Page 1

p

Natural Gas

Propane Gas

MODEL:

2903512

MODEL:

2903511

Installation Instructions and Owner’s Manual

Direct-Vent Wall Furnace

WARNING: Improper installation, adjustment,

alteration, service, or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional

information, consult a qualified installer,

service agency or the gas supplier.

WARNING: Installation and repair must be

done by a qualified service person. The

furnace should be inspected before use and at

least annually by a professional service

person.

WARNING: If not installed, operated and

maintained in accordance with the

manufacturer’s instructions, this

product could expose you to substances in

fuel or from fuel combustion which can cause

death or serious illness and which are known

to cause cancer, birth defects or other

re

roductive harm.

WARNING: If the information in this

manual is not followed exactly; a fire

or explosion may result, causing

property damage, personal injury or

loss of life.

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Open all windows.

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Extinguish any open flame.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Williams Furnace Co., 250 West Laurel Street, Colton, CA 92324 U.S.A.

Page 2

Table of Contents

General Information and Technical Data

Instructions to Installer ……………………………………………………………………………………………………………………1

Safety and General Warnings ………………………………………………………………………………………………………….. 2

Technical Data …………………………………………………………………………………………………………………………… 3

Installation

Wall Installation ….................................................................................................................................................................... 4

Outside Location for Vent Terminal …...................................................................................................................................... 6

Gas Conversions ….................................................................................................................................................................. 8

Gas Supply …........................................................................................................................................................................... 9

Electrical Wiring Diagrams …….............................................................................................................................................. 11

Operating Instructions ……………………..……………………………………………………………..……………………………... 12

Servicing

Checking and Adjusting the Gas Manifold Pressure ………………………………………………………………………….……. 14

Checking, Removing and Reassembling of the Vent Air Intake System ………………………………………………………… 14

Lubrication of Moving Parts …………………………………………………………………………………………………………… 14

Flame Visual Check ………………………………………………………………………………………………………………….... 14

Annual Maintenance Requirements ………………………………………………………………………………………………….. 15

Programmable Timer

Overview ………………………………………………………………………………………………………………………………… 16

Setting and Adjustment ………………………………………………………………………………………………………………... 17

Troubleshooting

Starting Sequence …………………………………………………………………………………………………………………….. 19

Replacement Parts ………………………………………………………………………………………………………………...………. 22

General Information and Technical Data

This furnace is design certified to ANSI Z21.86-2004 / CSA 2.32-2004 Gas–Fired Gravity and Fan-Type, Direct-Vent Wall

Furnaces as a Fan-Type Direct-Vent Wall Furnace to be installed on an outside wall according to these instructions.

Any alteration of the original design, installed other than as shown in these instructions or used with a type of gas not shown on

the rating plate is not permitted.

Instructions to Installer

Installation and repair should be done by a QUALIFIED SERVICE TECHNICIAN.

The installation must conform to local codes or in the absence of local codes; the installation must conform to the National Fuel

Gas Code ANSI Z223.1/NFPA 54, Natural Gas and Propane Installation Code CSA B149.1.

Mobile (Manufactured) home installations must conform with the “Manufactured Home Construction and Safety Standard Title 24

CFR, Part 3280” or, when such a standard is not applicable, the Standard for Manufactured Home Installations, ANSI A 225.1

NFPA/501A, Mobile Home Standard, CAN/CSA Z240 MH Series, in Canada. Installer must leave instruction manual with the

home owner after installation. Installer must show home owner how to start and operate furnace and thermostat. Installer must

provide a 1/8-inch NPT plugged tapping for test gauge connection immediately upstream of the gas supply connection of the

furnace.

During initial firing of the furnace, residual manufacturing grease will bake out and smoke will occur which is not a health danger.

To prevent nuisance and operation of fire alarms, ventilate the room for the first two hours of operation.

WARNING: Any change to this furnace or its controls can be dangerous. This is a heating appliance and any

panel, door or guard removed for servicing this furnace must be replaced prior to operating the furnace.

1

Page 3

Safety Rules and General Warnings

DO NOT OPERATE THIS FURNACE WITHOUT THE FRONT PANEL INSTALLED

• Due to high temperatures, the furnace should be

located out of traffic and away from combustible

materials such as furniture and draperies.

• Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised

when they are in the same room as the furnace.

• Clothing or other flammable material should not be

placed on or near the furnace.

• Any safety screen or guard removed for servicing

an furnace must be replaced prior to operating the

furnace.

• Keep burner and control compartment clean.

• The outside vent cap is hot while furnace is in

operation.

• Installation and repair should be done by a

QUALIFIED SERVICE TECHNICIAN. The furnace

should be inspected before use and at least

annually by a qualified service technician.

• More frequent cleaning may be required due to excessive

lint from carpeting, bedding materials, etc. It is imperative

that control compartments, burners and circulating air

passageways of the furnace be kept clean.

• DO NOT put anything around the furnace that will obstruct

the flow of combustion and ventilation air.

• DO keep the furnace area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO examine burner periodically. Clean and replace

damaged parts.

• DO NOT use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect

the furnace and to replace any part of the control system

and any gas control which has been under water.

Safety Information for Users of LP Gas

Propane (LP Gas) is a flammable gas which can cause fires and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions which can protect both you and your family from an accident.

Read them carefully now, then review them point by point with the members of your household. Someday, when there may

not be a minute to lose, everyone’s safety will depend on knowing exactly what to do. If, after reading the following information,

you feel you still need more information, please contact your gas supplier.

LP Gas Warning Odor

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP Gas.

That’s your signal to go into immediate action!

• Do not operate electric switches, light matches or use your phone. Do not do anything that could ignite the gas.

• IMMEDIATELY get everyone out of the building, vehicle, trailer or area.

• Close all gas tank or cylinder supply valves.

• LP Gas is heavier than air and may settle in low areas such as basements. When you have reason to suspect a gas

leak, keep out of basements and other low areas. Stay out until firefighters declare them to be safe.

• Use your neighbor’s phone and call a trained LP Gas service technician and the fire department. Even though you may

not continue to smell gas, do not turn on the gas again. Do not re-enter the building, vehicle, trailer or the area.

• Have the service technician or fire department air out the area before you return. A properly trained LP Gas service

technician must repair the leak, check and relight the gas furnace for you.

2

Page 4

Some Points to Remember

• Learn to recognize the odor of LP Gas. Your local LP Gas Dealer can give you a ”Scratch and Sniff” pamphlet. Use

it to find out what the propane odor smells like. If you suspect that your LP Gas has a weak or abnormal odor, call

your LP Gas Dealer.

• If you are not qualified, do not light pilot lights, perform service, or make adjustments to furnaces on the LP Gas

system. If you are qualified, consciously think about the odor of LP Gas prior to and while lighting pilot lights or

performing service or making adjustments.

• Sometimes a basement or a closed–up house has a musty smell that can cover up the LP Gas odor. Do not try to

light pilot lights, perform service or make adjustments in an area where the conditions are such that you may not detect

the odor if there has been a leak of LP Gas.

• Odor fade, due to oxidation by rust or absorption on walls of new cylinders and tanks, is possible. Therefore, people

should be particularly alert and careful when new tanks or cylinders are placed in service. Odor fade can occur in

new tanks or reinstalled old tanks if they are filled and allowed to set too long before refilling. Cylinders and tanks

which have been out of service for a time may develop internal rust which will cause odor fade. If such conditions

are suspected to exist, a periodic sniff test of the gas is advisable. If you have any question about the gas odor,

call your LP Gas dealer. A periodic sniff test of the LP Gas is a good safety measure under any condition.

• If, at any time, you do not smell the LP–Gas odorant, and you should, assume you have a leak. Then take

the same immediate action recommended above for the occasion when you do smell the odorized LP Gas.

• If you experience a complete ”gas out” (the container is under no vapor pressure), turn the tank valve off immediately.

If the container valve is left on, the container may draw in some air through openings such as pilot light orifices.

If this occurs, some new internal rusting could occur. If the valve is left open, then treat the container as a new tank.

Always be sure your container is under vapor pressure by turning it off at the container before it goes completely

empty or having it refilled before it is completely empty.

