Williams 6038531, 6058531, 6008532A, 6018532A, 6058532A Owner's Manual

...

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Open all windows.

Do not try to light any appliance.

Do not touch any electrical switch; do not

use any phone or cell phone in your

building.

Extinguish any open flame.

Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

If you cannot reach the gas supplier,

call the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

Owner’s Manual Save this manual for future reference.

Magnum Forsaire

Counterflow Top-Vent Gas

Williams Furnace Co. 250 West Laurel Street Colton, California 92324 U.S.A.

Wall Furnace

Model Numbers:

6008532; 6038532; 6058532

FOR USE WITH NATURAL GAS ONLY

Model Numbers:

6008531; 6038531; 6058531

FOR USE WITH PROPANE GAS ONLY

READ THIS OWNER’S MANUAL CAREFULLY BEFORE YOU

INSTALL YOUR NEW WILLIAMS WALL FURNACE.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause injury

or property damage. Refer to this manual. For

assistance or for additional information consult a

qualified installer, service agency or the gas

supplier.

Warranty & Installation Record – 2

Warranty

The manuf acturer, Williams Furnace Co., warrants this wall f urnace or heater to the original purchaser under the f ollowing conditions:

LIMITED ONE-YEAR WARRANTY

1. Any part thereof which prov es to be defective in material or workmanship within one year from date of original purchase for use will be replaced at the Manuf ac turer’s

option, FOB to its factory .

2. No liability is assumed by the Manufacturer f or removal or installation labor costs, nor for freight or delivery charges.

LIMITED EXTENDED WARR ANTY

1. In addition to the abov e limited one-year warranty on the complete unit, any combustion chamber which burns out or rusts under normal installation, use and service

conditions during a period of nine years following expiration of the one-year warranty period will be exchanged f or a like or f unctionally similar part.

2. No liability is assumed by the Manufacturer f or removal or installation labor costs, nor for freight or delivery charges.

LIMITATION S

1. THIS LIMITED WARRANTY IS THE ONLY WARRANTY MADE BY THE MANUFACTURER, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE ARE LIMITED TO THE SAME ONE YEAR TERM AS THE EXPRESS WARRANTY. UNDER NO CIRCUMSTANCES SHALL THE

MANUFACTURER BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, SPECIAL OR CONTINGENT DAMAGES OR EXPENSES ARISING DIRECTLY OR INDIRECTLY

FROM ANY DEFECT IN THE PRODUCT OR ANY COMPONENT OR FROM THE USE THEREOF. THE REMEDIES SET FORTH HEREIN ARE THE EXCLUSIVE

REMEDIES AVAILABLE TO THE USER AND ARE IN LIEU OF ALL OTHER REMEDIES.

Some states do not allow limitation on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you.

2. This warranty does not include any charge for labor or installation.

3. This warranty does not extend to painted surfaces or to damage or defects resulting from accident, alteration, misuses or abuse or improper installation.

4. This warranty does not cov er claims which do not involv e defective workmanship or materials.

DUTIES OF THE CONSU MER

1. The heating equipment must be installed by a qualified installer and operated in accordance with the installation and homeowner’s instruct ions f urnis hed with the

equipment.

2. Any trav el, diagnostic costs, service labor, and labor to repair the defectiv e unit will be the responsibility of the owner.

3. A bill of sale, cancelled check, payment record or permit should be kept to v erify purchase date to establish the warranty period.

4. Hav e the installer enter the requested information in the space below.

GENERAL

1. The manuf acturer neither assumes nor authorizes any person to assume f or it any other obligation or liability in connection with said equipment.

2. Service under this warranty should be obtained by contacting your dealer. Provide the dealer with the model number, serial number, and purchase date v erification.

3. If , within a reasonable time after contacting your dealer, satisfactory service has not been received, contact: Customer Service Department, 250 West Laurel Street,

Colton, CA 92324 f or assistance.

4. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

Installation Record

Model No. ____________________________________________________________ Serial No.__________________________

Original Purchaser________________________________________________________________________________________

Address ________________________________ _______________________________________________________________

City and State _________________________________________________________ Zip _______________________________

Dealer ________________________________________________________________________________________________ _

Address ________________________________ _______________________________________________________________

City and State _________________________________________________________ Zip _______________________________

Installation Date ______________ Name ________________________________ Signature_________________________________

(Dealer or authorized representativ e who certifies that this appliance is installed in accordance with Manuf acturer’s inst ruct ions and loc al c odes. )

2

Contents

Your Williams Warranty .........................................................................2

Installation Record..................................................................................2

Table of Contents ...................................................................................3

Safety Rules ............................................................................................4

Introduction..............................................................................................5

Basic Description....................................................................................5

Basic Tools Needed ...............................................................................5

Basic Materials Needed ........................................................................5

Optional Accessories.....................................................................6

Installing Your Wall Furnace.................................................................7

Locating Wall Furnace and Thermostat.......................................... 7-8

Combustion and Ventilation Air......................................................8-11

Installation

Recessed Mount Installation............................................. 11-13

Surface Mount Installation................................................. 13-14

Vent Installation................................................................... 14-16

Mounting Your Furnace ................................................................ 16-17

Gas Supply and Piping ................................................................. 18-19

Electrical Wiring ................................................................................... 19

Thermostat Installation ....................................................................... 20

Optional Accessory Installation ................................................... 21-23

Start Up Procedure ............................................................................. 24

Operating Your Furnace............................................................... 25-26

How To Care For Your Furnace.................................................. 27-28

Furnace Technical Information.......................................................... 28

TROUBLESHOOTING CHART................................................... 29-30

Wiring Diagrams .................................................................................. 30

Repair Parts ................................................................................... 31-32

Repair Parts List ............................................................................ 33-34

Forsaire Hardwire Accessary - 9940 ................................................ 35

SERVICE HINTS ................................................................. Back Cover

How To Order Repair Parts ............................................... Back Cover

Quick Reference: Here’s how to…

Unpack the furnace ............................................................................... 6

Learn how to unpack the new Williams Furnace and verify that all

its parts are in working order.

Install the furnace ............................................................................ 7-20

Recessed Mount, Surface Mount, and Vent Installation is all

explained starting on page 11.

Operate the furnace ...................................................................... 25-26

Igniting the furnace for the first time.

Caring for Your Furnace ............................................................... 27-28

Learn how to keep your new Williams Furnace operating.

Safety Rules

WARNING: Read these rules and the instructions

carefully. Failure to follow these rules and

instructions could cause a malfunction of the

furnace. This could result in death, serious bodily

injury and/or property damage.

INSTALLATION MUST CONFORM TO LOCAL CODES. IN THE

ABSENCE OF LOCAL CODES, INSTALLATION MUST

CONFORM TO THE NATIONAL FUEL GAS CODE, ANSI Z223.1.

