Page 1

.................................................................................................

=_ INSTRUCTIONS _OR WILLIAMS GAS APPLIANCE

CONVERSION KITS 7685, 7687, 7688, 7690 & 7691

iil=Jl_' i=,t;tl=_;,},]il'ii n_!l NATURAL G_S TO LIQUID PROPANE GAS

THIS KIT IS FOR USE

WITH MODEL NUMBERS:

This conversion kit shall be installed by a qualified

service agency in accordance

manufacturer's instructions and all

applicable

codes and requirements of the authority having

jurisdiction. If the information in these instructions

is not followed exactly, a fire, explosion or

production of carbon monoxide may result, causing

property damage, personal injury or loss of life.

The qualified service agency is responsible for the

proper installation of this kit, The installation is not

proper and complete until the operation of the

converted appliance is checked as specified in the

manufacturer's instructions supplied with the kit,.

3508332; 3508732; 5008732;

5508332; 6_08732; 6008532

PPL!CATION: THESE CONVERSION KITS ARE USED ON

E FORSAIRE TOP VENT WALL FURNACES WHEN

I_QUIPPED WiTH NATURAL GAS VALVES;

P323209 (STANDING PILOT MODELS)

i P3232t0 (ELECTRONIC IGNITION MODELS)

with the WITHhOmm STAINLESS STEEL BURNER 12956

dONVERTtNG TO L P GAS

THIS K_ CONTAINS:

(1} CAP SCREW

(t) PRESSURE REGULATOR ADJUSTMENT SCREW

(t) SPR_NG (RED)

(3) CONVERSION LABELS

(1 OR 2) PILOT ORIRCES (LP. GAS')

(1 OR 2) BURNER ORIRCES (LP GAS)

{1) LPG. TAG

{1) "O" RING

_AUTION:THE GAS SUPPLY MUST BE

SHUTOFF PRIOR TO DISCONNECTING THE

ELECTRICAL POWER BEFORE PROCEEDING

WITH THE CONVERSION,

I,,

2.,

3.,

4_

5_

,.

7,,

8_,

9,,

10o

11_

12.

13

I4.

!5

16,

17.,

18.

19,

2&

CONVERSION INSTRUCTIONS - NATURAL GAS TO LP. GAS

Shut off gas to the furnace,

Shut off electric power to the furnace,

Disconnect gas supply linefrom control valve

Remove electronic ignition module (ifequipped).

CAUTION: Label all wires prior to disconnection for'proper reconnection,

STANDING PILOT MQDELS ONLY_ Disconnect (2) tw$ wires from terminal block on thermocouple

and (2) two wires from control valve.

Use a 7/16" open end wrench to remove outer end nuts rom burner wire hangers and swing them up to

drop burner down. '_

NOTE: On single burner models, (2) two sheet metal ;crews are used instead of end nuts°

Pull the burner and control assembly forward to free itfrom he rear burner support bracket,

Once removed, all work can be performed on work bench.

Use a 7/16" boxed end wrench and remove the burner orifice(s) from the manifold and replace with the orifice(s)

provided in thiskit. Refer to Figure 1 on page 2

Remove pilot orifice from pilot and replace with orifice prov_ed in this kit, Refer to Figure 2A or B on page 2.

Remove regulator cap screw and pressure regulator adjust!ng screw Refer to Figure 3 on page 2.

Remove the existing spring, i

insertthe replacement red spring. Refer to Figure 4 on pa{e 2_

Install the new plastic pressure regulator adjustment screw !Assure that the screw top is flush with the regulator

top. I

Turn pressure regulator adjustment screw clockwise efever_complete turns. The preliminary pressure setting

isapproximately I0.,5 in, w.c. for LP gas regulator and 4,0 i_. w,,c.,for natural gas regulator

J

Check the regulator setting using a manometer or by ctock_nnthe gas meter°

installthe new cap screw and O ring,

Reassemble the furnace by following the steps above in re{,erse order°

Use information from chart on page 3 to fill in blanks on sepplemental data label_ A_ach label permanently

adjacent to the rating plate on a cteer surface area° i

Leave these instructionswith the homeowner.

