Page 1

Wilo-Fluidcontrol / - EK

D Montageanleitung

GB Assembly Instructions

F Notice de montage

NL Inbouw- en gebruikshandleiding

E Instrucciones de instalación y funcionamiento

I Istruzioni di montaggio, uso e manutenzione

2 049 542 / ed04-0804

H Beépítési és üzemeltetési útmutató

GR Οδηγίες εγκατάστασης και λειτουργίας

Page 2

6

5

3

2

4

1

12

Fig. 1

10 11 9 8

Page 3

Fig. 2

Fig. 2

Page 4

220-240 V

50 - 60 Hz

M

1

L1

Fig. 4

N

U

V

Fig. 5

7

Page 5

Einbau- und

Betriebsanleitung

Installation and

operating instructions

Notice de montage et

de mise en service

Inbouw- en

gebruikshandleiding

……..6

……12

……18

……24

D

GB

F

NL

Instrucciones de instalación y

funcionamiento

Istruzioni di montaggio, uso e

manutenzione

Beépítési és

üzemeltetési útmutató

Οδηγίες εγκατάστασης

και λειτουργίας

……30

……36

……42

……48

E

I

H

GR

Page 6

ENGLISH

1 General

Installation and service by qualified personnel only!

1.1 Application

The electronic control system Wilo-Fluidcontrol (... EK) can be screw-attached

to water supply and pressure booster pumps. It enables the automatic

operation of these pumps without use of a separate pressure vessel.

Product Information

1.2

1.2.1 Technical Data

Flow medium

Max. capacity

Max. working pressure

Switch on pressure

Max. water temperature:

Power supply:

F.L.C.

Enclosure:

Connections suction/discharge

clean water free of suspended matter

10 m3/h

10 bar

1.5 - 2.7 bar

60° C

Single phase

max. 10 A

IP 65

1" BSP

1~ 220-250V,

50-60 Hz

The shut-off head generated by the applicable pump must be approx. 0.5 bar

higher than the 2.2 bar switch-off pressure.

State all name plate data when ordering spare parts.

2 Safety Notes

These instructions contain basic rules on safety which must be strictly adhered

to on installation and operation. It is therefore imperative for the Installer and

the Operator to read these instructions prior to installation and commissioning.

Please observe, not only the general safety references listed under the main

heading SAFETY NOTES, but also those added to and specially highlighted

under the ensuing headers.

12 (55)

Page 7

ENGLISH

2.1 Safety symbols contained herein

Safety notes contained herein which, if not strictly adhered to, may cause injury

to persons are specially highlighted by general danger symbol:

Warnings from electrical causes by the special symbol:

Safety references which, if not complied with, may result in damage to the plant

or its function are marked by the word:

ATTENTION!

2.2 Trade Qualifications

Only suitably qualified personnel may work on this equipment.

2.3 Hazards arising from non-compliance with safety notes

Non compliance with safety notes may cause bodily harm to persons or

damage to the plant. Failure to comply with safety notes may invalidate any

damage claims. Non-compliance may, for example, lead to the following

hazardous consequences:

● failure of vital plant functions,

● hazards to persons due to electrical and/or mechanical causes.

2.4 Safety notes for the Operator

Local regulations regarding the prevention of accidents must be observed.

Hazards from electrical energy must be excluded (conforming to local or

general regulations such as EC, BSI, UL, VDE, etc.).

2.5 Safety rules for inspections and installation work.

It is the Operator's responsibility to ensure that inspection and installation

works are carried out by authorized and qualified personnel only, after

having made themselves fully conversant with these instructions.

Work on this plant must on principle be carried out with the plant switched off

and completely pressure-relieved.

The safety valve must not be removed.

2.6 Arbitrary alterations and spare part procurement

Any alterations to the plant are only permitted with the manufacturers' consent.

Original and manufacturer authorized spare parts serve safety. The use of

other parts can invalidate any claims for consequential damages.

13 (55)

Page 8

ENGLISH

2.7 Non-permissible operating conditions

Operational safety of the plant is conditional on it being used in accordance

with Chapter 1 of these instructions. Operational criteria must not exceed or

fall short of the limits stated in catalogue/data sheets.

3 Transport and Storage

ATTENTION!

During transport and intermediate storage it is necessary

to protect the WILO-Fluidcontrol from moisture and

mechanical damage.