THE APPLIANCE, WHEN INSTALLED MUST BE

ELECTRICALLY CONNECTED AND GROUNDED IN

ACCORDANCE WITH LOCAL CODES OR, IN THE ABSENCE

OF LOCAL CODES, WITH THE CURRENT NATIONAL

ELECTRICAL CODE ANSI/NFPA NO. 70.

In Canada:

1. Installation must conform to local codes or, in

the absence of local codes, the current

CAN/CGA B149 installation code.

2. The appliance, when installed, must be

electrically connected and grounded in

accordance with local codes or, in the absence

of local codes, with the current CSA C22.1

Canadian Electrical code.

3. Field conversions for high altitude are not

permitted in Canada.

4. Reference is made in this manual regarding gas

type as L.P.G. Be advised that L.P.G. is not

available in Canada, refer to propane/L.P. Gas.

1. Use only manufacturer's replacement parts. Use of any

other parts could cause injury or death.

2. DO NOT install this furnace where it could be isolated by

closing doors to the heated space.

3. DO NOT install this furnace in a travel trailer or

recreational vehicle.

4. MAINTAIN all clearances specified in section "Locating

Wall Furnace and Thermostat".

5. BE SURE this furnace is for type of gas to be used.

Check the rating plate by the gas valve in the lower

cabinet. Do not change it to use other gases without the

proper manufacturer’s Gas Conversion Kit.

6. For natural gas, the minimum inlet gas supply pressure

for the purpose of input adjustment is 5" water column.

The maximum inlet gas supply pressure is 7" water

column.

For L.P. Gas, the minimum inlet gas supply pressure for

the purpose of input adjustment is 11" water column. The

maximum inlet gas supply pressure is 13" water column.

7. Any safety screen, guard or parts removed for servicing

this appliance must be replaced prior to operating the

appliance to avoid property damage, bodily injury or

death.

8. Install the furnace vent directly to the outdoors so that

harmful combustible flue gases will not collect inside the

building. Follow the venting instructions for your type of

installation exactly. Use only the type and size of vent

pipe and fittings specified.

9. BE SURE to provide for adequate combustion and

ventilation air. The flow of this air to the furnace must not

be blocked.

10. NEVER vent flue gases into another room, a fireplace or

any space inside a building. This could cause property

damage, bodily injury or death.

11. Never test for gas teaks with an open flame. Use a soap

solution to check all gas connections. This will avoid the

possibility of fire or explosion.

12. ALLOW the furnace to cool before servicing. Always shut

off electricity and gas to furnace when working on it. This

will prevent any electrical shocks or burns.

13. DUE TO HIGH TEMPERATURES, locate the furnace out

of traffic and away from furniture and draperies.

14. ALERT children and adults to the hazards of high surface

temperatures and warn them to keep away to avoid

burns or clothing ignition.

15. CAREFULLY supervise young children when they are in

the same room with the furnace.

16. DO NOT place clothing or other flammable material on or

near furnace.

17. INSTALLATION and REPAIR must be done by a qualified

service person. The appliance should be inspected

before use and at least annually by a professional

service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material,

etc. It is imperative that control compartments, burners

and circulating air passages be kept clean.

18. BEFORE INSTALLING: To avoid electrical shock, tum off

electrical circuits that pass through the wall where you

are going to install the furnace.

19. BE AWARE of good safety practices by wearing personal

protective equipment such as gloves and safety glasses

to avoid being injured by sharp metal edges in or around

furnace and while cutting or drilling holes in wood and/or

sheet metal.

WARNING: Do not use this furnace if any part has

been under water. Immediately call a certified

service technician to inspect the furnace and to

replace any part of the control system and any gas

control which has been under water.

WARNING: Do not install any of these furnaces

(Natural or L.P. Gas) in mobile homes, trucks or

recreational vehicles.

4

Introduction – 5

Introduction

Please read our instructions before you install and use your furnace. This will help you obtain the full value from this furnace. It will also

help you avoid any needless service costs if the answer to the problem is found within this instruction manual.

Basic Description

Your Counterflow Top Vented Wall Furnace is shipped ready

to install on the surface of a wall or recessed up to 9-1/4 inches

in a wall, with wall studs spaced 16 inches center to center.

Vent piping and exhaust are not part of the Williams furnace

package and must be purchased separately.

Always consult your local heating or plumbing inspector,

building department or gas utility company regarding

regulations, codes or ordinances which apply to the installation

of a counterflow top vented wall furnace.

Air is drawn in at the top by the fan and discharges through a

grille near the floor. A two-speed fan is used with all models.

The furnace contains multi-slot burners and burns either

Natural or L.P. (Liquefied Petroleum) Gas, depending on the

model you have purchased.

This appliance is equipped with a vent safety shutoff system

designed to protect against improper venting of combustion

products. Operation of this wall furnace when not connected to

a properly installed and maintained venting system or

tampering with the vent safety shutoff system can result in

carbon monoxide (CO) poisoning and possible death.

The combustion system draws combustion air directly from the

room in which the furnace is installed, and through ventilation

grilles or ducts connected to the outdoors, such as an attic or

crawl space. The combustion gases are discharged through

the roof within a listed vent pipe.

The furnace heat exchanger is built of heavy gauge steel

treated for corrosion resistance, The fan at the top forces air

down along the front, back and sides of the heat exchanger

where it is discharged into the room, The furnace cabinet is

also constructed of heavy gauge steel and has a neutral beige

color enamel paint finish.

The furnace controls are located behind an access door on the

lower front of the furnace. AII models are equipped with

American Gas Association listed gas valves and pilots.

Tools Needed

Hand drill or properly grounded electric drill

Expansion bit 1/2" to 1-5/8" or 1/2'' and 1-1/2" blade bits

1/8" and 3/16" drill bit (metal)

6 ft. folding rule or tape measure

Screwdriver (med. blade)

Screwdrivers (Phillips Head)

Pliers (wire cutting)

Hammer

Hole Saw - 2"

1/8" Allen wrench

Stud locator or small finishing nails.

Tin snips

8 and 12" adjustable wrenches

Keyhole or sabre saw

2 - 10" or 12" pipe wrenches

Gloves and safety glasses

Materials

Pipe and fittings to make connections to furnace (See page 18).

Caulking compound-silicone rubber with a temperature rating of

500F.

DO NOT use caulking advertised as paintable or for bath tub use

as most contain fillers and will not withstand high temperatures.

Pipe Joint Compound resistant to L.P. gases.

Electrical wiring supplied as needed (see page 19).

Minimum wire size is #14 gauge copper.

3/4" Quarter Round or other wood trim molding approximately

16' long or Trim Accessory 4791 is recommended.

