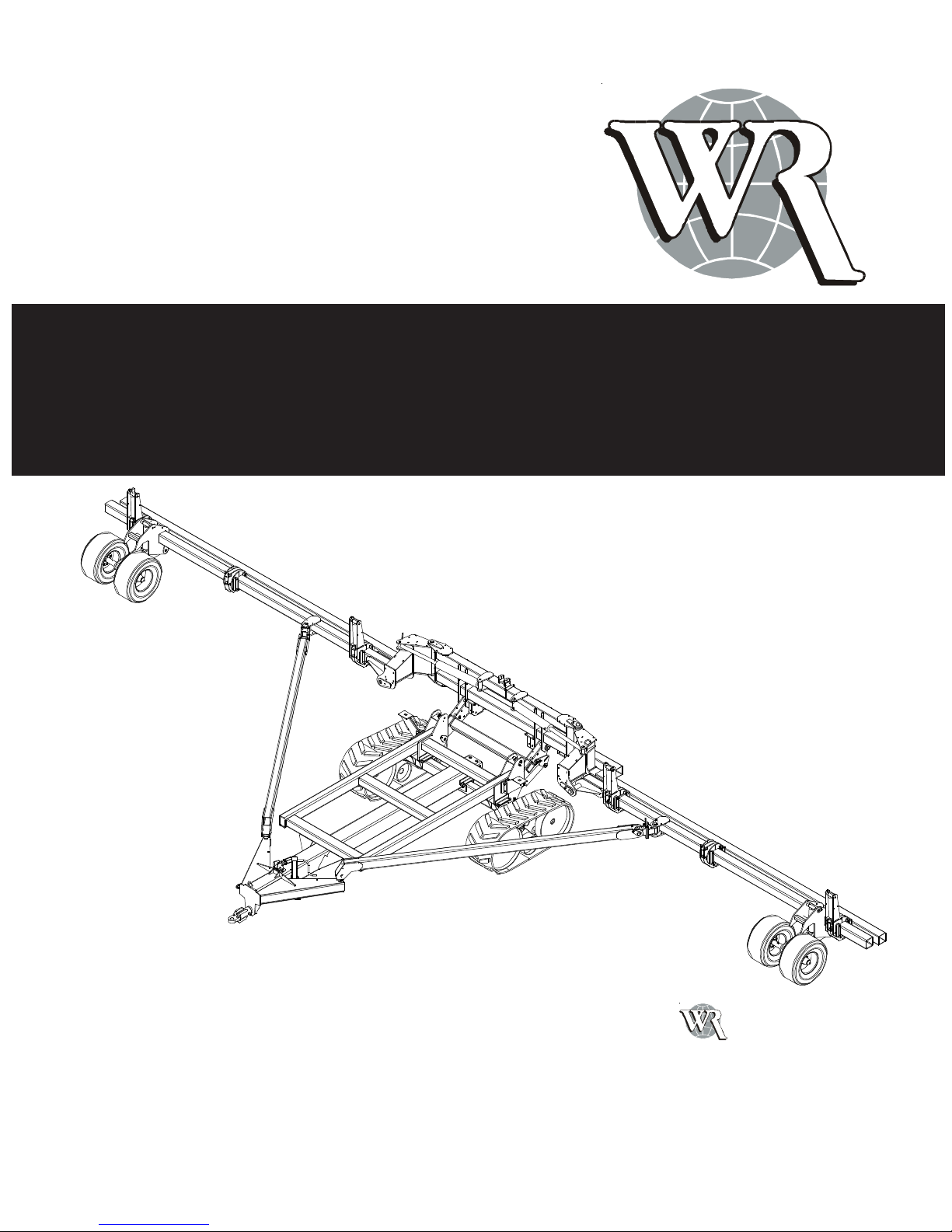

WIL-RICH 10K Assembly & Operators Manual

ASSEMBLY/OPERAT OR’S

1

MANUAL

10K FOLDING TOOLBAR

STRIP TILL

Printed in USA (74283) 8/18

WIL-RICH

PO Box 1030

Wahpeton, ND 58074

PH (701) 642-2621

Fax (701) 642-3372

www .wil-rich.com

AGCO-Amity JV LLC LIMITED WARRANTY TERMS AND CONDITIONS – UNITED STATES AND CANADA

2

EFFECTIVE FOR EQUIPMENT RETAILED AND DELIVERED AFTER JANUARY 1, 2018

WHAT IS WARRANTED AGCO Amity JV warrants its new equipment to be free of defects in material and workmanship at time of delivery to the first retail

purchaser, renter, or lessee. These terms apply to all Wishek, Wil-Rich, and Amity brands of new equipment originally marke ted in the United States and

Canada.

WARRANTY PERIOD

• 12 Months from the date of delivery to the first retail purchaser, renter or lessee.

• Field Cultivator and Disk Cultivators: 3 years on main frames, wing frames, and shank assemblies

• Precision Shank Drill: 3 years on main frame, wing frame, and rockshafts.

EXCEPTIONS FROM THIS WARRANTY

• Freight Charges - This warranty does not cover freight charges.

• Improvements, Changes, or Discontinuance AGCO Am ity JV reserve s the right to make changes and improvements in design or changes in

specifications at any time to any product without incurring any obligations to owners of products previou sly sold.

• Repairs and Maintenance Not Covered Under Warranty - This warranty does not cover conditions resulting from misuse, natural calamities,

use of non-AGCO-Amity JV parts, negligence, alteration, accident, use of unapproved attachments, usage which is contrary to the intended

purposes, or conditions caused by failure to perform required maintenance. Replacement of Wear or Maintenance items (unless defective) such

as but not limited to, filters, hoses, belts, lubricants, light bulbs, wheel alignment, tightening of nuts, belts, bolts, and fittings, service tune-up,

computer parameter adjustments and general adjustments which may from time to time be required are not covered.

• Rubber Tire Warranty - Rubber tires are warranted directly by the respectiv e manufacturer only and not by AGCO Amity JV.

• Satellite Outages - Interruptions in satellite interfaces and satellite communications are outside the control of this product and are not covered by

this warranty. The company is not responsible for issues or degradation of system performance resulting from such interruptions in satellite

interfaces and satellite communications where the issues are not related to defect s in this product.

OWNER’S OBLIGATION

It is the responsibility of the Owner to transport the equipment or parts to the service shop of an authorized AGCO Amity JV Dealer or alternatively to

reimburse the Dealer for any travel or transportation expense involved in fulfilling this warranty. This Warranty does NOT cover rental of replacement

equipment during the repair period, damage to products which have been declared a total loss and subsequently salvaged, overtime labor charges, freight

charges for replacement parts, or special handling requirements (such as, but not limited to, the use of cranes).

EXCLUSIVE EFFECT OF WARRANTY AND LIMITATION OF LIABILITY

THIS WARRANTY IS IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PURPOSE OR OTHER REPRESENTATIONS, WARRANTIES

OR CONDITIONS, EXPRESSED OR IMPLIED. The remedies of the Owner set forth herein are exclusive. The Company neither assumes nor authorizes any

person to assume for it any other obligation or liability in connection with the sale of covered machines. Correction of defects, in the manner and for applicable

period of time provided above, shall constitute fulfillment of all responsibilities of AGCO Amity JV to the Owner, and AGCO Amity JV shall not be liable for

negligence under contract or in any manner with respect to such machines. IN NO EVENT SHALL THE OWNER BE ENTITLED TO RECOVER FOR INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES SUCH AS BUT NOT LIMITED TO, LOSS OF CROPS, LOSS OF PROFITS OR REVENUE, OTHER COMMERCIAL

LOSSES, INCONVENIENCE OR COST OF RENTAL OR REPLACEMENT EQUIPMENT.

Some States or Provinces do not permit limitations or exclusions of implied warranties or incidental or consequential damages, so the limitations or exclusions in this warranty may

not apply.

“AGCO Amity JV” AS REFERRED TO HEREIN WITH RESPECT TO SALES IN: UNITED STATES and CANADA: AGCO Amity JV LLC

PO Box 1030

Wahpeton, ND 58074

Additional Warranty Information

New Equipment Warranty - Equipment is eligible for warranty service only if it qualifies under the provisions of the New Equipment Warranty. The selling

dealer will deliver this Warranty to the original retail purchaser at the time of sale, and the dealer will register the sale and Warranty with AGCO Amity JV

LLC.

Subsequent Owners - This Warranty covers the first retail purchaser and all subsequent owners of the equipment during the specified warranty period.

Should the AGCO Amity JV Dealer sell this equipment to a subsequent owner, the Dealer must deliver the warranty document to the subsequent owner so the

subsequent owner can register ownership with AGCO Amity JV and obtain the remaining warranty benefits, if available, with no intermission in the Warranty

Period. Subsequent Owner Procedure will apply. It is the responsibility of the subsequent owner to transport the equipment to the service shop of an

authorized AGCO Amity JV Dealer or alternatively to reimburse the Dealer for any travel or transportation expense involved in fulfilling this warranty. This

Warranty does NOT cover charges for rental or replacement equipment during the repair period, products which have been declared a total loss and

subsequently salvaged, overtime labor charges, freight charges for replacement parts, or units sold at auction.