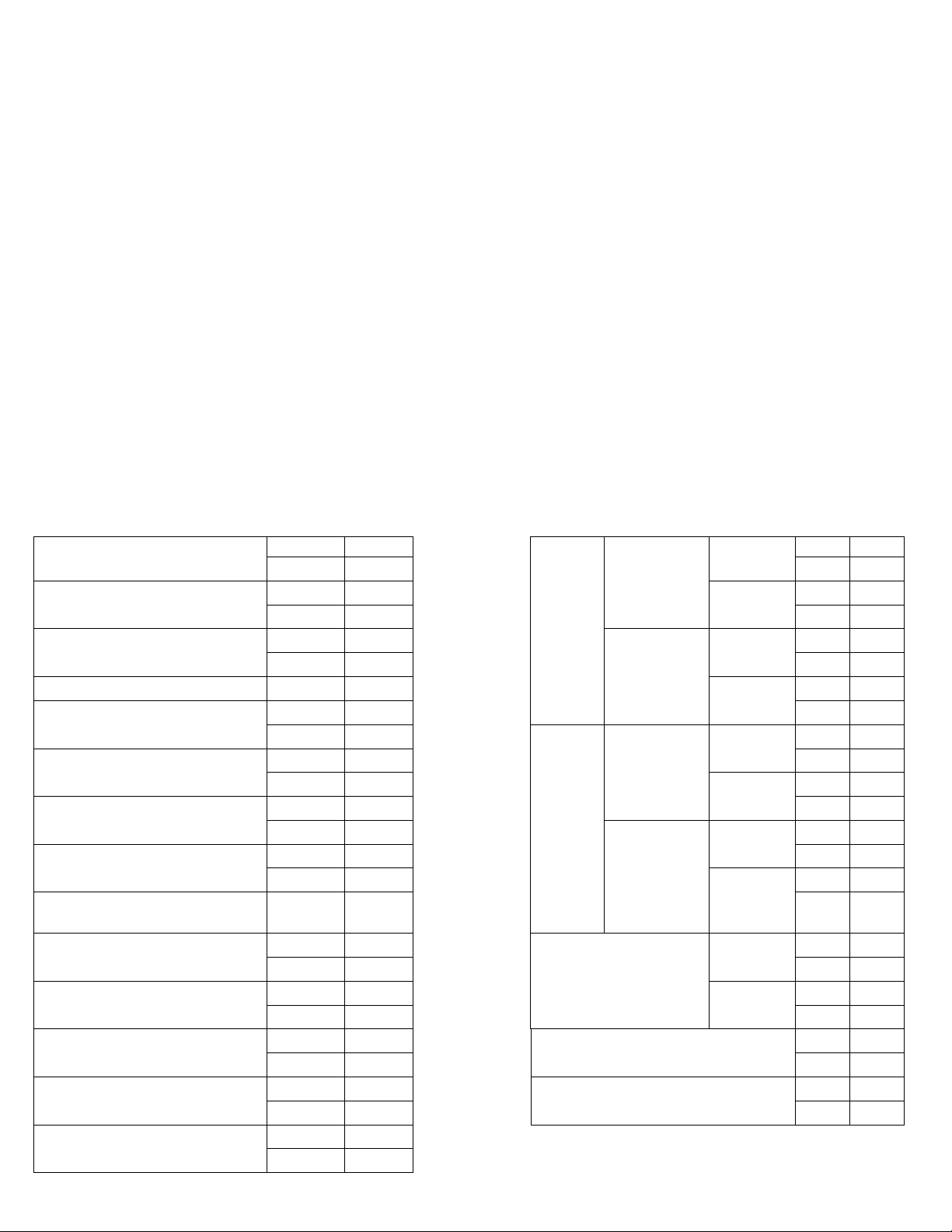

Technical Data

OUTPUT HEATING CAPACITY

INPUT RATING (High Input)

MINIMUM INPUT RATING

(Low Input)

THERMAL EFFICENCY % 82 mbar 16.2

LENGTH

HEIGHT

DEPTH

WEIGHT

GAS CONNECTION NPT /h 8.7

WALL HOLE DIAMETER

AIR INLET DIAMETER LP

EXHAUST PIPE DIAMETER

MAX WALL THICKNESS

MIN WALL THICKNESS

kW 6.98 8.0

kBTU/hr 23,817

kW 8.5 mbar 26.5

MAX

kBTU/hr 29,000

kW 5.89 mbar 4.6

kBTU/hr 20,100

mm 1006 6.5

MANIFOLD PRESSURE

MIN

in 39-5/8” m

mm 715 ft3/h 30.1

in 28-1/8” m

MAX

mm 208

in 8-1/4” m

kg 42

lbs. 93 m

½”

FEMALE

mm 50 mbar 17.4

in 2”

mm 49 mbar 27.4

in 1-7/8” in

mm 35 m³/h 450

in 1-3/8”

mm 500 m³/h 330

in 19-5/8”

GAS RATE

MIN

MINIMUM INLET

PRESSURE

AIR FLOW

MINIMUM AIR FLOW

mm 150

in 5-7/8”

NATURAL

GAS

LP

NATURAL

GAS

LP

NATURAL

GAS

LP

NATURAL

GAS

LP

NATURAL

GAS

mbar

in

W.C.

in

W.C.

in

W.C.

in

W.C.

3

3

3

/h 11.6

ft

3

3

/h 21.3

ft

3

3

ft

in

W.C.

W.C.

3.2

10.6

1.8

/h .9

/h .3

/h .6

/h .2

7.0

11.0

cfm 265

cfm 194

3

Page 5

Installation

Installation should be done by a QUALIFIED SERVICE TECHNICIAN.

The furnace must be located on an outside wall.

Wall Installation

Minimum clearances from combustible materials:

• Furnace to the top surface of carpeting, tile:

2-inches (50 mm)

• Furnace to back wall (0” to spacers):

0-inch (0 mm).

• Vent to wall enclosure:

0-inch (0 mm)

• Furnace to sidewalls:

3.15-inches (80 mm)

• Furnace to ceiling:

10-inches (254 mm)

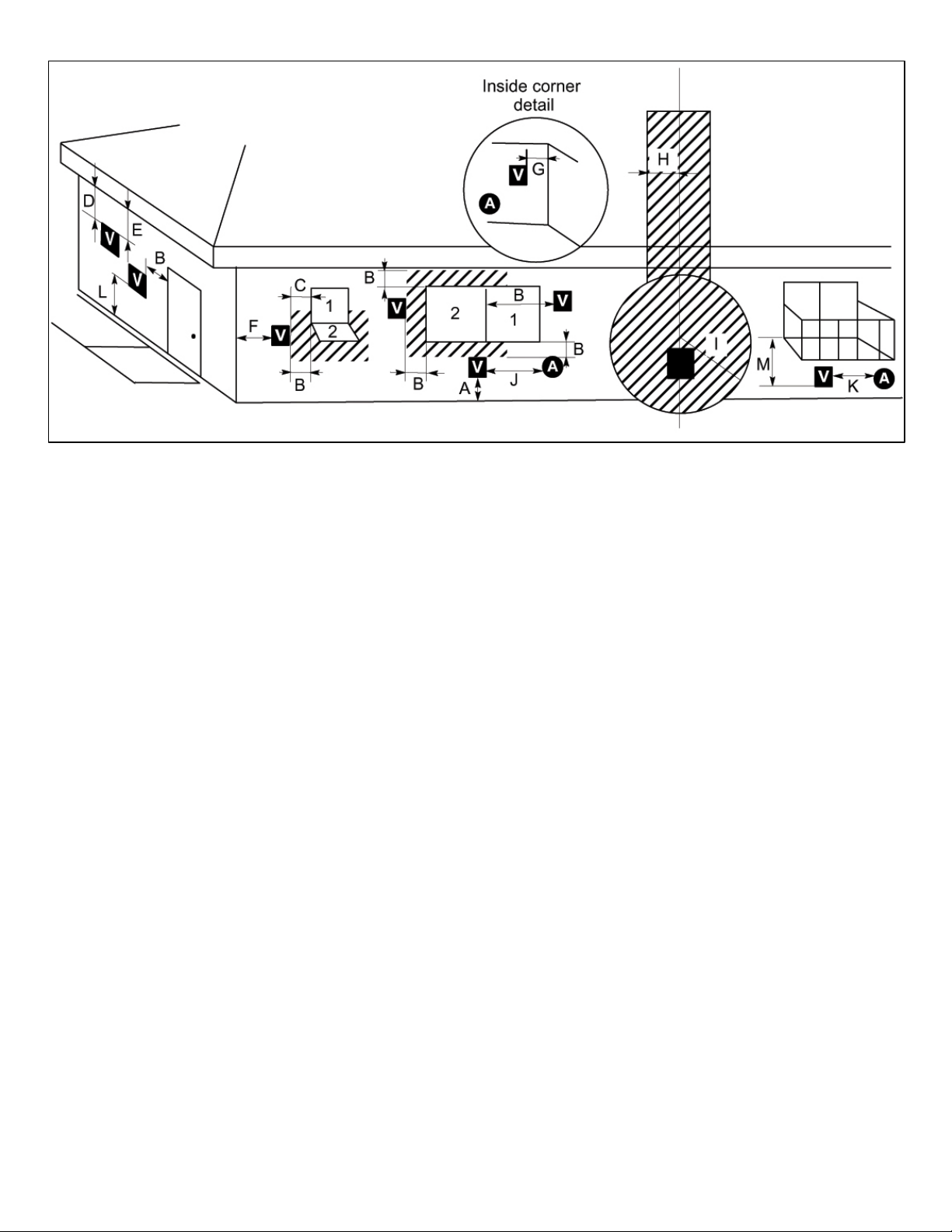

See Figure 1 showing clearance for installation of vent cap.

