Wilo Helix V 22, Helix V 52, Helix V First 22, Helix V First 36, Helix V First 52 Installation And Operating Instructions Manual

...Page 1

Wilo-Helix V 22-36-52

Wilo-Helix V FIRST 22-36-52

Pioneering for You

de Einbau- und Betriebsanleitung

en Installation and operating instructions

fr Notice de montage et de mise en service

nl Inbouw- en bedieningsvoorschriften

ru Инструкция по монтажу и эксплуатации

es Istruzioni di montaggio, uso e manutenzione

it Istruzioni di montaggio, uso e manutenzione

4 120 943-Ed.09 / 2016-03-Wilo

pt

Manual de Instalação e funcionamento

tr

Návodkmontážiaobsluze

el

Инструкцияпомонтажуиэксплуатации

sv

Iнструкціязмонтажутаексплуатації

no

Paigaldus- ja kasutusjuhend

fi Uzstādīšanasunekspluatācijasinstrukcija

da

Montavimo ir naudojimo instrukcija

hu Beépítési és üzemeltetési utasítás

pl Instrukcja montażu i obsługi

cs

Návod k montáži a obsluze

et

Paigaldus- ja kasutusjuhend

lv

Uzstādīšanas un ekspluatācijas instrukcija

lt

lt Montavimo ir naudojimo instrukcija

sk

Návod na montáž a obsluhu

sl

Navodila za vgradnjo in obratovanje

hr

Upute za ugradnju i uporabu

sr Uputstvo za ugradnju i upotrebuU

Uputstv

ro Instrucţiuni de montaj şi exploatare

bg

Инструкция за монтаж и експлоатация

Page 2

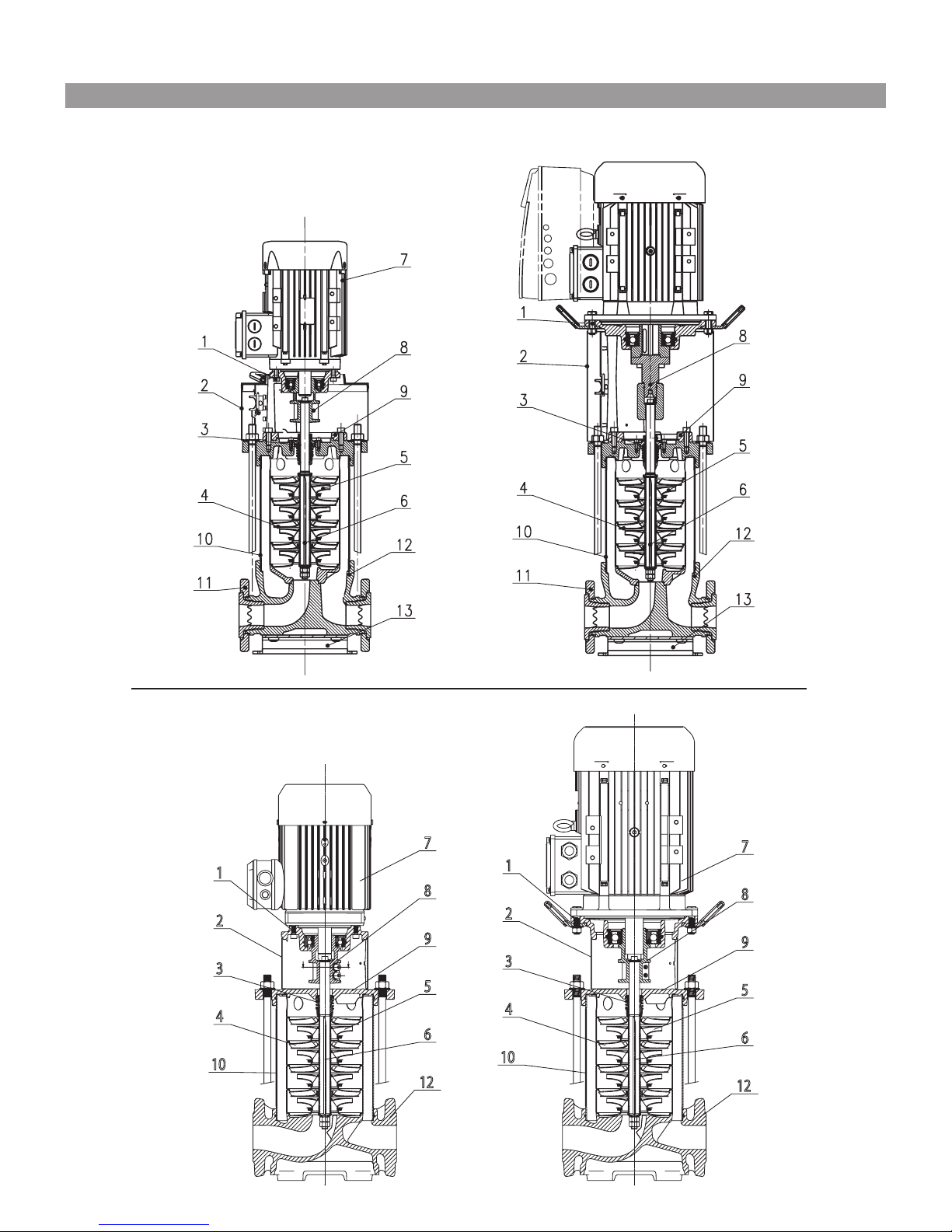

Fig. 1

FIRST

Page 3

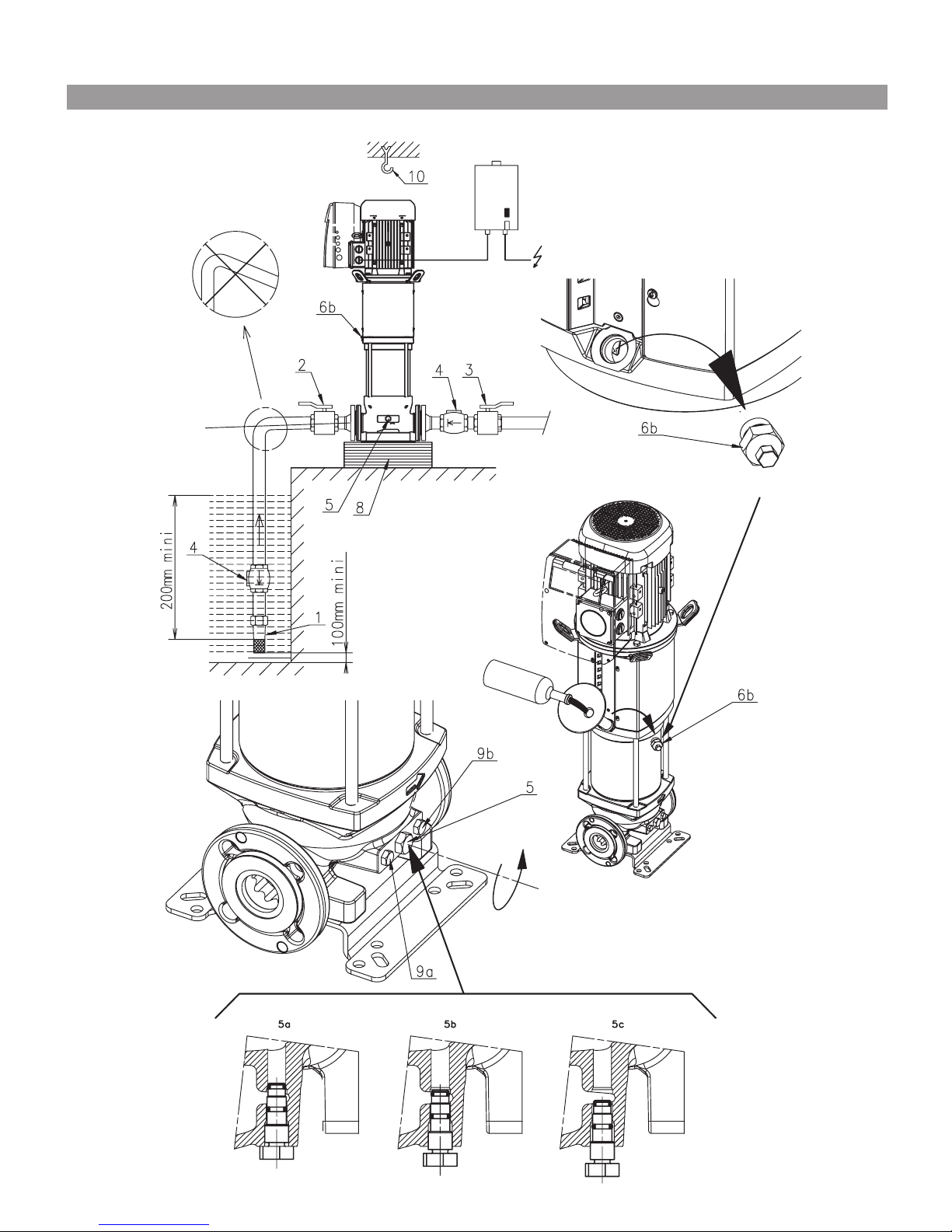

Fig. 2

Page 4

Fig. 3

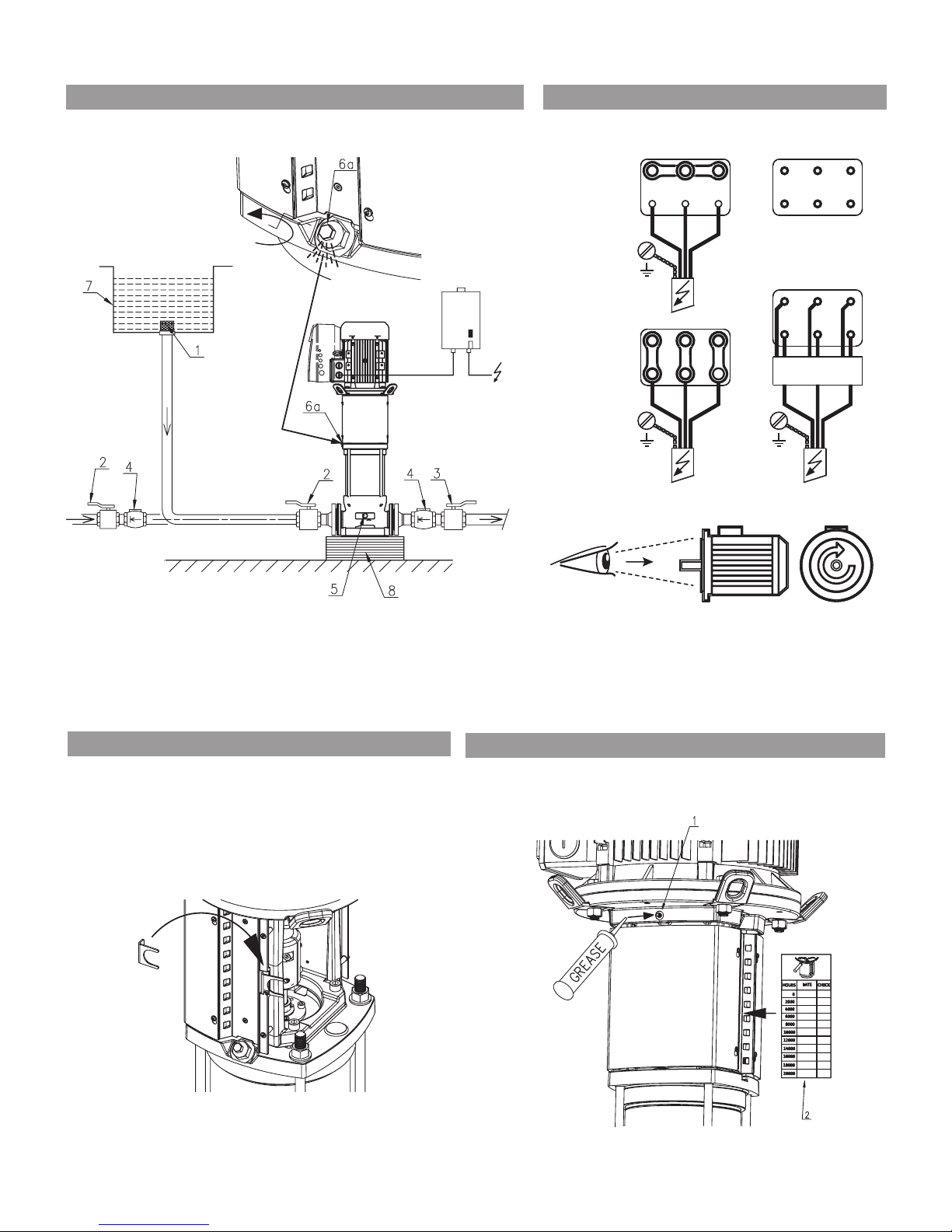

Fig. 6

Fig. 7

Fig. 5

HIGH

VOLTAGE

LOW

VOLTAGE

<ܾ

L1 L2 L3

W1

V2U2W2

U1 V1

L1 L2 L3

L1 L2 L3

<

Page 5

A

A

A

D

E

C

AK

AK

AK

AG

AG

AJ

AJ

AJ

AG

AH

AH

AH

B

C

B

C

B

D

E

D

E

F

F

F

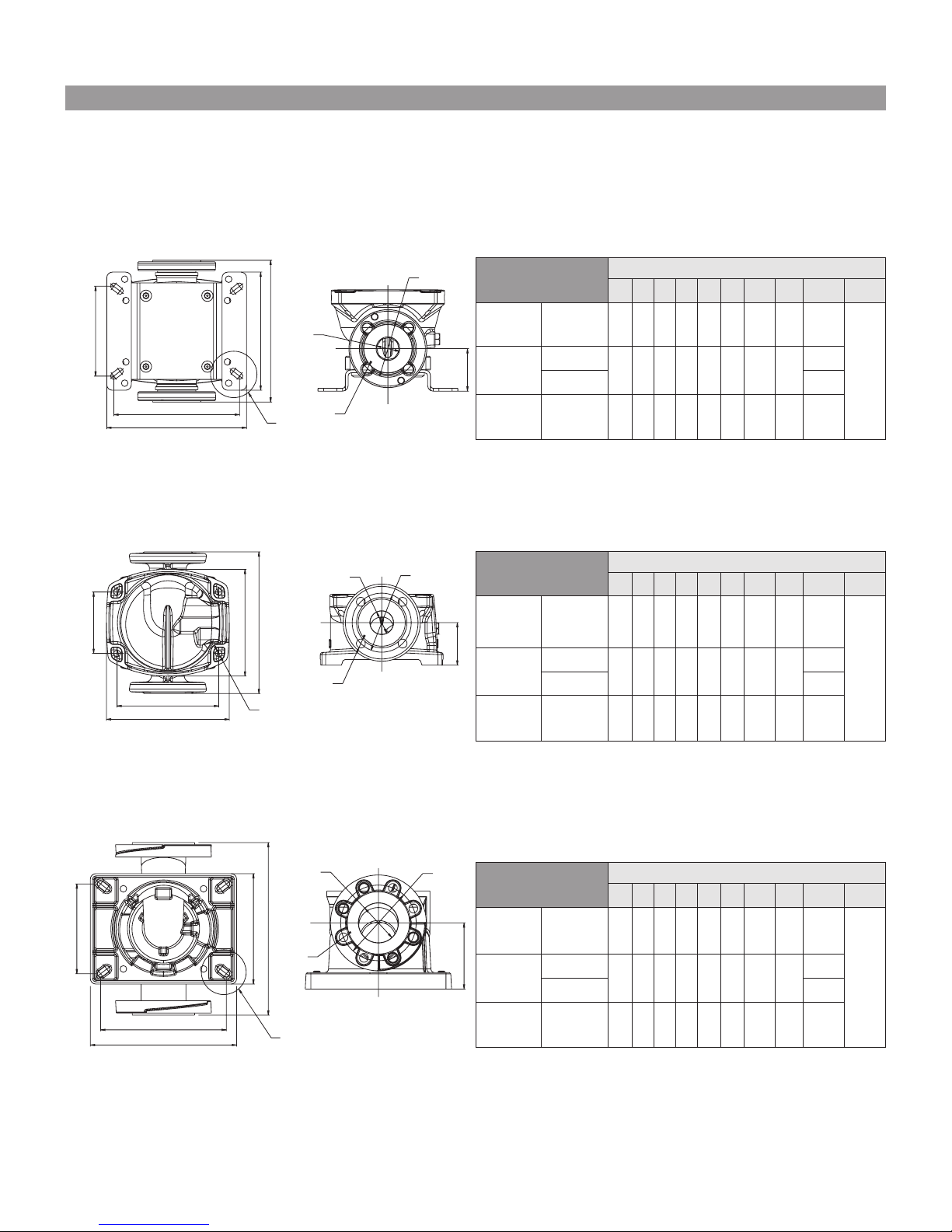

Fig. 4

Type

(mm)

A B C D E F G H J K

Helix V 22

PN16/PN25/

PN30

130 296 215 250 300 90 DN50 125 4 x M16

16 x

Ø14

Helix V 36

PN16

170

or

220

296

240

or

220

250 320 105 DN65 145

4 x M16

PN25/PN30 8 x M16

Helix V 52

PN16/PN25/

PN30

190

or

220

296

266

or

220

250 365 140 DN80 160 8 x M16

Type

(mm)

A B C D E F G H J K

Helix FIRST

V22

PN16/PN25/

PN30

130 260 215 226 300 90 DN50 125 4 x M16

4 x Ø14

Helix FIRST

V36

PN16

170 294 240 226 320 105 DN65 145

4 x M16

PN25PN30 8 x M16

Helix FIRST

V52

PN16/PN25/

PN30

190

or

170

295

266

or

240

226 365 140 DN80 160 8 x M16

Type

(mm)

A B C D E F G H J K

Helix V 22

PN16/PN25 130 255 215 226 300 90 DN50 125 4 x M16

4 x Ø14

Helix V 36

PN16

170 284 240 230 320 105 DN65 145

4 x M16

PN25 8 x M16

Helix V 52

PN16/PN25

190

or

170

310

266

or

240

234 365 140 DN80 160 8 x M16

Material code -2 -3

Material code -4 -5

Material code -1

Page 6

Fig. 8

;

;

;

Page 7

15

English

WILO SE 03/2016

1. General

1.1 About this document

The language of the original operating instructions is English. All other languages of these instructions are translations of the original operating

instructions.

