Willoughby Stainless Fountains WODF-1, WODF-2-CHD, WODF-2-PET, WODF-3-CHD-PET, WODF-2-HC Installation & Operation Manual

...

WODF-1

Installation &

Operation Manual

WODF Series

One-, Two-, and Three-station

Outdoor Drinking Fountains

Table of Contents

Pre-Installation Information �������������������������������������3

Standard Fountain Congurations �������������������������� 4

Physical Dimensions ����������������������������������������������5

Rough-in Dimensions ���������������������������������������������6

Required Installation Supplies �������������������������������� 8

Parts List and Exploded-view Drawings ����������������� 9

Hardware Identication ����������������������������������������12

Installation Instructions ���������������������������������������������

Step 1: Fixture Installation �������������������������������13

Step 2: Adjusting Drinking Spout Flow �������������14

Care and Maintenance �����������������������������������������15

Troubleshooting ��������������������������������������������������������

WODF Drinking Fountain ���������������������������������16

Drawings �������������������������������������������������������������������

Physical Dimensions ����������������������������������������17

Rough-in Dimensions ���������������������������������������20

Push Button Details ������������������������������������������ 22

Freeze Resistant Valve Installation Details������� 23

Warranty ���������������������������������������������������������������26

Rev. 3/2018

Willoughby Stainless Fountains

5105 West 78th Street

Indianapolis, IN 46268

Toll Free: (800) 428-4065

Local: (317) 875-0830

Fax: (317) 875-0837

www.willoughbystainlessfountains.com

MADE IN THE U.S.A.

Outdoor Drinking Fountains

WODF Series

(Page intentionally left blank)

Installation & Operation Manual

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 2Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

INSTALLATION INSTRUCTIONS

Installation notice!

INSTALLATION INSTRUCTIONS

Installation notice!

WODF Series

Installation & Operation Manual

Pre-Installation Information

Check Rough-In location PRIOR to installation

Flush lines thoroughly PRIOR to hook-up

When installing the Willoughby Stainless Fountains' WODF Series drinking fountain system:

Before step 1 of the installation instructions, ensure that rough-ins are in the correct location.

The valve assembly, including the spray head, MUST NOT BE connected until after all lines have

been ushed to remove the small particles of debris that are inherent with new construction projects

and all chemicals that are used in ushing are purged from the system.

Chemicals used in ushing plumbing systems can attack the internal components of the valve and

spray head and severely damage them, so any ushing of the system must be followed by a full

ushing with pure water to clear any harsh chemicals remaining in the system. Debris in the system if

allowed to enter the valve assembly and spray head can cause poor performance or outright failure.

Again DO NOT attempt to connect the valve assembly and spray head until after all ushing is

complete and pure water is the only media that will be passing through the system. Damage to the

valve assembly or spray head caused by harsh chemicals or debris will not be covered by the

manufacturer's warranty�

Any ttings provided by the installer should be made of plastic to electrically isolate the unit from the

building or connected plumbing system.

The grounding of electric equipment such as telephones, computers, etc, to water lines is a common

procedure. This grounding can cause electrical feedback into a water fountain or similar xture,

causing electrolysis, which results in a metallic taste or an increase in the metal content of the water.

This can easily be avoided by using the proper materials as indicated.

Check Rough-In location PRIOR to installation

Flush lines thoroughly PRIOR to hook-up

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 3Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

