TM

BrewKeg10

User Manual

OVERVIEW 01

PROCESS SUMMARY 02

SETTING UP YOUR

BREWKEG10

SET UP 03

EQUIPMENT 03

TM

SPECIAL NOTE ON

PRESSURE AND CARBONATION 12

CO2 LEVELS FROM

PRESSURE VS CARBONATION 12

ADJUSTING CARBONATION 13

CARBONATION FOR WARMER BEVERAGES 13

BREWING INSTRUCTIONS

STEP 1: CLEAN 04

STEP 2: MIX 06

STEP 3: ADJUST 07

STEP 4: DISPENSE 10

DOWNLOAD OUR 3

MOST POPULAR RECIPES.

Simply register your brewery at

brew.williamswarn.com/register-now.html

Help us to support you by registering your new

brewing equipment. Registration is easy and is

helpful for warranty and support queries!

© 2017 WilliamsWarn NZ Ltd

VERSION 8

OVERVIEW

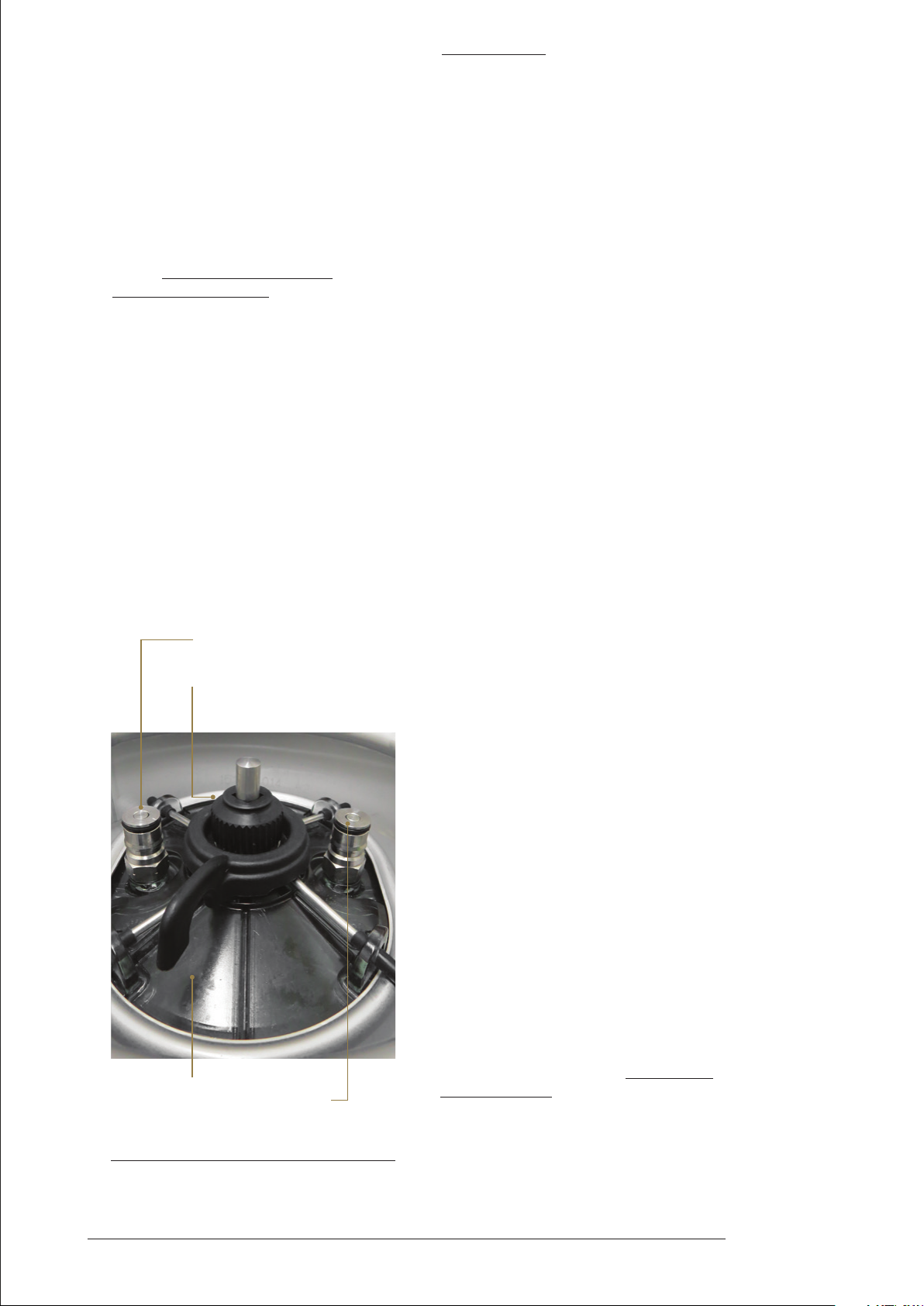

BrewKeg10TM Structure

VESSEL LID

BREWING INSTRUCTIONS

SEDIMENT BOTTLE

STAINLESS STEEL VESSEL

1

VESSEL BUTTERFLY VALVE

USER MANUAL

PROCESS

SUMMARY

CLEAN

01. Rinse off the internal yeast ring – ensure the

internal surface is visibly clean.

02. Add hot water and detergent – shake with lid

on – take some liquid out the beer line.

03. Open the vessel butterfly valve and add

remaining detergent to the sediment bottle.

04. Rinse the detergent from the BrewKeg10™,

its lid, sediment bottle and beer line.

MIX

01. Add the extracts to the vessel with hot water

and stir to dissolve.

02. Add any extra ingredients (e.g. hop tea).

03. Top up with water. Target 25ºC (77ºF)

when full. Stir.

04. Rehydrate yeast in sediment bottle in

25ºC (77ºF) water and add to vessel.