These installation and operating instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions

is a precondition for the proper use and correct

operation of the product.

These installation and operating instructions correspond to the relevant version of the product

and the underlying safety standards valid at the

time of going to print.

EC declaration of conformity:

A copy of the EC declaration of conformity is a

component of these operating instructions.

If a technical modification is made on the designs

named there without our agreement, this declaration loses its validity.

2. Safety

These instructions contain important information

which must be followed when installing and operating the pump. It is therefore imperative that

they be read by both the installer and the operator before the circulator is installed or started up.

Both the general safety instructions in the ‘Safety

precautions’ section and those in subsequent

sections indicated by danger symbols should be

carefully observed.

2.1 Symbols and signal words used in these

operating instructions

Symbols

General safety symbol.

Hazards from electrical causes.

NOTE: ....

Signal words:

DANGER! Imminently hazardous situation. Will

result in death or serious injury if not avoided.

WARNING! Risk of (serious) injury. ‘Warning’

implies that failure to comply with the safety

instructions is likely to result in (severe) personal injury.

CAUTION! Risk of damage to the pump/installation. ‘Caution’ alerts to user to potential product damage due to non-compliance with the

safety instructions.

NOTE: Useful information on the handling of the

product.

It alerts the user to potential difficulties.

2.2 Personnel qualification

The personnel installing the pump must have the

appropriate qualification for this work.

2.3 Risks incurred by failure to comply with the

safety instructions

Failure to comply with the safety precautions

could result in personal injury or damage to the

pump or installation. Failure to comply with the

safety precautions could also invalidate any claim

for damages.

In particular, failure to comply with these safety

instructions could give rise, for example, to the

following risks:

• the failure of important parts of the pump or installation,

• personal injury due to electrical and mechanical

causes,

• material damage.

2.4 Safety instructions for the operator

Existing regulations for the prevention of accidents must be observed.

National Electrical Codes, local codes and regulations must be followed.

2.5 Safety instructions for inspection and assembly

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

• If hot or cold components on the product/the

unit lead to hazards, local measures must be

taken to guard them against touching.

• Guards protecting against touching moving

components (such as the coupling) must not be

removed whilst the product is in operation.

• Leakages (e.g. from the shaft seals) of hazardous

fluids (which are explosive, toxic or hot) must be

led away so that no danger to persons or to the

environment arises. National statutory provisions

are to be complied with.

• Highly flammable materials are always to be kept

at a safe distance from the product.

• Danger from electrical current must be eliminated. Local directives or general directives [e.g.

IEC, VDE etc.] and local power supply companies

must be adhered to.

2.6 Unauthorised modification and manufacture of

spare parts

Alterations to the pump or installation may only

be carried out with the manufacturer’s consent.

The use of original spare parts and accessories

authorized by the manufacturer will ensure safety. The use of any other parts may invalidate

claims invoking the liability of the manufacturer

for any consequences.

Page 8

2.7 Improper use

The operational safety of the pump or installation

supplied can only be guaranteed if it is used in

accordance with paragraph 4 of the operating

instructions. The limits given in the catalogue

or data sheet must under no circumstances be

exceeded.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accordance with Section 4 of the operating instructions. The limit values must on no account fall

under or exceed those specified in the catalogue/

data sheet.

3. Transport and interim storage

When receiving the material, check that there has

been no damage during the transport. If shipping

damage has occurred, take all necessary steps

with the carrier within the allowed time.

CAUTION! Outside influences may cause damages. If the delivered material is to be installed

later on, store it in a dry place and protect it from

impacts and any outside influences (humidity,

frost etc.).

The product should be cleaned thoroughly before

it is put into temporary storage. The product can

be stored for at least one year.

Handle the pump carefully so as not to damage the

unit prior to installation.

4. Application

This pump’s basic function is to pump hot or cold

water, water with glycol or other low viscosity

fluids that contain no mineral oil, solid or abrasive

substances, or materials having long fibres. The

manufacturer’s approval is required for use to

pump corrosive chemicals.

CAUTION! Risk of explosion!

Do not use this pump to handle flammable or

explosive liquids.

4.1 Applications areas

- water distribution and boosting installations,

- industrial circulation systems,

- process fluids,

- cooling water circuits,

- fire-fighting and washing stations,

- watering installations, etc.

16

English

WILO SE 03/2016

5. Technical data

5.1 Type key

Example: Helix V2205/2-1/16/E/KS/400-50xxxx

Helix V

Helix FIRST V

Vertical high-pressure multistage

centrifugal pump in in-line design

22 Nominalowinm3/h

05 Number of impellers

2

Number of trimmed impellers (if

any)

1

Pump material code

1 = Pump housing Stainless steel

1.4308 (AISI 304)

+ Hydraulics 1.4307 (AISI 304)

2 = Modular pump housing Stain-

less steel 1.4409 (AISI 316L)

+ Hydraulics 1.4404

(AISI 316L)

3 = Modular pump housing Cast

Iron EN-GJL-250 (ACS and

WRAS approved coating)

+ Hydraulics 1.4307 (AISI 304)

4 = Monobloc Pump housing cast

iron EN-GJL-250 (ACS and

WRAS approved coating)

+ Hydraulics 1.4307

(AISI 304)

5 = Monobloc Pump housing cast

iron EN-GJL-250

(standard coating)

+ Hydraulics 1.4307

(AISI 304)

16

Pipe connection

16 = PN16

25 = PN25

30 = PN40

E

Seal type code

E = EPDM

V = FKM Viton

KS

K = Cartridge seal, versions without “K” are equipped with simple

mechanical seal

S = Lantern orientation align with

suction pipe

X = X-Care version

400

460

Motor electrical

voltage ( V )

50

60

Motor frequency ( Hz)

xxxx Options code (if any)

Page 9

17

English

WILO SE 03/2016

5.2 Technical data

Outline and pipe dimensions (Fig. 4).

