THE COMFORT PRODUCTS PEOPLE

WINDOW WALL FURNACE

DIRECT-VENT NATURAL GAS HEATER

OWNER’S OPERATION AND INSTALLATION MANUAL

2503532

4003532

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

25,000 and 40,000 BTU/Hr Furnaces

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

WARNING: Improper installation, adjustment,

alteration, service, or

maintenance can cause

injury or property dam-

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

age. Refer to this manual

for correct installation

and operational procedures. For assistance or

FOR YOUR SAFETY

additional information

consult a qualified in-

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

staller, service agency,

or the gas supplier.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed

by a qualified installer,

service agency, or the

gas supplier.

This appliance may be installed in an aftermarket*, permanently located, manufactured (mobile) home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This

appliance is not convertible for use with other gases.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

Save this manual for future reference.

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

SAFETY

INFORMATION

WARNINGS

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate,

or service this furnace. Improper

use of this furnace can cause serious injury or death from burns, fire,

explosion, electrical shock, and

carbon monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the flu,

with headaches, dizziness, and/or nausea. If

you have these signs, the furnace may not be

working properly. Get fresh air at once! Have

furnace serviced. Some people are more affected by carbon monoxide than others. These

include pregnant women, people with heart or

lung disease or anemia, those under the influence of alcohol, and those at high altitudes.

Natural Gas: Natural gas is odorless. An odor-

making agent is added to natural gas. The odor

helps you detect a natural gas leak. However,

the odor added to natural gas can fade. Natural

gas may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this furnace.

WARNING: Any change to

this heater or its controls can

be dangerous.

Due to high temperatures, the

appliance should be located out

of traffic and away from furniture

and draperies.

Carefully supervise young children when they are in the same

room with furnace.

Do not place clothing or other

flammable material on or near

the appliance. Never place any

objects on the furnace.

Surface of furnace becomes very

hot when running furnace. Keep

children and adults away from

hot surface to avoid burns or

clothing ignition. Furnace will remain hot for a time after shutdown. Allow surface to cool before touching.

Turn off furnace and unplug and let

cool before servicing. Unless you

need gas supply for testing, shut

off equipment shutoff valve before

servicing. Only a qualified service

person should service and repair

furnace and venting system.

Replace any safety screen or

guard removed for servicing before operating furnace.

You must keep control compartments, burners, and circulating

air passages clean. More frequent

cleaning may be needed due to

excessive lint and dust from carpeting, bedding material, etc.

Turn off the gas valve and unplug

before cleaning furnace.

1. A qualified service person must install

furnace.

2. This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases.

3. Use only natural gas. Do not convert

furnace to use different fuel type.

4. If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

5. Do not block the flow of combustion

air (outside air) or heated air (room air)

to the furnace.

6. This furnace must have fresh air for

proper operation. If not, poor fuel combustion and improper venting of flue

gases will result. Carbon monoxide

poisoning from backed-up flue gases

could occur. The State of California

lists carbon monoxide as a reproductive toxin under Proposition 65.

7. Never install the furnace

• in a recreational vehicle

• in an alcove

• on an inside wall

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

• behind a door or where an open door

would block normal air flow

8. Provide the following minimum furnace clearances from furnace front

cover to combustibles (as viewed from

the front of furnace):

Below Front Cover: 6 inches

Adjoining Wall: 12 inches

Above Front Cover: 12 inches

Front: 8 feet

9. Do not obstruct the flow of combustion and ventilation air in any way . Provide adequate clearances around air

openings into the combustion chamber

along with adequate accessibility clearance for servicing and proper operation.

10. Provide the following minimum furnace

clearances from furnace cabinet (portion

of cabinet extending into outside air, as

viewed from the rear of furnace):

Cabinet Back: 36 inches

Cabinet Sides: 6 inches

Cabinet Bottom: Must be high enough

off the ground to prevent snow, water,

leaves, or any other objects from blocking cabinet vents.

11. Always follow lighting instructions.

Never attempt to light burner with a

match or butane torch.

12. Do not run furnace

• where flammable liquids or vapors

are used or stored

• under dusty conditions

13. Do not use furnace as a cooking device.

14. Do not alter furnace or its controls. Any

change may create a safety hazard.

15. Do not use furnace if any part has been

under water. Immediately call a qualified service person to inspect the furnace and to replace any part of the control system and any gas control which

has been under water.

2

201842

OWNER’S MANUAL

LOCAL CODES

Install and use furnace with care. Follow all

local codes. In the absence of local codes, use

the latest edition of the following:

• National Fuel Gas Code ANS Z223.1,

also known as NFPA 54 * (USA)

• National Electric Code ANS/NFPA 70*

• CAN/CGA-B149[.1 or .2] Installation

Codes** (Canada).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

**Available from:

Standards Council of Canada

350 Sparks Street

Ottawa, Ontario K1R 7S8

This furnace must be grounded when installed. Follow all local codes. In the absence of local codes, refer to the National

Electrical Code ANS/NFPA No. 70 (U.S.A.)

or CSA C22.1 Canadian Electrical Code,

Part I (Canada).