WODF Series

Installation & Operation Manual

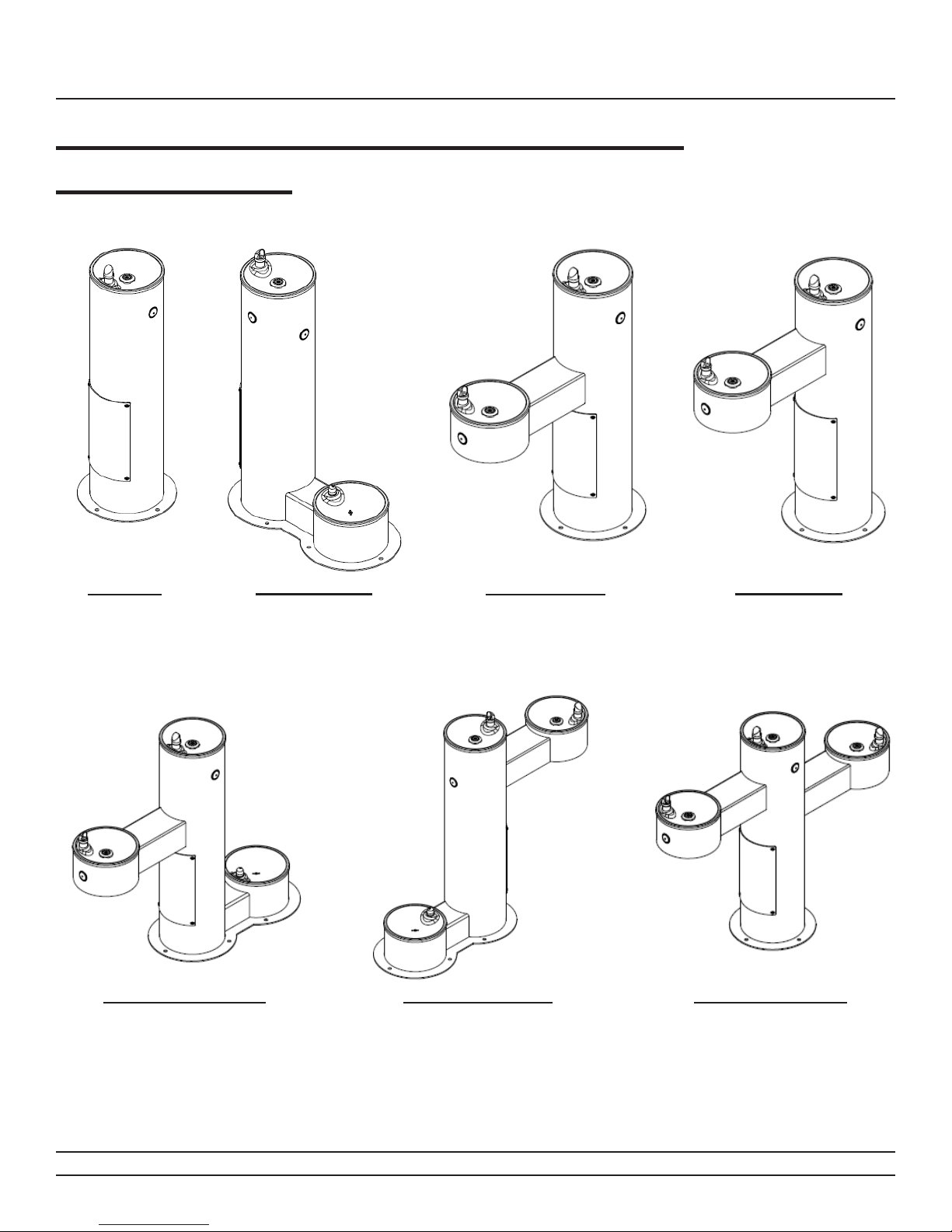

Standard Fountain Congurations-

WODF Series

WODF-1

WODF-3-CHD-PET WODF-3-HC-PET WODF-3-HC-CHD

WODF-2-PET

WODF-2-CHD

WODF-2-HC

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 4Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

