Wilson Manifolds 810100 User Manual

Installation Instructions for Pro-Flow Part. No.

810100 Progressive Nitrous Controller and

CAUTION: CAREFULLY READ INSTRUCTIONS BEFORE PROCEEDING

NOT LEGAL FOR USE OR SALE ON POLLUTION CONTROLLED VEHICLES.

Vehicle Data Logger

OVERVIEW

Pro-Flow Part. No. 810110 is a combination

progressive nitrous controller and vehicle data logger

with the following features:

• Controls two nitrous stages and purge solenoid. 40

amp output drive capability on each nitrous stage.

• Each stage is independently programmable based

on throttle position, RPM, vehicle speed, time

delay, and first gear lockout. Progressive control

based on RPM or time.

• Programmable automatic purge when system is

armed.

• Flexible RPM input compatible with high level coil

drive (vehicles with coil packs or distributor

ignition), standard 12V tach signal, or low level

logic drive (newer vehicles with coil-on-plug).

• General purpose input/output (GPIO) terminal.

Programmable for use as shift light output,

additional stage enable input, or control output for

ignition retard.

• Status LED output (ideal for use with arming switch

containing LED).

• Built-in data logging. Ideal as basic vehicle data

logger during dyno tuning or drag racing. Logs

data whenever system is armed. Stores last 5

minutes of data at 10 samples/second.

• Data logged includes throttle position, RPM,

vehicle speed, status of all inputs and outputs, and

two 0-5V analog inputs.

• 0-5V analog inputs are compatible with Daytona

Sensors dual channel WEGO III systems for

logging wide-band air/fuel ratio data.

• Heavy duty industrial grade clamping terminal

blocks allow easy and reliable hookup without

soldering or crimping.

• Compact size: is 4.1”L x 2.8”W x 1.1”H (not

including mounting feet and terminal block).

• USB interface to laptop PC. Powerful Windows

software for programming controller and

downloading logged data.

Nitrous Pro-Flow, 4700 NE 11

(954) 771-6216 www.nitrousproflow.com

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

1/2008

Page 1

Figure 1 – Progressive Nitrous Controller

ADDITIONAL REQUIRED PARTS

The nitrous controller comes with a USB cable

and software on CDROM. To complete the installation,

you will require: wire, wire labels, crimp terminals,

fuses, switches, and relays. If you are adding the

controller to an existing nitrous system installation, you

may already have most of these items but some

rewiring may be required. The Appendix includes a list

of recommended parts and suppliers.

Throttle position sensor (TPS), RPM, and

vehicle speed sensor (VSS) signal connections are

required to utilize all the capabilities of the nitrous

controller. You will require a vehicle wiring diagram

to locate these signal connections.

INSTALLATION

1. Turn off the ignition switch and disconnect the

battery ground cable before proceeding.

2. Select a convenient mounting location for the

nitrous controller. The unit is not sealed and must

be mounted in a dry location away from sources of

heat. We recommend underdash mounting. The

unit is not intended for underhood mounting. You

can secure the controller with two sheet metal

screws or Velcro tape strips. Orient the unit so that

you will have easy access to the terminal blocks

and USB port.