Leave at least three-feet in front of the wall furnace for servicing and proper operation. The wall furnace must be installed in such

a way that the external casing can be completely removed for servicing.

If there is a shelf above the furnace, it must be be noncombustible. A minimum clearance of 12-inches (300 mm) is

recommended between the furnace and the noncombustible shelf above it.

Gas equipment in residential garages must be installed so that all burners and burner ignition devices are located not less than

18-inches (460 mm) above the floor. Such equipment must be located, or protected, so it is not subject to physical damage by a

moving vehicle.

The vent terminal of this direct-vent furnace must be located at least 9-inches (230 mm) from any opening through which flue

gases could enter a building. The bottom of the vent terminal and the air intake must be located at least 12-inches (300mm)

above grade.

DO NOT cover the furnace.

Make sure that the correct gas supply is available.

The furnace requires a 120V, 60 Hz electrical supply.

The furnace must be electrically grounded in accordance with local codes or in the absence of local codes, with the National

Electrical Code ANSI/NFPA 70 (latest edition) or in Canada with CAN/CSA-C22.2 No. 3.

WARNING: For the installation of this furnace, the

following items must be used as a vent air intake

External Vent Cap

(Part Number: WFR–TRM000)

Flanged Air Inlet Tube

(Part Number: WFR–TBO002)

(Part Number: WFN–RNG003)

Flue Outlet Tube

(Part Number: WFR-795)

(All the above items are supplied with the furnace)

system:

O-Ring

WARNING: The nearest point of the vent cap should be a minimum horizontal distant of six (6) feet (1,830 mm)

from any pressure regulator. In case of regulator malfunction, the six (6) feet (1,830 mm) distance will reduce

the chance of gas entering the vent cap.

4

Page 6

(

Figure 1

1 = Fixed/Closed 2 = Openable V = Vent Terminal A = Air Supply 1 = Fixed/Closed 2 = Openable V = Vent Terminal A = Air Supply

A. Clearance above grade, veranda, porch, deck or

balcony 12-inches (30 cm) minimum.

B. Clearance to window or door that may be opened 12-

inches (30 cm) minimum.

C. Clearance to permanently closed window (minimum 12-

inches (30 cm) recommended to prevent condensation

on window.

D. Vertical clearance to ventilated soffit located above the

terminal within a horizontal distance of 2-feet (60 cm)

from the centerline of the terminal 18-inches (46 cm)

minimum.

E. Clearance to unventilated soffit 12-inches (30 cm)

minimum clearance to vinyl soffit 36-inches (90 cm)

minimum.

F. Clearance to outside corner 12-inches (30 cm)

minimum.

G. Clearance to inside corner 18-inches (46 cm) minimum.

H. Not to be installed above a meter/regulator assembly

within 3-feet (90 cm) horizontally from the centerline of

the regulator.

I. Clearance to service regulator vent outlet 6-feet (1.8 m)

minimum.

J. Clearance to nonmechanical air supply inlet to building

or the combustion air inlet to any other furnace 12inches

(3)

(3)

30 cm) minimum.

(3)

(3)

(3)

K. Clearance to a mechanical air supply inlet 6-feet (1.8 m)

minimum.

L. Clearance

located on public property 7-feet (2.1 m) minimum.

M. Clearance under veranda, porch, deck or balcony 12-

inches (30 cm) minimum.

Notes:

(1)

A vent must not terminate directly above a sidewalk

(2)

Only permitted if veranda, porch, deck or balcony is

(3)

As specified in CGA B149 installation codes (1991).

Note: Local codes or regulations may require different

clearances.

5

(3)

(1)

above paved sidewalk or a paved driveway

(2), (3)

or paved driveway which is located between two

single family dwellings and serves both dwellings.

fully open on a minimum of two sides beneath the

floor.

(3)

Page 7

Outside Location for Vent Terminal

A

Upon delivery, check to make sure the packaging has not been damaged.

1. Remove the furnace from box/packaging taking care not to damage the paper template to be used to mark the holes for

mounting the furnace.

2. After marking the appropriate holes using the above mentioned template, make a 2-inch diameter hole.

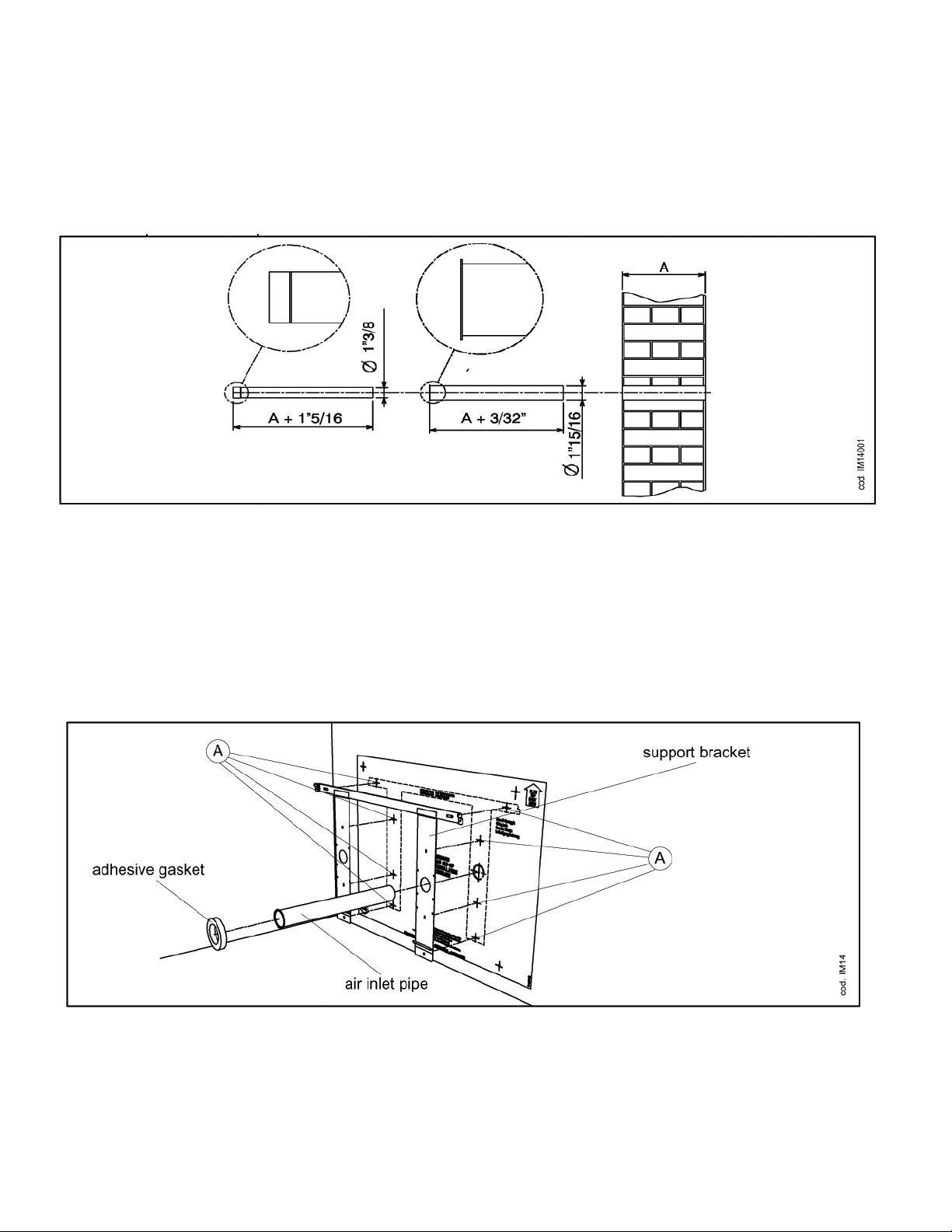

3. Cut the combustion exhaust and fresh air inlet tubes according to the wall thickness (Figure 2):

Air Inlet Tube Length = Wall Thickness + 3/32-inch

F Flue Outlet Tube Length = Wall Thickness + 1-5/16 inches

Figure 2

A + 33.3 mm

+ 2.3 mm

Ø 49.2

4. Drill the mounting holes “A” (8 holes) in the wall. If possible, use self-tapping screws, drill 1/8-inch diameter holes. If

self-tapping screws cannot be used, drill 1/4-inch diameter holes and use the plastic anchors provided.