The installation must conform with local

codes, in the absence of local codes, with the

National Fuel Gas Code, ANS Z223.1/Canadian Installation Code, CAN/CGA B149.

When installing furnace in a manufactured

(mobile) home, follow the Manufactured

Home Construction and Safety Standard,

Title 24CFR, Part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, part 280; 1975).

When such a standard is not applicable,

follow the Standard for Manufactured Home

Installations, 1982 (Manufactured Home

Sites, Communities, and Set-Ups), ANS

A225.1/NFPA 501A.

In Canada, install furnace in accordance with

Standard CSA Z240.4 - Gas Equipped Recreational Vehicles and Mobile Housing and

any applicable local codes and regulations.

Appliance input ratings are based on sea

level operation and need not be changed for

operation up to 2,000 feet elevation. For

operation at elevations above 2,000 feet,

manufactured to specified deration conditions for Canada and the United States.

UNPACKING

1. Remove furnace from carton.

2. Remove all protective packaging applied to furnace for shipment.

3. Remove the following items from carton:

• Hardware package containing four

large screws, two small screws, and

thermostat mounting plate

• Hardware package (thermostat and

two screws)

• Equipment shutoff valve

If any of these items are missing,

promptly inform dealer where you

bought furnace.

4. Check furnace for any shipping damage.

If furnace is damaged, promptly inform

dealer where you bought furnace.

PRODUCT

FEATURES

HOT SURFACE IGNITOR

This furnace has an electronic ignitor. There

is no standing pilot. No matches or batteries

are required.

THERMOSTATIC HEAT

CONTROL

The thermostat is temperature sensitive. It

automatically turns the furnace on and off.

This results in the greatest heating comfort.

This can also result in lower gas bills.

LIMIT SWITCH

The limit switch shuts off the gas to the main

burner if the furnace becomes too hot to

operate safely.

SPECIFICATIONS

25,000 Btu/Hr 40,000 Btu/Hr

*Rated Heating Input (BTU/Hr) 25,000 40,000

Thermal Output Capacity

(average loss calculation) 18,750 Btu/Hr 30,000 Btu/Hr

Type Gas Natural Only Natural Only

Ignition Hot Surface Ignitor Hot Surface Ignitor

Operating Amps 1.5 2

Volts/Cycles 120/60 120/60

Main Burner 1 2

Pressure Regulator Setting 3.5" W.C. 3.5" W.C.

Inlet Connection 3/8 NPT 3/8 NPT

Inlet Gas Pressure (in. of water)*

Maximum 7" 7"

Minimum 5" 5"

Dimensions, Inches (H x W x D)

Furnace 15 3/32 x 16 1/8 x 23 5/8 15 3/32 x 21 3/4 x 23 5/8

Weight (pounds)

Furnace 53 71

Shipping 65 98

* For purposes of input adjustment.