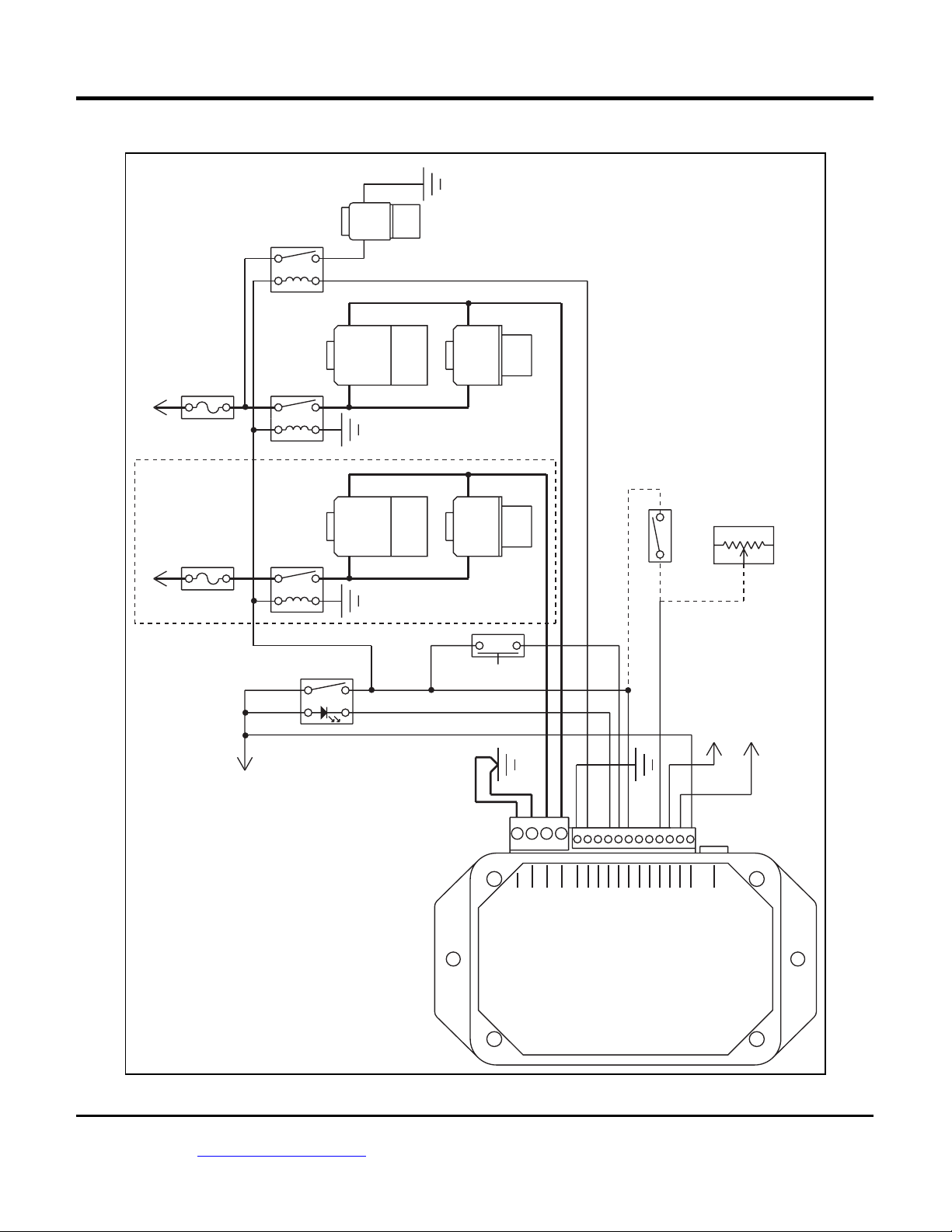

Figure 2 – Basic Hookup

GROUND

PURGE

SOLENOID

PURGE

RELAY

30

87

BATTERY+

STAGE 2

(OPTIONAL)

BATTERY+

50 AMP

MAXI FUSE

50 AMP

MAXI FUSE

STAGE 1

85

30

85

30

85

STAGE 1

STAGE 2

1

3

86

NITROUS

RELAY

87

86

GROUND

NITROUS

87

86

SOLENOID

GROUND

RELAY

1A

SOLENOID

MANUAL

FUEL

SOLENOID

FUEL

SOLENOID

PURGE

WIDE OPEN THROTTLE SWITCH

(NOT RECOMMENDED)

THROTTLE POSITION SENSOR

(RECOMMENDED)

4

VEHICLE SPEED SENSOR

(SEE NOTES)

SIGNAL (SEE NOTES)

RPM SIGNAL

ARMING SWITCH

WITH STATUS LED

(SEE NOTES)

TO SWITCHED AND

FUSED +12V POWER

Nitrous Pro-Flow, 4700 NE 11

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

(954) 771-6216 www.nitrousproflow.com

GROUND

GROUND

TPS

VSS

RPM

ARM

GPIO

STAGE 1

STAGE 2

GROUND

PURGE IN

ANALOG 1

POWER GROUND

POWER GROUND

PURGE SOL

STATUS LED

ANALOG 2

+12V POWER

USB PORT

1/2008

Page 2

Figure 3 – Hookup for Independent Control of Nitrous and Fuel Flow

GROUND

PURGE

SOLENOID

PURGE

RELAY

30

87

BATTERY+

50 AMP

MAXI FUSE

85

30

85

86

FUEL

STAGE

RELAY

87

86

SOLENOID

WIDE OPEN THROTTLE SWITCH

(NOT RECOMMENDED)

THROTTLE POSITION SENSOR

(RECOMMENDED)