2" x 4" x (length as required) Spacer Blocks (see Close

Off Stud Space, page 12).

Oval Vent Kit 9901 is recommended.

Vent Enclosure Kit 9812 or 9824 if furnace is to be surface

mounted is recommended.

1 x 1 wood strips if Optional Side Outlet Grille Register

6701 is used.

Helpful Installation Information

The following booklets will help you in making the installation:

ANSI/NFPA 70-1990 or current edition "National Electrical Code". In Canada: CSA C22.1 Canadian Electrical Code.

American National Standard NFPAS4/ANSI Z223.1 1988 or current edition "National Fuel Gas Code".

Obtained from: American National Standards Institute, Inc., 1430 Broadway, New York, N Y 10018.

In Canada: CAN/CGA B149.

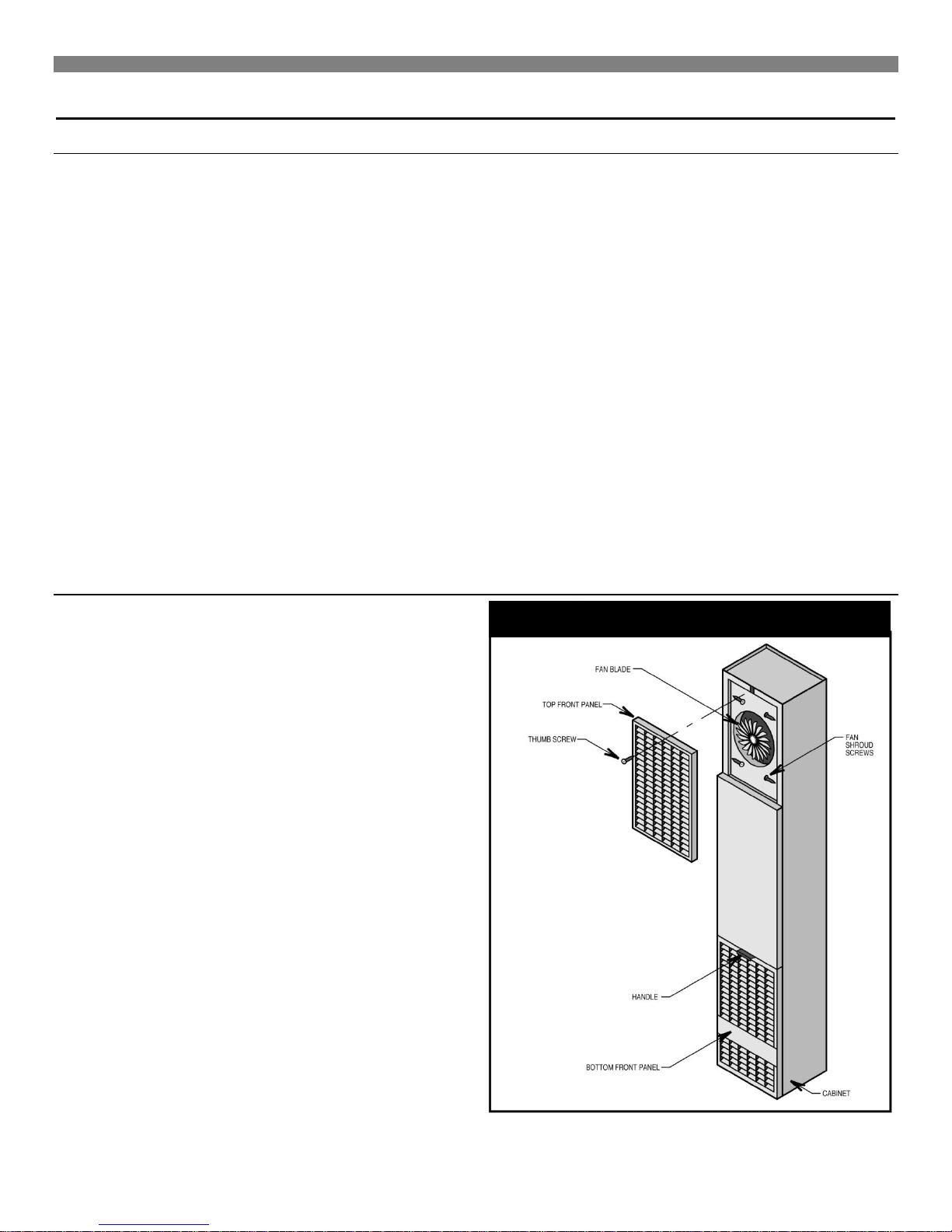

FIGURE 1

Introduction

Optional Accessories

SIDE OUTLET REGISTER 6701 Pg. 21

Let’s you route some heated air to a second room. Mounts on side

wall of second room and must be within 10 inches of wall furnace.

DIFFUSER GRILLE KIT 6703 as shown on Page 23, Fig. 32

Let’s you route some heated air in a two-way direction. Kit 6704

for one-way direction.

REAR OUTLET KIT 6801

Let’s you route some heated air to a second room behind the

furnace. Finished wall of second room must be within 10 inches of

furnace as shown on Page 8, Fig. D. Built-in damper lets you shut

off air flow to second room if desired.

SHORT REAR OUTLET KIT 6802

Let’s you route some heated air to a second room behind the

furnace when furnace is recessed mounted. Built-in damper lets

you control the air flow to the second room.

TRIM STRIP KIT 4701

OVAL VENT KIT 9901

This U.L. listed B/W vent kit contains 4 feet of oval double walled

vent pipe, plate spacers and starter or hold-down plate that starts

the venting from the top of the furnace. See page 16 for additional

items you will need.

VENT ENCLOSURE KITS 9812 or 9824

These kits are used only when the furnace is surface mounted.

They enclose the vent pipe from the top of the surface to the

ceiling.

SIDE OUTLET GRILLE KIT 6702 as shown on Page 22, Fig. 31

Allows you to direct heated air from the side of furnace into the

same room.

NOTE.

AII kits are identified on the carton by their Manufacturing Number

respectively, 6701, 6703, 6704, 6801, 6802, 4701, 9901, 9812,

9824 and 6702. These numbers are also listed on the furnace

rating plate.

Provides finished edge at sides of wall furnace. Neutral beige

enamel painted steel.

Unpack Your Furnace

The furnace is shipped in one carton containing the furnace,

installation instruction booklet and hardware bag.

1. Lay carton horizontally. Open carton and remove top trim

cover from its packing. Remove thumb screw at top of

furnace, raise top front panel ½ inch and remove panel from

cabinet. This is so you can get to the electrical connections

later.

2. Place these and other parts, as they are removed from

furnace, where they cannot be lost or damaged before you

need them.