The stock location must be dry and be frost-free.

4 Description of the Product

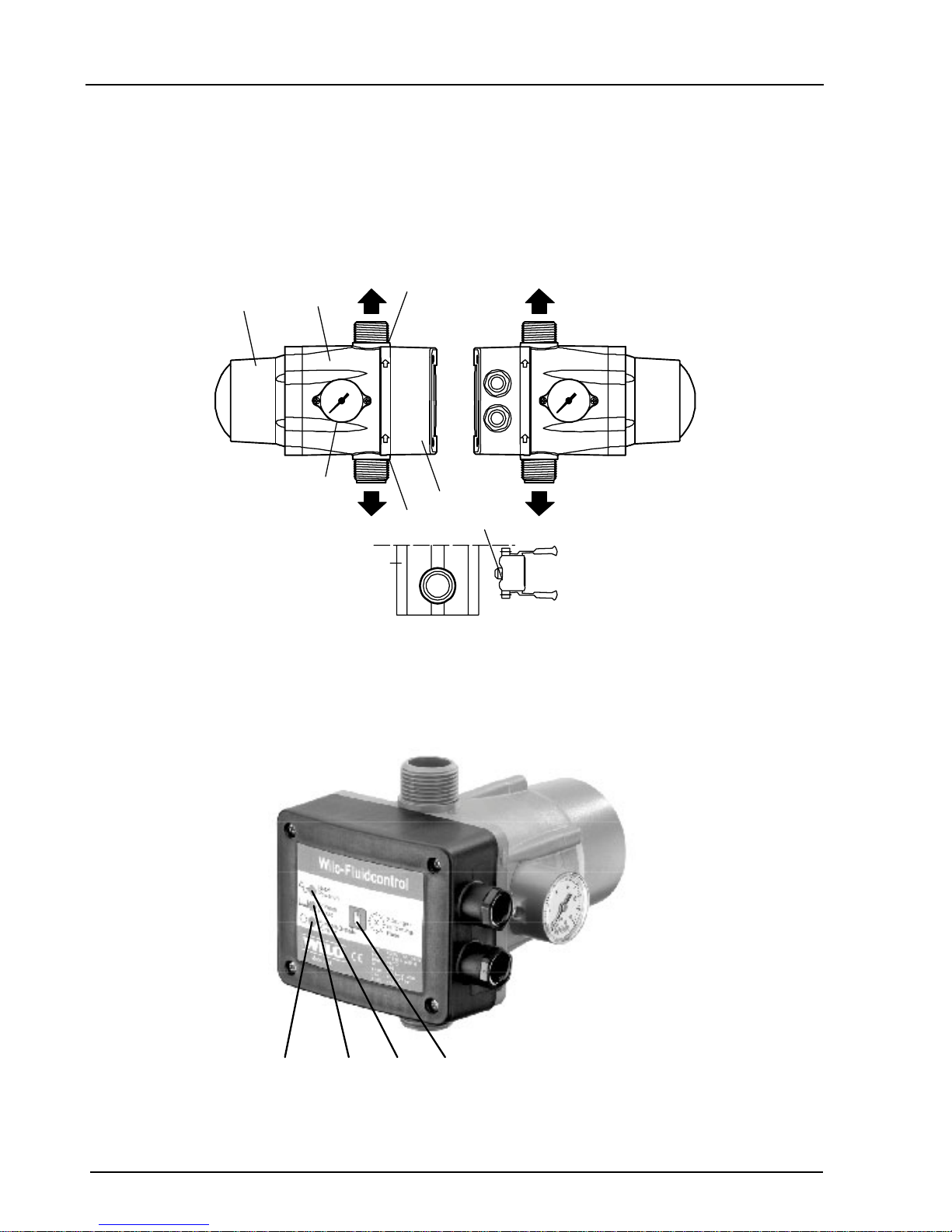

4.1 Description of the Device (Fig. 1 & 2)

1. Suction port with integrated non-return valve

2. Delivery port

3. Pressure gauge (0-10 bars) for control – possible mounting on right or left

side.

4. Electric box with electronic board including a protection against dry

running with motor stop and connection box for pump and network.

