Willoughby E1L1, E1L2 Installation & Operation Manual

Material:

2 Of 3

Part Number:

E1L11

2 Places +/- �03

3 Places +/- �015

Fractions +/- 1/32"

B

Willoughby Industries Inc.

Indianapolis, Indiana

Sheet:

Tolerances

Except as

N/A

Noted

Date:

Title or Part Description:

Drawing #:

Revision #:

E1L11 SINGLE TEMP ELECTRONIC VALVE ASSEMBLY O&M PAGE 2 ISO

TRB

STANDARD DWG�

980576

Job Name:

3/15/11

Drawn By:

N/A

Scale:

1:8

Qty:

Angle +/- 1

11/13/12

3

2

1

5 6

7

4

8

9

10

OPTIONAL 3/8" x 3/8" ELBOW

8

10

7

8

6

1

10

11

5

4

3

2

9

OPTIONAL 3/8" x 3/8"

ELBOW

N/A

2 Places +/- �03

3 Places +/- �015

Fractions +/- 1/32"

Title or Part Description:

Material:

N/A

Job Name:

Drawn By:

Date:

Revision #:

E1L21 DUAL TEMP ELECTRONIC VALVE ASSEMBLY O&M PAGE 4 ISO

TRB

Drawing #:

A

980610

Approved By:

Part Number:

E1L21

5/1/12

Scale:

1:8

Qty:

Sheet:

2 Of 3

Angle +/- 1

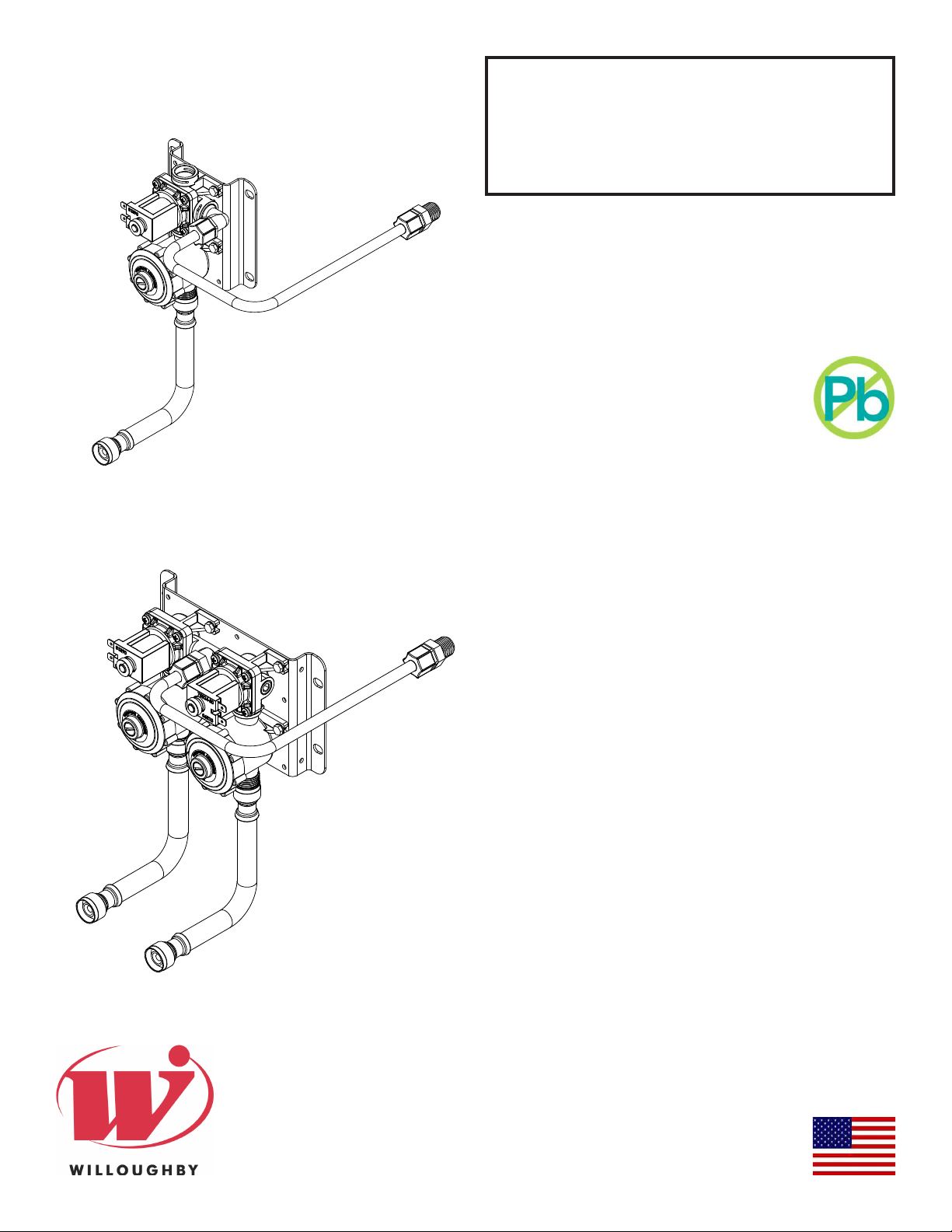

Installation &

Operation Manual

E1L1 and E1L2

Lead-Free Electronic Series

Valves

(Plastic Bodied)

Table of Contents

Pre-Installation Information �������������������������������������3

General Specications ��������������������������������������������4

E1L1

E1L2

Physical Dimensions ������������������������������������������������

E1L1 Single Temp Solenoid Valve Assembly

#980408 �������������������������������������������������������������� 5

E1L11 Valve Breakdown �������������������������������������6

E1L12 Manifold Valve Breakdown ���������������������� 7

E1L21 Valve Breakdown������������������������������������� 8

E1L22 Manifold Valve Breakdown ���������������������� 9

Checking Contents ����������������������������������������������� 11

Installation Instructions ����������������������������������������� 12

Electronic Piezo Switch Detail �������������������������� 13

Jaco Fitting Instructions ������������������������������������ 14

Care and Maintenance ���������������������������������������������

Electronic Valve Assembly Operation and

Maintenance ����������������������������������������������������� 15

Cleaning Instructions ���������������������������������������� 16

Troubleshooting Electronic Valves �����������������������17

Replacement Part Numbers �������������������������������������

E1L1 Single Temp Solenoid Valve Assembly

#980408 ������������������������������������������������������������ 18

Checkstop Breakdown P/N 980183 ������������������19

Drawings ������������������������������������������������������������������

Pushbutton Assembly #600313 ������������������������ 20

Pushbutton Assembly #600314LR ������������������� 21

Warranty ���������������������������������������������������������������22

Rev. 6/2019

Willoughby Industries, Inc.

5105 West 78th Street

Indianapolis, IN 46268

Toll Free: (800) 428-4065

Local: (317) 875-0830

Fax: (317) 875-0837

www.willoughby-ind.com

MADE IN THE U.S.A.

E1L1 and E1L2

Electronic Series Valves

(Page left intentionally blank)

Installation & Operation Manual

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 2www.willoughby-ind.comRev. 6/2019

E1L1 and E1L2

INSTALLATION INSTRUCTIONS

Installation notice!

INSTALLATION INSTRUCTIONS

Installation notice!