05. Attach sediment bottle and open vessel valve.

06. Top up again, attach lid, set VPRV to approx.

2.5 turns and set temperature to ideally

2

25ºC (77ºF) or within the range of 18-28ºC

(

64-82ºF) in your fridge or room.

ADJUST

01. Maintain temperature for 4 days.

02. Check and adjust the pressure as required

after

24 hours. Target 1.5 bar (22 psi).

03. Chill to 1-4ºC (34-39ºF) when fermentation

is finished.

04. Clarify beer - 2 step process. Cider does not

require clarification.

DISPENSE

01. Close the vessel butterfly valve and remove

the sediment bottle.

02. Ensure CO

the lid.

03. Connect draft tap to the beverage-out port on

the lid and pour a beverage.

Transfer the beverage to bottles or kegs if

required.

is connected to the gas-in port on

2

Instructional Videos available at

williamswarn.com/TheWilliamsWarn/BrewKeg10

SETTING UP

YOUR BREWKEG

BREWING INSTRUCTIONS

Please watch the brewing videos on our

website www.williamswarn.com/TheWilliamsWarn/BrewKeg10 before you make

your first brew. This will make the instructions

below easier to understand and assist you in

making a great brew first time and every time.

You can also use the videos as the instruction

manual rather than this printed manual, by

using the play and pause buttons on the video

to help you perform each step. The printed

words below are in fact generally the narration

to the videos.

SETTING UP YOUR BREWKEG10™

Unpack the BrewKeg10™ from its packaging.

It consists of three parts being the main

vessel, the lid and the sediment bottle. See

the image on the Process Summary page. The

BrewKeg10 is ready to use once unpacked.

GAS-IN PORT

(WITH NOTCHES ON ITS BASE HEX)

VARIABLE PRESSURE

RELIEF VALVE VPRV

EQUIPMENT YOU NEED

•

A BrewKeg10™.

•

The Sundry Accessories set, (spatula,

clarification agent, brewery detergent,

non-scratch sponge).

•

The Dosing Device.

•

The BrewKeg10™ pressure gauge.

•

Means to receive CO2 e.g. either a CO2 cylinder

or soda stream bottle with a gas regulator and

gas line with grey quick-disconnect fitting.

•

Means to dispense e.g. a draft beer line and

tap (and a fridge) or alternatively a kegerator

with a draft beer tap.

•

A set of ingredients for the BrewKeg10™.

•

A means to maintain temperature between

18-28ºC (64-82ºF) e.g. a heat-belt and a

temperature controller (sold by WilliamsWarn)

can be used to control the temperature inside

a kegerator or fridge during fermentation.

A room or cupboard with a thermostatically

controlled portable heater can also be used.

•

A standard 1.5L (51 fl. oz.) kitchen kettle,

scissors, a thermometer.

3

BK10 LID

BEVERAGE-OUT PORT

(WITHOUT NOTCHES ON ITS BASE HEX,

WITH TUBE EXTENDING INTO THE VESSEL)

Figure 1: BrewKeg10™ Lid

NOTES REGARDING THE GAS-IN

AND BEVERAGE-OUT PORTS.

It is a good idea to regularly check the state

of the O-rings on the gas-in and beverageout ports (these are also called posts).

The O-rings are very inexpensive parts and

should be regularly checked to ensure that

they aren’t worn or frayed or split. If they

don’t form a good seal gas or beverage can

leak out around the ports. A gas leak can

contribute to emptying of your CO

and a liquid leak will make a mess on your

floor. These parts are consumable parts and

can be purchased through our website.

It is also a good practice to wet the O-rings

with a little water when you put on and

take off the quick-disconnect fittings, as

shown at the beginning of the Step 1: Clean

instructional video. This will allow the rings

to last longer before they need replacing.

