WinAir ECO 1200, SC 800, ECO 800, SC 1200, SC 2200 Operating Manual

...

3

ENOPERATING MANUAL : Compressor Screw

1 - INDEX

2 - FOREWORD

2-1 Declaration of incorporation ................................................................................................................................ p.5

2-2 Notes on the compressor .................................................................................................................................... p.6

2-3 Intended use........................................................................................................................................................ p.6

2-4 Technical data ..................................................................................................................................................... p.7

2-5 Maintenance and care ......................................................................................................................................... p.7

2-6 General information ............................................................................................................................................. p.8

2-7 Garantee ............................................................................................................................................................. p.8

3 - SAFETY REGULATIONS

3-1 Identication of safety guidelines ........................................................................................................................ p.9

3-2 General safety instructions .................................................................................................................................. p.9

3-3 Changes and modications to the machine ...................................................................................................... p.10

3-4 Loading / Relocation / Travelling ....................................................................................................................... p.11

3-5 Installation / Starting and Normal ...................................................................................................................... p.12

3-6 Special work / Maintenance .............................................................................................................................. p.14

3-7 Warning of special dangers ............................................................................................................................... p.17

4 - CONSTRUCTION AND FUNCTIONAL DESCRIPTION

4-1 Construction ...................................................................................................................................................... p.22

4-2 Installation Scheme ........................................................................................................................................... p.23

4-3 Functional Description ....................................................................................................................................... p.24

4-4 Wiring Diagram.................................................................................................................................................. p.25

5- TRANSPORT AND INSTALLATION

5-1 Transport ........................................................................................................................................................... p.27

5-1-1 Loading into the vehicle ............................................................................................................................. p.27

5-1-2 Loading onto the platform .......................................................................................................................... p.27

5-2 Installation on site.............................................................................................................................................. p.28

6- PREPARATING THE COMPRESSOR FOR OPERATION

6-1 Checking oil levels............................................................................................................................................. p.29

6-2 Battery ............................................................................................................................................................... p.29

6-3 Filling up the fuel tank ....................................................................................................................................... p.30

4

EN OPERATING MANUAL : Compressor Screw

7- PUTTING THE COMPRESSOR INTO OPERATION

7-1 Initial operation .................................................................................................................................................. p.31

7-2 Start-up.............................................................................................................................................................. p.31

7-3 Shut-Down......................................................................................................................................................... p.33

7-4 Setting the operating pressure .......................................................................................................................... p.33

7-5 Regulating procedure ........................................................................................................................................ p.34

7-5-1 Regulating procedure for SC 800 / SC 1200 / ECO 800 / ECO 1200 ........................................................ p.34

7-5-2 Regulating procedure for SC 1900 / SC 2200 ........................................................................................... p.35

8- FUELS

8-1 Recommended lubricant for compressor .......................................................................................................... p.37

8-2 Recommended engine oil.................................................................................................................................. p.37

8-3 Tool lubricants ................................................................................................................................................... p.37

8-4 Fuel ................................................................................................................................................................... p.37

9- MAINTENANCE

9-1 Compressor maintenance / Maintenance schedule .......................................................................................... p.39

9-2 Maintenance Operations ................................................................................................................................... p.40

9-2-1 Compressor Air Filter .................................................................................................................................p.40

9-2-2 Compressor Oil Filter ................................................................................................................................. p.40

9-2-3 Oil Cooler ................................................................................................................................................... p.40

9-2-4 Draining Oil Circuit ..................................................................................................................................... p.40

9-2-5 Separator Cartbridge replacement ............................................................................................................. p.41

9-2-6 Belts ........................................................................................................................................................... p.42

9-2-7 Long term shutdown - garaging ................................................................................................................. p.43

10- TROUBLESHOOTING

5

ENOPERATING MANUAL : Compressor Screw

2 - FOREWORD

2-1 Déclaration d’incorporation

We declare under our sole responsibility that the partly completed machinery is in compliance with the following

standards and standardized documents:

■ EU directive 2006-42-CE / machine safety

■ EU directive 2014-30-UE : electromagnetic compatibility (EMC)

■ EU directive 2014-35-UE : low voltage

And in compliance with regulation:

■ 2004 / 108 CE

■ 2006 / 95 CE

BRAND

TYPE

SERIAL NUMBER

PRODUCTION YEAR

This partly completed machinery will be declared in conformity once it is assembled with other partly completed

machinery or machinery for the intended use under the responsibility of prime contractors.