GROUND

NITROUS

SOLENOID

1

3

1A

4

MANUAL

PURGE

VEHICLE SPEED SENSOR

(SEE NOTES)

SIGNAL (SEE NOTES)

RPM SIGNAL

ARMING SWITCH

WITH STATUS LED

(SEE NOTES)

TO SWITCHED AND

FUSED +12V POWER

Nitrous Pro-Flow, 4700 NE 11

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

(954) 771-6216 www.nitrousproflow.com

GROUND

GROUND

TPS

VSS

RPM

ARM

GPIO

STAGE 1

STAGE 2

GROUND

PURGE IN

ANALOG 1

POWER GROUND

POWER GROUND

PURGE SOL

STATUS LED

ANALOG 2

+12V POWER

USB PORT

1/2008

Page 3

3. Refer to Figure 2 for basic hookup. Figure 3 shows

hookup for a system with independent control of

nitrous and fuel flow (refer to page 16 for details).

All signal and low current connections (thin lines)

can be made with 18-20 AWG wire. High current

connections (thick lines) require 14 AWG wire.

4. Working with clamping terminal blocks. All

connections to the controller terminal blocks must

be clearly identified either by means of distinct wire

colors or the use of wire labels. If you use distinct

wires colors, mark up Figure 2 or 3 for future

reference. Refer to the Appendix for recommended

wire labels. Wire should be stripped back 3/16-1/4

inch. No bare wire should be visible outside the

terminal block. Use a miniature Phillips or flat

screwdriver to tighten the screws.

5. Solenoid connections. Relays with a minimum 40

amp rating are required. If your nitrous system

uses large solenoid valves, you should use the

heavy duty P&B/Tyco VF7 series 70 amp relays

listed in the Appendix. The use of 50 amp fuse

blocks such as the Littlefuse Maxi Fuse series

listed in the Appendix is recommended. Power

connections from the fuse blocks must go direct to

the battery positive terminal. The ground

connection from the solenoids must go to a chassis

ground stud or may be connected direct to the

battery negative terminal. Use 14 AWG wire. Keep

power and ground connections as short as

possible.

6. Arming switch and status LED. The hookup

diagrams show terminal numbers for the

recommended C&K DM series illuminated power

rocker switch (refer to the Appendix for details).

You can also use a separate switch and LED. The

controller has an internal 1K ohm current limiting

resistor on the status LED output and can directly

drive any LED. The status LED output cannot drive

a conventional lamp. Most vehicles will have an

accessory fuse that can be used as a source for

the switched and fused +12V power connection.

Refer to the Appendix for recommended fuse taps.

7. Manual purge switch. If you require manual purge

capability, connect a momentary switch as shown.

Refer to the Appendix for the recommended C&K

DM series rocker switch.

8. Throttle position sensor (TPS) signal. Most

vehicles manufactured since 1981 will have a TPS

with 0-5V output located on the throttle body or

carburetor. Refer to the vehicle wiring diagram for

details. You can check the TPS signal with a DVM.

Some late model vehicles with drive-by-wire

electronic throttle bodies will have a dual output

accelerator pedal sensor. The signal voltage on

one output will rise with increasing pedal position

and the other output will drop. Connect the nitrous

controller TPS input to the rising signal. Solder this

signal connection and wrap with self vulcanizing

electrical tape (refer to the Appendix). If a suitable

0-5V signal is not available, you can use a wide

open throttle switch as shown in Figures 2 or 3.

9. RPM signal. This connection is required to utilize

the full capabilities of the controller. Depending on

your vehicle type and engine control, there are

three possible sources for the RPM signal:

a. High level signal on the Coil- terminal of

most inductive discharge type

ignitions. This includes most original

equipment (OE) ignitions except coil-onplug with integrated drive electronics. For

distributorless systems with multiple coil s

or coil packs, you can use any one of the

Coil- signals. Refer to the vehicle wiring

diagram for details. The Coil- terminal will

connect to an ignition module or engine

control module (ECM). The Coil+ terminal

will connect to switched +12V.

b. Tach signal (preferred for best noise

immunity). The controller is compatible

with industry standard 12V square wave

tach signals such as what would be used

to drive an Autometer or similar

aftermarket tach. Most aftermarket

capacitive discharge (CD) ignitions

including the MSD-6 and Crane HI-6 series

have a tach output that you can use.

c. Low level logic signal. This type of signal

is found on late model vehicles, including

many imports, that use coil-on-plug with

integrated drive electronics. Refer to the

vehicle wiring diagram for details. You can

use the signal that goes from the ECM to

any one of the coil-on-plug units.