3. Bottom front panel can be removed by grasping just below

handle and pulling it outward and then upward. See Fig. 1.

NOTE

Check the burner rating plate, located in burner compartment, to

make sure your furnace is equipped to operate on the type of gas

available (either Natural or L.P. Gas). Do NOT convert unit from

Natural Gas to L.P. Gas or from L.P. Gas to Natural

4. Remove all literature and package containing thermostat, wire

and metal anchors used for free standing installation.

5. Check the fan blade to be sure it spins freely.

6

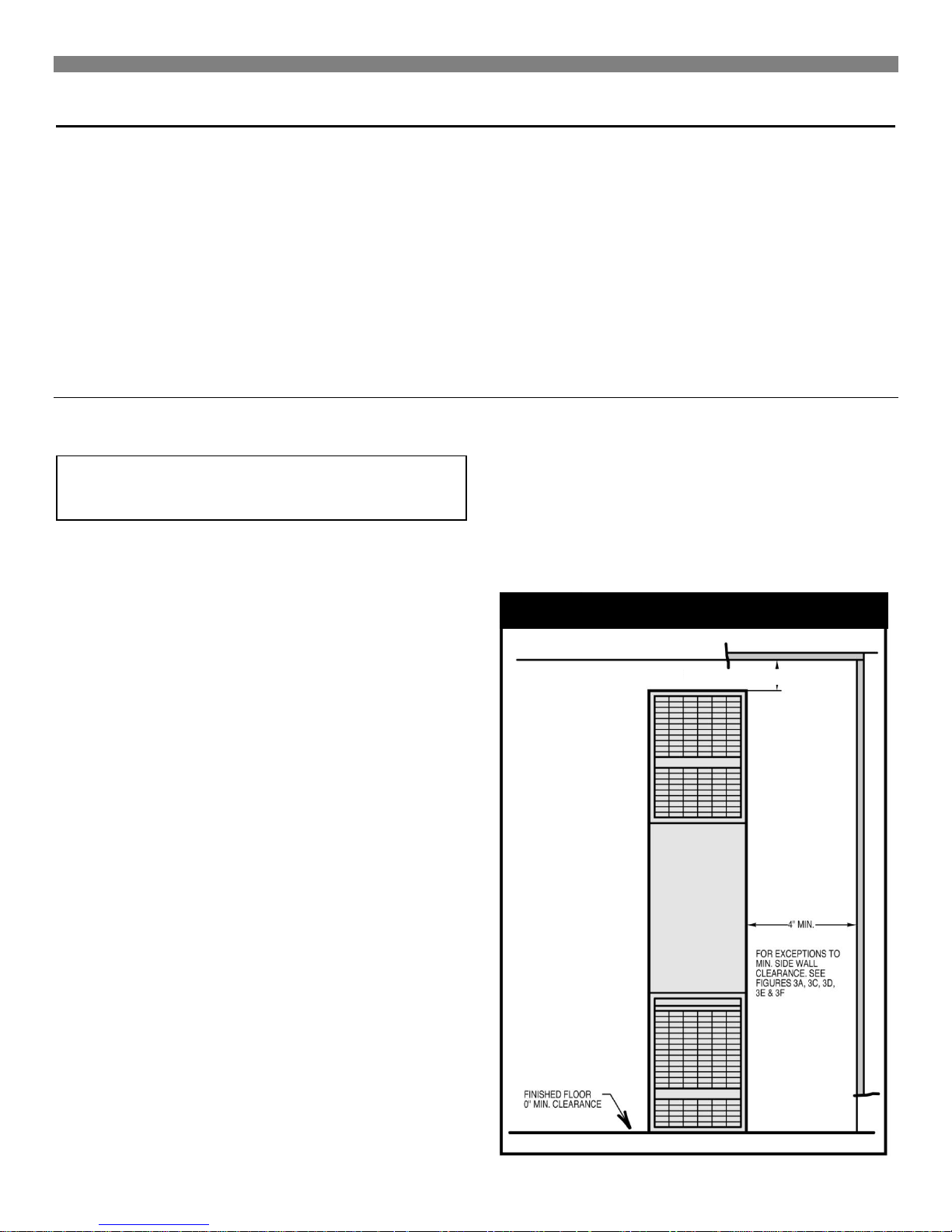

FIGURE 2 Minimum Clearances

CEILING CLEARANCE 2″ MIN

Installing Your Furnace

The following steps are needed for proper installation and safe

operation of your furnace. If you have any doubts as to any

requirements, always consult your local Heating or Plumbing

lnspector, Building Department or Gas Utility Company regarding

regulations, codes, or ordinances which apply to the installation of

a vented wall furnace. Obtain professional help where needed.

The CHECK AND ADJUSTMENTS on page 24 are vital to

the proper and safe operation of the furnace. Be sure they

are done.

IMPORTANT

For satisfactory and trouble-free operation, be sure to:

Locating Wall Furnace & Thermostat

Consider the following points before attempting to install the

furnace:

CAUTION: Do not make cut-outs in the wall or

ceiling before checking in the attic for ceiling joist

locations and proposed venting.

The counterflow vented wall furnaces are shipped ready to install

on the surface of the wall or recessed up to 9-1/4 inches into the

wall, with studs 16 inches center-to-center or stud space can be

framed to 16 inches, see page 11, Recessed Mounting.

1. Locate the furnace properly within the space to be heated.

2. Install the furnace in accordance with local codes or

ordinances and instructions provided. In the absence of local

codes or ordinances, install the furnace to conform with the

current edition of the National Fuel Gas Code, NFPA 54, ANSI

Z223.1/Canadian Installation Code, CAN/CGA B149.