5. Hydraulic chamber with diaphragm.

6. Compensating chamber with spring.

7. Adjusting screw for starting pressure of the pump.

8. Reset button (Störungs-quittierung/Reset).

9. Indicator light of the voltage (Netz/Power on).

10. Indicator light for pump running (Pumpe in Betrieb/Pump on).

11. Indicator light for activating the safety device (Störung/Failure)

12. Pressure gauge axis

The WILO-Fluidcontrol is offered as ancilliary equipment for WILO water

supply pumps.

The unit must be screwed onto the pump or into the discharge pipe. It is of

Inline design, with both connections axially in line.

On ready standby, with all outlet fitting closed and under max. system pressure,

the yellow LED is on (pos. 9).

The unit contains a small buffer space filled with water which can be varied by

means of a spring-tensioned diaphragm. If an outlet tap in the system is

opened water will flow out of the small buffer volume into the discharge pipe,

lifting the float.

14 (55)

Page 9

ENGLISH

The green diode (pos. 10) indicates normal pump operation.

The switch unit contains the electronic as well as the terminal block for power

supply and pump motor. The signal/operating elements at the switchbox cover

are (Fig. 2)

● Yellow LED: Mains power is on, the pump is on ready standby, (pos. 9)

● Green LED: Pump runs, (pos. 10)

● Red LED: Any fault leading to pressure loss in the

pipe system, (pos. 11)

● Reset button: After fault rectification the reset button (pos. 8) must be kept

pushed until the system is fully pressurized. This is also valid for renewed

start-up, otherwise the pump will again fail due to insufficient system

pressure.

4.2 Scope of Supply

● Wilo-Fluidcontrol (EK-series + integrated socket + 1.5 m connecting

cable).

● Installation and Operating Instructions.

