N

W

G

W

G

W

G

W

G

W

G

W

G

Sealed Combustion Oil Furnaces

SCH High Boy

SCL Low Boy

KEEP THESE INSTRUCTIONS

WITH FURNACE FOR FUTURE

REFERENCE.

DANGER

ARNIN

ARNIN

ARNIN

CAUTION

ARNIN

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

INSTALLER – Read all instructions before

installing. Read page 2 first. Follow all instructions

in proper order to prevent personal injury or death.

• Consider ducting, fuel supply, venting and

installation when determining furnace location.

• Any claims for damage or shortage in shipment

must be filed immediately against the transportation

company by the consignee.

Do not store or use gasoline or other flammable

liquids or vapors near this furnace or any other

appliance.

Ventilate house while operating furnace for the first

time. Odors may be emitted for a brief period.

Do not alter this furnace in any way. The

manufacturer will not be liable for any damage

resulting from changes made in the field to the

furnace or its components or from improper

installation. Failure to comply could result in severe

personal injury, death or substantial property

damage.

Hazard definitions

Furnace Manual

Contents

Read this first!............................................................................2

1. Prepare furnace location............................................................ 3

2. Prepare furnace and place in position .......................................5

3. Connect supply and return ducts............................................... 6

4. Venting – Sealed Combustion System ......................................9

5. Connect fuel oil piping..............................................................15

6. Wire furnace and burner.......................................................... 16

7. Start-up.................................................................................... 18

8. Checkout procedure.................................................................19

9. Troubleshooting....................................................................... 21

10. Service and maintenance ........................................................22

11. Components and replacement parts........................................ 25

12. Dimensions and ratings ...........................................................34

13. Owner’s information ................................................................. 38

CAUTIO

NOTICE

Page

Hazards that will or can cause minor personal

injury or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage.

ARNIN

ARNIN

NOTICE

USER – Please read the following. Failure to

comply could result in severe personal injury, death

or substantial property damage.

• This manual is for use only by your qualified

heating installer / service technician.

• Please see the Owner’s information only, on back

page of this manual.

• Have the furnace serviced by a qualified service

technician, at least annually.

This manual must only be used by a qualified

heating installer / service technician. Furnace and

burner must be installed and serviced only by a

qualified heating installer / service technician.

Failure to comply could result in severe personal

injury, death or substantial property damage.

When calling or writing about the furnace, please

refer to furnace model number and serial number

shown on the rating label. You may list the serial

number and model number in the space provided on

the “Installation and service certificate” found on

page 20.

670-000-006-1007

W

G

READ THIS FIRST!

ARNIN

Service and maintenance

1. To avoid electric shock, disconnect electrical supply before

performing maintenance.

2. To avoid severe burns, allow furnace to cool before performing

maintenance.

3. Perform service and maintenance as described in this manual

and the burner manual.

4. Do not attempt to make adjustments to the blower or motor while

the furnace is in operation. Disconnect power to the furnace and

be sure all parts have stopped moving before attempting

adjustments or maintenance.

5. The burner must be set up and adjusted using combustion test

instruments. Visual examination of the flame alone cannot

determine combustion performance.

Operation

6. Do not use the furnace as a construction heater.

7. Do not operate any furnace if the heat exchanger is damaged,

corroded or pitted. Toxic flue products could enter the air

stream.

8. Do not jumper, attempt to by-pass or override any limit control.

9. Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

10. Do not store or use combustible materials, gasoline, or other

flammable liquids or vapors in the furnace area.

11. Do not operate the furnace if the furnace area will be exposed to

air contaminants.

12. Should overheating occur, do not turn off or disconnect electrical

supply to furnace. Instead, shut off the oil supply at a location

external to the appliance, if possible.

13. Do not use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect the

furnace and to replace any part of the furnace, control system or

burner that has been under water.

14. Do not operate furnace if temperature rise through heat

exchanger exceeds 85

NOTICE

Installation –

1. Be sure to level the furnace, using a spirit level on the front and

one side. If the furnace is not level, oil can drip into the

combustion chamber after burner cycling, causing fouling of the

heat exchanger and the burner head.

2. Make sure all legs are in contact with the floor to distribute the

load and prevent the possibility of undue noise or vibration.

Failure to adhere to the guidelines below can result in severe personal injury, death or substantial property damage.

o

F.

Apply the following suggestions to prevent unsatisfactory operation of the furnace.

15. Inspect, clean and replace (if necessary) return air filter

regularly.

16. Do not obstruct return air grills or supply air outlets.

17. Supply only #2 fuel oil to the burner. Never attempt to use

gasoline, a mixture of gasoline and oil, waste fuel, refuse or any

other substance in the burner of furnace.

Installation

18. Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

19. Connect furnace only to a functional vent system in good

condition. Place the furnace so as to allow proper venting, with

the shortest possible venting and minimum number or elbows.

20. Always connect and seal a return air duct to the furnace unless

the furnace is located in a large space, such as an unpartitioned

basement. Route the return air duct to an adjacent room if no

return air manifold is used.

21. Install furnace maintaining minimum clearances for service and

separation from combustible surfaces described in this manual.

22. Install, start-up, service and maintain burner per instructions in

this manual and the burner manual.

23. Verify burner is properly inserted through the combustion

chamber opening.

24. Furnace must be installed so that burner and control system

components are protected from dripping, spraying water or rain

during operation or service.

25. If installing an air conditioning evaporator coil, install the coil

downstream of, or in parallel with, the furnace to prevent

condensation in the furnace heat exchanger. If the coil is in

parallel, provide means to prevent flow of chilled air into the

furnace, including an interlock to prevent simultaneous operation

of heating and air conditioning.

3. Avoid locating return grills in rooms that may contain undesirable

odors.

4. Never locate a return air grill closer than approximately 20 feet

from the furnace.

5. Locate the furnac e near the center of the supply and return duct

systems.

6. Always check the size of the ducts on a replacement installation,

particularly if adding air conditioning.

2 670-000-006-1007

W

G

SCH & SCL Oil Furnaces – Furnace Manual

1 Prepare furnace location

Pre-installation checklist

Verify code compliance

Local, state, and national codes, laws, regulations and

ordinances

NFPA-31, Installation of Oil-Burning Equipment

National Electrical Code

All local codes and/or regulations take precedence over the

instructions in this manual and should be followed accordingly.

NOTICE

SCH & SCL furnaces, their burners and controls have

met safe lighting and other performance criteria when

they underwent tests, specified in Underwriters

Laboratories Standard UL727.

Check location and furnace specifications

Furnace heating capacity

Space is large enough to provide required clearances

Verify the installation will meet the requirements of this manual:

Clearances (page 3)

Combustion/ventilation air openings (page 4)

Supply air duct (page 7)

Return air duct (page 7)

Vent system (page 9)

Fuel oil piping (page 15 plus burner manual)

Electrical connection (page 15)

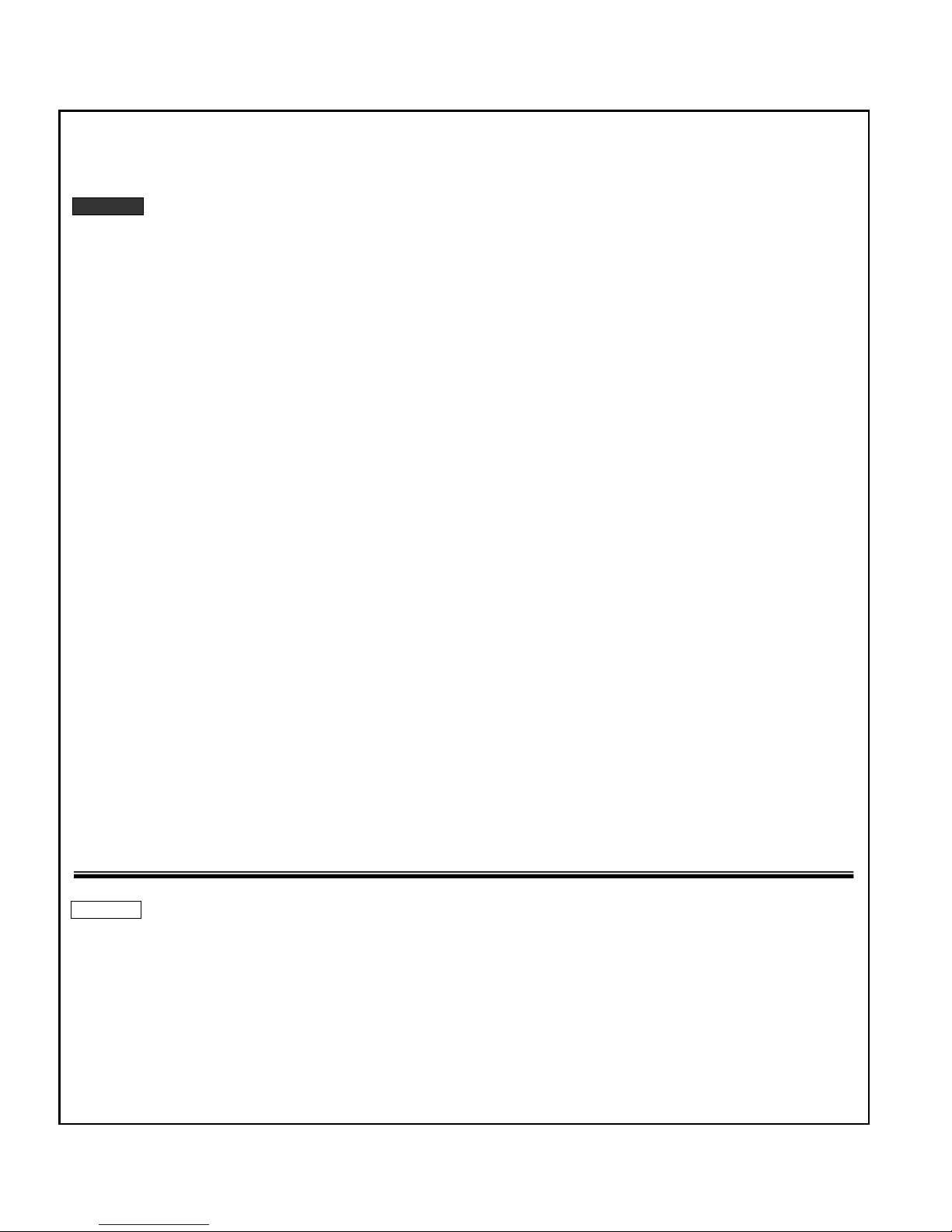

Clearances

Minimum clearances to combustible materials

1. Install the furnace, ductwork and vent such that no combustible

surface is closer than indicated in Table 1.