Warranty Service - To be covered by Warranty, service must be performed by an authorized AGCO Amity JV Dealer. It is recommended that you obtain

warranty service from the Dealer who sold you the equipment because of that Dealer’s continued interest in you as a valued customer. In the event this is

not possible, warranty service may be performed by any other authorized AGCO Amity JV Dealers in the United States or Canada. It is the responsibility

of the Owner to transport the equipment to the service shop of an authorized AGCO Amity JV Dealer or alternatively to reimburse the Dealer for any travel or

transportation expense involved in fulfilling this warranty.

Maintenance Service - The Owner’s Manual furnished to you with the equipment at the time of delivery contains important maintenance and service

information. You must read the manual carefully and follow all the maintenance and serv ice recommendations. Doing so will result in greater satisfaction with

your equipment and help avoid service and warranty problems. Please remember that failures due to improper maintenance of your equipment are not covered

by warranty.

Maintenance Inspections - To insure the continued best performance from your agricultural equipment, we recommend that you arrange to make your

equipment available to your selling Dealer for a maintenance inspection 30 days prior to warranty expiration.

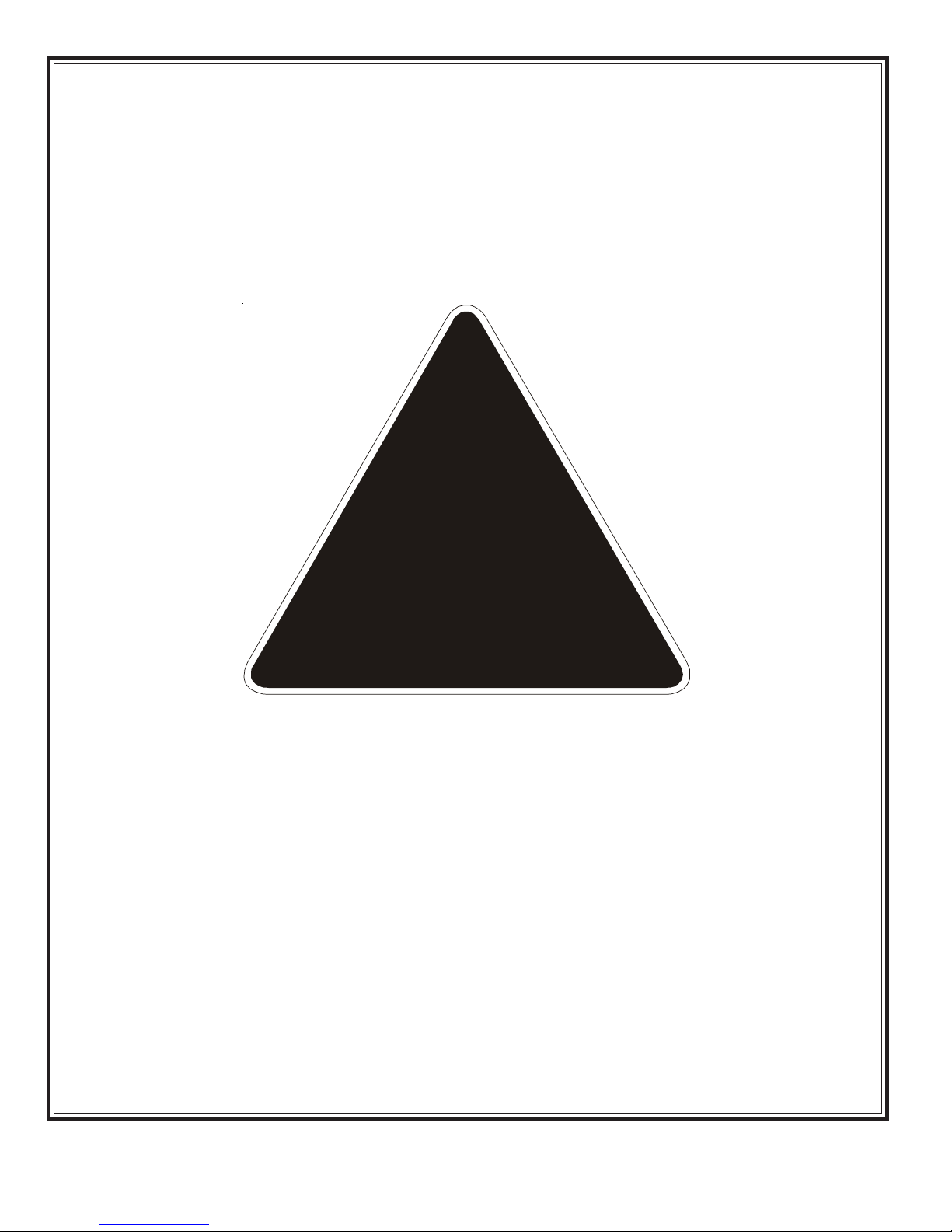

PERSONAL SAFETY IS IMPORT ANT!

!

3

ALL PERSONNEL INVOLVED WITH THE ASSEMBLY AND/OR OPERATION OF THIS

EQUIPMENT MUST BE INFORMED OF PROPER SAFETY PROCEDURES. OPERA TOR’S/

ASSEMBL Y MANUALS PROVIDE THE NECESSAR Y INFORMA TION. IF THE MANUAL IS

LOST FOR A PARTICULAR IMPLEMENT, ORDER A REPLACEMENT AT ONCE.

OPERATOR’S AND ASSEMBLY MANUALS ARE AV AILABLE A T NO CHARGE UPON REQUEST .

The Safety Alert symbol iden-

This Safety Alert symbol

means ATTENTION! BE-

COME ALERT YOUR

SAFETY IS INVOLVED!

tifies important safety messages on the Wil-Rich Folding

T oolbar and in this manual.

When you see this symbol, be

alert to the possibility of personal injury or death. Follow

the instructions in the safety

message.

3 Big Reasons

SIGNAL WORDS:

Note the use of the signal

words

and CAUTION with the safety

messages. The appropriate

signal word for each message

has been selected using the

following guidelines:

DANGER, WARNING

Why is SAFETY important to you?

Accidents Disable and Kill

Accidents Cost

Accidents Can Be A voided

DANGER

An immediate and specific hazard which WILL

result in severe personal

injury or death if the

proper precautions are

not taken.

ADDRESS INQUIRIES TO: AGCO AMITY JV LLC

2800 7th Avenue North

Fargo, ND 58102

PH (701) 232-4199 FAX (701) 234-17166

WARNING

A specific hazard or unsafe practice which

COULD result in severe

personal injury or death

if the proper precautions

are not t

aken

CAUTION

Unsafe practices which

COULD result in personal injury if proper

practices are not taken,

or as a reminder of good

safety practices.

Table of contents

4

Large Frame Folding Toolbar

1 Safety .....................................................................7

1.1 Introduction..........................................................8

1.1.1 Safety alert symbol .................................................8

1.1.2 Safety messages ...................................................8

1.1.3 Informational messages..............................................8

1.1.4 Safety signs. ......................................................8

1.1.5 A word to the operator. ...............................................9

1.1.6 This manual. ...................................................... 10

1.2 Operation . ......................................................... 11

1.2.1 Prepare for operation ........ ............. ............ .............11

1.2.2 General information. ................................................11

1.2.3 Personal protective equipment. .......................................12

1.2.4 Seat instructions .................................................12

1.2.5 Shield and guards ......................... ........................13

1.2.6 Exhaust warning . ................................................13

1.2.7 Flying debris . ............ ............. ............ ............ .14

1.2.8 Agricultural chemicals ... ............ ............. ............ ....14

1.3 Travel on public roads ... ............ ............. ............ ......15

1.4 Maintenance .. ........ ............. ............ ............. .......17

1.4.1 General maintenance information .......... ............ ............. .17

1.4.2 Fire prevention and first aid .. ............. ............ ............ .18

1.4.3 High pressure leaks . ............ ............. ............ ........ 19

1.4.4 Tire safety ............ ............. ............ ............. ... 20

1.4.5 Replacement parts ........ ............ ............. ............ .. 20

1.5 Transport locks ..... ............ ............. ............ ..........21

1.6 Marker lamps .......... ............ ............. ............ ...... 22

1.7 Safety sign location ........... ............ ............. .........23-24

Safety Decals ........ ............ ............. ............ ... 25-30

2 Introduction .............................................................. 31

2.1 Introduction ............. ........................................... 31

2.1.1 Units of measurement .............................................33

2.1.2 Replacement parts ................................................33

2.1.3 Intended use ....................................................33

2.1.4 Proper disposal of waste ........................................... 33

2.2 Machine identification ... ........................................... 34

2.2.1 Serial number plate location ......................................... 34

2.2.2 Serial number description ...........................................34

2.3 Major components ....... ............. .............................36

2.4 Operator manual storage ...........................................37

3 Operation ................... .............. ................................38

3.1 Connecting the machine to the tractor . ..... ............. ........... 39

3.2 Disconnecting the machine from the tractor ... ............ ...........40

3.3 Track operation....................................................41

3.3.1 New track break-in......................................... .........41

3.3.2 Track operation ...................................................41

3.4 Bleeding air from the hydraulic lift system ........................... 42

3.5 Bleeding air from the hydraulic fold system ..........................43

3.6 Bolt torque chart ....................................................44

Table of contents

5

3.7 Preparing the machine for operation ........... ............ ............. 45

3.8 Fold the machine . ............ ............ ..........................46- 47

3.9 Unfold the machine .. ... ........ ... .... ........ .....................48

3.9.1 Road the machine .. .... ....... ... ..... ....... . ............... .....49

3.9.1.1 Prepare to road the machine . ............ ............. ............ ...49

3.9.1.2 Safety precautions .... ....... .. . ... .. ... ... ...................49

3.9.1.3 Safety precautions ...... .............................................49

3.

