WIL-RICH QX2 Assembly Instructions Manual

ASSEMBLY INSTRUCTIONS

FIELD CULTIVATOR

Printed in USA (74304) 1/2011

WIL-RICH

PO Box 1030

Wahpeton, ND 58074

PH (701) 642-2621

Fax (701) 642-3372

www.wil-rich.com

1

QX2 ASSEMBLY MANUAL 74304 1/11

WARRANTY

The only warranty Wil-Rich gives and the only warranty the dealer is authorized to give is as

follows:

We warrant products sold by us to be in accordance with our published specifications or those

specifications agreed to by us in writing at time of sale. Our obligation and liability under this

warranty is expressly limited to repairing, or replacing, at our option, within 12 months after date of

retail delivery, any product not meeting the specifications. We make no other warranty, express

or implied and make no warranty of merchantability or of fitness for any particular purpose.

Our obligation under the warranty shall not include any transportation charges or costs or installation or any liability for direct, indirect or consequential damage or delay. If requested by us, products

or parts for which a warranty claim is made are to be returned transportation prepaid to our factory.

Any improper use, operation beyond rated capacity, substitution of parts not approved by us, or any

alteration or repair by others in such manner as in our judgment affects the product materially and

adversely shall void this warranty. No employee or representative is authorized to change this

warranty in any way or grant any other warranty.

Wil-Rich reserves the right to make improvement changes on any of our products without notice.

When warranty limited or not applicable: Warranty on hoses, cylinders, hubs, spindles, engines,

valves, pumps or other trade accessories are limited to the warranties made by the respective

manufactures of these components. Rubber tires and tubes are warranted directly by the respective tire manufacturer only, and not by Wil-Rich.

Warranty does not apply to any machine or part which has been repaired or altered in any way so

as in the our judgment to affect its reliability, or which has been subject to misuse, negligence or

accident.

A Warranty Validation and Delivery Report Form must be filled out and received by Wil-Rich

to initiate the warranty coverage.

WARRANTY CLAIMS PROCEDURE

1. The warranty form must be returned to Wil-Rich within fifteen (15) working days from the repair

date.

2. Parts returned to Wil-Rich without authorization will be refused. The parts must be retained at

the dealership for ninety (90) days after the claim has been filed. If the Service Department would

like to inspect the parts, a packing slip will be mailed to the dealer. The packing slip must be returned

with the parts. The parts must be returned prepaid within thirty (30) days of receiving authorization.

After the parts are inspected and warranty is verified, credit for the return freight will be issued to

the dealer.

3. Parts that will be scrapped at the dealership will be inspected by a Wil-Rich Sales Representative, District Sales Manager or Service Representative within the ninety (90) day retaining period.

QX2 ASSEMBLY MANUAL 74304 1/11

2

PERSONAL SAFETY IS IMPORTANT!

ALL PERSONNEL INVOLVED WITH THE ASSEMBLY AND/OR OPERATION OF THIS

EQUIPMENT MUST BE INFORMED OF PROPER SAFETY PROCEDURES. OPERATOR’S/

ASSEMBLY MANUALS PROVIDE THE NECESSARY INFORMATION. IF THE MANUAL IS

LOST FOR A PARTICULAR IMPLEMENT, ORDER A REPLACEMENT AT ONCE.

OPERATOR’S AND ASSEMBLY MANUALS ARE AVAILABLE AT NO CHARGE UPON REQUEST.

The Safety Alert symbol iden-

This Safety Alert symbol

means ATTENTION! BECOME ALERT YOUR

SAFETY IS INVOLVED!

tifies important safety messages on the Wil-Rich Quad X

Field Cultivator and in this

manual. When you see this

symbol, be alert to the possibility of personal injury or death.

Follow the instructions in the

safety message.

3 Big Reasons

SIGNAL WORDS:

Note the use of the signal

words DANGER, WARNING

and CAUTION with the safety

messages. The appropriate

signal word for each message

has been selected using the

following guidelines:

Why is SAFETY important to you?

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

DANGER

An immediate and specific hazard which WILL

result in severe personal

injury or death if the

proper precautions are

not taken.

ADDRESS INQUIRIES TO: WIL-RICH PO BOX 1030

WAHPETON, ND 58074

PH (701) 642-2621 FAX (701) 642-3372

WARNING

A specific hazard or unsafe practice which

COULD result in severe

personal injury or death

if the proper precautions

are not taken

3

QX2 ASSEMBLY MANUAL 74304 1/11

CAUTION

Unsafe practices which

COULD result in personal injury if proper

practices are not taken,

or as a reminder of good

safety practices.

GENERAL INFORMATION .......................................... 5

TRANSPORT SAFETY .................................................. 6

ASSEMBLY

OPENING BUNDLE ....................................................7-8

AXLES AND WALKING TANDEMS ............................. 9

MAIN FRAME .............................................................. 10

HITCH ASSEMBLY ...................................................... 11

HITCH ASSEMBLY CONTINUED ............................... 12

7’, 9’4”, & 11’8” WINGS ............................................ 13

3’ OUTER WING .......................................................... 14

5’ FLOATING OUTER WING W/GAUGE WHEEL ...... 15

6’ FLOATING OUTER WING W/GAUGE WHEEL ...... 16

WING LIFT COMPONENTS ....................................... 17

OUTER WING HYDRAULIC GAUGE WHEEL ............ 18

HYDRAULICS-OUTER GAUGE WHEEL .................... 19

PARALLEL LINK GAUGE WHEELS ...........................20

DEPTH INDICATOR .................................................... 21

SINGLE POINT DEPTH CONTROL ........................... 22

SINGLE POINT HANDLE ............................................ 23

CHECK VALVE ............................................................. 24

CHECK VALVES .......................................................... 25

HOSE CLAMP ............................................................. 26

LIFT HYDRAULICS

QX2 27 ................................................................. 27

QX2 32 ................................................................. 28

QX2 37 ................................................................. 29

WING FOLD HYDRAULICS

QX2 27 ................................................................. 30

QX2 32 & 37 ....................................................... 31

QX2 32 & 37 W/OUTERWINGS ..................... 32

CHARGING LIFT SYSTEM . .. ......................................33

CHARGING WING FOLD SYSTEM ............................ 34

OPTIONAL- HYD WEIGHT BALANCE KIT ..............35

BLANK PAGE FOR NOTES . ....................................... 36

TWIN SPRING SHANK ASSEMBLY ............ 37

SINGLE SPRING SHANK ASSEMBLY ........ 38

SHANK PLACEMENTS

13’ MAIN FRAME ...........................................39

7’ WING .............................................................. 40

9’ 4” WING ................................................................... 41

11’8” WING ................................................................. 42

2' OUTER RIGID STUB & 3’ OUTER WIN ................. 43

5' OUTER WING .......................................................... 44

6’ OUTER WING .......................................................... 45

OPTIONAL - HD AUXILIARY HITCH ......................... 46

LIGHTS ........................................................................47

SAFETY DECALS .................................................. 48-49

BLANK PAGE FOR NOTES . ....................................... 50

CONTENTS

QX2 ASSEMBLY MANUAL 74304 1/11

4

ASSEMBLY INFORMATION

Remove all wires and arrange the parts conveniently.

NOTE: Always wear safety glasses or

goggles and be careful when cutting wires

and steel bands as they are under tension and

will spring back when cut.

Wherever the terms "left" and "right" are used,

it must be understood to mean from a position behind and facing the machine.