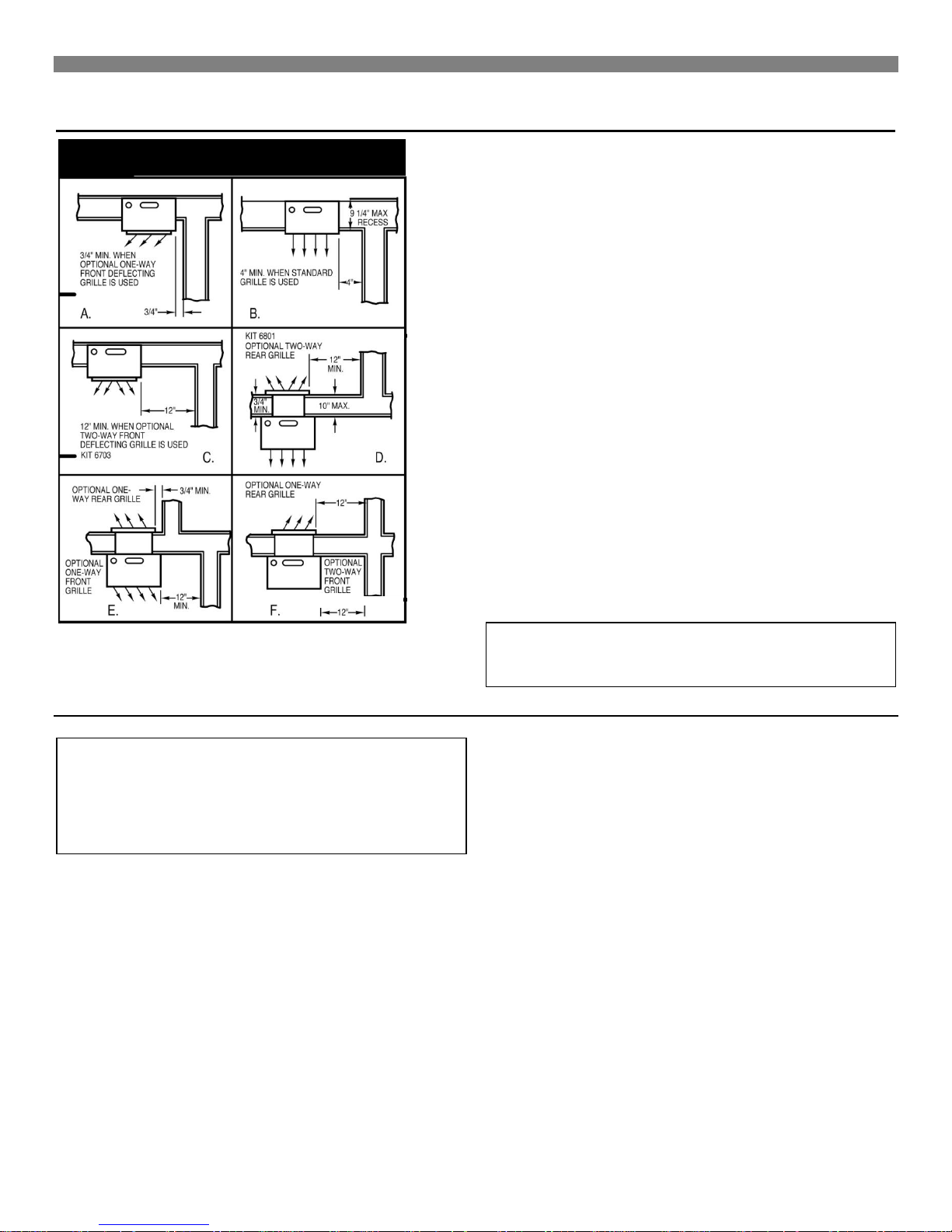

3. Maintain minimum clearance: Floor 0 inches or ceiling 2

inches, side wall 4 inches. For exception to minimum side wall

clearance, as shown on Page 8, Fig. 3.

4. Provide enough combustion and ventilation air.

With standard furnace discharge outlet, do not install closer than 4

inches to intersecting wall. See figure as shown on Page 8, Fig.

3B.

When using optional kits 6703 or 6704 maintain clearances as

shown on Page 8, Fig. 3A or 3C.

When using optional kit 6704 maintain clearance as shown in

Figs. 3A and 3F, page 8. Use only optional outlet and grille kits

available from manufacturer.

Place the furnace near the center of the space to be heated for

good air circulation. Do not put it behind a door or draperies.

Do not instatl the furnace in a closet, alcove, of small hallway

where the furnace could be isolated by closing doors to the heater

space.

Do not install the furnace in a mobile home, trailer, or recreational

vehicle.

The bottom of the furnace may rest directly on a wood or concrete

floor, If floor is other than wood or concrete there must be a piece

of wood or sheet metal under the furnace that is at teast the same

size as the bottom of the furnace.

On recessed installations the recessed portion rnay have 0 inches

clearance to combustible material.

To provide adequate clearance and service access the front of the

furnace must face the open room. Be sure that gas piping and

electrical wiring can be brought to the location. See sections

covering piping and electrical wiring for your type of furnace

mounting.

Furnace vent must be installed directly to the outdoors so that

combustion gases will not collect inside the building.

Provide an adequate vent or flue in accordance with local codes

or ordinances and instructions provided by the vent pipe

rnanufacturer.

Check the minimum spacing needs as shown on Page 7, Fig. 2

and Page 8, Fig. 3.

The top of the furnace must be at least 2 inches from the ceiling.

See Fig. 2.

FIGURE 3 Minimum Clearances

Installing Your Furnace

With standard furnace discharge outlet, do not install closer than 4

inches to intersecting wall.

Choose a location for the thermostat about 5 feet above the floor

on an inside wall. The thermostat wire supplied with your furnace

is 20 feet long, which should be enough to run up through the attic

so the thermostat can be a maximum of 16 feet from the furnace

measured in a straight line, or approximately 12 feet from the

furnace if the wire is run under the floor. The thermostat should be

sensing average room temperature, avoid the following:

HOT SPOTS: COLDSPOTS:

Concealed pipes or ducts Concealed pipes or ducts

Fireplaces Stairwells – drafts

Registers Doors – drafts

TV sets Unheated rooms on

Radios other side of wall

Lamps

Direct sunlight DEAD SPOTS

Kitchen Behind doors

Corners, and alcoves

Combustion & Ventilation Air

WARNING: Danger of property damage, bodily

injury or loss of life. The furnace and any other fuelburning appliances must be provided with enough

fresh air for proper combustion and ventilation of

flue gases. Most homes will require that outside air

be supplied into the heated area.

The high cost of energy for home heating has brought about new

materials and methods used to construct or remodel most current

homes. The improved construction and additional insulation has

reduced the heat loss and made these homes much tighter

around windows and doors so that infiltrated air is minimal. This

creates a problem to supply combustion and ventilation air for

gas-fired or other fuel burning appliances. Any use of appliances

that pull air out of the house (clothes dryers, exhaust fans,

fireplaces, etc.) increases this problem and appliances could be

starving for air.

In addition, these energy measures mean that your home will

retain more water vapor or a higher relative humidity.

After picking a location that meets the requirements, check the

walls, attic and roof to make sure there are no obstructions such

as pipes, electric wiring, etc., which could interfere with the

installation of the furnace or vent pipe. If required, move them or

pick a new location.

WARNING: Danger of property damage, bodily

injury or loss of life. Do not install furnace in any

area where oxygen is in use.

High humidity, especially during cold weather, may be damaging

to buildings because condensation forms on windows and inside

walls.