Jonage, on . . . . / . . / . .

Winair s.a.r.l - 2, rue Louis Renault 69330 JONAGE - France

Téléphone : +33 (0)4 78 04 05 30 - Télécopie : +33 (0)4 78 04 04 26

contact@winair-compressor.com - www.winair-compressor.com

SAS au capital de 9000€ - Siret : 411 520 703 00025 - APE2813Z

6

EN OPERATING MANUAL : Compressor Screw

2-2 Notes on the compressor

WINAIR screw compressors are the result of many

years of research and development. These prerequisites

combined with high quality standards guarantee the

manufacture of screw compressors providing a long

service life, high reliability and cost-eective operation.

It stands to reason that all requirements concerning

environmental protection are met.

2-3 Intended use

The machine / unit has been constructed in accordance

with state-of-the-art technology and the recognized

safety regulations.

Nevertheless, the operator or third parties may be

exposed to risk to life and limb in the course of the use

of the compressor (e.g. through ying pieces of building

material, swirling dirt or dust particles, electric current

or thermal impairment, vibration, noise or mechanical

hazard), and the machine or other tangible assets may be

impaired, for reasons that could not have been avoided

through preventive constructional safety measures.

Hazards occur particularly, when:

■ the compressor is not used for its intended purpose

■ the compressor is not operated by trained personnel

■ unauthorized changes or modications are carried

out on the compressor

■ you are not wearing the required protective clothing

■ you do not comply with the safety instructions

■ you do not observe the information in the operating

instructions.

For this reason every person involved in the operation,

maintenance and repair of the compressor must read and

observe the operation manual and the safety regulations.

This is to be conrmed by signature as required.

Furthermore, the following naturally apply:

■ the relevant accident prevention regulations

■ generally recognized safety and trac regulations

■ particular national regulations

The compressor is designed for providing compressed

air:

■ for operating compressed-air appliances

■ for conveying bulk material

■ for sandblasting and paint-spraying operations

■ for cleaning machines and shuttering material

■ for blow-cleaning drilled holes

Any other use, or any additional use, for example as

respiratory air, is regarded as not being for the originally

intended purpose.

The manufacturer / supplier accepts no liability for any

resulting damage. The risk is assumed by the user alone.

The compressor may only be used in a technically perfect

condition, for its intended purpose, with appropriate

awareness of safety regulations and hazards, subject to

compliance with the operating manual.

In particular, faults representing safety hazards are to be

corrected at once.

