75/62 31.5 26.5 20.5 15.9

70/57 24.4 19.5 15.2 11.5

85/72 52.2 47.5 41.8 35.0

80/67 43.6 38.3 31.9 24.5

75/62 35.2 29.5 22.7 16.2

70/57 27.1 20.7 15.5 11.4

85/72 52.2 47.5 41.8 35.0

80/67 43.6 38.3 31.9 24.5

75/62 35.2 29.5 22.7 16.2

70/57 27.1 20.7 15.5 11.4

85/72 75.3 67.8 56.8 47.1

80/67 62.6 54.6 44.2 34.5

75/62 50.2 41.3 32.0 22.9

70/57 37.8 30.1 21.5 16.2

85/72 75.3 67.8 56.8 47.1

80/67 62.6 54.6 44.2 34.5

75/62 50.2 41.3 32.0 22.9

70/57 37.8 30.1 21.5 16.2

85/72 75.3 67.8 56.8 47.1

80/67 62.6 54.6 44.2 34.5

75/62 50.2 41.3 32.0 22.9

70/57 37.8 30.1 21.5 16.2

85/72 82.1 73.7 64.1 54.4

80/67 68.6 60.1 50.5 39.5

75/62 56.3 47.0 37.3 29.2

70/57 43.5 36.0 28.3 21.6

85/72 91.6 82.4 71.3 59.4

80/67 76.5 65.4 54.6 42.8

75/62 61.3 51.2 40.0 30.5

70/57 47.5 38.1 28.7 22.3

85/72 98.0 88.6 77.4 66.4

80/67 82.6 72.6 61.7 50.6

75/62 68.5 57.6 47.5 36.6

70/57 53.9 44.8 35.0 28.4

85/72 91.6 82.4 71.3 59.4

80/67 76.5 65.4 54.6 42.8

75/62 61.3 51.2 40.0 30.5

70/57 47.5 38.1 28.7 22.3

85/72 91.6 82.4 71.3 59.4

80/67 76.5 65.4 54.6 42.8

75/62 61.3 51.2 40.0 30.5

70/57 47.5 38.1 28.7 22.3

85/72 100.6 89.8 78.2 64.7

80/67 83.5 73.7 59.8 48.0

75/62 67.8 55.8 44.7 32.5

70/57 52.3 41.5 30.7 23.7

85/72 100.6 89.8 78.2 64.7

80/67 83.5 73.7 59.8 48.0

75/62 67.8 55.8 44.7 32.5

70/57 52.3 41.5 30.7 23.7

4 Johnson Controls Ducted Systems

5493749-BTG-B-0619

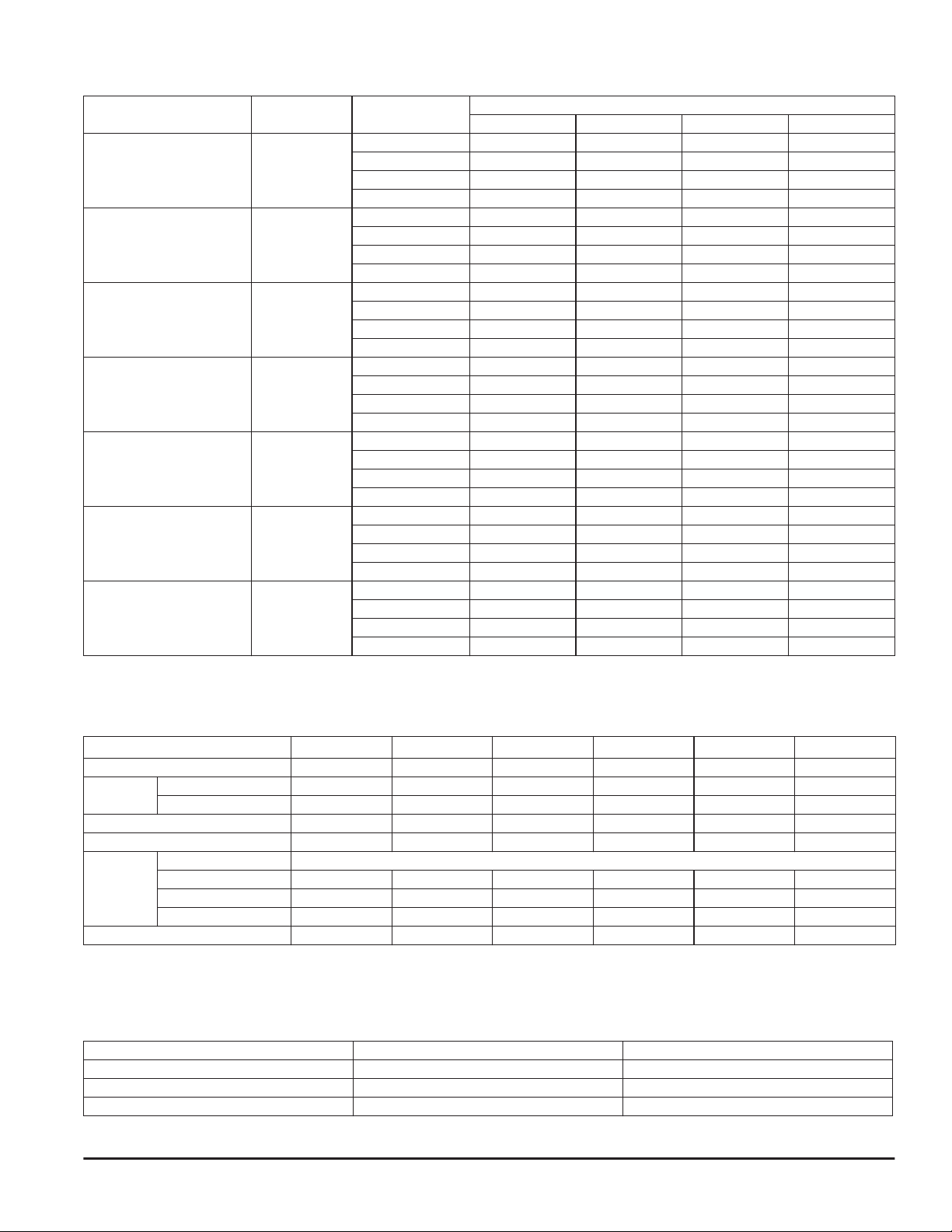

COOLING CAPACITY1 (Continued)

Entering Air

Models

CM48C 1400

CM48C 1600

CM48D 1600

CM60C 1800

CM61C 1800

CM60D 1800

CM64D 1800

1. See Condensing Unit or Heat Pump Technical Guide for Total Cooling Capacity and Sensible Capacity.

2. Airflow is calculated for each system tonnage.

Rated CFM

2

Dry/Wet Bulb (°F)

85/72 108.0 98.4 88.1 73.8

80/67 93.3 82.1 69.7 57.0

75/62 75.9 64.4 53.1 41.9