5. Install the supporting bracket to the wall; insert the air pipe in the wall through the hole provided in the support bracket.

Place the round adhesive gasket around the hole, so that the air pipe remains in its position.

6. Attach the supporting bracket with the screws provided. If possible, use self-tapping screws, drill 1/8-inch diameter

holes. If self-tapping screws cannot be used, use the plastic anchors provided.

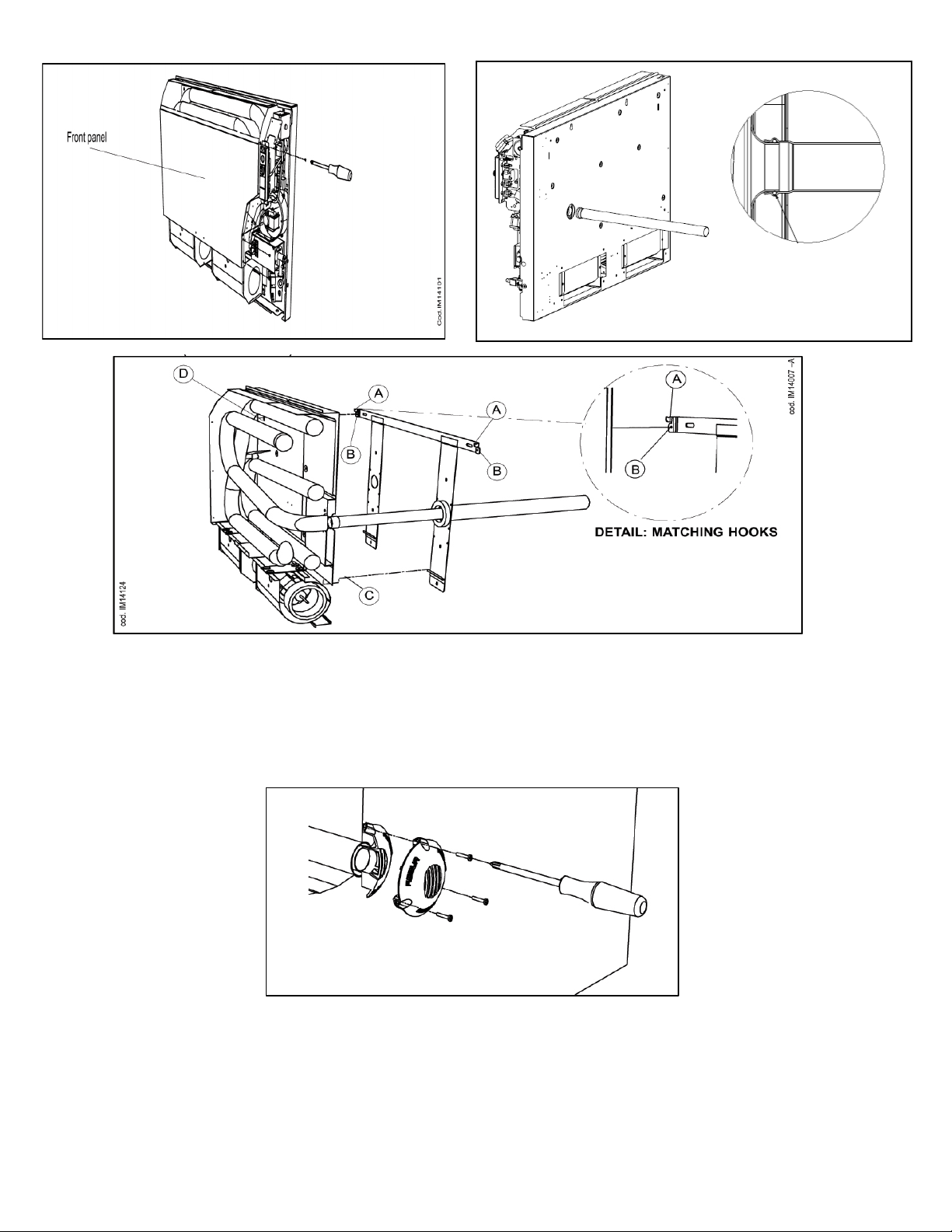

7. Remove the casing loosening the screws and disconnect the casing grounding cable.

8. Place the adhesive spongy lining behind the furnace. (Figure 3)

Figure 3

9. Attach the flue exhaust flue pipe end (diameter 1” 3/8) on the furnace pipe male connection (Figure 5).

BE SURE THAT THE RUBBER SILICONE O–RING GASKET IS IN POSITION.

10. Remove the front panel by loosing the lateral screws (Figure 4).

11. Install the furnace to the wall leaning the bottom edge of panel “C” (where the fan is located) on the supporting frame, as

shown in Figure 6. Attach the furnace to the matching hooks “A”, with light pressure against the wall). Install the

heating body of the furnace to the supporting bracket with the two lateral screws.

6

Page 8

Figure 4

Figure 6

O-Ring Gasket

Figure 5

12. When the inside installation is complete, proceed to the outside location of the aluminium vent cap on the external wall.

The vent cap should perfectly match the pipe end. Mark the location of the three holes for the screw anchors. (Figure 7)

The flue grid must be vertical.

13. Remove the vent cap and drill all the necessary holes (diameter 1/4 in. for the screw fittings provided with the furnace).

14. Position the vent cap and attach it with the screws (Figure 7).

15. Connect the female end of the three-prong plug to the furnace connection on the bottom of the furnace.

16. Connect the gas supply line. A gas tap must before the connection to the furnace must be installed.

17. Reattach the front panel. (Figure 4)

18. Reconnect the grounding wire to the casing and reinstall the casing then tighten the screws.

19. Turn on gas supply and check for gas leaks with soapy water on all gas connections. Seal any leaks prior to operating

the furnace.

7

Page 9

Gas Conversions

Converting to another gas type must be performed by a qualified service technician. If the type of the gas supplied to the dwelling is not the same type as your furnace (natural or LPG gas), it must be converted.

It will be necessary to do the following:

1. Change nozzle.

a. Remove the screw indicated

to the right.

2. Without removing anything else, remove the nozzle from the burner inserting the screwdriver as indicated by the arrow.

Nozzle

3. Change the nozzle, attach the screw indicated at point 1 and set the burner pressure as indicated in the table below:

Gas Type

Minimum Inlet Line Gas

Gas Type Nozzle Part Number Nozzle Diameter

Natural Gas JGLL069 0.1 in.

LP Gas JGLL062 0.06 in.

Maximum Minimum

Pressure

Manifold Gas Pressure Manifold Gas Pressure

Natural Gas 7.0-inches w.c. 3.2-inches w.c. 1.8-inches w.c.

LP Gas 11.0-inches w.c. 10.6-inches w.c. 6.5-inches w.c.

4. Check the gas pressure and settings.

Minimum Burner Pressure Setting:

1. Set LOW burner capacity by pressing button Z2

2. Connect a micro manometer to the test gauge B (Figure 8)

3. Rotate the internal screw “D” (Figure 8) and set the pressure at the correct value

Maximum Burner Pressure Setting:

1. Set HI burner capacity by pressing button Z2

2. Connect a micro manometer to the test gauge B (Figure 8)

3. Rotate the external screw “C” (Figure 8) and set the p

ressure at the correct value

8

Page 10

Gas Supply

Check all local codes for requirements, especially for the size and type of gas supply line required. On natural gas lines less than

15” (380 mm) long, use 1/2” tube; on longer runs, use 3/4” iron tube or equal. On LP gas lines, consult LP gas supplier.

