Page 1

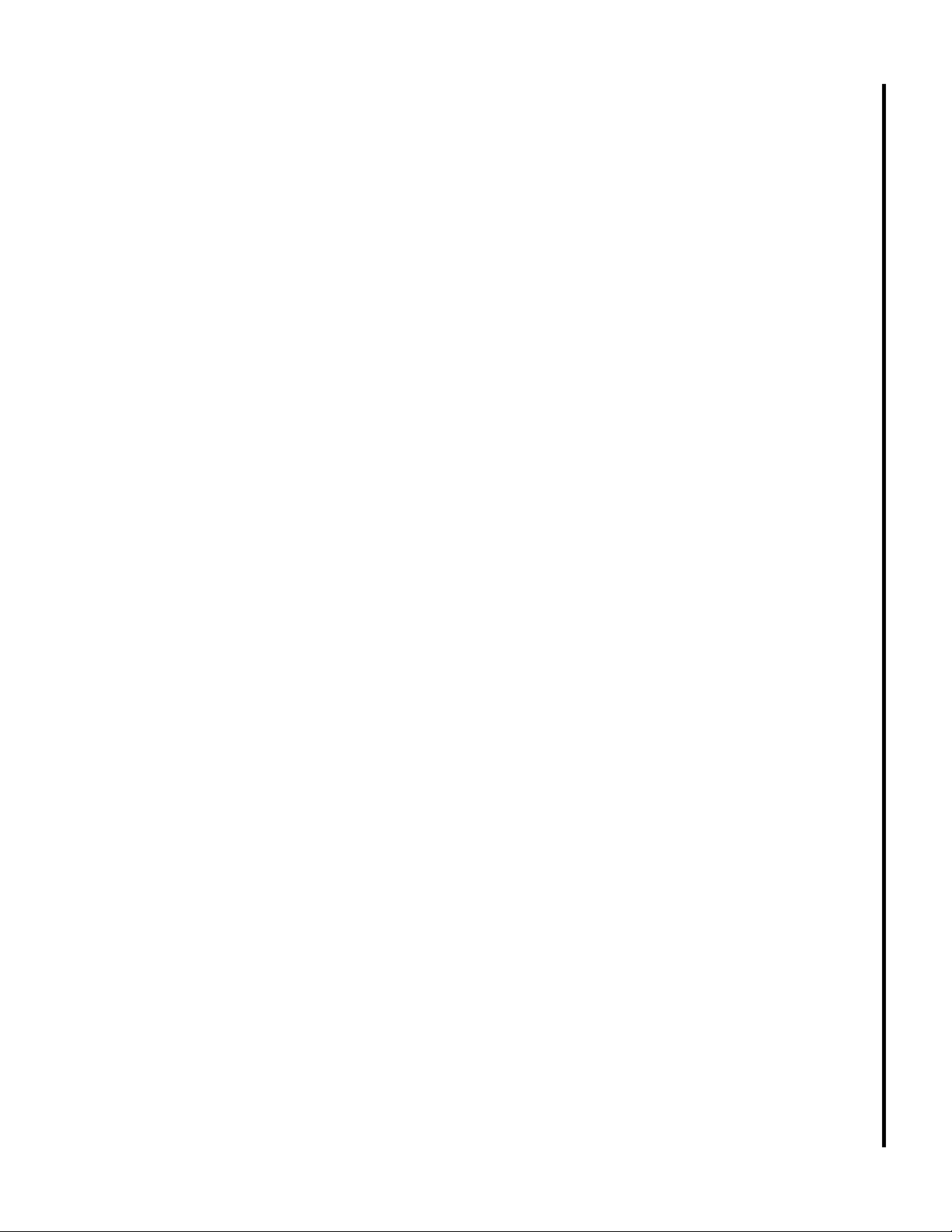

Radial Arm Drill Press

Model 1230

Operating instructions and parts manual

Part No. 9078241

Revision A

Page 2

Page 3

Table of Contents

Cover Page ........................................................................................................................ 1

General Specifications ...................................................................................................... 4

Operating Precautions ...................................................................................................... 5

Operating Instructions ....................................................................................................... 7

Lubrication and Coolant ................................................................................................ 13

Machine Set-up ............................................................................................................... 14

Wiring Diagram................................................................................................................. 16

Replacement Parts .......................................................................................................... 17

3

Page 4

General specifications

The Wilton Model 1230 is a powerful and

versatile radial arm drill press. The drill head is

mounted on an arm and can move along the arm to

position the spindle over the work piece. The arm,

itself, can be rotated on its support column to allow

centering the spindle over the work piece.

Drilling can be performed manually or with

power assistance. In addition, parameters of RPM,

power feed rate and drilling depth can be pre-set by

the operator, using controls conveniently positioned

on the drill head, to allow any hole to be drilled using

power feed.

A precision machined box table is delivered with

the Model 1230 to allow convenient positioning and

clamping of smaller work pieces. The box table may

be removed from the base to allow larger workpieces

to be positioned and clamped on the precision

machined base, itself.

Machining capacities

Drilling T apping Boring

Steel 2 1/8 in. (53mm) 1 1/8 in. (28mm) 3 3/8 in. (84mm)

Cast iron 2 1/2 in. (63mm) 1 3/4 in. (44mm) 4 3/4 in. (1 19mm)

Overall dimensions and specifications

Column diameter 1 1 13/16 in. (295mm)

Column to spindle center distance, max. 46 in. (1 150mm)

Column to spindle center distance, min. 13 3/8 in. (334mm)

Spindle travel along arm, total 35 in. (875mm)

Base surface to spindle end, max. (no tooling) 54 in. (1350.0mm)

Base surface to spindle end, min. (no tooling) 19 3/8 in. (484mm)

4

Quill (spindle) travel 9 7/8 in. (247mm)

Arm movement range on support column 34 5/8 in. (866mm)

Box table dimensions 27 7/8 x 20 1/2 x 16 1/2 in.

(697x513x413mm)

Base dimension 67 3/4 x 25 15/16 x 6 1/2 in.

(1694x648x163mm)

Spindle taper Morse #4

Spindle speeds, RPM 45-1550

Feed rates (distance/revolution) 0.002, 0.004, 0.006 in/rev

(0.005, 0.010, 0.030 mm/rev)

Main motor HP 5

Arm raising motor HP 1

Clamping motor 1

Coolant pump motor HP 1/8

Machine height (floor to max.) 109 1/2 in. (2,738mm)

Net weight (approx) 4,620 lb. (2,100 kg)

Page 5

- Misuse of this machine can cause serious injury.

- For safety , machine must be set up, used and

serviced properly .

- Read, understand and follow instructions in the

operator’s and parts manual which was shipped with

your machine.

When setting up machine:

- Always avoid using machine in damp or poorly

lighted work areas.

- Always be sure machine is securely anchored to

the floor.

- Always keep machine guards in place.

- Always put start switch in “OFF” position before

plugging in machine.

When using machine:

-Never operate with machine guards missing.

-Always wear safety glasses with side shields (See

ANSI Z87.1)

-Never wear loose clothing or jewelry .

-Never overreach — you may slip and fall into the

machine.

-Never leave machine running while you are away

from it.

-Always shut off the machine when not in use.

When servicing machine:

-Always unplug machine from electrical power while

servicing.

-Always follow instructions in operators and parts

manual when changing accessory tools or parts.

-Never modify the machine without consulting Wilton

Corporation.