7

ENOPERATING MANUAL : Compressor Screw

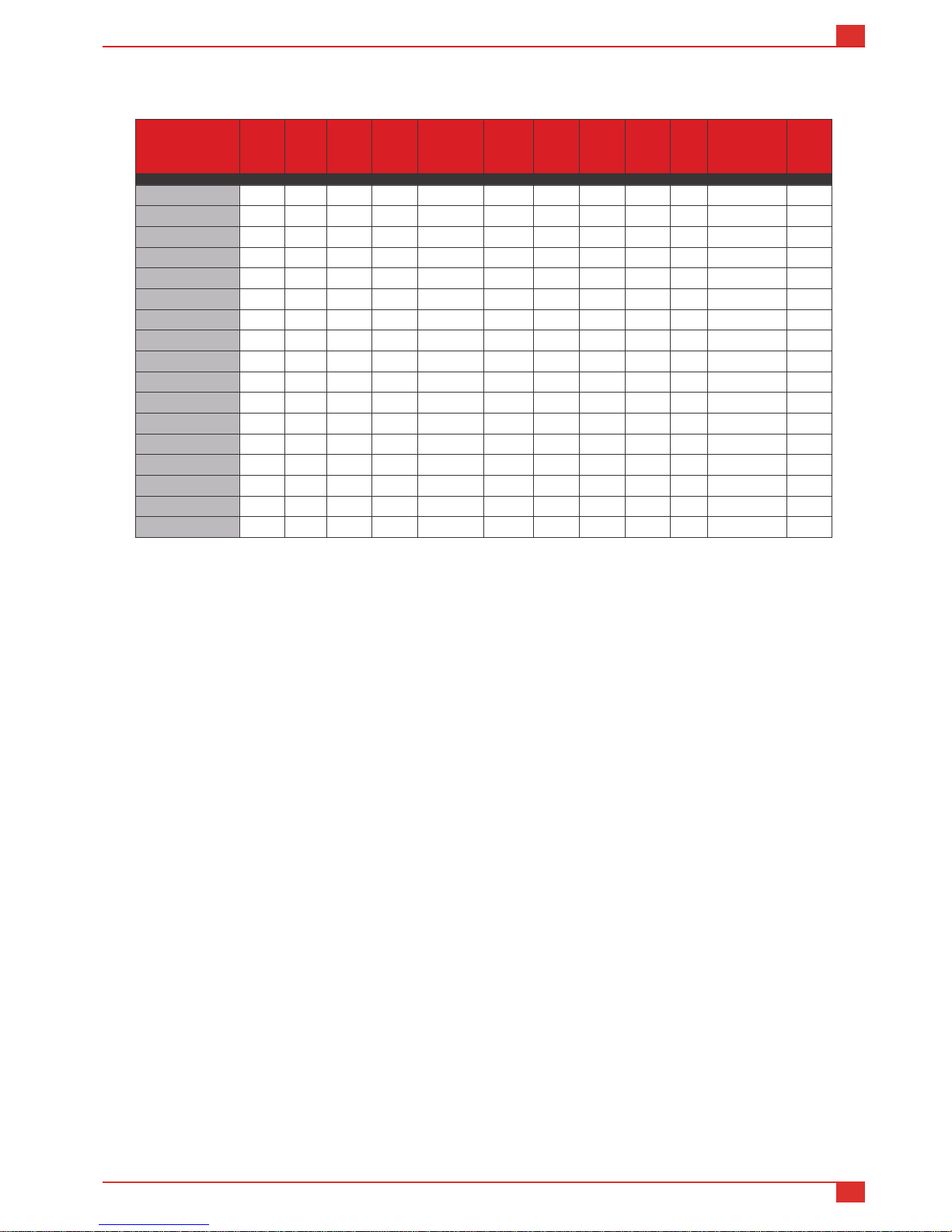

2-4 Technical data

2-5 Maintenance and care

Care and maintenance are all-important if the screw

compressor is to meet the demands placed upon it.

Compliance with the prescribed maintenance intervals

and careful execution of care and maintenance work

are therefore essential, especially under dicult working

conditions.

Service

In case of faults, or should you require spare parts for the

chassis-mounted compressor, please contact your local

WINAIR agent.

In case of damage, the trained technical sta will

guarantee a fast, expert repair using WINAIR spare

parts.

Original WINAIR spare parts are manufactured according

to the state of the art and guarantee continued reliable

operation.

In case of questions or orders for spare parts, please give

us the compressor type, compressor number as given

on the identication plate and the year of production as

given on the oil cooler.

If you give us this data you can be sure that you will be

given the correct information or sent the spare parts you

require.

Model Mass Flow

Operating

Pressure

Engine

HONDA

Engine

Output

Speed Range

Electric

start

Oil l

Engine

Fuel tank

Capacity

Oil tank

capacity

Weight

Size

L x l x H

Sound

level

LwA(2)

L/mn bar réf. kW/CV trs/min litres litres litres kg

ECO 800 HDM 800 6/7 GX 270 6.3/9 2500 to 3500 - 1.1 5.3 4 69 820 x 560 x 610 97

ECO 800 HDE 800 6/7 GX 270 6.3/9 2500 to 3500 Yes 1.1 5.3 4 79 820 x 560 x 610 97

ECO 1200 HDM 1200 7/8 GX 390 8.7/13 2400 to 3500 - 1.1 6.1 4 80 820 x 560 x 610 97

ECO 1200 HDE 1200 7/8 GX 390 8.7/13 2400 to 3500 Ye s 1.1 6.1 4 90 820 x 560 x 610 97

SC 800 HDM 800 6/7 GX 270 6.3/9 2500 to 3500 - 1.1 5.3 4 79 820 x 560 x 610 97

SC 800 HDE 800 6/7 GX 270 6.3/9 2500 to 3500 Yes 1.1 5.3 4 89 820 x 560 x 610 97

SC 1200 HDM 1200 7/8 GX 390 8.7/13 2400 to 3500 - 1.1 6.1 4 100 820 x 560 x 610 97