Unless you are using the tach terminal on an

aftermarket ignition or a screw terminal on a coil,

you should solder the RPM signal connection and

wrap with self vulcanizing electrical tape (refer to

the Appendix). During initial setup, you must

configure an RPM signal level jumper inside the

nitrous controller. Refer to the Initial Setup section

on page 15 for details.

Nitrous Pro-Flow, 4700 NE 11

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

(954) 771-6216 www.nitrousproflow.com

1/2008

Page 4

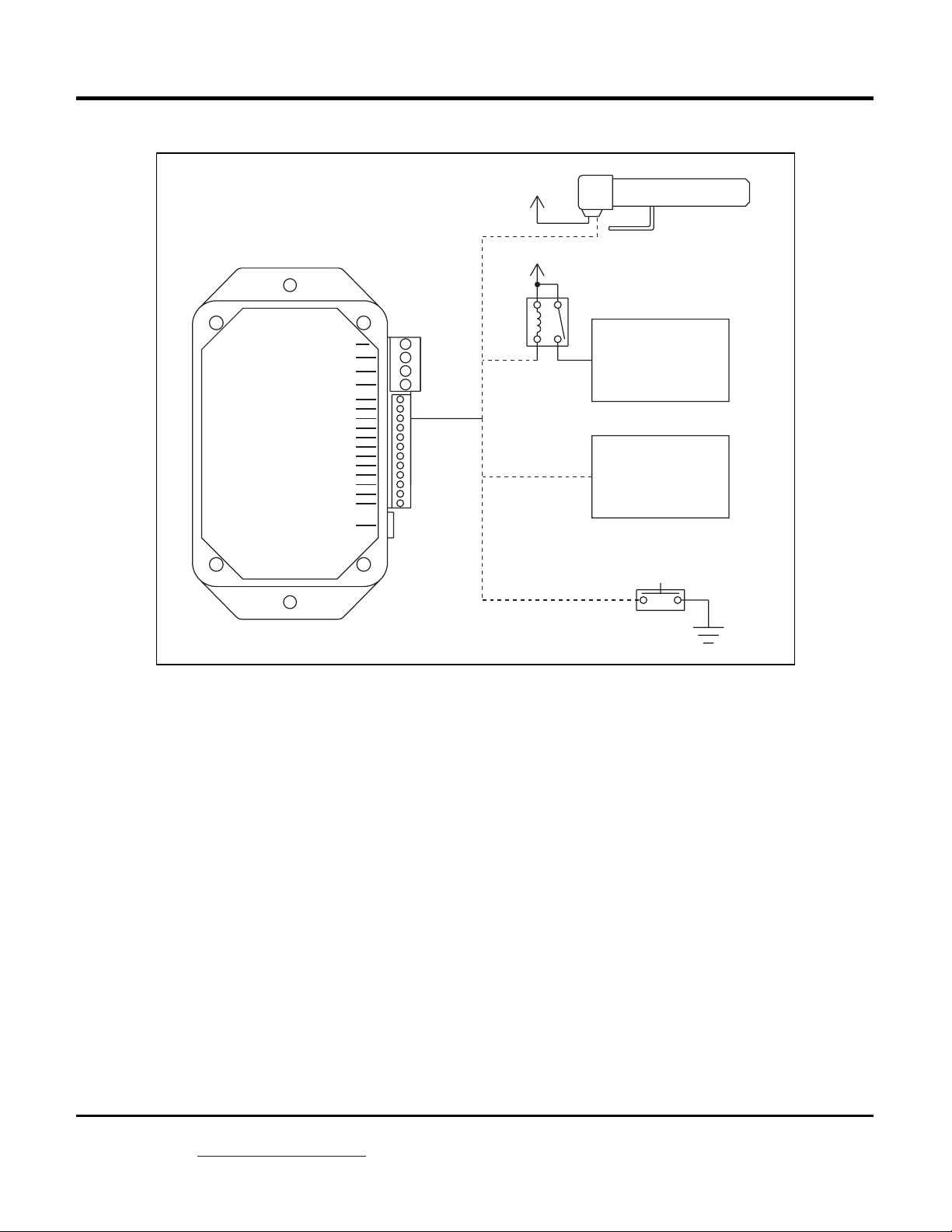

Figure 4 – GPIO Hookup Options

POWER GROUND

POWER GROUND

STAGE 2

STAGE 1

GROUND

PURGE SOL

GPIO

STATUS LED

PURGE IN

ARM

ANALOG 2

ANALOG 1

RPM

+12V POWER

USB PORT

TPS

VSS

SWITCHED +12V

SWITCHED +12V

85

RETARD

RELAY

86

LED SHIFT LIGHT

(AUTOMETER 5330)