WODF Series

Installation & Operation Manual

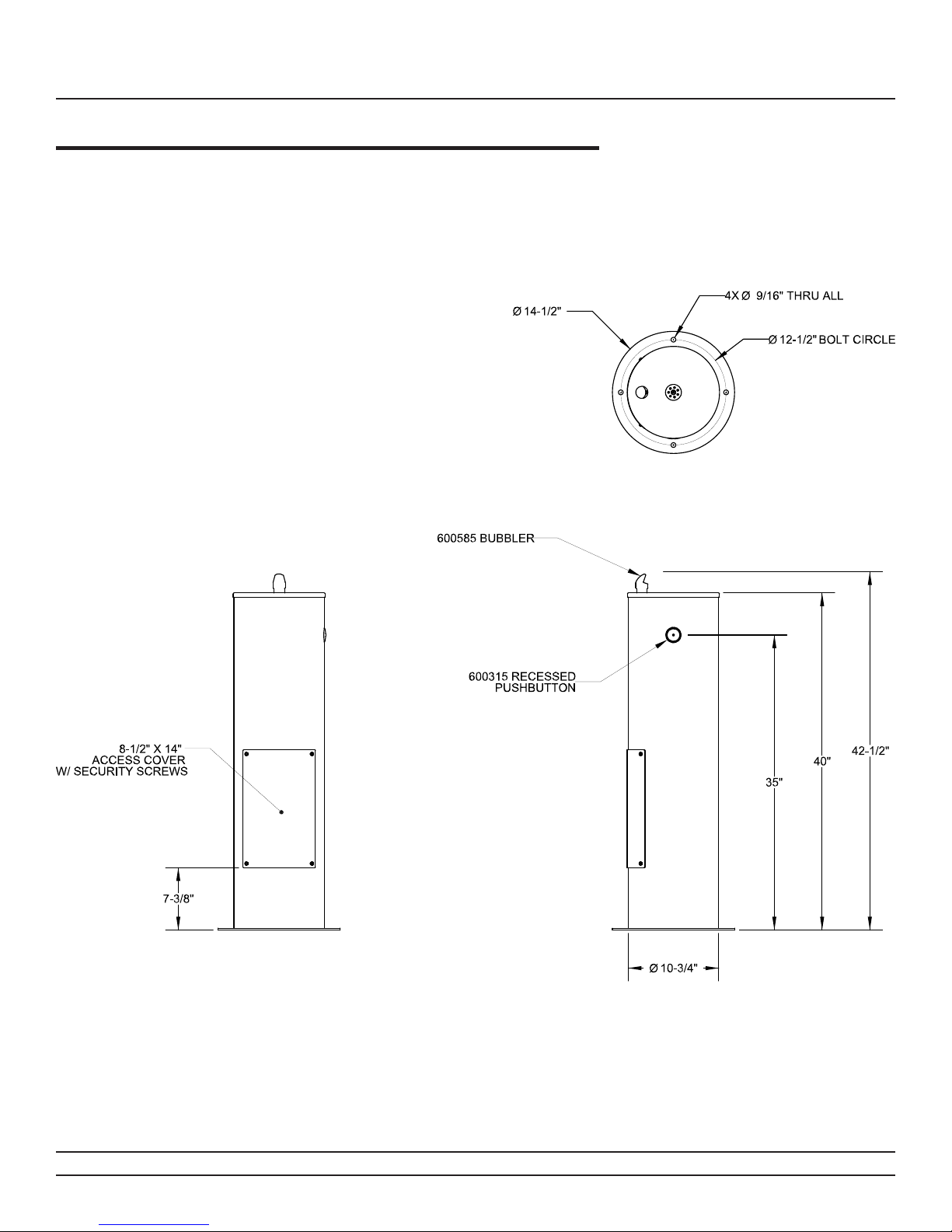

Physical Dimensions- WODF-1

*WODF-1 shown; for WODF-2 and WODF-3 model variations, refer to

factory drawings. Contact Willoughby Stainless Fountains if further

information is needed.

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 5Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