REV 6/00 P323213_A917 74 SHT 1 OF

Page 2

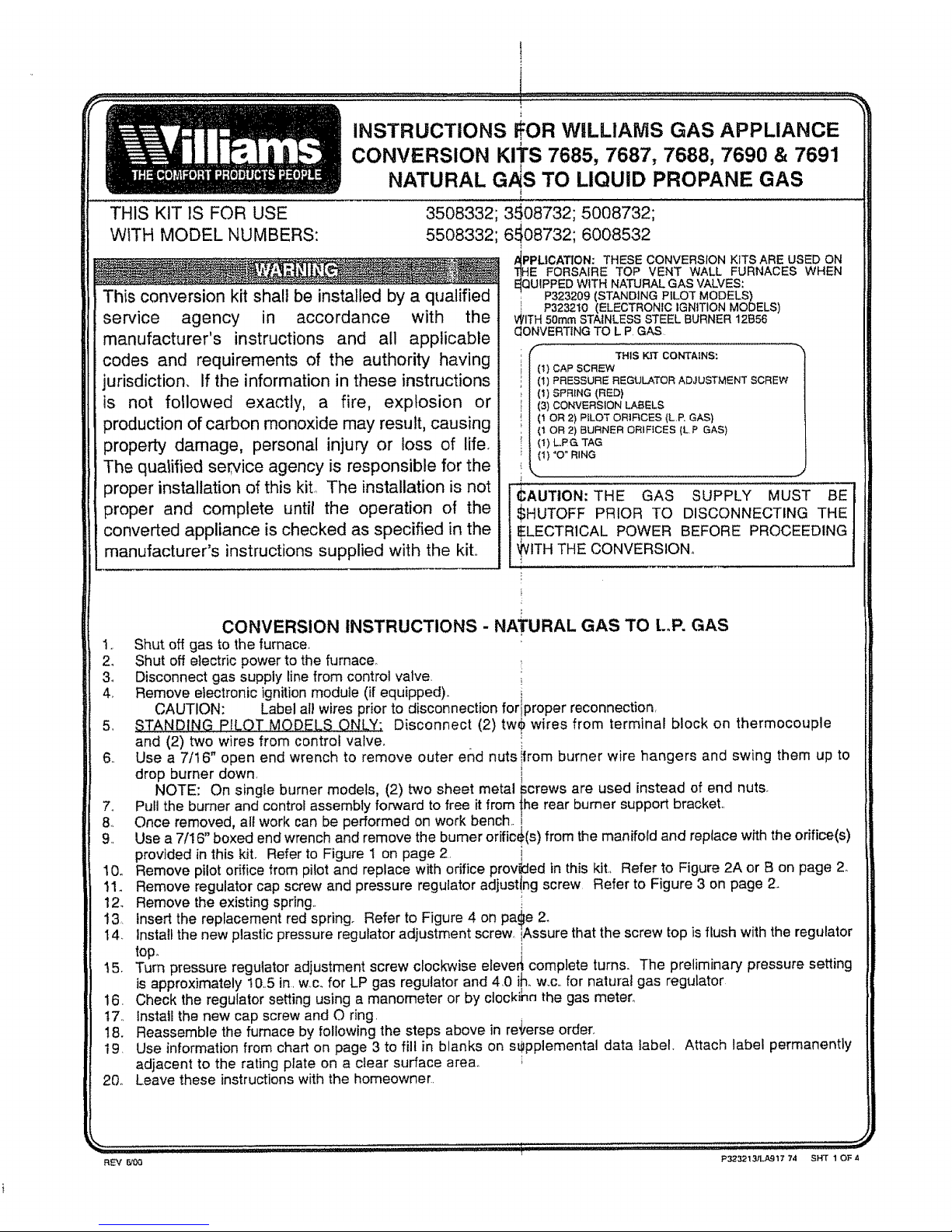

,. I'_T NO.

7685

7657

7688

7690

769t

MODEL NOoON

RATINGPLATE

3508332

3508732

5008732

55O8332

6508332

6508732

6OO8532

FIGURE 5

CHART

TO BE USI_ ON CONVICTION LABEL

NEW MOD_

NO.