SC 1200 HDE 1200 7/8 GX 390 8.7/13 2400 to 3500 Ye s 1.1 6.1 4 110 820 x 560 x 610 97

SC 1900 HDE 1900 7/8 GX 630 15.5/20 2200 to 3600 Yes 1.9 20 4 145 890 x 635 x 670 97

SC 2200 HDE 2200 7/8 GX 690 16.5/22 Yes 1.9 20 4 145 890 x 635 x 670 97

PLATINE SC 800 HDE 800 6/7 GX 270 6.3/9 2500 to 3500 Yes 1.1 5.3 4 59 740 x 540 x 530 97

PLATINE SC 1200 HDE 1200 7/8 GX 390 8.7/13 2500 to 3500 Ye s 1.1 6.1 4 65 740 x 540 x 530 97

PLATINE SC 1900 HDE 1900 7/8 GX 630 15.5/20 2200 to 3600 Ye s 1.9 22 4 110 750 x 560 x 560 98

PLATINE SC 2200 HDE 2200 7/8 GX 690 16.5/22 2200 to 3500 Ye s 1.9 22 4 110 750 x 560 x 560 98

8

EN OPERATING MANUAL : Compressor Screw

Warranty claims will not be accepted in the case of:

■ operating errors

■ incorrect maintenance

■ wrong auxiliary materials

■ use of spare parts other than WINAIR original spare

parts

■ changes to the unit

The warranty and liability conditions of the general terms

and conditions of WINAIR will not be extended by the

notes above.

Any unauthorized change to the compressor unit /

station, or the installation of components not accepted

by the manufacturer (e.g. ne separator) will result in

the withdrawal of the CE mark. As a consequence, the

manufacturer will not accept any liability or warranty

claim.

Safety regulations

Technical changes

In the course of technical development, we reserve the

right to modify the units without further notice.

The safety regulations in chapter 3 of

the operating Instructions have to be

strictly observed

2-6 General Information

This operating manual is to help you to get to know the

compressor and to use it for its intended applications.

It contains important information about how to operate

the compressor safely, costeectively and with due care.

Compliance with the instructions in this manual will help

to avoid danger, reduce repair costs and downtime, and

increase the reliability and service life of the compressor.

This operating manual is to be supplemented by

instructions concerning current national regulations for

accident prevention and environmental protection. It

must always be available at the site of the compressor.

The operating manual is to be read and used by all

persons in charge ot work with the compressor, for

example, operation, including setting up, correcting

faults during operation, disposal of waste products from

production, care, disposal of process materials, upkeep

(maintenance, inspection, repair) and transport.

Besides the operating instructions and the current

regulations applicable in the user’s country and at the

sites of operation concerning accident prevention, the

recognized technical rules for safe and proper working

are also to be complied with.

2-7 Guarantee

Only operate this compressor with exact knowledge of

and in compliance with these instructions.

WINAIR cannot be held responsible for the safe

operation of the machine / unit if it is used in a manner,

which does not correspond to the intended use, or for

other applications, which are not mentioned in these

instructions.

9

ENOPERATING MANUAL : Compressor Screw

3-1 Identication of safety guidelines

WINAIR is not liable for any damage or injury resulting

from the non-observance of these safety instruc- tions

or negligence of the usual care and attention required

during handling, operation, maintenance or repair, even

if this is not explicitly mentioned in these operating

instructions.

If any of the regulations contained in these instructions -

especially with regard to safety - does not correspond to

the local legal provisions, the stricter of both shall prevail.

These safety regulations are general and valid for

various types of machines and equipment. It is therefore

possible that some information may not apply to the

unit(s) described in these instructions.

Passages marked with this sign indicate a possible

danger to machines or part of machines.

Passages marked with this sign provide technical

information on an optimal cost eective use of the

machine.

Passages marked with this sign

indicate a possible danger to persons.

Important

Notes

3-2 General safety instructions

Organizational measures

The operating instructions must always be at hand at the

place of operation of the machine.

In addition to the operating instructions, all other generally

applicable legal and other mandatory regulations relevant

to accident prevention and environmental protection

must be adhered to and passed on to others.

These compulsory regulations may also deal with the

handling of hazardous materials or the issuing / wearing

of personal protective equipment, or trac regulations.

Instructions, including supervisory responsibility and

duty of notication for taking into account of special in-

plant factors, for example regarding work organization,

sequences of operations, personnel as signed to certain

tasks, are to be added to the operating instructions.