Installing a New Main Gas Shutoff Valve

Each appliance should have its own manual gas shutoff valve. A manual main gas shutoff valve should be located in the vicinity

of the furnace. Where none exists, or where its size or location is not adequate, contact your local authorized installer for

installation or relocation.

Compounds used on threaded joints of gas piping must be resistant to the action of propane (LP) gas. The gas lines must be

checked for leaks by the installer. This should be done with a soap solution watching for bubbles on all exposed connections,

and if unexposed, a pressure test should be made. Repair all leaks prior to operating the furnace.

Never use an exposed flame to check for leaks. Appliance must be disconnected from piping at inlet of control valve

and pipe capped or plugged for a pressure test. Never pressure test with appliance connected; the control valve will

sustain damage!

A gas shutoff valve and ground joint union should be installed in the gas line upstream of the gas control to aid in servicing. It is

required by the National Fuel Gas Code that a drip line be installed near the gas inlet. This should consist of a vertical length of

pipe tee connected into the gas line that is capped on the bottom in which condensation and foreign particles may collect.

The use of the following gas connectors is recommended:

– ANSI Z21.24 Appliance Connectors of Corrugated Metal Tubing and Fittings, CGA 6.10

– ANSI Z21.45 Assembled Flexible Appliance Connectors of Other than All–Metal Construction.

The above connectors may be used if accepted by the local codes or authority having jurisdiction.

Pressure Testing of the Gas Supply System

1. To check the inlet pressure to the gas valve, a plugged tapping, accessible for test gauge connection, is provided on the

gas valve (Figure 8).

2. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of in excess of 1/2 psig (3.5 kPa).

3. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

Attention: If any of the above procedures results in pressures in excess of 1/2 psig (14” w.c., 3.5 kPa) on the appliance gas

valve, it will result in a hazardous condition.

High Altitudes (U.S. Only)

For altitudes/elevations above 2,000 feet (610 m), ratings should be reduced at the rate of 4 percent for each 1,000 feet (305 m)

above sea level by reducing the manifold pressure at a rate of 8% on the gas supply. Maximum altitude allowed for installation is

5,500 feet (1680 m).

High Altitudes (Canada Only)

The appliance is tested according to CGA 2.17 M91 for installation between 0 and 4,500 feet (0 and 1370 m) altitude. For

altitudes/elevations above 2,000 feet (610 m), ratings should be reduced at the rate of 4 percent for each 1,000 feet (305 m)

above sea level by reducing the manifold pressure at a rate of 8% on the gas supply. Maximum altitude allowed for installation is

5,500 feet (1680 m).

High Altitude Adjustment

Based on the altitude of the installation site, reduce the manifold pressure specified in the “Technical Data” chart and as

shown in the table below:

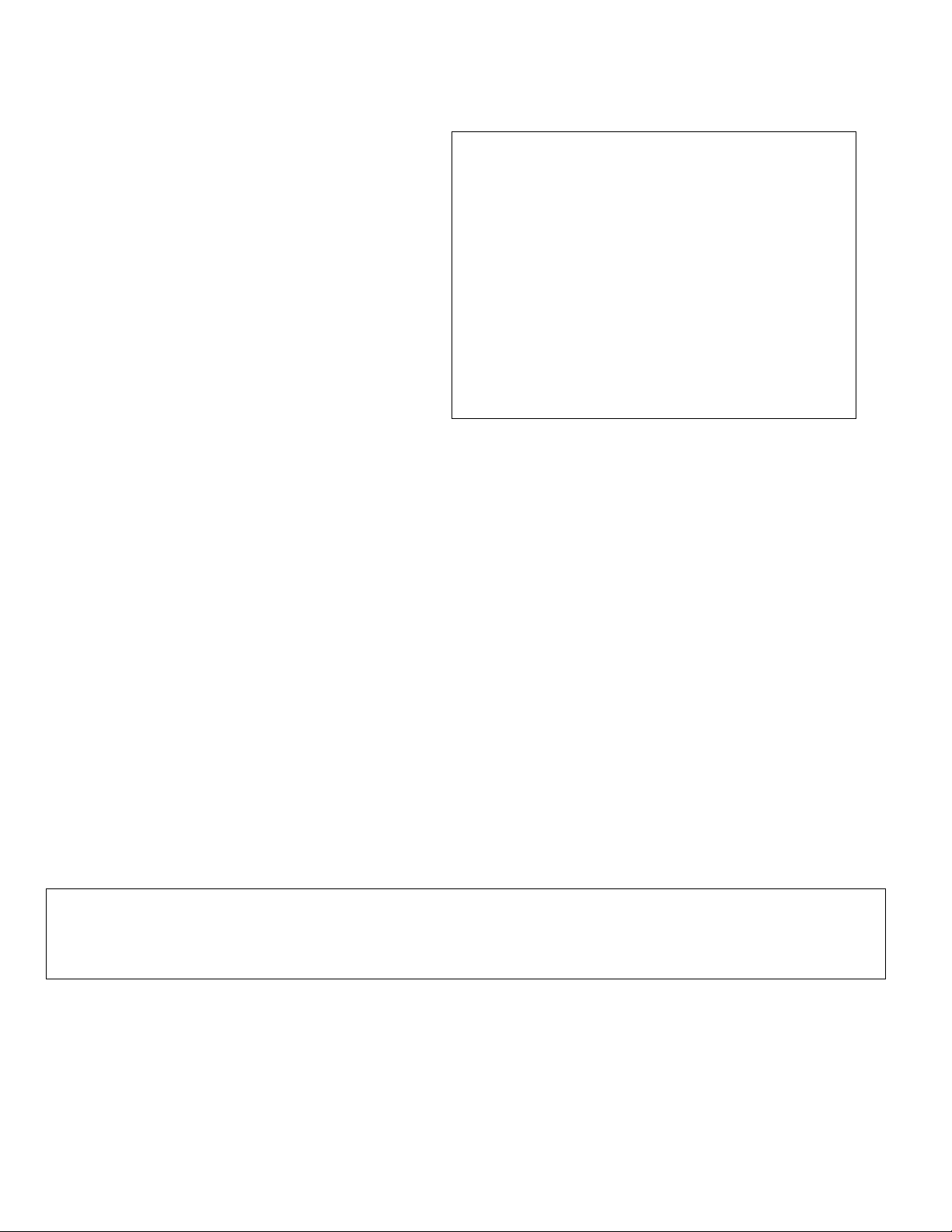

Manifold Pressure

Altitude

0-2,000 ft 0%

2,000-3,000 ft 8%

3,000-4,000 ft 16%

4,000-5,000 ft 24%

5,000-5500 ft 32%

Reduction Rate

9

Page 11

First Firing of the Furnace

A

Start the furnace following the instructions given in the “Operating Instructions“. The initial pilot lighting may be difficult due to air

trapped in the gas lines. During initial firing of the furnace, residual manufacturing grease will bake-out and smoke will occur

which is not a health danger. To prevent nuisance and operation of fire alarms, ventilate the room for the first two hours of

operation.

Checking the Gas Inlet Pressure

The gas inlet pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8 - A)

Once installation is complete, the gas inlet pressure must be checked. The minimum gas inlet pressure must be as shown in

“Technical Data”. After checking the gas inlet pressure, disconnect the test gauge and firmly tighten the screw of the gauge

connection, then check for gas leaks.

Checking the Gas Manifold Pressure

The gas manifold pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8).

The furnace comes set from the factory at the correct manifold gas pressure. After the installation is completed, the gas

manifold pressure must be checked both in Hi and Lo input. The gas manifold pressure must be as shown in the “Technical

Data”. Differences of plus or minus 0.1 in. w.c. are accepted. If the Hi or Lo gas manifold pressures are different from the

values given in the “Technical Data” table, or are more than 0.1 in. w.c., shut off the furnace and contact a qualified service

technician for correction. For instructions about adjustment of the manifold Hi and Lo pressures, see the “Servicing” section.

After checking the gas manifold pressure, disconnect the test gauge and firmly tighten the screw of the gauge connection and

then check for gas leaks from it.