3508331

3508731

50(38731

5508331

6508331

6508731

6008531

PEW INPUT

BI'UtHR

35,(X)0

35,000

5O,000

55,000

65,000

65,000

7/8

- (_8)

_ DURNg_I

NEWHEATING

DAPACITY BTLt91R

2B,000

28,000

37,500

44,000

52,000

52,000

60,000 49,200

.r- 3/_2 (lo)

HONEYWELLP322.954(Q314}

(AFTER

CONVERSION)

i

OFJRCE

SIZE

#52

#52

#54

#54

#52

#52

#53

IMPORTANT: LABEL PLACEMENT

After conversion is completed, the large

conversion label provided in this kit must be

filled out completely (using chart

information). Attach small conversion label

to gas valve, and attach large data

conversion label to inside of casing door

next to rating plate° Remove "Natural Gas"

tag from burner and replace with "Liquid

Propane Gas" tag provided with this kit.

This is necessary to provide information for

future servicing. Failure to do so could

result in property damage, personal injury

or death.,

t

(,,25) (I S

ROBERTSHAW "_L-__._=

! P3226B0 _

I (AFTER

dONVERSION)

0£ BURNER

,

Refer to the Lighting and Operating Instruction Plate located in _ontrol area of furnace for instructions on lighting

the burner°

I

Any adjustments must be performed by a qualified service techr dcian only. Improper adjustments could result in

property damage, personal injuryor death., t

!

The following information is provided for use by a qualified servic_ technician.

With main burner in 0peration, check aii"pipe connections, pilot _jas tubin'g"and around pressure regulator for gas

leaks with a rich soap and water solution. Bubbles indicate gas t_akage. Never use a match or open flame totest

for leaks. Correct even the slightest leak at once before using fu!nace.

ADJUST PILOT BURNER

NOTE: Pilot gas may need adjustment depending on inlet

pressure, increase or decrease to obtain proper

setting,.

Pilot flame should surround 3f8 inch to 1/2 inch of the

therrnocouple or generator tip, To adjust, if needed, remove

pilot adjustment cap (do not lose gasket).

i. Remove screw cover over pilot adjusting screw,

2 insert small screwdriver. Adjust flame as needed°

Turn screw counterclockwise _ to increase

flame or clockwise _ to _ecrease flame

3o Turn thermostat to-highest setting. Main burner

should light quickly and smoothly. Turn thermostat

to lowest setting,. Main burner should go out. Pilot

should remain liL

4 Replace screw cover over pilot adjusting screw.

t

D[ANGER OF PROPERTY DAMAGE, BODILY

iNJURY OR DEATH,

L_uid Petroleum (L,P,) is heavier than air and it will

s_)ttle in any low area, including open depressions,

a_d it will remain there unless area is ventilated°

Nbver attempt startup of unit before thoroughly

v+ntilating area,

children, clothing, furniture and flammable

t

P323213,.'LA_l 7_74 SHT. 3 OF 4

Page 3

CHECK GAS PRESSURE

J w

The minimum inlet pressure in the gas supply pipe should be 111,0 w,c, for Propane Gas., The maximum inlet

pressure should never exceed 13" w_c- This should be checked at the 1/8 inch N.,PT, plugged tapping in the supply

line with a manometer,

The manifold pressure for this appliance is !0,5" w,c, for Propane!Gas, Check with a manometer at the pressure tap

on the control valve,, To adjust pressure, remove ca_from! regulator and turn regulator adjustment screw

clockwise _ to increase and counterclockwise _ X, _ decrease pressure,

RATE VERIFICATION

Refer to the Lighting and Operating Instruction Plate located in cdntrol area of furnace for instructionson lighting the

burner.

I_ Make certainthereisno gas flowthroughthemeterothertha41otheappliancebeingchecked,Otherappliances

must remainoffand thepilotsextinguished(ortheirconsum#tiondeductedfromthemeterreading),

2. With gas control knob in "ON" position, cycle main burner o_ and off several times by means of thermostat to

stabilize PRV diaphragm,, i

3, With second hand on watch, carefully clock gas meter to detet'mine exact rate of gas flow to main burner in cubic

feet per hour (see CONVERSION TABLE below)° ,,

4. Compare actual input with manufacturer's recommended houily input stamped on rating platen Convert BTU per

hour input rating to cubic feet of gas per hour (cfh) by using _e following formula.

