System Manual

Patented technology

WELCOME

Thank you for investing in a Wilson Benesch product.

The Torus Infrasonic Generator is completely original in thought and execution, and is

manufactured by Wilson Benesch in Sheffield. The finest materials in the world have been

designed into this product, materials technologies that you will not find in any other audio

product.

This manual has been constructed to facilitate both ease of installation and long-term use as

well as important safety information and helpful advice. It is strongly advised that you carefully

absorb this before embarking upon the installation.

1

WORLD WIDE WARRANTY

In addition to any local warranty, Wilson Benesch offers a 3 year conditional warranty to the end user.

This is done in collaboration with our distributors.

The conditions of this warranty are:

1. That Wilson Benesch receive the necessary registration details from the end user.

2. That these details are received within six weeks of purchase.

3. That it is only valid for the first owner and that it is not transferable.

4. Neither transportation, nor any other costs, nor any risk for removal, transportation and installation of

products is covered by this warranty.

5. That it is limited to the repair of the equipment only.

6. That any claim is accompanied by the necessary proof of purchase.

7. That cover does not extend to damage caused by faulty or unsuitable ancillary equipment.

8. That the serial number has not been altered, deleted, removed or made illegible.

9. That it shall be for a term of 3 years from the data of purchase.

10. That the product has not been abused or modified in any way.

11. That it was purchased originally from a Wilson Benesch authorised dealer.

This warranty is offered in good faith and is in addition to any statuary rights or existing Warranty that may be

available to the end user.

Should your Wilson Benesch Torus system exhibit a problem, please contact your dealer who will be able to make

the necessary arrangements to correct it.

SERVICE AFTER WARRANTY

Please contact your dealer in the first instance before returning the product directly to us. Should the unit need to

be returned for any reason, all carriage costs will be payable by the customer. Losses or damage caused during

transit are the customers’ risk.

How to claim repairs under warranty:

Should service be required, please follow the following procedure:

1. If the equipment is being used in the country of purchase, you should contact the Wilson Benesch authorised

dealer from whom the equipment was purchased.

2. If the equipment is being used outside the country of purchase, you should contact the Wilson Benesch

national distributor in the country of residence who will advise where the equipment can be serviced. You can

call Wilson Benesch in the UK or visit our web site to get the contact details for your local distributor. To

validate your warranty, you will need to produce this warranty booklet completed and stamped by your dealer

on the date of purchase. Alternatively, you will need the original sales invoice or other proof of ownership and

date of purchase.