Lubricate all bearings and moving parts as

you proceed and make sure they work freely.

Loosely install all bolts connecting mating

parts before final tightening.

When tightening bolts, they must be torqued

to the proper number of foot-pounds as indicated in the table unless specified. It is important that all bolts be kept tight.

On new machines, all nuts and bolts must be

rechecked after a few hours of operation.

When replacing a bolt, use only a bolt of the

same grade or higher. Except in shear bolt

applications, where you must use the same

grade bolt.

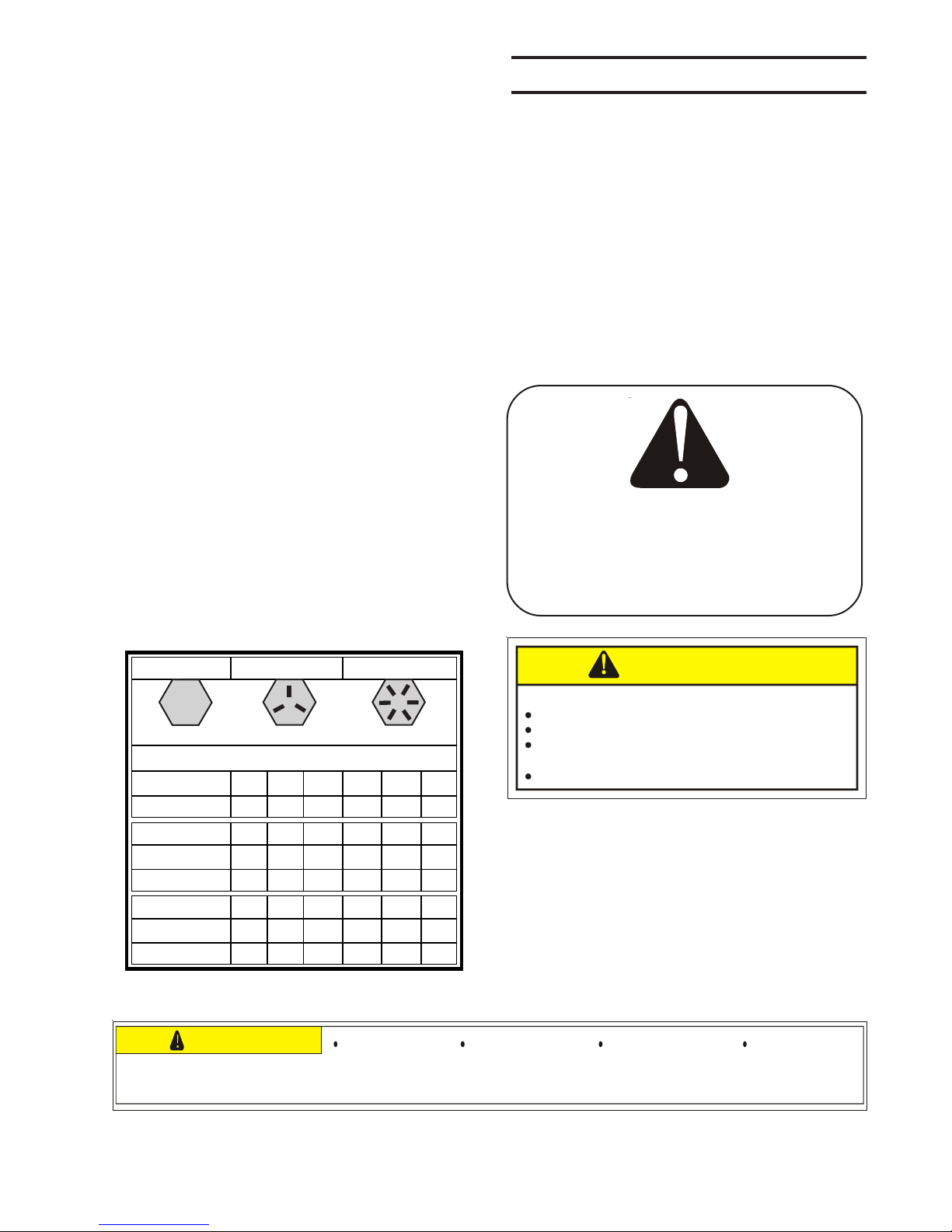

Bolts with no markings are grade 2

Grade 5 bolts furnished with the machine are

identified by three radial lines on the head.

Grade 8 bolts furnished with the machine are

identified by six radial lines on the head.

All U-bolts are grade 5.

THIS SYMBOL USED TO CALL YOUR ATTENTION TO INSTRUCTIONS CONCERNING YOUR

PERSONAL SAFETY.

BE SURE TO OBSERVE AND FOLLOW THESE

INSTRUCTIONS

GRADE 2 GRADE 5 GRADE 8

TORQUE IN FOOT POUNDS

BOLT DIA 3/8 1/2 5/8 3/4 7/8 1

HEX HEAD 9/16 3/4 15/16 1-1/8 1-5/1 1-1/2

UNC GR2 18 45 89 160 252 320

UNC GR5 30 68 140 240 360 544

UNC GR8 40 100 196 340 528 792

UNF GR2 21 51 102 178 272 368

UNF GR5 32 70 168 264 392 572

UNF GR8 48 112 216 368 792 840

CAUTION

FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE.

Just before and during

operation be sure no one is

on or around the

implement.

CAUTION

TO AVOID INJURY AND/OR MACHINE DAMAGE:

Refer to Operator's Manual for safety instructions.

Do not stand or climb on machine when operating.

Use clean hazard flashers and SMV sign when

transporting.

Observe highway traffic regulations.

MODIFICATIONS

It is the policy of Wil-Rich to improve its products whenever possible and practical to do so.

We reserve the right to make changes, improvements and modifications at any time

without incurring obligation to make such

changes, improvements on any equipment

sold previously.

Before activating the

hydraulic system, check

hoses for proper

connections.

Before lowering the wings for

the first time, make sure the

entire system has been charged

with oil.

With wings down always

install hydraulic cylinder

channel lock(s) for

transporting.