The combination of a tight energy efficient home with the use of

exhaust fans, fireplaces, clothes dryers, and gas appliances res ult

in more and more air being drawn from the house until fresh air

may be sucked back into the house down a furnace flue or

fireplace chimney. Carbon monoxide can be the result. Carbon

monoxide (CO) is a colorless, odorless gas produced when fuel is

not burned completely or when the flame does not receive

sufficient oxygen. Automobiles, charcoal, wood fires and

improperly vented or air-starved coal, oil and gas furnaces or

other appliances can produce carbon monoxide.

Be aware of these air-starvation signals:

1. Headaches, nausea, dizziness.

2. Excessive humidity shown by heavily frosted windows or a

moist "clammy" sensation.

3. Fireplace smoke fills the room or will not draw.

4. Furnace flue backs up.

8

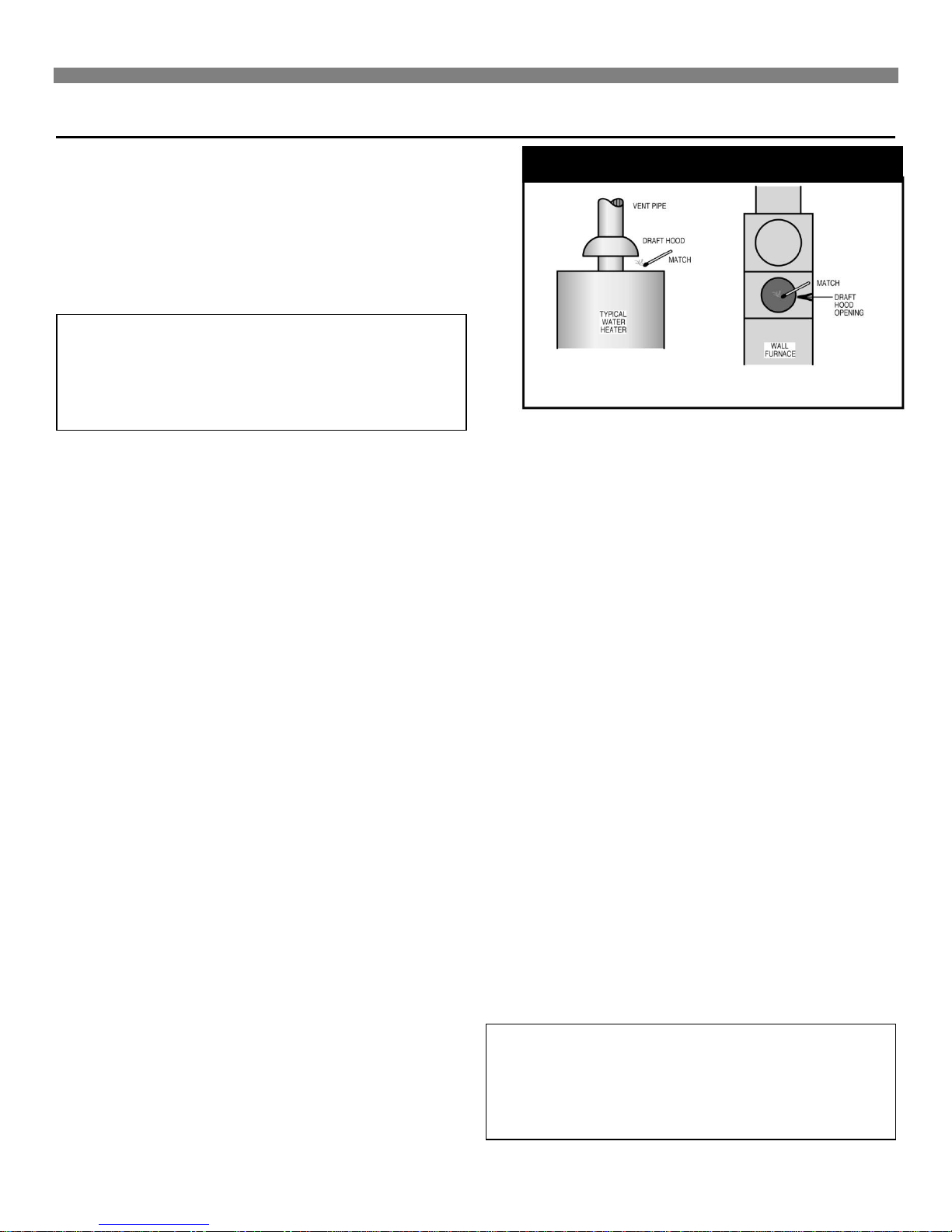

FIGURE 4 Draft Hood Spillage

Installing Your Furnace

AIR REQUIREMENTS

The requirements for providing air for combustion and ventilation

are listed in the National Fuel Gas Code NFPA 54/ANSI Z223.1 (in

Canada: CAN/CGA B149). Most homes will require that outside

air be supplied to the heated area by means of ventilation grilles

or ducts connecting directly to the outside or spaces open to the

outdoors such as attic or crawl space. The only exception is when

the heated area meets the requirements and definitions for an

unconfined space with adequate air infiltration.

WARNING: Danger of property damage, bodily

injury or loss of life. The furnace and any other fuelburning appliances must be provided with enough

fresh air for proper combustion and ventilation of

flue gases. Most homes will require that outside air

be supplied into the heated area.

All air openings and connecting ducts must comply with the

following:

If the furnace is installed in an area with another gas appliance(s),

the total input rating of all appliances must be considered when

determining the free area requirements for combustion and

ventilation air openings.

Ducts must have the same cross-sectional area as the free area

of the openings to which they connect. The minimum dimension

of rectangular air ducts must not be less than 3-inches in length or

height.

LOUVERS / GRILLES AND SCREENS COVERING

FREE AREA OPENINGS

If a screen is used to cover the opening(s), it must not be smaller

than 1/4-inch mesh. Use the free area of a louver or grille to

determine the size opening required to provide the free area

specified. If the free area is not known, assume a 20% free area

for wood and a 60% free area for metal louvers or grilles.

EXAMPLE 1

FURNACE LOCATED IN UNCONFINED SPACE.*

*

An unconfined space must have a volume of a minimum 50 cubic

feet per 1000 Btu/hr. of total of all appliances in area. Adjoining

rooms may be included only if there are no doors between the

rooms, or if special provisions are made such as ventilation grilles

installed between connecting rooms.