Y ou — the stationary power tool user — hold the key

to safety .

Read and follow these simple rules for best results

and full benefits from your machine. Used properly ,

Wilton’s machinery is among the best in design and

safety . However , any machine used improperly can

be rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be

properly trained in how to use them correctly . They

should read and understand the Operators and Parts

Manual as well as all labels affixed to the machine.

Failure in following all of these warnings can cause

serious injuries.

Machinery general safety warnings

1. Always wear protective eye wear when

operating machinery . Eye wear shall be impact

resistant, protective safety glasses with side shields

which comply with ANSI Z87.1 specifications. Use of

eye wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

breakage of eye protection.

2. Wear proper apparel. No loose clothing or

jewelry which can get caught in moving parts.

Rubber soled footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain

proper working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with guards

removed.

5. Avoid dangerous working environments. Do

not use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

Special electrics should be used when working on

flammable materials.

6. Avoid accidental starts by being sure the start

switch is “OFF” before plugging in the machine.

7. Never leave the machine running while

unattended. Machine shall be shut off whenever it is

not in operation.

8. Disconnect electrical power before servicing.

Whenever changing accessories or general maintenance is done on the machine, electrical power to the

machine must be disconnected before work is done.

9. Maintain all machine tools with care. Follow

all maintenance instructions for lubricating and the

changing of accessories. No attempt shall be made

to modify or have makeshift repairs done to the

machine. This not only voids the warranty but also

renders the machine unsafe.

10. Machinery must be anchored to the floor.

1 1. Secure work. Use clamps or a vise to hold

work, when practical. It is safer than using your

hands and it frees both hands to operate the machine.

12. Never brush away chips while the machine

is in operation.

13. Keep work area clean. Cluttered areas

invite accidents.

14. Remove adjusting keys and wrenches

before turning machine on.

15. Use the right tool. Don’t force a tool or

5

Page 6

attachment to do a job it was not designed for.

16. Use only recommended accessories and

follow manufacturers instructions pertaining to them.

17. Keep hands in sight and clear of all moving

parts and cutting surfaces.

18. All visitors should be kept at a safe distance

from the work area. Make workshop completely safe

by using padlocks, master switches, or by removing

starter keys.

19. Know the tool you are using — its applica-

tion, limitations, and potential hazards.

General Electrical Cautions

This machine should be grounded in accordance with the National Electrical Code and local

codes and ordinances. This work should be done by

a qualified electrician. The machine should be

grounded to protect the user from electrical shock.

Conductor length

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

AWG (American wire gauge) number

Wire sizes

Caution: for circuits which are far away from

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended:

Safety instructions on drill presses

1. All work shall be secured using either clamps

or a vise to the drill press table. It is unsafe to use

your hands to hold any workpiece being drilled.

2. Drill press head and table shall be securely

locked to the column before operating the drill press.

This must always be checked prior to starting the

machine.

3. Always use the correct tooling. Tooling shall

always be maintained and properly sharpened. All

tooling must be run at the proper speeds and feeds

as they apply to the job. Use only recommended

accessories and follow those manufacturers instruc-

6

tions pertaining to them. T ooling shall not be forced

in to any workpiece but fed according to the proper

specifications. Failure to follow these instructions will

not only ruin the tooling as well as the machine, but

can cause serious injury.

4. Never brush away any chips while the

machine is in operation. All clean up should be done

when the machine is stopped.

5. Keep hands in sight. Do not put hands or

fingers around, on, or below any rotating cutting

tools. Leather safety gloves should be used when

handling any sharp objects or cutting tools. See

Figure A.

6. Always wear protective eye wear when

operating, servicing or adjusting machinery .

Eyewear shall be impact resistant, protective safety

glasses with side shields complying with ANSI Z87.1

specifications. Use of eye wear which does not

comply with ANSI Z87.1 specifications could result in

severe injury from breakage of eye protection. See

figure B.

7. When drilling in material which causes dust,

a dust mask shall be work. See Figure C.

8. Avoid contact with coolant, especially

guarding the eyes.

9. Non-slip footwear and safety shoes are

recommended. See figure D.

12. Wear ear protectors (plugs or muffs) during

extended periods of operation. See figure E.

Page 7

Operating Instructions

Clamping workpieces to the machine

Both the box table and the base surface are

slotted to accept a suitably sized T-slot clamp.

Before begining any work on the drill press, anchor

the work piece, and the box table, too, if used, to be

certain the workpiece and/or box table will not move

when the drill, tap or boring tool enters the

workpiece.

Caution

Failure to properly anchor the workpiece

and box table could result in damage to the

machine, damage to the workpiece, and worse -severe injury and possibly

operator.

clamping the materials using a T-slot system setup.