WODF Series

Installation & Operation Manual

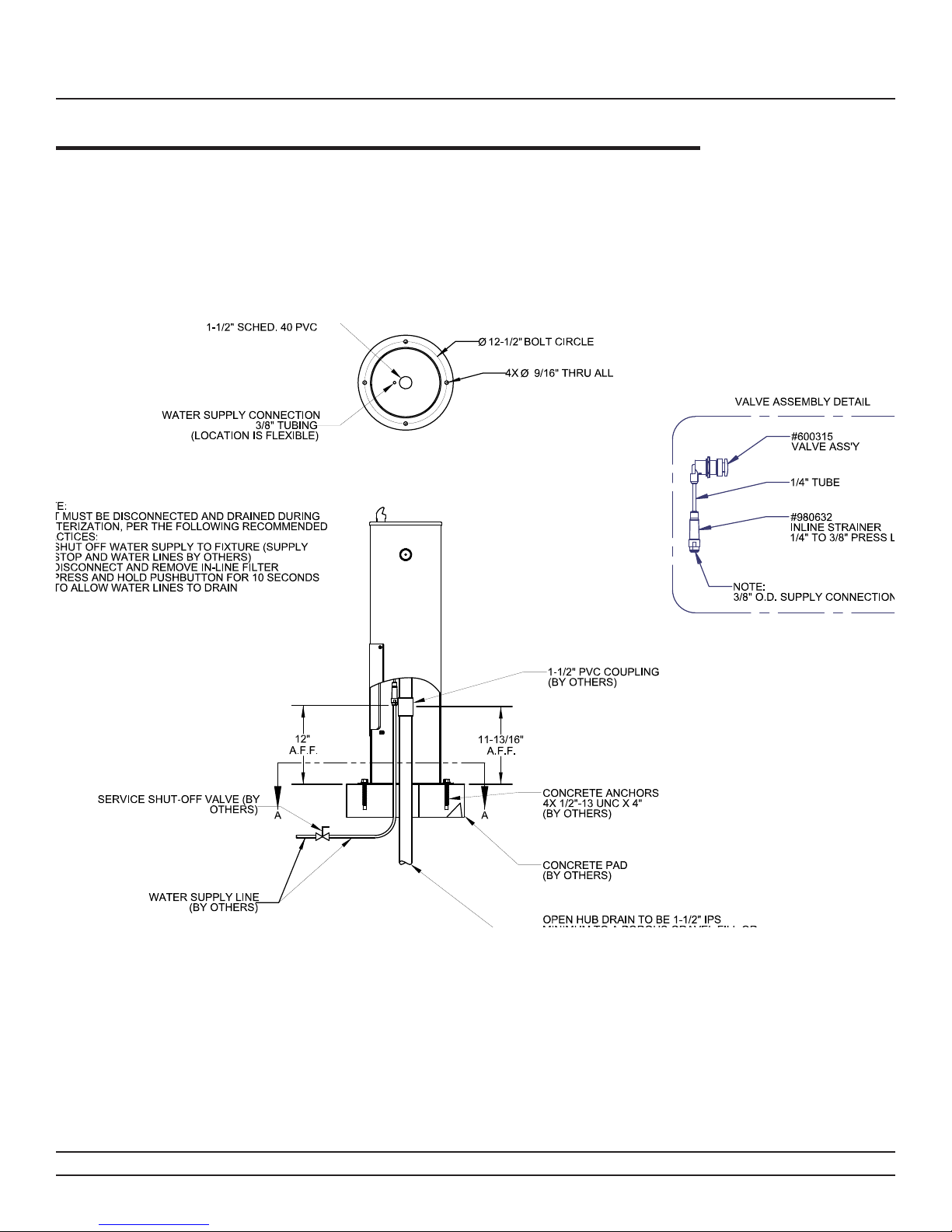

Rough-in Dimensions- WODF Series

*WODF-1 shown; applicable to all WODF-2 and WODF-3 model variations

without Pet Fountain

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 6Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