+

-

30

IGNITION SYSTEM

87

WITH ACTIVE HIGH

RETARD

RETARD INPUT

INPUT

SUCH AS MSD OR

ACCEL

IGNITION SYSTEM

WITH ACTIVE LOW

RETARD

RETARD INPUT

INPUT

SUCH AS CRANE

HI-6

ADDITIONAL TRIGGER SWITCH

10. Vehicle speed sensor (VSS) signal. This

connection is required to utilize the full

capabilities of the nitrous controller. Most

vehicles manufactured since 1981 will have a

VSS. Refer to the vehicle wiring diagram for

details. Some late model vehicles with anti-skid

braking (ABS) and electronic stability control

(ECS) systems utilize individual wheel sensors

use to calculate an average vehicle speed.

Accessing a discrete vehicle speed signal on

these systems may not be possible. You may

have to install a driveshaft sensor (contact tech

support for details). For Nissan 350Z

applications, you can access vehicle speed on

the 8P/R signal (pin 26 on the unified meter and

A/C amp module behind the center console).

11. Optional general purpose input/output (GPIO)

signal. Refer to Figure 4 for GPIO hookup

options. If you use the GPIO to drive a shift light,

you must use an 12V LED type. The GPIO

cannot drive a conventional lamp. If you use the

GPIO to retard an aftermarket ignition that

Nitrous Pro-Flow, 4700 NE 11

(954) 771-6216 www.nitrousproflow.com

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

1/2008

requires a 12V (active high) signal, you must use

a relay as shown. Refer to the Appendix for

recommended relays.