23325

53334

5

QX2 ASSEMBLY MANUAL 74304 1/11

SAFETY

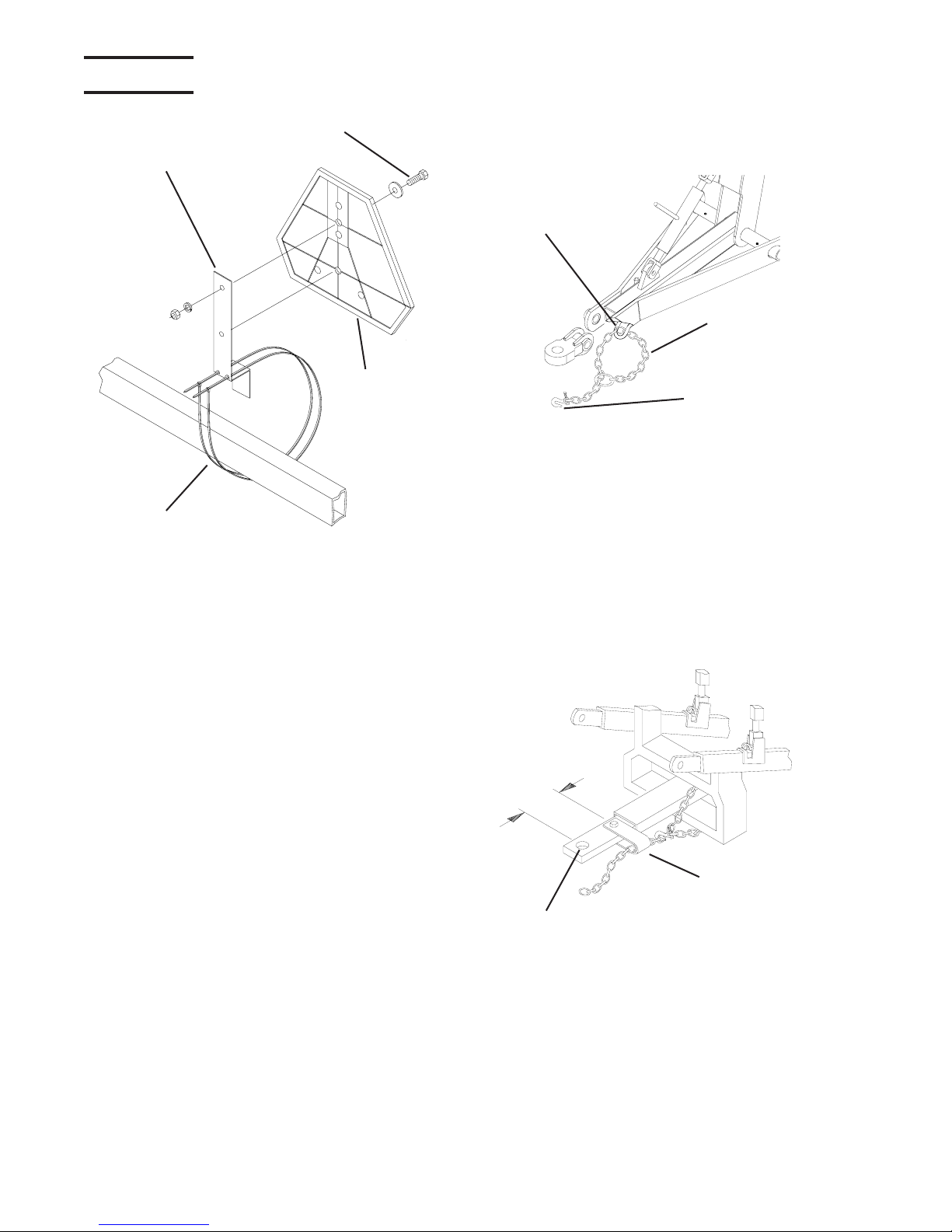

1/4NCx3/4 BOLT

SMV MOUNTING BRACKET

The safety chain should be hooked long

enough to permit full turns. Unnecessary slack

should be taken up.

SAFETY CHAIN

MOUNT

SAFETY CHAIN

SMV EMBLEM

CLEVIS END TO

TRACTOR

Intermediate support is to be used if there is

more than 6" of unsupported chain on either

side of the primary attaching point.

NYLON TIE WRAP

CI-77643

The bracket provided is designed to mount to

numerous frame sizes and can be orientated

in different positions to avoid interference with

implement components.

The SMV emblem is to be secured as near to

the rear and centered, or as near to the left of

center of implement as practical.

Emblem is to be 2 to 6 feet above the ground

measured from the lower edge of the emblem.

Keep safety decals clean. Replace any safety

decals that are damaged, destroyed, missing, painted over or can no longer be read.

Replacement safety decals are available

through your dealer.

The intermediate support should not be

mounted more than 6" from the primary attaching point. (See figure below)

The intermediate support is available from

your Wil-Rich dealer.

6" MAX

INTERMEDIATE

SUPPORT

PRIMARY ATTACHING POINT

CI-77825

The purpose of the safety chain is to provide

an auxiliary attaching system to retain the connection between towing and towed machine

in the event of separation of the primary attaching system.

QX2 ASSEMBLY MANUAL 74304 1/11

6

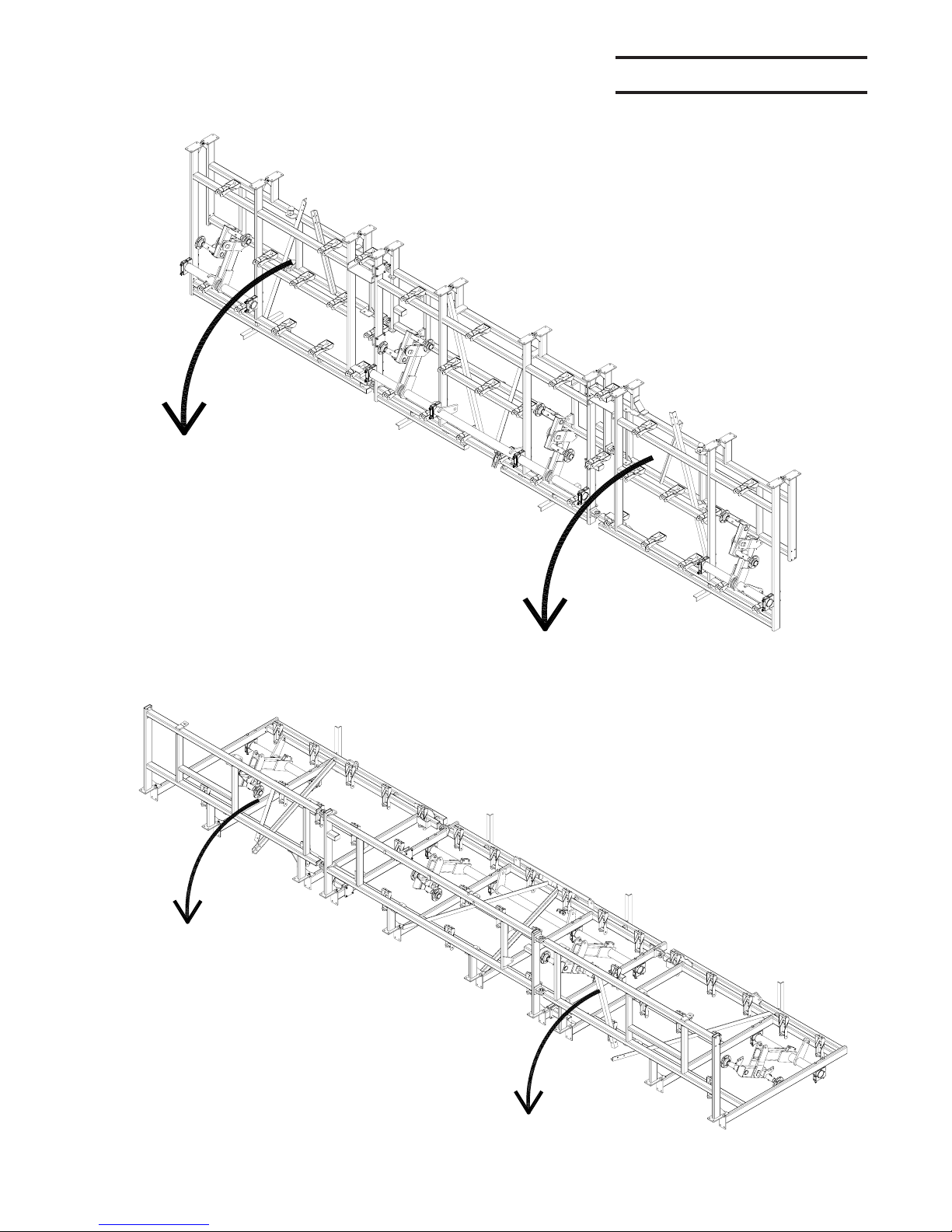

OPENING BUNDLE

Step #1

Lay bundle down, supporting frame securely

36 to 40 inches off the ground.