WODF Series

Installation & Operation Manual

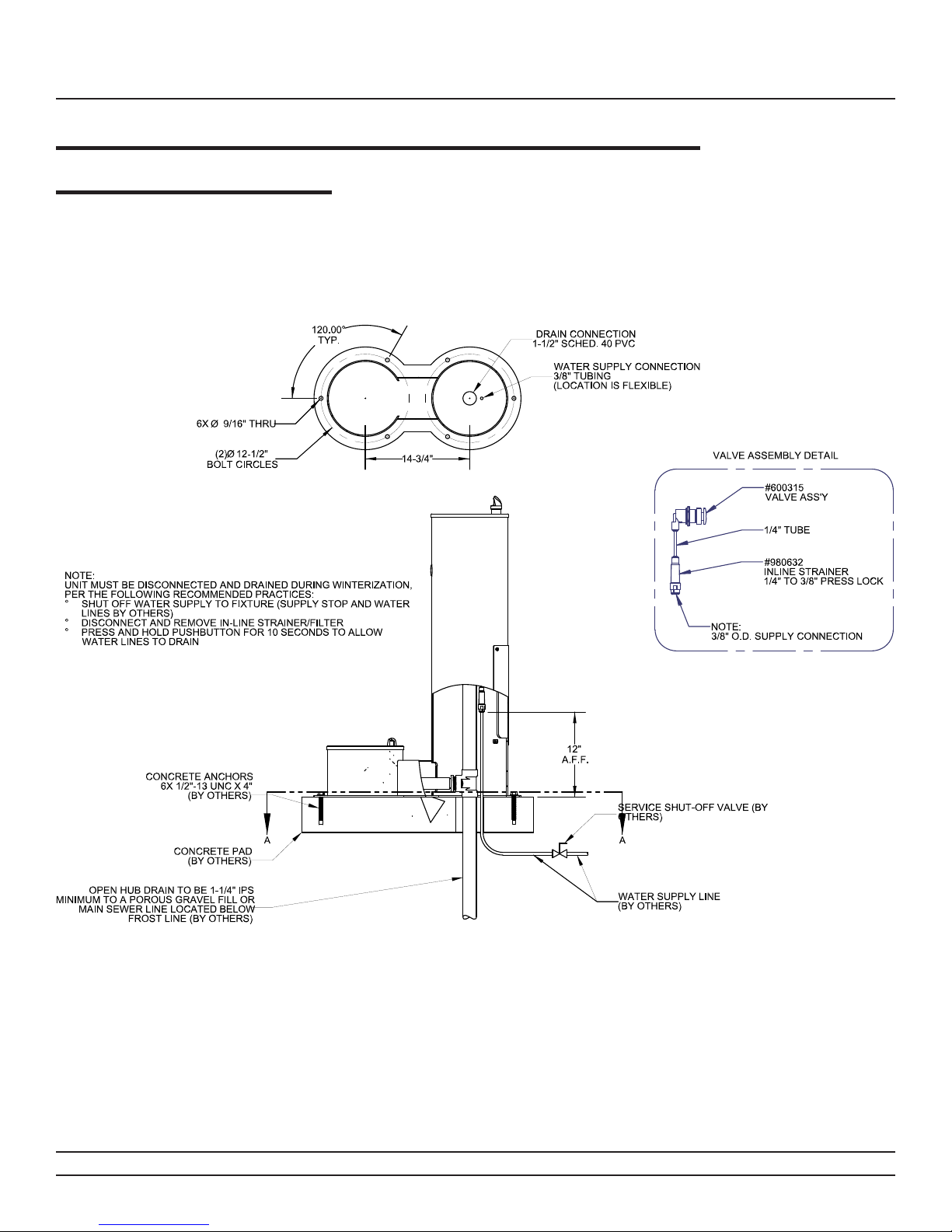

Rough-in Dimensions- WODF Series

w/ Pet Fountain

*WODF-2-PET shown; applicable to all WODF-2 and WODF-3 model

variations with Pet Fountain

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 7Rev. 3/2018 www.willoughbystainlessfountains.com

Outdoor Drinking Fountains

WODF Series

Required Installation Supplies

• Proper mounting hardware

• Proper plastic ttings as indicated

• Hardware for waste oulet connections

• Gasket for waste outlet connection

• Shims (for installation if necessary)

• Supply piping

• Silicone caulk

Installation & Operation Manual

• Plumbers putty

WARNING: Willoughby Stainless Fountains does not assume

any responsibility for personal injury or damage to equipment

due to an improperly installed WODF Series Drinking

Fountain

Willoughby Stainless Fountains

TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 8Rev. 3/2018 www.willoughbystainlessfountains.com

Loading...

Loading...