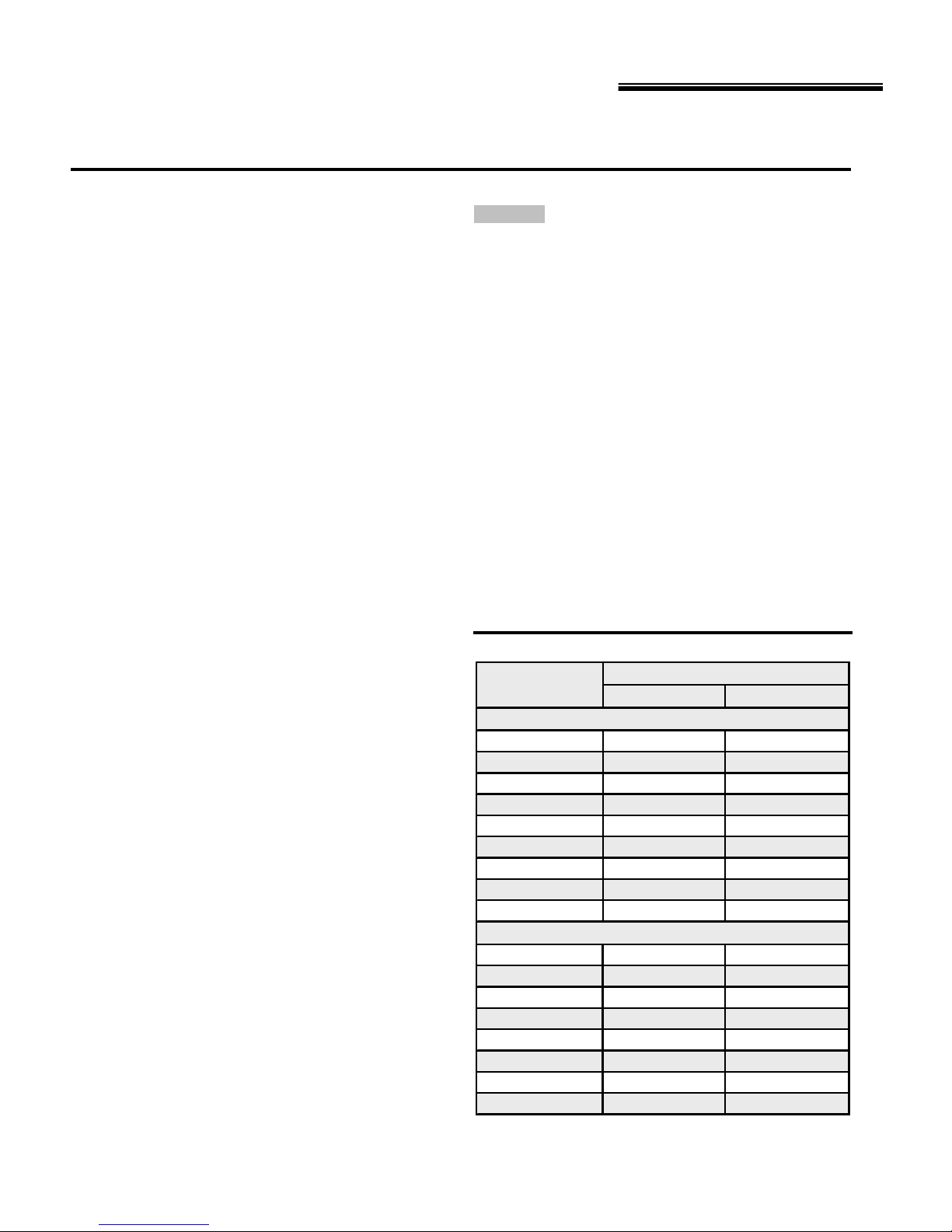

Table 1 Minimum clearances

Service accessibility clearances are

recommended minimum dimensions to

allow access to furnace components

(motor, blower, filters, etc.)

Side of furnace or supply plenum

Rear of furnace

Top of furnace casing or supply

plenum (warm-air duct within 6 ft. of

furnace)

Bottom of furnace

Front of furnace

Flue pipe

Minimum clearances from furnace, ductwork and vent

SCH-105 (3” vent dia.) SCH-160 (4” vent dia.) SCL-105 (3” vent dia.) SCL-160 (4” vent dia.)

To

combustible

construction

1"

For

service

accessibility

24"

(one side)

1" 24" 18" 24" 1" 24" 18" 24"

1" --- 2" --- 1" --- 2" --0" --- 0" --- 0" --- 0" ---

1" 24" 24" 24" 1" 24" 24" 24"

REFER TO SECTION 4 (VENTING)

NOTICE

Flue pipe clearances must take precedence over

jacket clearances (listed below).

Service accessibility clearances

1. Provide no less than the minimum clearances given in Table 1 to

ensure the furnace can be properly operated, serviced and

maintained.

2. Always apply whichever clearance is LARGER – combustible

construction or service accessibility.

Flooring and foundation

Flooring

SCH & SCL furnaces are approved for installation on combustible

flooring, but must never be installed on carpeting.

ARNIN

Do not install furnace on carpeting even if foundation

is used. Fire can result, causing severe personal

injury, death or substantial property damage.

Foundation

1. Provide a solid brick or minimum 2 inch thick concrete

foundation pad if any of the following is true:

• the floor can become flooded.

• the furnace mounting area is not level.

Residential garage installations

Take the following special precautions when installing the furnace in

a residential garage. Il the furnace is located in a residential garage:

• Mount the furnace a minimum of 18 inches above the floor

of the garage.

• Locate or protect the furnace so it cannot be damaged by a

moving vehicle.

To

combustible

construction

1"

For

service

accessibility

24"

(one side)

To

combustible

construction

1"

For

service

accessibility

24"

(one side)

To

combustible

construction

1"

For

service

accessibility

24"

(one side)

670-000-006-1007 3

3

N

W

G

SCH & SCL Oil Furnaces – Furnace Manual

1 Prepare furnace location (continued)

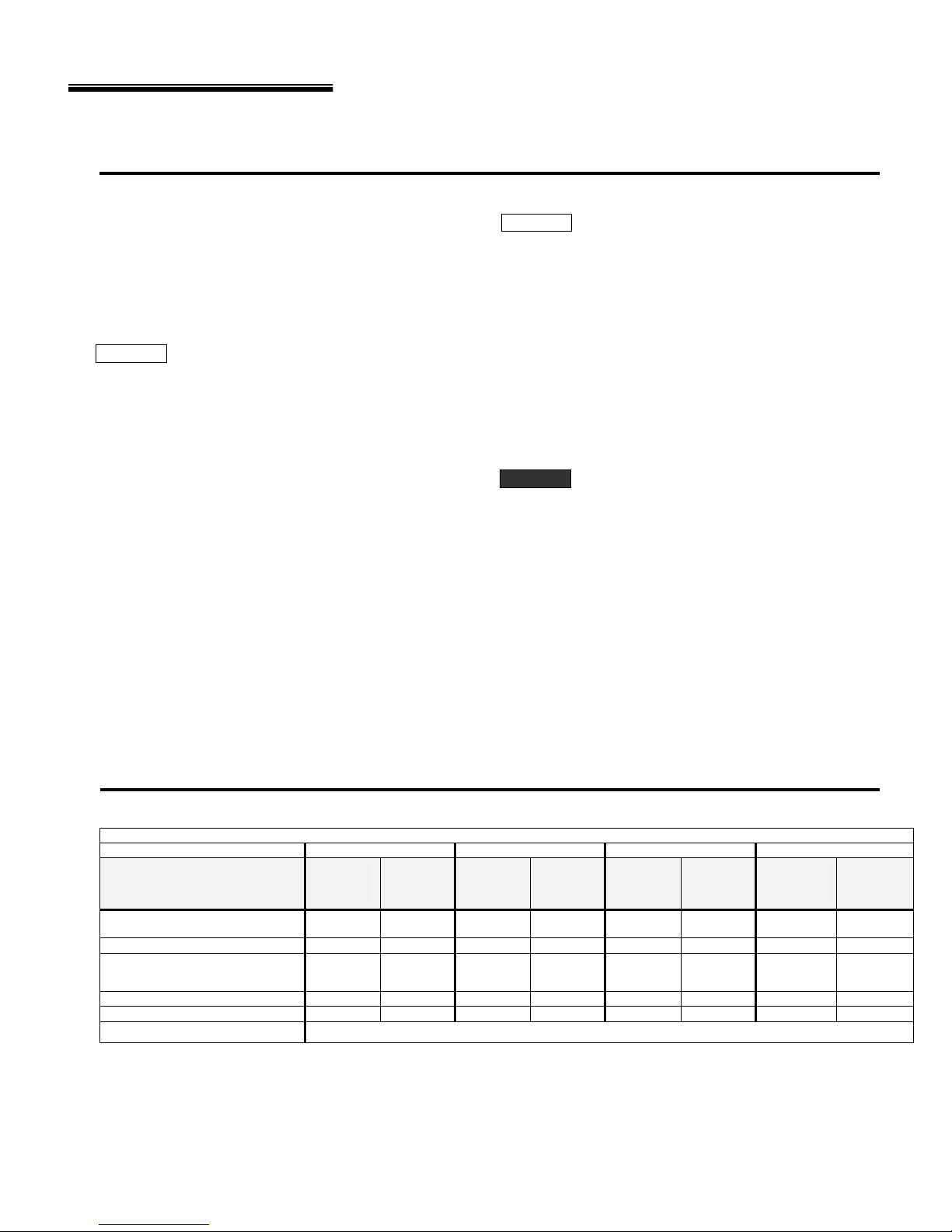

Vent pipe clearances

Table 2 Minimum clearances – side-wall venting

CLEARANCES

Vent pipe, up to vent terminal 3"

Vent terminal Zero

Figure 1

ARNIN

Do not enclose venting in a ceiling or combustible

structure.

Vent terminal location

Select a location for the vent terminal in accordance with all local

and national codes. The following requirements shall be considered

to be minimum requirements that can be overridden by stricter local

and national codes.

Following are excerpts from the NFPA 31 code:

The vent shall terminate at least 3 ft. above any air inlet to the

structure that is within 10 ft. of the termination point.

The combustion air inlet and flue gas outlet of a direct vent

appliance shall terminate at least 1 ft. (0.3 m) from the soffit of the

roof of the structure and at least 3 ft. (0.9 m) from an inside corner of

an L-shaped structure.

The vent terminal shall be located at least 1 ft. (0.3 m) from any

door, window or air inlet to the structure. The flue gas outlet terminal

shall also terminate at least 1 ft. (0.3 m) above grade.

The vent shall not be less than 7 ft. ( 2.1 m) above grade, when

located adjacent to public walkways.