Step #2

Unfold front frame and bolt into place using

3/4x2 inch grade 8 bolts as shown on main

frame and wing assembly pages.

7

QX2 ASSEMBLY MANUAL 74304 1/11

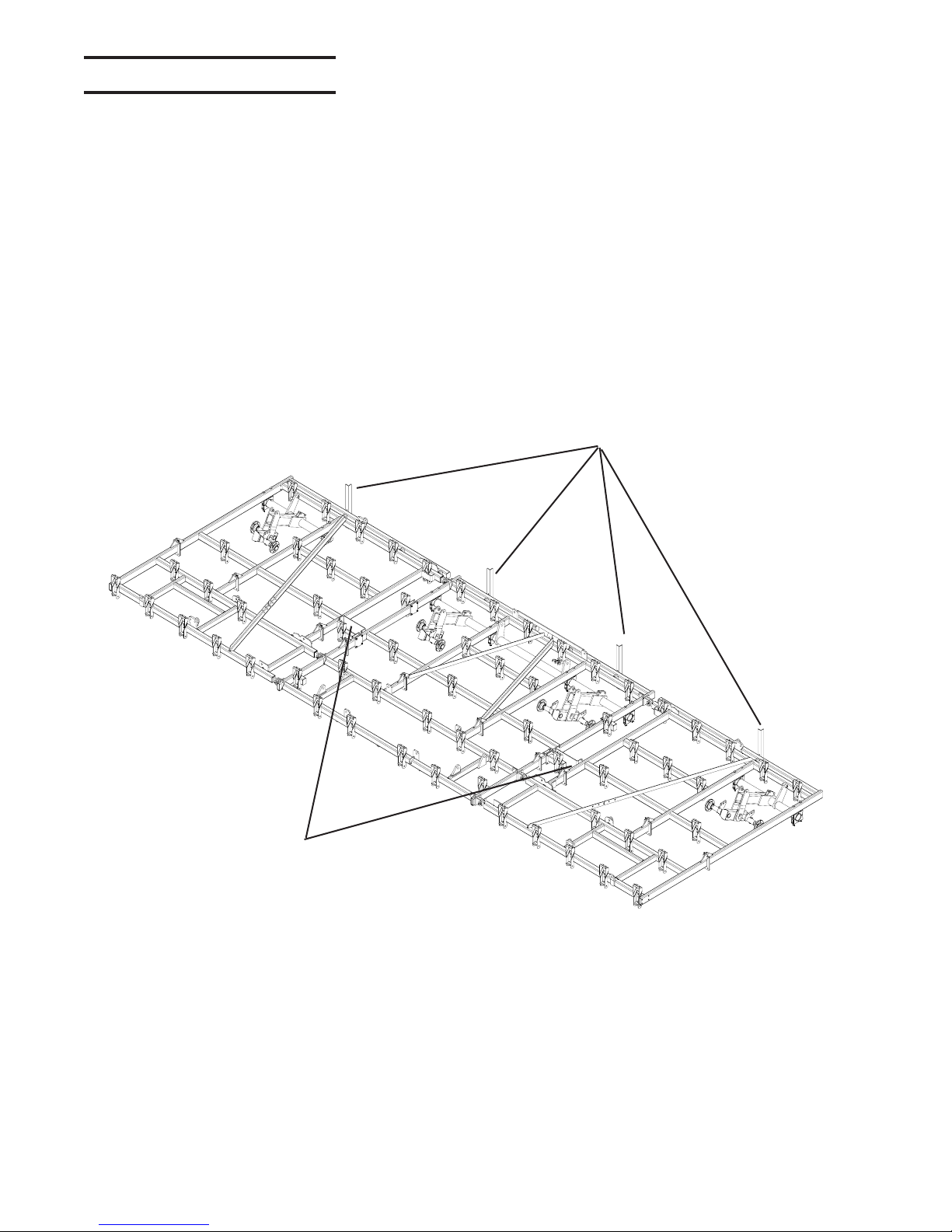

OPENING BUNDLE

Step #3

After bundle is unfolded and the two frame

halves are bolted together remove shipping

stands and brackets.

After the shipping stands and brackets are

removed the rest of the cultivator may be assembled as shown in this book.

Remove

shipping stands

Remove

shipping brackets

QX2 ASSEMBLY MANUAL 74304 1/11

8

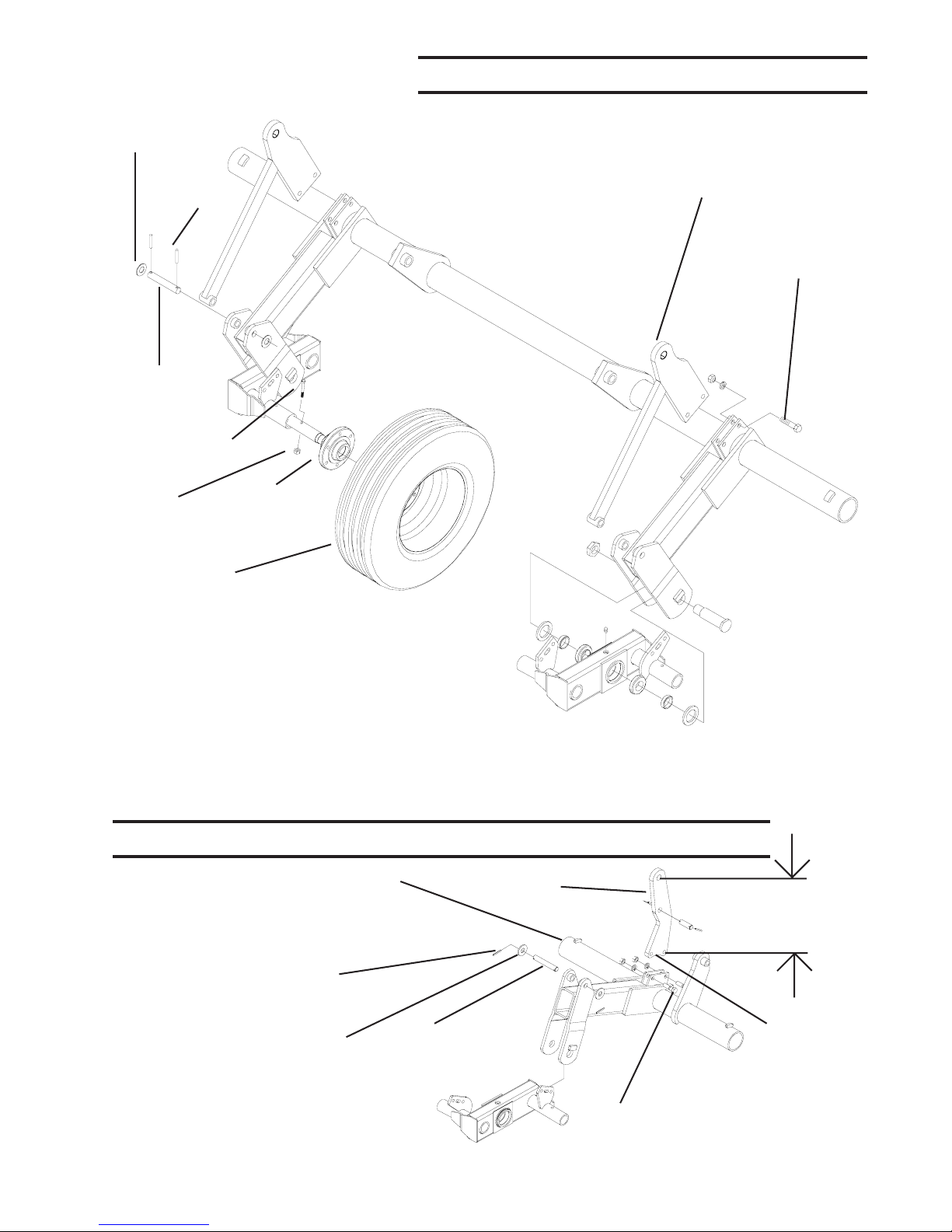

1” FLAT

WASHER

(88196)