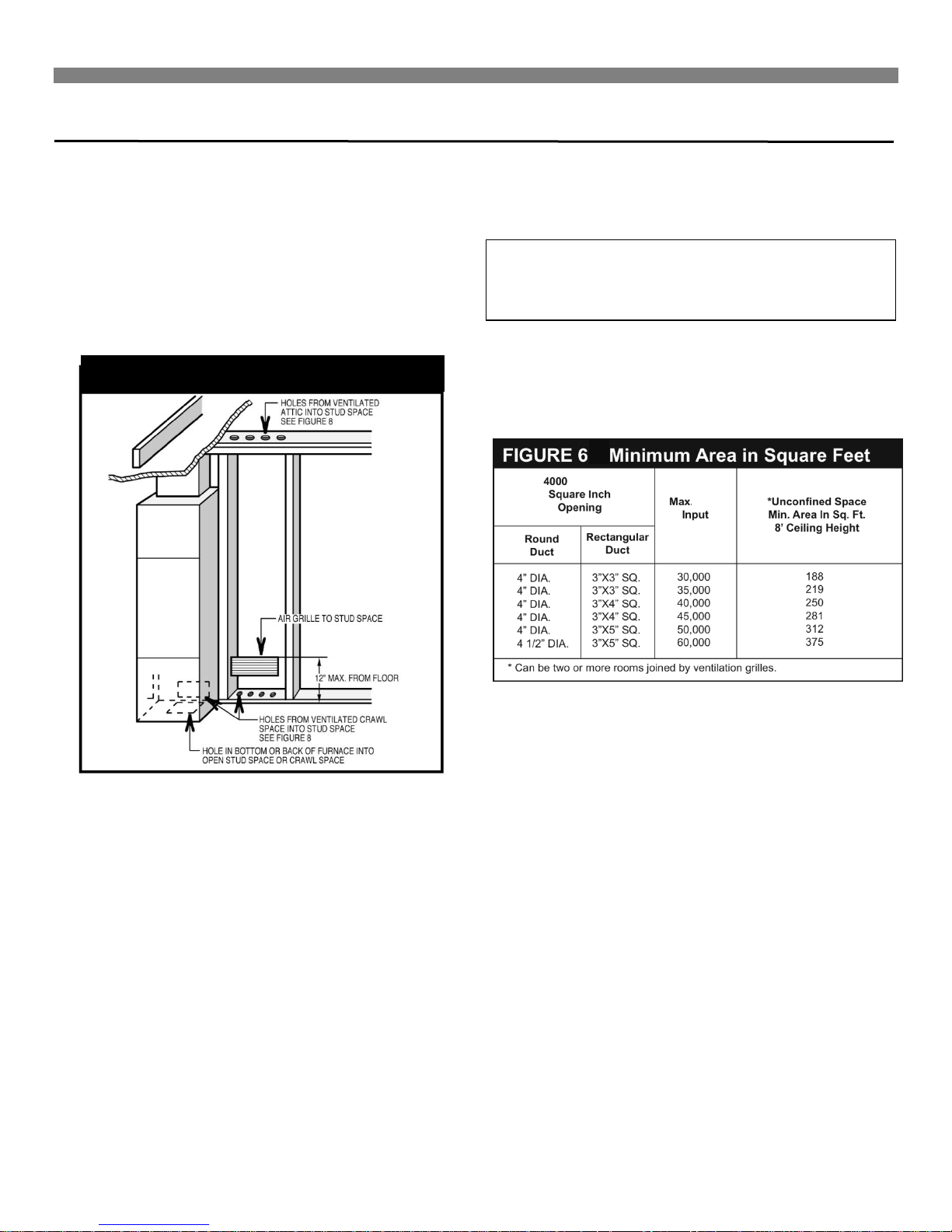

Fig 6, page 10 shows the minimum area in square feet' based on

8 foot ceiling heights, required for different Btu/hr. input ratings.

A. If your furnace is in an open area (unconfined space*) the

air that leaks through the cracks around doors and windows

may be enough for combustion and ventilation air. The doors

should not fit tight. The cracks around windows should not

be caulked or weather stripped.

To determine if infiltration air is adequate, following checks:

1. Close all doors and windows. If you have a fireplace,

start a fire and wait until flames are burning vigorously.

2. Turn on all exhausting devices, such as:

kitchen and bathroom exhaust fans

dryers (gas and electric)

3. Turn on all vented gas appliances, such as:

heating equipment (includes any room heaters)

water heater

4. Wait ten (10) minutes for drafts to stabilize.

5. Check for draft hood spillage at each appliance. (Hold a

lighted match 2 inches from draft opening. See Fig. 4.)

B. No Spillage

If the match flame pulls toward draft hood - this indicates

sufficient infiltration air:

1. Return exhausting devices and appliances to the

condition you found them.

C. Draft Hood Spills

If there is spillage at a draft hood (match goes out or flame

wavers away from draft hood):

1. Check for plugged flue connectors and chimneys. Check

and repair, stoppage and test again.

2. If you have a fireplace, open a window or door near the

fireplace and then check for spillage.

a) If spillage stops, do not use the fireplace without a

nearby window or door open until you can supply

fresh air by a permanent duct.

3. If you have kitchen and bathroom exhaust fans, turn

them off and check for spillage.

a) If spillage stops, do not use exhaust fans until you

can supply fresh air by a permanent duct.

WARNING: Danger of property damage, bodily

injury or loss of life. Draft hood spillage, with

unobstructed vents, indicates that additional air

must be brought into the structure from outside.

Keep a window open (minimum 2 inches) near the

appliance until a permanent air duct is installed.

FIGURE 5 Fresh Air duct

Btu/hr. Per

Btu/hr.

Installing Your Furnace

4. Spillage means air starvation and a fresh air duct or air

intakes must be installed to provide air directly to the

furnace or other gas appliance.

D. If spillage exists or when the furnace is in a building of tight

construction where the windows and doors are weatherstripped, air for combustion and ventilation must be obtained

from outdoors or space open to the outdoors.