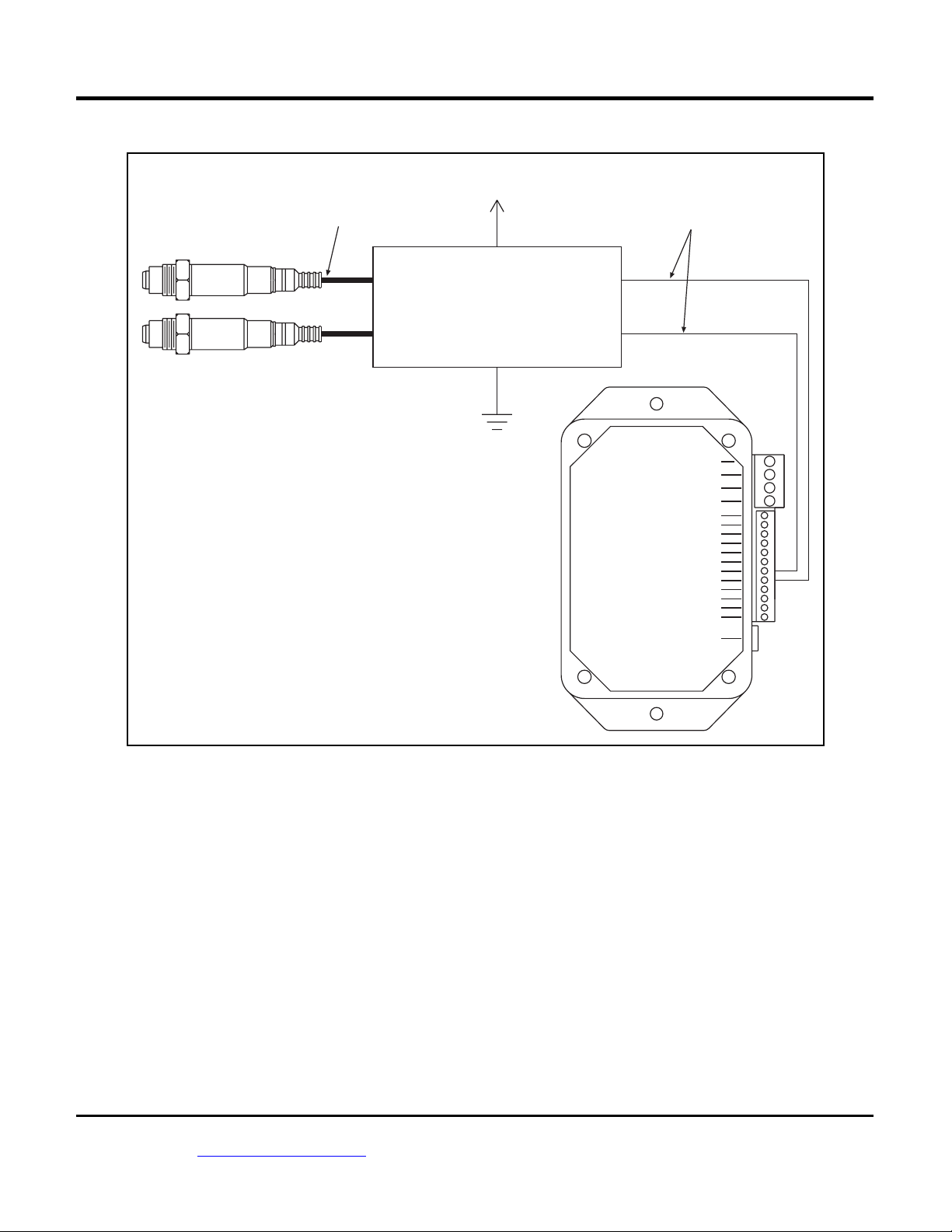

12. Optional analog input signals. The nitrous

controller will log 0-5V data on two analog inputs.

Uses include logging air/fuel ratio from a wideband sensor system such as the Daytona

Sensors WEGO IIID shown in Figure 5. The

Nitrous Log software is used to set the units and

scaling for the analog inputs. Refer to the Nitrous

Log section for details.

13. Ground connections. Use 18 AWG wire for the

signal ground and two 14 AWG wires for the

power ground. Keep the ground connections as

short as possible. The ground connections must

go to a chassis ground stud (you can usually find

one under the dash). If you are using the analog

inputs, use the same ground point for any

associated devices in order to avoid signals

errors due to a ground loop.

14. Reconnect the battery ground cable.

Page 5

Figure 5 – Analog Input Hookup to Daytona Sensors WEGO IIID Wide-Band System

TO SWITCHED

SENSOR 1 CABLE

IDENTIFIED BY

YELLOW BAND

+12V POWER

RED

0-5V OUTPUT SCALED:

AFR = 10 + (2 x VOUT)

BOSCH

LSU 4.2

BOSCH

LSU 4.2

SENSOR 1 INPUT

WEGO IIID

SENSOR 2 INPUT

GROUND

SENSOR 1 AFR

OUTPUT

SENSOR 2 AFR

OUTPUT)

BLACK (2)

WHITE

BLUE

POWER GROUND

POWER GROUND

STAGE 2

STAGE 1

GROUND

PURGE SOL

GPIO

STATUS LED

PURGE IN

ARM

ANALOG 2

ANALOG 1

TPS

RPM

VSS

+12V POWER

USB PORT

OVERVIEW OF INITIAL SETUP

The nitrous controller requires initial setup to

establish nitrous system control parameters. PC Link

Nitrous software is used for setup. In addition, the

Nitrous Log data logging software is used to check for

proper scaling of the throttle position, RPM, and

vehicle speed inputs. Complete the software

installation and read the software sections of this

instruction manual, then continue the initial setup steps

on page 15.

PC REQUIREMENTS

The nitrous controller connects to your PC by

means of a USB interface. A USB cable is supplied

with the unit. The PC must have a free USB port. If you

have an older PC without USB capability, you cannot

use the controller.

Nitrous Pro-Flow, 4700 NE 11

(954) 771-6216 www.nitrousproflow.com

th

St., Ft. Lauderdale, FL 33334 Pro-Flow Part. No. 810100

1/2008

We recommend a laptop PC with Pentium

processor and super VGA display (SVGA with 1024 x

768 pixel resolution) running Windows 98/ME/XPVista.

Data chart display is graphics intensive and a high

speed Pentium processor is recommended.

Processors slower than 300 MHz will exhibit sluggish

program loading and response. The PC must have a

CDROM drive for program loading.

PC Link Nitrous and Nitrous Log software

include print commands to print downloaded data. The

programs have been tested with Hewlett-Packard laser

and inkjet printers and Epson inkjet printers. We

recommend using a color inkjet printer.

Page 6

Loading...

Loading...