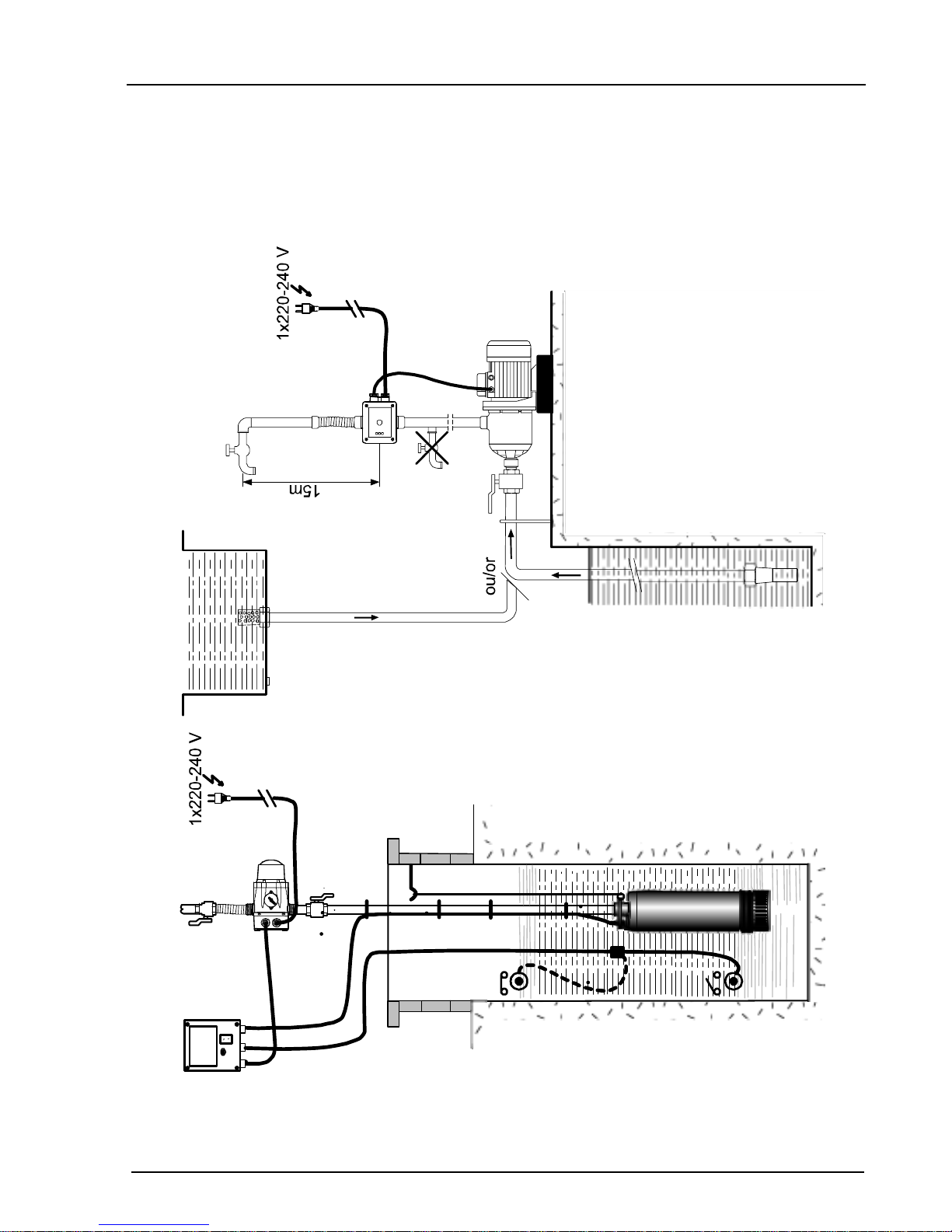

5 Siting/Installation

5.1 Installation

For installation and mounting requirements refer to the pump installation and

operating instructions.

The arrow at the housing indicates direction of flow.

The WILO-Fluidcontrol must only be mounted into a vertically run discharge

pipe.

● The WILO-Fluidcontrol to be screwed onto the discharge port of the pump

using

suitable connecting fittings, to be sealed with hemp or Teflon band.

● If the water column between pump and highest outlet tap exceeds 15 m,

the unit must be installed at a higher level in the discharge pipe ensuring

a maximum vertical head onto the unit of not more than 15 m. In such

case no outlet tap must be located at a level below that of the WILOFluidcontrol (Fig. 3).

● In order to avoid noise transmission from the pump onto the pipe system

it is recommended to provide and install a flexible connector at the

discharge side of theWILO-Fluidcontrol.

15 (55)