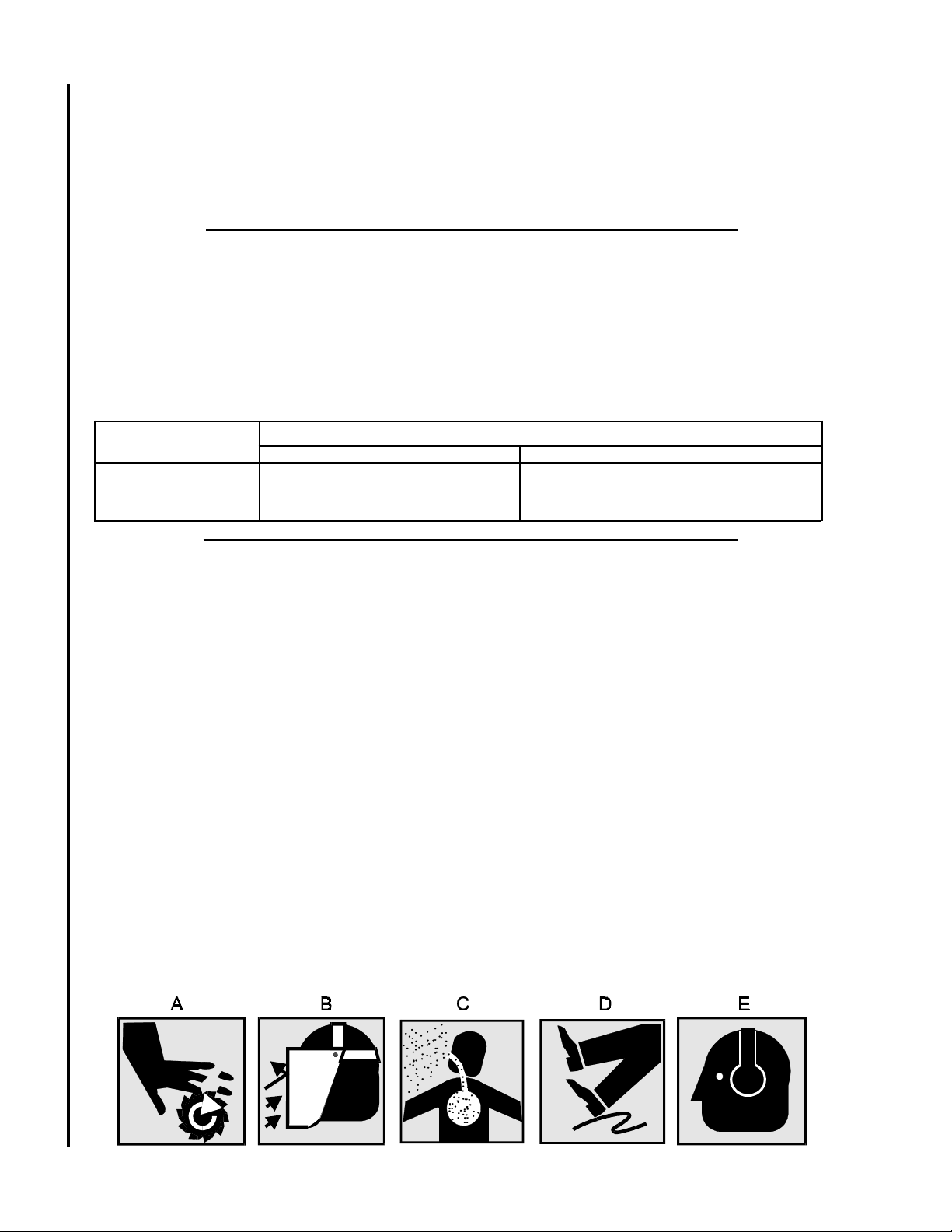

Figure 1: Drill press nomenclature

Never

work on the drill press without

death

to the machine

7

Page 8

Inserting tooling

The Model 1230 uses a #4 Morse taper in the

spindle to secure tooling. Any drill, milling cutter, or

tool holder with a #4MT can be inserted into the quill.

Caution

The first step in removing or inserting any

tooling is to be absolutely certain the machine

cannot be accidentally started during the insertion

or removal operation. The only way to be certain

of this fact is to disconnect power to the machine

using the service box cut-out switch. The service

box (typically the one holding the fuses or circuit

breakers will have been installed by the electrician

who connected the machine to its service branch)

should have a cut-out switch or lever on the outside

of the box. Put the switch or lever in the OFF

position before inserting or removing tooling.

To insert tooling:

1. Observe the caution, above, and be certain all

power to the machine has been disconnected.

2. Be certain the spindle is clean, free from oil, and

ready to accept the shank of any tooling.

3. Check the shank of the tooling to be certain the

tooling is free from dirt, nicks or burrs. If any nicks

or burrs are discovered, file and/or stone the shank

until the shank is smooth.

4. Be certain the quill is in the full UP position.

5. Slide the shank of the tooling into the spindle until

it seats.

6. Use a soft-faced mallet (such as lead, plastic,

brass, etc.) to give the tooling a sharp tap on its tip.

This will secure the tooling firmly in the taper.

7. Re-establish power to the machine and the drill is

ready to use.

To remove tooling:

8

1. Observe the caution above and be certain all

electrical power to the drill press has been cut off.

2. Place a wood block under the tooling in the

spindle to prevent it from being damaged, should it

fall out of the quill during the removal process.

3. Lower the quill by using the feed levers until the

tool removal window is exposed.

4. Using a suitable tapered drift, insert the drift in

the removal window, above the tip of the tooling

shank.

5. Using leather gloves to prevent cuts from the

tooling, hold the tooling with you hand to prevent it

from falling from the quill.

6. With your free hand, using a hammer, tap the

tapered drift and the tooling will loosen from the taper

and can be removed. The spindle is now ready for

the insertion of other tooling with a #4 MT .

Positioning the tooling over the

workpiece.

After the workpiece has been clamped to the

base or table you can position the tooling over the

workpiece by doing any or all of the following:

1. Adjusting the height of the arm on the support

column.

2. Moving the drill head along the arm.

3. Rotating the column upon which the arm and head

are attached.

Unlocking the arm and column

mechanisms

A motorized locking system is used to lock the

head to the arm, the arm to the column, and the

column to the base.

The lock and unlock buttons which control the

locks are located on the right-hand side of the drill

head. When you push UNLOCK, all of the locks are

unlocked. When you push LOCK, all of the locks are

locked.

Caution

Always be certain the locks are engaged before

using the drill press. Pull on the arm handle and

try to rotate the head locating wheel before

pushing the spindle ON button. Failure to have

all locks locked may result in damage to tooling,

damage to the work piece, and possible injury to

the operator.

Raising and lowering the radial arm

1. Power to the drill press must be ON -- then release

the machine locks by pushing the UNLOCK push

button.

2. Use the control lever -- push it upward or downward as required -- (see Fig. 3) to raise or lower the

arm to the required height. See also,

control lever

3. When the arm is at the required height and if no

other adjustments to spindle location are required,

push the LOCK push button to re-lock all machine

locks.

.

Using the

To move the drill head along the arm

1. Power to the drill press must be ON -- then release

the machine locks by pushing the UNLOCK push

button.

2. Using the wheel in the center of the drill head, turn

the wheel to move the drill head along the arm. (See

Fig. 1.)

3. When the drill head is at the desired position on

the arm and if no other adjustments to spindle location

are required, push the LOCK push button to re-lock all

machine locks.

Page 9

CAUTION

NEVER swing the drill press arm using the

support column unless you are absolutely certain

the drill press base is firmly attached to the shop

floor. You can tell if the base is bolted to the floor

by checking the mounting pads at the four corners

of the base. There should be a securing bolt

through each mounting pad.

If the arm is moved off of its position directly

above the base and the base is not bolted to the

floor, THE DRILL MAY TIP OVER AND CAUSE

SERIOUS INJURY OR DEA TH TO THE DRILL

PRESS OPERA TOR (YOU!!) and will certainly

result in serious damage to the drill press, itself.

Don't take chances. Always look for bolts at the

mounting pads before swinging the drill press arm.

on LOW or HI speed. There is a chart on the front of

the drill head which shows you the spindle speeds

available and the gear change lever and motor switch

values required to select each speed. See Fig. 1.

On the gear change table you will also find the

recommended drill sizes for the various speeds which

are selectable. THESE RECOMMENDA TIONS ARE

ONL Y APPROXIMA TE. With the wide variety of drill

types and coatings available, the variety of cutting

fluids which might be used, and the even wider

variety of work piece materials which you might be

machining -- you need to consult with your tooling,

coolant and/or work piece suppliers to determine the

best spindle speed to use for any specific drilling

operation.

Moving the arm on the support column

1. Power to the drill press must be ON -- then

release the machine locks by pushing the UNLOCK

push button.

2. Use the handle at the end of the arm (see Fig. 1)

to move the column (and, therefore, to swing the arm)

as necessary to the required spindle position.

3. When the spindle is positioned correctly and no

other adjustments are quired, push the LOCK push

button to re-lock all machine locks.

Setting spindle speed

Spindle speeds are established using the gear

change levers on the upper right-hand side of the drill

head. (See Fig. 1.) The shorter of the two levers

operates a two-speed mechanism which puts the

gearbox in either high gear or low gear. There is a

"HI/LOW" readout on the upper left hand side of the

drill head which tells you which speed range is

selected.

The longer gear change lever operates a three

speed gearbox mechanism. The lowest gear and

spindle speed is selected by pushing the lever away

from you -- that is, by rotating the change shaft

counterclockwise. The highest gear and spindle

speed is selected by pulling the lever toward you -rotating the shaft clockwise. There is a detent in the

middle of the lever travel to tell you when the lever is

in the intermediate gear position.

This gearbox set-up gives you a total of six

spindle speeds which may be selected. The twospeed spindle drive motor, therefore, increases the

number of available spindle speeds to 12. The

specific spindle speed selected clearly depends on

the position of

the

motor switch

both gear change levers

on the top front of the drill head is

and whether

Caution

Do not try to change gears while the spindle

is turning. This may cause serious damage to the

spindle drive system.