9.1.4 Lamp operation ......

................................

...............

50

3.9.2 Beginning field operation ... ............ ................................51

3.9.2.1 Operate in the field ....... ............. ................................51

3.9.3 Center section adjustment - Leveling ....................................52

3.9.4 Adjusting the wing to run parallel ............................... ...... 53

3.9.5 Track system ..........................................................54

3.9.5.1 Track tension .......................................................54

3.9.5.2 Align the track .......................................... ............54

4 Maintenance ..............................................................55

4.1 Service schedule .... ............ ............. ............ ............. ..56

4.2 Checklists ..... ............. ............ ............. ............ ....... 57

4.2.1 Beginning of the day ....... ............ ............. ............ .......57

4.2.2 End of the day ......... ............. ............ ............. ........ 57

4.2.3 Beginning of the season . ............ ............. ............ .......... 57

4.2.4 Storage ........... ............ ............. ............ ............ 57

4.3 Track system maintenance ............. ............ ............. ........ 58

4.4 Lubrication points .. ............. ............ ............. ............ .. 59

4.4.1 Sealed bearings ...... ............. ............ ............. .......... 59

4.4.2 Frame lubrication points ...... ..... ..... ........ ......... ... .... .....59-60

4.4.3 Cylinder lubrication points ......... ............. ............ ............. 61-62

4.4.4 Track lubrication points ..... ............. ............ ............. ......62-63

4.5 Wheel bearing assemblies ........ ............. ............ ............. . 64

4.6 Prime the hydraulic circuits ....... ............ ............. ............ .65-66

Table of contents

6

5 Assembly ... ............. ............

5.1 Assembly safety ..... .. ..... ... ...... ... . ..... ....... . . .. ...68

5.2 Before delivery ..... .. ..... ... ...... ... . ..... ....... . . .. ..... 69

5.3 New track break-in ..... .. ..... ... ...... ... . ..... ....... . . .. .....70

5.4 Assembly sequence ..... .. ..... . .. ...... ... . ..... ....... . . .71

5.5 Axle & tracks .... . ....... ... .... . .... . ..... ...... .. . .. .....72

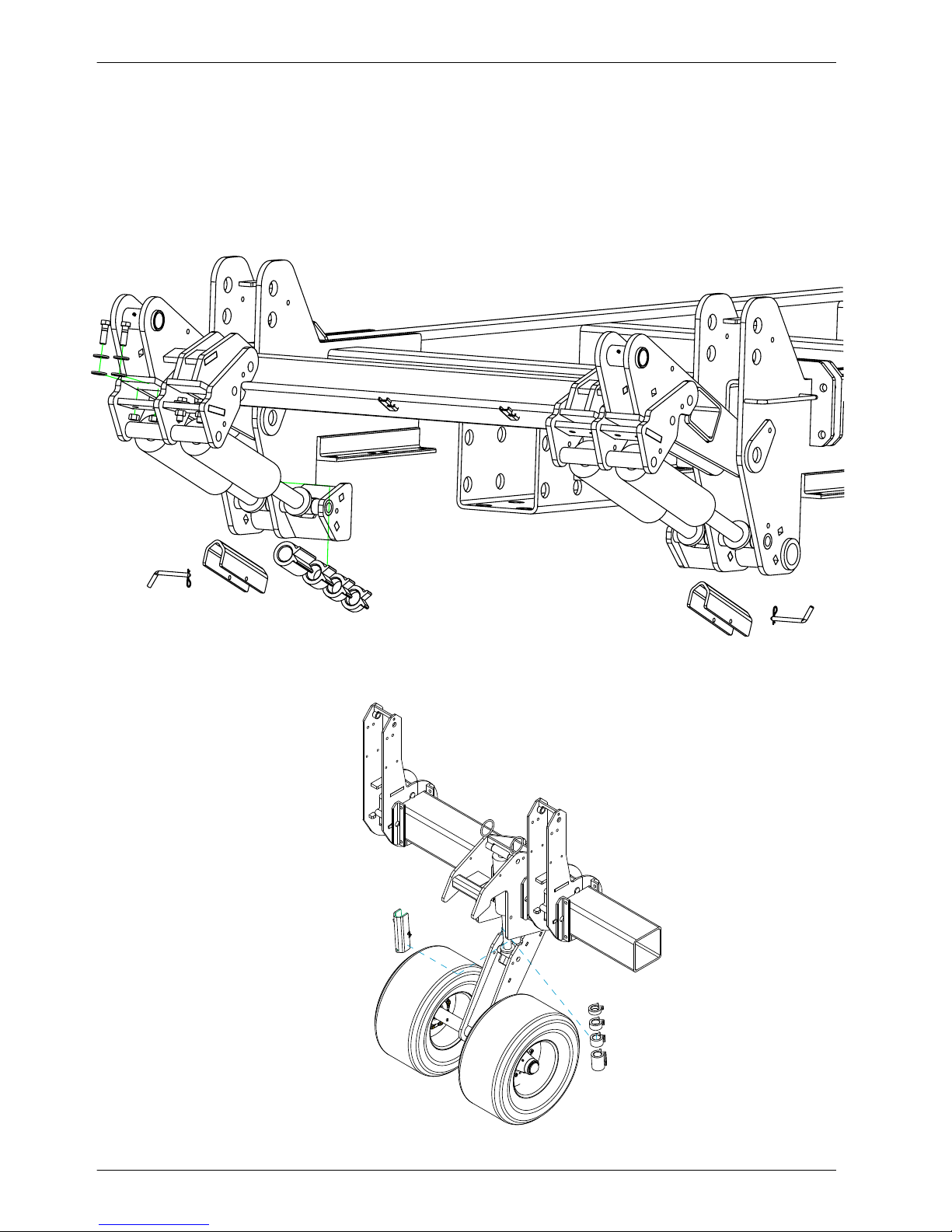

5.6 Axle & transport pad . .... ....... ... .. .. ..... . ..... ... ..... . .. ..... 73

5.7 Rubber track carriage system . .... ....... ... .. .. ..... . ..... ... 74

5.8 Telescoping tongue . .... ....... ... .. .. ..... . ..... ... ..... . .75

5.9 Hydraulic jack ... .. ....... . .. .... ..... . ..... ..... ... ... .....76

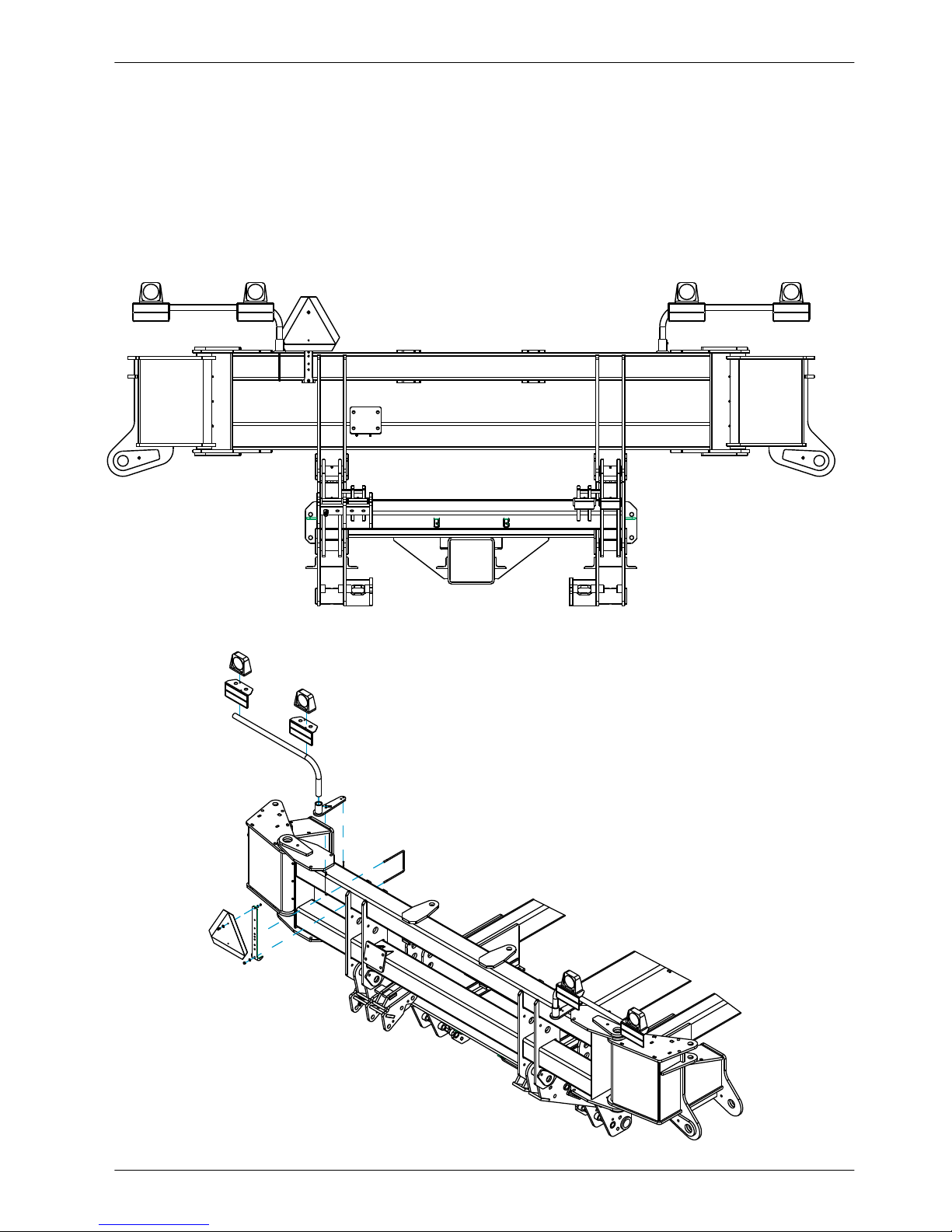

5.10 Center frame & main hinge ... .. .. .. ... ... ... ... .. . . . .... ..77

5.11 Brace arm hinge ... .. .. .. ... ... ... ... .. . . . .... .. ..... . . 78

5.12 Wing wheel ... .. .. .. ... ... ... ... .. . . . .... .. ..... . . .. .. 79

5.13 Bearing w/tilt cylinder 10sq .. .. . ....... ... . .... .... . ..... ...80

5.14 Secondary toolbar - center . .. .. ....... ... . . ....... . ..... ... 81

5.15 Secondary toolbar - wing . .. .. ....... ... . . ..... .. . . .... ... 82

5.16 Hydraulic hose brackets . .. .. ..... .. .. . . . ....... . ..... . .. 83

5.17 Three bank selector valve ..... ... .. .. . .. .. ....... . .. ... ...84

............. . ...... .......67

5.18 Hydraulics - center main lift .. ... ....... ... ... ...... . .. ... ...85

5.19 Hydraulic cylinder guards .. . .. ...... . ... . .. ...... . ..... ... 86

5.20 Hydraulics - tongue latch .. .. . ....... ... .. . ...... . .. ... ... 87

5.21 Hydraulics - center section ..... ...... . . .. . ... ..... . ..... .. .88

5.22 Hydraulics - LH wing 10sq ..... ...... . .. . ....... .. . ... .. ....89

5.23 Hydraulics - RH wing 10sq . ... . . ..... . ... ....... .. . . .. .. ..90

5.24 Hose clamp assembly . .... . ..... . ... ......... . . .. .. .. .....91

5.25 Electrical components . . ... ... . ... .. . . ... ... .. . ..... . . ..92

5.26 2600 gal poly tank & frame .. ... ....... ... .. . ... .. . . ..... . . 93

5.27 Rear hitch - light duty .. .. . ....... ... .. . ...... . . .... ... ....94

5.28 Rear hitch - heavy duty .. ... ....... ... ... ...... .. . ..... .. . .95

5.29 Rear hitch - center section connection ..... .. ..... ... . ........ 96

5.30 Rear hitch - tire assembly ..... ... .. . ....... .. . ... . . ...... .97

5.31 Rear hitch - hyd base plate . .. .. . ..... . ... ..... .... . . .. .. .98

5.32 Hydraulics LH side rear hitch . .... . . .... . ... ......... . . .. ..99

5.33 Hydraulics LH side rear hitch .... . ... ... . ... ....... .. . ... ..100

5.34 Toolbar bearing locations ... .. .. .... . ... ...... . .. . ... .. ..101

5.35 Check lists ... .. .. .... . ... ...... . .. . ... .. ....... . ... . ..102

Table of contents

7

6.1 Specifications ..........................................................103