Electronic Series Valves

Installation & Operation Manual

Pre-Installation Information

Check Rough-In location PRIOR to installation

Flush lines thoroughly PRIOR to hook-up

When installing the Willoughby Industries' E1L1 and E1L2 Lead-free Electronic Series Valves:

Before step 1 of the installation instructions, ensure that rough-ins are in the correct location�

The valve assembly, including the spray head, MUST NOT BE connected until after

all lines have been ushed to remove the small particles of debris that are inherent

with new construction projects and all chemicals that are used in ushing are purged

from the system�

Chemicals used in ushing plumbing systems can attack the internal components of

the valve and spray head and severely damage them, so any ushing of the system

must be followed by a full ushing with pure water to clear any harsh chemicals

remaining in the system� Debris in the system if allowed to enter the valve assembly

and spray head can cause poor performance or outright failure�

Again DO NOT attempt to connect the valve assembly and spray head until after all

ushing is complete and pure water is the only media that will be passing through the

system� Damage to the valve assembly or spray head caused by harsh chemicals or

debris will not be covered by the manufacturer's warranty�

Check Rough-In location PRIOR to installation

Flush lines thoroughly PRIOR to hook-up

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 3www.willoughby-ind.comRev. 6/2019

E1L1 and E1L2

Electronic Series Valves

Installation & Operation Manual

General Specications

Electronic valve assembly shall be Willoughby Model No� E1L1 or E1L2 as noted� Valve shall be constructed of plastic and stainless steel materials and complies with NSF-61 standard�

Stainless steel pushbutton switches on the xture shall be wired to an appropriate electronic valve

control (select from the list of control choices)� The vandalproof pushbuttons shall be keyed and

non-removable from the front of the xture. The pushbuttons shall require less than 5 lbs. of force to

operate�

The single temperature solenoid valve assembly shall include a stainless steel screwdriver stop and

an integral mounting bracket. Replaceable stainless steel strainer and optional 0.5 GPM ow

control shall be eld serviceable. The connection to the ller/bubbler/showerhead shall be 3/8" O.D.

exible tubing. The water inlet shall be 1/2" FPT (S/S exible supply line) and shall be reversible for

either top or bottom supply� Valve assembly shall be accessible from the pipe chase only�

Flexible tubing shall be supplied for walls up to 8 inches thick� Recommended operating pressure

shall be 35-70 psi� The valve shall withstand pressures up to 90 psi� Cost reducing manifolded

valves shall consist of multiple valve assemblies served by a common supply line� A 24 volt AC

source shall be required for timer and valve operation.

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 4www.willoughby-ind.comRev. 6/2019

E1L1 and E1L2

3 Places +/- �015

3/15/11

Willoughby Industries Inc.

Indianapolis, Indiana

Tolerances

Except as

Title or Part Description:

Material:

Drawn By:

Date:

Revision #:

Drawing #:

Fractions +/- 1/32"

Approved By:

TRB

Sheet:

980408

Job Name:

Part Number:

N/A

Scale:

Qty:

E1L VALVE ASSEMBLY

1 Of 1

E

Noted

2 Places +/- �03

Angle +/- 1

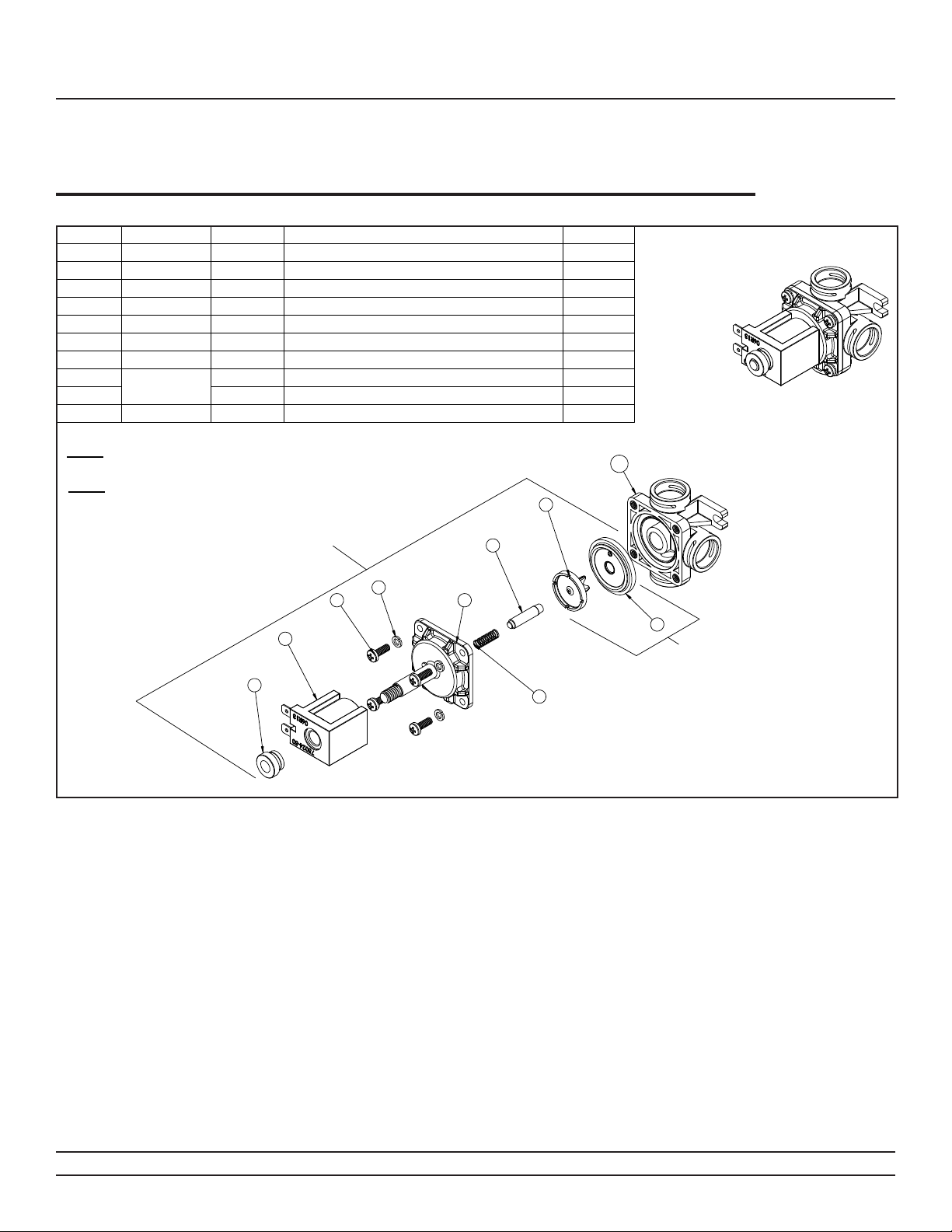

ITEM # SUB-ASSY# PART # DESCRIPTION QTY�

WILLOUGHBY

Electronic Series Valves

Installation & Operation Manual

Physical Dimensions

E1L1 Single Temp Solenoid Valve Assembly #980408

1 N/A 980534 NYLON NUT, 5/16-18 1

2 N/A 980532 COIL, 24V DC 1

3 N/A 980170 #8-32 x 1/2 " SCREW 4

4 N/A 980002 SPLIT LOCK WASHER 4

5 N/A 980530 ARMATURE CAP, 24v VALVE 1

6 N/A 980533 SPRING, 5/8 24v VALVE 1

7 N/A 980565 ARMATURE BUMPER ASSEMBLY, EL VALVE 1

8

9 980129 WATER SIDE DIAPHRAGM 1

10 N/A 980420 SINGLE TEMP BASE W/INSERTS 1

NOTE:

NOTE:

980305

REPAIR KIT ORDERING #'S ARE

LISTED IN THE EXPLODED VIEW�

PARTS LISTED IN THE PVK REPAIR

KITS ARE NOT SOLD INDIVIDUALLY

980128 3 PRONGED INSERT 1

10

8

ASSEMBLED VIEW

(1-9) PLUS (*) BELOW

EVK-4 KIT

2

1

4

3

7

5

6

* EVK-4 KIT INCLUDES

380897 VALVE SEAT W/ 0-RING (NOT SHOWN)

9

PVK-3

(8,9)

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 5www.willoughby-ind.comRev. 6/2019

E1L1 and E1L2

Material:

2 Of 3

Part Number:

E1L11

2 Places +/- �03

3 Places +/- �015

Fractions +/- 1/32"

B

Willoughby Industries Inc.