Allow the spindle to come to a complete stop

before attempting to change gears. If the gear

change lever you want to move does not slip

easily into the new position you require, jog the

motor for a second using the control lever. Then

allow the spindle to come to a stop again before

attempting to change gears, again. Repeat this

jogging process, as necessary , until the gears

match up properly for changing.

Setting feed rate and depth of cut

The Model 1230 has limit switches on the quill

which cuts off electric power to the drive motor when

the quill has reached either the upper or lower limit of

its travel. This system is designed to prevent gearbox

damage if the power feed mechanism is engaged -damage which would occur if the quill were to bottom

out against the upper or lower limit of quill travel. In

the event of failure of either limit switch there is also a

safety clutch mechanism which will slip when the

limits of travel are reached.

However, while you are able to use virtually the

full travel of the quill for drilling or other operations,

the drill press operator typically sets both the rate of

feed -- travel-per-revolution of the spindle -- and the

depth of cut -- that is, the total distance the quill

moves to make the required depth of cut.

These two operations are described, here:

Setting feed rate

The feed rate is set using the knob and dial on

the front of the drill head. See Fig. 1. The knob on

the dial can be rotated to select any of three different

9

Page 10

feed rates, plus a neutral position where the power

feed does not operate on the quill.

It is recommended that when doing operations

which do not require power feed that the dial be set to

the neutral position. This minimizes any wear on the

power feed mechanism.

The feed rate selected is indicated by a pair of

rivet heads on the edge of the rate setting dial. These

values are indicated on the far outer edge of the

readout.

Clearly , whenever the indicator rivets are at an

"N" position, no feed or "neutral" has been selected.

Any of the three feed rates are available for

selection using any of the spindle speeds available.

There will be a recommended feed rate for any

drilling or boring operation, and this rate must be

determined by consulting appropriate machining

handbooks or by consulting with your tooling, coolant

and work piece suppliers.

Setting depth of cut using the power

feed system

There is a mechanism for engaging the power

feed and there is also a mechanism (a "trip mechanism) which can be set to disengage the power feed

when a pre-set depth has been reached.

The feed levers can be pulled outward -- or

pushed inward -- on pivots which are in the feed lever

hub. When the feed levers are pushed toward the

drill head, the power feed mechanism is disengaged.

When the feed levers are pulled outward, the power

feed system is engaged. In the power feed position

(outward) the quill and spindle will be driven EITHER

until they reach the limit of travel and the limit

switches cut off power -- OR until the trip mechanism

disengages the power feed, automatically -- OR until

the drill press operator pushes the feed levers into the

disengaged position.

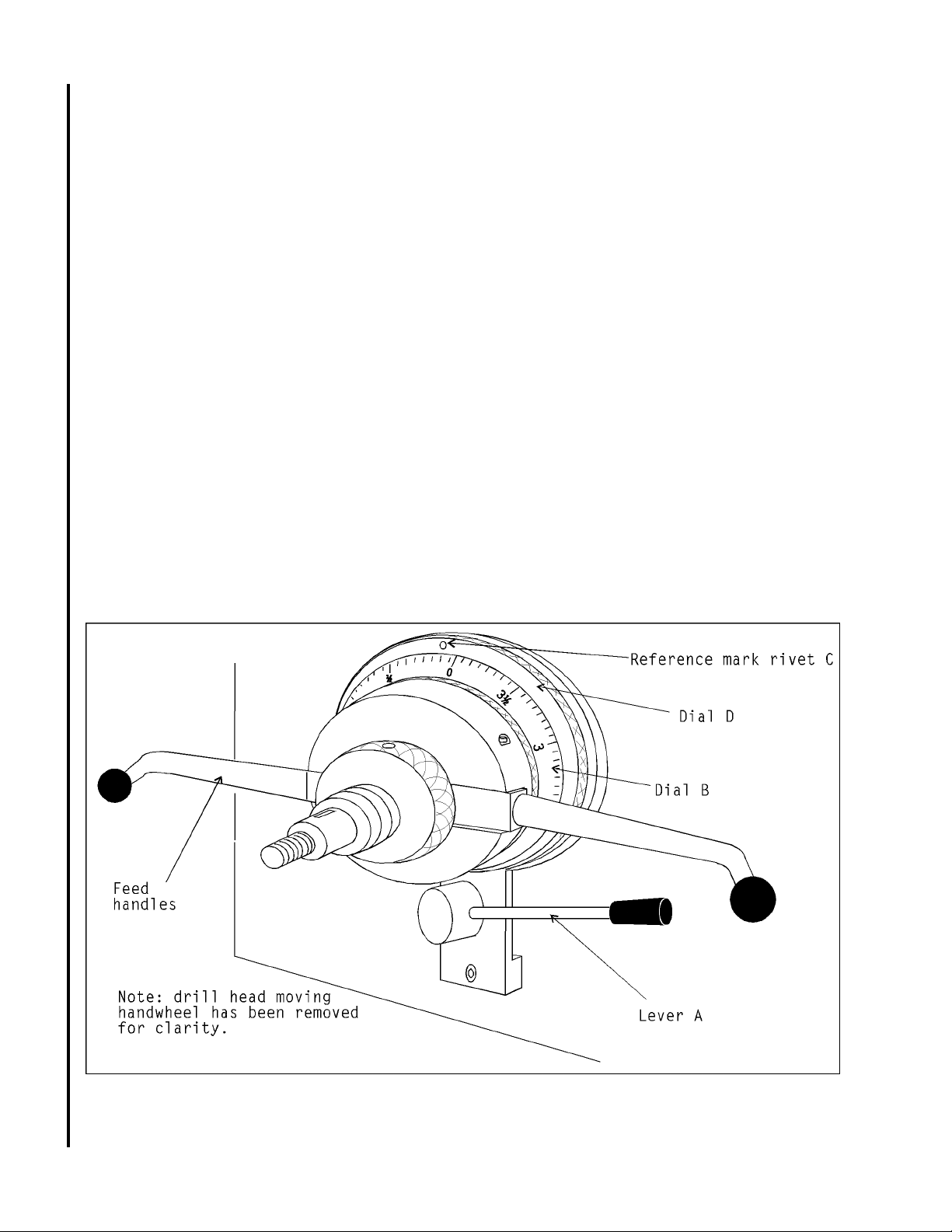

To set the depth of cut

1. Unlock lever A -- See Fig. 2.

2. Use the feed levers to lower the drill until it touches

the work piece.

3. Rotate the dial D until the rivet on the dial -- C -- is

at the feed depth required on the scale on graduated

dial B.

4. Lock lever A.

5. Pull the feed levers out to engage the power feed

clutch.

Note: Because the ring for Dial B makes one

rotation before contacting the mechanical trip dog,

you are limited to 4 inches (100mm) of travel during

any power feed operation. If you need to make

deeper holes you will need to do the machining in

steps.

10

Figure 2: Power feed controls

Page 11

Spindle direction and power feed

The spindle can be driven clockwise or counterclockwise. The direction of rotation is controlled by

the control lever on the left hand side of the drill head.

See Fig. 1.

Clockwise or "forward" rotation is the direction

of rotation for right-hand tooling -- which is the vast

majority of tooling used in machine operations.