6.1.1 Frame specifications ...............

6.1.2 Tire specifications ....................................................104

6.1.3 Track specifications ...................................................104

6.1.4 Machine dimensions ..................................................104

6.1.5 Hydraulic system specifications ..........................................105

6.1.6 Hydraulic flow requirements .............................................105

6.1.7 Approximate shipping weights .......................................... 105

6.1.8 Tractor requirements ................................................. 105

6.1.9 Maximum transport speed ............................................. 105

...................................104

1. Safety

1.1 Introduction . ...

1.1.1 Safety alert symbol ..... ............

1.1.2 Safety messages .. ............

1.1.3 Informational messages ..................................................8

1.1.4 Safety signs ...........................................................8

1.1.5 A word to the operator ..

1.1.6 This manual ........... .

............. ............ .............

............. ............ ..........

.............

............

..... .......

............. ............ ...........

............ ............. ...

..... ............ ............. ...

1.2 Operation ... ............. ............ ............. ............

1.2.1 Prepare for operation .........

1.2.2 General information ...

1.2.3 Personal protective equipment ...

1.2.4 Seat instructions ..... ............

1.2.5 Shield and guards . ............. ........... . ............ ..............13

1.2.6 Exhaust warning ..... .............

1.2.7 Flying debris .... .....................................................14

1.2.8 Agricultural chemicals .

............

............ ............. ............ ...........

1.3 Travel on public roads ...

1.4 Maintenance ...... .............

1.4.1 General maintenance information . ............. ............ ............. ..

1.4.2 Fire prevention and first aid ............. ............ ............. ....... 18

1.4.3 High pressure leaks ...... ............ ............. ............ ........19

1.4.4 Tire safety ......... ............ ............. ............ ........... .20

1.4.5 Replacement parts ........... ............. ............ ............. ... 20

1.5 Transport locks ..........

1.6 Marker lamps .... .............

1.7 Safety sign location .........

Safety decals . ........ ............. ............ ............. .......25-30

............. ............ ............. ...11

............. ............ ...........

............. ............ ............. ..

.............

............

............ .............

............ .............

............ ............. ............ .........21

............ ............. ............ ....22

............. ... ......

............ ........ 8

.........11

............ ...........12

............. ..........13

............ .........15

............ ..17

......... .... .....

8

8

9

10

11

12

14

17

23-24

1. Safety

8

1.1 Introduction

1.1.1 Safety alert symbol

The safety alert symbol means Attention! Become

Alert! Your Safety Is Involved!

Look for the safety alert symbol both in this

manual and on safety signs on this machine. The

safety alert symbol will direct your attention to

information that involves your safety and the

safety of others.

1.1.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety alert symbol. Learn to

recognize these safety alerts and follow the

recommended precautions and safety practices.

Fig. 1

DANGER:

Indicates an imminently hazardous

situation that, if not avoided, will

result in DEATH OR VERY SERIOUS

INJURY.

WARNING:

Indicates a potentially hazardous

situation that, if not avoided, could

result in DEATH OR SERIOUS

INJURY.

CAUTION:

Indicates a potentially hazardous

situation that, if not avoided, may

result in MINOR INJURY.

Fig. 2

1.1.3 Informational messages

The words important and note are not related to personal safety, but are used to give additional

information and tips for operating or servicing this equipment.

IMPORTANT: Identifies special instructions or procedures which, if not strictly observed, could result in

damage to or destruction of the machine, process, or its surroundings

NOTE: Identifies points of particular interest for more efficient and convenient repair or operation.

1.1.4 Safety signs

WARNING:

Do not remove or obscure safety signs. Replace any safety signs that are not readable or

are missing. Replacement signs are available from your dealer in the event of loss or

damage. The actual location of the safety signs is illustrated at the end of this section.

Keep signs clean by wiping off regularly. Use a mild soap and water solution if necessary.

1. Safety

9

If parts have been replaced or a used machine has been purchased, make sure all safety signs are present

and in the correct location and can be read. Illustrations of safety sign locations are located at the rear of

this section.