The vent shall terminate at least 5 ft. (1.6 m) from the vent outlet of a

supply tank.

CAUTIO

Most codes have a notwithstanding clause which

states that, products of combustion shall not enter

the dwelling under any circumstances, even if all

other code requirements as to construction and

location have been complied with. The installer is

ultimately responsible to do whatever is necessary

to ensure that flue gases do not enter the dwelling.

4 670-000-006-1007

W

G

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

2 Prepare furnace and place in position

Inspect & prepare furnace

Remove furnace from carton

Remove the furnace from its shipping carton and inspect thoroughly.

Remove access panels to inspect the furnace interior.

NOTICE

ARNIN

Immediately file a claim with the transportation

company if you discover concealed damage.

Do not install or attempt to operate the furnace if the

heat exchanger, burner or controls have been

damaged. Immediately contact your furnace

supplier. Operating a damaged furnace could result

in severe personal injury, death or substantial

property damage.

Prepare furnace (SCH models)

SCH furnaces require cutting the return air opening into one side of

the furnace. Carefully cut the opening on the correct side of the

furnace, using the four knock-outs on the side as guides.

Prepare burner

Remove the burner from its shipping carton and inspect thoroughly.

Read the burner manual and follow instructions for preparing and

installing the burner.

Install the correct nozzle for the required firing rate, using the burner

manual and the information in Section 12 of this manual. Follow the

burner manual instructions for nozzle installation. Verify the correct

setting of electrodes after nozzle and burner oil tube assembly are in

place.

Openings in walls, floor & ceiling

General

Ensure that the finished door opening to the furnace room is large

enough to install and remove the furnace, water heater or any other

appliances in the room.

Before placing furnace in a closet or small room, cut all openings

required in floor, ceiling or walls for ducts and vent. This will simplify

the work and prevent construction dust from entering the furnace

heat exchanger.

ARNIN

Duct locations and sizing

Verify the size of the supply and return duct system is sufficient for

the application. The pressure drop through the duct system must not

exceed 0.25 inch water column. The total drop through the duct

system and air conditioning evaporator coil (if used) must not

exceed 0.5 inch water column.

Verify that all clearances to combustible construction

and as needed for service accessibility will be met.

The vent must be no closer than 3 inches to any

combustible surface. Failure to comply could result

in severe personal injury, death or substantial

property damage.

Openings in walls, floor… (continued)

See suggested duct sizing in this manual. For more detailed sizing

information refer to ACCA Manual D.

Return air duct

You must install a return air duct, sealed to the furnace, even if no

return manifold is used. The only exception is when the furnace is

located in a large unpartitioned room, such as a basement. (A room

whose volume is at least 50 cubic feet per 1,000 BTU/h input of all

appliances in the room is considered large). For large rooms, return

air may be taken directly at the furnace, without a return air duct. No

return air register should be within 20 feet of the furnace.

Cut the required opening for the return air duct in the wall (or floor or

ceiling) of the room before placing the furnace.

Install filter

Install return air filter of the size listed in Section 12.

You will need to install a filter rack provided with the furnace for

Model SCH only.

NOTICE

Verify that the filter will be easily accessible for

removal after the furnace is in place.

Install furnace and burner

Place furnace

Place the furnace in the desired location. Measure clearances and

verify per page 3 of this manual.

Using a spirit level on the front and one side of the furnace, level it

using the 4 or 6 levelling legs. Make sure each of the legs is firmly in

contact with the floor.

Inspect combustion chamber

Inspect the combustion chamber. Verify it is in good condition and

correctly in position inside the heat exchanger. The burner opening

in the chamber must align with the burner heat exchanger opening.

ARNIN

Insert burner

Following the burner manual instructions, install the burner and its

gasket in the burner opening. Make sure the burner is aligned with

the opening in the combustion chamber and that burner insertion

corresponds to the value specified in Section 12.

Secure the burner in place with the three nuts and washers

provided. Wire and pipe fuel to the burner per burner manual and

this manual.

Burner orientation

Always keep the motor shaft in a horizontal position

The combustion chamber is constructed of ceramic

fiber materials See the WARNING information on

page 23 of this manual. Comply with these

instructions when handling any ceramic fiber or

fiberglass materials. Failure to adhere to these

guidelines could result in severe personal injury or

death.

670-000-006-1007

5

N

SCH & SCL Oil Furnaces – Furnace Manual

3 Connect supply and return ducts

Duct sizing

Determine air flow CFM

The temperature rise through the furnace must not exceed 85o F and

should be at least 55°F for comfort. When calculating air flow,

assume a temperature rise of 70°F.

The sensible heat temperature change for cooling would be

approximately 27-30°F. Actual temperature change will be

approximately 18-21°F due to humidity of the air.

To calculate the sensible heat temperature change (ΔT), you can

use the formula:

ΔT = BTU/h/(1.1 x CFM) Eq. 3-1

To calculate air flow when you know temperature change (ΔT), you

can use:

CFM = BTU/h/(1.1 x ΔT) Eq. 3-2

You can estimate air flow using the following rules of thumb:

Heating: 14 CFM per 1,000 BTU/h output Eq. 3-3

Cooling: 400 CFM per ton air conditioning Eq. 3-4

Determine the required air flow based on whichever is larger –

heating mode or air conditioning mode.

Examples:

1. What would the temperature rise be for a 100,000 BTU/h output

furnace with an air flow rate of 1200 CFM?

Use Equation 3-1 since you know CFM and BTU/h:

ΔT = 100,000/(1.1 x 1200) = 76°F

• The temperature rise would be 76°F.

• If the air enters the furnace at 70°F, it would leave the

furnace at 70°F + 76°F = 146°F.

2. What would the air flow be to obtain a 70°F rise through a

120,000 BTU/h output furnace?

Use equation 3-2 since you know ΔT and BTU/h:

CFM = 120,000/(1.1 x 70) = 1,558 CFM

• The air flow would have to be 1,558 CFM to obtain a

temperature rise of 70°F.

3. Estimate the required air flo w for a 75,000 BTU/h output fu rnace

installed with a 2-ton air conditioning evaporator coil.

Heating mode air flow (use Equation 3-3):

CFM = 75 x 14 = 1,050 CFM

Cooling mode air flow (use Equation 3-4):

CFM = 2 x 400 = 800 CFM

• The larger number is 1,050 CFM (heating), so the duct

system should be sized for 1,050 CFM.

• The supply duct would need to be 16" round or a rectangular

equivalent such as 8" x 25" or 12" x 16", using Table 4, page

7.

4. Estimate the required air flow for the same furnace installed with

a 4-ton air conditioning evaporator coil.

Heating mode air flow is still 1,050 CFM.

Cooling mode air flow (use Equation 3-4):

CFM = 4 x 400 = 1,600 CFM

• The larger number is 1,600 CFM (cooling), so the duct

system should be sized for 1,600 CFM.

• The supply duct would need to be 18" round or a rectangular

equivalent such as 8" x 36" or 12" x 21", using Table 4, page

7.

6 670-000-006-1007

CAUTIO

Always check the size of existing ducts, particularly

if you are adding air conditioning. The air pressure

loss through the cooling evaporator coil reduces

available air flow. If the ducts are too small as well,

the system may not work satisfactorily on either

heating or cooling.

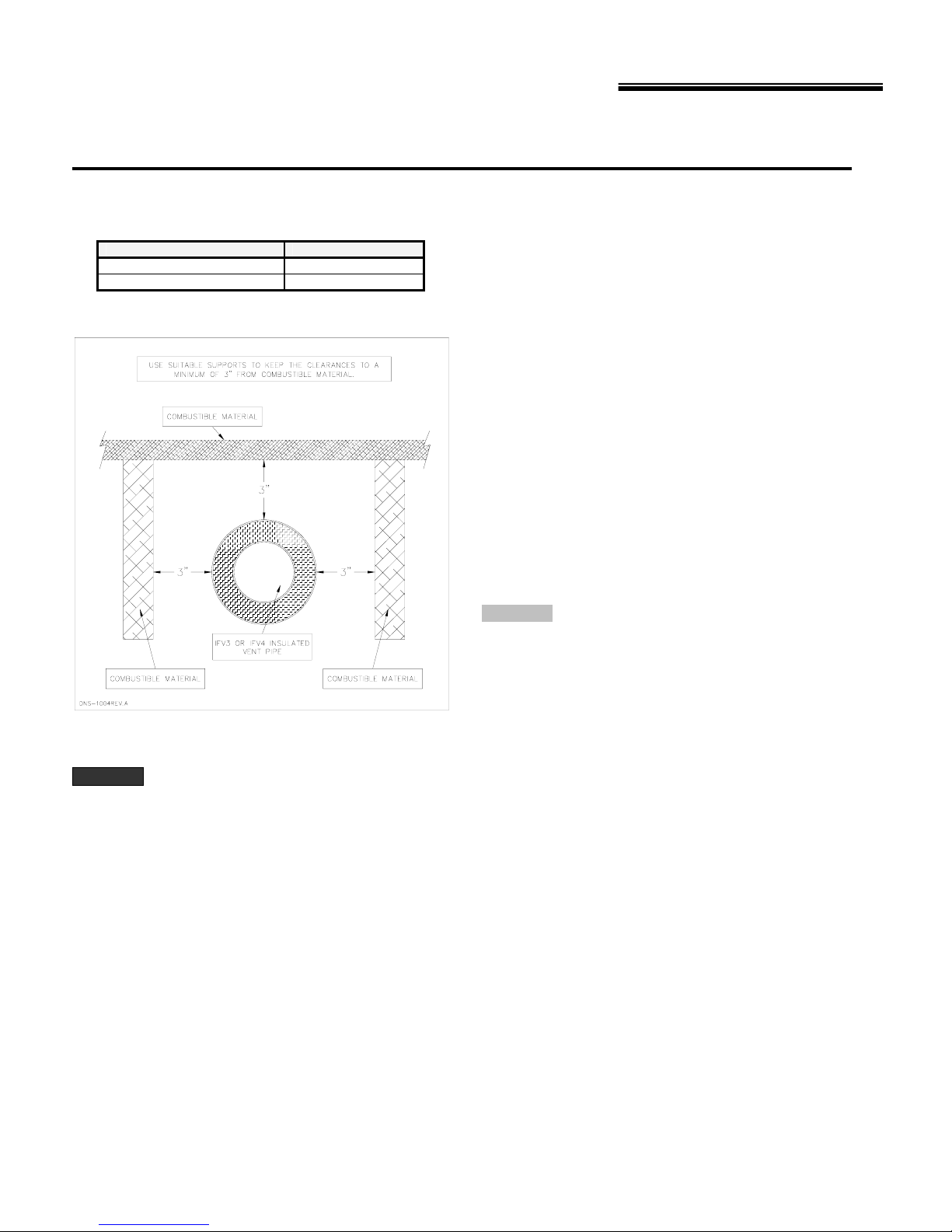

Determine duct dimensions

Table 4, page 7 and Table 5, page 8, provide typical round and

rectangular duct sizes for rectangular and flat oval galvanized ducts.