cylinder

2

USER MANUAL

BREWING

INSTRUCTIONS

Step 1 – Clean

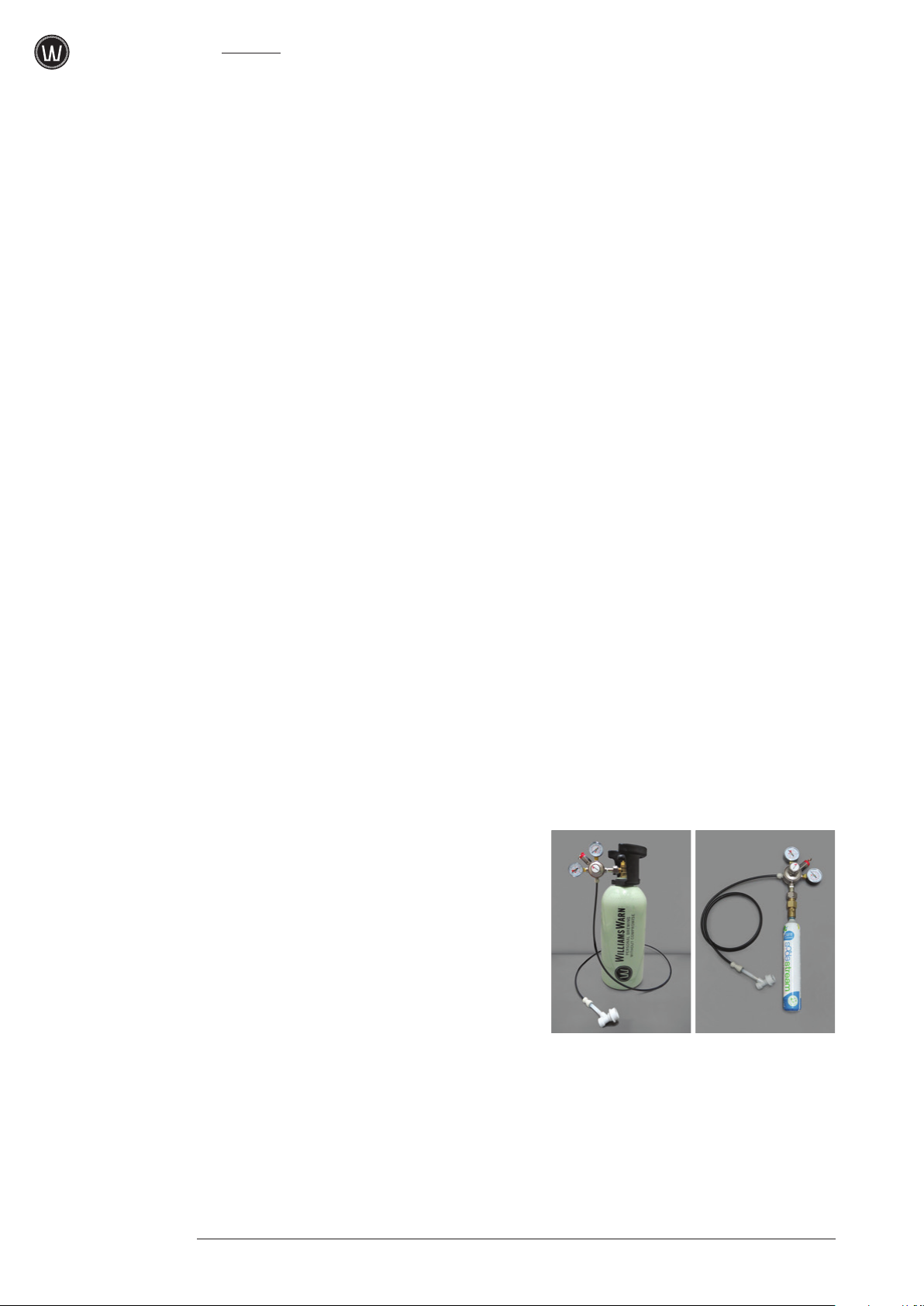

A. Firstly, set up your CO

Figure 2. Ensure the gas line with the grey

quick-disconnect fitting is inserted all the way

into the push-lock fitting under the adjusting

knob on the gas regulator as shown. If you are

using a large CO

regulator to the cylinder securely and open

the cylinder top valve. If you are using a soda

stream bottle, first screw the special adaptor

onto the regulator well and then screw the

complete regulator set-up onto the soda stream

bottle securely. Please see the video on our

website or on vimeo (vimeo.com/

for a clear explanation on how to set up a soda

stream bottle to a regulator. Then set the pressure

on the low pressure gauge (the one sitting

above the adjusting knob) to 1.1 bar (

by turning the adjusting knob clockwise.

Please note that it is always most accurate to

set the pressure by winding the adjusting knob

4

anti-clockwise first to release pressure and be

under the set-point and then wind it clockwise

to increase the pressure to its set-point. Once you

have set the pressure, your CO

ready to provide pressure to the BrewKeg

each time the grey quick-disconnect fitting is

connected to the gas-in port on the BrewKeg

lid. The gas-in port is the port with the notches

on the hex of the fitting (see Figure 1). Note: if

you need to remove the gas line from the regulator,

push in the end of the fitting and pull the tubing

out at the same time.

Caution: When connecting the Gas dispense

line to the BrewKeg™ or any other Keg, DO

NOT connect to the liquid post. If this is done

and the regulator is not on or not set to your

desired dispense pressure, beer can flow back

into the regulator and cause damage. If you are

concerned about this you can buy a non-return

valve from our website and insert it into the line

to prevent this happening.

B. Start to boil 1L (34 fl. oz.) of water in the

kitchen kettle.

C. Remove any pressure in the vessel by pressing

the button on the VPRV (indicated in Figure

supply as shown in

2

cylinder, then connect the

2

196807721)

16 psi)

system is then

2

10™

10™

1) until all pressure is released. Remove the

lid by turning its locking knob anti-clockwise

and slipping the lid out from under the rim.

Ensure the vessel butterfly valve is closed and

then remove the sediment bottle (it screws off

clockwise looking down on it).

D. Place the BrewKeg10™ over a sink or drain

and open the butterfly valve. Use a water source

to rinse off any beverage residue or yeast ring

from a previous brew. The water source can be

for example, a tap or a water hose or a rinse

bottle full of water. Drain all the liquid out of

the vessel and close the vessel butterfly valve.

Fill the vessel cone with the tap water and dip

the non-scratch sponge into the water in the

cone and scrub the entire internal surface of

the vessel with the cold water. It is important

to especially scrub off any yeast ring from a

previous brew. Open the vessel butterfly valve

again, dump this water and then rinse the

internal surface of the vessel with water again.

Then close the vessel butterfly valve. The idea

here is to scrub off most of the visible solids

and beverage residue from a previous brew.

Wash the lid with cold water until visibly clean.

Next, remove the VPRV and pour boiling water

into the VPRV socket and over the seal end of

the fitting. After this, re-fit the VPRV.

Fig 2: CO2 cylinder and soda stream attached to

regulator and gas side connection

E. Ensure the vessel butterfly valve is closed.

Add

15g (1 heaped tablespoon/1 cap full) of

WilliamsWarn Brewery Detergent to the vessel.

Then add the 1L (

34 fl. oz.) of boiling water

BREWING INSTRUCTIONS

from the kettle into the vessel. Ensure the

lid seal is still in its proper position and then

put the lid on the BrewKeg

10™ by slipping

it under the vessel rim and turning its locking

knob clockwise to seal it. Circulate the keg in

an upright position for

10 seconds to dissolve

the detergent in the cone into the hot water.

Then tip the keg upside down and circulate

it again for

10 seconds so that the hot liquid

soaks and cleans the underside of the lid and

the vessels internal top area. Then hold the

keg horizontally and shake it up and down for

10 seconds so that the hot liquid loops around

the walls of the keg. The hot detergent will

dissolve all organic residues that you didn’t

scrub off in the previous water rinse step.