5.3 Scope of Supply

• Multistage pump.

• Installation and operating instructions.

Maximum operating pressure

Pump casing 16, 25 ou 30 bars depend on the model

Maximum suction pressure

10 bars

Note:realinletpressure(Pinlet)+pressureat0owdeliveredbythe

pump must be below the maximum operating pressure of the pump. In

case of exceeding maximum operating pressure, the ball bearing and the

mechanical seal could be damaged or lifetime could decrease.

PInlet+Pat0ow≤Pmaxpump

See pump nameplate to know the maximum operating pressure: Pmax

Temperature range

Liquid temperatures

-20°C to +120 °C

-30°C to +120° C (if full stainless steel)

-15°C to + 90°C (Viton version for O’ring and mechanical seal )

Ambient temperature

-15° to +40 °C

Other temperature on request

Electrical data

Motor efciency Motor according to IEC 60034-30

Motor Protection index IP 55

Insulation class 155 (F)

Frequency See motor plating

Electrical voltage See motor plating

Other data

Humidity < 90% sans condensation

Altitude

< 1000 m

(> 1000m on request)

Maximum suction head according to NPSH of the pump

Sound pressure level dB(A)

0/+3 dB(A)

Power (kW)

0.37 0.55 0.75 1.1 1.5 2.2 3 4 5.5 7.5 11 15 18.5 22 30 37 45

50Hz 56 57 58 62 64 68 69 71 74

76

60Hz 60 61 63 67 71 72 74 78 81

84

Page 10

18

English

5.4 Accessories

Original accessories are available for HELIX range:

The use of new accessories is recommended.

6. Description and function

6.1 Product description

FIG. 1

1 - Motor connection bolt

2 - Coupling guard

3 - Mechanical seal

4- Hydraulic stage casing

5 - Impeller

6 - Pump shaft

7 - Motor

8 - Coupling

9 - Lantern

10 - Tube liner

11 - Flange

12 - Pump housing

13 - Base plate

FIG. 2, 3

1 - Strainer

2 - Pump suction valve

3 - Pump discharge valve

4 - Check valve

5 - Drain + priming plug

6 - Air bleed screw + Filling plug

7 - Tank

8 - Foundation block

9 - In option : pressure plugs (a-suction,

b-discharge)

10 - Lifting hook

6.2 Design of product

• HELIX pumps are vertical high pressure non-self

priming pumps with inline connection based on

multistage design.

• HELIX pumps combine use of both high efficiency hydraulics and motors (if any).

• All metallic parts in contact with water are made

of stainless steel or grey cast iron.

• For aggressive fluid, special versions exist with

stainless steel only for all wetted components.

• Helix pumps are equipped with a simple mechanical seal or with a cartridge seal to facilitate

maintenance.

• In addition, for heaviest motor, a specific coupling allows to change this seal without removing the motor.

• HELIX lantern design integrates an additional ball

bearing that withstand hydraulic axial forces: this

allows the pump to use a fully standard motor.