Indianapolis, Indiana

Sheet:

Tolerances

Except as

N/A

Noted

Date:

Title or Part Description:

Drawing #:

Revision #:

E1L11 SINGLE TEMP ELECTRONIC VALVE ASSEMBLY O&M PAGE 2 ISO

TRB

STANDARD DWG�

980576

Job Name:

3/15/11

Drawn By:

N/A

Scale:

1:8

Qty:

Angle +/- 1

11/13/12

Electronic Series Valves

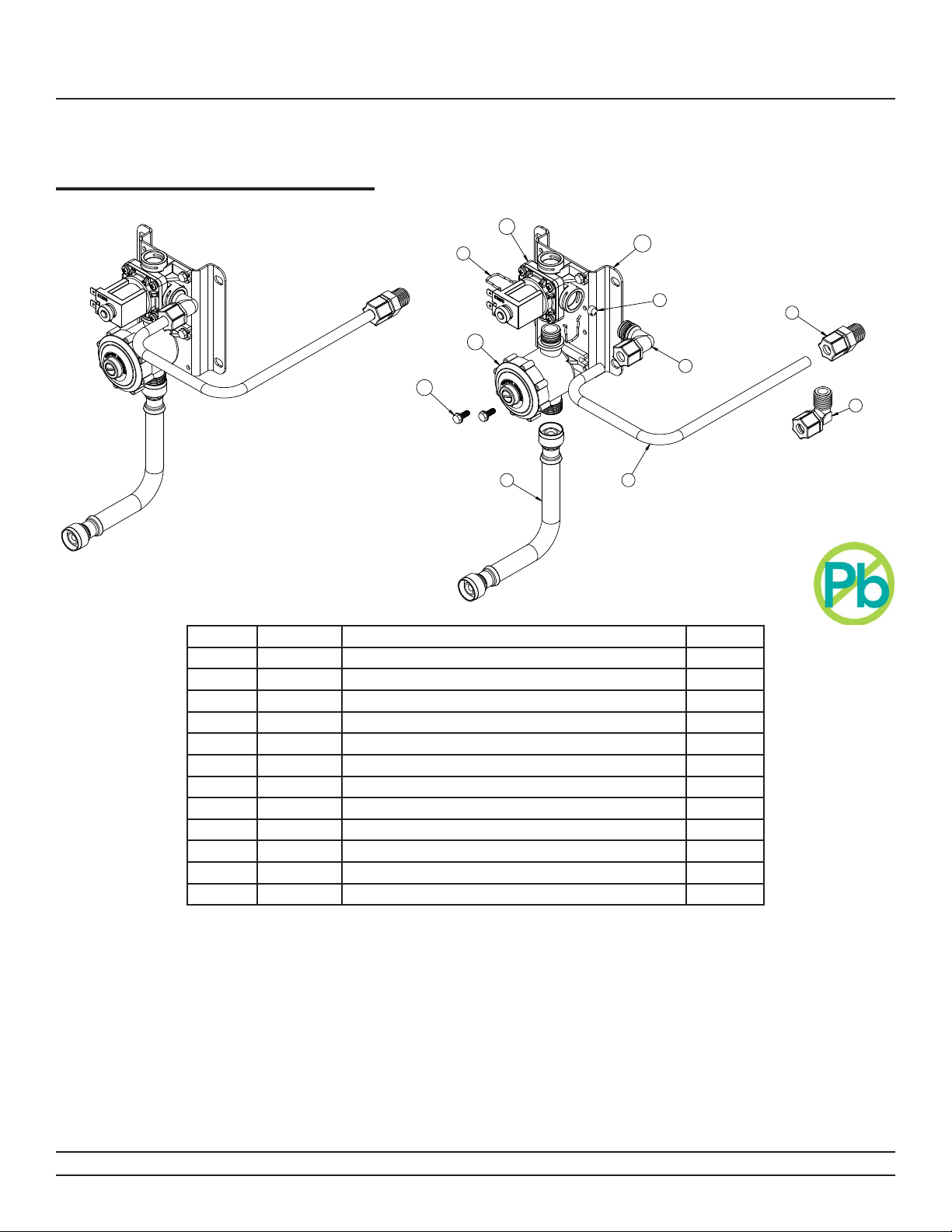

Physical Dimensions

E1L11 Valve Breakdown

Installation & Operation Manual

1

2

10

ITEM NO� PART # DESCRIPTION QTY

9

3

7

4

OPTIONAL 3/8" x 3/8" ELBOW

5 6

1 980408PR E1L VALVE ASSEMBLY, RIGHT-PLUGGED PORT 1

2 980140 SPRING CLIP 2

3 980183 CHECKSTOP ASSEMBLY 1

4 800133 #10-16 SELF TAP TYPE B HEX HEAD SCREW 4

5 980506 (OPTIONAL) 6" STAINLESS STEEL FLEX HOSE 1

5 980520 (OPTIONAL) 20" STAINLESS STEEL FLEX HOSE 1

6 600523 FLEXIBLE TUBING 3/8" (10mm) O�D� 20 FT� TOTAL PERFOOT

7 980600A VALVE FITTING ASSEMBLY, 3/8" ELBOW 1

8 320566 (OPTIONAL) CONNECTOR, 3/8" TUBE x 3/8" MPT 1

8 320577 (OPTIONAL) ELBOW, 3/8" TUBE x 3/8" MPT 1

9 380138 FLOW CONTROL 0�5 GPM (RED) 1

10 980501 PM1 VALVE BRACKET 1

8

8

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 6www.willoughby-ind.comRev. 6/2019