Do not apply these tables to size ductwork if the total equivalent

length of the duct exceeds approximately 100 feet. For longer

systems or for duct board, fiberglass-lined or flexible duct sizing, use

the ACCA Manual D or the ACCA duct sizing slide rule. These

tables are based on pressure loss of approximately 0.10 inch water

column per 100 feet equivalent length of duct.

Use Table 3 below to size or check sizing of take-offs to supply

registers or return grills.

Verify the size and type of registers, diffusers and grills from the

manufacturer’s ratings. Do not exceed the recommended flow rate.

The pressure drop allowance for each should not exceed

approximately 0.05 inch water column.

Install a return air filter, sized per specifications in Section 12.

Use only a return air filter mounted to the furnace. Do not add

additional filters unless the duct system is carefully sized to allow for

the additional pressure drop.

Table 3 Suggested maximum flow to runouts

TAKE-OFF SIZE

(Inches)

Sheet metal or ductboard

5 Round 60 45

6 Round 100 75

7 Round 140 110

8 Round 210 160

3 ¼ x 8 Stack 70 55

3 ¼ x 10 Stack 100 75

3 ¼ x 14 Stack 140 110

2 ¼ x 12 Stack 70 55

2 ¼ x 14 Stack 90 70

Flexible duct (keep bends to minimum)

6 Round 55 40

8 Round 120 90

10 Round 200 160

12 Round 320 250

14 Round 480 375

16 Round 660 530

18 Round 880 680

20 Round 1200 900

SUPPLY RETURN

CFM

W

G

SCH & SCL Oil Furnaces – Furnace Manual

3 Connect supply and return ducts (continued)

Duct sizing (continued)

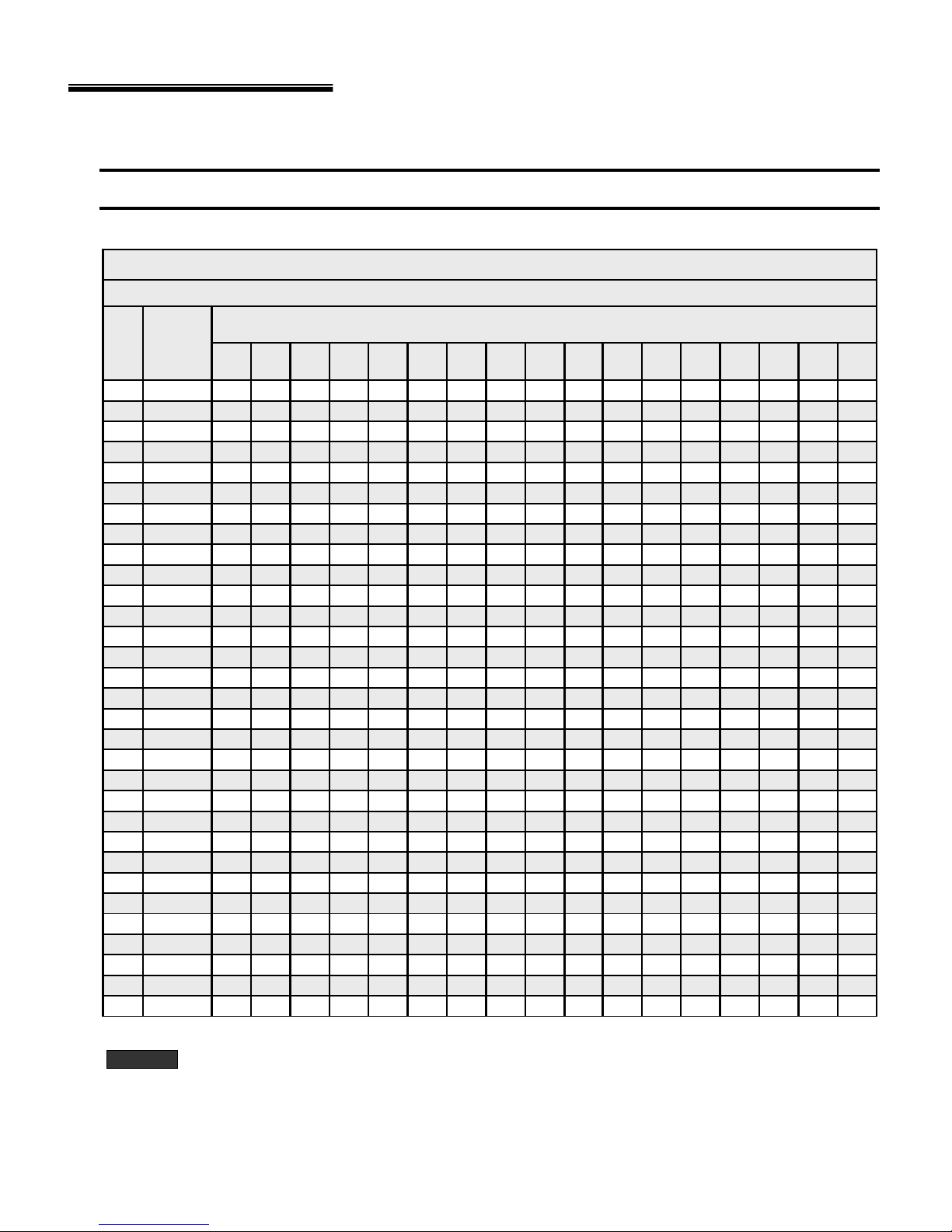

Table 4 Typical duct sizing for systems not over 100 feet equivalent length – round or rectangular galvanized

CFM

(For approximately 0.10 inch w.c. in a typical residential installation of galvanized metal duct)

Round

duct

diameter4567891012141618202224262830

(inches)xxxxxxxxxxxxxxxxx

45

65

100

150

200

250

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2200

2400

2600

2800

3000

3500

4000

ARNIN

Rectangular duct equival ent si zes

Mini mum width

4

5

6

7

8

9

9

10

12

12

12

14

14

16

16

16

16

18

18

18

18

18

20

20

20

22

22

22

22

24

26

444-------------6544-- - - --- - -----

865544-- - -- -----1297655544- -- ----141198766544- - ----181310987665544----20 15 12 10 9 8 7 6 6 5 5 4 4 - - - 2619151311109876655544322318151312119876665555

3828221815131210987766655

46322520171514111098777666

523628231917151311109887766

5841312521191714121110988777

6445342823201815131110998877

72493830252219161412111099887

-5441332724211715131211109988

- 58443529252218161412111010 9 9 8

- 6347383127241916141312111010 9 9

- 685140342925201715141212111010 9

- 725443363027211816141312111110 9

- - 58 45 38 32 28 23 19 17 15 14 13 12 11 10 10

- - 61 48 40 34 29 24 20 17 16 14 13 12 11 11 10

- - 64 51 42 35 31 25 21 18 16 15 14 13 12 11 11

- - 68 53 44 37 32 26 22 19 17 15 14 13 12 12 11

- - - 59 48 41 35 28 23 20 18 16 15 14 13 12 12

- - - 64 52 44 38 30 25 22 19 17 16 15 14 13 12

- - - 69 56 47 41 32 27 23 21 19 17 16 15 14 13

----61514434292522201817151514

----65544737302623211917161514

-----635442342926232119181716

-----726147393329262321201918

Do not apply this table for duct systems over approximately 100 equivalent feet length. For longer systems or systems using

other duct materials, refer to ACCA Manual D. Incorrectly sizing duct systems can result in unsafe or uncomfortable

operation.

(inches)

Typical duct sizing

for duct height s

(inches)

of :

670-000-006-1007

7

W

G

SCH & SCL Oil Furnaces – Furnace Manual

3 Connect supply and return ducts (continued)

Duct sizing

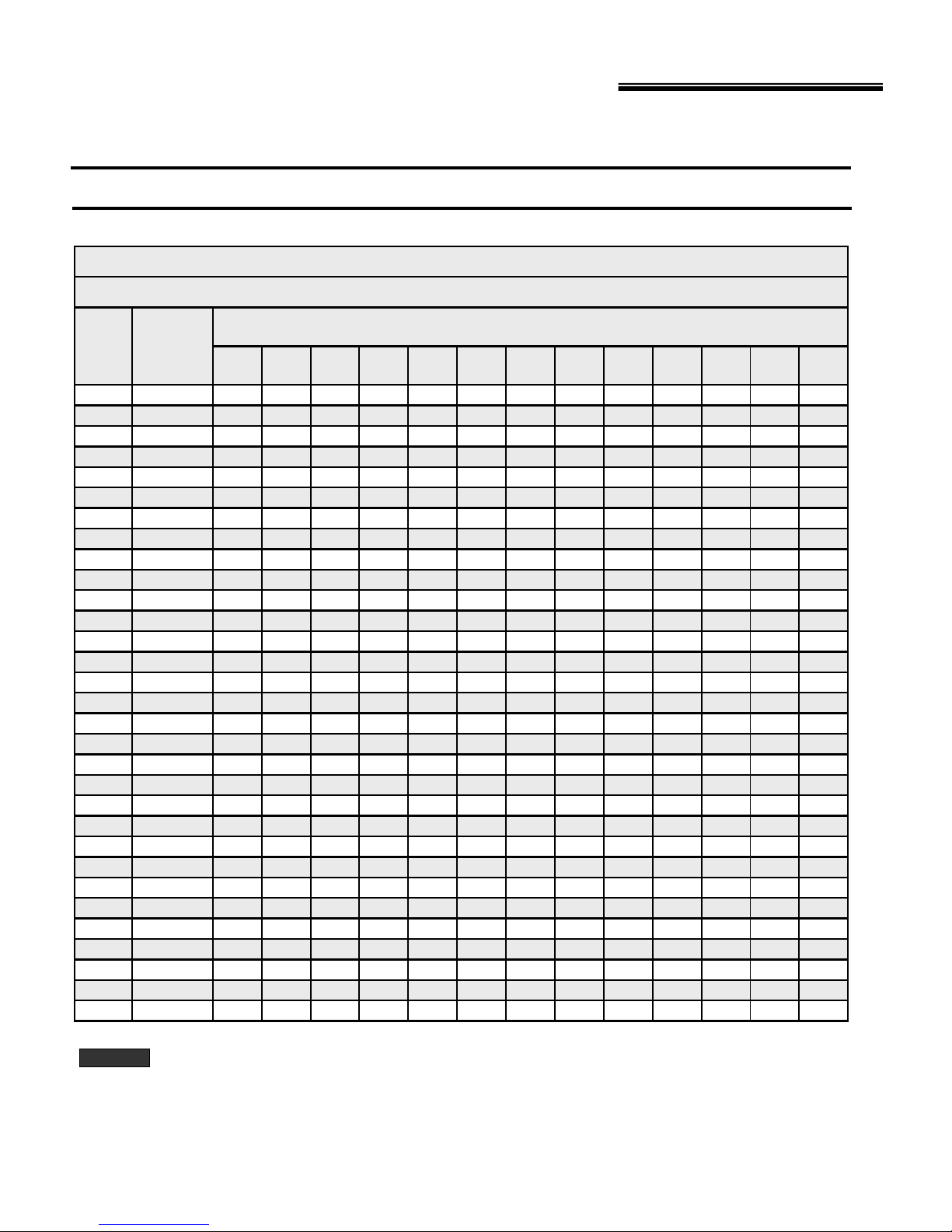

Table 5 Typical duct sizing for systems not over 100 feet equivalent length – round or flat oval galvanized