2

INTRODUCTION

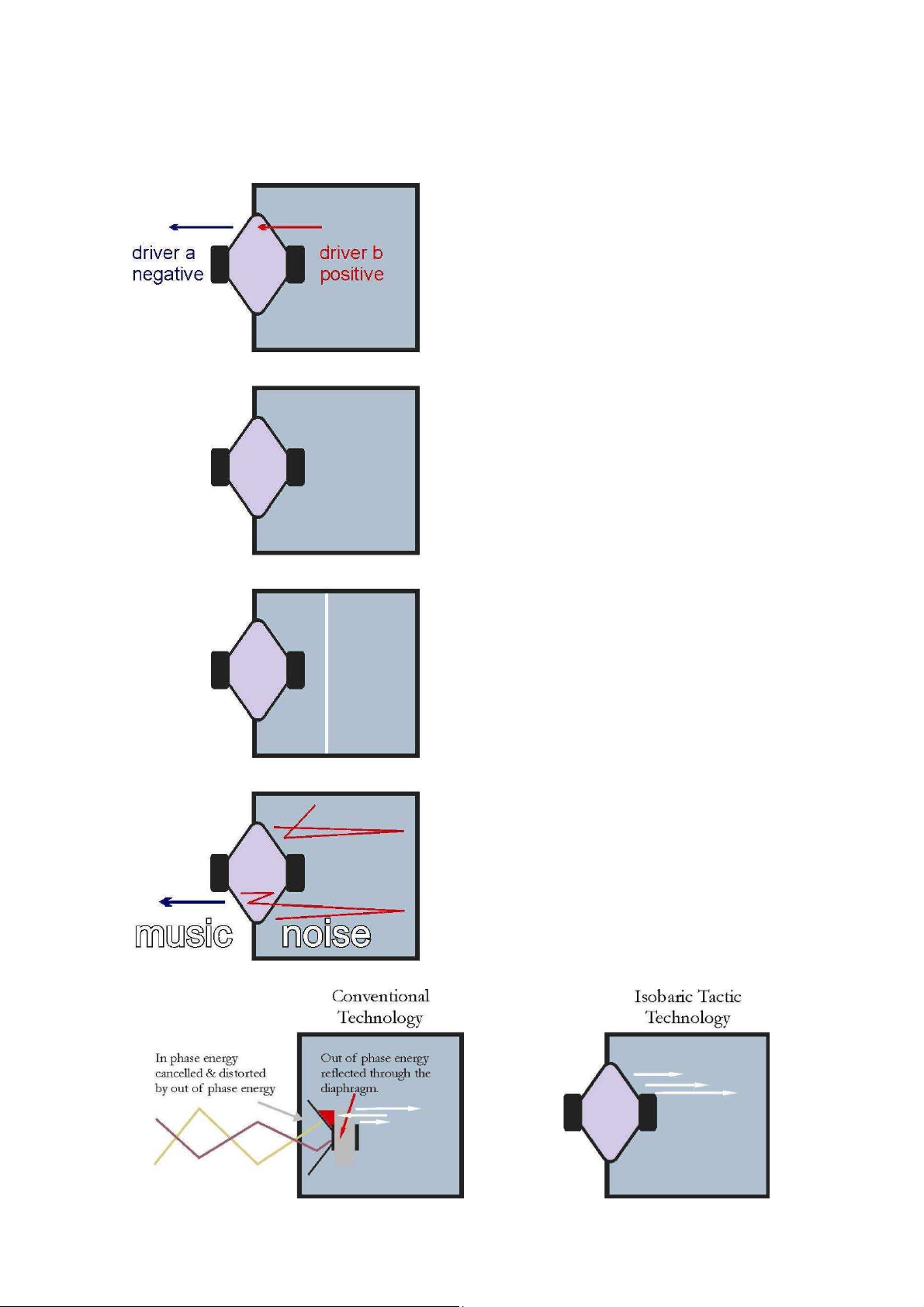

Because These

Don’t Work…..

We Designed Something That Does!