201842

3

THE COMFORT PRODUCTS PEOPLE

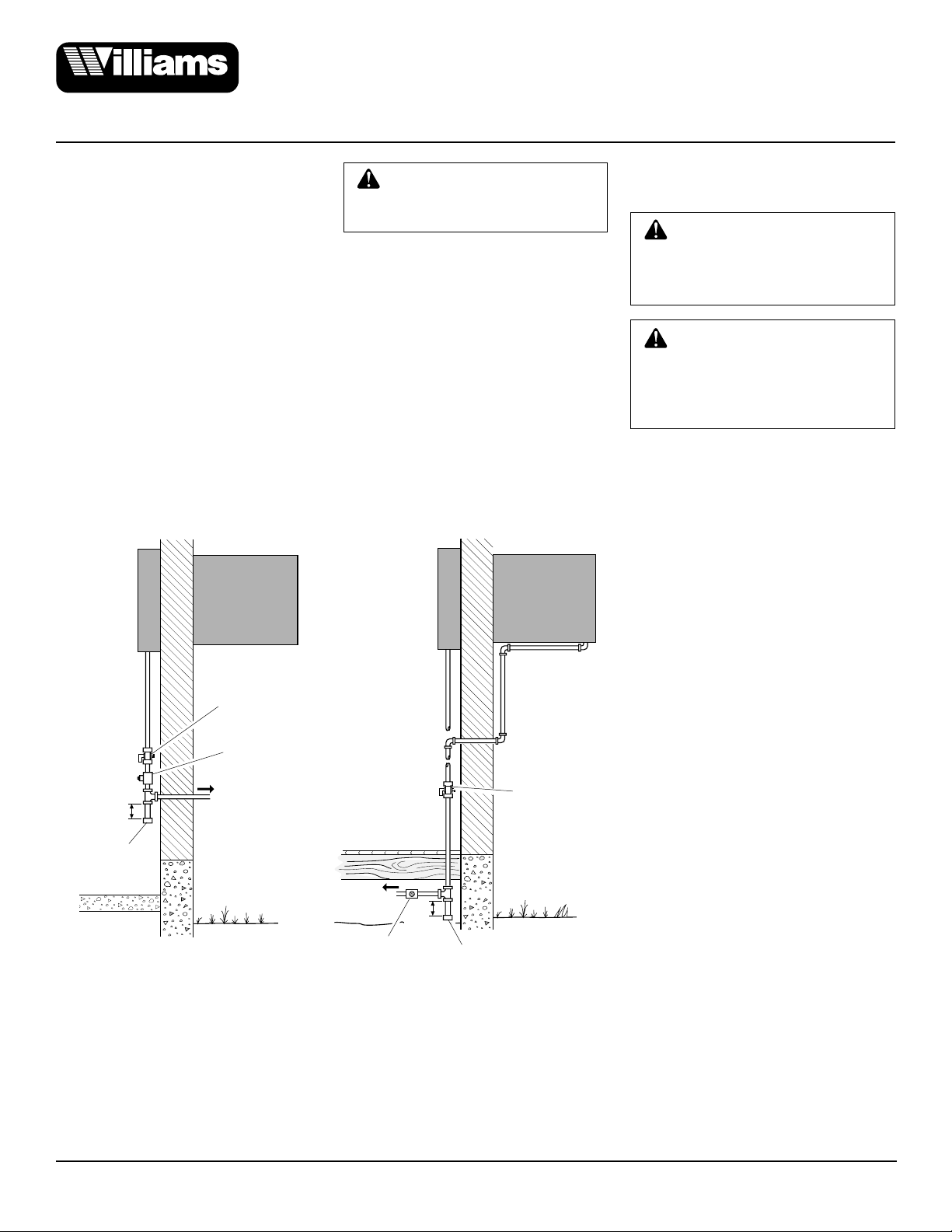

6" Minimum

Adjacent

Side

Wall

Ceiling

Finished Floor, Carpet, Tile, etc.

12"

Minimum

12" Minimum

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

Mounting hardware needed to mount furnace into wall is included with the furnace.

No venting material is needed. You must

furnish tools and all gas piping from the gas

source to the furnace inlet.

WARNING: A qualified service person must install furnace.

Have service person inspect furnace before use and at least annually. Follow all local codes.

NOTICE: This furnace must be

electrically grounded. Follow all

local codes. In the absence of

local codes, follow the

Electric Code, ANS/NFPA 70

(U.S.) or Canadian Electrical Code

Part I-CSA C22.1 (Canada).

CHECK GAS TYPE

Use only natural gas. If your gas supply is

not natural gas, do not install furnace. Call

dealer where you bought furnace for proper

type furnace.

INSTALLATION ITEMS

Before installing furnace, make sure you

have all items below:

• electric drill

• drill bits

• Phillips screwdriver

• hammer

• pipe wrench

• stud locator or small finishing nails

• equipment shutoff valve (supplied)

• test gauge connection (see Figure 15,

page 10)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• ground joint union

• sediment trap

• tee joint

National

LOCATING FURNACE

This furnace is designed to be mounted in a

wall that is 4 to 18 inches thick. You can also

mount furnace in a window.

WARNING: Do not install furnace in interior wall of building. You

must install furnace in exterior wall

of building. Rear of furnace must

extend into open, outside air. This

lets poisonous exhaust gases ventilate to the outdoors.

WARNING: Turn off electrical

circuits that pass through the wall

where you are going to install the

furnace.

WARNING: Maintain the minimum clearances shown in Figure

1. If you can, provide greater clearances from floor, ceiling, and

joining wall.

WARNING: Due to high temperatures, never install the furnace:

• in an inside wall

• in a recreation vehicle

• in a window recessed in a thick

wall (creating an alcove)

• in an alcove

• behind a door or where an open

door would block normal air flow

• as a fireplace insert

• in high traffic areas

• near furniture or draperies

• in windy or drafty areas

CAUTION: If you install the

furnace in a home garage, locate

furnace where moving vehicle will

not hit it.

For convenience and efficiency, install furnace:

• where there is easy access for operation,

inspection, and service

• in a central location, near an electrical

outlet

• where there is adequate clearance around

vents outside

Before installing furnace, inspect the wall,

floor, and outside areas. Make sure there are

no pipes, wiring, or anything else that would

interfere with furnace installation. If you are

installing thermostat in a wall, make sure

there are no pipes or wiring in the hollow

wall above the furnace. The thermostat wires

will pass through this wall from the attic.