Page 10

ENGLISH

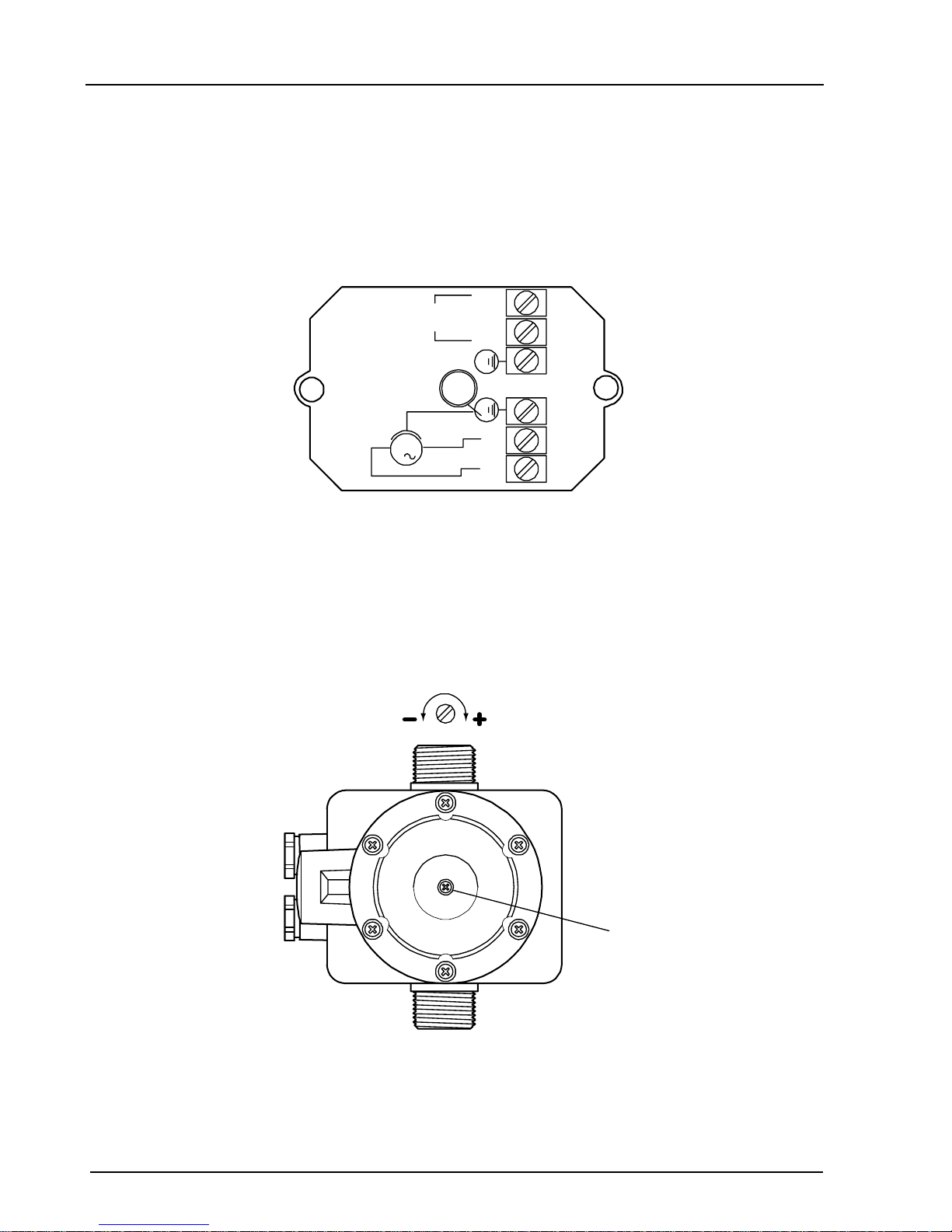

5.2 Electrical Wiring

All electrical site works to be carried out by qualified and

locally licenced electricians strictly in accordance with locally

● Check available power supply,

● take note of pump name plate data requirements,

● power wiring 3 x 1.5 mm". (Minimum cable size 6 mm, maximum 9 mm

OD).

● To ensure water tightness and pull-force relief from the cable glands the

power

cable must be of sufficient outside diameter (e.g. 05 VV-F 3 (7) G 1,5

oder AVMH-I 3 (7) x 1,5).

● All electrical wiring to be executed according to Fig.4.

● Supply side fuse: see as for pump; maximum however 10 A, inert.

ruling regulations.

● Strictly adhere to local earthing regulations.

● If required (see VDE 0100), a ground fault circuit interruptor (GFCI)switch

must be provided and installed by others.

6 Commissioning

For possibly required prestart and commissioning procedures for the pump

refer to the separate installation and Operating Instruction for the pump.

Before initial start-up it must be ensured that sufficient suction capability is

available and that the pump is primed and filled.

On initial start-up the pump will run for 8 seconds, after that a renewed start-up

can be effected by keeping the reset button pushed.

7 Maintenance

Warning!

Electrical Shock Hazard!

Prior to maintenance or repair work turn off the pump and

ensure that it is not turned on by unauthorised personnel.

16 (55)

Page 11

ENGLISH

8 Faults, Causes

Fault Unit-related Cause Unit-unrelated Cause

Pump does not start - defect printed circuit board

- defect diaphragm

Pump does not stop - defect printed circuit board

- jammed flow controller - stuck

reset button

- Pump does not generate sufficient

pressure

Pump runs irregularly - defekt printed circuit board

- Pump does not generate sufficient

pressure (air)

Pump is jammed - defect printed circuit board

- pump generates pressure < start

pressure

- defect diaphragm

- refer to Installation & Maintenance

Instr. of the pump

- Power failure

- Pump capacity too low

- Pump mechanically jammed

- WILO-Fluidcontrol wrongly

connected

- Lack of water at suction side

- Leakage loss greater than 0.6

l/min

- Leakage loss greater than 0.6

l/min

- Lack of water at suction side

- Pump capacity too low

If the fault cannot be located or rectified, please contact your nearest

Wilo representative.

Technical modifications reserved!