ROLL PIN

1/4x2-1/4

(42484)

PIN 1x6-3/8

(68033)

1/2NFx3-1/4 GR5

BOLT

(88429)

LK NUT 1/2NF

(88304)

MAIN AXLE & WALKING TANDEM

AXLE ANCHOR

(220769)

3/4NCx2-3/4 GR5

BOLT

(88841)

2” HUB &

SPINDLE

(14131)

WHEEL ASSY

NOTE: WING WALKING

TANDEM COMPONENTS

ARE THE SAME AS THE

MAIN AXLE WALKING TANDEM.

AXLE & WALKING TANDEM 7’, 9’4” & 11’8” WING

WING AXLE ASSY

LH - (220782)

RH - (220781)

ROLL PIN

1/4x2-1/4

(42484)

1” FLAT

WASHER

(88196)

PIN 1x6-3/8

(68033)

10.8 MAST ANCHOR

(221261)

10.8 WING

MAST ANCHOR

(221261)

79144.PLT

19-7/8

3/4NCx2-3/4 GR5

BOLT - (88841)

9

QX2 ASSEMBLY MANUAL 74304 1/11

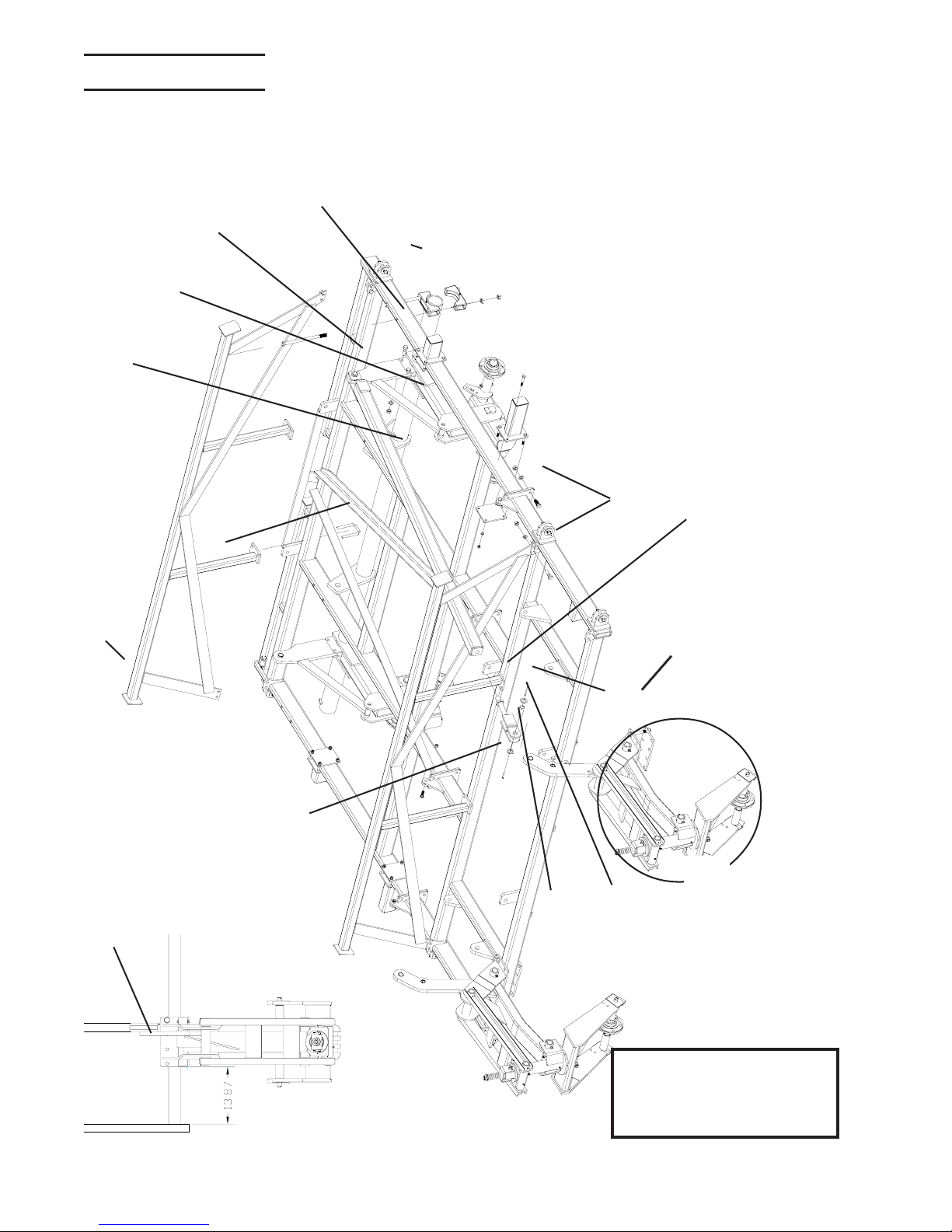

MAIN FRAME

NOTE - ORIENTATION

QUADX AXLE ANCHOR

(220769)

QUADX MAIN MAST TUBE

(221461)

3/4NC X 2-3/4

GR5 BOLT

(88841)

3/4NCx2

GR8 BOLT

(88290)

1-1/4NC JAM NUT

(88622)

WING REST (240818)

MUST BE MOUNTED

BEFORE MAST TUBE

NOTE: OFFSET ANCHOR

ON ARM, RIGHT SHOWN,

LEFT IS OPPOSITE

5/8NCx3x5-1/4

U-BOLT

(88503)

1/4x2-1/4

SPIRAL PIN

(42484)

CLEVIS

ADJUST

ROD

3/4NCx6 GR5

(88293)

1-1/4 FLAT

WASHER

(88440)

TUBE PIN

1-1/4 X 3-3/8

(54800)

(68034)