Replace any safety signs that can not be read, are damaged, or are missing. Clean the machine surface

thoroughly with a mild soap and water solution before replacing signs. Replacement safety signs are

available from your dealer.

1.1.5 A word to the operator

It is your responsibility to read and understand the

safety section in this manual and the manual for all

attachments before operating this machine.

Remember you are the key to safety. Good safety

practices not only protect you, but also the people

around you.

Study the content in this manual and make the

content a working part of your safety program.

Keep in mind that this safety section is written

only for this type of machine. Practice all other

usual and customary safe working precautions,

and above all remember - safety is your

responsibility. You can prevent serious injury or

death.

Fig. 3

This safety section is intended to point out some

of the basic safety situations that may be

encountered during the normal operation and

maintenance of your machine. This section also

suggests possible ways of dealing with these

situations. This section is not a replacement for

other safety practices featured in other sections of

this manual.

Personal injury or death may result if these

precautions are not followed.

Learn how to operate the machine and how to use

the controls properly.

Do not let anyone operate the machine without

instruction and training.

For your personal safety and the personal safety of

others, follow all safety precautions and

instructions found in the manuals and on safety

signs affixed to the machine and all attachments.

Use only approved attachments and equipment.

Make sure your machine has the correct

equipment needed by the local regulations.

WARNING:

An operator should not use alcohol or

drugs which can affect their alertness

or coordination. An operator on

prescription or 'over the counter'

drugs needs medical advice on

whether or not they can properly

operate machines.

1. Safety

10

CAUTION:

If any attachments used on this

equipment have a separate Operator

Manual, see that manual for other

important safety information.

1.1.6 This manual

This manual covers general safety practices for this machine. The operator manual must always be kept

with the machine.

Right-hand and left-hand, as used in this manual, are determined by facing the direction the machine will

travel when in use.

The photos, illustrations, and data used in this manual were current at the time of printing, but due to

possible in-line production changes, your machine can vary slightly in detail. The manufacturer reserves the

right to redesign and change the machine as necessary without notification.

WARNING:

In some of the illustrations and photos used in this manual, shields or guards may have

been removed for clarity. Never operate the machine with any shields or guards removed.

If the removal of shields or guards is necessary to make a repair, they must be replaced

before operation.

1. Safety

11

1.2 Operation

1.2.1 Prepare for operation

Read and understand all operating instructions and precautions in this manual before operating or servicing

the machine.

Make sure you know and understand the positions and operations of all controls. Make certain all controls

are in neutral and the park brake is applied before starting the machine.

Make certain all people are well away from your area of work before starting and operating the machine.

Check and learn all controls in an area clear of people and obstacles before starting your work. Be aware of

the machine size and have enough space available to allow for operation. Never operate the machine at

high speeds in crowded places.

Emphasize the importance of using correct procedures when working around and operating the machine.

Do not let children or unqualified persons operate the machine. Keep others, especially children, away

from your area of work. Do not permit others to ride on the machine.

Make sure the machine is in the proper operating condition as stated in the Operator Manual. Make sure

the machine has the correct equipment required by local regulations.

1.2.2 General information

When parking, park the machine and the tractor on

a solid level surface. put all controls in neutral and

apply the tractor park brake. Stop the tractor

engine and take the key with you.

Make sure the tractor and implement are in the

proper operating condition according to the

operator manuals. Make sure the tractor brakes

and the machine brakes are adjusted correctly.

The tractor must have enough weight and braking

capacity, especially when operating on roads and

terrain that is not even. Use a tractor of

recommended size and weight to tow the

machine. See the machine specifications for the

minimum tractor size and weight.

Tractor must be equipped with rollover protective

structure (ROPS) and a seat belt. use seat belt

during operation.

Do not dismount from moving machinery.

Always operate the machine with the terminal

turned on.

Never start the tractor with the PTO engaged or

terminal turned on.

Stay off slopes too steep for operation.

Where possible avoid operating the machine near

ditches, embankments, and holes. Reduce ground

speed when operating on rough, slippery, or

muddy surfaces and when turning or crossing

slopes.

Fig. 4

Be aware of the size of the machine and have

enough space available to allow for operation.

1. Safety

12

Always lower the machine when not in use and

relieve the pressure in the hoses and cylinders.

Do not stand between the tractor and the

implement to install the hitch pin when the tractor

engine is running.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

1.2.3 Personal protective equipment

Fig. 5

Wear all personal protective equipment (PPE) and

protective clothing issued to you or called for by

job conditions and country/local regulations. PPE

includes, but is not limited to, equipment to

protect eyes, lungs, ears, head, hands and feet

when operating, servicing, or repairing equipment.

Always keep hands, feet, hair, and clothing away

from moving parts. Do not wear loose clothing,

jewelry, watches, or other items that could

entangle in moving parts. Tie up long hair that can

also entangle in moving parts.

1.2.4 Seat instructions

Securely fasten the seat belt before operating the

machine. Always remain seated and have the seat

belt fastened while operating the machine.

Replace the seat belts when they become worn or

broken.

Never wear a seat belt loosely or with slack in the

belt system. Never wear the seat belt in a twisted

condition or pinched between the seat structural

members.

Fig. 6

When using the instructional seat, if equipped,

securely fasten the seat belt. The instructional seat

is to be used only to train new operators or

diagnose a problem. The instructional seat is only

intended for short periods of use. Extra riders,

especially children, are not permitted on the

machine.

Fig. 7

When the instructional seat is used the machine

13

must be driven at a slower speed and on level

ground. Avoid quick starts, stops, and sharp turns.

Avoid driving on highways or public roads.

1.2.5 Shield and guards

All shields and guards must be in the correct

operating position and in good condition.

Do not open, remove, or reach around shields

while the engine is operating. Entanglement in

rotating belts and components can cause serious

injury or death. Stay clear of rotating components.

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death. Stay

clear of rotating components.

1. Safety

Fig. 8

Make sure rotating guards turn freely.

1.2.6 Exhaust warning

Never operate the engine in a closed building

unless the exhaust is vented outside.

Do not tamper with or modify the exhaust system

with unapproved extensions.

Fig. 9

Fig. 10

1. Safety

14

1.2.7 Flying debris

WARNING:

Be careful when operating along the

side of a road or building. Rocks or

other debris can be thrown from the

machine during operation possibly

resulting in injury.

Never stand near the machine during operation.

Debris can be thrown from the machine during

operation possibly resulting in injury.

Fig. 11

1.2.8 Agricultural chemicals

Agricultural chemicals can be very hazardous. Improper use of fertilizer, fungicides, herbicides, insecticides

and pesticides can injure people, plants, animals, soil and other people's property.

Always read and follow all manufacturers' instructions before opening any chemical container.

Even if you think you know the instructions, read and follow instructions each time you use a chemical.

Use the same precautions when adjusting, servicing, cleaning or storing the machine as used when

installing chemicals into the hoppers or tanks.

Inform anyone who comes in contact with chemicals of the potential hazards involved and the safety

precautions required.

Stand upwind and away from smoke from a chemical fire.

Store or dispose of all unused chemicals only in a manner as specified by the chemical manufacturer.

1.3 Travel on public roads

15

Make sure you understand the speed, brakes,

steering, stability, and load characteristics of this

machine before you travel on public roads.

Use good judgment when traveling on public

roads. Maintain complete control of the machine at

all times. Never coast down hills.

The maximum speed of farm equipment is

governed by local regulations. Adjust travel speed

to maintain control at all times.

Familiarize yourself with and obey all road

regulations that apply to your machine. Consult

your local law enforcement agency for local

regulations regarding movement of farm

equipment on public roads. Use head lamps,

flashing warning lamps, tail lamps and turn signals,

day and night, unless prohibited by local law.

Make sure all the flashers are operating prior to

driving on the road. Make sure reflectors are

correctly installed, in good condition, and wiped

clean. Make sure the Slow Moving Vehicle (SMV)

emblem is clean, visible, and correctly mounted on

the rear of the machine.

1. Safety

Fig. 12

Lock brake pedals together (if equipped with dual

brake pedals) so both wheel brakes will be applied

at the same time.

Raise implements to transport position and lock in

place. Place all implements into narrowest

transport configuration.

Disengage the power take-off and differential lock.

With towed implements, use a proper hitch pin

with a clip retainer and safety transport chain.

Be aware of other traffic on the road. Keep well

over to your own side of the road and pull over,

whenever possible, to let faster traffic pass.

Be aware of the overall width, length, height, and

weight of the machine. Be careful when

transporting the machine on narrow roads and

across narrow bridges.

1. Safety

16

Watch for overhead wires and other obstructions.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

Fig. 13

1. Safety

17

1.4 Maintenance

1.4.1 General maintenance information

Before doing any unplugging, lubricating, servicing,

cleaning, or adjusting:

• Park the machine on a solid level surface.