Whereas: Input Rating in BTUperHouJr = Cubic Feet of

PRV= Pressure BTU Content of Gas per cu tt Gas per Hour

RegulatorValve

MJ = Megajoule Input Rating in MJ/hr = m3ihr

m3 = MetricCube MJ of Gas per m3

5. If actual gas flow (cfh) does not conform to manufacturer's r_commended input rating (cfh or_U converted to

cfh), a limited adjustmen_tof the PRV may be made. Turn PI_V adjusting screw clockwise [ % to increase

or counterclockwise / "\ to decrease gas flow. Burne_ input must not exceed nameplate rating.

6. Replace cap screw in PRV adjustment stack. Turn gas suppl,/to other appliances back on and re4ight all pilots.

7o Place furnace in operation and observe through at least one €omplete cycle to be sure all controls are operating

satisfactorily., i

co"w"s'o"

This table shows the gas flow rate for measured time per revolution of the ONE CUBIC Foot

DIAL in cubic feet per hour (=th) and m3/hr.

,i ,,,,,,i ,H,, ,

TIM_ FLOW

sec cfh

40 90

......... ,,, ,,,

41 88

42 86

43 84

44 82

45 80

46 78

47 77

....... | ,,,,,,

75

73

72

FLOW TIME

m3/hr sec

2.55 56

2.50 57

5B

FLOW

cfh

64

63

62

2.44

2.38

2,32

2.21

.... , =

2.18

2,12

2.07

2,04

59

6O

62

64

66

68

70

6t i 1.73

60 _ 1.70

5B I 1.64

5s !1,59

54 ,,i,,,1.53

53 _ 1.50

51 il 1.44

FLOW TIME

m3/hr sec

}1.81 88

11.78 g2

= ................. __ ....

I 1,76 96

48

49

5O

51 71 2.01

52 69 1.95

53 68 1.93

54 67 1.90 80 _ 45

e5 ...........

For 1/2 cu froper revolution of meter dial, multiply

For 2 cu, ft. per revolution of meter dial, diTde flow

74 49

76 47

78 46

..........72 ...... i,50 _} 1.42-'

I 1_39

! 1.33

! !.3o

1.27

I 1.22

FLOW

cfh

41

39

38

36

34

33

31

30

29

I00

105

110

115

120

125

130 28

135 27

140 26

150 24

160 23

170 21

180 20

rate by 2.

by 2,

FLOW

m3/hr

1.16

1.10

1.o8

1.02

.96

.93

.88

.85

.82

.79

.76

,74

.68

.65

.59

.57

REV 6-'00

P3232134LA917..74

SH'f 4 OF 4

|

Page 4

FIGURE 1

BRACKET

OTEMI)

SCREWJ_

CONTROL ASSEMBLY

FOR MODELS

3508332; 3508732 (shown)

50087'32; 5508332 (not shown)

6508732; 60DB532 (not shown)

PILOT

BURNER

2)

I

_'- SCREW

FIGURE 2

A

INTERMITTENT JGNITJDN SYSTEMS

PILOT BURNER

STAMPED 3S24F

i /FORIFICE (LP SHOWN)

/STAMPED 11LP

#

/

B

HIGH BTU

BUILT-fN THERMOSTAT MODELS

PILOT BURNER

STAMPED Q314AFK

ORIFIC{ (UP, SHOWN)

(RED MARKING ON L.,P ORIFICE)

STAMPED BBRIO

t

i /r_PilO T

tlJ ,u==o

,/,/ PILOT HOOD

FIGURE 3

I_RESSURE REGULATOR CONVENIENCE

(,_NNNDU_TMEN'T TERMINALS [2) / WIRING

ER CAP SCREW)\\ (OPI3ONAL) i " / TERMINALS (2)

i£

! _R_SURE TAP, _ _ _'I/IUET_uRE

dO.N=CTiON,! A/.1 '_s \_ILOTADJUSTMENT

.ES_ COBOL(UNOE.CAPS_

BUTTON KI_K_B

A THERMOGOUPLE CONNECTION AND RED RESET

BUTTON ON STANDING PILOT MODELS ONLY

I FIGURE 4

PRESSURE

REGULATOR

HOUS1NG

!

1

P323213/L.A_17_74 SHT 2 OF ,_

Loading...

Loading...