CFM

45

65

100

150

200

250

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2200

2400

2600

2800

3000

3500

4000

ARNIN

(continued)

Typical duct sizing

(For approximately 0.10 inch w.c. in a typical r esidential i nstallation of galvanized metal duct)

Round

duct

diameter3456789101214161820

(inches)xxxxxxxxxxxxx

10

12

12

12

14

14

16

16

16

16

18

18

18

18

18

20

20

20

22

22

22

22

24

26

Do not apply this table for duct systems over approximately 100 equivalent feet length. For longer systems or systems using

other duct materials, refer to ACCA Manual D. Incorrectly sizing duct systems can result in unsafe or uncomfortable

operation.

Flat oval duct equi val ent si zes

Mini mum width

4

5

6

7

8

9

9

65-----------

86----------1187---------161198--------211511108-------26181411109------302016131110------40262016141211-----4932241916141312----5938282219161513----694432252118161513----

-5036292420181614----

-5641322622201815----

- 634535292422191715 - - -

- 694938312623211816 - - -

- 755341332825221917 - - -

- - 58 44 36 30 26 24 20 18 - - -

- - 62 47 38 32 28 25 21 18 17 - -

- - 66 50 41 34 30 26 22 19 18 - -

- - 71 54 43 36 31 28 23 20 18 - -

- - - 57 46 38 33 29 24 21 19 - -

- - - 60 48 40 35 31 25 22 20 - -

- - - 63 50 42 36 32 26 23 21 19 -

- - - 67 53 44 38 33 27 24 21 20 -

- - - 73 58 48 41 36 29 25 23 21 -

----635244393227242221

----685648423429252322

-----6051443630272423

-----6454473832282624

------63544336322826

------71614840353129

(inches)

for duct heights

(inches)

of :

8 670-000-006-1007

W

G

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

4 Venting – Sealed Combustion System

ARNIN

Failure to follow all instructions can result in flue gas

spillage and carbon monoxide emissions, causing

severe personal injury or death.

The furnace can be side-wall vented without the use of a side-wall

power vent, using a venting system with the high static pressure

Beckett AFII and Riello 40-BF oil burners. Outdoor combustion air

must be directly connected to the burner or the venting system will

not function..

The notable characteristics of the vent system are as follows:

a) Certified for use of the following materials for ducting the intake

air from the terminal to the burner: Schedule 40 PCV DWV,

Schedule 40 ABS DWV and ASTM D-2729 sewer pipe;

b) One hole of minimal size (6 inches) is required to be cut into

the side-wall and the terminal is designed to fit through a

minimum 2 x 8 joist space.

c) Incorporates a vent blockage safety shutdown system. If the

vent or intake opening ever becomes partially or fully blocked,

the burner will shut down before a #1 smoke condition occurs;

d) The intake vent circuits within the terminal can be accessed for

cleaning.

There are three main components to the venting system:

- Vent terminal kit VTK-1 for the 105 series models or VTK-2 for the

160 series models.

- Flexible insulated venting material for IFV3 for the 105 series

models or IFV4 for the 160 series models

- Field supplied 3 inch PVC or ABS intake piping.

ARNIN

Poisonous carbon monoxide gas hazard.

Even though the flexible venting is insulated, it must

not run through an unheated space.

To do so can cause residual condensation inside the

stainless steel liner, which may eventually perforate

the liner and allow vent gases to enter the dwelling,

which can result in personal injury and/or death or

property damage.

Insulated flexible venting

The certified venting materials come in 3 lengths, Model # IFV3-15,

IFV3-23 and IFV3-30 for the 105 model series or IFV4-15, IFV4-23

and IFV4-30 for the 160 model series, correspond to 15, 23 and 30

feet of continuous lengths of vent. The vent construction is coaxial

and incorporates a stainless steel corrugated, flexible liner,

surrounded by a thick insulation blanket and covered with an outer

layer of flexible corrugated aluminum sleeve to protect the insulation.

Splicing vent lengths together is prohibited. The maximum and

minimum continuous vent lengths permitted for installation are:

5 feet minimum 30 feet maximum

Side-wall venting installation

ARNIN

Cut and abrasion hazard.

Always wear protective gloves and eye protection

when handling the vent material.

The process of cutting and fitting the flexible vent

material exposes the installer to sharp edges that can

cause severe cuts to the skin.

670-000-006-1007

Connection to the furnace breach

1. Determine in which direction the venting will be routed from the

furnace;

2. The flexible venting has 4 pieces of corrugated spi n sleeve that

has been temporarily screwed over top of it. Remove the spin

sleeve completely by unscrewing it in a counter-clockwise

direction;

3. Using tin snips, cut the aluminium outer sleeve back by 5

inches on the IFV Series vent (see Figure 1.1). Ensure the

snips are well adjusted and sharp or the cut end of the venting

will be too jagged to start the threads of the spin sleeve (see

Figure 1.1).

4. Prepare the furnace breach end of the insulated flex vent by

first screwing the spin sleeve onto the corrugated aluminum

jacket (see Figure 1.2) until the trailing edge of the spin sleeve

is about 12 inches from the end of the vent (see Figure 1.3).

5. Pull the insulation back to expose the corrugated stainless steel

core.

6. Cut the corrugat ed stainless steel core back by 3 inches on the

IFV Series vent. You should now have about 3 inches of

insulation hanging out past the stainless steel core (see Figure

1.4);

7. Push the stainless steel core onto the breach pipe as far as it

will go (see Figure 1.5) and mechanically attach the vent to the

breach using three of the #8 x 1/2" self-drilling screws provided

with the VTK Series kit. The screws should be equally spaced

around the circumference of the stainless steel core, starting

with the first screw at top dead center. Start the drill point of the

screws in the valleys of the corrugations at 3/8"-5/8" back from

the end of the stainless steel core, so the screw heads can be

properly sealed in the forthcoming operations (see Figure 1.6);

8. With the stainless steel core now firmly attached to the breach,

apply sealant all around the joint, where the corrugated

stainless steel core meets the smooth outer surface of the

breach pipe (see Figure 1.7). In other words, the sealant must

be centered over the joint;

9. Also, make sure that the heads of the self-drilling, stainless

steel screws are completely covered with the sealant;

10. Two stainless steel band clamps are provided with the VTK

Series kits. Position one stainless steel band clamp over the

sealant, so that the edge of the clamp closest to the breach

lines up with the sealant that is closest to the breach. Ensure

that the band will close with an action of one strip sliding over

the other - not under the gear head of the draw clamp (see

Figure 1.8). Tighten the band clamp with considerable torque to

cause the sealant to be squeezed into all crevices and to ooze

out of the edge of the clamp closest to the breach (see Figure

1.9);

11. The seal is permanent and should never need to be broken,

since the breach plate can be removed for cleaning and

inspection using the 4-bolt joint;

12. Tuck the vent insulation into the breach collar;

13. Screw the spin sleeve tightly into the breach collar for a finished

appearance. Wrap the other end of the spin sleeve with

aluminum tape to cover any metal burrs that may be present

(see Figure 1.10);

14. Bend the venting into the desired radius coming off the breach.

9

N

SCH & SCL Oil Furnaces – Furnace Manual

4 Venting – Sealed Combustion System (continued)

Connection to the vent terminal

1. Prepare the terminal end of the insulated flex vent b y first

screwing the spin sleeve onto the corrugated aluminum

jacket until the trailing edge of the spin sleeve is about 10

inches from the end of the vent;

2. Using sharp tin snips, cut the aluminum outer sleeve back

by 5 inches on the IFV Series vent;

3. Pull the insulation back to expose the corrugated stainless

steel core;

4. Cut the corrugated stainless steel core back by 3 inches on

the IFV Series vent. You should now have about 3 inches of

insulation hanging out past the stainless steel core;

5. Push the stainless steel core onto the pipe on the back of

the terminal as far as it will go and mechanically attach the

vent to the terminal using three of the #8 x 1/2" self-drilling

screws provided with the VTK Series kit. The screws should

be equally spaced around the circumference of the stainless

steel core, starting with the first screw at top dead center.

Start the drill point of the screws in the valleys of the

corrugations at 3/8"-5/8" back from the end of the stainless

steel core;

6. With the stainless steel core now firmly attached to the

terminal, apply sealant all around the joint where the

corrugated stainless steel core meets the smooth outer

surface of the breach pipe (see Figure 1.7). In other words,

the sealant must be centered over the joint;

7. Also, make sure that the heads of the self-drilling, stainless

steel screws are completely covered with the sealant;

8. Position the other stainless steel band clamp over the

sealant so that the edge of the clamp closest to the terminal

lines up with the edge of the sealant that is closest to the

terminal. Tighten the band clamp with considerable torque to

cause the sealant to be squeezed into all crevices and to

ooze out of the end of the clamp closest to the terminal (see

Figure 1.11);

9. The seal is permanent and should never need to be

disconnected as the end of the terminal can be opened for

cleaning and inspection by removing the screened end-cone

assembly. Tuck the vent insulation into the recess in the

terminal body;

10. Screw the spin sleeve tightly into the recess for a finished

appearance. Wrap the other end of the spin sleeve with

aluminum tape to cover any metal burrs that may be present

(see Figure 1.12);

11. Bend the venting into the desired radius coming off the

terminal.

Installing terminal in the wall

1. Cut a 6 inch hole in the side-wall in accordance with the

location considerations outlined in the previous section;

2. Fasten the wall plate to the inside-wall using 4 field-provided

fasteners, appropriate for the material behind the wall plate.