SEE PAGE 20 FOR

ASSY HDWR

COMPONENT LIST

GAUGE WHEEL

LOCATION

QX2 ASSEMBLY MANUAL 74304 1/11

74304-1

10

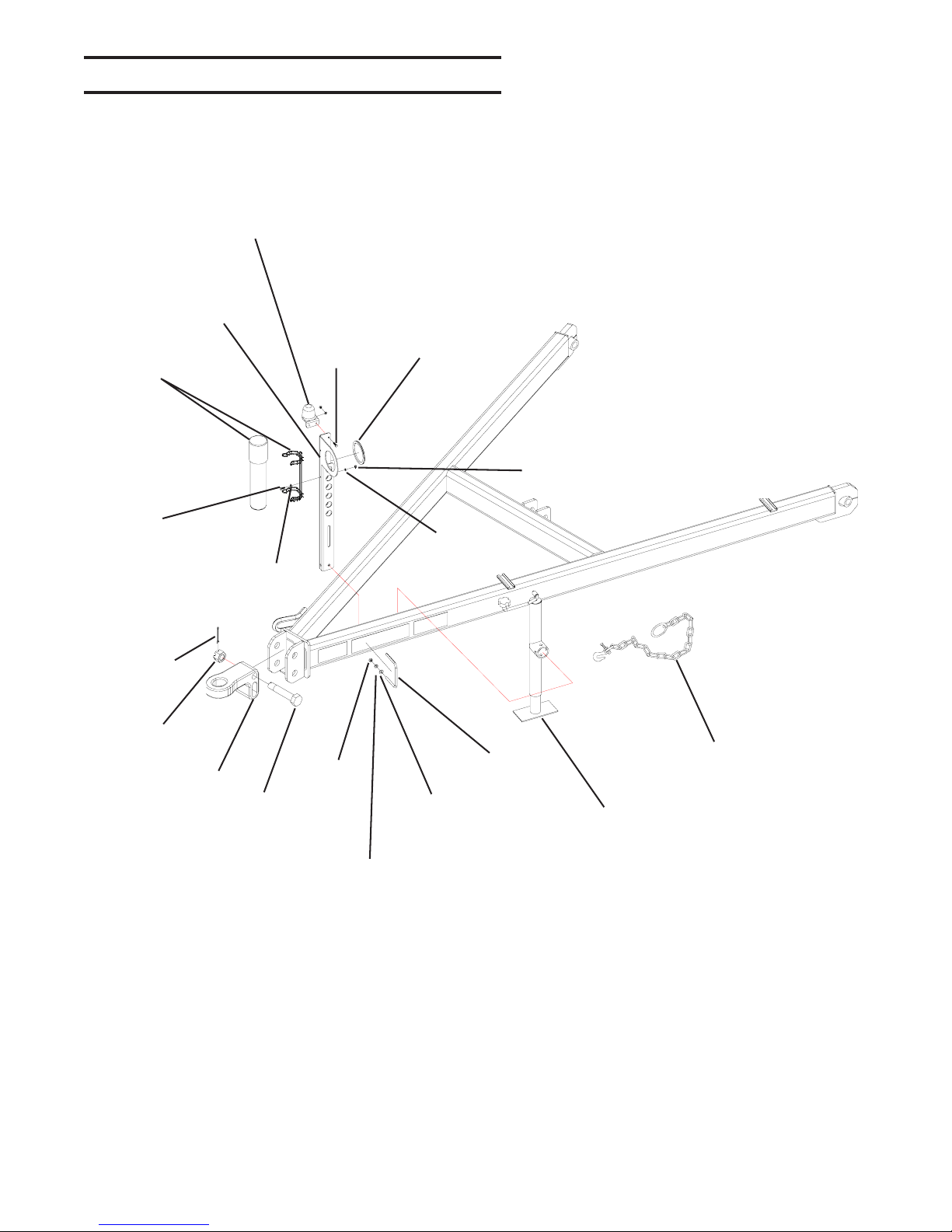

HITCH ASSEMBLY

ASSY HDWR

74304-2

LEFT HITCH TUBE

(220796)

3/4NCx6 GR5

BOLT

(88293)

4 HOLE PLATE

(3-3/4x4-11/16)

DIAMOND

5/8NCx2 GR5

(68040)

1-1/4NC JAM

NUT

BOLT

(88622)

1-1/4NCx6-1/2 GR5

BOLT

NOTE: ASSEMBLE ALL

RIGHT, LEFT AND CENTER HITCH TUBE BEFORE TIGHTENING

(88294)

(88349)

RIGHT HITCH TUBE

(220795)

HITCH TUBE-

(220792)

HITCH

(221445)

3/8 LOCK

3/8 FLAT

WASHER

(88362)

WASHER

( 88282)

RUBBER

3/8 HEX NUT

EDGING

(236092)

(88103)

3/8x6x4-3/4

U-BOLT

(89069)

SAFETY CHAIN

(24459)

JACK

(24415)

HITCH BOLT

(11638)

1-1/4NC

SLOTTED

NUT

DUAL HITCH

(18236)

(88350)

79149-3-2006

LIGHT PLUG

RETAINER

1/4NCx1 GR5

(223329)

TUBE HOLDER

BOLT

(88203)

11

(234313)

1/4NCx3/4 GR5

BOLT

(88993)

TUBE-OPERATORS

MANUAL

(234313)

QX2 ASSEMBLY MANUAL 74304 1/11

3/16x2 COTTER

PIN

UTILITY POLE

(236142)

(88133)

HITCH ASSEMBLY CONTINUED

LIGHT PLUG

RETAINER

(223329)

UTILITY

POLE

(236142)

TUBE &

TUBE

HOLDER

(234313)

1/4NCx3/4

GR5 BOLT

(88993)

1/4NCx1 GR5

BOLT (88203)

1/4 FLAT

WSAHER

(88261)

RUBBER

EDGING

(236092)

1/4 LOCK

WASHER

(88262)

1/4 NC NUT

(88172)

3/16x2 COTTER

PIN (88133)

1-1/4 SLOTTED

NUT (88350)

DUAL HITCH

(18236)

HITCH BOLT

(11638)

3/8NC HEX

NUT

(88103)

3/8 LOCK

WASHER

(88362)

3/8NCx5x4 UBOLT (89069)

3/8 FLAT

WASHER

(88282)

700160

SAFETY CHAIN

(24459)

JACK

(24415)