The personnel entrusted with working on the machine

must have read the operating instructions and in

particular the chapter on safety regulations before

starting work. Reading the instructions after work has be

gun is too late. This applies especially to persons working

only occasionally on the machine, e.g. for setting up or

maintenance.

Safety and danger-conscious working by the personnel

in compliance with the operating manual should be

checked at least occasionally.

For safety reasons, long hair must be tied back or

otherwise secured, garments must be close-tting and

no jewellery - such as rings - may be worn.

Injury may result from being caught up in the machinery

or from rings catching on moving parts. As necessary

or as required by regulations, personal protective

equipment should be used.

3 - SAFETY REGULATIONS

10

EN OPERATING MANUAL : Compressor Screw

Observe all safety and warning notices attached to the

machine / unit.

See to it that safety instructions and warnings attached to

the machine are always complete and perfectly legible.

In the case of safety-relevant changes to the machine

/ unit or its operating behaviour, stop the machine /

unit immediately and report the fault to the responsible

department / person.

Spare parts have to comply with the technical

requirements specied by the manufacturer. This can

always be ensured by using original spare parts.

Hydraulic hoses have to be changed within stipulated

and periodic intervals, even if no safety-relevant faults

have been detected.

Adhere to prescribed intervals or those specied in the

operating instructions for routine checks and inspections.

For the execution of maintenance work, tools and

workshop equipment adapted to the task on hand are

absolutely indispensable.

The personnel must be made familiar with the location

and operation of re extinguishers.

Observe all re-warning and re-ghting procedures.

Limit values (pressures, time settings, etc.) have to be

permanently identied.

Selection and qualication of personnel; basic

responsibilities

Work on / with the machine / unit may be carried out

by reliable personnel only. Statutory minimum age limits

must be observed.

Employ only trained or instructed personnel and clearly

set out the individual responsibilities of the personnel for

operation, set-up, maintenance and repair.

Ensure that only authorized personnel work on or with

the machine.

Dene the machine operator’s responsibilities giving

the operator the authority to refuse instructions by third

persons that are contrary to safety regulations.

Do not allow persons to be trained or in structed or

persons taking part in a general training course to work

on or with the machine / unit without being permanently

supervised by an experienced person.

Work on the electrical equipment of the machine /

unit must be carried out only by a skilled electrician

in accordance with electrical engineering rules and

regulations.

Work on system elements, e.g. pressurized components,

may only be carried out by personnel with special

knowledge and experience of hydraulics.

3-3 Changes and modications to the

machine

Do not make any changes, modications or attachments

to the machine / unit, which could aect safety, without

the supplier’s prior permission. This also applies to the

installation and the setting of safety equipment and

safety valves as well as for welding on structural and

pressurized parts. Unauthorized changes to the machine

are not permitted for safety reasons.

Original parts were especially designed for this machine.

We would like to point out that we have not approved

and will not approve parts and special accessories which

have not been supplied by us. The installation and / or

use of such products can therefore aect the active and

/ or passive safety.

The manufacturer is not liable for dam age resulting

from the use of nonoriginal part’s or special accessories.

This applies also to the installation and setting of safety

equipment and valves as well as to welding on structural

or pressurized parts.

mportant

The general type approval becomes invalid in the

case of modications or changes, which change

or infringe upon the external geometry and the

admissible axle data.

Note

11

ENOPERATING MANUAL : Compressor Screw

3-4 Loading / Relocation / Travelling

Loading / Relocation

All loose parts that could fall down when the machine

is lifted must rst be removed or secured; moveable or

pivoted parts like doors, etc. must be immobilized.

For lifting heavy parts, lifting gear and heavy-lift facilities

with the appropriate capacities, which have been

checked and approved in accordance with local safety

regulations, must be used.

For lifting machines or machine parts with one or more

lifting eye(s), only hooks or shackles complying with local

safety regulations may be used. Never fasten cables,

chains or ropes directly to or through lifting eyes.

Lifting hooks, lifting eyes, shackles, etc. must never be

bent and must always be stressed in alignment with the

loadcarrying axis. The load bearing capacity of the lifting

gear is reduced if the lifting force is applied at an angle

to the axis.

All bearing parts must be stressed vertically, as far as

possible, for maximum safety and optimum performance

of the lifting gear. If required, a support is to be installed

between the lifting gear and the load.