Depending on the angle of access, the pressure control

bracket may need to be removed to access the top right wall

plate screw hole. For concrete and block, Tapcon™ screws

or equivalent are recommended. Install the wall plate so that

the top of the hole in the wall plate is positioned 1/8” lower

than the top of the 6 inch hole in the wall. This will

accommodate the proper downward slope of the terminal, in

the direction from the inside to the outside;

10 670-000-006-1007

3. Remove the 2 screws fastening the end cone in place and

remove the cone;

4. Remove the 2 screws fastening the stabilizer shroud in

place and remove the stabilizer shroud;

5. Insert the main body of the terminal through the wall plate so

that the end of the terminal extends about 2 inches past the

outside wall;

6. Install the stabilizer shroud and replace the two mounting

screws. (see Figure 1.13);

7. On concrete and block wall installations in particular, if it

appears that the flange on the back of the stabilizer shroud

is not large enough to cover the irregularities in the hole, a

field fabricated wall plate can be constructed out of 304,

316, or 316L stainless steel;

8. Silicone seal the circumference of the joint where the

stabilizer shroud connects to the main body of the terminal;

9. Apply caulking to the back plate of the stabilizer shroud and

push the terminal back firmly against the wall, making sure

the pressure switch is located at the top, in a horizontal

position;

10. While pushing down gently on the top of the stabiliser

shroud, install the 3 stainless steel 2 inches screws provided

with the kit to secure the back of the shroud to the wall. Do

not overtighten the screws or it will distort the stabiliser

shroud. The screws will not be necessary in a concrete or

block wall as the mortar can provide positive positioning;

11. Tighten the clamp on the wall plate to secure the terminal in

place;

12. Apply more caulking all around the seam where the

stabilizer shroud meets the wall. It is important to have a

good seal to prevent water from entering the dwelling (see

Figure 1.14). A considerable amount of caulking may be

necessary for irregular wall surfaces such as lapped siding;

13. Install the end cone and replace the two mounting screws;

14. Support the vent and intake air piping so that a 1/4" to 1/2"

downward slope (toward the outside) results for proper

drainage out the terminal body.

Ducted outdoor combustion air (Sealed Combustion System)

The burners are set up to duct outside combustion air directly to

the burner: the Beckett AFII and the Riello 40-BF for side-wall

venting.

CAUTIO

The venting system is a sealed system and completely isolates

the furnace from the interior of the building. The burner is totally

unaffected by any pressure fluctuations within the building

makes it ideal for tight home construction.

The use of ducted outside combustion air is

mandatory with side-wall venting systems. The

system operates on a balanced flue principle

and will not function properly if the combustion

piping is not attached and sealed at all

connections between the vent terminal and

burner inlet.

which

SCH & SCL Oil Furnaces – Furnace Manual

4 Venting – Sealed Combustion System (continued)

The venting system requires additional parts, which are not included

with the kit. These parts must be constructed of 3 inch Schedule 40

PVC, PVC-SWV, 26-SDR, SDSR-21, Septic Sewer Pipe or ABS

plastic pipe, fittings and sealant. Also, installation procedures, piping

and fittings must conform to the following ANSI/ASTM standards:

PVC ASTM D-1785

SDR-26, SDR-21 ASTM D-2241

Septic Sewer Pipe ASTM D-2729

PVC-DWV ASTM D-2665

PVC Primer and Solvent Cement ASTM D-2564

ABS Pipe and Fittings ASTM D-2235

Procedure for Cementing Joints ASTM D-2855

Additional parts required (not included in VTK kit)

a. 3 inch elbow fitting as required;

b. 3 inch plastic pipe;

c. 3 inch 90° elbow, female-female (for terminal);

d. 3 inch female to 2 inch female reducer (Riello 40-BF burner

only);

e. 2 inch 90° elbow, street t ype, female-male (Riello 40-BF burner

only);

f. 3 inch female-female PVC or ABS coupling, not sewer pipe

(Beckett AFII burner only);

g. Transition bushings to go from PVC or ABS to ASTMD-2279

Septic Sewer Pipe (if applicable).

If PVC fittings are mixed with ABS fittings, use solvent cement that is

approved for bonding the two plastics.

Intake pipe length

The venting system has been certified for 120 equivalent feet o f 3

inch intake pipe. Count a 90° elbow as 10 equivalent feet and a 45°

elbow as 5 equivalent feet in the calculation.

For example:

1 length of 5 feet = 5 equivalent feet

2 lengths of 10 feet = 20 equivalent feet

3 elbows, 90° = 30 equivalent feet

2 elbows, 45° = 10 equivalent feet

1 elbow, 90° (terminal) = 10 equivalent feet

1 elbow, 90° (Riello burner)

Total: = 85 equivalent feet, which is less

than 120 feet and therefore acceptable.

Intake pipe installation

Obtain the necessary additional parts, to complete the installation

and start by piping at the burner. If the optional vestibule was

installed, remove the appropriate knockouts in the side panels of the

vestibule. The lower 5 inch knock outs in the right-hand panel is

used for the Beckett AFII burner. The higher 5 inch knockouts on the

right and left-hand panels are for right or left connection to the Riello

40-BF burner.

= 10 equivalent feet

Beckett AFII burner

Remove the burner intake cover by removing 3 screws securing it in

place. Discard the cover and screws. Apply silicone liberally around

the end of a 3 inch coupling and fully insert the siliconed end into the

burner opening. Fasten securely with 3 self-tapping sheet metal

screws.

Riello 40-BF burner

Fully insert the female end of the 2 inch, 90° street elbow into the

combustion air fitting on top of the burner. Fasten securely with 3

self-tapping sheet metal screws. Cement the 2 inch end of the 3 inch

female to 2 inch female reducer into the male end if the 2 inch 90°

street elbow. If the parts are not easily obtained, use a 3 inch 90°

street elbow with the male end fitted over the combustion air fitting.

The fitting will have to be silicone sealed, as the fit will be a bit loose.

Fasten securely with 3 self-tapping sheet metal screws.

Terminal connection

Insert the 3 inch 90° female-female elbow onto the stainless steel air

intake fitting located on the right side of the vent terminal (viewed

from the rear). Fasten with 3 self-tapping sheet metal screws.

Intermediate piping

Pipe as required between the terminal and the burner. Ensure that

the 3 inch piping is routed and supported in accordance with local

and national codes. Obey minimum furnace clearances to

combustibles when routing any section of 3 inch piping in the vicinity

of the furnace. If Septic Sewer Pipe is to be used, install transition

bushings at the 3 inch female ends of the fittings at the burner and at

the terminal. Transition bushings are readily available and are

required because 3 inch PVC and ABS pipes have a typical outside

diameter of 3.5 inches, whereas Septic Sewer Pipe has a typical

outside diameter of 3.25 inches.

670-000-000/1007 11

SCH & SCL Oil Furnaces – Furnace Manual

12 670-000-006-1007

SCH & SCL Oil Furnaces – Furnace Manual

670-000-006-1007

13

SCH & SCL Oil Furnaces – Furnace Manual

14 670-000-006-1007

W

G

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

5 Connect fuel oil piping

General oil piping requirements

• Location and installation of oil tanks, oil piping and burners

must follow:

• NFPA 31, Standard for the Installation of Oil-Burning

Equipment.

• In Canada, CSA B139, Installation of Oil-Burning

Equipment.

• Local codes and regulations.

• Information provided with burner and fuel pump.

• If an y part of fuel oil tank is above level of burner, an anti-

siphon device must be used to prevent flow of oil in case of

oil line break.

• Support oil lines as required by codes.

• Make tank connections with swing joints or copper tubing to

prevent breaking in case the tank settles. Make swing joints

so they will tighten as tank settles. Non-hardening pipe joint

compounds should be used on all threads.

ARNIN

• Underground pipe must be run in a casing to prevent oil

leaking into ground or under floor. Check local codes for

information.

Oil piping connection at burner

• Connect oil line to burner using a flare fitting.

ARNIN

• See local codes for appropriate arrangement and piping of

filter, control valves, etc. connecting to oil tank.

• Refer to burner manual for oil system requirements. Verify

that suction lift does not exceed stated limit. Where lift

exceeds limit for a one-pipe system, use a two-pipe system

as directed in burner manual.

ARNIN

Do not use Teflon tape as an oil pipe sealant. It

can cause valves to fail, creating hazards. Use

only flare fittings. Do not use compression fittings.

Failure to comply could result in severe personal

injury, death or substantial property damage from

oil leakage and/or fire hazard.

Use of any connection other than a flare fitting at

the oil connection to the burner could result in a

fuel oil leak, with the potential for severe personal

injury, death or substantial property damage.

Electric shock hazard. Can cause severe

personal injury or death if power source, including

service switch on furnace, is not disconnected

before installing or servicing.

6 Wire furnace & burner

Wire burner

The burner harness is factory-wired to the furnace at the factory.

Plug the burner harness into the mating burner connector to wire

the burner. Refer to the wiring diagram on pages 16 and 17 for

further information.

Install and wire thermostat / shut-off

system

Mount the room thermostat on an interior wall in the natural

circulating path of room air. Do not locate the thermostat so it is

exposed to cold air infiltration, drafts from windows or doors, air

currents from supply or return air registers, behind obstructions,

on a shelf, in a closet, or in a corner.

Ensure that the thermostat will not be exposed to heat from a

nearby fireplace, radio, television, lamp or rays from the sun. Do

not mount the thermostat on a wall over a supply or return duct,

chimney or vent.

Wire thermostat to the vent terminal pressure switch and to the

furnace electrical box (refer to wiring diagram). Set thermostat

anticipator as shown on wiring diagrams on pages 16 and 17.

Connect power wiring

All wiring must conform to:

• National Electrical Code, ANSI/NFPA 70, latest edition and

any additional national, state or local codes.

• In Canada, CSA C22.1 Canadian Electrical Code Part On e

and any local codes.

• Wiring must be N.E.C. Class 1. If original wire as supplied

with furnace must be replaced, type 105° C wire or equivalent

must be used. Supply wiring to furnace must be sized for the

load required (see Section 12).

• Provide electrical ground at furnace as required by codes.

Connect 120 VAC/60 Hertz, single phase separate electrical line

from the main house panel to the power leads in the furnace

electrical box as shown on wiring diagram, pages 12, 13, 14 and

15. Provide a fused disconnect in the power wiring, following all

local codes.

Ensure the wire size and type are adequate for the electrical load

(see Section 12 and furnace nameplate for value).

Limit control

The furnace is equipped with a fan switch/limit control. This

control limits the air leaving the heat exchanger to 200° F or less.

The fan switch continues fan operation until the air drops to a

preset temperature. For most installations, set the blower ON

setting at 110° F and blower OFF setting at 90° F. If a longer cool

down period is desired, lower the OFF setting.