In addition to that, the internal keg walls

should all now be hot to the touch and have

risen in temperature to at least

80˚C (176˚F)

for 2 seconds, which is enough to pasteurise

them and kill any unwanted micro-organisms

that might be on the internal surfaces and

that could potentially cause an infection. The

pressure will build up as you shake and we will

use that pressure in the next step. So this step

is a combined cleaning and pasteurising step

and it eliminates the chance of contamination

of the brew by spoiling bacteria.

F. We need to take some hot detergent out the

beer tube in the keg and your draft beer line to

clean and pasteurise them too. So as soon as you

have finished shaking the keg and while there

is still pressure in the keg (it reduces as the keg

cools), place the keg upright and attach your

draft beer line. In the case of a kegerator, this

will be the black quick-disconnect fitting and line

inside the kegerator that goes to the draft beer tap

on the font. In the case of a normal fridge being

used in your setup up, this may be a plastic beer

tap or stainless tap and line with a black quickdisconnect fitting (as sold by WilliamsWarn).

In any case, attach the black quick-disconnect

fitting of your draft tap line to the beverage-out

port on the lid and open your draft tap and pour

the hot detergent out the tap into a cup for just

1 second. We don’t want to take out more than

100ml (3.4 fl. oz.) of hot liquid out the beer

line because we need the remaining

900ml of

liquid in the vessel for the sediment bottle clean

in a following step, so the idea is to just ensure

some comes out the tap and then close the tap.

Then remove the black quick-disconnect from

the beverage-out port on the lid. The beverage

out tube in the keg and draft beer line will both

remain full of hot detergent and soak to clean and

pasteurise them as we perform the next steps.

G. NOTE: If no liquid flows (the pressure reduces

slowly as the detergent cools down in the keg),

you’ll need to add some pressure manually

by connecting your low pressure CO

to take

2

out a sample. You can do this by connecting

the grey quick-disconnect fitting of your CO

2

supply to the gas-in port on the keg lid, as

shown in Figure 3, and adding some pressure

for 3 seconds. You should hear the gas go into

the vessel. Then remove the grey fitting. Then

open the tap and pour the hot fluid out for no

more than 1 second before closing the tap.

Then remove the black quick-disconnect from

the beverage-out port on the lid.

Fig 3: Grey quick-disconnect fitting attached to

gas-in port from the CO2 cylinder. The gas-in port

has notches on its base hex.

H. Next, remove pressure in the vessel by pressing

the button on the VPRV, then screw the

sediment bottle back onto the vessel butterfly

valve and open the vessel butterfly valve and

allow the remaining hot liquid to flood the

sediment bottle. Let it stand for

20 seconds

minimum. Note: by this time the temperature

of the liquid is about

natural cooling down and the

72˚C (158˚F) due to

20 seconds is

enough to pasteurise the bottle. Do not add

water above

85°C (185°F) to the sediment

bottle at any time as that will melt it. If you

feel at some stage that you need to give the

sediment bottle an extra clean, do it by hand

with detergent and water below

I. Next, close the vessel butterfly valve and

85°C (185°F).

remove the sediment bottle. Dump its contents

and rinse the sediment bottle several times with

cold water to remove the detergent residue.

Remove the BrewKeg

10™ lid and rinse the

internal surface of the lid and the outside of

the beverage-out tube both well with water,

to remove all detergent residue and place it

upside down on a table.

5

USER MANUAL

J. You now need to rinse the detergent off

the keg’s internal surface, so place the

BrewKeg

10™ over your drain again and open

important to scoop into the area above the valve

to dissolve any settled extract there. Then add

500ml (17 fl. oz.) of cold water and stir that in.

the vessel butterfly valve. Use water to rinse all

the detergent off the internal surfaces of the

keg including the underneath of the rim at the

top of the keg. Drain all the liquid and then

close the butterfly valve.

C. Then use the scissors to open the 645g bag

of dry malt extract (DME) and add this to the

BrewKeg

10™. Stir the DME into the liquid

with the spatula. You may find that there are

a few lumps that don’t dissolve but this is

K. You now need to rinse the detergent from the

beer line and draft beer tap. So fill the cone of

acceptable as they will dissolve by themselves

over the next few hours.

the keg half full of water and screw the lid back

on well and add some pressure manually by

connecting the grey quick-disconnect fitting of

your CO

supply to the gas-in port on the keg lid,

2

as shown in Figure 3. Add some pressure for

3 seconds then remove the grey fitting. Connect

your draft beer tap’s black quick-disconnect

D. For cider brews, just open the cider pouch

with the scissors and add to the BrewKeg

Then add the

500ml (17 fl. oz.) of boiled water

from the kitchen kettle. (This is performed

to get the final temperature correct when the

vessel is full).

10™.

fitting to the beverage-out port on the lid again

and open the tap and allow the water in the cone

to flow out into a cup and flush the lines of the

detergent. Wait until all the liquid is out and gas

comes out the tap for a few seconds and then

disconnect the black fitting from the beverageout port.

L. Push the button on the VPRV to release

all remaining pressure and remove the

BrewKeg

6

a table. Then place the BrewKeg

10™ lid and place it upside down on

10™ ready for

the addition of the ingredients.

M. Note: Every 5th brew or so its good practice to

clean the vessel lid seal and its groove on top

of the vessel rim manually with some detergent

and then rinse and put it back in its groove.

Step 2: Mix

(Add ingredients)

A. Boil 500ml (17 fl. oz.) of water in the kitchen

kettle.

E. At this point you can add extra ingredients. For

example, for beer brews a hop tea made with

e.g.