17 (55)

Page 12

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T +49 231 4102-0

F +49 231 4102-7363

www.wilo.com

Algeria

Bad Ezzouar, Dar El

Beida

T +213 21 247979

chabane.hamdad@

salmson.fr

Armenia

375001 Yerevan

T +374 10 544336

info@wilo.am

Bosnia and

Herzegovina

71000 Sarajevo

T +387 33 714510

zeljko.cvjetkovic@

wilo.ba

Georgia

0177 Tbilisi

T +995 32317813

info@wilo.ge

Macedonia

1000 Skopje

T +389 2 3122058

valerij.vojneski@

wilo.com.mk

Moldova

2012 Chisinau

T +373 2 223501

sergiu.zagurean@wilo.md

Rep. Mongolia

Ulaanbaatar

T +976 11 314843

wilo@magicnet.mn

Tajikistan

734025 Dushanbe

T +992 37 2232908

farhod.rahimov@wilo.tj

Turkmenistan

744000 Ashgabad

T +993 12 345838

wilo@wilo-tm.info

Uzbekistan

700046 Taschkent

sergej.arakelov@wilo.uz

January 2008

Wilo – International (Subsidiaries)

Wilo – International (Representation offices)

Argentina

WILO SALMSON

Argentina S.A.

C1270ABE Ciudad

Autónoma de Buenos

Aires

T +54 11 43015955

info@salmon.com.ar

Austria

WILO Handelsges.

m.b.H.

1230 Wien

T +43 5 07507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1065 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2503393

wilobel@wilo.by

Belgium

WILO SA/NV

1083 Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILO Bulgaria Ltd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Canada

WILO Canada Inc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILO China Ltd.

101300 Beijing

T +86 10 80493900

wilobj@wilo.com.cn

Croatia

WILO Hrvatska d.o.o.

10090 Zagreb

T +38 51 3430914

wilo-hrvatska@wilo.hr

Czech Republic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILO S.A.S.

78390 Bois d'Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO (U.K.) Ltd.

DE14 2WJ BurtonUpon-Trent

T +44 1283 523000

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILO Magyarország

Kft

2045 Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

Ireland

WILO Engineering Ltd.

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 3272 785961

in.pak@wilo.kz

Korea

WILO Pumps Ltd.

621-807 Gimhae

Gyeongnam

T +82 55 3405800

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 7 145229

mail@wilo.lv

Lebanon

WILO SALMSON

Lebanon

12022030 El Metn

T +961 4 722280

wsl@cyberia.net.lb

Lithuania

WILO Lietuva UAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

The Netherlands

WILO Nederland b.v.

1948 RC Beverwijk

T +31 251 220844

info@wilo.nl

Norway

WILO Norge AS

0901 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILO Polska Sp. z.o.o.

05-090 Raszyn

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal Lda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILO Romania s.r.l.

077040 Com. Chiajna

Jud. Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592 Moscow

T +7 495 7810690

wilo@orc.ru

Saudi Arabia

WILO ME - Riyadh

Riyadh 11465

T +966 1 4624430

wshoula@wataniaind.com

Serbia and

Montenegro

WILO Beograd d.o.o.

11000 Beograd

T +381 11 2850242

office@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

82008 Bratislava 28

T +421 2 45520122

wilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

Salmson South Africa

1610 Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILO Ibérica S.A.

28806 Alcalá de

Henares (Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 8368020

info@emb-pumpen.ch

Taiwan

WILO-EMU

Taiwan Co. Ltd.

110 Taipeh

T +886 227 391655

nelson.wu@

wiloemutaiwan.com.tw

Turkey

WILO Pompa Sistemleri

San. ve Tic. A.S¸.

34530 Istanbul

T +90 216 6610211

wilo@wilo.com.tr

Ukraina

WILO Ukraina t.o.w.