670-000-006-1007

15

r

SCH & SCL Oil Furnaces – Furnace Manual

6 Wire furnace & burner (continued)

Figure 2 Wiring – SCH & SCL furnaces with direct-drive blowe

DNS-0988 Rev. D

16 670-000-006-1007

r

SCH & SCL Oil Furnaces – Furnace Manual

6 Wire furnace & burner (continued)

DNS-0890 Rev. C

Figure 3 Ladder wiring – SCH & SCL furnaces with direct-drive blowe

670-000-006-1007

17

W

G

SCH & SCL Oil Furnaces – Furnace Manual

7 Start up

DANGER

To start furnace

1. Factory burner adjustment and settings may not be suitable for

specific job conditions. Refer to burner manual for burner start

up, adjustment and checkout procedures.

2. Set room thermostat to call for heat.

3. Start burner as described in burner manual.

4. The furnace blower will delay for a short time after burner starts,

until the limit/fan switch senses air temperature above the fan

ON setting.

5. Set room thermostat to its lowest setting. Burner should turn off.

6. Furnace blower will continue to run until the limit/fan switch

senses air temperature below the fan OFF setting.

7. Set the room thermostat to call for heat again. Allow furnace to

heat to design temperature. Then adjust burner for correct

combustion, using combustion test equipment. Adjust burner for:

CO

To take an overfire pressure reading, replace the sight glass

assembly with the washer supplied with the appliance.

After having taken the reading, put the sight glass back (see

Figure 2).

Follow information below to prevent severe personal

injury, death or substantial property damage:

• Do not use gasoline, crankcase drainings or any oil

containing gasoline. See burner manual for proper

fuel oil.

• Do not attempt to start burner when excess oil has

accumulated, when unit is full of vapor or when

combustion chamber is very hot.

• Do not start burner unless collector box, breeching

and burner mounting plate are secured in place.

• Never burn garbage or paper in the furnace.

• Never leave combustible material around it.

: between 10 % and 11½ %, with 0 smoke.

2

To start furnace

ARNIN

8. Check furnace and duct system for proper operation and

conditions.

9. Inspect vent system for proper operation.

10. To set limit/fan switch:

The blower operates until the air temperature drops below the

fan OFF setting. If the air at the supply registers is too warm at

blower start up or shutdown, lower the fan OFF and ON settings

on the limit/fan switch.

To check operation of the limit switch, slide a piece of cardboard

into the furnace filter slot. After a few minutes of operation (not

more than 5 minutes), the burner should shut off (limit switch

open). The blower will operate until the furnace cools down.

Remove cardboard when finished.

11. Check the proper operation of the vent pressure switch by

completely blocking the outlet of the vent terminal with a metal

plate. The burner must shut-off immediately and remain in the

pre-purge mode without firing.

12. Complete testing of the burner cad cell control, using the

instructions in the burner manual.

Make final burner adjustments using combustion test

equipment to assure proper operation.

To shut down furnace

1. Set the room thermostat to its lowest setting.

2. Turn off the disconnect switch in the 120-VAC power line to the

furnace.

3. If the burner will be shut down for an extended time, tightly close

all oil valves.

4. Refer to burner manual for any additional instructions.

Sight Glass Assembly

(continued)

Figure 2

18 670-000-006-1007

W

G

SCH & SCL Oil Furnaces – Furnace Manual

8 Checkout procedure

Furnace selection

..1. Heat loss ............................... BTU/h at ............ °F outdoor

design temperature.

..2. Furnace model.........................

output.......................................BTU/h.

..3. Burner model ........................................................................

nozzle: ............ gph ................ ° type............... .

..4. Burner pump pressure ........................................ psig.

Furnace installation

..5. Furnace level and all legs in contact with floor?

..6. Return and supply ducts securely attached to furnace?

..7. Fuel filter and fuel lines installed per burner manual and

inspected?

..8. Furnace and burner wired per wiring diagram?

..9. 120 VAC wiring: type ... size ... AWG

Vent and combustion air

..10. Existing chimney/vent system inspected and in good

condition?

..11. New vent piping installed, sealed and in good condition?

..12. Vent sizing checked against furnace manual and codes?

Ductwork

..13. Duct sizing checked against furnace manual and/or ACCA

Manual D?

..14. Supply and return registers checked for size based on air

flow?

..15. Balancing dampers installed as needed?

..16. Ductwork sealed and insulated as needed?

670-000-006-1007

Furnace operation

.. 17. Clean air filter in place?

.. 18. Temperature rise through furnace checked (not to exceed

85° F) and blower speed adjusted if necessary?

.. 19. Thermostat heat anticipator set per wiring diagram?

.. 20. Burner started and tested per burner manual?

.. 21. Proper draft and burner flame? Final adjustment made with

combustion test equipment?

.. 22. Air purged from oil piping? Piping checked for leaks?

.. 23. Burner sealed to furnace and nuts tight? Burner harness

securely plugged in?

ARNIN

.. 24. Limit control tested per “To start furnace” in this manual?

.. 25. Did the burner shut-off immediately when the vent terminal

.. 26. Furnace cycled with thermostat? Raise to highest setting

.. 27. Observed several operating cycles for proper operation?

.. 28. Set room thermostat(s) to desired room temperature?

Obtain gas-tight seal at burner flange, cleanout

plates and/or flue collector box to prevent possible

flue gas leakage and carbon monoxide emissions,

leading to severe personal injury or death.

was completely blocked?

and verify furnace goes through normal start up cycle. Lower

to lowest setting and verify furnace goes off.

After installation

.. 29. Complete “Installation and service certificate” below.

.. 30. Review Owner’s information in this manual with owner or

maintenance person and instruct person to keep for future

reference.

.. 31. Replace all instructions provided with furnace for future

reference.

19

SCH & SCL Oil Furnaces – Furnace Manual

Installation and service certificate

Furnace model__________________________________________________ Series ________________________

Serial number ______________________________________ Date installed________________________

Installation instructions have been followed.

Checkout sequence has been performed.

Above information is certified to be correct.

Information received and left with owner / maintenance person.

Installer _ ____

Company

______ _________________________ ____ _________

_

Address

____________________________________________________________

Phone

________________________________________________

Installer’s signature

_______________________

20 670-000-000/1007

g

g

y

gauge (

)

gaug

y)

SCH & SCL Oil Furnaces – Furnace Manual

9 Troubleshooting

Before beginning these troubleshooting procedures, ALWAYS :

Check 120 volt supply to furnace. If there is no s upply To successfully service the oil furnace, you must

volta

e, check fuses and service switch. CAUTION : have these instrument s :

When testin

standard electrical safet

Make sure thermostat i s calling for burner operation.

Check oil supply and mak e sure all valves are open.

Burner motor does not start.

Burner short cycles or locks out on

primary relay safety.

Unable to achieve clean combustion

by setting air adjustments.

To check CAD cell operation, use the

following procedure :

Symptom – Furnace blower

electrical equipment, always follow smoke tester

procedures.

Check fuses and make sure service switch

is on.

Check for line voltage into furnace junction

box.

If the primary relay control is not poppi ng out

the reset button, measure the milliamperage

at the thermostat and set the heatanticipator accordingly. Also check wiring

from the thermostat to t he burner.

Check nozzle and electrode position. Check ignition transformer output

(Reference burner manufacturers

instructions).

Check tube insertion and alignment. Check nozzle and electrode position

Replace nozzle. Check pump pressure (varies with

Check overfire draft.

1. Remove CAD cell leadwires from the f-f

terminals on the primary safety control, then

start burner. Shortly after burner starts,

place a temporary jumper between terminals

f-f. Connect ohmeter across CAD cell

leadwires-resistance should be under 1,600

ohms.

2. Stop burner and remove temporary jum per. 4.

carbon-dioxide (CO

presuure

volt/OHM/milliamper multimeter

pressure

Be familiar with these instruments as well as the burner

manufacturer's rec ommended settings.

Possible corrections :

Check belt and pulleys.

Furnace blower will not start.

Check wiring from Fan and Limit control.

See if blower motor will run when it is

switched on manually at the thermostat subbase (if sub-base is installed).

Blower cycles on and off after the

burner has shut down.

Blower short cycles on limit control.

Adjust fan "off" setting to 90° and adjust fan

"on" setting to 110°.

Return ducts may be undersized.

) or oxygen (O2) analyzer

2

scale should read from -0.25" w.c . to +0.25" w.c.

e capable of reading 0-200 lb/sq. inch (for oil onl

Check for voltage from primary relay to

burner motor. Make sure the primary relay

has not locked out on safety.

Make sure the thermostat is calling for heat

and that the wiring to the thermostat is

Check the alignment of the cad cell to

assure it is aimed at the fire.

(Reference burner manufacturer's

instructions).

manufacturer and application; see burner

manual).

3. With burner off, check dark cell resistance

across CAD cell leadwires. Resistance

should be greater than 20,000 ohms. If cell

resistances are different from above,

recheck wiring and location of cell, etc. If

necessary, replace plug-in portion of cell.

Also use procedure described in Honeywell

R7184 instruction manual.

Check for 120V to the blower motor. If

present, replace motor.

670-000-006-1007

21

W

G

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

10 Service and maintenance

Annual service and start-up

ARNIN

ARNIN

ARNIN

Follow the “Service and maintenance” procedures given throughout this manual and in component literature shipped with the

furnace. Failure to perform the service and maintenance could result i n damag e to the furnace or system. Failure to follow the

directions in this manual and component literature could result in severe personal injury, death or substantial property

damage.

The furnace should be inspected and started annually, at the beginning of the heating season, only by a qualified service

technician. In addition, the maintenance and care of the furnace outlined in the tabl e below, and explained on the following

pages must be performed to assure maximum furnace efficiency and reliability. Failure to service and maintain the furnace

and system could result in equipment failure.

This furnace contains fiberglass and ceramic fiber materials. These materials require special attention. Please refer to the

WARNING and guidelines given on page 20. Failure to comply could result in severe personal inj ury, death or substantial

property damage.

Service technician annual maintenance/start up

(see following pages and burner manual for instructions)

Service and maintenance

Annual start up

Furnace and air system

Consult with homeowner to see if there were any Check sequence of operation

problems with furnace or system duri ng the prior Check flame characteristics

heating season (or cooling season) Perform combustion checks/tests per burner manual and

Clean, inspect, and lubricate blower motor and wheel furnace manual

Check condition of electrical wiring and tightness of

terminals and connectors Check thermostat heat antici pat or setting

Clean and inspect heat exchanger and combustion Check safety controls (high-temperature limit switch, flame

chamber

Clean and inspect system accessories

Check temperature rise

cutoff time, vent pressure switch, etc.)