However, if you use left-hand tooling for any operations, the spindle direction can be set to counterclockwise or "reverse."

The power feed direction is determined by the

spindle direction. When the spindle is set to its most

common direction -- clockwise or forward -- the quill

and spindle are driven downward. When the spindle

direction is set to counterclockwise or reverse

direction, the quill and spindle are driven upward.

Hand feed -- roughing operations

When the feed levers are pushed toward the

drill head the power feed mechanism is disengaged.

In this position, the feed levers can be used to move

the quill and spindle and perform manual drilling or

other machining operations.

the tooling is installed, you can restablish power to

the machine by turning the cut-out panel back ON.

This will reestablish power to the machine control

system and will allow you to use the motor which

raises and lowers the arm to position the tooling over

the work piece. Raising and lowering of the arm is

controlled by the control stick -- see Fig. 3 and read

page 7,

Raising and lowering the radial arm

.

Power ON light

When the cutout box power is ON, the POWER

light on the upper left hand side of the drill head (Fig.

1) will be lit. In this mode, power to the coolant pump

and to the spindle drive motor is controlled by the

switches on the control console.

Flood coolant control

The flood coolant system provided with the drill

press is turned on by turning the switch to the ON

position. Power OFF to the coolant pump is achieved

by turning the switch counterclockwise to its OFF

position. (If coolant does not flow, check the pump

rotation by observing the pump shaft. It should be

rotating in the direction of the arrow on the pump

casting. If it is not rotating in the correct direction,

see

Electrical,

for more information.)

Fine hand feed using the power feed

system

The fine feed control wheel is located on the

underside of the right-hand side of the drill head.

See Fig. 1. The fine feed control is used as follows:

1. Set the feed rate dial to N -- neutral.

2. Pull the feed levers out so the power feed clutch is

engaged.

3. Turn the drill press POWER switch ON and set the

control lever so the spindle is turning in the correct

direction for the operation you are performing.

4. Turn the fine feed control wheel by hand. The

quill and spindle will move downward or upward

(depending upon which way you turn the wheel and

the direction the spindle is turning) until you stop

turning the control wheel.

Power ON and power OFF

If your Model 1230 was connected to its service

branch correctly , there will be a service disconnect

with an external power cutoff lever or switch which

disconnects the drill press from the service branch.

This is your ultimate protection against accidental

machine start-up when clamping work pieces to the

machine and/or inserting or removing tooling. Always

be certain you have turned off power at this disconnect before doing these operations.

Once your workpiece is clamped securely and

Spindle motor controls

The power to the spindle motor controlled as

follows:

1. The cutout box control lever must be in the ON

position so power is being fed to the drill press.

2. The two speed spindle drive motor switch must be

in either HI or LOW position.

3. The control ON/OFF switch must be pushed ON.

4. The arm/spindle control lever must be pulled

forward (clockwise rotation) or backward (counterclockwise rotation.) See

page 1 1.

Turning spindle drive motor power OFF

T o turn power OFF on the spindle drive motor do

one of the following:

1. Put the two speed motor switch in OFF position,

OR...

2. Push the Control ON/OFF switch off, OR...

3. Put the arm/spindle control lever in its middle

(neutral) position, OR...

4. Push the large, red emergency off STOP switch,

OR...

5. When servicing the tooling or other machine

components, put the service disconnect lever in OFF

position.

Once the STOP switch has been pushed (4.,

above) none of the other switches on the panel can

be used to control power to the spindle drive motor or

coolant pump until the STOP switch has been re-set.

Using the control lever,

11

Page 12

Resetting the STOP switch

1. Turn the switch in the direction of the arrow on the

red button -- clockwise. The switch is reset and the

other spindle motor controls can be used.

Using the load ammeter

An ammeter on the control console is used to

monitor the load on the spindle drive motor. It is

connected into one of the three power lines which

supply the main drive motor.

When the drive motor is ON and up to speed,

and there is no tooling being used to drill, tap or bore

a hole, the ammeter should read approximately 2.5

amps. If it is above this value there is a problem

internally (such as lack of lubrication in the gearboxes, bad bearings, etc.) which means you should

turn off the machine and determine the cause of the

excessive free-running load.

Monitor the the ammeter during machining

operations. The ammeter should stay below 9 amps

or current draw during machining. Y ou should adjust

your spindle speed, feed rate and coolant use to

maintain the full load current draw below the 9 amp

value.

If you exceed 9 amps current draw a thermal

limiter switch in the electrical control panel will trip. If

this occurs, a licensed electrician should be used to

locate and re-set the thermal limiter switch.

Using the control lever

The four-position control lever is located on the

left hand side of the drill head console. See Figs. 1

and 3.

The control lever can move up or down, backward or forward, or can be left in its most central,

OFF or

control power.

arm up or down when positioning the tooling over the

work piece. This ability to control the height of the

arm is available when:

1. The main power to the machine is ON at its

branch service panel.

2. The emergency STOP switch is set to its ON

mode.

3. The Control ON/OFF switch (lower left hand side

of the face of the drill head, see Fig. 1) pushed ON.

4. The column and arm UNLOCK button (right hand

side of the drill head -- see Fig. 1) is pressed to

unlock the machine locks. See page 6.

it is released. It stays in the position in which you

have placed it. This means unless you return it to

neutral, the arm will keep raising or lowering until it

contacts one of its limit switches.

set to either HI or LOW position, the control lever can

be moved backward or forward to turn the spindle

drive motor ON and control the direction of rotation of

the spindle. The control lever is not spring loaded to

return to the neutral or OFF position when you

neutral

The control lever moves up or down to move the

The control lever does not return to neutral when

When the motor speed control switch has been

position so no functions are under its

12

Tapping operations

When performing tapping operations :

1. Determine the most efficient tapping speed

(spindle speed) by consulting appropriate machinist's

tables, your tap supplier, coolant supplier and/or work

piece supplier.

2. Be certain the power feed dial is in N or neutral

position. See

3. Turn the spindle motor ON. Also, turn on the

coolant pump if coolant is being used.

4. Move the control lever to FORWARD.

5. Use the feed levers to move the tap into its pilot

hole until the tap makes its initial thread cut and is

engaged in the workpiece.

6. Allow the tap to "self feed" into the pilot hole until it

has completed its tapping operation.

7. Move the control lever into its center/neutral

position until the spindle has come to a complete

stop.

8. Move the control lever into its reverse direction so

the tap unscrews itself from the hole it has just

threaded.

Setting power feed rate

, page 8.

Figure 3: Control lever for spindle and arm.

Page 13

release it. Rather, the lever stays in the position in

which you put it when you are controlling the spindle.

There is no need to hold it in position to keep the

spindle running.

All of these functions are clearly labeled on the

plate which surrounds the control lever and boot.

Periodic maintenance

The only maintenance for the Model 1230 is

lubrication and changing of the coolant according to

the schedule, below.

