Williams by Bachmann F7A Instructions Manual

Bachmann Industries, Inc.

1400 East Erie Avenue, Philadelphia, PA 19124 USA

www.bachmanntrains.com

Customer Service Telephone 800-356-3910

F7A POWERED DIESEL LOCOMOTIVE INSTRUCTIONS

Thank you for purchasing a Williams by Bachmann® locomotive. This locomotive has been manufactured to provide

years of use and enjoyment. Please follow the simple instructions below.

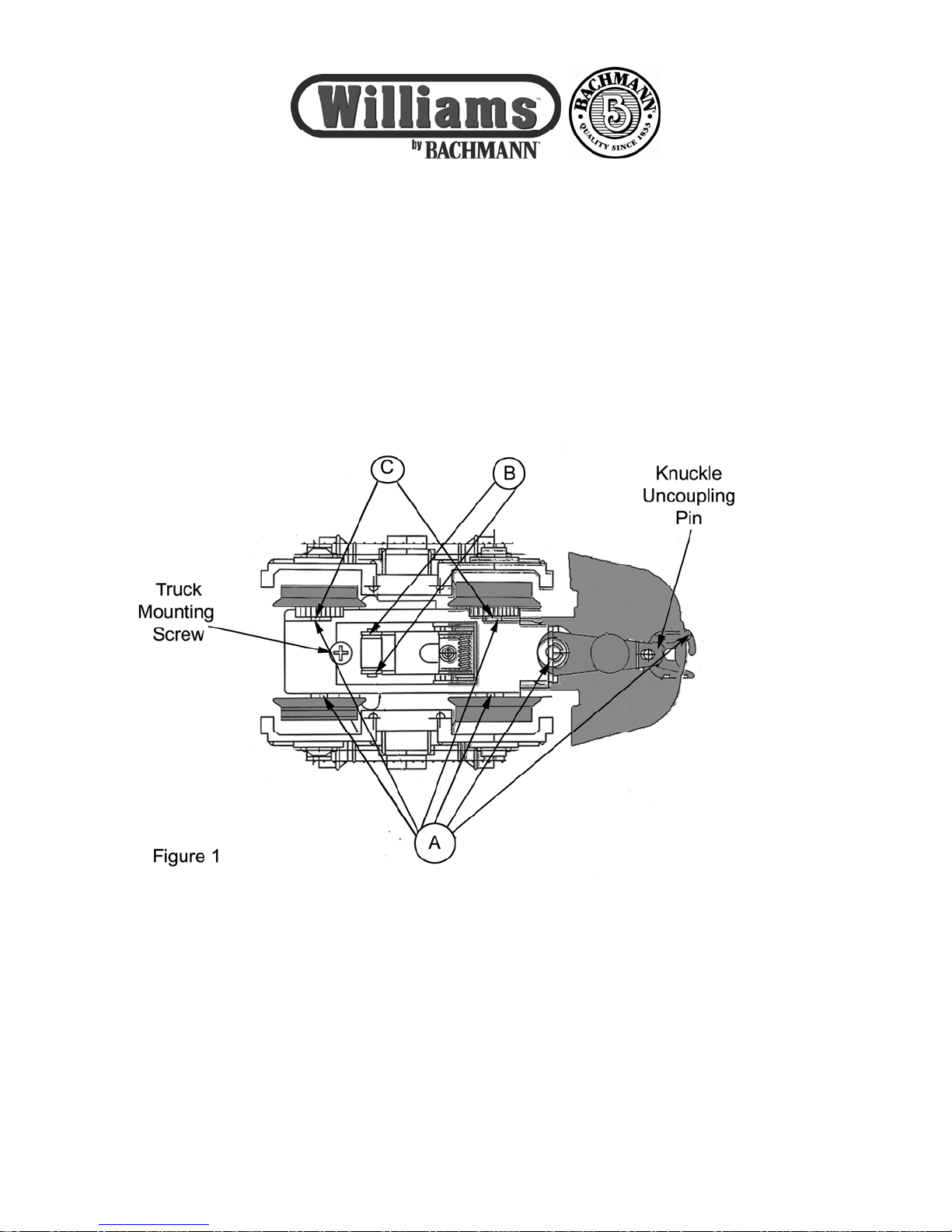

This locomotive has been greased and tested before leaving the factory. Before operating, please lightly lubricate the

points shown in the diagram below. Do not over-lubricate and take extra care to avoid getting lubricants on the wheel

surfaces or traction tires.