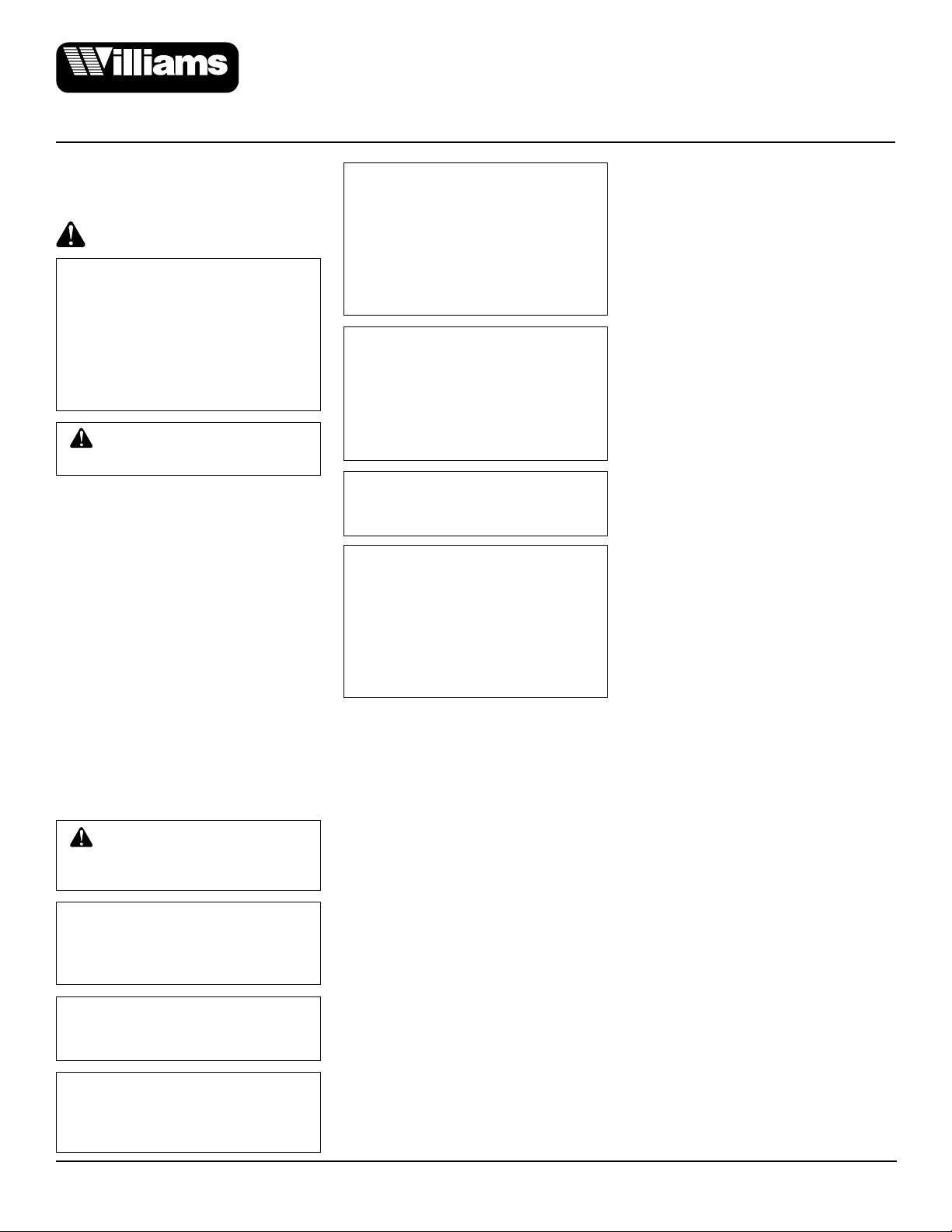

Minimum Clearances

Provide the following minimum clearances

from furnace front cover to combustibles

(as viewed from the front of furnace, see

Figure 1):

Below Front Cover: 6 inches

Above Front Cover: 12 inches

Adjoining Wall: 12 inches

Front: 8 feet

Figure 1 - Mounting Clearances as Viewed

from Front of Furnace

The clearance between the cabinet and the

wall it passes through is 0 inches.

Provide the following minimum clearances

from furnace cabinet (portion of cabinet

extending into outside air, as viewed from

the rear of furnace) to obstructions:

Cabinet Back: 36 inches

Cabinet Sides: 6 inches

Cabinet Bottom: Must be high enough

off the ground to prevent snow, water,

leaves, or any other objects from blocking vents.

4

201842

OWNER’S MANUAL

INSTALLATION

(Continued)

CREATING WALL OPENING

AND MOUNTING FURNACE

Remove furnace front cover. Remove the

two screws at the lower edges of front cover.

Lift front cover away.