Item Location Action Interval Lubricant

Oiling cup T op and bottom of arm Add lubricant with lube gun Daily Mobil Vactra oil AA

at column

Oiling cup T op of drill head Add lubricant with lube gun Daily Mobil V actra oil AA

Oiling cups Right hand side of Add lubricant with lube gun Daily Mobil V actra oil AA

drill head

Arm raising Rear of column Oil using lube gun Daily Mobil V actra oil AA

worm

Sight glass On drill head Check for level -- fill through Daily Mobil V actra oil AA

pipe plug hole top of drill head

Lift chains On rear of arm Lubricate with lube gun Weekly Mobil Vactra oil AA

Ways On arm Lubricate with lube gun Twice daily Mobil Vactra oil AA

Coolant In tank Monitor for cleanliness When cutting

and efficiency. Replace when

dirty or when cutting becomes

inefficient

Oil fitting On quill Lubricate with gun Daily Mobil V actra oil AA

Rack On arm Lubricate with gun Every 3 days Mobil V actra oil AA

Figure 4: Lubrication diagram

13

Page 14

Machine set-up

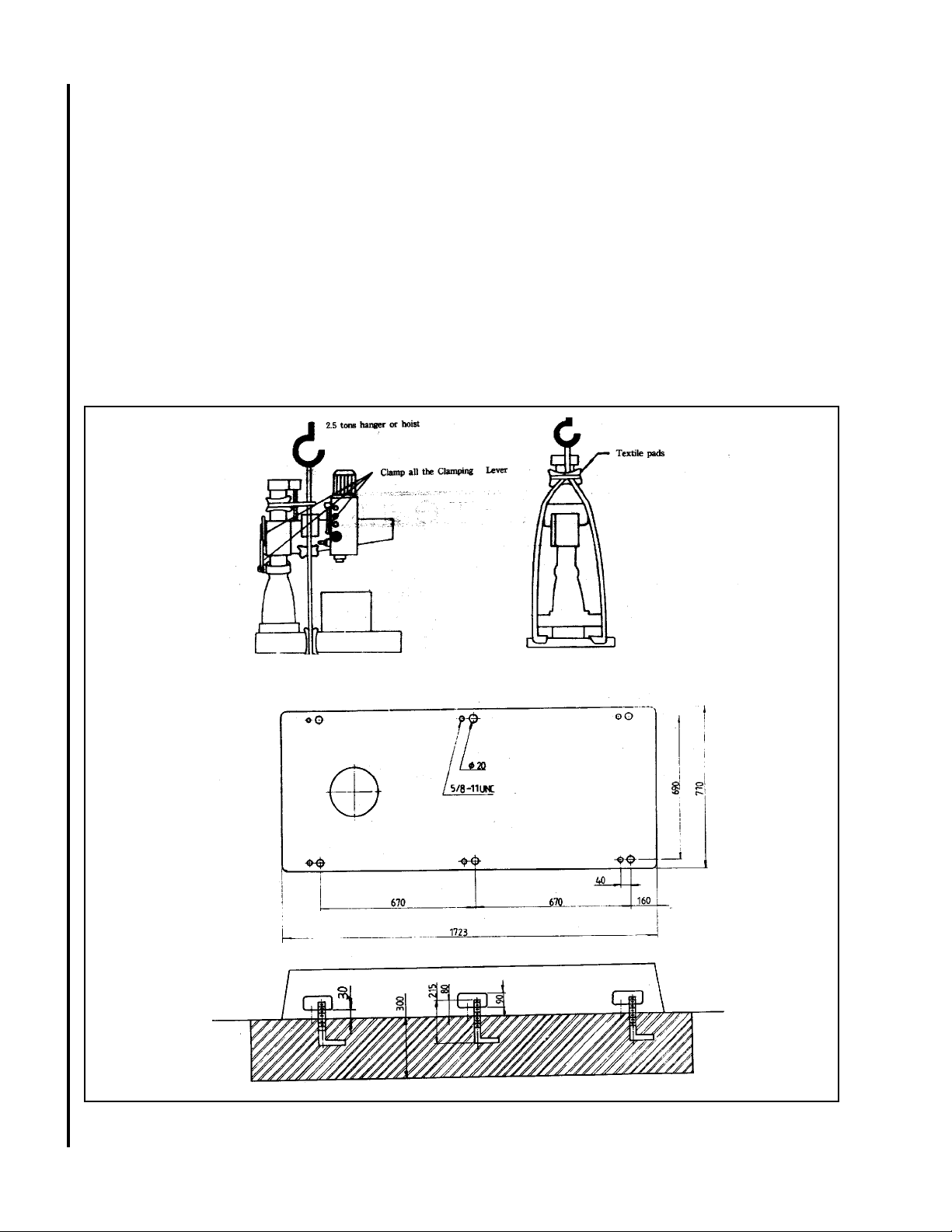

1. Lift the drill press from its shipping skid according

to the diagram, below.

2. Secure the drill press to the floor

The drill press MUST be anchored to the floor

according to the layout diagram below.

Failure to anchor the machine properly , according to

these diagrams, could result in the machine tipping

over and consequent damage to the machine and

possible injury or DEA TH to the machine operator

and bystanders.

3. Connect the electrical service branch to the

machine according to the instructions which follow

under

Electrical

qualified and licensed electrician who is familiar with

machine service and national and local codes.

. This work should be done only by a

4. Wipe the surfaces of the machine which might be

coated with protective coating using mineral spirits or

other nonflammable solvent.

5. Look in the sight glasses on the machine to be

certain they are filled to their level lines. If low, add

fluid as necessary according to instructions in

Lubrication

6. Perform a lubrication check at all points recommended in the table in

7. Use instructions in the

section of this manual to check all operating functions

of the drill press. If coolant is being used in this

machine, put coolant in the sump and test coolant

delivery , as well.

8. When all of the above operations are complete the

machine is ready for service.

.

Periodic Maintenance.

Operating Instructions

14

Figure 5: Machine lifting, transport and anchoring diagrams -- all dimensions

in mm, except anchor bolts (inches, as noted)

Page 15

Caution

Electrical set-up should be performed only by

a licensed electrician who is familiar with national

and local electrical codes.

The Model 1230 is shipped after testing all

functions and circuits under electrical power

specified for the machine and motors. The only

hook-up requirement should be for correct connection to an appropriate cutout on an appropriate

service branch.

Where the following instructions do not agree

with local electrical codes and procedures, the

applicable codes and procedures should be

followed, exclusively .

to the ON position.

6. Observe the direction of rotation of the

coolant pump. Y ou can see the pump shaft rotate

on top of the pump at the rear of the drill press.

There will be an arrow cast into the pump, and the

shaft should be rotating in the direction of the arrow.

If the shaft is rotating in the wrong direction, the

power is connected, backwards. Correct as follows:

7. Disconnect power to the machine by turning it off

at the cutout box.

8. Reverse

9. Repeat steps 4, 5, and 6, above, and you should

observe the pump shaft turning in the correct direction. The electrical service to the machine is now

complete.

any two

of the power lead connections.

Electrical

Electrical branch service

The machine is wired for either a 230 or 460 3phase service branch. The cable supplying the drill

press will be tagged with the voltage at which the

machine was tested and corresponding to the

customer's order.

If the tag has been lost, it will be necessary for

you to open the electrical cabinet on the rear of the

drill press and examine the connections on the

transformer found inside the box. The transformer

can be connected to either a 230 or 460 volt source

and its taps are labeled for voltage. By locating the

source tap on the transformer you will be able to

determine the branch voltage required.

A service disconnect is recommended. The

use of fuses or circuit breakers for each of the

voltage supply wires is required. Use fuses or circuit

breakers which are appropriate to the voltage for the

motor system delivered.

A positive cut-out/lock-out lever or rocker switch

should be located on the outside of the service

disconnect to allow the machine operator to disconnect the machine from the branch circuit when

working with tooling on the machine.

