© 2017 WilliamsWarn NZ Ltd

SAFETY INSTRUCTIONS 01

FERMENTING & DISPENSING 02

TYPICAL SINGLE TAP INSTALLATION

FOR BREWKEGS

TM

AND CORNELIUS KEGS 04

D-SANKE KEGS 06

INSTALLATION INSTRUCTIONS

SETTING UP YOUR KEGERATOR 07

MINIMUM CLEARANCES 10

WATCH OUR HELPFUL

INSTRUCTION VIDEOS

For instructional videos on installing and

using your WilliamsWarn Kegerators check

out www.williamswarn.com/how-to-videos/

Kegerator

User Manual

1

SAFETY WARNINGS

SAFETY FIRST

CO2 gas can be dangerous. Make sure to always use

CO2 in a well-ventilated place.

Never exceed 40psi on your keg system.

Flush out chemicals from your beer line completely

before tapping keg.

Always thoroughly check for gas leaks once you

have set up your system.

WARNING

If fridge has just been moved do not turn on unless

the fridge has been standing upright for 24hrs.

Failure to do so will void warranty. Stand fridge in

the upright position for 24hrs before plugging into

mains power socket.

!

!

VERSION 5

3

KEGERATOR

2

USER MANUAL

FERMENTING &

DISPENSING

The WilliamsWarn Kegerator can be

used to both ferment and dispense

fresh beer using WilliamsWarn

brewing technology.

FERMENTING

The WilliamsWarn Kegerator has the

ability to ferment and dispense up to two

BrewKeg10s™ at one time. The Kegerator

works in conjunction with the heating

belt and temperature controller and the

brewer can set the desired fermentation

temperature. Once fermentation is complete

the brewer can then set the fridge at 1°C

and perform the clarification steps. Once

clarified the brewer can then connect the

BrewKeg10™ to the tap using the fittings

provided and dispense directly from the

BrewKeg10™. See Figure 1.

DISPENSING

The WilliamsWarn Kegerator can dispense

a variety of dispensing keg once the

brewing process is complete. There are

two styles of kegs that are used, the most

common for personal use is a Cornelius

Keg which is available in 9.5 and 19L

(as shown in Figure 3). The other style of

keg which is commonly used in bars is a

D- Sanke keg which is available in 20L,

30L and 50L kegs. The D-Sanke kegs

will require a Coupler and a Liquid

and Gas Adapter, which connects onto

the Gas and Liquid ports (available on

http://www.williamswarn.com/Shop/

Dispensing-Accessories ). See Figures 4 and

5. Additionally a BrewKeg25™ can fit into

the WilliamsWarn Kegerator once it has

finished the brewing process and the

sediment bottle and stand has been

removed. A BrewKeg25™ has the same

connections as a Cornelius Keg.

See Figure 2.