1. For the axles and coupler pivot points Marked A, we recommend that you lubricate with a small amount of light

oil such as Bachmann E-Z Lube® #99984 Light Gear Oil. Do not over-lubricate.

2. For areas that require electrical flow, such as roller pick-ups Marked B, please use Bachmann E-Z Lube®

#99981 Conductive Contact Lube. Never use any Teflon® based oil on these areas because this type oil has

insulating properties.

3. For the gears Marked C we recommend that you lubricate with a small amount of heavy gear oil such as

Bachmann E-Z Lube® #99983 Heavy Gear Oil. Do not over-lubricate.

– Page 1 of 2 –

OPERATION

After unpacking the locomotive, make sure that the uncoupling plunger is in the correct position with the pin inserted in

the knuckle (see figure 1). Failure to do so will allow the uncoupling plunger to contact the center rail and a direct short

will occur when power is applied to the track. We recommend using an AC hobby transformer with maximum voltage

output of 18 VAC and a wattage rating of at least 90 watts.

Throttle Control

The throttle control will allow you to operate your train at a wide range of speeds. Slowly turn the control knob until you

are familiar with the response of the locomotive that you are operating. Please note that our sound systems require 6 volts

or greater to operate correctly.

Horn Operation

To operate the horn of your locomotive, simply depress the horn /whistle button on your transformer. Our True Blast™

Horns will play a 6 second sequence one time.

Bell Operation

To operate the bell on your locomotive, press and hold the bell button for one second. To stop the bell, press and hold the

button for one second.

Direction Control

Williams reverse units sequence FORWARD, NEUTRAL, REVERSE, NEUTRAL, and again FOWARD. To sequence

the reverse board, simply depress and hold the direction button, release the button 1 second after the train has come to a

complete stop. PLEASE NOTE: If you do not wait for your train to come to a complete stop the reverse unit may not

always sequence properly. After approximately 7 seconds without power, the reverse board will reset to FORWARD.

Uncoupling

This locomotive is equipped with an operating knuckle coupler at the pilot end. The rear end of the locomotive has a fixed

coupler, to allow close coupling with the matching dummy A unit. To uncouple, position the uncoupling plunger over the

center of electro-magnetic track uncoupling section and activate the magnet. If you run this locomotive alone, or with a

Dummy B unit, you will need to use the operating coupler on the first piece of rolling stock in your consist.

PERIODIC MAINTENANCE

Disassembly Instructions

For periodic maintenance, you will have to remove the body shell and motor trucks to gain access to the parts that require

servicing. The body shell is attached with four screws on the bottom of the locomotive frame. The screws are located in

each corner of the frame. After removing the body shell, unscrew the truck mounting screw shown in figure 1. This will

allow you to disengage the motor from the truck assembly. When servicing is complete re-attach the motor to the truck.

Make sure the worm gear is meshing with the truck gear before tightening the mounting screw completely. You can test

this by rotating the flywheel on top of the motor and the wheels on the truck will turn. Re-attach body shell using care not

to over-tighten the screws.

Lubrication

We recommend that you lubricate as directed on page 1 every 10 hours of operation. In addition, you also should check

the motor gearbox every 25 hours. After gaining access to the gearbox as instructed above, you can inspect the gears and

apply any necessary lubrication. We recommend Bachmann E-Z Lube® #99982 Grease, or equivalent.

Traction Tire Replacement

Our traction tires are very durable and should not need replacing very frequently. They should last hundreds of hours

under normal conditions. If they wear out prematurely, check to make sure your track joints are tight. Gaps in your track

can cause damage to the tires. To replace the traction tires follow the disassembly instructions above. Next remove the

two screws that attach each sideframe. Remove old tire if present, clean wheel groove with any degreasing agent making

sure to follow the safety and handling instructions on the degreasing agent’s bottle. Wipe dry with paper towel or

clean rag. Stretch the new traction tire over the wheel making sure that it does not twist and seats smoothly in the wheel

groove. Re-attach the sideframes and re-assemble as directed above.

Light Bulb Replacement

This locomotive uses a 12 volt bayonet style bulb. The standard replacement bulb number is 53.

– Page 2 of 2 –

Printed In China

Loading...

Loading...