Wiring diagram

A wiring diagram for the drill press is found on

the facing page. This diagram is for reference by

your licensed installing or servicing electrician. In

addition to using a licensed electrician for connection

to the drill press service branch, the servicing of

components and circuits inside the control box should

be serviced only by a qualified electrician. This

includes fuse replacement, if required. If any of

these fuses, upon replacement, should continue to

fail at short service intervals, the electrician should be

asked to check all machine components for excessive

loads, short circuits or other failures.

15

To connect the branch to the drill press

1. Disconnect the service branch to the machine by

moving the lever or rocker switch on the cutout box to

OFF .

2 Connect the green wire (or green with white trace)

to the branch ground.

3. Connect the remaining three wires in the cable

(labeled R,S and T) to the three power lines in the

branch.

4. Turn the power to the machine ON at the cutout

box.

5. Turn the coolant pump power switch (See Fig. 1)

Page 16

16

Figure 6: Wiring diagram

Page 17

Replacement Parts

This section provides exploded view illustrations that show the replacement parts for the Wilton 4 foot arm,

Model 1230 Radial Drill. Also provided are parts listings that provide part number, description, and quantity.

The item numbers shown on the illustration relate to the item number on the facing page of the parts listing.

Order replacement parts from:

Wilton Corporation

300 South Hicks Road

Palatine, IL 60067

TEL: 1-888-594-5866

F AX: 1-800-626-9676

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model number

and serial number of your machine when ordering replacement parts to assure that you will receive the correct

part.

17

Page 18

Exploded View - Column and Base

18

Page 19

Parts List - Column and Base

Ref no. Wilton part no. Description

1 523291 1 Base

2 5232921 Bolt

3 5232931 Needle bearing

4 5232941 Internal column

5 5232951 Bolt

6 5232961 T op bearing cover

7 5232971 Thrust bearing

8 5232981 Fixed brg. housing

9 5232991 Thrust bearing

10 523301 1 Washer

1 1 5233021 Ball bearing

12 5233031 T op bearing cover

13 5233041 External column

14 5233051 Slip blocket

15 5233061 Retaining ring

16 5233071 Slip bar

17 5233081 Fixing shaft

18 5233091 Retaining ring

19 52331 11 Nut

20 5233121 Roller

21 5233131 Wedge

22 5233141 Key

23 5233151 Elevating shaft

24 5233161 Screw

25 5233171 Roller

26 5233181 Ship blocket

27 5233191 Slip bar

28 523321 1 Shaft

29 5233221 Bushing

30 5233231 Locking blocket

31 5233241 Bolt

32 5233251 Key

33 5233261 Clamping gear

34 5233271 Locking shaft

35 5233281 Locking cover

19

Page 20

Parts List - Column Gear Box

Ref no. Wilton part no. Description

1 5235751 Bolt

2 5235761 Washer

3 5235771 Bushing

4 5235781 Round bar

5 5235791 Plain washer

6 523581 1 Nut

7 5235821 Nu t

8 5235831 Bolt

9 5235841 Chain frame

10 5235851 Screw

1 1 5235861 Limit switch

12 5235871 Retaining ring

Ref no. Wilton part no. Description

13 5235881 Needle bearing

14 5235891 Shaft

15 523591 1 Retaining ring

16 5235921 Retaining ring

17 5235931 Needle bearing

18 5235941 Shaft

19 5235951 Retaining ring

20 5235961 Chain

21 5235971 Bolt

22 5235981 Chain adapter

23 5235991 Cast iron block

20

Page 21

Parts List - Arm (Front)

Ref no. Wilton part no. Description

1 523331 1 Lamp cover

2 5233321 Screw

3 5233331 Lamp

4 5233341 Lamp seat

5 5233351 Arm rack

6 5233361 Bolt

7 5233371 Arm

8 5233381 Locking shaft

9 5233391 Oil fill cup

10 523341 1 Fixed clamping block

1 1 5233421 Bolt

12 5233431 Locking nut

13 5233441 Thrust bearing

14 5233451 Plain washer

15 5233461 Ball bearing

16 5233471 Bolt

17 5233481 Aluminum ring

18 5233491 Screw

19 523351 1 Ball bearing

20 5233521 Plain washer

21 5233531 Thrust bearing

21

Page 22

Exploded View - Arm (Rear)

22

Page 23

Parts List - Arm (Rear)