3

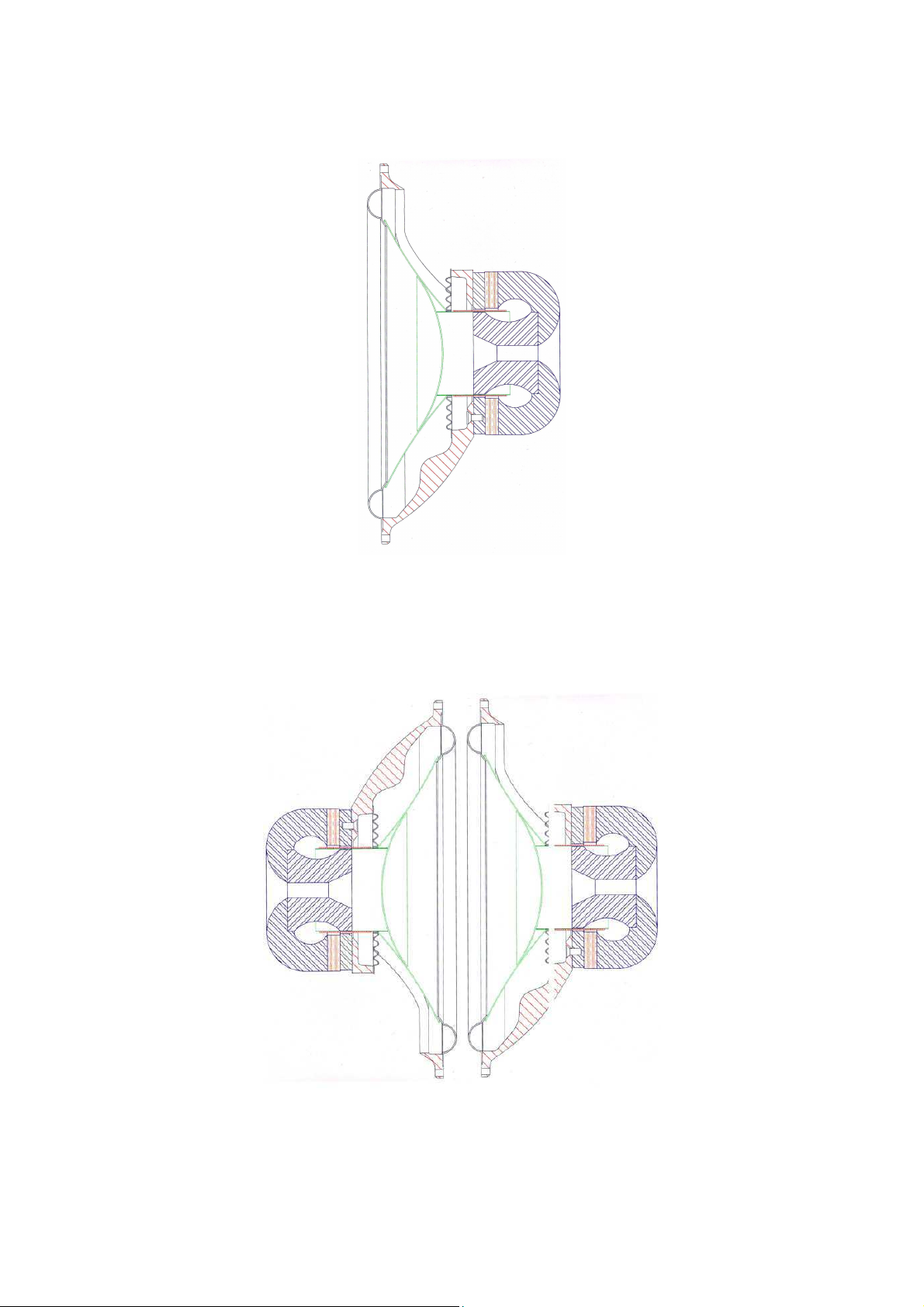