Figure 1: Two BrewKeg10™

Figure 4: One 20L and One 30L D-Sanke Keg

Figure 5: One 50L D-Sanke Keg

Figure 3: Three 19L Cornelius Kegs

Figure 2: One BrewKeg25™

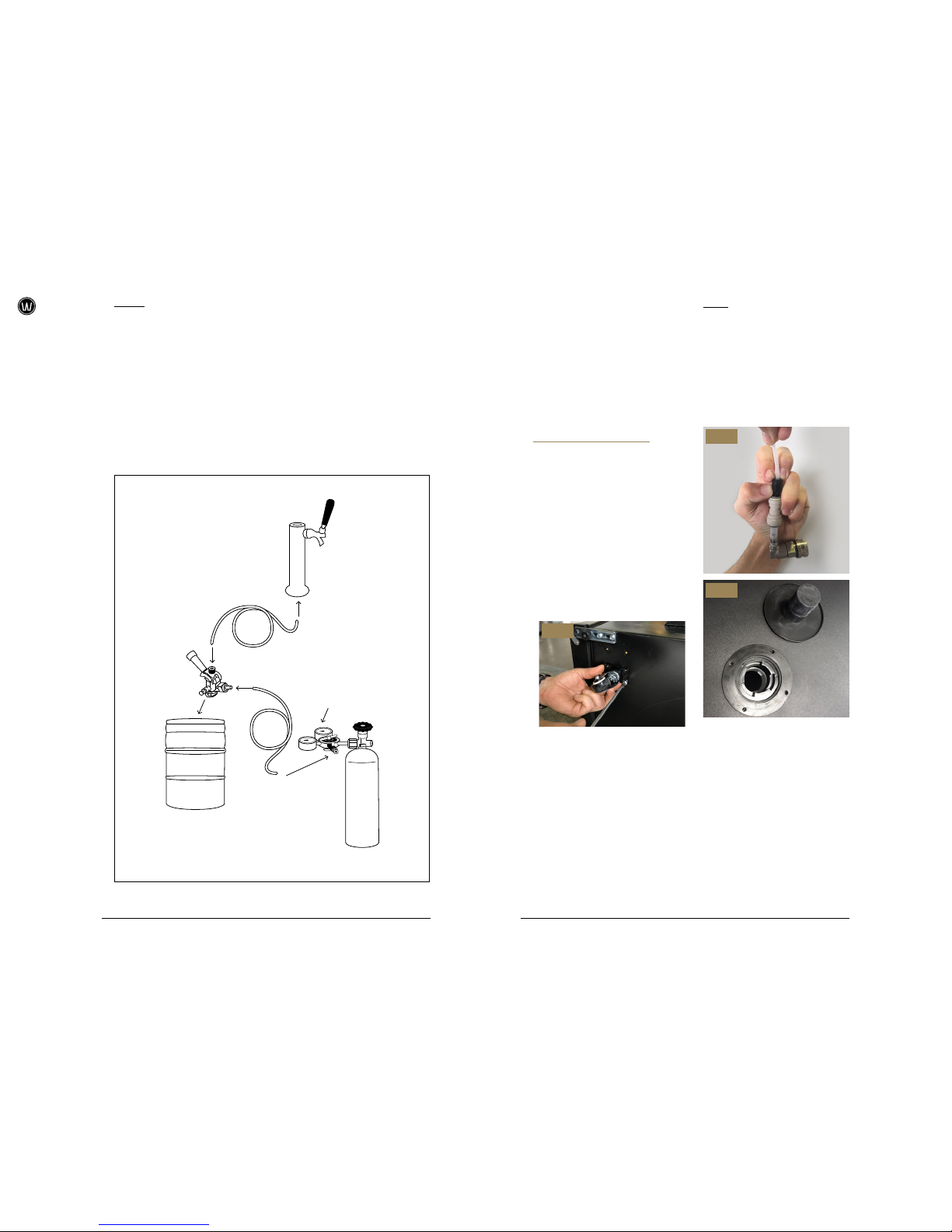

Beer Font

Beer Line

Ball Lock

Disconnect

Gas Line

Cornelius Kegs

CO

2

Regulator

CO

2

Gas Cylinder

Ball Lock Disconnect

54

USER MANUAL

KEGERATOR

TYPICAL SINGLE TAP

INSTALLATIONS

The following diagrams illustrate a

single typical single tap installation.

FOR BREWKEG™ AND CORNELIUS KEGS

CORNELIUS KEGS

The beer line that is attached to the beer font

connects to the ‘Out’ port on your Cornelius

Kegs. It will not be able to be attached to the

in port. You have the ability to connect up to

two Cornelius Kegs at one time. The Gas Line

connects to the “In” port on your Cornelius

kegs and you can connect up to two Cornelius

kegs at one time. Show close up photo of the

difference between the two fittings so they

know which is the in port and out port.

