Williamson-Thermoflo OSB User's Information Manual

Oil-Fired Steam Boilers

User’s Information Manual

Hazard definitions

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

Hazards that will or can cause minor personal in-

jury or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage.

Failure to adhere to the guidelines on this page can result in severe

personal injury, death or substantial property damage.

At the beginning of each heating season, contact your qualified service technician to inspect, clean and start-up the

boiler per the Boiler Manual. Failure to comply could result in boiler failure, leading to potential severe personal injury,

death or substantial property damage.

The User’s Information Manual provides information to the boiler

owner/user for routine operation and maintenance and emergency

shutdown. Detailed information on boiler installation, operation,

start-up, service and parts is included in the Boiler Manual. The

Boiler Manual is intended only for use by a qualified installer/

service technician.

INSTALLER — Please take time to review this

User’s Information Manual with the boiler owner.

Explain all maintenance and service procedures.

Service and maintenance

1. To avoid electric shock, disconnect electrical supply before

performing maintenance.

2. To avoid severe burns, allow boiler to cool before performing

maintenance.

3. You must maintain the boiler as outlined in the manual and

have the boiler started up and serviced at least annually by a

qualified service technician to ensure boiler/system reliability.

Boiler water

4. DO NOT use petroleum-based cleaning or sealing compounds

in boiler system. Water seal deterioration will occur, causing

leakage between sections and damage to heating system

components. This can result in substantial property damage.

5. DO NOT use "homemade cures" or "boiler patent medicines".

Serious damage to boiler, personnel and/or property may

result.

6. Continual fresh makeup water will reduce boiler life. Mineral

buildup in sections reduces heat transfer, overheats cast iron,

and causes section failure. Addition of oxygen and other gases

can cause internal corrosion. Leaks in boiler or piping must

be repaired at once to prevent makeup water.

7. DO NOT add cold water to hot boiler. Thermal shock can

cause sections to crack.

Boiler operation

8. DO NOT block flow of combustion or ventilation air to boiler.

If vent or air blockage is easily accessible and removable,

remove it. If blockage is not obvious or cannot be removed,

have the boiler and system checked by a qualified service

technician.

9. Should overheating occur or oil supply fail to shut off, turn off

power to boiler and shut off the oil supply at a location external

to the appliance.

10. DO NOT use this boiler if any part has been under water.

Immediately call a qualified service technician to inspect the

boiler and to replace any part of the control system and any

burner control that has been under water.

11. Have the building monitored when it is vacant for an extended

period. Safety controls can shut down the boiler at any time.

The loss of heat can result in significant damage due to

freezing.

Air contamination

12. Carefully read and follow instructions on page 2.

Part Number 550-110-755/0402

OSB

Oil-Fired Steam Boilers – User’s Information Manual

Please read this page first

Air contamination

To prevent potential of severe personal injury or death, check for

products or areas listed in table below before installing boiler. If

any of these contaminants are found, do one of the following:

• Remove contaminants permanently. — or —

• Isolate boiler and provide outside combustion air. See

applicable codes for further information. — or —

• Contact your qualified service technician to install an

outside air kit (if available) for the burner. An outside air

kit allows ducting of outside air directly to the burner.