Ref no. Wilton part no. Description

1 5236011 Motor

2 5236021 Gear

3 5236031 Key

4 5236041 Bolt

5 5236051 Pin

6 5236061 Bolt

7 5236071 Upper cover

8 5236081 T aper bearing

9 5236091 Gear

10 52361 11 Washer

1 1 5236121 Bolt

12 5236131 Gear case cover

13 5236141 Gear case

14 5236151 Worm shaft

15 5236161 Taper bearing

16 5236171 Retaining ring

17 5236181 Cover

18 5236191 Bolt

19 523621 1 Key

20 5236221 Bushing

21 5236231 Cover

22 5236241 Bolt

23 5236251 Oil cup

24 5236261 Locking shaft

25 5236271 Bushing

26 5236281 Bolt

27 5236291 Bushing

28 523631 1 Block

29 5236321 Arm

30 5236331 Gear

31 5236341 Bolt

32 5236351 Retaining ring

33 5236361 Cover

34 5236371 Bearing

35 5236381 Shaft

36 5236391 Worm gear

37 523641 1 Plain washer

38 5236421 Bolt

39 5236431 Bearing

40 5236441 Bushing

41 5236451 Bolt

42 5236461 Gear

43 5236471 Ke

44 5236481 Bolt

45 5236491 Block

46 523651 1 Bolt

47 5236521 Key

48 5236531 Shaft

49 5236541 Key

Ref no. Wilton part no. Description

50 5236551 Bolt

51 5236561 Gear

52 5236571 Block

53 5236581 Block

54 5236591 Bolt

55 523661 1 Rack shaft

56 5236621 Rack

57 5236631 Bolt

58 5236641 Block

59 5236651 Shaft

60 5236661 Gearbox

61 5236671 Bushing

62 5236681 Shaft

63 5236691 Key

64 523671 1 Retaining ring

65 5236721 Retaining ring

66 5236731 Bushing

67 5236741 Bushing

68 5236751 Bushing

69 5236761 Retaining ring

70 5236771 Gear

71 5236781 Gear

72 5236791 Bolt

73 523681 1 Bolt

74 5236821 Gear

75 5236831 Bolt

76 5236841 Rubber tap

23

Page 24

Parts List - Riser Mechanism

24

Ref no. Wilton part no. Description

1 5232451 Motor

2 5232461 Key

3 5232471 Screw

4 5232481 Adapter

5 5232491 Plastic sheet

6 523251 1 Screw

7 5232521 Adapter

8 5232531 Bolt

9 5232541 Cover

10 5232551 Oil seal

1 1 5232561 Bearing

12 5232571 Key

13 5232581 Key

14 5232591 Shaft

15 523261 1 Screw

16 5232621 Worm shaft

17 5232631 Oil level gage

18 5232641 Worm housing

19 5232651 Bearing

20 5232661 Bearing cover

Ref no. Wilton part no. Description

21 5232671 Bolt

22 5232681 T op cap

23 5232691 Screw nut

24 523271 1 Key

25 5232721 Lead screw

26 5232731 Thrust bearing

27 5232741 Collar

28 5232751 Ball bearing

29 5232761 Brass sleeve

30 5232771 Bolt

31 5232781 Cover

32 5232791 Safety device nut

33 523281 1 Safety device cover

34 5232821 Bolt

35 5232831 Collar

36 5232841 Collar

37 5232851 T apered bearing

38 5232861 Collar

39 5232871 Worm gear

40 5232881 Up/Down rolling shaft

Page 25

Exploded View - Head

25

Page 26

26

Parts List - Head

Ref no. Wilton part no. Description

1 5233551 Hand wheel lock nut

2 5233561 Hand wheel

3 5233571 Plastic knob

4 5233581 Feed handle

5 5233591 Pin

6 523361 1 Clutch housing

7 5233621 Stopper cotter

8 5233631 Spring

9 5233641 Pin

10 5233651 Dial

1 1 5233661 Dial seat

12 5233671 Pin

13 5233681 Key

14 5233691 Clutch

15 523371 1 Spring

16 5233721 Steel ball

17 5233731 Bolt

18 5233741 Pinion shaft

19 5233751 Retaining ring

20 5233761 Clutch

21 5233771 Worm gear

22 5233781 Gear shaft

23 5233791 Retaining ring

24 523381 1 Key

25 5233821 Feed speed change rack

26 5233831 Copper block

27 5233841 Screw

28 5233851 Spring

29 5233861 Steel ball

30 5233871 Feed speed selector

31 5233881 Bolt

32 5233891 Gear box front plate

33 523391 1 Feed speed change gear

34 5233921 Plate

35 5233931 Screw

36 5233941 Ball bearing

37 5233951 Bushing

38 5233961 Bolt

39 5233971 Ball bearing

40 5233981 Bushing

41 5233991 Bolt

42 523401 1 Steel ball

43 5234021 Spring

44 5234031 Speed change shaft

45 5234041 T aper pin

46 5234051 Screw

47 5234061 Shaft

48 5234071 Oil seal

49 5234081 Oil seal

50 5234091 Clutch lower gear

51 52341 11 Clutch upper gear

52 5234121 Ball bearing

53 5234131 Washer

54 5234141 Ball bearing

Ref no. Wilton part no. Description

55 5234151 Gear box cover

56 5234161 Aluminum cover

57 5234171 Oil cup

58 5234181 Bolt

59 5234191 T aper pin

60 523421 1 Gasket

61 5234221 Key

62 5234231 Spindle shaft

63 5234241 Ball bearing

64 5234251 Lock nut

65 5234261 Lock washer

66 5234271 Ball bearing

67 5234281 Gear

68 5234291 Key

69 5234311 Gear

70 5234321 Gear

71 5234331 Gear

72 5234341 Retaining ring

73 5234351 Key

74 5234361 Gear shaft

75 5234371 Key

76 5234381 Gear shaft

77 5234391 Ball bearing

78 523441 1 Key

79 5234421 Bolt

80 5234431 Motor

81 5234441 Gear

82 5234451 Plain washer

83 5234461 Bolt

84 5234471 Bushing

85 5234481 Lock nut

86 5234491 Lock washer

87 523451 1 Ball bearing

88 5234521 Gear

89 5234531 Gear

90 5234541 Key

91 5234551 Key

92 5234561 Gear shaft

93 5234571 Key

94 5234581 Gear

95 5234591 Retaining ring

96 523461 1 Ball bearing

97 5234621 Shaft

98 5234631 Shaft cover

99 5234641 Screw

100 5234651 3-step change lvr . adapter

101 5234661 Oil seal

102 5234671 Speed change rocker arm

103 5234681 Copper block

104 5234691 Bolt

105 523471 1 Copper block

106 5234721 Speed change rocker arm

107 5234731 Screw

108 5234741 Oil seal

Page 27

Parts List - Head

Ref no. Wilton part no. Description

109 5234751 Oil level gage

1 10 5234761 Gear box

1 11 5234771 Gear

1 12 5234781 Spring

1 13 5234791 Steel ball

1 14 523481 1 Sleeve

1 15 5234821 Worm gear sleeve

1 16 5234831 Worm gear

117 5234841 Bolt

118 5234851 Gear

119 5234861 3-step speed change lever

120 5234871 Plastic knob

121 5234881 Key

122 5234891 Lower feed gear shaft

123 523491 1 Screw

124 5234921 Middle gear

125 5234931 Ball bearing

126 5234941 Bushing

127 5234951 Bolt

128 5234961 Bolt

129 5234971 Bushing

130 5234981 Ball bearing

131 5234991 Key

132 523501 1 Lower feed gear shaft

133 5235021 Screw

134 5235031 Retaining ring

135 5235041 Ball bearing

136 5235051 Bolt

137 5235061 Bearing cover

138 5235071 Ball bearing

139 5235081 Helical tooth

140 5235091 Chain

141 52351 1 1 Sprocket shaft

142 5235121 Key

143 5235131 Lock nut

144 5235141 Lock washer

145 5235151 Spindle

146 5235161 Ball bearing

147 5235171 Thrust bearing

148 5235181 Quill

149 5235191 Needle bearing

150 523521 1 T aper bearing

151 5235221 Set screw

152 5235231 Handle

153 5235241 Handle wheel

154 5235251 Bolt

155 5235261 Bearing housing

156 5235271 Grease inlet

157 5235281 Ball bearing

158 5235291 Ball bearing

159 523531 1 Key

160 5235321 Shaft

161 5235331 Helical tooth

162 5235341 Plain washer

163 5235351 Key

27

Page 28

Parts List - Rear of Head

28

Ref no. Wilton part no. Description

1 523541 1 Bolt

2 5235421 Eccentric shaft

3 5235431 Gear box

4 5235441 Bolt

5 5235451 Adjustable collar

6 5235461 Adjustable collar

7 5235471 Bearing bracket

8 5235481 Cam shaft

9 5235491 Cam shaft sleeve

10 523551 1 Bearing bracket

1 1 5235521 Bolt

12 5235531 Adjustable collar

13 5235541 Bolt

14 5235551 Bearing

15 5235561 Aluminum plate

Ref no. Wilton part no. Description

16 5235571 Bushing

17 5235581 Bushing

18 5235591 Adjustable cam

19 523561 1 Bolt

20 5235621 Bearing

21 5235631 Adjustable cam

22 5235641 Adjustable cam

23 5235651 Bolt

24 5235661 Bearing

25 5235671 Bushing

26 5235681 Bearing

27 5235691 Bushing

28 523571 1 Adjustable cam

29 5235721 Aluminum plate

30 5235731 Bolt

Page 29

Parts list - Flood Coolant System

Ref no. Wilton part no. Description

1 5232251 Fixed blade

2 5232261 Cross screw

3 5232271 Hose

4 5232281 HH Screw

5 5232291 Coolant pump

6 523231 1 Fitting

7 5232321 Elbow

8 5232331 Fitting

9 5232341 Elbow

Ref no. Wilton part no. Description

10 5232351 Tube sleeve

11 5232361 Tube sleeve

12 5232371 Tu be

13 5232381 Screw

14 5232391 Screw

15 523241 1 Fitting

16 5232421 Brass valve

17 5232431 Coolant hose

Page 30

Notes:

30

Page 31

Page 32

Wilton Corporation

300 South Hicks Road

Palatine, IL 60067

TEL: 1-888-594-5866

FAX: 1-800-626-9676

Loading...

Loading...