BREWKEGS™

The beer line that is attached to the beer

font connects to the beverage out port on

your BrewKegs™. It will not be able to

be attached to the in port. You have the

ability to connect up to two BrewKeg10™

or one BrewKeg25™ at one time. The

Gas Line connects to the gas in port on

your BrewKegs™ and you can connect

up to two BrewKeg10™ or one BrewKeg25™

at one time. See diagrams below.

BREWKEG10

TM

BREWKEG25

TM

/ BREWKEG50

TM

BEVERAGE-OUT PORT

(WITHOUT NOTCHES ON ITS BASE HEX,

WITH TUBE EXTENDING INTO THE VESSEL)

BK10 LID

VARIABLE PRESSURE

RELIEF VALVE VPRV

GAS-IN PORT

(WITH NOTCHES ON ITS BASE HEX)

LIDGAS-IN PORT PRESSURE GAUGE

BEVERAGE-OUT PORT

VIEWING PORTS

VARIABLE PRESSURE RELIEF VALVE (VPRV)

Beer Font

Beer Line

Commercial Keg

Keg Coupler

Gas Line

CO

2

Regulator

CO

2

Gas Cylinder

Image 2

Image 3

76

USER MANUAL

KEGERATOR

D-Sanke Kegs

To use Sanke Kegs you will need to purchase

a D-type Coupler, Liquid D-type adapter and

a Gas D-type adapter. The Gas line connects

onto the side port of the coupler (reads

Gas In) and the beer tube connects to the

top port on the coupler. If you are putting

multiple D-Sanke kegs in the Kegerator

e.g. a 20L and 30L you will need 2 x D-type

Couplers, 2 x Liquid D-type adapters and

2 x Gas D-type adapters

For D-Sanke Kegs

INSTALLATION

INSTRUCTIONS

Setting up Your Kegerator

Watch the kegerator installation video on

www.williamswarn.com/how-to-videos

You will require 1 x Philips screwdriver

A. Carefully remove all products from packaging.

B. If not required remove shelf and glass rack

from the inside of the WilliamsWarn Kegerator.

C. If you are wanting to fit the wheels now is the

best time to install them:

1. Turn the Kegerator on its side (you may

want to put some cardboard down if

assembling on a hard surface.

2. Screw on the wheels using the screws

provided. Two of the wheels have a brake,

these should be installed at the front of

the Kegerator (See image 1).

3. Position Kegerator upright (do not turn on

Kegerator for

24 hours after being on its side.).

D. Remove the fittings from the end of the Beer

font tubing. These are John Guest connections

and can be removed by pushing in the end of

the fitting and pulling the tubing out at the

same time. (See image 2).

E. Remove the black cover and place gasket over

the hole and line it up with the 4 holes (See

image 3).

F. Feed the tubes through the top of the Kegerator.

Using a Phillips screw driver and the 4 screws

provided screw the font in place (See image 4).

with the taps facing towards you (if you are

standing facing the door of the Kegerator). Refit

the fittings on to the end of the beer lines –

ensure they are tight by gently pulling the tubing

away from the fittings and you should be unable

to pull the tube out (Photo of installation).

G. If you wish to mount the CO

2

cylinder on

the back of the kegerator there is a bracket

supplied that locates on the rear of the unit

(See Image 4a & 4b).

H. Take the CO

2

cylinder and attach the gas

regulator to it. Use the spanner provided to

tighten it.

Image 1

Image 4A

Image 4B

Image 4

Image 5

Image 8

Image 6

Image 7

98

USER MANUAL

KEGERATOR

I. Place the CO

2

cylinder onto the bracket at

the back of the kegerator. Thread the velcro

belt supplied through the holes at each end ensure it is tightly in place.

J. Unscrew the black cap on the back of the

Kegerator and remove the small bung (see

image 5). *Note if you are using the The

Kegerator as a fridge only do not remove the

black bung.

K. Feed the black gas line through the white hole

from the inside of the Kegerator and screw

the black cap back on (see image 6). Connect

the gas line to the regulator provided to the

regulator fitting as shown in image 7. Push

the line in well and pull on it to make sure it

is secure in the fitting.