25g (0.9 oz.) of pellet hops in a French

Press coffee plunger is a great way to boost

the flavour of any beer. In the same way, fruit

flavourings can be added to the cider. For

more examples for these sorts of methods,

visit the WilliamsWarn® website and download

our Recipes pdf. www.williamswarn.com/The-

WilliamsWarn/Recipes

F. You can now top up to the 10L (2.64 US

gallons) full mark with water. The target

temperature when full is near

or within the range

18-28°C (64-82°F). If your

25°C (77°F)

water source is cold e.g. in winter and between

12-16°C (54-61°F), add another 500ml

(

17 fl. oz.) of boiled water from the kitchen

kettle during your top up to the

If it is colder than that and between 8-

(

46-52°F) out of the tap, then include 1L

(

34 fl. oz.) total of extra boiled water from the

kitchen kettle during your top up to the

10L mark.

11°C

10L

mark. Otherwise just top up with ambient tap

water. This target temperature range is very

important as it helps to ensure a quick onset of

B. For beer malt extract brews, firstly open the

800g can of liquid malt extract (LME) and add

the extract directly to the BrewKeg

10™ cone.

Keep the can and its remaining residue. Fill

the can halfway with the boiled water from

the kettle and dissolve the extract residue

by stirring with the spatula. Hold the can

at the top area where it is less hot and add

the content to the BrewKeg

10™. Add the

remaining boiled water in the kitchen kettle

to the extract in the cone and stir it all with

fermentation.

G. The fill level is marked on the outside of the

BrewKeg

Internally the fill level is 6cm (2.

10™ and is 10L (2.6 US gallons).

36”) from the

bottom of the vessel rim. Fill up close to this

level (we are more exact in the next step) and

stir the contents to even out the temperature

and dissolve all the extract evenly into the

water, ahead of adding the yeast in the next

step.

the spatula and dissolve it completely. It is

BREWING INSTRUCTIONS

H. Next add about a cup of water (approx.

200ml/6 fl. oz.) at 25°C (77°F) to the sediment

bottle. Open the yeast sachet with the scissors

and add the yeast to this water. If the water

temperature is more than

40ºC (104°F) you

will kill the yeast. Swirl the sediment bottle

for

30 seconds to rehydrate the yeast. After a

minimum of

30 seconds, add the rehydrated

yeast directly to the top of the wort in the

keg. Then screw the sediment bottle onto the

vessel butterfly valve under the BrewKeg

10™

and open the butterfly valve fully so that the

liquid wort fills the sediment bottle fully.

Leave the valve open. Then top up to the

(2.6 US gallons) fill mark accurately. You have

now made

10.85L (2.9 US gallons) of wort,

but during the process the sediment bottle

fills up with yeast and haze and gets dumped,

so the final volume to consume will be

10L

(2.6 US gallons).

I. Ensure the lid seal is in its place and then

put the lid back on well.

J. If you’d like to check the lid is on correctly,

you can pressurise the BK

as a check. Connect your CO

gas-in port and pressurise to 1.1 bar (

10 temporarily

source to the

2

16psi)

or whatever you have on the low pressure.

Disconnect the gas-in fitting and attach

the pressure gauge and wait a few moments.

If you are satisfied there is no leak, push

the button on the VPRV and release all

the pressure. It’s best to let the yeast start

fermentation without any pressure and let

them build up the pressure themselves

naturally as fermentation kicks in. Then set

the Variable Pressure Relief Valve (VPRV) to

2½ full turns open from fully closed, which

will allow the pressure during fermentation

to build up to about 1.5 bar (

22 psi). Always

ensure the VPRV set pressure is higher than

the regulator set pressure. Each VPRV will

be slightly different depending on their

natural spring tension and after several brews

you will know how many turns of the VPRV

you should set to achieve the pressure level.

The higher the pressure achieved, the more

carbonation there is in the beverage, so if

you prefer a less carbonated beverage, you

can set the VPRV at less turns to achieve a

lower pressure during fermentation.

10L

K. Put the BrewKeg10™ pressure gauge onto the

gas-in port on the lid, as shown in Figure 4. If

you brew with multiple BrewKeg

10™ vessels

and only have one pressure gauge, just use

the gauge as required in the subsequent steps

below. It can be put on and then removed

whenever you need it to check the pressure.

Fig 4: Pressure gauge on lid

The BrewKeg

10™ is now at its fermentation

stage.

Step 3: Adjust

FERMENTATION

If you ferment WilliamsWarn brew kits in the

range of 18-28°C (64-82°F), the process will

be as follows:

Day 0 to

Day 4

Day 4 Chill to 1-4°C (34-39°F)

Day 4.5 First clarification for beer, and

Day 5.0 Second clarification for beer.

Day 5.5-6.0 Dispense stage for beer.

If you have temperature control we

suggest you target 25°C (77°F). You can

of course optionally ferment lagers at a

lower temperature which is more traditional

but do start near the warmer 25°C (77°F)

temperature at yeast pitching (the MIX

step above) and then adjust your ambient

Monitor temperature and pressure

during fermentation and determine

when fermentation is finished.

Dispense stage cider.

7

USER MANUAL

temperature down in this step. This method

allows fermentation to start quicker. If you

have temperature control and want to ferment

the lagers a bit colder, our recommendation

is to ferment our lagers and pilsners at 15°C

(59°F) for 3 days and then 18°C (64°F) for 3

days, so a total of 6 days. However great lagers

can also be made at the warmer temperatures

associated with ale fermentations (as the yeast

actually prefer it warmer and ferment quicker),

so it’s not wrong to ferment a lager at an ale

temperature range (18-28°C/65-82°F), if you

prefer the lagers to be brewed a bit quicker

than they are at the colder temperatures.

and tightened but it isn’t necessary and not

preferred as the heat belt can get quite hot

and add too much heat to a localised area on

the vessel. It is better to use the heat belt to

warm the ambient air inside the kegerator/

fridge so that heat is distributed evenly around

the vessel. Plus, if you have more than one

keg fermenting inside the kegerator/fridge,

with this method you still only need one heat

belt not two or more. The best position for

the controller’s temperature probe would be

hanging down into the middle of the kegerator/

fridge, but just having it taped to a wall is

most practical so it is not in the way when you

moved kegs in and out. It will ensure a good

A. The ideal set up for fermentation is to place

the BrewKeg

10™ inside a kegerator or a

fridge with a heat-belt and temperature

controller to control the temperature at your

temperature control within a degree or so of

the set point, which is totally acceptable and

will ensure a steady fermentation and a good

beverage produced.

set point during fermentation, as shown in

Figure 5. However, as long as you maintain

the temperature range, during fermentation,

any set up will work and ensure fermentation

proceeds and finishes before the chilling step.