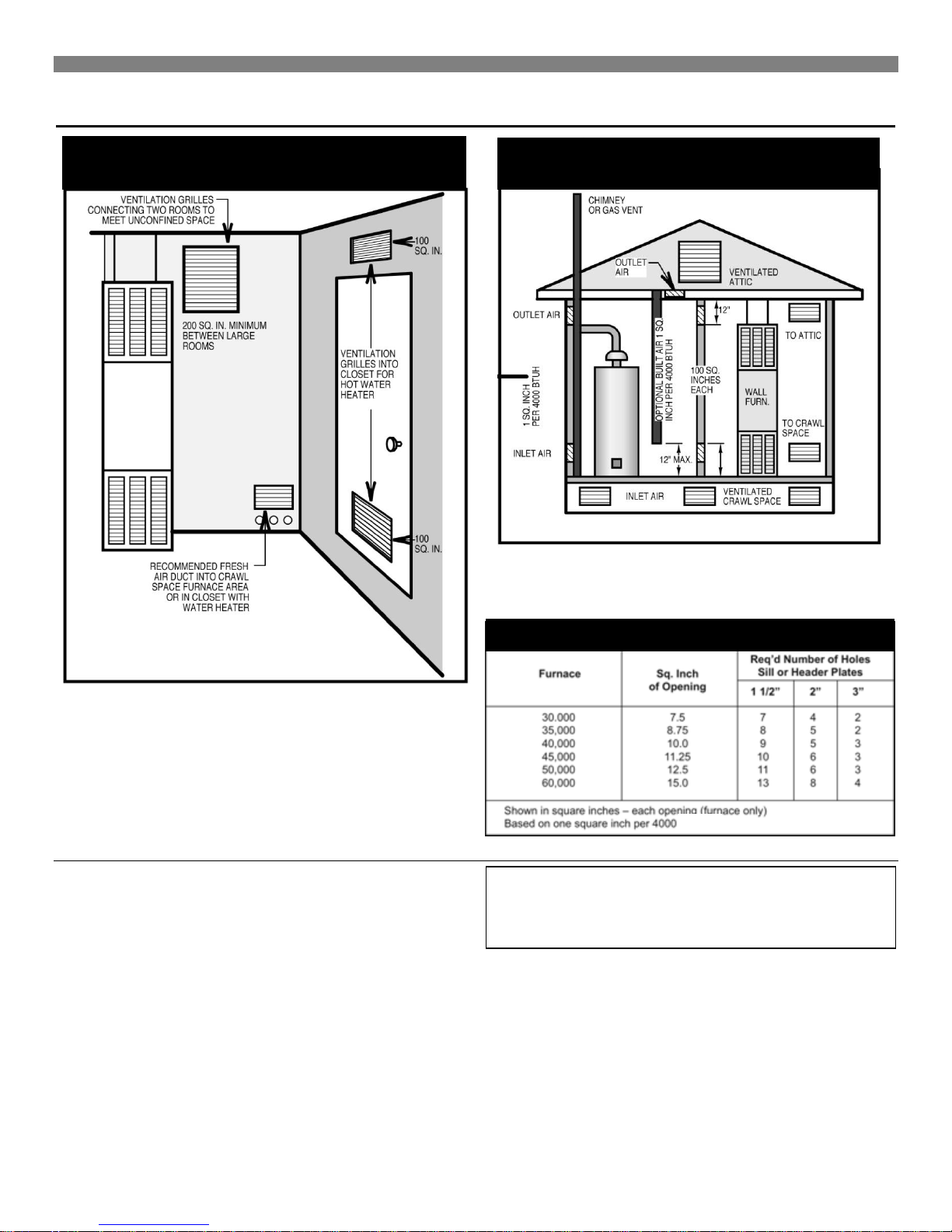

Provide an opening(s) having a total free area of 1-square inch

per 4000 Btu/hr. for the total of all appliances. The required area

is shown on page 11, Fig. 9 under the column for (40,000).

within 12 inches of the bottom of the room connecting directly to

unconfined space. Each opening must have a free area of at least

100 square inches or 1 square inch per 1000 Btuh combined input

of appliances in one room if combined input exceeds 100,000

Btuh.

WARNING: Danger of property damage, bodily

injury or loss of life. The adjoining unconfined

space must have adequate air infiltration as defined

in example 1.

FOR EXAMPLE: Your furnace is rated at 60,000 Btu/hr. The water

heater is rated at 30,000 Btu/hr. The total is 90,000 Btu/hr. You

need two grilles, each with 100 square inches of free opening.

Metal grilles have about 60% free area, so you need two metal

grilles each with 160 square inches of louvered area.

Fig 5 shows a typical duct going into ventilated crawl space

or attic.

1. Duct must terminate at a point not more than 1 foot

above the floor.

2. Duct size must be at least 1 inch of free area for each

4000 Btu/hr. of input of all appliances in area.

EXAMPLE 2.

FURNACE LOCATED IN CONFINED SPACE.

If furnace is installed in a confined space, it must be provided with

free air for proper combustion and ventilation of flue gases by one

of the following methods.

A. All Air From Inside Building:

If the confined space adjoins an unconfined, provide two

permanent openings, one within 12 inches of the top and one

Refer to figure as shown on Page 11, Fig. 7, which shows grille

installation. Using the previous example, the two connecting

rooms plus the closet must equal at least 500 sq. feet to handle

the combined input 60,000 plus 30,000.

B. All Air From Outdoors:

If confined space doesn't adjoin an unconfined space then air

must be provided from outdoors or spaces open to outdoors such

as attic or crawl space.

Provide two permanent openings, one within 12 inches of top, one

within 12 inches of bottom of room connecting directly, or by using

ducts, with the outdoors or areas open to outdoors.

If opening connects directly to, or within vertical ducts, the free

area of each opening must be at least 1 square inch per 4000

Btu/hr. combined input of appliances in area.

If horizontal ducts are used, the free area of each opening must

be at least 1 square inch per 2000 Btu/hr. combined input of

appliances in area.

10

FIGURE 7 Grilles Connecting Rooms to

Make Unconfined space

FIGURE 8 Air from outdoors or crawl space

FIGURE 8 Air from Outdoors or Crawl

Space

FIGURE 9 Free Area

Btu/hr.

Btu/hr./Input

Installing Your Furnace

FOR EXAMPLE: Your furnace is rated at 60000 Btu/hr. The water

heater is rated at 30,000 Btu/hr. The total is 90,000 Btu/hr. You

need two grilles, each with 22½-square inches of free opening,

unless connected by horizontal ducts which would require each

grille or opening to have a free area of 45 square inches.

Recessed Mount Installation

FIND THE STUDS (See CAUTION on page 7)

Use a stud locator or small finishing nails. Repeatedly drive and

remove a nail into the wall in the area of the stud until it is located.

Then find the inside edge of the stud. Leave the nail at this

location.

The other stud should be about 14½-inches from the one found.

Drive finishing nails on the inside of this stud. Draw wall cutout to

required size as shown on Page 13, Fig. 13. If wall studs are not

on 16-inch centers see "CLOSE OFF STUD SPACE.” (As shown

on Page 12, Fig. 12).

CUT WALL OPENING

Provide an opening as shown on Page 12, Fig. 10. Work from the

top in the attic to cut away the ceiling plate.

*Openings for inlet or outlet air should not be made into attic area

if attic is equipped with a thermostat controlled power vent.

WARNING: BEFORE INSTALLING: To avoid

electrical shock, turn off electrical circuits that pass

through the wall where you are going to install the

furnace.

ATTACH HEADER PLATE

MODELS: 6008531; 6008532

Locate header plate between wall studs at 81 3/4 inches from

finished floor and nail into position with end flanges pointing up.

Make sure header plate is level.

ALL MODELS

Hole or electrical conduit is located on left side of header plate as

you face the wall.

Loading...

Loading...