E1L1 and E1L2

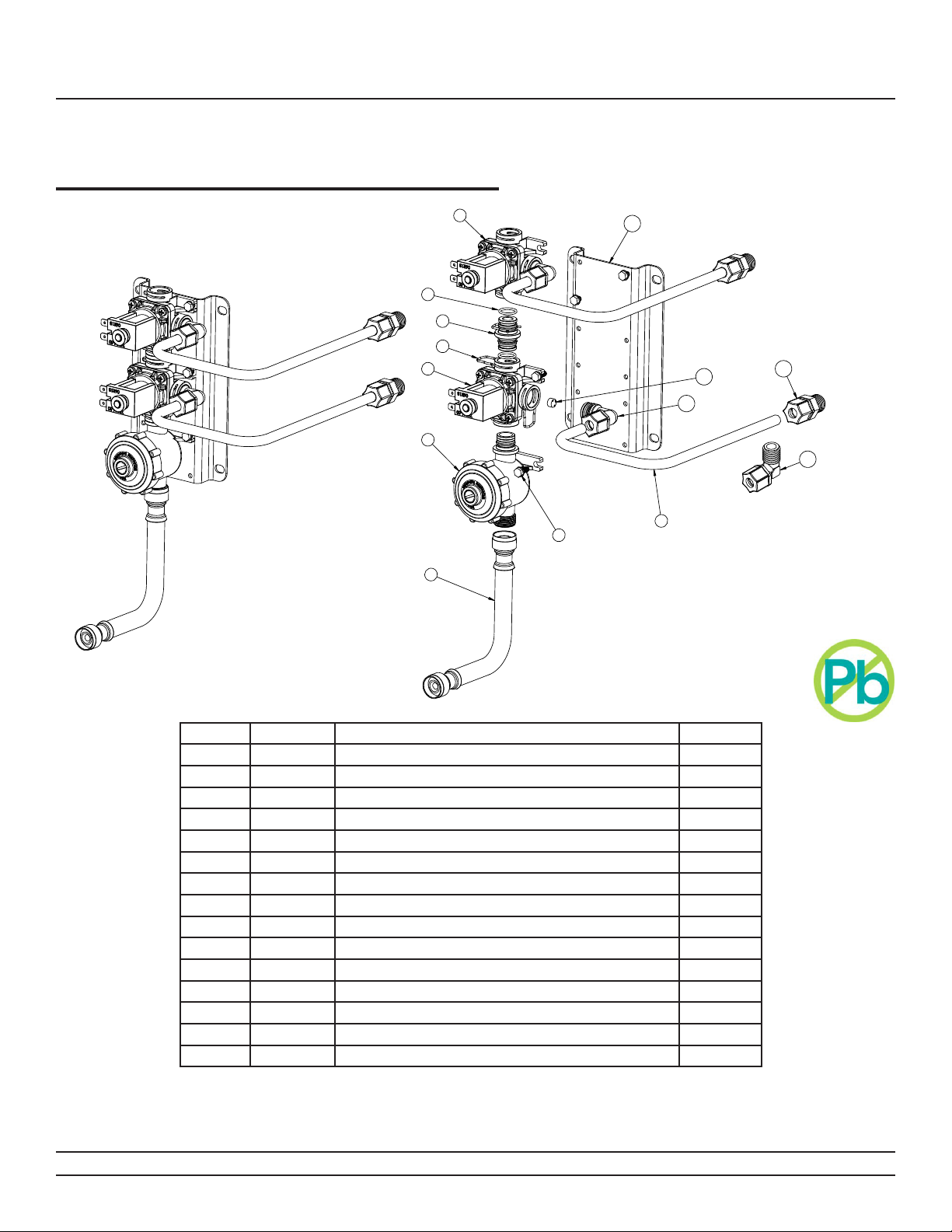

Electronic Series Valves

Physical Dimensions

E1L12 Manifold Valve Breakdown

Installation & Operation Manual

1

2

3

4

6

8

7

13

12

11

OPTIONAL 3/8" x 3/8" ELBOW

9

105

10

ITEM NO� PART # DESCRIPTION QTY

1 980408PR E1L VALVE ASSEMBLY, RIGHT-PLUGGED PORT 1

2 980164 'O'-RING, #015 2

3 980197 PLASTIC VALVE COUPLING 1

4 980140 SPRING CLIP 5

5 980408 E1L VALVE ASSEMBLY 1

6 980183 CHECKSTOP ASSEMBLY 1

7 980506 (OPTIONAL) 6" STAINLESS STEEL FLEX HOSE 1

7 980520 (OPTIONAL) 20" STAINLESS STEEL FLEX HOSE 1

8 800133 #10-16 SELF TAP TYPE B HEX HEAD SCREW 6

9 600523 FLEXIBLE TUBING 3/8" (10mm) O�D� 20 FT� TOTAL PER FOOT

10 320566 (OPTIONAL) CONNECTOR, 3/8" TUBE x 3/8" MPT 2

10 320577 (OPTIONAL) ELBOW, 3/8" TUBE x 3/8" MPT 2

11 980600A VALVE FITTING ASSEMBLY, 3/8" ELBOW 2

12 380138 FLOW CONTROL 0�5 GPM (RED) 2

13 9805012 PM1-MA2 VALVE BRACKET-PLASTIC 1

Willoughby Industries, Inc. TOLL FREE (800) 428-4065 ● LOCAL (317) 875-0830 ● FAX (317) 875-0837

Page 7www.willoughby-ind.comRev. 6/2019

Loading...

Loading...