• Make sure all controls are in the neutral

position and apply the park brake.

• Make sure all implements and attachments

have been lowered to the ground.

• Stop the engine and take the key with you.

• Look and Listen! Make sure all moving parts

have stopped.

• Put blocks in front of and behind the wheels of

the machine before working on or under the

machine.

Do not leave the tractor or implement unattended with the engine running.

Do not pull crop or any other object from the machine while the machine engine is running. Moving parts

can pull you in faster than you can move away.

Fig. 14

Check all nuts and bolts periodically for tightness, especially wheel mounting hardware.

Do not attempt to service or adjust the machine until all moving parts have stopped.

Check all nuts and bolts periodically for tightness, especially wheel mounting hardware.

Be aware of the size of parts when doing service work. Never stand under or near a part being moved with

lifting equipment.

After unplugging, lubricating, servicing, cleaning, or adjusting the machine make sure all tools and

equipment have been removed.

Make sure electrical connectors are clean and free of dirt or grease before connecting.

Check for loose, broken, missing, or damaged parts. Make sure the machine is in good repair. Make sure

all guards and shields are in position.

Always raise implement, shut off tractor engine, apply the parking brake, shift to park position (or neutral)

remove the key and install the cylinder stops channels before working around the machine.

Avoid working under the machine. However, if it becomes unavoidable to do so, make sure the machine is

securely blocked and the cylinder lockup channels are in position.

When working around discs or shanks, be careful to not get cut on sharp edges.

Never service, check or adjust drive chains or belts

while the engine is running.

Fig. 15

1. Safety

18

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death.

Stay clear of rotating components.

Make sure rotating guards turn freely.

A loose yoke can slip off a shaft and result in injury

to persons or damage to the machine.

When installing a quick disconnect yoke, the

spring activated locking pins must slide freely and

be seated in the groove on the shaft. Pull on the

driveline to make sure the quick disconnect yoke

can not be pulled off the shaft.

Remove spilled oil, antifreeze or fuel immediately

from the steps, platform, and other access areas.

Keep all access areas clean and free of

obstructions.

Fig. 16

1.4.2 Fire prevention and first aid

Be prepared for emergencies.

Keep a first aid kit handy for treatment of minor

cuts and scratches.

Always carry one or more fire extinguishers of the

correct type. Check fire extinguishers regularly as

instructed by the manufacturer. Make sure fire

extinguishers are properly charged and in

operating condition.

Due to the nature of the crops this machine will

operate in, the risk of fire is of concern. Use a

water type fire extinguisher or other water source

for a fire in crop.

For fires involving anything other than crop, such

as oil or electrical components, use a dry chemical

fire extinguisher with an ABC rating.

Mount fire extinguishers within easy reach of

where fires can occur.

Frequently remove accumulated crop material

from the machine and check for overheated

components. Check the machine daily for any

noises that are not normal. Such noises could

indicate a failed component that can cause excess

heat.

Fig. 17

Fig. 18

If any flame cutting, welding, or arc welding is to

19

be done on the machine or attachments, make

sure to clear any crop material or debris from

around the area. Make sure the area below the

work area is clear of any flammable material as

falling molten metal or sparks can ignite the

material.

If fire occurs stand upwind and away from smoke

from the fire.

1. Safety

Fig. 19

1.4.3 High pressure leaks

Fluid leaking from the hydraulic system or the fuel

injection system under high pressure can be very

hard to see. The fluid can go into the skin causing

serious injury.

Fluid injected into the skin must be surgically

removed within a few hours. If not removed

immediately, serious infection or reaction can

develop. Go immediately to a doctor who knows

about this type of injury.

Use a piece of cardboard or wood to search for

possible leaks. Do not use your bare hand. Wear

leather gloves for hand protection and safety

goggles for eye protection.

Relieve all pressure before loosening any hydraulic

lines. Relieve the pressure by lowering raised

equipment, shutting off accumulator valve, if

equipped, and shutting off the engine. Tighten all

connections securely before applying pressure.

Fig. 20

Fig. 21

1. Safety

20

1.4.4 Tire safety

Check tires for cuts, bulges, and correct pressure.

Replace worn or damaged tires. When tire service

is needed, have a qualified tire mechanic service

the tire. Tire changing can be very hazardous and

must be done by qualified tire mechanic using

proper tools and equipment. See the

Specifications Section for the correct tire size.

Tire explosion and/or serious injury can result from

over inflation. Do not exceed the tire inflation

pressures. See the Specifications Section for the

correct tire pressure.

Do not inflate a tire that is seriously under inflated

or has been run flat. Have the tire checked by

qualified tire mechanic.

Do not weld on the rim when a tire is installed.

Welding will make an air/gas mixture that can

cause an explosion and burn with high

temperatures. This danger applies to all tires,

inflated or deflated. Removing air or breaking the

bead is not enough. The tire must be completely

removed from the rim prior to welding.

Fig. 22

When preparing a calcium chloride solution for

fluid ballast the tractor tires, never pour water onto

the calcium chloride. A chlorine gas can be

generated which is poisonous and explosive. This

can be avoided by slowly adding calcium chloride

flakes to water and stirring until they are dissolved.

When seating tire beads onto rims, never exceed

2.4 bar (35 psi) or the maximum inflation pressure

specified on the tire. Inflation beyond this

maximum pressure may break the bead, or even

the rim, with explosive force.

1.4.5 Replacement parts

Where replacement parts are necessary for

periodic maintenance and servicing, genuine

replacement parts must be used to restore your

equipment to original specifications.

The manufacturer will not accept responsibility for

installation of unapproved parts and/or accessories

and damages as a result of their usage.

Fig. 23

1. Safety

21

1.5 Transport locks

The machine is equipped with transport locks and depth stop collars. Remove

the transport locks (1) and depth stop collars (2) before moving the machine

on roads. When not in use, keep the transport locks and depth stop collars in

the storage position (3). Install transport locks when machine is completely

unfolded before doing any maintenance or service work.

CENTER SECTION

3

2

1

700187

WING SECTION

3

1

2

701405

1.

22

Safety

1.6 Marker lamps

The machine has marker lamps that must be used when moving the

machine in the folded position on roads.

The machine is equipped with two red lamps (1) located toward the

rear center of the machine.

The machine is equipped with two amber lamps (2) located toward the

rear center of the machine.

2

1

2

1

AMBER LIGHTGHT

(223143)

12 X 36 LIGHT ARM

(235460)

SMV EMBLEM

(30651)

SMV BRACETKET

(350933)

RED LIGHTGHT

(223144)

LIGHT BRACKETKET

(223126)

LONG BASE PIVOT

(223131)

3/8 X 7 X 8-1/4

U-BOLT (89277)