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and other similar products

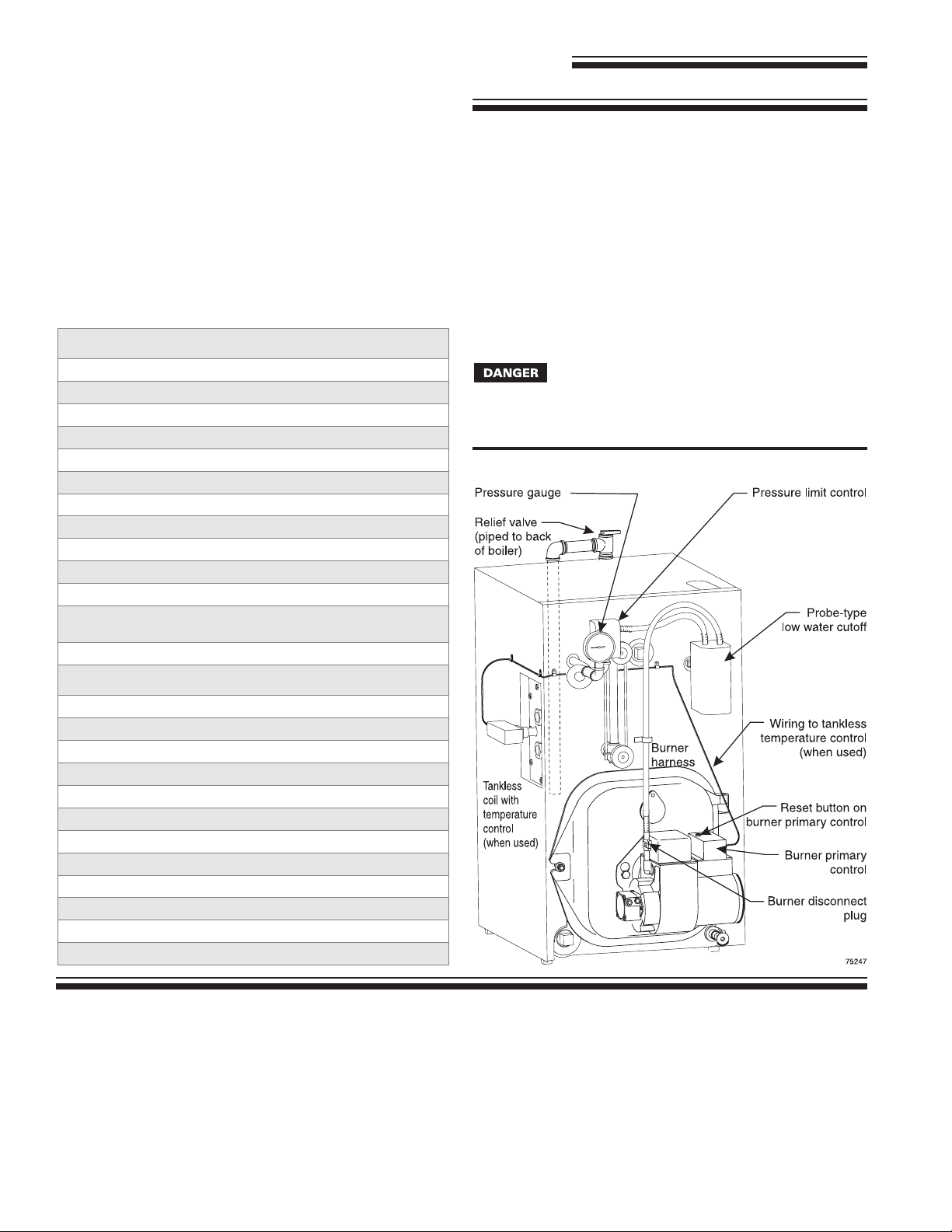

Start-up

1. If burner does not fire, check for:

• Boiler switch turned off?

• Fuses blown or breaker tripped?

• Thermostat set below room temperature?

• Fuel valves turned off?

• Water not visible in gauge glass?

• Not enough oil in tank to supply burner?

2. Correct problems found in step #1. If burner does not fire,

press the reset button on burner primary control only once.

Repeated presses will deposit oil in chamber, creating a fire

hazard.

Burner must never be fired when oil is in combustion

chamber. Immediately call a qualified service

technician.

3. If burner still does not fire, call a qualified service technician.

Figure 1 Boiler and components

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

❏ Check daily

Boiler area

1. Check that boiler area is free from combustible materials,

gasoline and other flammable vapors and liquids. Ensure that

no air-contaminating materials (see above) are present in the

area.

Pressure gauge

1. Pressure gauge must not show more than 15 psig (normally

5 psig). Contact a qualified service technician if high pressure

occurs.

Air openings

1. Verify that combustion and ventilation air openings to the boiler

room and/or building are open and unobstructed.

2 Part Number 550-110-755/0402

Loading...

Loading...