Secure the load properly.

If heavy loads are to be transported by means of lifting

gear, it is strictly forbidden to stay under or near this load.

Never leave the load suspended on the lifting gear.

Acceleration and deceleration of the load must take

place within the admissible limits.

The lifting gear must be set up in such a way that the

load is lifted vertically. If this is not possible, take relevant

precautions in order to prevent the load from swinging.

For example, two lifting gears can be used, both with an

inclination angle of not more than 30° to the vertical.

Appoint an experienced supervisor for the lifting

procedure.

Lift the machine only in accordance with the operating

instructions (fastening points for the load lifting tackle,

etc.) using suitable lifting gear.

Always use a suitable transport vehicle with sucient

load carrying capacity.

Before and immediately after completion of loading

secure the machine / unit against accidental shifting.

Attach corresponding warning signs.

Before putting the machine / unit back into operation, the

securing devices have to be duly removed.

Parts, which have to be removed for transport purposes,

must be carefully retted and xed again before putting

the machine / unit back into operation.

When putting the machine / unit back into operation

again, only proceed in accordance with the operating

instructions.

Travelling

Make sure that the air vessels are depressurized.

Lift and secure supporting gear.

Check to make sure that the wheels are properly

tightened, that the tyres are in a roadworthy condition,

that the tyre pressure is correct.

Before transporting the machine, always check to make

sure that the accessories are rmly attached so that they

can cause no accidents.

Always keep a safe distance to foundation ditches and

embankments.

Never travel across slopes transversely; always keep

working equipment near ground level (for example, do

not place it on the bodywork).

Avoid all operations that adversely aect the stability of

the machine.

12

EN OPERATING MANUAL : Compressor Screw

3-5 Installation / Starting and Normal

operation

Installation

In addition to the general technical operation in

accordance with the stipulations of the local authorities,

we would like to refer in particular to the following

regulations.

Before switching on the machine / unit, or starting it up,

make sure that nobody can be injured by the machine as

it starts up.

The system has to be set up in such a way that it is

adequately accessible and the required cooling is

guaranteed. Never block the air intake.

The air intake is to be located so that no hazardous

constituent (solvent vapour, etc., but also dusts and

other hazardous material) can be sucked in. This applies

also to ying sparks.

The air intake is to be positioned so that no loose clothing

of persons can be sucked in.

The pressure line connected to the air outlet of the

system must be tted stress free.

Compressed air lines have to be clearly marked in line

with the local regulations.

If several compressors are arranged in a system,

manually operated valves have to be installed so that each

machine may be shut o individually. When operating

pressure systems, do not rely on the eectiveness of

check valves alone to isolate these systems.

Safety equipment, protective covers or insulation must

not be removed or modied. Any pressure vessel, which

is located outside the system, the permissible operating

pressure of which is higher than the atmospheric pressure

and which is tted with two or more pressure supply lines,

has to be equipped with additional safety equipment,

which will automatically prevent the admissible operating

pressure from rising by more than 10%.

Pipes and / or other parts with a surface temperature

higher than 80°C have to be suitably identied and

shielded against touching.

Electrical connections must comply with local regulations.

Install the machine so that it is as horizontal as possible;

a slight inclination is permissible (see chapter 5).

Set up the machine in such a way that no inlets, outlets

or gates are blocked, even when the doors are open.

If a machine with a combustion engine has to work in a

re-risk environment, the unit must be tted with a spark

catcher.

In dusty environments, set up the machine in such a way

that the wind does not blow dust in its direction.

During operation in clean environments / the intervals for

cleaning the air intake lter and the cooler elements are

much longer.

Do not install the machine directly in front of walls. Make

sure that the warm air coming from the engine and

cooling systems is not drawn into the air intake under

any circumstances. Drawing this warm air in through the

engine or cooler fan could lead to overheating; it is drawn

into the combustion chamber, this will result in a loss of

power.

Never relocate the machine if external lines or hoses

are connected to the discharge valves, in order to avoid

damage to the valve and / or collecting pipe and hoses.

No force may be exerted on the discharge valves, for

example by pulling the hoses.

Make sure that:

■ all bolted connections have been tightened,

■ all electrical wiring has been connected correctly and

is in good condition,

■ the engine exhaust system is operationally safe and

that no inammable material is in its vicinity,

■ The wheel nuts are properly tightened; never exceed

the specied torques.