A Test Gauge Connection for Gas Inlet Pressure

B Test Gauge Connection for Gas Manifold Pressure

9

C Nut for Hi Pressure Adjustment (Pressure Regulator)

D Screw for Lo Pressure Adjustment (Hi – Lo Operator)

E Electric Clamp Connection

G Electric Cable Inlet

H Hole for Gas Supply Inlet

L Flame View

L

B

D

C

H

E

G

10

Page 12

Electrical Wiring

EV

EV1

EV2

M

M1

M2

M9

NP

RP8

RP7

S

GAS VALVE 1 (SAFETY SHUTTER)

HI-LO FLAME OPERATOR (*)

FAN MOTOR (n. 2 MOTORS ON 8001/8002)

OVERHEAT THERMOSTAT

FAN THERMOSTAT

MAINS FUSE – 5X20 size – 4A

PRESSURE SWITCH

FLAME SENSOR

SPARK IGNITER (n. 2 pcs)

COMBUSTION BLOWER MOTOR

SF

SB

TR

Z1

Z2

Z3

Z8

Z9

L1

L2

GND

FLAME VIEW LAMP (GREEN LAMP)

LOCK-OUT LAMP (RED LAMP)

CURRENT TRANSFORMER 120-24 V

RESET AND SUMMER – WINTER SWITCH (*)

HI-LO FLAME AND FAN SPEED SWITCH (*)

MANUAL – PROGRAM MODE SWITCH (*)

PROGRAMMABLE TIMER (*)

ROOM THERMOSTAT

SUPPLY LINE – LIVE WIRE

SUPPLY LINE – NEUTRAL WIRE

SUPPLY LINE – GROUND WIRE

11

Page 13

Operating Instructions

T

T

X

/

/

Before operating the furnace, read carefully all warnings and safety information in this manual.

FOR YOUR SAFETY READ BEFORE OPERATING

A. This appliance does no t ha ve a pilot which must F ollow the gas sup pl ie r's ins tructions.

WARNING :

may result causing property damage, pe onal injury or loss of life.

be lighted by m eans of th e piezo igniter installed

on the fu rnace. Do not

hand.

C. U se only your hand to push in or turn the gas control

B. B EFORE LIGHTING, smell all around th e nob. Neve r use tool s. I f the kno b will n ot push in or

If you d o not f ol lo w these instructions exactly, a fire or expl osion

rs

- If you cannot reach your gas supplier, call the fire

try to light the pilot by epartment.

d

k

appliance area for gas. Be sure t o smell next t urn b y hand, do not try to rep air it, call a qualified

to the floor because some gas is heav ier than service te chnician. Force o r attemp ted repair m ay result

air and will sett le on the floor. n a fire or explosion.

WHAT TO DO IF YOU SMELL GAS:

i

D. D o not use this ap pliance if a ny part has been under

- Do not try to ligh t any a ppliance water. Im mediately call a qu al if i ed service tec hn ician

- Do not touch any electric switch to inspect the appliance an d to replace a ny part of the

- Do not use any p hone in your b uilding ntrol system and any g as control which has been

- Im mediately call your gas supplier from a nder water.

neighbor's phone.

co

u

OPERA TING INabSTRUCT IO NS

1.

ST OP! Read the safety information above on this l el.

2.

Set th e therm ostat to the lowest setting by turning it ount erclockwise

completely. Do not force.

3. Turn o ff all el ectric power to app liance.

4.

This appliance is equipped with an ign ition device th t autom atically lights th e

burne r. Do not

5.

Turn off gas supply to the unit b y turning off the ga s hutoff va lve.

6.

Wait five minu tes to cl ear out any gas. If you then ell gas, S TOP! Fo llow

try to light the burn er by hand.

the safety inf ormation in sect ion "B" abo ve. If you d no t sme ll gas, go to the

next step.

7.

Turn o n the gas supply to the unit.

8.

Turn on electri c power to the appliance.

9.

Push the MIN /MAX b utto n to MIN po sition (button d n).

10.

Switch t he SUM ME R/W INTER bu tton to WINTER p sition (butt on up ).

11.

Set th erm ostat to desired setting.

12.

The red lam p wil l be lit for 40 seconds, then the f lam ignite. The red lam p

will th en shut of f a nd the g reen lam p wil l be lit.

13. If the appliance will not ope rate, fo llow t he instructio s below "T o Turn Off Gas Of Appliance" and call you r

serv ice t echnician or gas supp lier.

14.

If you cho ose the high heat outp ut sett ing, pu sh the IN/MAX button to MAX position (button up). If you

pref er soft heating and silent ope ration, keep it on M N position (button down).

15.

This appliance has an automatic f lame control system. When the f l am e is li t, the green lamp is lit also.

In case of flam e f ault, the red lamp will ligh t an d th e gree n lamp will turn o ff . If this occurs, set the

SUMMER/WINTE R button to the S UMM ER position button d own) an d wait t en (10) seconds; then turn

the switch back t o the W INTE R po sition (button up) he appliance will att em pt to relight after

approximately 40 seconds. During th ese 40 second the red lam p will be lit. If the second attempt is

unsuc cessful, turn off the electric p ower to the app li e and ca ll your Servic e A gen cy.

c

a

s

sm

o

ow

o

e

n

M

I

(

. T

s

anc

SUMMER/WIN

MIN/

GREEN

TER

MA

LAMP

G

GREEN

LAMP

RESET

MIN

MAX

RED

TIMER

LAMP

R

MANUAL/PROGRAMMED

BUTTON

THERMOSTA

THERMOSTAT

RESE

SUMMER

BUTTON

MIN

BUTTON

WINTER

MAX

RE D

LA MP

TO TURN OFF GAS TO APPLIANCE

1.

Set the therm ostat t o the lowest s etting by turning i t un terclockwise complet ely. Do not force.

2. Turn off all electric power to th e appliance if servic e to be perform ed.

3. Turn the gas tap i nstalled on the gas supply to the C OSED p osition.

is

12

co

L

Page 14

A

r

WHAT TO DO IF THE RED LAMP IS LIT

This appliance has an e lectronic flame superv is ion de vice. If the f l am e disappea rs the ga s f lo w will be autom ati cally

shut o ff and the red lamp will light instead of th e green one. The appliance will a ttempt to relight if you do

the f ol lowing :

T urn off the electric supply to the app liance for approximately 40 seconds and turn it on a gain;

A.

B. T urn th e th ermostat knob to the zero setting, then turn it back to a comfo rtable sett in g af ter approximately 40

seconds;

C. P ress the SUMM E R/WI NTER but ton to the SUMMER position (button down) for a pproxim ately 40 secon ds and

set it back (but ton up) to the WIN TER positio n.

OR

of

ONE

OR

HOW TO SHUT OFF THE APPLIANCE

1. Turn the thermo stat knob to the Z ERO position.

2. T urn th e I-O switch on the programm able c lock to t he ZERO p osition.

3 . T urn off all electric supply to the appliance.

4. T urn th e gas shuto ff valve installed on the gas supply line upstream to th e un it to t he C LOSED positi on.

USING THE FEATURES OF YOUR

GREEN LAMP

RED LAMP

lamp will be lit. The furnace is locked-out. To reset the furnace, follow the instructions

above, "WHAT TO DO IF THE RED LAMP IS LIT."

MANUAL/PROGRAM BUTTON:

temperature set by the thermostat according to the clock's program. When the

button is up, the furnace thermostat maintains the temperature.

THERMOSTAT:

to decrease it.

: It is lit when the flame is ON.

: In case the flame disappears, the gas flow will be shut off and the red

Turn clockwise to increase the temperature, turn counterclockwise

FURNACE

When the button is down, the furnace keeps the

When the button is up, the furnace will operate in heating mode

RESET

SUMMER/WINTER:

according to the thermostat and/or clock's program. When the button is down, the

appliance will provide ventilation.

MIN

MAX

MIN/MAX BUTTON:

silent operation, keep this button down.

For faster heating, keep this button up. For soft heating and

HUMIDIFIER:

water filling hole

HUMIDIFIER:

easy to use. Using a funnel, periodically add water to the small tank located on the

top left side of the furnace. Normally, the tank needs to be refilled after 4 - 5 days.

NOTE:

any possible calcareous sedimentation that may be difficult to remove.