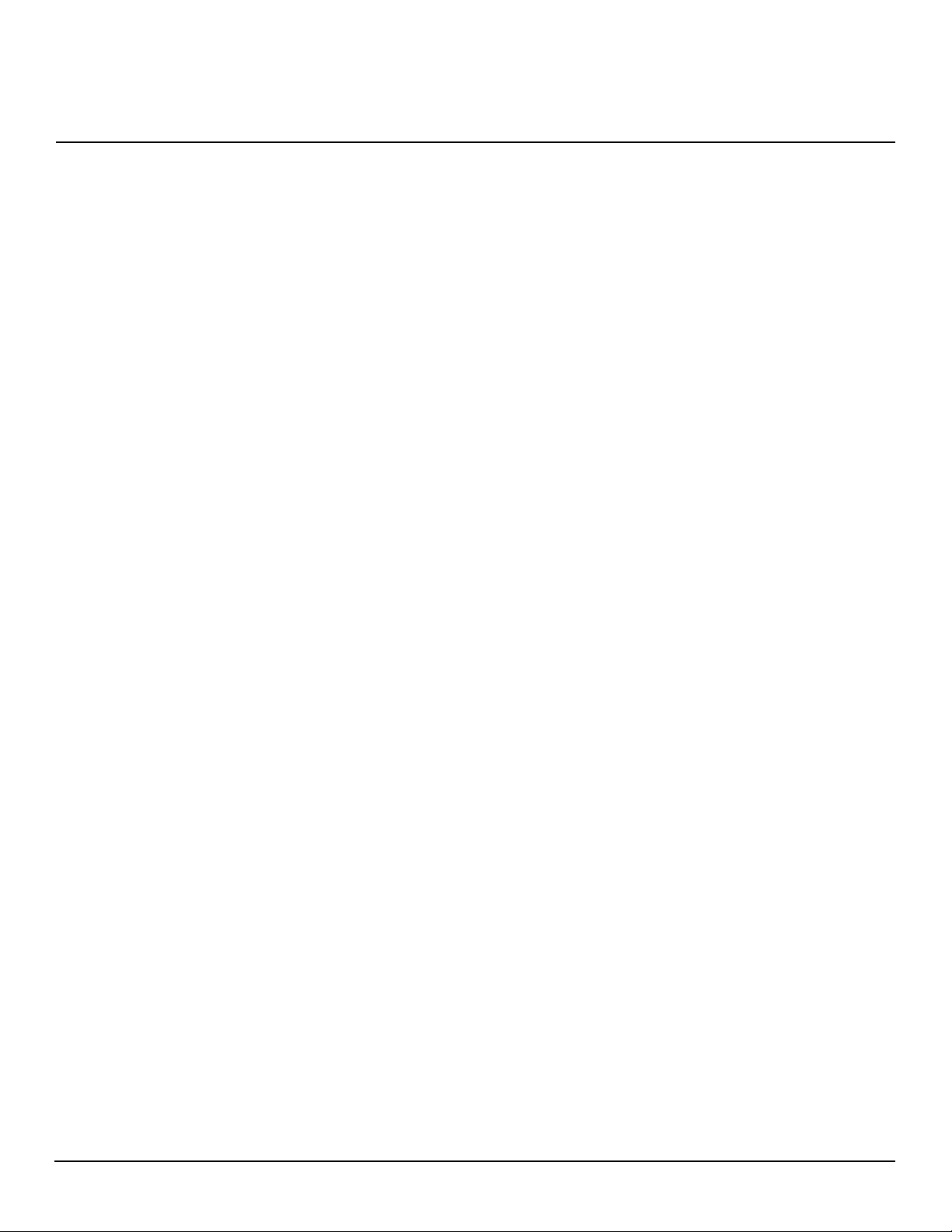

Installing in Normal Frame Wall

The 25,000 BTU/Hr model is designed to fit

between two wall studs set at 16 inch on

center. The 40,000 BTU/Hr model will not

fit between wall studs. Follow the steps

below to install.

1. Turn off electrical circuits that pass

through mounting wall. Make sure

there are no pipes or electrical wires in

area you intend to cut.

2. Use stud locator or small finishing nail

to find wall studs. When you locate

studs, drive a small finishing nail into

each stud. This provides a visual reference for stud locations.

3. 25,000 BTU/Hr Model: Cut an opening in wall between the two studs. Make

opening 141/4" wide by 135/8" high

(see Figure 2).

must install furnace horizontally. Do

not install furnace vertically.

40,000 BTU/Hr Model: Cut a 20

wide by 14 3/8" high opening in wall (see

Figure 2). Start your cut right next to

stud you are going to anchor cabinet to.

Cut across wall and through the next

stud. Stop cut at proper width.

IMPORTANT:

horizontally . Do not install furnace vertically .

4. 25,000 BTU/Hr Model: Mark screw

locations on wall (see Figure 2). Make

sure screws will anchor into studs.

Make sure screw locations match screw

holes on cabinet flange.

40,000 BTU/Hr Model: Mark screw

locations on wall (see Figure 2). Make

sure screws on one side will anchor into

studs. Screws on other side will only

anchor in wall material. Make sure

screw locations match screw holes on

cabinet flange.