For example, it could be placed in a small

cupboard with a small portable heater which

B. Monitor the temperature during fermentation.

If you don’t have accurate temperature

control, try and maintain a range between

18-28°C (64-82°F). This will ensure a strong

fermentation for all beer styles. Fermentation

can take longer at colder temperatures.

has a standard adjustable thermostat, so that

the cupboard’s ambient air can be kept in the

8

temperature range required for the period of

fermentation. For brewers using a kegerator or

a fridge, before you set up your temperature

controller, plug your kegerator or fridge into

the wall socket and make sure it is set to cold.

In the case of a kegerator set the temperature

to 1

ºC (34ºF). Next unplug your kegerator or

fridge from the wall socket. Then plug the

C. After about 12 hours following the pitching

of the yeast, if you shine a torch on the

sediment bottle, you should see the signs of

the beginning of fermentation. After

there should be a lot of CO

being produced by

2

24 hours

the yeast and hundreds of tiny bubbles rising

constantly. Please see the Adjust video for

images of how the brewing should look with

respect to CO

bubbles.

2

temperature controller into a wall socket next

to the kegerator/fridge and take the controller

temperature probe and place it or tape it to

a wall inside the kegerator/fridge. Then plug

the fridge into the temperature controller’s

cooling socket and plug the heat belt into the

temperature controller’s heating socket. Then

place the heat belt around a BrewKeg as a loop

on the kegerator/fridge floor and then close

the door. In this set up you will be closing

the kegerator/fridge door on the heat belt and

probe chords, but the seals on the doors will

close around them well and keep the inside

insulated from the outside temperatures. Turn

the temperature controller on and set the

temperature to your target e.g.

25°C (77°F).

The temperature controller will now control

the temperature inside the kegerator/fridge

and turn the heat-belt or fridge on as required.

The heat belt can be place around the keg

BREWING INSTRUCTIONS

some settled yeast in the sediment bottle and

only the odd bubble rising once and a while

from the sediment. Fermentation is officially

over when the Specific Gravity (SG) no longer

reduces and is constant. If you need to take

a sample to check the SG, attach your draft

beer tap to the beverage-out port on the lid,

take a sample, degas it and measure the SG

as shown in the Adjust video online. The

alcohol level can be calculated by the (OGSG) x

131.25. The OG is the original specific

gravity reading in the wort measure before

fermentation and the SG is the specific gravity

measured in the final beverage, both at

(

68°F). e.g. (1.045-1.010) x 131.25 = 4.59%

20°C

alcohol by volume. If you think fermentation

isn’t finished, wait another day before cooling.

1

Temperature Controller

2

Temperature Probe

3

Heat Belt

Fig 5: Temperature control set up during fermentation

in a kegerator and a fridge.

D. After 24 hours the pressure will have built up

and the beverage is carbonated. It is important

to monitor the pressure during fermentation,

so aim for fermenting at 1.5 bar (

adjust the VPRV to achieve this after

22 psi) and

24 hours,

once pressure has built up. If you prefer lower

carbonation, brew at a lower pressure to suit

your tastes. If the pressure is higher than your

target, turn the VPRV anti-clockwise as this

will release some pressure. Conversely, if you

can hear or smell CO

emitting out the VPRV

2

and you aren’t at your target pressure, then

turn the VPRV clockwise a little, to establish a

new set point then come back in a few hours

and check. You do not need to be over-precise

here because when you hook up your CO

2

cylinder to the BrewKeg during Clarification

and Dispense, an equilibrium will establish

itself, so the idea is to get close to the final

pressure you will set when consuming the

beverage.

E. At the temperature range of 18-28°C

(

64-82°F), after 4 days, fermentation should

be completed (for WilliamsWarn extracts)

and you should able to cool the beverage.

Lagers brewed at the colder temperature

range of

15°C (59°F) to 18°C (65°F) will

take 6 days. But first check fermentation is

finished. Fermentation is over when there is

F. To cool, wind the VPRV right down to its closed

position (to avoid losing all the CO

CO

bottle once it gets connected) and ensure

2

the BrewKeg

10™ is in a kegerator or fridge or

out of your

2

chiller of some kind and that it is set to cold.

If you were fermenting in a kegerator/fridge

with a heat-belt and temperature controller,

change the set point to 1-4°C (

34-39°F),

unplug the heat belt from the controller and

remove it from the kegerator/fridge, ready for

the next brew. The fridge will then come on

and cool the beverage down. Or conversely

you can turn the temperature controller off,

remove its temperature probe, remove the

heatbelt, and plug the kegerator/fridge back into

the wall socket and use its own temperature

controller to refrigerate the beverage. If you were

fermenting at room temperature or on a warm

area such as a cupboard with a small portable

thermostatically controlled heater in it, you now

need to move the keg into a fridge or chiller and

ensure it is set to cold. Wait

12 hours so that

the entire vessel contents cools down, before

moving to the next step. The pressure will

naturally reduce a little bit during this period as

the natural CO

becomes more dissolved in the

2

beverage as it cools.