13

ENOPERATING MANUAL : Compressor Screw

Normal operation

Before starting work, make yourself familiar with the

working environment at the place of operation. The

working environment includes, for example, obstacles in

the working and transport areas, the carrying capacity of

the ground, and any necessary cordoning o of the site

from public trac areas.

Take the necessary precautions to make sure that the

machine / unit is only operated in a safe, functional

condition.

Only operate the machine when all protective devices,

shutdown devices, soundinsulating equipment and

extraction equipment is in place and working.

Be careful: loose articles of clothing, hair or limbs can

still be drawn in by revolving parts.

Check regularly that:

■ all means of protection are correctly tted and xed,

■ all hoses and / or pipes within the system are in

good condition, rmly xed and do not chafe,

■ there are no leakages (fuel, oil or coolant),

■ all ttings are rmly tightened,

■ all wires are connected correctly and are in good

condition,

■ all safety valves and other pressure relief

mechanisms are in good order and not blocked by

e.g. dirt or paint,

■ the safety mechanisms are fully functional.

All connected components must be of the correct size

and be suitable for the specied operating pressure and

temperature.

Only use hose couplings and ttings of the right type and

the correct size.

Before blowing through a hose or an air pipe ensure that

the open end is positively held. A free end whips and can

cause injuries or damage.

Refrain from any working method which is doubtful in

terms of safety.

Never play around with compressed air.

Never aim compressed air at your skin or at other

persons.

Never use compressed air to clean your clothing. When

using compressed air to clean equipment take the utmost

care and always wear protective goggles.

The compressed air generated by these compressors

must never be used for breathing unless it has been

conditioned for those applications in line with the «safety

requirements for respiratory air».

When breathing apparatus with car tridges is used, make

sure that the correct cartridge has been inserted and that

its service life has not expired.

Never use the machine in environments where the

possibility cannot be ruled out that inammable or toxic

vapours may be taken in.

Never operate the system at pressures and temperatures

below or above the values indicated in the technical data

sheet.

Persons working in environments or rooms in which the

acoustic pressure is 85 dB(A) or higher must wear ear

protectors.

Caution: This may impair communication between

persons. Warnings may not be heard. Inform supervisor.

Never ll up with fuel while the engine is running. Make

sure that the fuel does not come into contact with hot

machine parts.

Do not smoke while lling up with fuel.

Filling up at a pump can cause staticelectricity and

possibly sparks. In order to avoid this, a ground cable

must be connected to the system while it is being lled

up.

The machine must not be used in closed or poorly

ventilated areas (tunnel, cellar, ...). The exhaust

emissions of combustion engines contain carbon

monoxide - a lethal gas.

If a machine with such an engine has to work in an

enclosed room, the exhaust gases must therefore be

conducted outside or to the open air by means of a hose

or pipe with an internal diameter of at least 100 mm. The

use of extraction systems is highly recommended in test

rooms for mobile machines.

14

EN OPERATING MANUAL : Compressor Screw

Before connecting or disconnecting hoses, always close

the compressor outlet valves.

Before disconnecting a hose, always make sure that it is

not under pressure.

A hose connected to an air valve must be tted with a

safety wire for operating pressures above 7 bar; it is in

fact recommended that this safety device should be used

for pressures above 4 bar. The steel wire has a diameter

of 8 mm and is rmly clamped to the hose at least every

500 mm. Both ends are tted with cable lugs.

Check the machine / unit for external damage and faults

at least once per shift.

Any changes noticed (included changes in the operating

performance) must be reported immediately to the

authority or person in charge. If necessary, shut down

and secure the machine immediately.

In case of malfunction, shut down and secure the

machine / unit immediately. Have malfunctions corrected

immediately.

Observe operating instructions for startup and shutdown

procedures as well as control displays.

3-6 Special work / Maintenance

Carefulness

Observe the adjusting, maintenance and inspection

activities and intervals set out in the operating

instructions, including information on the replacement of

parts and equipment. These activities may be carried out

by skilled personnel only.

Maintenance work, tests and repairs should be carried

out in a well ventilated room, away from heat, open

ames or sparks. Appropriate prohibition signs (re,

open ames, no smoking) must be put up.

Loss of oil leads to a very slippery oor.