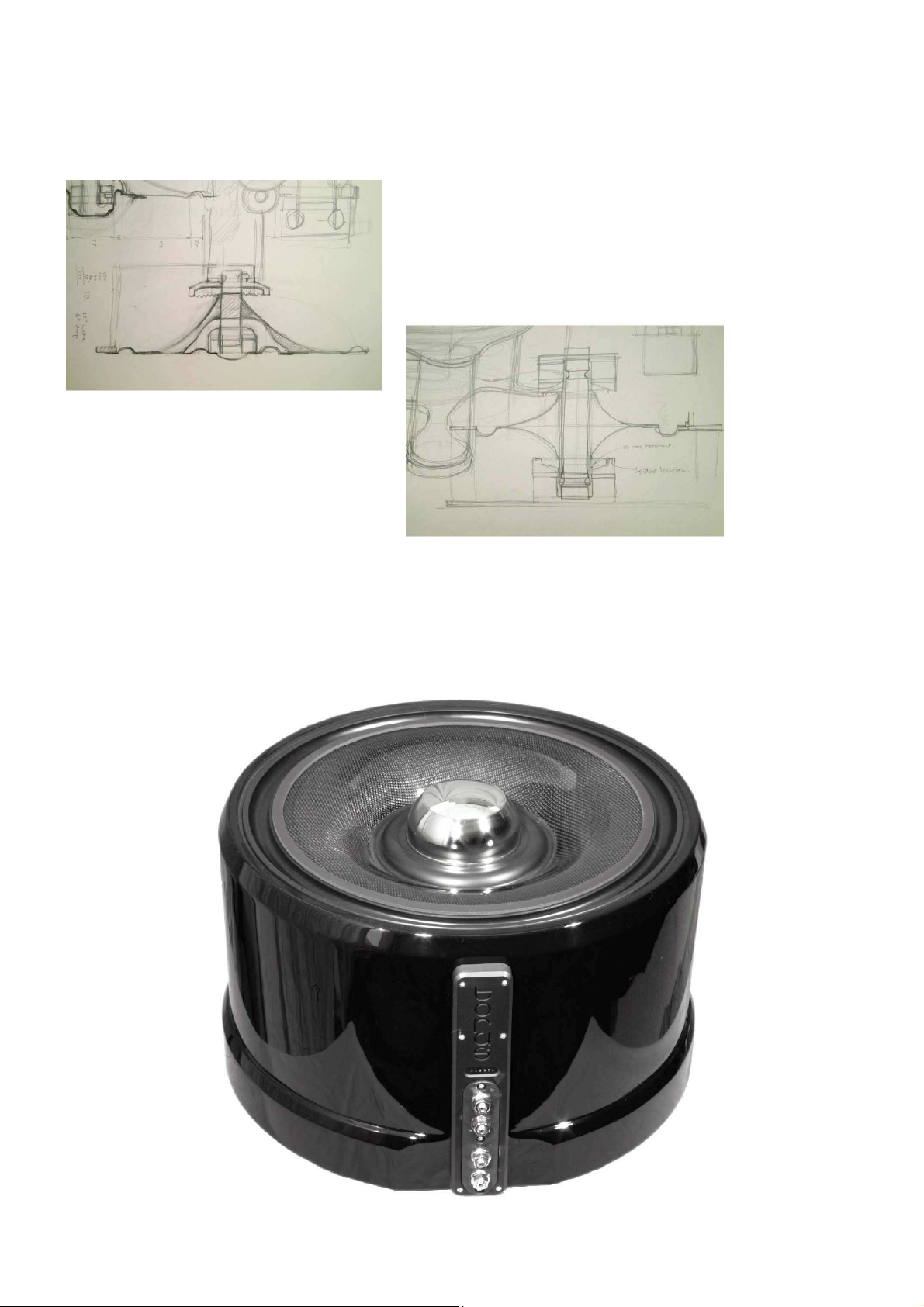

So we started here!