70/57 60.7 49.9 39.4 32.4

85/72 115.2 105.0 93.9 79.0

80/67 88.3 78.2 65.5 52.6

75/62 72.7 60.8 50.1 37.6

70/57 57.7 46.9 36.6 29.7

85/72 115.2 105.0 93.9 79.0

80/67 88.3 78.2 65.5 52.6

75/62 72.7 60.8 50.1 37.6

70/57 57.7 46.9 36.6 29.7

85/72 115.1 103.0 91.7 78.6

80/67 96.8 85.9 73.7 60.5

75/62 80.7 69.4 57.5 43.5

70/57 58.7 48.9 37.7 32.7

85/72 122.9 111.8 98.0 82.6

80/67 102.2 89.8 75.7 59.9

75/62 82.5 69.7 54.9 38.7

70/57 64.3 50.8 38.2 29.4

85/72 115.1 103.0 91.7 78.6

80/67 96.8 85.9 73.7 60.5

75/62 80.7 69.4 57.5 43.5

70/57 58.7 48.9 37.7 32.7

85/72 133.6 118.5 103.2 86.6

80/67 111.4 96.2 80.3 62.8

75/62 90.7 75.1 60.0 43.5

70/57 70.6 56.9 42.5 32.8

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

PHYSICAL AND ELECTRICAL DATA - COOLING ONLY

Models ME08B ME12B ME12C ME14D ME16C ME20D

Blower - Diameter x Width 10 x 8 10 x 8 11 x 10 11 x 10 11 x 10 11 x 10

Motor

Voltage 208/230 208/230 208/230 208/230 208/230 208/230

Full Load Amps @230 V 2.6 3.8 3.8 3.8 5.4 5.4

Filter

Shipping / Operating Weight (lb) 52/51 52/51 68/67 75/74 68/67 75/74

1. Field Supplied.

HP 1/3 HP 1/2 HP 1/2 HP 1/2 HP 3/4 HP 3/4 HP

Nominal RPM 1050 1050 1050 1050 1050 1050

Type DISPOSABLE OR WASHABLE

Size 16 x 20 x 1 16 x 20 x 1 20 x 20 x 1 22 x 20 x 1 20 x 20 x 1 22 x 20 x 1

1

Bottom Rack Kit 1BR01117 1BR01117 1BR01121 1BR01124 1BR01121 1BR01124

Permanent Type Kit 1PF0601 1PF0601 1PF0602 1PF0603 1PF0602 1PF0603

kW AND MBH CONVERSIONS - FOR TOTAL POWER INPUT REQUIREMENT

For a power distribution voltage that is different than the provided nominal voltage, multiply the kW and MBH data from the table by

the conversion factor in the following table.

DISTRIBUTION POWER NOMINAL VOLTAGE CONVERSION FACTOR

208 V 240 V 0.75

220 V 240 V 0.84

230 V 240 V 0.92

Johnson Controls Ducted Systems 5

Loading...

Loading...