Check operation

Vent system

Clean and inspect flue pipe, chimney/vent, and draft regulator

Fuel oil system

Check oil tank and piping for leaks

Replace oil filter

Oil burner

Clean and inspect oil burner assembly

Bleed system of air (single-pipe system)

Check oil pump pressures

Check combustion air ducts, grilles, etc. (if applicable)

22 670-000-006-1007

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

Handling ceramic fiber and fiberglass materials

HANDLING OR REMOVAL OF COMBUSTION CHAMBER

ARNIN

Avoid breathing dust and contact with skin and eyes.

• Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA

requirements for cristobalite at the time this document was written. Other types of respirators

may be needed depending on the job site conditions. Current NIOSH recommendations can

be found on the NIOSH web site at

approved respirators, manufacturers, and phone numbers are also listed on this web site.

• Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

Apply enough water to the combustion chamber lining to prevent airborne dust.

Remove combustion chamber lining from the furnace and place it in a plastic bag for disposal.

Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer

thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately

Breathing: Fresh air.

HANDLING OR REMOVAL OF FIBERGLASS WOOL – OR –

INSTALLATION OF FIBERGLASS WOOL OR COMBUSTION CHAMBER :

ARNIN

Avoid breathing dust and contact with skin and eyes.

• Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA

requirements for fiberglass wool at the time this document was written. Other types of

respirators may be needed depending on the job site conditions. Current NIOSH

recommendations can be found on the NIOSH web site at

http://www.cdc.gov/niosh/homepage.html. NIOSH approved respirators, manufacturers, and

phone numbers are also listed on this web site.

• Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

Operations such as sawing, blowing, tear out, and spraying may generate airborne fiber

concentration requiring additional protection.

Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer

thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately

Breathing: Fresh air.

The combustion chamber in this product contains ceramic fiber materials.

Ceramic fiber can be converted to cristobalite in very high temperature

applications. The International Agency for Research on Cancer (IARC) has

concluded, “Crystalline silica inhaled in the form of quartz or cristobalite from

occupational sources is carcinogenic to humans (Group 1)”.

http://www.cdc.gov/niosh/homepage.html. NIOSH

This product contains fiberglass jacket insulation and ceramic fiber materials in

combustion chamber. Airborne fibers from these materials have been listed by

the State of California as a possible cause of cancer through inhalation.

670-000-006-1007

23

R

W

G

W

G

W

G

W

G

SCH & SCL Oil Furnaces – Furnace Manual

10 Service and maintenance (continued)

Service/maintenance procedures

To inspect blower motor

Belt-drive motor – Blower bearings and the motor are permanently

lubricated and do not require oiling. Verify that the blower, motor

pulleys and belt are in good condition. Replace if necessary.

Direct-drive motor – Blower bearings and the motor are permanently

lubricated and do not require oiling.

Clean blower wheel – Vacuum dust from blower wheel blades and

surrounding area.

To clean heat exchanger

ARNIN

ARNIN

1. Remove the burner.

2. Inspect the heat exchanger using a mirror inserted through the

burner opening.

3. Usi ng a brush on a fle xible handle, loosen the soot on the inside

of the heat exchanger.

4. Remove the soot with a vacuum. Be careful not to damage the

combustion chamber while cleaning the heat exchanger.

5. Open the heat exchanger cleanout cover, if present. Using a

brush on a flexible handle, loosen the soot from the heat

exchanger surfaces. Remove as much soot as possible using a

vacuum.

6. Close cleanout cover.

7. Inspect combustion chamber and replace with a new one if

chamber is damaged in any way.

8. Re-install burner.

ARNIN

Inspect vent system

Thoroughly inspect the entire vent system at least annually. Ensure

vent system is repaired or replaced if necessary before placing

furnace in operation.

Oiled-bearing burner motors

The burner may need to be lubricated if motor is equipped with oiling

cups. Refer to burner manual for specific instructions. If instructed,

apply a few drops only of S.A.E. 20 detergent oil (never use

household oils). Do not attempt to “fill up” the oil cup. Over-oiling can

damage the motor.

24 670-000-006-1007

The heat exchanger must be cleaned and/or

inspected at least once each year. Operating the

furnace with a fouled or leaking heat exchanger

could result in severe personal injury, death or

substantial property damage.

The combustion chamber contains ceramic fiber

materials. Wear a NIOSH-approved respirator while

cleaning the furnace and follow WARNING on page

20 for proper handling.

Obtain gas-tight seal at burner flange and cleanout

plates to prevent possible flue gas leakage and

carbon monoxide emissions, leading to severe

personal injury or death.

Annual start up

DANGE

Follow information below to prevent severe personal

injury, death or substantial property damage:

• Do not use gasoli ne, crankcase drainings or any oil

containing gasoline. See burner manual for proper

fuel oil.

• Do not attempt to start burner when excess oil has

accumulated, when unit is full or vapor or when

combustion chamber is very hot.

• Do not start burner unl ess vent and burner mounti ng

plate are secured in place.

• Never burn garbage or paper in the furnace.

• Never leave combustible material around it.

To start furnace

1. Factory burner adjustment and settings may not be suitable for

specific job conditions. Refer to burner manual as well as the

“Dimensions and Ratings” section of this manual for burner start

up, adjustment and checkout procedures.

2. Set room thermostat to call for heat.

3. Refer to burner manual for start up.

4. The furnace blower will delay for a short after burner starts, until

the limit/fan switch senses air temperature above the fan ON

setting.

5. Set room thermostat to its lowest setting. Burner should turn off.

6. Furnace blower will continue to run until the limit/fan switch

senses air temperature below the fan OFF setting.

7. Set the room thermostat to call for heat again. Allow furnace to

heat to design temperature. Then adjust burner for correct

combustion, using combustion test equipment. Adjust burner for:

: between 10 % and 11 ½ %, with 0 smoke.

CO

2

8. Take an overfire pressure reading (refer to Section 7)

ARNIN

8. Check furnace and duct system for proper operation and

conditions.

9. Inspect vent system for proper operation.

10. To set limit/fan switch:

The blower operates until the air temperature drops below the

fan OFF setting. If the air at the supply registers is too warm at

blower start up or shutdown, lower the fan OFF and ON settings

on the limit/fan switch.

To check operation of the limit switch, slide a piece of cardboard

into the furnace filter slot. After a few minutes of operation (not

more than 5 minutes), the burner should shut off (limit switch

open). The blower will operate until the furnace cools down.

Remove cardboard when finished.

11. Complete testing of the burner cad cell control using the

instructions in the burner manual.

Make final burner adjustments using combustion test

equipment to assure proper operation.

SCH & SCL Oil Furnaces – Furnace Manual

COMPONENTS

AND

REPLACEMENT PARTS

670-000-006-1007

25

SCH & SCL Oil Furnaces – Furnace Manual

11 Components and replacement parts

Figure 3 Model SCH-105 furnaces – Component locations

26 670-000-006-1007

B50016A

7

5

7

R

5

5

5

A

A

T

5

A

T

X

5

C

A

R

A

A

SCH & SCL Oil Furnaces – Furnace Manual

11 Components and replacement parts (continued)

Model SCH-105 furnaces – Replacement parts list

ITEM PART NUMBER DESCRIPTION

1 B30756-01 HEAT EXCHANGER ASSEM BLY

2 B30465-01 HEAT EXCHANGER ASSEM BLY, TOP

3 B30518 COMBUST ION CHAM BER ASSEM BLY

4 B3051

B3075

6 F07O001 FLAN G E N U T, HE X A G O N A L 3/8"-16NC B R AS S

7 B30431 PANEL, DIVIDER

8 B30513 SLIDE SUPPORT, BLOWER

9 B30534 GASKET, BURNER

10 B30430 FLOO

11 Z04F004 PAPER FILTER 20" x 20" x 1"

12 B30083 FILTER RACK ASSEMBLY

13 B30458-04 PANEL ASSEMBLY, LEFT SIDE

14 B30418 PANEL INSULATION, LEFT SIDE

1

B30426 BAFFLE

16 B30457-01 PANEL ASSEMBLY, REAR

17 B30419 INSULATION, REAR PANEL

18 B30458-03 PANEL ASSEMBLY, RIGHT SIDE

19 B30415-02 GASKET, HEAT EXCHANGER

20 B30812-01 PANEL ASSEMBLY, FRONT

21 B30761 INSULATION, FRONT PANEL

22 B30808 ELECTRICAL BOX COVER ASSEMBLY

23 B30515-01 FLANGE 3", FLUE OUTLET ASSEMBLY

24 Z99F050 RECESSED HANDLE, BLACK

2

B30455-01 BOTTOM FRONT PANEL ASSEM BLY

26 F06F00

27 F07F024 HEX N U T 3/8"-16NC BR A SS

28 B30753 WASHER GASKET, OBSERVATION TUBE

29 B30752-01 WASHER, OBSERVATION TUBE

30

K30011 PEEP HOLE KIT ASSEMBLY

30B K30012 PRESSURE TEST KI

31 B3005

32 B30041-01 WINDOW, NEOCE R A M 1.031" DI

33 B30796 BURNER, ELECTRICAL WIRE KI

34 B30806 ELECTRICAL BO

3

L01F009 TRANS FORMER 120-24V olts, 40VAC

36 L01H009 R E L A Y S P D T 24 VA

37 R02I005 FAN-LIMIT 8" HON L6064

38 L05F011 TERMINAL STRIP 90 DEGREES, 6 POSITIONS

39 B30809-02 ELECTR ICAL K IT, BLO WE R

40 L01I002 CAPACITOR, 7.5 MF

41 B01024 CAPACITOR HOLDE

42 B01291-01 SEAL STRIP 1-1/2" x 13-1/8"

43 B30433 BLOWER SLIDE RAILS

44 Z01L002 BLOWER WHEEL G T10-10DD

45

Z01I004 BLOWER GT10-10DD

45B B01979-01 BLOWER REPLACEMENT ASSEMBLY

46 B01888 BELLY BAND ASSEMBLY

47 L06H004 MOTOR 1/2 D D 4V

GASKET, HEAT EXCHANGER ASSEMBLY

HEAT EXCHANGER ASSEMBLY, BOTTOM

WASHER, 3/8" BOLT ZINC A

GASK E T, 1.062" OD WIND O W

B50016

670-000-006-1007

27

SCH & SCL Oil Furnaces – Furnace Manual

11 Components and replacement parts

Figure 4 Model SCH-160 furnaces – Component locations

B50015 Rev. A

28 670-000-006-1007

B50015A

Y

Y

Y

Y

X

Y

X

A

SCH & SCL Oil Furnaces – Furnace Manual

11 Components and replacement parts (continued)

Model SCH-160 furnaces – Replacement parts list

ITEM PART NUMBER DESCRIPTION

1 B30786-01 HEAT EXCHANGER ASSEMBL

2 B30597 HEAT EXCHANGER ASSEMBLY, TOP