01033 Kiew

T +38 044 2011870

wilo@wilo.ua

Vietnam

Pompes Salmson

Vietnam

Ho Chi Minh-Ville

Vietnam

T +84 8 8109975

nkm@salmson.com.vn

United Arab Emirates

WILO ME - Dubai

Dubai

T +971 4 3453633

info@wilo.com.sa

USA

WILO-EMU USA LLC

Thomasville,

Georgia 31792

T +1 229 5840097

info@wilo-emu.com

USA

WILO USA LLC

Melrose Park,

Illinois 60160

T +1 708 3389456

mike.easterley@

wilo-na.com

Page 13

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Germany

T 0231 4102-0

F 0231 4102-7363

wilo@wilo.de

www.wilo.de

G1 Nord

WILO AG

Vertriebsbüro Hamburg

Beim Strohhause 27

20097 Hamburg

T 040 5559490

F 040 55594949

hamburg.anfragen@wilo.de

G2 Ost

WILO AG

Vertriebsbüro Berlin

Juliusstraße 52–53

12051 Berlin-Neukölln

T 030 6289370

F 030 62893770

berlin.anfragen@wilo.de

G3 Sachsen/Thüringen

WILO AG

Vertriebsbüro Dresden

Frankenring 8

01723 Kesselsdorf

T 035204 7050

F 035204 70570

dresden.anfragen@wilo.de

G4 Südost

WILO AG

Vertriebsbüro München

Landshuter Straße 20

85716 Unterschleißheim

T 089 4200090

F 089 42000944

muenchen.anfragen@wilo.de

G5 Südwest

WILO AG

Vertriebsbüro Stuttgart

Hertichstraße 10

71229 Leonberg

T 07152 94710

F 07152 947141

stuttgart.anfragen@wilo.de

G6 Rhein-Main

WILO AG

Vertriebsbüro Frankfurt

An den drei Hasen 31

61440 Oberursel/Ts.

T 06171 70460

F 06171 704665

frankfurt.anfragen@wilo.de

G7 West

WILO AG

Vertriebsbüro Düsseldorf

Westring 19

40721 Hilden

T 02103 90920

F 02103 909215

duesseldorf.anfragen@wilo.de

Kompetenz-Team

Gebäudetechnik

WILO AG

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7516

T 01805 R•U•F•W•I•L•O*

7•8•3•9•4•5•6

F 0231 4102-7666

Kompetenz-Team

Kommune

Bau + Bergbau

WILO EMU GmbH

Heimgartenstraße 1

95030 Hof

T 09281 974-550

F 09281 974-551

Werkskundendienst

Gebäudetechnik

Kommune

Bau + Bergbau

Industrie

WILO AG

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7900

T 01805 W•I•L•O•K•D*

9•4•5•6•5•3

F 0231 4102-7126

Erreichbar Mo–Fr von

7–17 Uhr.

Wochenende und feiertags 9–14 Uhr elektronische Bereitschaft mit

Rückruf-Garantie!

– Kundendienst-

Anforderung

– Werksreparaturen

– Ersatzteilfragen

– Inbetriebnahme

– Inspektion

– Technische Service-

Beratung

– Qualitätsanalyse

Wilo-International

Österreich

Zentrale Wien:

WILO

Handelsgesellschaft mbH

Eitnergasse 13

1230 Wien

T +43 5 07507-0

F +43 5 07507-15

Vertriebsbüro Salzburg:

Gnigler Straße 56

5020 Salzburg

T +43 5 07507-13

F +43 5 07507-15

Vertriebsbüro

Oberösterreich:

Trattnachtalstraße 7

4710 Grieskirchen

T +43 5 07507-26

F +43 5 07507-15

Schweiz

EMB Pumpen AG

Gerstenweg 7

4310 Rheinfelden

T +41 61 8368020

F +41 61 8368021

Standorte weiterer

Tochtergesellschaften

Argentinien, Aserbaidschan,

Belarus, Belgien, Bulgarien,

China, Dänemark, Estland,

Finnland, Frankreich,

Griechenland, Großbritannien,

Irland, Italien, Kanada,

Kasachstan, Korea, Kroatien,

Lettland, Libanon, Litauen,

Niederlande, Norwegen,

Polen, Portugal, Rumänien,

Russland, Saudi-Arabien,

Schweden, Serbien und

Montenegro, Slowakei,

Slowenien, Spanien,

Südafrika, Taiwan,

Tschechien, Türkei, Ukraine,

Ungarn, Vereinigte Arabische

Emirate, Vietnam, USA

Die Adressen finden Sie

unter www.wilo.de oder

www.wilo.com.

Stand Januar 2008

Wilo-Vertriebsbüros in Deutschland

Erreichbar Mo–Fr von 7–18 Uhr.

– Antworten auf

– Produkt- und Anwendungsfragen

– Liefertermine und Lieferzeiten

– Informationen über Ansprechpartner vor Ort

– Versand von Informationsunterlagen

* 14 Cent pro Minute aus dem deutschen Festnetz

der T-Com. Bei Anrufen aus Mobilfunknetzen

sind Preisabweichungen möglich.

Loading...

Loading...