Statistics have shown that many accidents can be

attributed to the installation or maintenance of machines

on oily oors or machine components. For this reason,

always start maintenance work by cleaning the oor and

the machine exterior.

Brief the operating personnel prior to starting special

operations or maintenance work. Appoint a person to

supervise the activities.

After completing repair work, always check to see

whether any tools, loose parts or clothes have been left

in or on the machine, driving engine or driving equipment.

Maintenance and repair work is only to be carried out

under the supervision of or by a person qualied for this

work.

For all work concerning the operation, production

adjustment, conversion or settings of the machine / unit

and its safety-relevant equipment, as well as servicing,

maintenance and repair, observe the operating

instructions for start-up and shut down procedures and

the instructions for maintenance work.

All maintenance and repair work may only be carried out

when the system is shut down, or, with electrical systems,

when the mains power supply is switched o. Make sure

that the equipment cannot be switched on by accident.

If the machine / unit has been completely switched

o for maintenance and repair work, it must be

safeguarded against being switched on again

unexpectedly, or, with electrical systems, the mains

power supply must be disconnected:

■ remove the ignition key and / or put up a warning

sign on the main switch «Attention! Maintenance

work.» Close o the complete maintenance area, if

required.

■ disconnect the starter battery.

Individual parts and larger subassemblies must be

carefully attached to the lifting gear and secured in the

case of replacement.

Only use suitable, technically perfect lift - ing gear and

load suspension devices with adequate lifting capacity.

Never work or stand under suspended loads.

15

ENOPERATING MANUAL : Compressor Screw

Before removing any pressurized part, separate the

power unit eectively from all sources of pressure and

release the pressure from the complete system.

Never use inammable solvents or carbon tetrachloride

to clean parts.

Take precautions against poisonous vapours from

cleaning agents.

Absolute cleanliness is essential during maintenance

and when carrying out repairs.

Only carry out maintenance and repair work when the

machine is located on an even, stable base and is

secured against running away and against buckling.

Checks, maintenance and repair work may only be

carried out with the screw compressor being at rest and

depressurized.

Protective devices, i.e. protective grids, may not be

removed during operation.

Be careful when the screw compressor is in operation.

Protective equipment to be removed for this work, has to

be retted after completion of these activities.

Operation of the machine without protective equipment

is not permitted.

When working on a running screw com pressor system,

working clothes have to be close-tting.

Maintenance

During maintenance and repair work, the employer has

to inform the insured persons about the dangers that

can occur during their work and about measures to avert

such dangers.

The personnel have to support all measures to improve

safety at work.

Safety equipment for the prevention or elimination of

danger has to be maintained regularly and functionally

checked at least once a year. Faults observed have to be

immediately rectied and / or reported to the responsible

person.

Only use the correct tools for maintenance and repair

work. Only use original spare parts.

All maintenance and repair work may only be carried out

when the system is shut down, or, with electrical systems,

when the mains power supply is switched o. Make sure

that the equipment cannot be switched on by accident.

If the machine / unit has been completely switched

o for maintenance and repair work, it must be

safeguarded against being switched on again

unexpectedly, or, with electrical systems, the mains

power supply must be disconnected:

■ remove the ignition key and / or put up a warning

sign on the main switch « Attention! Maintenance

work. ». Close o the complete maintenance area, if

required.

■ disconnect the starter battery.

Before removing any part under pressure, separate the

power unit eectively from all sources of pressure and

release the pressure from the complete system.

Observe the safety precautions for work on batteries.

Pay attention to cleanliness. Prevent dirt from entering

by sealing the parts and exposed openings with a clean

cloth, paper, or tape.

Before the power unit is approved for operation after

maintenance or an overhaul, make sure that operating

temperatures and time settings are correct and that the

control and shutdown devices are working properly.

The electric motor, generator, air lter, electrical

components and control equipment are to be protected

against the pen etration of dampness - for example when

cleaning with a steam jet - by covering and sealing them.

Under no circumstances should the sound-insulating

material be removed or modied.

Never use solvents with dangerous properties for

cleaning parts.

Maintenance work, tests and repairs should be carried

out in a well ventilated room, away from heat, open

ames or sparks. Appropriate prohibition signs (re,

open ames, no smoking) must be put up.

Wear suitable eye protection when inspecting the system.

Make sure that the openings of spray containers, valves.

Loading...

Loading...