IMPORTANT:

Yo u

5

/16"

Y ou must install furnace

5. 25,000 BTU/Hr Model: Use a propersized drill bit. Drill holes through wall

and into studs at marked locations.

40,000 BTU/Hr Model: Use a proper-

sized drill bit. On wall stud side of

opening, drill holes through wall and

into studs at marked locations. On other

side, drill holes through wall material.

6. Insert furnace into opening. Do this

from inside the room. Secure furnace

to wall with four large screws provided.

7. On outside of wall, caulk opening between the cabinet and the rough edges

of opening.

Wall Studs

1

/4"

Approx.

Screw

Locations

14

13

/8"

Wall

Opening

5

Approx.

Screw

Locations

25,000 BTU/Hr Model

Wall Studs

Approx.

Screw

Locations

20 5/16"

Wall Opening

14

3

/8"

40,000 BTU/Hr Model

Figure 2 - Wall Openings and Screw

Locations

Installing in Masonry Wall

You can mount both models in a masonry

wall. Follow the steps below to install.

1. Cut opening in wall. Make opening 14 1/4"

wide by 13 5/8" high for 25,000 BTU/Hr

models. Make opening 20 5/16" wide by

14 3/8" high for 40,000 BTU/Hr models.

IMPORTANT:

furnace horizontally . Do not install furnace vertically.

You must install

2. Secure furnace to wall with toggle bolts

or hook bolts set in mortar.

3. Insert furnace into opening. Do this

from inside the room. Secure furnace

to wall with toggle bolts or hook bolts.

4. On outside of wall, caulk opening between the cabinet and the rough edges

of opening. You can also use mortar to

seal opening.