CLARIFICATION

A. A WilliamsWarn cider kit does not need

clarification because once it is cold, the yeast

should all settle out and the cider look clear.

So once the cider is cold, just follow the steps

in the Dispense instructions below and in

the Dispense video. Beer on the other hand

requires clarification.

B. Beer Clarification 1: Remove the cold

BrewKeg

10™ from its kegerator/fridge to

9

USER MANUAL

give yourself some space to work on it and

close the BrewKeg

10™ butterfly valve above

the sediment bottle. Ensure you have your

CO

cylinder regulator connected to the gas

2

line with the grey quick-disconnect fitting as

in Figure 2, ready to be used, with the low

pressure set at 1.1 bar (

16 psi) pressure.

D. Next remove the grey quick-disconnect fitting

from the clarification pot lid, remove the

clarification pot lid and add

30ml of rinse

water to the pot. Then put the pot lid back on,

reconnect the grey fitting to the pot lid port

and blow that water through the lines for a just

a few seconds. If the water doesn’t flow out of

the pot because the gas supply and the vessel

are in equilibrium, just press the button on

the VPRV to release some pressure out of the

vessel and look for the water to exit the pot. It

just needs to rinse the line, not mix into the

beer like the clarification agent needed to.

Then remove the grey fitting from the pot lid

again. Then remove the black quick-disconnect

fitting from the BrewKeg

10™ lid beverage-

out port and remove the pressure gauge from

the gas-in port. Then disconnect the pressure

gauge and then connect the grey fitting of

your CO

BrewKeg

bottle to the gas gas-in port of the

2

10™ lid. The pressure from the CO

bottle is now connected onto the vessel and

the beverage inside and maintains the natural

carbonation. Ensure the CO

set at 1.1 bar (

16 psi) or another level you are

bottle regulator is

2

targeting.

2

E. The clarification agent will have reacted with

haze proteins and yeast and a new sediment

1

0

Fig 6 Dosing Device set up

C. Measure 15ml (0.5 fl. oz.) of clarification

agent into dosing device (it has graduations

on it to indicate the volume) and put

its lid back on. Then connect the grey

quick-disconnect fitting to the port on the

layer will settle down. So now open the vessel

butterfly valve to allow this sediment to fall

into the sediment bottle over the next

12 hours

and form a new layer on the already naturally

sedimented yeast. Then put the BrewKeg

and the CO

bottle (still connected to the

2

10™

vessel lid) inside the kegerator/fridge to

maintain the cold temperature and pressure.

dosing device lid. Press the VPRV button

and release CO

until the gauge reads 0.6 bar (9 psi). The

principle is that the vessel needs to be 0.5 bar

(7 psi) lower in pressure than the CO

low pressure to be able to dose clarification

agent in. Then connect the black quickdisconnect fitting to the beverage-out port on

the BrewKeg

in Figure 6 (previous page). As soon as you

out of the BrewKeg10™

2

supply

2

10™ lid. This set up is shown

F. Beer Clarification 2: After 12 hours, there will

be a new layer of sediment settled, with beer

seen above that in the sediment bottle. Remove

the grey fitting on the gas-in port and put the

pressure gauge back on that port. Then repeat

the above steps from B to E, but this time with

10ml (0.34 fl. oz.) of clarification agent at step

C. A third yeast and haze layer will fall into the

sediment bottle over the next

12 hours.

connect the black fitting, the higher pressure

in the clarification pot will force the agent

down the line and into the keg. Bubble the

Step 4: Dispense

agent into the beer for a few seconds or until

the vessel pressure equalises with the pressure

you have set on your regulator, e.g. 1.1 bar

(

16 psi). You must hear the bubbling

to confirm it is working. Note that the

BrewKeg

10™ pressure will increase during

bubbling as seen on its pressure gauge.

A. After another 12–24 hours the beer will be

ready for dispense. For WilliamsWarn cider

this stage will coincide with the 6-

12 hour

mark after cooling (Day 4.5), as that beverage

doesn’t need the clarification step. In both

cases the sediment bottle will be part full

of sediment, and you should see a clear

line between the sediment and the beverage

above it.

B. Disconnect the grey fitting from the lid gas-in

port and close the vessel butterfly valve. Take

the BrewKeg

10™ out of the kegerator/fridge

and take it to the sink or drain. Then remove

the sediment bottle as shown at the beginning

of the Dispense video. It screws off clockwise

looking down on it. Dump the sediment, rinse

the sediment bottle well with water and rinse

the butterfly valve with some water too. Then

put the sediment bottle back onto the butterfly

valve as a safety mechanism, in case someone

opens the valve accidentally during the

Dispense period.

C. Put the keg back in the kegerator/fridge and

connect the CO

supply grey fitting back

2

onto the gas-in port on the lid. Then connect

the black fitting of your draft beer tap to the

beverage-out port on the lid. See Figure 7 for

this set up.

BREWING INSTRUCTIONS

D. The beverage is ready for dispense so open the

draft beer tap to allow flow of the final product

into a glass and enjoy your brew.

Pull the tap towards you to open the tap. A

Williamswarn kegerator has taps with a flow

control lever on the side. The closed positions

are both fully up and fully down, so open the

lever part way down to get the flow you desire.

Horizontal is fully open.

You can also transfer beverage brewed in a

BrewKeg

10™ into bottles or Cornelius kegs

and get on with another brew in the BrewKeg.

See the WilliamsWarn website for videos and

manuals of those transfers.

Special note for Kegerator users: Most

kegerators have a hole at the back of the

kegerator for the CO

this instance the CO

line to go through. In

2

bottle sits outside the

2

kegerator. Use this set up if you prefer it to

placing the CO

bottle inside the kegerator with

2

the keg/kegs. It is particularly useful when you

have 2 kegs inside a kegerator, in which case

you will need a splitter to split the CO

line

2

coming off the regulator into several gas lines

with grey quick-disconnect fittings on their

ends, to supply CO

pressure on the gas-in ports

2

on several kegs at the same time. See figure 8.