701406

701406 ISO

243812 10K DECAL

23

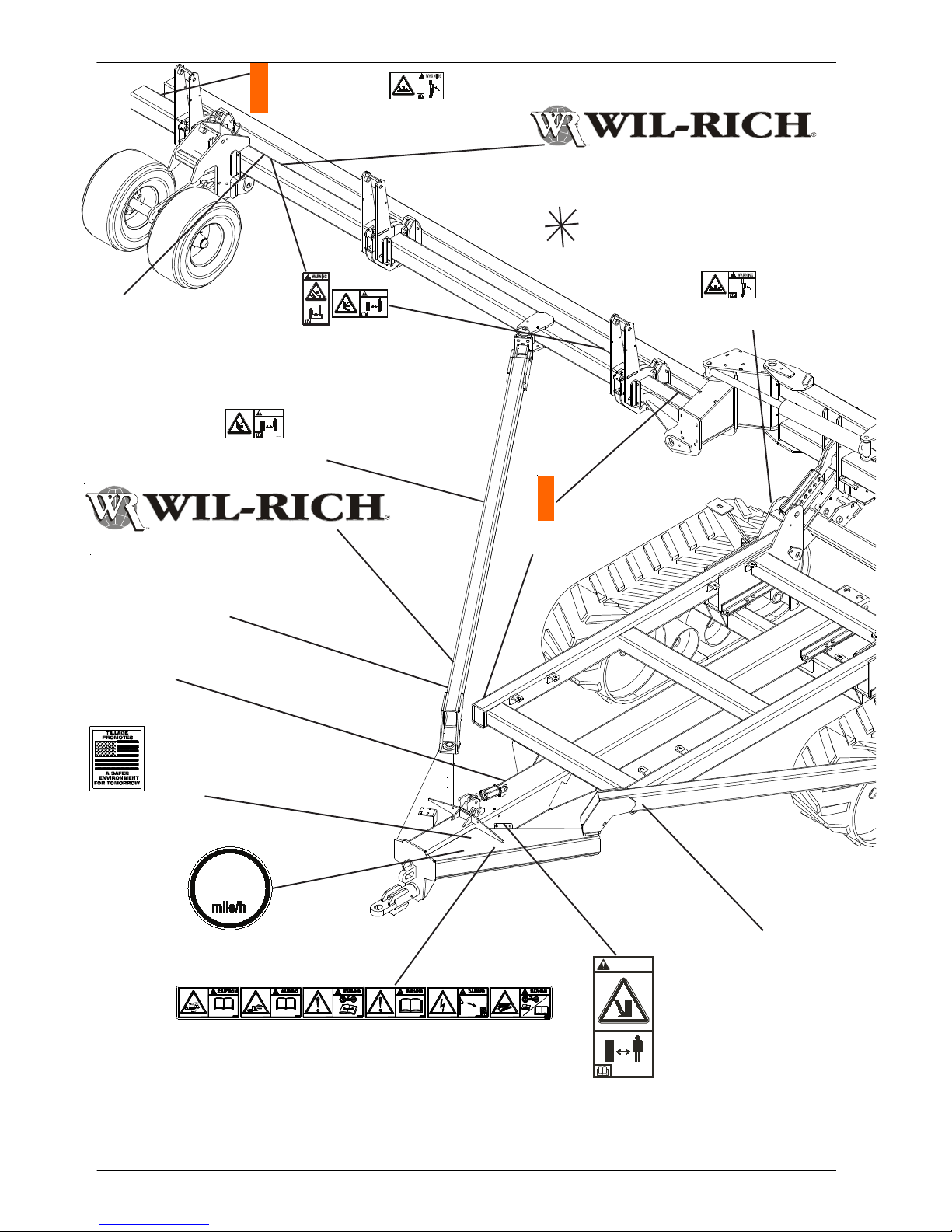

700730610 SAFETY SIGNDANGER CRUSHING

22372 AMBER

REFLECTOR

700730781 WARNING LOCKOUT

DANGER

700730610

700730619 WARNING

CRUSHING

700730610 DANGER

CRUSHING

DANGER

700730610

WAR NI NG

1. Safety

700730781

1.7 Safety sign location

65342 WIL-RICH DECAL

ALL DECALS F ACING

REAR ON THE WINGS

ARE PLACED ON THE

MAIN BAR

WAR NI NG

700730781

700730781 WARNING LOCKOUT

65342 WIL-RICH DECAL

243812 10K DECAL

SERIAL NUMBER

LOCA TION

997263 TILLAGE

SAFE ENVIRONMENT

5

1

700731295

DECAL 15 MPH

22372 AMBER

REFLECTOR

WAR NING

9971 163 SAFETY DECAL SET

243812 10K DECAL

700731801

700731801 SAFETY SIGNWARNING CRUSHING (LOCATE ON HYDRAULIC JACK

TUBE)