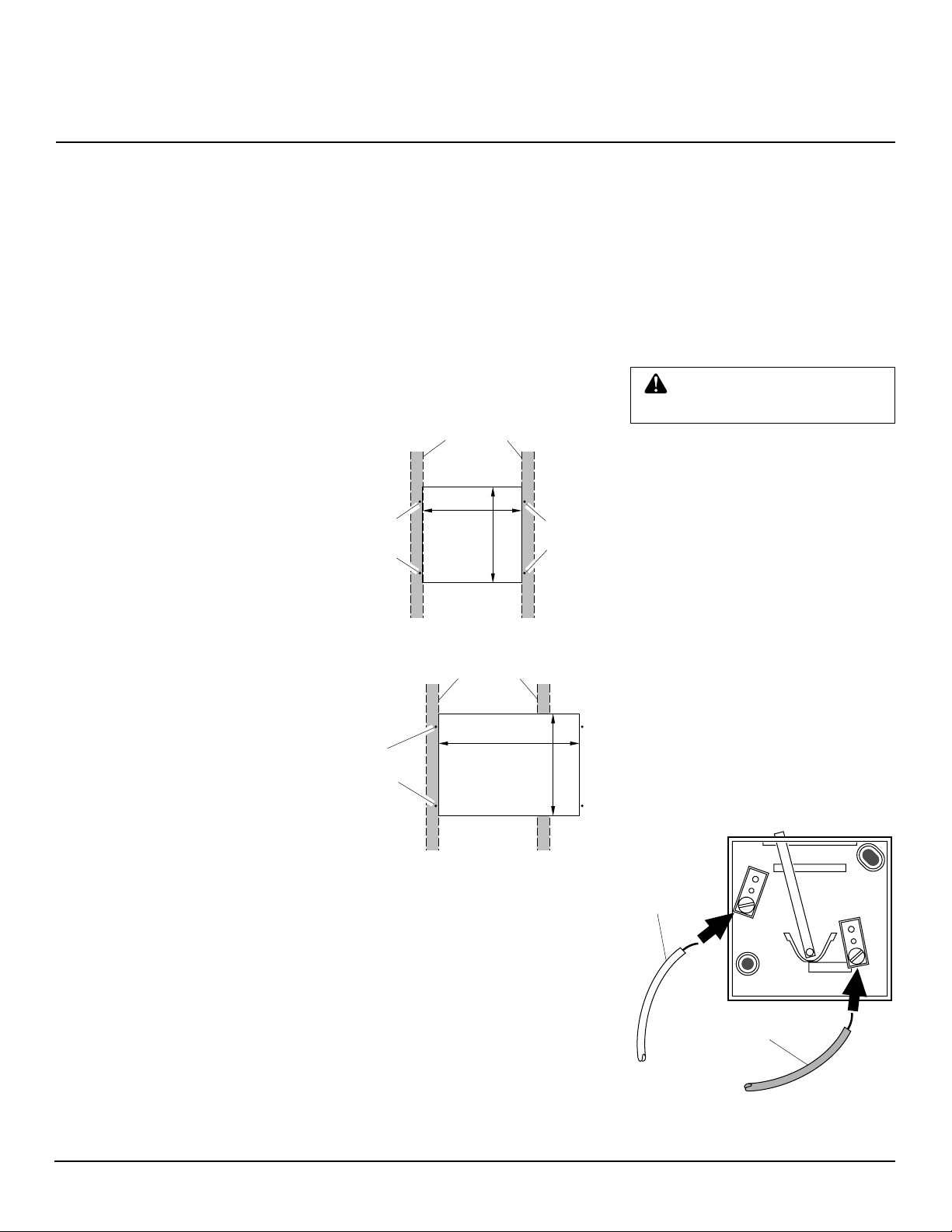

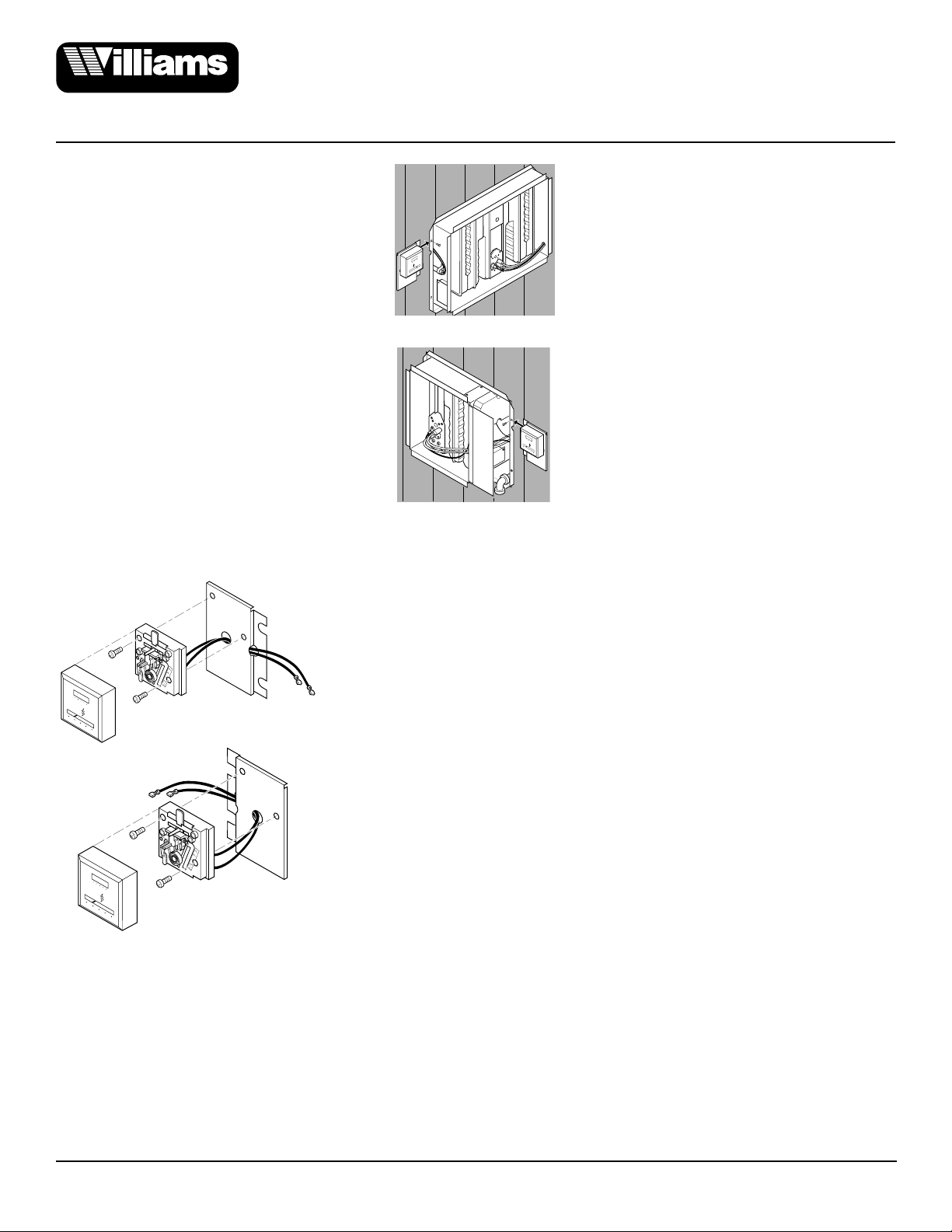

INSTALLING THERMOSTAT

WARNING: Unplug furnace

before installing thermostat.

Mount the thermostat directly on the furnace or on a wall in another part of the room.

If you have solid or masonry walls, mount

the thermostat on the furnace.

Mounting Thermostat to Furnace

1. Unplug furnace.

2. Locate red and white thermostat wires

coming out of side of furnace. These

wires are labeled “Thermostat.”