The use of water low in limestone or distilled is advisable in order to prevent

For better comfort this furnace is equipped with a humidifier. It is very

nticalcareous tablets for humidifiers are commercially available. The humidifie

capacity is 11.8 fluid ounces (0.35 liters).

13

Page 15

Servicing

All servicing activities must be carried out by a qualified service technicial or a service agency. The home owner may not

service the furnace. The home owner must read this section to be informed of the periodic maintenance and checks the

required. All servicing (except on vent system) must be carried out with the external casing removed. After any servicing, the

external casing must be reinstalled properly and the grounding wire of the external casing reconnected.

Checking and Adjusting the Gas Manifold Pressure

The furnace comes set from the factory at the correct HI and LO gas manifold pressures as shown in “Technical Data”. It is

recommended to check the pressures periodically (minimum once a year). If adjustment is required, this can be done by

adjusting screws “C” and “D”. (Figure 8) A test gauge must be connected as explained in “Checking the Gas Manifold

Pressure”.

Proceed as follows:

1. Place the furnace on and in the HI mode (knob in HI position).

2. Completely turn down screw “C” (HI – LO operator adjustment) by turning it clockwise. Do not force.

3. Adjust the HI pressure by turning the screw D (pressure regulator) to the value given in the “Specifications”

table. Turn clockwise to increase the pressure, turn counterclockwise to decrease it.

4. Switch the furnace to LO mode (button MAX–MIN down).

5. Loosen screw “C” until the correct value for the LO pressure is achieved.

6. Switch the furnace between LO to HI mode to verify that both the HI and LO pressures are correct. A tolerance

of plus or minus 0.1 in. w.c. on the pressure value is acceptable. Readjust starting from point 1 if needed.

7. Disconnect the test gauge and firmly tighten the screw of the gauge connection. Check for gas leaks with a

soapy water solution and correct any leaks prior to operating the furnace.

The HI and LO pressures must be adjusted as explained above. Never try to adjust them independently from each other.

Checking, Removing and Reassembling of the Vent Air Intake System

It is essential that the vent air intake system is examined periodically (minimum once a year) to verify it is clean from dust and

deposits of solid materials such as leaves or nests. The vent air intake system is checked from outside. Proceed as follows:

1. Remove the vent cap by removing the three outer screws. (Figure 7)

2. Remove the inner flue pipe. Do not use tools; the pipe can be extracted by hand.

3. Remove dust and desposits from the vent cap and flue pipes. Deposits in the air pipe must be taken outside.

Do not push them inside the furnace. The outer air pipe may not be removed from outside.

4. Check the O-ring gasket in the flue pipe. If it is damaged in must be replaced (Part No. WFN-RNG003).

5. Reinstall the flue pipe from outside. Do not use glue or sealants.

6. Reinstall the vent cap on the flue pipe. Do not use glue or sealants. Tighten the three outer screws.

Lubrication of Moving Parts

This furnace does not require lubrication. Do not try to lubricate any part of the furnace such as motors bearings, keys, knobs,

screws, etc.

Flame Visual Check

Correct and proper operation of the burner may be checked by examinng the burner flame. Check the burner flame anytime the

external casing is removed from the furnace. The flame may be examined through the flame viewer. (Figure 8) The flame must

be stable and have blue color. Some small yellow tips are acceptable with propane gas. If the flame is yellow or has excessive

turbulence, check the gas manifold pressure and the vent air intake system. If all these are acceptable, call a qualified service

technician for a complete check of the furnace. Call also your gas supplier to check the composition of the gas in use.

14

Page 16

Annual Maintenance Requirements

1. Clean fan blades.

2. Clean air blower.

3. Check and clean silicone red pipes.

4. Check air flow switch.

5. Clean and check exhaust flue pipe and air intake pipe.

6. Check for gas leaks on all connections.

7. Check and adjust gas pressure.

Gas inlet pressure

(pipeline)

Gas burner

adjustment

pressure

Gas

manifold

pressure

(burner)

15

Check red O-Ring Gasket

(NRNG003). If it is

damaged, replace it.

Page 17

Programmable Timer

The programmable timer allows precise operating and timing control and is standard on this furnace. (Figure 10)

Overview

The programmable timer has the following features:

• Long life lithium battery

• Daily and weekly programs

• One minute minimum switching time

• Quick progression

• Sixteen programs (8 on and 8 off)

• Days of the week and hours of the day selection

• Programmable day blocks: 1-2-3-4-5 (Monday – Friday)

1-2-3-4-5-6 (Monday – Saturday)

1-2-3-4-5-6-7 (Monday – Sunday)

6-7 (Saturday – Sunday)

Figure 10

KEY

A On/Off Switch Pos. I The appliance is controlled by the room thermostat

Pos. AUTO The appliance is controlled by both the timer and the room thermostat

Pos. O The appliance is turned off

B Setting / Regulator Switch

C Program Selection

D Day Selection

E Hours Setting

F Minutes Setting

G SKIP Button

R Reset Button

Pos.

Time setting

Pos. RUN Normal operating mode (the display shows the current time)

Pos.

Ê Setting of programming

16

Page 18

0

E

0

0

0

0

Setting and Adjustment

Initial Conditions

A. Set the Setting/Regulator switch (Figure 10-B) in RUN position (center). Press the

Reset button R. The display will flash.

B. With the Setting/Regulator switch selector in position (right), press the Reset button,

R, the display error EEE will appear. Move the Setting/Regulator switch, (Figure 10-B)

to the RUN (center) position. The display will disappear.

C. If the Setting/Regulator switch, (Figure 10-B) is moved to position the display is

frozen.

D. If the Setting/Regulator switch, (Figure 10-B) is moved to RUN position the display is

frozen with the colon flashing.

E. If the Setting/Regulator switch, (Figure 10-B) is moved to position (right), the

Manual Operation

Move the On/Off switch, (Figure 10-A) to the I position (left).

• The symbol of a light ( ) will appear on the display. In this condition the heater is controlled by the furnace thermostat

Move the On/Off switch, (Figure 10-A) to the O position (right).

• The symbol of the light ( ) on the display will disappear. In this condition the furnace is turned off.

Move the On/Off switch, (Figure 10-A) to the AUTO position (center).

• The program function is activated. The furnace will operate according to the programs. The furnace is controlled both

Day and Time Setting

A. The Setting/Regulator switch, (Figure 10-B) is placed in the position (left).

B. To set the day of the week, press the Day Selector button, (1….7, Figure 10-D), a triangular

C. To set the time press the Hour Selector button (h, Figure 10-E) to set the hour and the

D. After setting the day and the time move the Setting/Regulator switch, B to the RUN position

Programming the Timer

Sixteen settings may be programmed on the timer. Eight odd numbers (1-3-5-7-9-11-13-15) for the

ON position and eight even numbers (2-4-6-8-10-12-14-16) for the OFF position. Program numbers

are to the left of the symbol on the display.

A. Move the Setting/Regulator switch, (Figure 10-B) to the position (right). On the right side

B. Press the Day selection, (1…...7, Figure 10-D) button to the day or the block of days you

C. Press the Program Selection ( , Figure 10-C). The right side of the display will show a

display is flashing: ,1,1.

and is independent of the timer program.

by the timer and by the furnace thermostat.

shaped indicator proceeds one day at a time. Number 1 stands for Monday, number 2

stands for Tuesday, etc.

Minutes Selector button (m, Figure 10-F) to set the minutes. The hours are set using military

time.

(center). The display is frozen and the colon is flashing.

☼

of the display the number 1, 1, will appear. The ON time may now be set.

want the furnace to turn ON. Number 1 stands for Monday, etc. To set the desired time,

press the Hours Selection (h, Figure 10-E) button to set the hour and the Minute Selection

(m, Figure 10-F) button to set the minutes (for example 09:03). The time is set using military

time.

number 2 without the light symbol. The OFF time may now be set.

☼

☼

☼

☼

17

1 2 3 4 5 6 7

:00

1 2 3 4 5 6 7

EE

1 2 3 4 5 6 7

:00

1 2 3 4 5 6 7

:00

1 2 3 4 5 6 7

:00

1 2 3 4 5 6 7

1

☼

:00

1 2 3 4 5 6 7

15:16

Example: Set

Wednesday, 15:16

hours (military time).