4

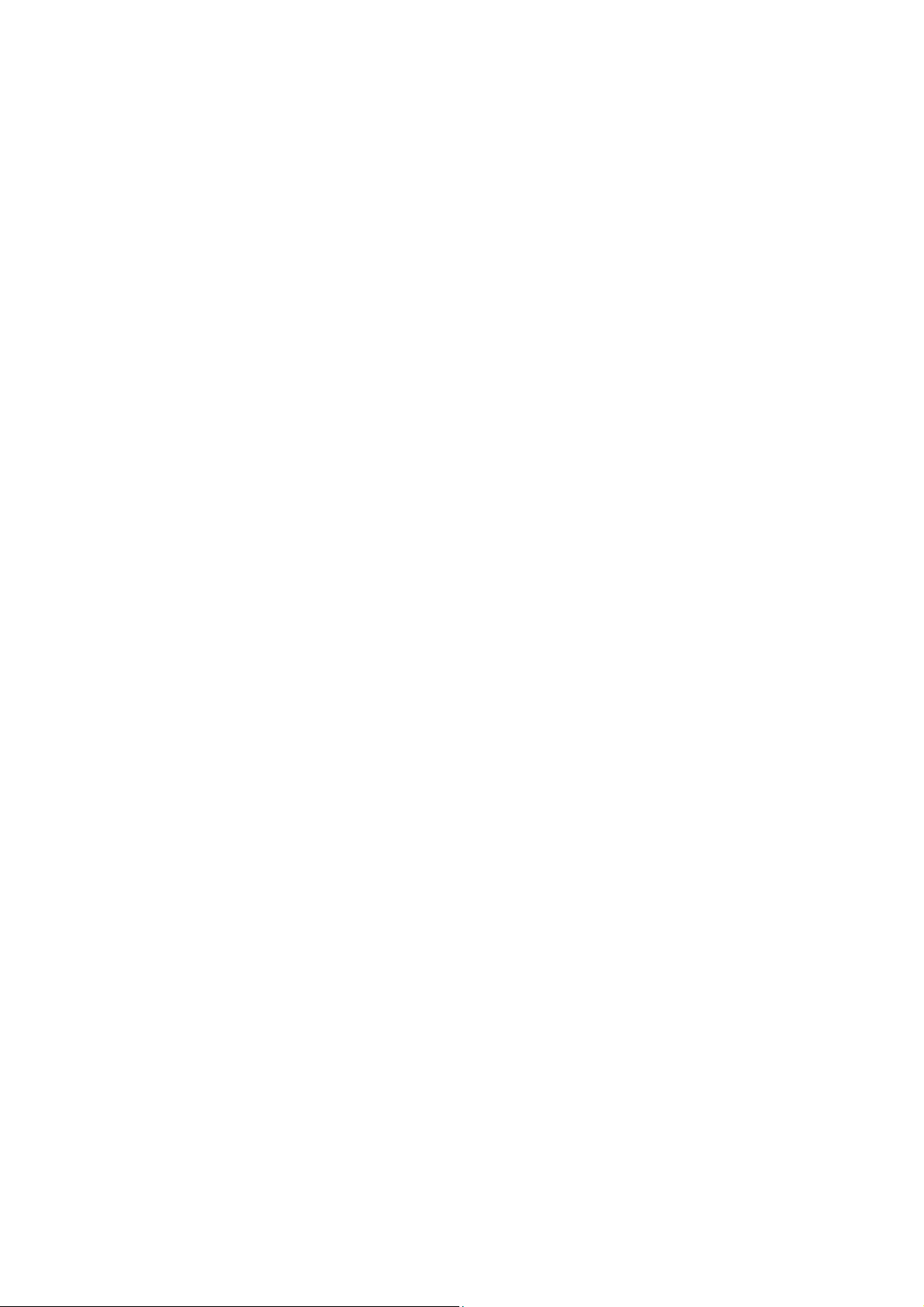

And created this

To do this

®

Isobaric Tactic

5

Benefits of the ‘CLAMSHELL’ Design

given limit of low frequency,

olume required by

CLAMSHELL orientation of

Tactic drive unit cancels third

order non-linearity’s.

At 200 Hz and below the

composite diaphragm is coupled

and can be seen as a solid,

super lightweight structure.

For a

the enclosure v

the Isobaric is half that of the

single driver, conventional option.

The composite diaphragm

defeats the communication of

internal reflections and other

distortion that is unwanted

energy acting against the music.