QX2 ASSEMBLY MANUAL 74304 1/11

12

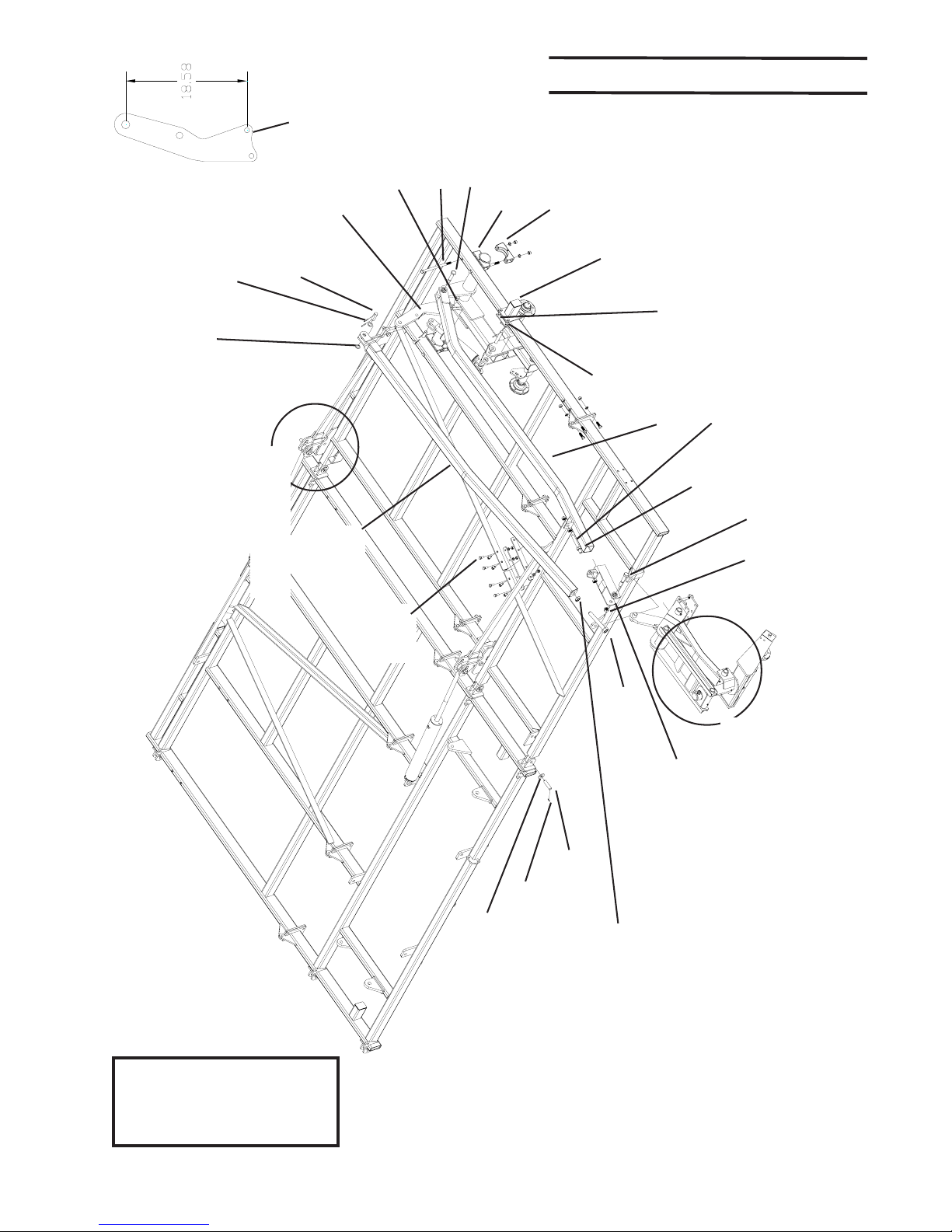

1/4X2-1/4

ROLL PIN

(42484)

MACHINERY BUSHING

(1-1/4x1.78x14 GA.)

(88440)

3/4NC X 2-3/4

GR5 BOLT

10.8 MAST ANCHOR

(221261)

PIN (1-1/4x2.88)

(68034)

(88841)

3/4NCx13 GR5 BOLT

1NCx6GR5 BOLT

(89165)

(88264)

AXLE CLAMP ASSY

7’, 9' 4”AND 11’8” WING

11’8” LEFT WING

(SHOWN)

(34132)

AXLE CLAMP ASSY

(34132)

6-1/2” SHANK STUB

(68021)

BOLT PLATE

(65688)

1/2NCx3-1/2

GR5 BOLT

(88507)

WING TUBE

1NCX8

(221504)

1NC NUT(3)

(88125

ADJUSTMENT

ROD

(48890)

3” ANGLE IRON

TO ANGLE IRON

1NCx6

GR5 BOLT

(88264)

WING

ADJUST

ARM

SEE PAGE 17 FOR

COMPONENT LIST

(67709)

5/8NCx1-1/2

GR5 BOLT

(88577)

1 FLAT

WASHER

(88196)

ADJUSTER ROD

1X3-7/8 PIN

(221714)

1-1/4NC

JAM NUT

79143-3-2006.DWG

(9.5)

(69799)

GAUGE TUBE

(88622)

TIGHTEN JAM

1NC NYLON

LOCK NUT

(89075)

SEE PAGE 20 FOR

ADJUST BRACKET

NUT TO BACK

COMPONENT LIST

(220843)

OF ADJUST

EAR

5-1/2” TUBE

TO PLATE

ALIGN GAUGE WHEEL AN-

CHOR WITH WING ADJUST

TUBE & WING AXLE ANCHOR

ASSY HDWR

74304-3

13

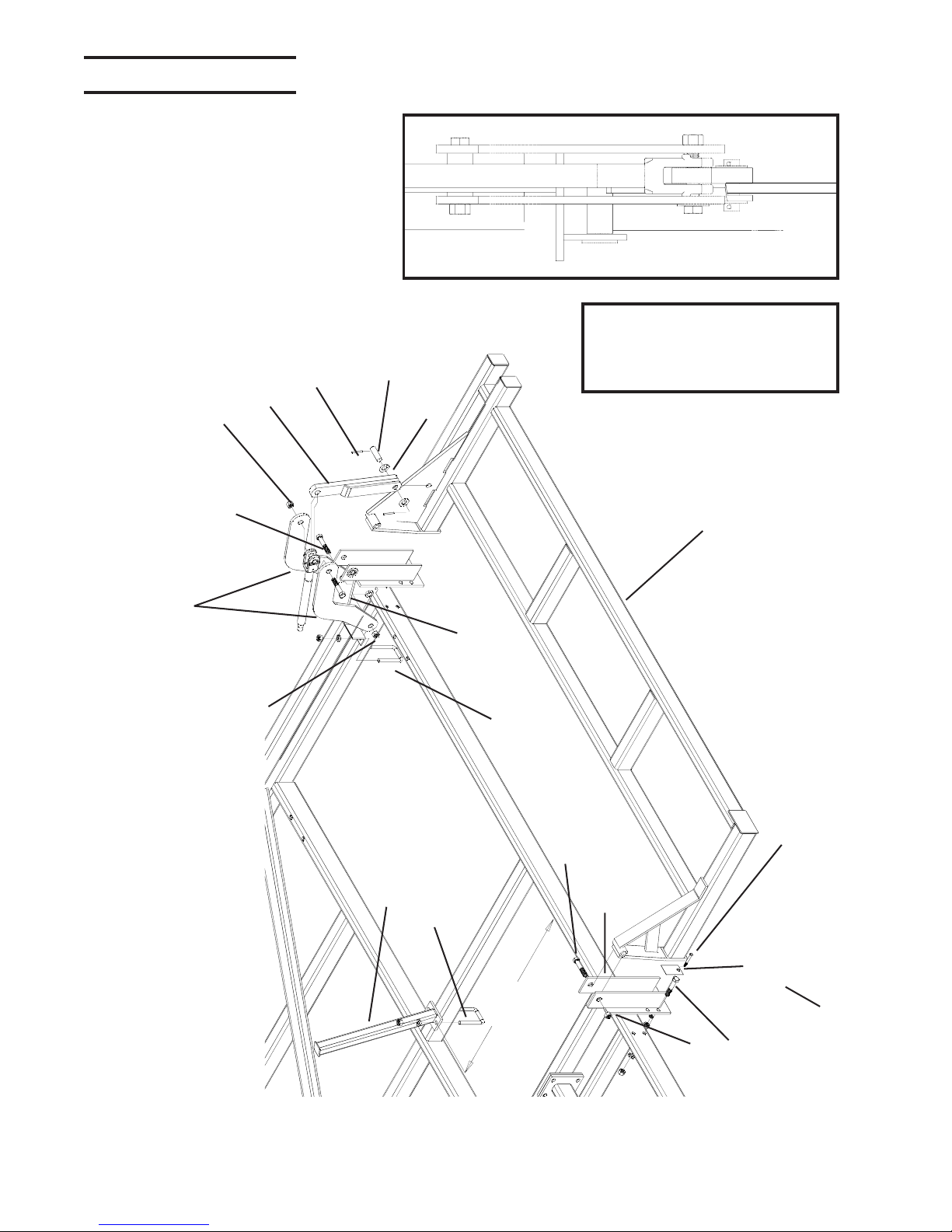

1/4X2-1/4 ROLL PIN

(42484)

QX2 ASSEMBLY MANUAL 74304 1/11

3' OUTER WING

HINGE AREA

TOP VIEW

ASSY HDWR

PIN (1x3-1/4)

SPIROL PIN

(42844)

LINKAGE ARM

(67903)

1NC LOCK NUT

NOTE: DO NOT OVERTIGHTEN WING

FOLD LINKAGE BOLTS. LINKS NEED

TO ROTATE FREELY.