23

700730610

DANGER

700730781

WARNING

700730781

WARNING

700730610

DANGER

1. Safety

24

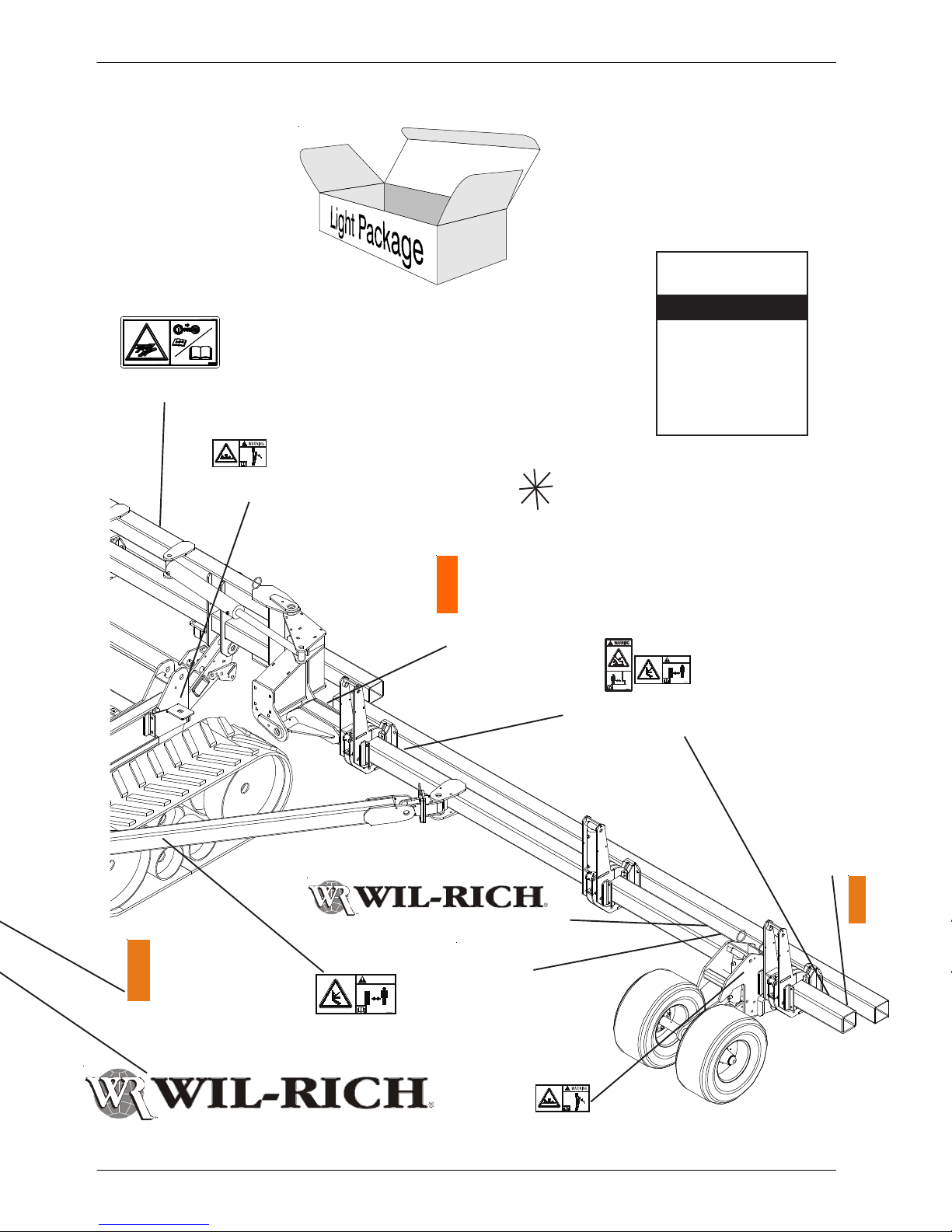

1.7 Safety sign location

997267 FLUID UNDER

PRESSURE

41426 CLEARANCE LIGHT PACKAGE

2

74283 ASSY/OPERA TORS

MANUAL

ASSEMBLY/OPERATORS

MANUAL

WIL-RICH

FOLDING

TOOLBAR

700730781 WARNING LOCKOUT

ALL DECALS F ACING REAR ON THE

WINGS ARE PLACED ON THE MAIN BAR

22372 AMBER

REFLECTOR

700730619 WARNING

CRUSHING

700730610 DANGER

CRUSHING

22372 AMBER

REFLECTOR

65342 WIL-RICH DECAL

22372 AMBER

REFLECTOR

700730610 SAFETY SIGNDANGER CRUSHING

65342 WIL-RICH DECAL

243812 10K DECAL

700730781 WARNING LOCKOUT

9971163 SAFETY DECAL SET

25

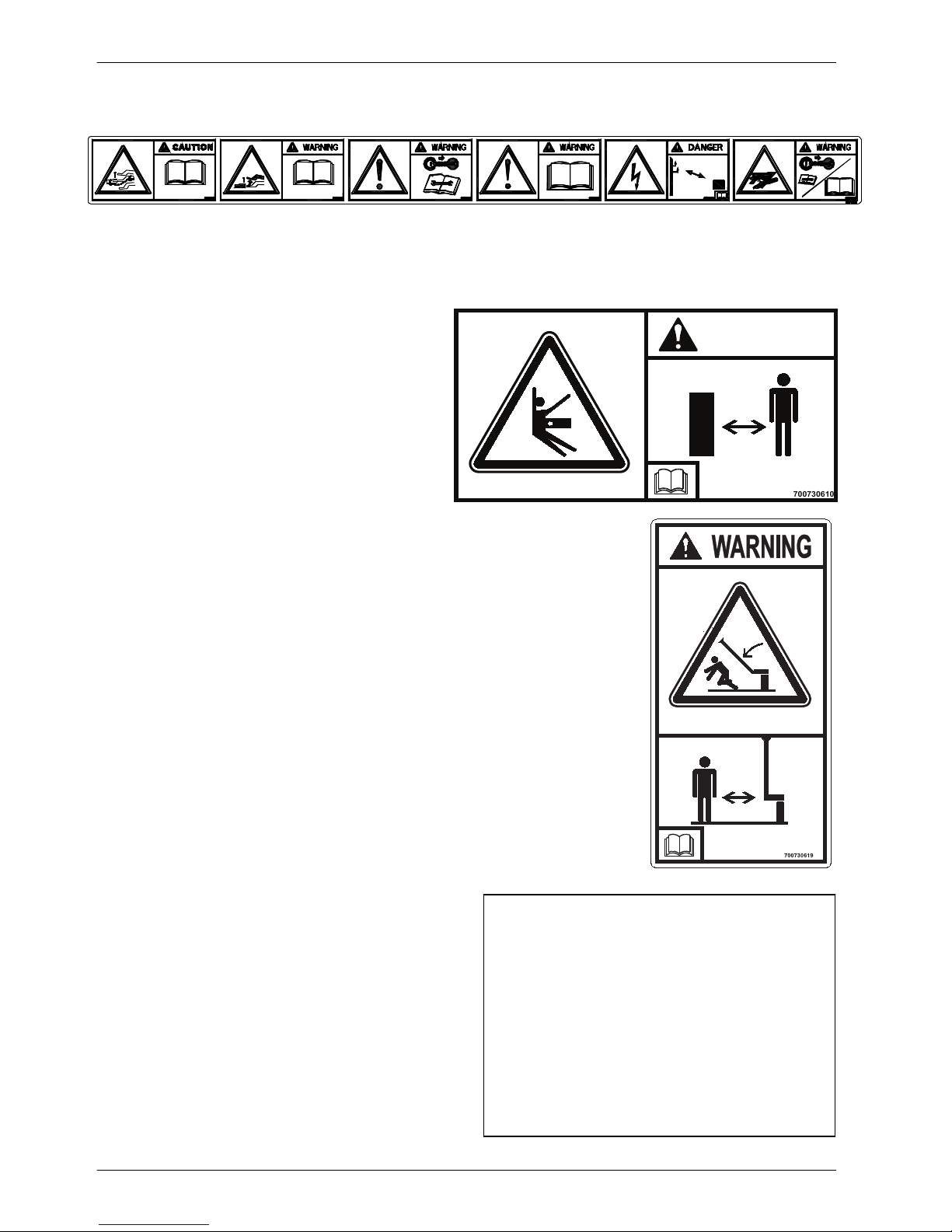

Warning/lockout

Hazard (A): Crushing hazard. Toolbar frame

movement.

Avoidance (B): Stay clear of this area while

engine and machine are operating. For service

work, install the wing lock pins before getting under

the wing.

1. Safety

1.7 Safety sign location

DANGE R

700730610

Warning/lockout

Hazard (A): Crushing hazard. Toolbar rotation -

row unit.

Avoidance (B): Stay clear of this area while

engine and machine are operating. For service

work, install the wing lock pins before getting under

the wing.

(1) Danger/folding wings

Hazard (A): Overhead crushing hazard from

lowering or falling wing.

700730610

700730619

Avoidance (B): Stay clear of this area while engine

and machine are operating. For service work,

install the wing lock pins before getting under the

wing.

Fig. 27

1. Safety

26

(2) Warning/lockout

Hazard (A): Crushing hazard.

Avoidance (B): Stay clear of this area while engine

and machine are operating. For service work,

install the wing lock pins before getting under the

wing.

Fig. 27

700730781

(3) Caution/safety chains

Hazard (A): Loss of machine control.

Avoidance (B): Install the safety chains when

connecting the machine to the tractor. Read the

operators manual for safety information and the

operating instruction before operating the

machine.

Fig. 28

Fig. 28

Fig. 29

(4) Warning/negative tongue weight

27

Hazard (A): Negative tongue weight will cause the

tongue to rise immediately when disconnecting

the machine.

Avoidance (B): Stay clear of the tongue when

disconnecting the machine from the tractor. Read

the operators manual for safety information and

operating the instructions before operating the

machine.

1. Safety

Fig. 29

(5) Warning/remove key

Hazard (A): General safety alert.

Avoidance (B): Turn off the machine and remove

the key before maintenance or repair.

Fig. 30

Fig. 30

Fig. 31

1. Safety

28

(6) Warning/read operators manual

Hazard (A): General safety alert.

Avoidance (B): Read and understand the

operators manual before operating the machine.

Fig. 31

(7) Danger/high line

Hazard (A): Electrical shock hazard - risk of

personal injury and component damage.

Avoidance (B): Keep the correct distance away

from electrical power lines.

Fig. 32

Fig. 32

Fig. 33

(8) Warning/hydraulic fluid pressure

29

Hazard (A): Injection hazard into skin - escaping

fluid under high pressure.

Avoidance (B): Turn off the engine, remove the

key, relieve the pressure before maintenance or

repair. Refer to the operator manual for the correct

service procedures.

1. Safety

Fig. 33

997867

(9) Maximum speed

The maximum speed safety sign displays the

maximum speed to transport the machine.

Fig. 34

Fig. 34

700731295

15

Fig. 35

1. Safety

30

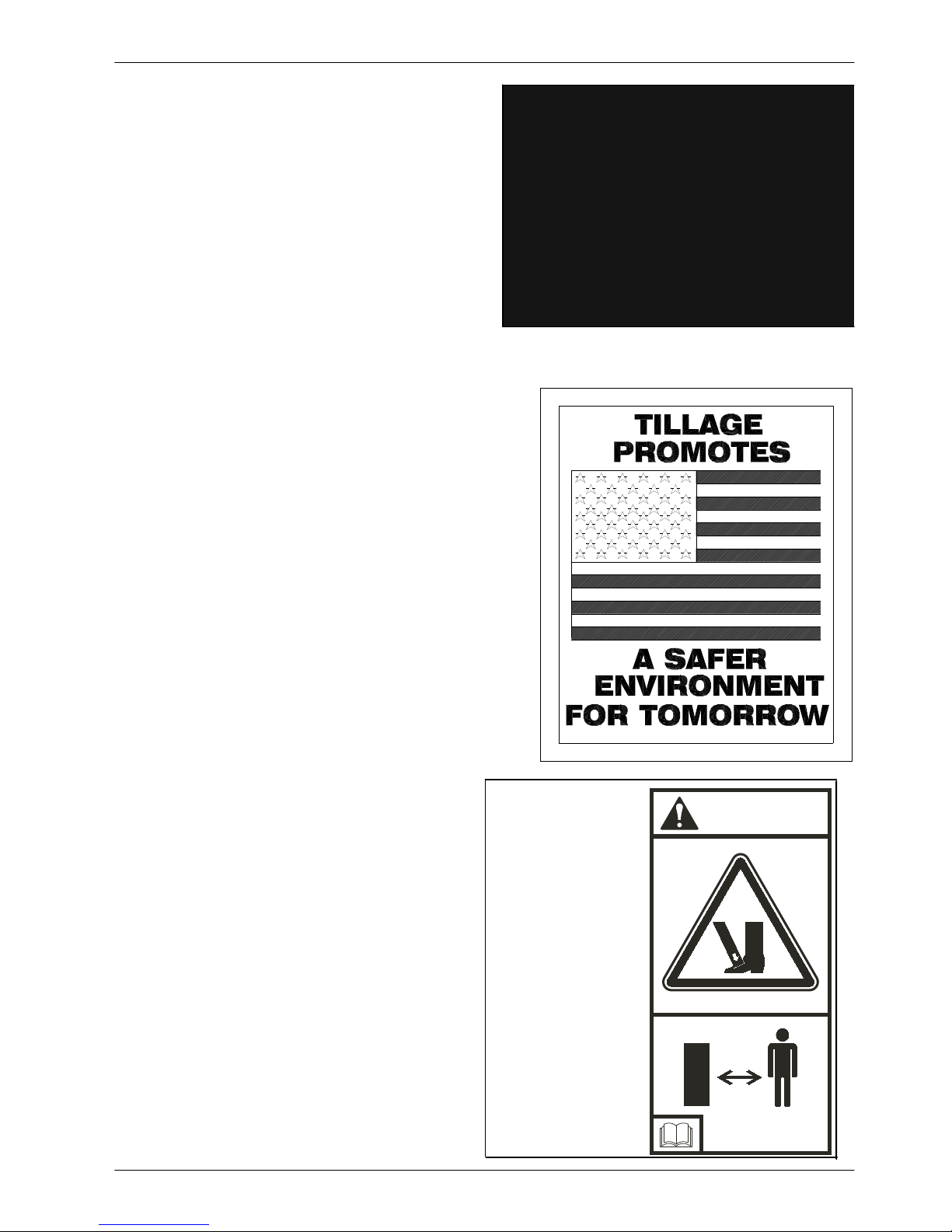

(10) Reflector/yellow

Tillage safe environment

22372

Fig. 36

997263

Warning sign

Hazard (A): Foot crushing hazard part may lower

without warning.

Avoidance (B): Turn off the engine, remove the

key, relieve the pressure before maintenance or

repair. Refer to the operator manual for the correct

service procedures.

700731801

WARNING

A

B

700731801

Loading...

Loading...