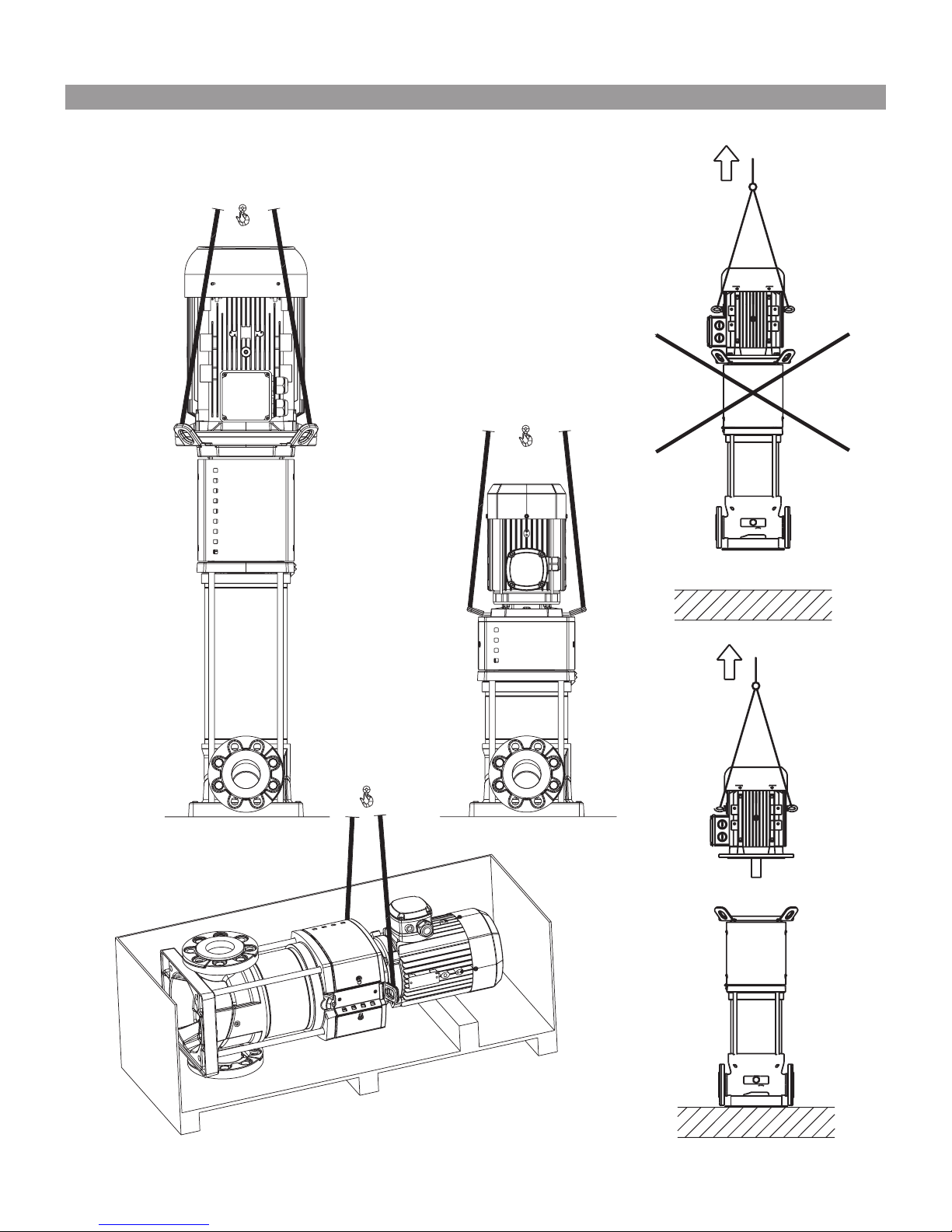

• Special handling devices are integrated in order

to facilitate pump installation (Fig. 8).

7. Installation and electrical connection

Installation and electrical work in compliance

with any local codes and by qualified personnel

only.

WARNING! Bodily injury!

Existing regulations for the prevention of accidents must be observed.

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

7.1 Commissioning

Unpack the pump and dispose of the packaging

in an environmentally-responsible manner.

7.2 Installation

The pump must be installed in a dry, well-ventilated and frost-free place.

CAUTION! Possible damage of the pump!

Dirt and solder drops in to the pump body can

effect the pump operation.

• It is recommended that any welding and soldering work be done before installing the pump.

• Thoroughly flush the system out before

installing the pump.

- The pump must be installed in an easily accessible position to facilitate inspection or replacement.

- For heavy pumps, install a lifting hook (Fig. 2,

item 10) above the pump in order to ease its

disassembly.

WARNING! Risk of accident by hot surfaces!

The pump must be positioned so that someone

cannot come into contact with the hot pump

surfaces while operation.

- The pump must be installed in an easily accessible position to facilitate inspection or replacement.

WARNING! Risk of fall!

The pump must be screwed to the ground.

Designation

Article no.

2

Round counterflanges, stainless steel,

1.4404 (PN16 – DN50) 4038587

2

Round counterflanges, stainless steel,

1.4404 (PN25 – DN50) 4038589

2 Round counterflanges, steel,

(PN16 – DN50) 4038585

2 Round counterflanges, steel,

(PN25 – DN50) 4038588

2

Round counterflanges, stainless steel,

1.4404 (PN16 – DN65) 4038592

2

Round counterflanges, stainless steel,

1.4404 (PN25 – DN65) 4038594

2 Round counterflanges, steel,

(PN16 – DN65) 4038591

2 Round counterflanges, steel,

(PN25 – DN65) 4038593

2

Round counterflanges, stainless steel,

1.4404 (PN16 – DN80) 4073797

2

Round counterflanges, stainless steel,

1.4404 (PN25 – DN80) 4073799

2 Round counterflanges, steel,

(PN16 – DN80) 4072534

2 Round counterflanges, steel,

(PN25 – DN80) 4072536

Bypass kit 25 bar

4124994

Bypass kit (with pressure gauge 25 bar)

4124995

Baseplate with dampers for pumps up to 5.5kW

4157154

WILO SE 03/2016

Page 11

19

English

- Place the pump where it will be easy to reach, to

facilitate inspection and removal work. The pump

must always be installed perfectly upright on a

sufficiently heavy concrete base.

CAUTION! Risk of parts inside the pump!

Take care to remove closure members of the

pump housing before installation.

NOTE: Each pumps could be tested regarding

hydraulic features in factory, some water may

remain in them. It is recommended for hygienic

purposes, to carry out a rinsing of the pump

before any using with potable water supply.

- The installation and connection dimensions are

given § 5.2.

- Lift the pump carefully by using the integrated

hooks rings, if necessary with a hoist and suitable

slings according to the current hoist guidelines.

WARNING! Risk of fall!

Take care to pump fixations especially for the

highest pumps whose centre of gravity may lead

to risk during pump handling.

WARNING! Risk of fall!

Use integrated rings only if they are not damaged

(no corrosion ...). Replace them if needed.

WARNING! Risk of fall!

The pump must be never carried by using motor

hooks: these are only designed to lift the motor

alone.

7.3 Pipe connection

- Connect the pump to the pipes by using appropriate counterflanges, bolts, nuts and gaskets.

CAUTION!

Tightening of bolts must not exceed 80 Nm

Use of impact wrench is prohibited.

- The circulation sense of the fluid is indicated on

the identification label of the pump.

- Pump must be installed in such a way that it is

not stressed by the pipework. The pipes must be

attached so that the pump does not bear their

weight.

- It is recommended that isolation valves be installed on the suction and discharge side of the

pump.

- Use of expansion joints may mitigate noise and

vibration of the pump.

- As regards the nominal cross-section of the suction pipe, we recommend a cross-section at least

as large as that of the pump connection.

- A check valve could be placed on the discharge

pipe in order to protect the pump against hammer shock.

- For direct connection to a public drinking water

system, the suction pipe must also have a check

valve and a guard valve.

- For indirect connection via a tank, the suction

pipe must have a strainer to keep any impurities

out of the pump and a check valve.

- In case of half flanges pump design, it is recommended to connect the hydraulic network and

then keep out the plastic fixation links to prevent any leakage risk.

7.4 Motor connection for bare-shaft pump

(without motor)

- Remove coupling guards.

NOTE: Helix pumps are equipped with captive

screws as required in the Machinery Directive.

- Install the motor on the pump by using screws

(FT lantern size – see product designation) or

bolts, nuts and handling devices (FF lantern

size – see product designation) provided with

the pump : check motor power and dimension in

WILO catalogue.