Fig 7: Dispense from a kegerator (above) and a

fridge (below) with CO2 bottle inside.

1

1

Fig 8: Kegerator with CO2 bottle going through the

back.

USER MANUAL

Special Note on Pressure and Carbonation

Beverage Typical Grams

per Litre (g/L) CO

British Ales 3.0 - 4.0

Porter, Stout 3.5 - 4.5

Belgian Ales 4.0 - 4.5

American Ales 4.5 - 5.5

European Lagers, Belgian Lambics 5.0 - 5.5

Some Lagers, New World Ales 5.5 - 6.0

Cider and Mead Still - 8.0

American Wheat 5.5 - 6.5

German Wheat Beers 6.5 - 8.0

2

Beverage Typical Serving

British Ales

Porter, Stout

Belgian Ales

American Ales

European Lagers, Belgian Lambics

Some Lagers, New World Ales

Temperature

1 – 7°C / 34 – 45°F

1 – 8°C / 34 – 46°F

6 – 10°C / 43 – 50°F

7 – 13°C / 45 – 55°F

5 – 16°C / 41 – 61°F

10 – 15°C / 41 – 59°F

The typical serving temperature for beers also has

a historical basis and ranges from 1ºC–15/16ºC

(34ºF–59/61ºF). The brewers in New Zealand,

Historically the amount of CO2 in a beer has

depended on its beer style and this ranges from

3g/L to 8g/L. We’ve found over the years that

Australia and the USA tend to like the colder

beers, so we’ve targeted 1ºC (34ºF) as the starting

point for these instructional manuals.

WilliamsWarn brewers like to target around about

6–6.4g/L CO

in their beers.

2

CO2 Levels From Pressure vs Temperature

Temp (ºC)

13

12

11

1

2

Tank Pressure (BAR)

10

9

8

7

6

5

4

3

2

1

CO2 Level g/L

WilliamsWarn brewers tend to like quite highly

carbonated beers so we’ve targeted 6.4g/L in a

BrewKeg10 at 1ºC. This means, as you can see on

this graph, we need a pressure of 1.1 bar during

dispense. So that’s why we set 1.1 bar pressure

on the low pressure gauge on our CO

supply

2

regulator.

Adjusting Carbonation

BREWING INSTRUCTIONS

Carbonation g/L CO2Pressure on CO2 Supply for

Clarification and dispense (1ºC/34ºF)

High 6.4 g/L 1.10 bar

High 6.2 g/L 1.03 bar

High 6.0 g/L 0.96 bar

Moderate 5.8 g/L 0.90 bar

Moderate 5.6 g/L 0.83 bar

Average 5.4 g/L 0.76 bar

Average 5.2 g/L 0.70 bar

Average 5.0 g/L 0.63 bar

Low 4.8 g/L 0.56 bar

Low 4.6 g/L 0.49 bar

Carbonation for Warmer Beverages

Carbonation g/L CO2Pressure on CO2 Supply for

Clarification and dispense (5ºC/41ºF)

High 6.4 g/L 1.41 bar

High 6.2 g/L 1.34 bar

High 6.0 g/L 1.26 bar

Moderate 5.8 g/L 1.19 bar

Moderate 5.6 g/L 1.11 bar

Average 5.4 g/L 1.03 bar

Average 5.2 g/L 0.96 bar

Average 5.0 g/L 0.88 bar

Low 4.8 g/L 0.81 bar

Low 4.6 g/L 0.73 bar

If you find this high carbonation level is a little

bit too high for your personal preference, or you

are getting a little too much foam out of the draft

beer tap, then for your next brews just target a

lower dispense pressure. For example 0.9 bar will

give you 5.8g/L carbon dioxide. So that is what

you would set on the low pressure gauge on your

CO

supply. During fermentation set your VPRV to

2

release at about 0.4 bar higher than the dispense

pressure you’ve chosen to allow for a pressure

drop during cooling and to have a little excess

carbonation in the beer before clarification. Also

when you press the button on the VPRV to reduce

the pressure in the vessel before you dose in the

clarification agent, lower the vessel pressure to

0.5 bar lower than the dispense pressure you

might be choosing from this table, to be able to

force the agent into the beer.

Please note, if you prefer a warmer beverage

temperature at dispense, for the same amount

of carbonation you need more pressure. So

choose the amount of carbonation you want

and use the graph on the left to set the dispense

pressure you need. If you find your beverage

is over carbonated to your personal taste or

maybe over foaming through your beverage

tap system, put the pressure gauge back on

and open the VPRV up to a lower pressure

and let it stand overnight. This will reduce

the carbonation level. If you’re short of time,

you could try shaking the keg a little bit to help

force the CO

out of the beverage.

2

1

3

A Simple Rule of Thumb

If you like the level of carbonation that 1.1 bar

(16 psi) gives you at 1ºC (34ºF), but would like

a warmer beer, a simple rule of thumb is to try

1.2 bar at 2ºC (35.6ºF), or 1.3 bar at 3ºC (37ºF),

or 1.4 bar at 4ºC (39ºF), or 1.5 bar at 5ºC (41ºF).

This works well for those who like a high

carbonation level and it will not result in foaming

of the beer out the tap when the beer is poured.

USER MANUAL

FINAL

WORDS

These instructions represent

a means for anyone to

make great beer or cider

the first time they use a

BrewKeg10™. As you

brew more, you may find

you come up with your

own tweaks to what is

written here or develop

radically different methods

that suit you better. As long

as you and your friends are

happy with the final beer

1

4

or cider, feel free to make

you own adjustments to the

process if you feel the need

or see an easier way to brew

using your set up.

NOTES

BREWING INSTRUCTIONS

1

5

Loading...

Loading...