PLATE

(67934)

(89075)

1NCx5 GR5 BOLT

(88312)

1NC LOCK NUT

(89075)

(42472)

1 FLAT WASHER

(88196)

1NCx5 GR5 BOLT

(88312)

5/8NCx3x5-1/4 U-BOLT

(88503)

79146

74302-4

(67924)

(67925)

3FT OUTER WING - RIGHT

3FT OUTER WING - LEFT

NOTE: POSITION WING REST TO CONTACT

OUTER TUBE WHEN FOLDED.

QX2 ASSEMBLY MANUAL 74304 1/11

EXC OUTER WING REST

(68066)

5/8NCx3x5-1/4 U-BOLT

(88503)

37-3/16”

14

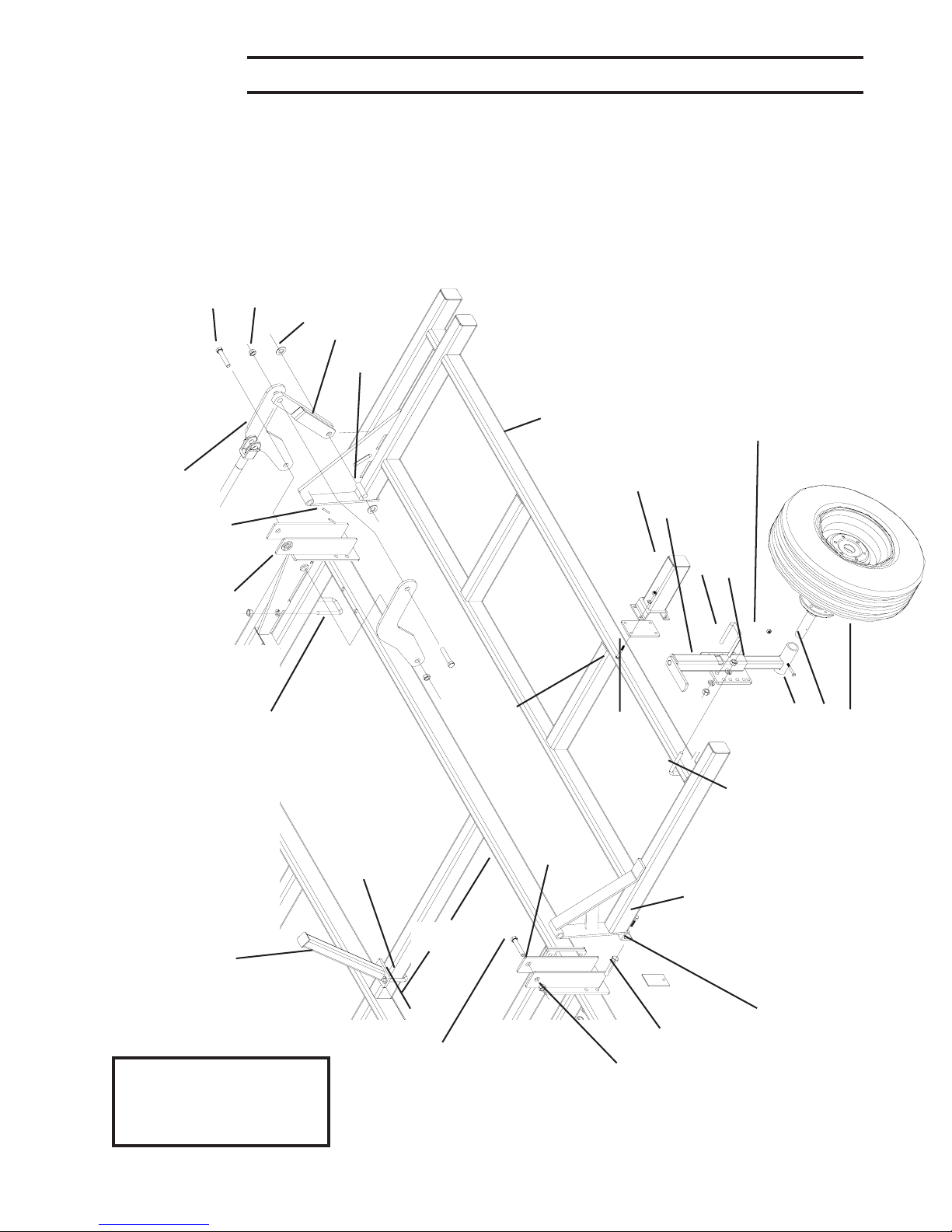

1NCx6 GR5 BOLT

(/88264)

EXC WING HINGE

RH- (68023)

LH- (68024)

1/2NCx1-1/2 GR5

SHIM

(51469)

5/8NCx3-1/2

GR5 BOLT

(88292)

1NC LOCK NUT

(89075)

BOLT

(88475)

STACK SHIMS AS REQUIRED

TO CONTROL WING LEVEL

5’ FLOATING OUTER WING W/GAUGE WHEEL

1NCx5 GR5 BOLT

(88312)

1NC LOCK NUT

(89075)

1 FLAT WASHER (88196)

LINKAGE ARM (67903)

PIN (1x3-1/4) (42473)

NOTE: DO NOT OVERTIGHTEN

WING FOLD LINKAGE BOLTS.

LINKS NEED TO ROTATE FREELY.

PLATE

(67934)

700405

5FT OUTER WING

(241884-RH)

(241885-LH)

12" SADDLE STUB (49025)

TOP ADJUST ASSY (15485)

1/2NC LOCK NUT

(88304)

1/4x2-1/2

ROLL PIN

(42484)

WING HINGE

(68024-LH)

(68023-RH)

5/8NCx3x5-1/4

U-BOLT

(88503)

5/8NCx3x5-1/4 U-

NOTE: POSITION WING REST TO CONTACT

OUTER TUBE WHEN FOLDED.

BOLT (88503)

1/2NCx1-1/2 GR5

BOLT (88475)

44-1/16”

BACKING

PL ATE

WING HINGE

(67932)

(26817)

5/8NCx2-1/2x3-3/4 U-BOLT (88311)

GAUGE WHEEL LEG (15475)

(88388)

5/8NCx4x3-1/4 U-BOLT

1/2NFx3 GR5 BOLT (88313)

1-3/4" HUB & SPINDLE (41233)

1/2NCx1-1/2 GR5

BOLT (88475)

95Lx15 WHEEL ASSY (16290)

OUTER WING REST

(68066)

ASSY HDWR

74302-5

1NCx6 GR5

BOLT (88264)

15

5/8NCx3-1/2

GR5 BOLT

(88292)

WING FOLD STOP (222156)

HOLDS OUTER WING APPROX

1NC LOCK

NUT (89075)

QX2 ASSEMBLY MANUAL 74304 1/11

LEVEL WITH MAIN FRAME,

REMOVE IF OUTER WING

DOWN - FLOAT IS REQUIRED

Loading...

Loading...