Winbest PCP User Manual

by

PCP Pump

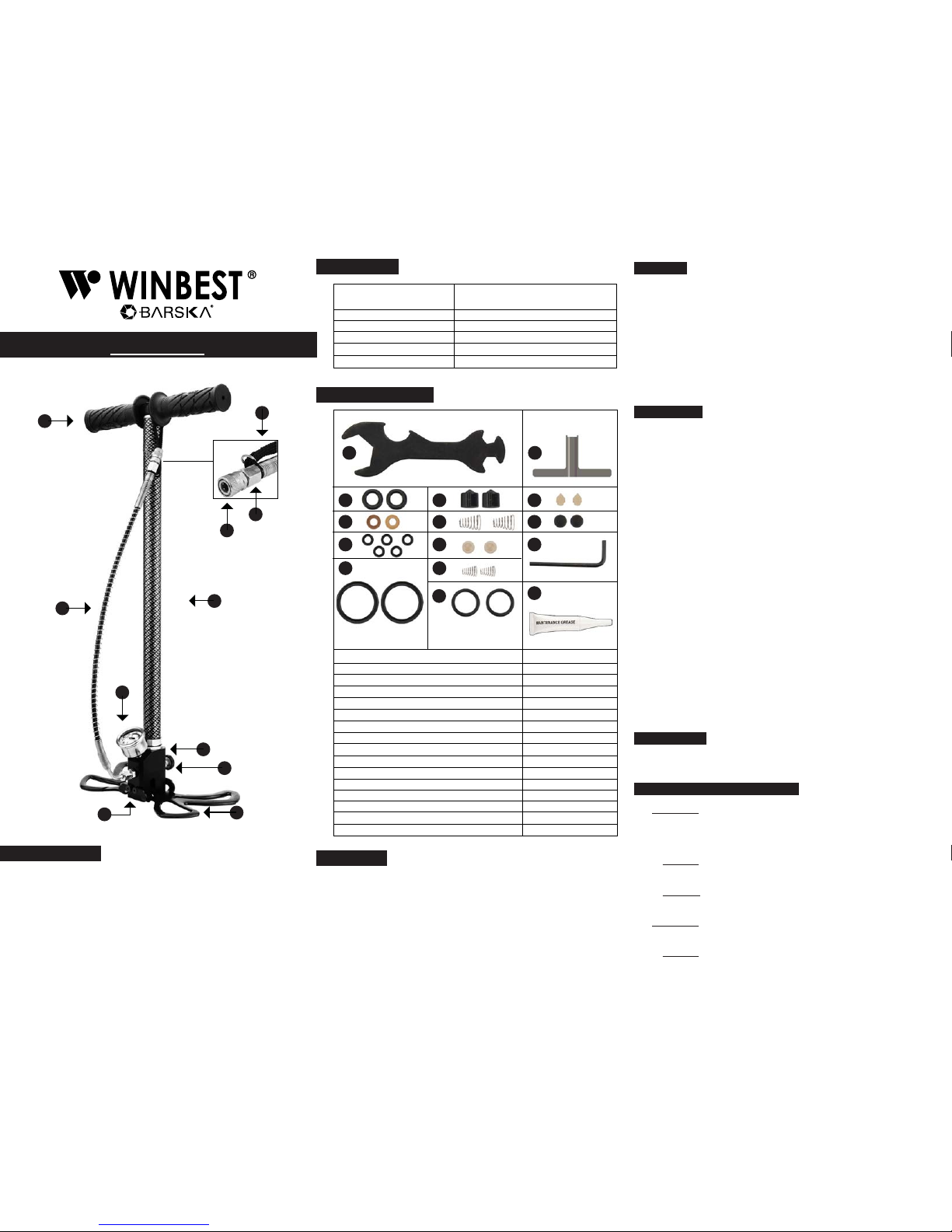

A - Rubber Grip

B - Pump Barrel

C - Base Plate

D - Pressure Gauge

E - Moisture Filter

F - Hose

G - Quick Connector

H - Test Plug

I - Bleed Valve

J - Folding Base Plate

K - Belt

A

B

F

D

E

J

I

C

H

G

Length:

Weight:

Maximum Pressure:

Time:

Output Nut:

Quick Connector:

25.6 inches / 650mm retracted

44.1 inches / 1120mm expanded

5.29 lbs / 2.4kg

4500 psi / 310 bar

At 200 bar 2 hours continuously

M10x1

8/16” / 8mm size

Specifications

Included Accessories

Item

Special Wrench

T Spanner

High Pressure Stem Sealing Ring

High Pressure Piston Ring

O-Ring

Other Tube Piston Ring

Check Valve

Check Valve Spring

Sealing Gasket of Bleed Valve

High Pressure Piston Spring

Low Pressure Piston Ring

High Pressure Spool Valve

Inlet Hole One Way Seal Ball

Allen Spanner

Maintenance Grease

Qty

1

1

2

2

5

2

2

2

2

2

2

2

2

1

1

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

1 2

3

4

11

5

6

7

8

9

12

13

14

15

10

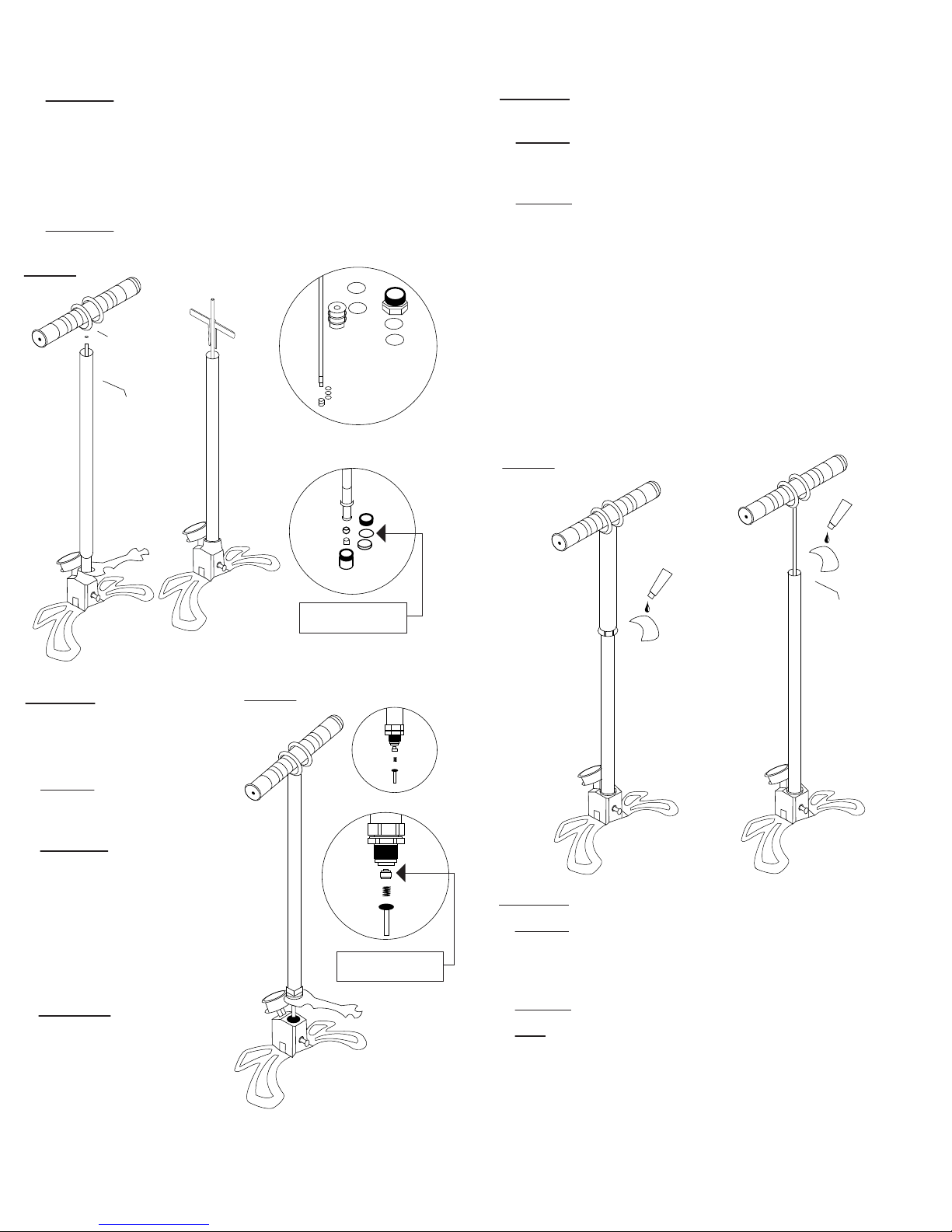

Install

Open the package and inspect all items. Read the instructions

before use. Familiarize yourself with proper operational method.

The wrong operation can be harmful to the user and may damage

the pump.