L. Turn on the CO

2

bottle and ensure there are

no leaks. Set the regulator at the pressure

you require. An average pressure would be

about 1.1 bar (

110 kPA) or 16 psi, but this

does depend on the beverage type and the

temperature you are serving at. If you are

using a D-Style keg (Sanke keg) bought

from a brewery in your kegerator, follow their

guidelines for pressure and temperature. If

you have brewed a beverage in a WilliamsWarn

BrewKeg

25

TM

or a BrewKeg10TM and are

serving it from the kegerator, or if you have

brewed in a BrewMaster and have transferred

the beverage into a Cornelius keg for

dispense, we’d recommend a temperature

between 1-4°C and a pressure range of about

1.1 bar (

110 kPA or 16 psi). The higher

the pressure the higher the carbonation,

and the colder the beverage the higher the

carbonation, so if you find your beverage is

too carbonated, you can brew and dispense on

the lower side of the range, to suit your taste.

Conversely, if you find not enough bubbles are

in your beverage, increase your brewing and

dispensing pressures to the higher end of the

range. The BrewKeg

10

TM

is a small vessel so

you may find that a brewing and dispensing

pressure nearer the 1 bar level (

100kPA, 14.5

psi) is preferable to avoid over-carbonating

the beverage. An over-carbonated beverage

will foam more when poured and taste more

effervescent. Please note that when a beer

cools, the CO

2

dissolves better, and the

pressure drops a little bit, so a WilliamsWarn

vessel’s brewing pressure is usually set about

0.

25 bar (250 kPA) higher than the dispense

pressure, to account for the drop once it’s

cooled after fermentation.

M. Plug in and set temperature to the desired

dispense temperature. The table below shows

typical serving temperatures for various

beverages. In general, ales are traditionally

served warmer than lagers, but you can of

course choose whatever temperature you

prefer to drink a beverage at. A temperature

set around 1-4°C is a good range to start at

for a first time user.

The Kegerator also comes with a fan and

tubing that can be inserted up into the font in

order to cool the font down. Just push the fan

button on the control panel to activate the fan.

N. The Stainless steel connections connect to the

Keg fittings by pulling back on the collar (See

image 8) and pushing onto the fitting onto the

BrewKeg™ or Cornelius Kegs.

O. Then place the font guard rail on top of the

kegerator and place the drip tray in front of

the font.

BEVERAGE

TYPICAL SERVING

TEMPERATURE

Lagers 1 - 7°C / 34 - 45°F

Ales in New World Countries 1 - 8°C / 34 - 46°F

Wheat Beers 6 - 10°C / 43 - 50°F

British and Belgian Ales 7 - 13°C / 45 -55°F

Cider and Mead 5 - 16°C / 41 - 61°F

Strong Dark Ales and

Barley Wines

10 - 15°C / 41 - 61°F

1

1

1

0

USER MANUAL

KEGERATOR

Minimum Clearances

Around the Kegerator

The Series 4 Kegerator has radiators in the

left and right hand wall of the Kegerator in

the outside skin. These radiators need to be

well ventilated so heat can escape from the

Kegerators. A minimum of 100mm (4inches)

clearance should be given to the Kegerator

on the left and right hand wall. This allows

the Kegerator to breathe and for the heat

to escape. If the Kegerator is incorrectly

installed it may void the warranty, cause high

electrical consumption and the Kegerator may

fail prematurely.

For instance it is not a good idea to push the

Kegerator right up into the corner of a room

against two walls as this will prevent adequate

ventilation of one of the sides of the Kegerator

limiting its ability to operate efficiently.

See diagram to the below. This is an incorrect

Kegerator installation. Little or no ventilation

is given to the Kegerator on the left and right

hand wall.

For any questions contact

service@williamswarn.com

NOTES

100mm clearance required on

left and right hand side. This

installation will void warranty

and cause poor performance.

Loading...

Loading...