NOTE: Depending on fluid characteristics,

motor power could be modified. Contact WILO

Customer Services if needed.

- Close the coupling guards by screwing all screws

provided with the pump.

7.5 Electrical connection

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

• Electrical work by a qualified electrician only!

• All electrical connections must be performed

after the electrical supply has been switched off

and secured against unauthorized switching.

• For safe installation and operation a proper

grounding of the pump to the power supply’s

grounding terminals is required.

- Check that operating current, voltage and frequency used comply with motor plating data.

- The pump must be connected to the power supply by a solid cable equipped with a grounded

plug-connection or a main power switch.

- Three-Phase motors must be connected to an

approved motor starter. The set nominal current

must correspond to the electrical data on the

pump motor name plate

- The supply cable must be laid so that it never touches

the pipework and/or the pump and motor casing.

- The pump/installation should be grounded in

compliance with local regulations. A ground fault

interrupter can be used as extra protection.

- The connection to the network must be in

accordance with the connection plan (Fig. 5).

7.6 Operation with frequency converter

- Motors used can be connected to a frequency

converter in order to adapt pump performance to

duty point.

- The converter must not generate voltage peaks

at motor terminals higher than 850V and dU/dt

slope higher than 2500 V/µs.

- In case of higher value, an appropriate filter must

be used : contact converter manufacturer for this

filter definition and selection.

- Strictly follow instructions provided by the

converter manufacturer data sheet for installation.

- Minimum variable speed should not be set below

40% of pump nominal speed.

WILO SE 03/2016

Page 12

WARNING!

When the pumped liquid is hot and the pressure

high, the stream escaping at the air bleed screw

may cause burns or other injuries.

- Open the guard valve on the discharge side completely (3).

- Close the drain-priming plug (5a).

8.2 Starting up

CAUTION!

The pump must not operate at zero flow (closed

discharge valve).

WARNING! Risk of injury!

When the pump runs, coupling guards must be in

place, tightened with all appropriate screws.

WARNING! Important noise!

Noise emitted by most powerful pumps could be

very high : protection must be used in case of long

stay close to the pump.

WARNING!

Installation must be designed in order that no one

could be hurt in case of fluid leakage (mechanical

seal failure …).

9. Maintenance - Service

All servicing should be performed by an authorized service representative!

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

All electrical work must be performed after the

electrical supply has been switched off and

secured against unauthorized switching.

WARNING! Risk of scalding!

At high water temperatures and system pressure

close isolating valves before and after the pump.

First, allow pump to cool down.

- These pumps are maintenance free. Nevertheless

a regular check is recommended every 15 000

hours.

- Optionally, the mechanical seal for certain

models can be replaced easily thanks to its cartridge design.

- In case of pump with half flanges design and installation again after maintenance operation, it is

suggested to add plastic link to maintain in easy

way the half flanges together.

- For pumps equipped with one grease feeder (Fig.

7, pos. 1), respect lubrication frequences mentioned on sticker glued on lantern part (2).

- Insert its adjusting wedge in its housing (Fig. 6)

once mechanical seal position is set.

- Always keep the pump perfectly clean.

- Pumps which are not being used during periods

of frost should be drained to avoid damage:

Close the guard valves, open completely the

drain-priming plug and the air bleed screw.

- Service life : 10 years depending on the operating

conditions and whether all requirements described

in the operation manual have been met.

20

English

8. Start up

8.1 System filling - Venting

CAUTION! Possible damage of the pump!

Never operate the pump dry.

The system must be filled before starting the

pump.

8.1.1 Air evacuation process – Pump with sufficient

supply pressure (Fig. 3)

- Close the two guard valves (2, 3).

- Unscrew the air bleed screw from filling plug

(6a).

- Slowly open the guard valve on the suction side

(2).

- Retighten the air-bleed screw when air escapes

at the air bleed screw and the pumped liquid

flows (6a).

WARNING!

When the pumped liquid is hot and the pressure

high, the stream escaping at the air bleed screw

may cause burns or other injuries.

- Open the guard valve on the suction side completely (2).

- Start the pump and check if direction of rotation

matches the one printed on pump plating. If this

is not the case, interchange 2 phases in the terminal box.

CAUTION!

A wrong direction of rotation will cause bad

pump performances and possibly coupling

damage.

- Open the guard valve on the discharge side (3).

8.1.2 Air evacuation process – Pump in suction

(Fig. 2)

- Close the guard valve on the discharge side (3).

Open the guard valve on the suction side (2).

- Remove the filling plug with air bleed screw (6b).

- Open the drain-priming plug not completely

(5b).

- Fill the pump and the suction pipe with water.

- Make sure that there is no air in the pump and in

the suction pipe : refilling until complete removal

of air is required.

- Close the filling plug with air bleed screw (6b).

- Start the pump and check if direction of rotation

matches the one printed on pump plating. If this

is not the case, interchange two phases in the

terminal box.

CAUTION!

A wrong direction of rotation will cause bad

pump performances and possibly coupling

damage.

- Open the guard valve on the discharge side a

little (3).

- Unscrew the air bleed screw from filling plug for

air venting (6a).

- Retighten the air-bleed screw when air escapes

at the air bleed screw and the pumped liquid

flows.

WILO SE 03/2016

Page 13

21

English

WILO SE 03/2016

10. Defects - causes - remedies

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be excluded.

All electrical work must be performed after the

electrical supply has been switched off and

secured against unauthorized switching.

WARNING! Risk of scalding!

At high water temperatures and system pressure

close isolating valves before and after the pump.

First, allow pump to cool down.

If the fault cannot be solved, please

contact WILO customer services.

11. Spare parts

All spare parts must be ordered through WILO

Customer Services.

In order to avoid any mistakes, please specify the

name plate data for orders.

Spare parts catalogue is available at www.wilo.

com.

12. Safe disposal

Proper disposal and recycling of this product

prevents damage to the environment and risks to

personal health.

Disposal in accordance with the regulations

requires the product to be drained and cleaned.

Lubricants must be collected. The pump components are to be separated according to material

(metal, plastic, electronics).