Loosen the belt on the pump, unscrew the bleed valve, pump up

and down 10 times to empty the pump. Tighten the bleed valve

and pump up to 200 bar (usually 6 times) then wait for 2 minutes

under 200 bar state to check whether there is leakage (check

pressure gauge needle). The best way to check for a leakage

point is to place the pump underwater.

Operation

1. Remove test plug from pump by pressing down on silver ring.

2. Before pumping, be sure the hose has no knots. Pull

and push the pump quickly. You will feel resistance when the

pressure in the container reaches 100 bar, this is normal.

3. Connect the pump to the container according to the

container’s instructions.

Note: Before starting to fill the container, read the instruction

booklet about that container to ensure the correct amount of

pressure.

4. Check that the bleed valve is tightened correctly. Keep the

pump steady by standing on the base of the pump. Pull

and push the pump quickly to inflate the gas.

5. Open the bleed valve screw to relieve pressure in the hose.

Make sure the pressure gauge needle is at 0 before

disconnecting the container.

Note: You could directly open the bleed valve if the container

has a unidirectional valve. If your container does not have

a unidirectional valve, first turn off the valve to release residual

gas in the pump barrel and hose when filling the container. It is

normal to find small amounts of gas and water leaking from

the bleed valve.

6. Disconnect the pump from the container according to the

container’s instructions.

High Piston

1. First to screw the nut off.

2. Use T spanner to take the pole out.

Common Problems and Solutions

Problem 1: The needle of pressure gauge does not move or

moves very slowly when pumping. Generally speaking a 0.5L

standard container should cause the needle to reach the 200 bar

when pumped for 420-450 times.

Reason: The needle has not moved or is moving very slowly is

because of a leak.

Solution: To confirm leak place pump underwater to find a

leakage point.

Problem 2: In the process of pumping, it pulls heavy and pump

automatically pumps down

Reason: The stage 3 piston has a malfunction

WARNING

DO NOT disassemble any joint when there is residual gas, it is

dangerous to take apart the joint in this situation.

DO NOT put your hand near the air vent or point it at people when

you release the bleed valve screw, it can cause serious damage.

DO NOT add lubricating oil to the pump. Use appropriate grease

as necessary.

Parts of the Pump

K

Solution 1: Open the bleed valve to take apart the tube and the

connecting screw which is on the top of the pump barrel. Fill

the tube with water or silicon oil (not included), then

reassemble the pump, remove test plug and continuously

pump (10 times). When the pump automatically sucks back

remove any debris from the valve and replace the o-ring.

See image 1.

Solution 2: Take apart the Level 3 piston set to find the

leakage or change the o-ring.

Problem 3: In the process of

pumping the pull is very light but

pushing down has resistance or

it will automatically run up.

Reason: Setup instructions

may have not been followed

correctly.

Solution 1: Add lubricating oil

or silicone oil, do not release

excess gas in high pressure,

this can cause a gas

explosion if the pressure is

above 150 bar resulting in a

damaged check valve or a

carbon deposit in the

check valve.

Solution 2 : Clean or

replace the check valves

when the pump automatically

runs up. Use the included

special wrench to open the

base to replace or clean

the check valve. See image 2.

Problem 4: The resistance builds up when pulling and pushing

the pump.

Reason: Dust may have accumulated on the seals surface and

is interfering with the self-lubricating function. The pump now

requires maintenance.

Solution: Disassemble pump, apply maintenance grease on a

cloth, then dry wipe all sealing rings, cylinder surfaces, 5mm

solid core rod and the whole external high-pressure piston. After

assembly, ensure that all sliding surfaces have a thin layer of

maintenance grease.

To test if there is enough lubrication pour out the excess

maintenance grease and the base absorption ball inside. Empty

the pump by pumping it about 50 times to discharge excess

maintenance grease. Clean the base adsorption ball and check

valve with detergent and water. Make sure items are dry and

place them back into the base. Use the test plug to test the

pump according to problem 3. When you feel a heavy pull

during the inflation process, apply a small amount of

maintenance grease. See image 3.

Problem 5: The pressure gauge needle is not at zero.

Reason: Lubricating oil and silicone oil was not added or

drained properly causing an explosion under the pressure of

150 bar or higher. Damage may also been caused

during transportation.

Solution: Pressure gauge needs to be replaced.

Note

You will hear a hissing and water sound when you release

residual gas in the pump and hose. Normally a small volume of

gas is released, if the volume of the gas is large the check valve

may not work properly or the check valve is not fastened well. If

the problem still exists contact the manufacturer.

Image 2

Image 1

Image 3

O-Ring

Accessory Number 5

Check Valve

Accessory Number 7

Loading...

Loading...