1 2 3 4 5 6 7

0:00

1 2 3 4 5 6 7

0:00

1 2 3 4 5 6 7

9:03

1 2 3 4 5 6 7

0:00

1 2 3 4 5 6 7

11:04

1

1

1

1

1

☼

☼

☼

Page 19

D. Press the Day Setting, (1……7, Figure 11-D) button to program another day or block of days.

E. To set further programs repeat steps item B through D above.

NOTE: When the same ON and OFF times are desired for different days of the week, the setting procedure may be simplified.

• 1-2-3-4-5 (from Monday through Friday)

• 1-2-3-4-5-6 (from Monday through Saturday)

• 1-2-3-4-5-6-7 (from Monday through Sunday)

• 6-7 (Saturday and Sunday)

F. To avoid undesired operation verify that the programs do not overlap one another. You can check the settings by

pressing the Program Selection button. ( , Figure 10-C)

G. Move the Setting/Regulator switch to the RUN position (center). The display will show the current day and time.

IMPORTANT: All the programs set will be activated ONLY the day after the setting has been carried out.

During operation, the ON status of the timer is shown on the display with the symbol on the right end. When the symbol

does not appear, the timer is OFF.

☼ ☼

Cancelling a Single Program

To cancel a single program:

A. Move the Setting/Regulator switch (Figure 10-B) to the ( , Figure 10-C) position (right).

Press the Program Selector ( , Figure 10-C) button and select the program to be

cancelled.

B. Simultaneously press the Program Selector ( , Figure 10-C) and SKIP button (

Figure 10-G) for at least 2 seconds. The selected program will be cancelled.

C. Verification that program has been cancelled is the continual blinking of 0:00.

1 2 3 4 5 6 7

0:00

1

Cancelling of all Preset Programs

To cancel all the preset programs, press the Reset button, R, for at least 2 seconds. All the preset programs will be cancelled.

Using the Skip Function

To skip a program:

A. Move the Setting/Regulator switch in the RUN position (center).

B. Press the SKIP button (

programmed. The SKIP symbol (

C. The SKIP command may be stopped, by pressing the SKIP button. (

The preset program will restart and SKIP symbol (

the display.

Figure 10-G). The next program will be activated as

Figure 10-G) is shown on display.

Figure 10-G) will disappear from

Figure 10-G)

1 2 3 4 5 6 7

15:16

1 2 3 4 5 6 7

1

☼

X

15:16

Skip Function Procedure During Operation

A. The SKIP function can be activated only in RUN mode.

B. The SKIP function starts immediately after the pressing the SKIP button, and disappears when next program starts.

C. The SKIP function can be stopped manually by pressing the SKIP button and the preset program will be activated.

18

Page 20

Troubleshooting

Starting Sequence (Electrical)

Step 1

1. Check L1 – L2 (Supply 120 V, 60 Hz)

2. Check M9 (Main fuse)

Troubleshooting Step 1

Point 1 (L1-L2)

No voltage (120 V).

Check the electrical supply line, wiring and

connections.

Point 2 (M9)

Fuse damaged.

Check the electrical supply line and replace the

fuse.

Summer Mode

Step 2

3. Check Z1 (Reset summer/winter switch). The

4. Check Z2 (Hi-Lo flame and fan speed switch)

Button down - Minimum velocity

Button up – Maximum velocity

Troubleshooting Step 2

Point 3 (Z1)

Z1 is open and no ignition.

Check wirings and connections. If everything is okay,

replace the switch.

Point 4 (Z2)

Z2 is down but the fan motor runs at the maximum

velocity (120 V).

Z2 is up but the fan motor runs at the minimum

velocity (<120 V).

Check wiring and connections. If they are okay,

replace the switch.

Winter Mode

Step 3

5. Check Z1 (Reset summer/winter

6. Check Z3 (Manual-automatic switch).

7. Check M2 (Fan thermostat).

switch is closed if there is no ignition block.

switch).

Button up – winter mode.

Button up – manual mode

Button down – automatic mode.

The thermostat is closed only when its

temperature is higher than 104 °F.

19

Page 21

Troubleshooting Step 3

Point 5 (Z1)

Z1 is open and no ignition.

Check wiring and connections. If

everything is okay, replace the switch.

Point 7 (M2)

M2 is closed and fan thermostat

temperature lower than 104 °F.

Check wiring and connections. If they

are okay, replace the thermostat.

Step 4

8. Check Z9 (Room thermostat).

Close the thermostat with a

clockwise rotation.

9. Check M1 (Overheat thermostat,

automatic reset). The thermostat is

closed at a temperture lower than

140 °F.

10. Check S (Combustion blower

motor).

Troubleshooting Step 4

Point 8 (Z9)

After a clockwise rotation, the contact is still

open. Check wiring and connections. If they are

okay, and the room temperature is cold, replace

the switch.

Point 9 (M1)

M1 is open and fan thermostat temperature is

lower than 140 °F. Check wiring, connections,

gas pressure and fan motor. Clean fan blades

and air grids. If everything is okay, replace the

thermostat.

Point 10 (S)

S motor does not run. Check voltage, wiring and

connections.

If everything is okay, replace the motor.

Step 5

11. Check NP (Pressure switch).

12. Check electrical supply to flame control box

(120 V)

13. Check TR (electrical transformer)

(120V/24V)

14. Check EV1 (Min gas valve, 24V)

15. Check RP7 (ignition electrode)

16. Check RP8 (flame sensor)

17. Check EV2 (Max gas valve, 24 V)

Troubleshooting Step 5

Point 11 (NP)

NP contact is open and air blower ON.

Check wiring and connections. Check and clean

blower pipes.

Check and clean burner and flue gas pipe.

Clean blower.

If everything is okay, replace the switch.

24 V

120 V

20

Page 22

Point 13 (TR)

No inlet voltage (120 V).

Check 5 pole connector and control box.

If everything is okay, replace the connector.

No outlet voltage (24 V) during ignition.

Check wiring and connections.

If everything is okay, replace the transformer.

Point 14 (EV1)

Valve closed during ignition (Z2 down).

Check wiring, connections and voltage.

If everything is okay, replace the gas valve.

Point 15 (RP7)

No spark during ignition.

Check electrode, wiring and connections.

If everything is okay, replace the flame control box.

Point 16 (RP8)

No flame sensing.

Check flame sensor, wiring and connections.

…Check gas pressure and exhaust flue pipe.

If everything is okay, replace the flame control box.

Point 17 (EV2)

No voltage on EV2 with Z2 up.

Check wiring and connections.

If everything is okay, replace the switch.

Valve closed with voltage with Z2 up.

Check wiring, connections and voltage.

If everything is okay, replace the gas valve.

Starting Sequence (Gas)

1. Check and clean exhausted flue pipes;

2. Check and clean air blower and fan motor;

3. Check and clean burner and combustion chamber;

4. Check and clean gas nozzle;

5. Check gas type;

6. Check supply gas line pressure (see the manual);

7. Check gas losses;

8. Set burner gas pressure (see the manual).

21

Page 23

Replacement Parts

TR – 120/24V Transformer Part Number: JTRS017

Ignition Control Box Part Number: JCNT019

NP – Pressure Switch Part Number: JPRS009

Z9 – Room Thermostat Part Number: JTLT005

Electric Box

Gas Assembly

Z1 – Reset and Summer/Winter

Switch

Z8-Z3 – Timer and Manual-

Program Mode Switch

Z2- Hi-Lo Flame and

Fan Speed Switch

SF/SB – Green and Red Lamps

Z8 - Timer

Gas Burner and Gas Nozzle Part Number: JPRT011

Natural Gas Nozzle Part Number: JGLL069

LP Gas Nozzle Part Number: JGLL062

EV1/2

Min/Max Gas Valve

Part Number: NTST000

Part Number: N19800202

Part Number: N19800201

Part Number:

ELMP006 – ELMP007

Part Number:

E-PRG005

Part Number: GVLV022

22

Page 24

RP8 : Flame

Sensor

RP7: Spark Igniter

(2 pieces)

Part Number: JLTT015

Part Number: JLTT023

S – Combustion Blower Motor Part Number: JMTR020

M1 – Overheat Thermostat Part Number: JTRM006

M2 - Fan Thermostat Part Number: J12301018

Fan Blades

(4 Pieces)

Part Number:

VVNT003-VVNT002

M - Fan Motor Part Number:

(2 Pieces) JMTR018

Williams Furnace Co., 250 West Laurel Street, Colton, CA 92324 U.S.A.

Loading...

Loading...