1. Use public or private disposal organizations

when disposing of all or part of the product.

2. For more information on proper disposal, please

contact your local

council or waste disposal office or the supplier

from whom you obtained the product.

NOTE: The pump must not be disposed of along with

household waste. Further information on recycling

can be found at www.wilo-recycling.com.

Subject to technical alterations!

Defects Causes Remedies

Pump fails to operate No current Check the fuses, the wiring, and the

connectors

The thermistor tripping device has tripped out, cutting off power

Eliminate any cause of overloading of the

motor

Pump runs but delivers too little Wrong direction of rotation Check the direction of rotation of the

motor and correct it if necessary

Parts of the pump are obstructed by foreign bodies

Check and clean the pipe

Air in suction pipe Make the suction pipe airtight

Suction pipe too narrow Install a larger suction pipe

The valve is not open far enough Open the valve properly

Pump delivers unevenly Air in pump Evacuate the air in the pump; check that

the suction pipe is airtight. If required,

start the pump 20-30s – open the air

bleed screw in order to move air away

– close the air bleed screw and repeat it

several times until no more air is going

out of the pump

Pump vibrates or is noisy Foreign bodies in pump Remove the foreign bodies

Pump not properly attached to ground Retighten the screws

Bearing damaged Call WILO Customer Service

Motor overheats. Its protection trips out A phase is open-circuit Check the fuses, the wiring, and the

connectors

Ambient temperature too high Provide cooling

Mechanical seal is leaking Mechanical seal is damaged Replace the mechanical seal

Page 14

Wilo – International (Subsidiaries)

Argentina

WILO SALMSON

ArgentinaS.A.

C1295ABI Ciudad

Autónoma de Buenos Aires

T+ 54 11 4361 5929

info@salmson.com.ar

Australia

WILO Australia Pty Limited

Murrarrie, Queensland,

4172

T +61 7 3907 6900

chris.dayton@wilo.com.au

Austria

WILO Pumpen

ÖsterreichGmbH

2351 Wiener Neudorf

T +43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1014 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2535363

wilo@wilo.by

Belgium

WILO SA/NV

1083Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILOBulgariaLtd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Brazil

WILO Brasil Ltda

Jundiaí – São Paulo – Brasil

ZIPCode:13.213-105

T +55 11 2923 (WILO)

9456

wilo@wilo-brasil.com.br

Canada

WILOCanadaInc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILOChinaLtd.

101300 Beijing

T +86 10 58041888

wilobj@wilo.com.cn

Croatia

WiloHrvatskad.o.o.

10430 Samobor

T +38 51 3430914

wilo-hrvatska@wilo.hr

Czech Republic

WILOCS,s.r.o.

25101Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6 509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILOS.A.S.

78390Boisd‘Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO(U.K.)Ltd.

Burton Upon Trent

DE14 2WJ

T +44 1283 523000

sales@wilo.co.uk

Greece

WILOHellasAG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILOMagyarországKft

2045Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

India

WILOIndiaMatherand

PlattPumpsLtd.

Pune 411019

T +91 20 27442100

services@matherplatt.com

Indonesia

WILO Pumps Indonesia

Jakarta Selatan 12140

T +62 21 7247676

citrawilo@cbn.net.id

Ireland

WILO Ireland

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILOItalias.r.l.

20068Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

info@wilo.kz

Korea

WILOPumpsLtd.

618-220Gangseo,Busan

T +82 51 950 8000

wilo@wilo.co.kr

Latvia

WILOBalticSIA

1019 Riga

T +371 6714-5229

info@wilo.lv

Lebanon

WILO LEBANON SARL

Jdeideh12022030

Lebanon

T +961 1 888910

info@wilo.com.lb

Lithuania

WILOLietuvaUAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

Morocco

WILO MAROC SARL

20600 CASABLANCA

T + 212 (0) 5 22 66 09

24/28

contact@wilo.ma

The Netherlands

WILONederlandb.v.

1551NAWestzaan

T +31 88 9456 000

info@wilo.nl

Norway

WILO Norge AS

0975 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILOPolskaSp.z.o.o.

05-506Lesznowola

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

PortugalLda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILORomanias.r.l.

077040Com.Chiajna

Jud.Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592Moscow

T +7 495 7810690

wilo@wilo.ru

Saudi Arabia

WILOME-Riyadh

Riyadh11465

T +966 1 4624430

wshoula@wataniaind.com

Serbia and Montenegro

WILOBeogradd.o.o.

11000 Beograd

T +381 11 2851278

office@wilo.rs

Slovakia

WILOCSs.r.o.,org.Zložka

83106Bratislava

T +421 2 33014511

info@wilo.sk

Slovenia

WILOAdriaticd.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

SalmsonSouthAfrica

1610Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILOIbéricaS.A.

28806AlcaládeHenares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILOSverigeAB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMBPumpenAG

4310Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILOTaiwanCompanyLtd.

SanchongDist.,NewTaipei

City 24159

T +886 2 2999 8676

nelson.wu@wilo.com.tw

Turkey

WILO Pompa Sistemleri

San.veTic.A.S¸.

34956İstanbul

T +90 216 2509400

wilo@wilo.com.tr

Ukraina

WILOUkrainat.o.w.

01033Kiew

T +38 044 2011870

wilo@wilo.ua

United Arab Emirates

WILO Middle East FZE

JebelAliFreeZone–South

PO Box 262720 Dubai

T +971 4 880 91 77

info@wilo.ae

USA

WILO USA LLC

Rosemont, IL 60018

T +1 866 945 6872

info@wilo-usa.com

Vietnam

WILOVietnamCoLtd.

HoChiMinhCity,Vietnam

T +84 8 38109975

nkminh@wilo.vn

May 2013Furthersubsidiaries,representationandsalesofficesonwww.wilo.com

Page 15

Pioneering for You

WILO SE

Nortkirchenstraße 100

D-44263 Dortmund

Germany

T +49(0)231 4102-0

F +49(0)231 4102-7363

wilo@wilo.com

www.wilo.com

Loading...

Loading...