6

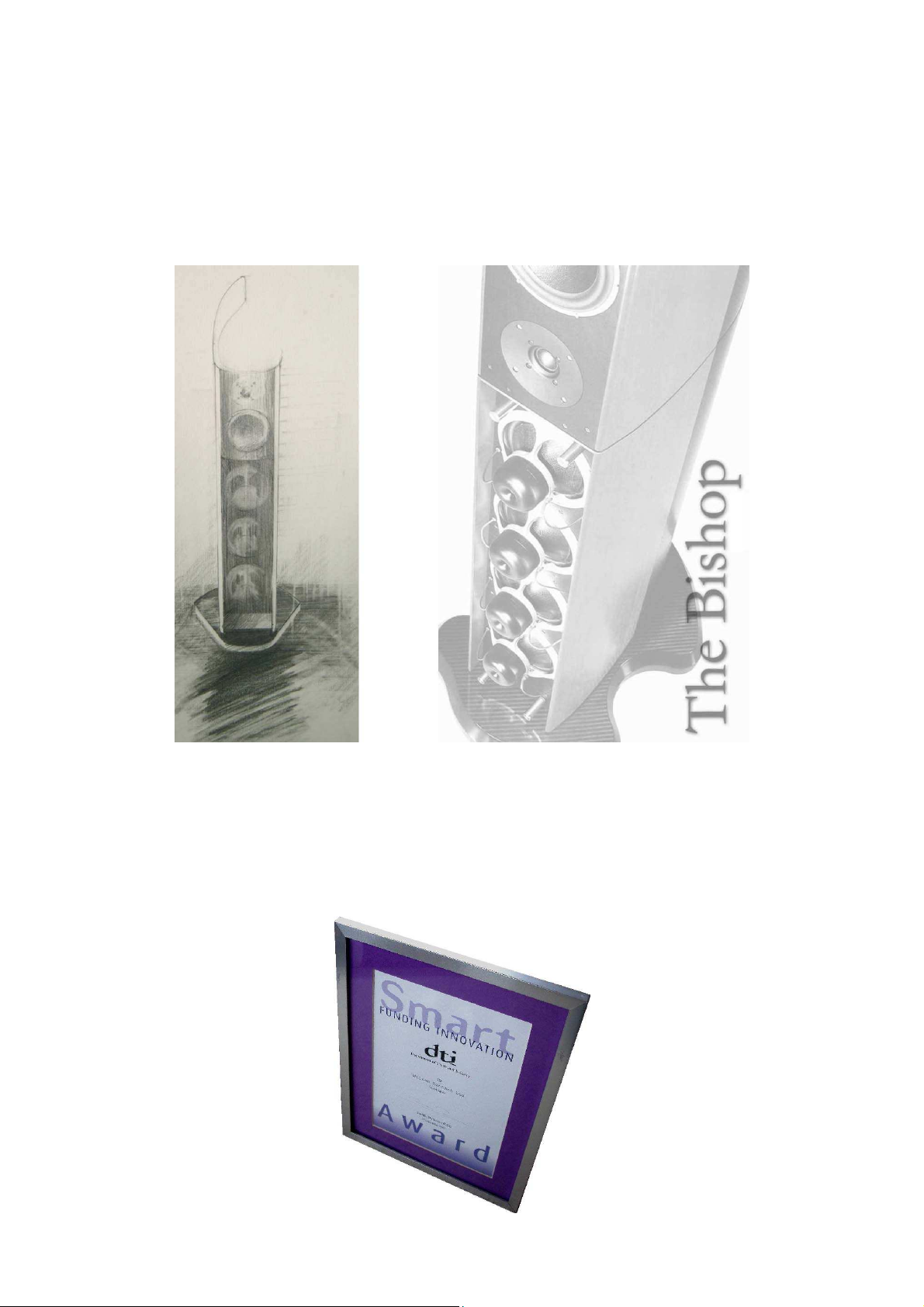

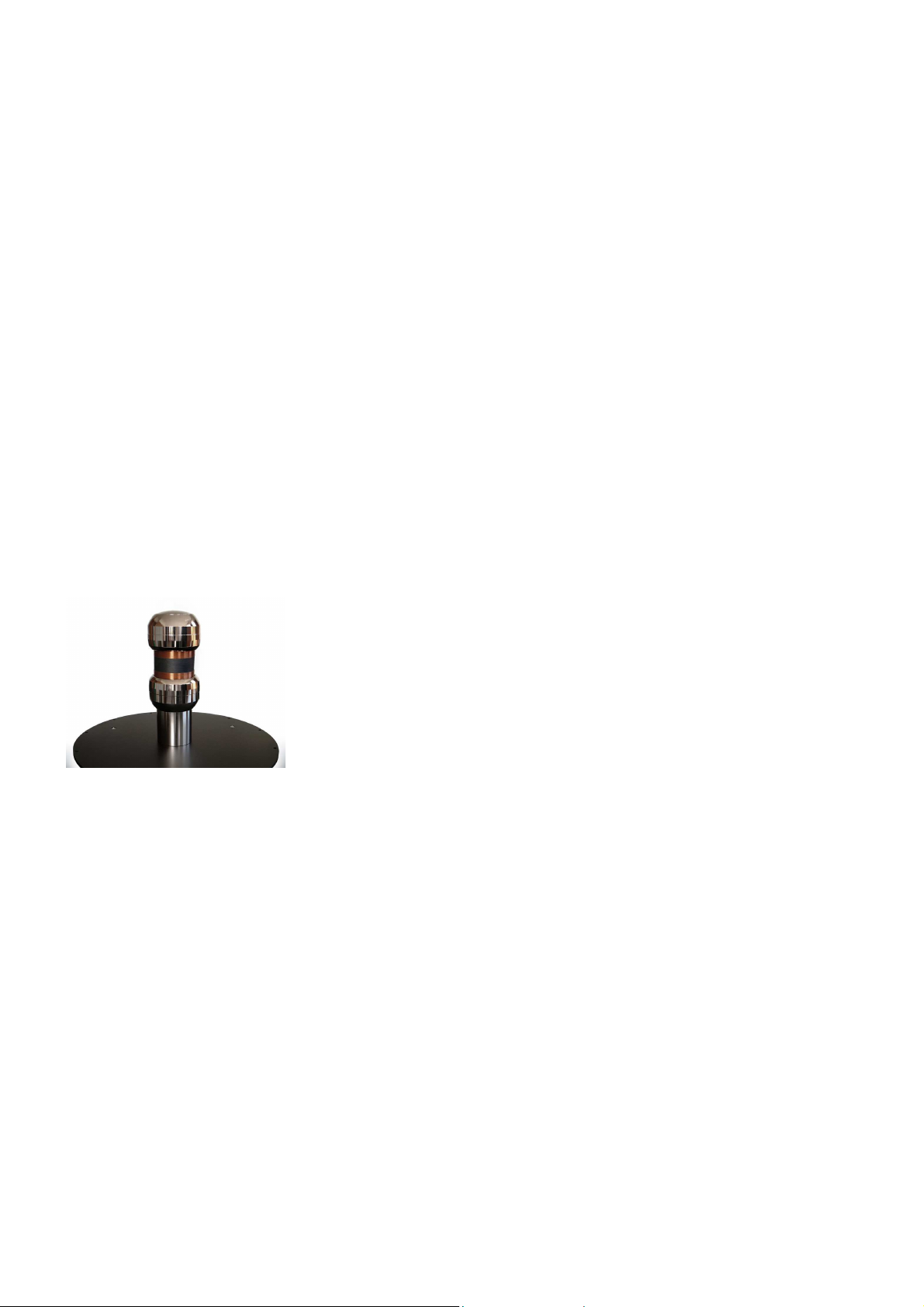

Which led to The Bishop

Reference

8 Motors driving 8 cones to achieve dynamics

(1999)

Five years later a feasibility study grew out

of this work that led to this

7

Which then led to these ideas

That enabled this!

8

WILSON BENESCH DESIGN PHILOSOPHY AND LOW

FREQUENCY SOUND

To date, all audio designers attempting to create low frequency sound have produced a variable of

the ubiquitous Subwoofer. In reality, the only option available to the consumer, has been to opt for

brand A’s version of the collection of parts, as opposed to brand B’s version. As competition has

grown, the variables have changed. Bigger amplifiers to drive more inefficient woofers or different

cabinet materials, essentially they have remained the same. After three years of research and

development, the Torus System can be seen to offer a significant departure from the Subwoofer

solution for developing infrasonic sound. This product is so different, that it clearly demonstrates the

fundamental flaws in the design of the Subwoofer and provides a real alternative for Music and

Cinema effects. Wilson Benesch designs have always been driven by the goal of introducing

something that is alternative and superior. The Isobaric Tactic¨ is one good example of this

approach It demonstrates how one innovative development can make another possible.

SUBWOOFER HISTORY

Richard Lord of R.E.L. was the architect of the Sub woofer. It was and still is today, two decades

later, still based around three elements (i) the wooden box (ii) woofer (iii) built in amplifier. Almost

without exception every other audio company has followed the same formula. Even those who claim

to have achieved something different can be seen to use the Woofer and an identical formula, with

subtle variations, such as two drivers instead of one, or different materials for the cabinet. Which

ever design you chose to look at, for the last fifteen years the entire audio industry has devoted all of

its energy to creating designs based upon the same formula. Notably, Wilson Benesch has always

rejected this solution. In fact to its credit it has never seen fit to use large drive units to solve any low

frequency problems. There is no way around the fundamental problems that come with the large

woofer designs, either in loudspeakers or Sub Woofer designs. Insurmountable obstacles stand in

the way of the successful Sub woofer solution, whether it is large or small.

9

Small option:

Here the drive unit will be unable to move large amounts of air instantaneously, because in order to

move any real volume of air, the small diaphragm will need to travel a long distance to make up for

its small size. This pumping action will be incapable of reproducing the explosive timpani. The main

benefit of this design comes from the relatively small sound signature from the cabinet. However the

small volume of air available will create a strong spring effect on the moving parts that will elevate

the resonant frequency of the drive unit, severely limiting its ability to produce energy below 35

Hertz.

Large option:

Making the parts larger confounds the designer in a different way because the large diaphragm

becomes more difficult to control, so stiffer suspensions are needed. These stiff suspensions

elevate the resonant frequency of the drive unit. What follows is a balancing act between adding

mass to the diaphragm to lower the resonant frequency and the Stiffness of the suspension. Both

these options impact upon the movement of the coil thought the air gap. This often requires

increases in the air gap and consequential decline in power. There are severe limits here also, due

to the inexpensive drop forged components and ceramic magnets that are used almost without

exception in the vast majority of Woofers.

THE WEAKEST LINK

The most important problem that is accepted without exception in every sub woofer is in fact the

woofer itself. Although large diaphragm systems are commonly accepted, it is easy to demonstrate

that they cannot integrate with the fast small drive units used to reproduce the mid range sound

energy. The laws of physics dictate that you cannot accelerate and decelerate large systems like

you can small ones. Woofer designers have attempted to reduce the problems by using stiff

suspensions, and in some cases doubling the numbers deployed, in order to provide the restoring

force to the diaphragm. This solution defeats the dynamic capabilities even more! The problems do

not end here. The next major compromise of the woofer, is its dependence upon the external

structure. The Woofer is of course attached directly to the external structure. The huge forces

injected into this structure cause massive sympathetic resonance’s that are clearly audible and

impact directly upon the sound that is heard. As the cabinet increases in size, so do the resonance

problems. In fact it must be accepted that there will be an exponential increase in cabinet

resonance’s.

10

As its name suggests, the Core is at the heart of the Torus design.

It is a formidable structural element of Brunelian proportions.

machined assembly,

a dual

The Core also provides a number of other important benefits that

Summary of major flaws of the Sub Woofer:

• The woofer is fastened to and relies fundamentally upon the cabinet structure.

• The inefficiency of the woofer.

• The inaccuracy of the woofer components.

• The amplifier is housed in the same enclosure as all the high levels of energy being

produced by the system.

Summary of the major design elements of the Torus System:

The first and most important design element of the Torus solution is that it is not based upon the

Woofer and this is why it is not called a Subwoofer. By designing out the woofer, all the design flaws

that have been tolerated to date are eliminated at the beginning of the design.

THE CORE

Weighing in at over 16 kg, the precision

combines with high energy Rare Earth magnets to create

motor / push pull drive.

are elaborated upon below:-

1. Converts electrical energy into kinetic energy.

2. High capacity metal sink conducts all structural borne resonant energy directly to ground with

zero reference to the outer enclosure.

3. High metal mass efficiently conducts all heat away from the coils.

4. Unlike in the Woofer where high hysteresis suspensions are axiomatic, the control of the

diaphragm in the Torus is achieved electrically. The two powerful motors subsequently waste

no energy overcoming these losses.

5. The combination of two high power motors, low mass moving parts, and low stiffness

suspensions, is quite unlike anything seen before, and enables a dynamic performance, and

level of control that is beyond the capabilities of any sub woofer.

11

Loading...

Loading...