3. Cut thermostat wires to desired length.

4. Route thermostat wires through slot/

hole in side of thermostat mounting

plate. Then route wires through 5/8"

diameter hole in center of plate (see

Figure 4, page 6).

5. Connect thermostat wires to the two

terminal screws on back of thermostat

(see Figure 3). Connect red wire to “R”

terminal. Connect white wire to “W”

terminal.

White Wire

W

R

Red Wire

Figure 3 - Connecting Thermostat Wires

to Thermostat

Continued

201842

5

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

(Continued)

6. Attach thermostat to thermostat mounting plate with screws provided (see Figure 4).

IMPORTANT:

plate position in Figure 4. Correctly

position mounting plate for your model

furnace.

7. Insert thermostat mounting plate between wall and cabinet flange. Line up

top notch on mounting plate with top

screw on flange (see Figure 5).

IMPORTANT:

BTU/Hr model mounts on right side of

furnace (see Figure 5). Thermostat for

40,000 BTU/Hr model mounts on left

side of furnace (see Figure 5).

8. Insert screw in cabinet flange and thermostat mounting plate and tighten firmly .

IMPORT ANT :

wires do not touch combustion chamber.

.2

.3

.4

OFF

.5

.7

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

Figure 4 - Attaching Thermostat to

Thermostat Mounting Plate

1.0

40,000 BTU/Hr Models

OFF

25,000 BTU/Hr Models

Note mounting

Thermostat for 25,000

Make sure thermostat

.2

.3

.4

.5

.7

1.0

00

0

0 00

00

00

00000000000 00000000

00 00 00 00 00

40,000 BTU/Hr Models

50 60 70 80 90

S

O

L

ID

S

T

A

T

E

IG

N

IT

IO

50 60 70 80 90

N

25,000 BTU/Hr Models

Figure 5 - Inserting Thermostat Mounting

Plate Between Wall and Cabinet Flange

Locating Thermostat on Wall

1. Locate thermostat 4 1/2 to 5 feet above

the floor on an inside wall away from

any heat sources. The thermostat needs

to sense average room temperature.

Avoid the following:

HOT SPOTS

Concealed pipes or ducts

Fireplaces

Registers

TV sets and radios

Lamps or direct sunlight

Kitchen

COLD SPOTS

Concealed pipes or ducts

Stairwells (drafts) or doors (drafts)

Unheated rooms on other side of wall

DEAD SPOTS

Behind doors

Corners and alcoves

2. Before installing thermostat, inspect the

wall, floor, and attic areas. Make sure

there are no pipes, wiring, or anything

else that would interfere with installing thermostat. Do not mount thermostat to stud. If there are any obstructions, choose a new location.

3. Provide two 18-gauge insulated stranded

wires for the thermostat wire. Also provide two wire nuts, and two wall anchors.

There is a red and a white thermostat wire

coming from the furnace. The extra thermostat wires you furnish attach to these

wires. Make sure you furnish a red and a

white wire. This will insure correct

hookup. Purchase enough thermostat wire

to go from the furnace to the thermostat

location. Do not cut and splice this wire.

The thermostat wire must be unbroken.

Routing Thermostat Cable

All wiring must meet local codes. The following instructions cover routing the wire

through the attic. You can run wiring from

a basement or crawl space.

1. Unplug furnace.

2. Before drilling hole in wall, drive a small

finishing nail through ceiling directly

above thermostat location. Pull nail out

and push a small stiff wire through hole.

This helps you locate thermostat mounting location when in attic.

3. In attic, locate stiff wire. Drill 1/2" hole

in center of ceiling wall plate next to

stiff wire. Remove wire.

4. Probe through drilled hole in wall plate

with a stiff wire to make sure there are

no pipes, wiring, or anything else

blocking the way for thermostat wires.

If you find blockage, choose new location for thermostat.

5. Drill a 1/2" hole through the wall at

thermostat mounting location.

6. From attic, feed thermostat wires

through hole in ceiling plate until wires

reach thermostat location.

7. Make a small hook with a piece of stiff

wire. Run wire hook through 1/2" hole

in wall. Hook thermostat wires. Pull

wires through hole in wall. Make sure

6" of wires stick out.

8. Drive a small finishing nail in ceiling

above furnace.

25,000 BTU/Hr Model - Drive nail

above right side of furnace.

40,000 BTU/Hr Model - Drive nail

above left side of furnace.

Pull nail out and push a small stiff wire

through hole. This helps you locate wire

routing location when in attic.

9. Repeat steps 3 and 4 above.

6

201842

OWNER’S MANUAL

INSTALLATION

(Continued)

10. Feed thermostat wires from attic to

furnace through 1/2" hole in ceiling

wall plate.

11. Connect thermostat wires from attic to

thermostat wires on furnace. Connect

red wires together, then connect white

wires together. Use wire nuts to make

connections.

thermostat wires do not touch combustion chamber.

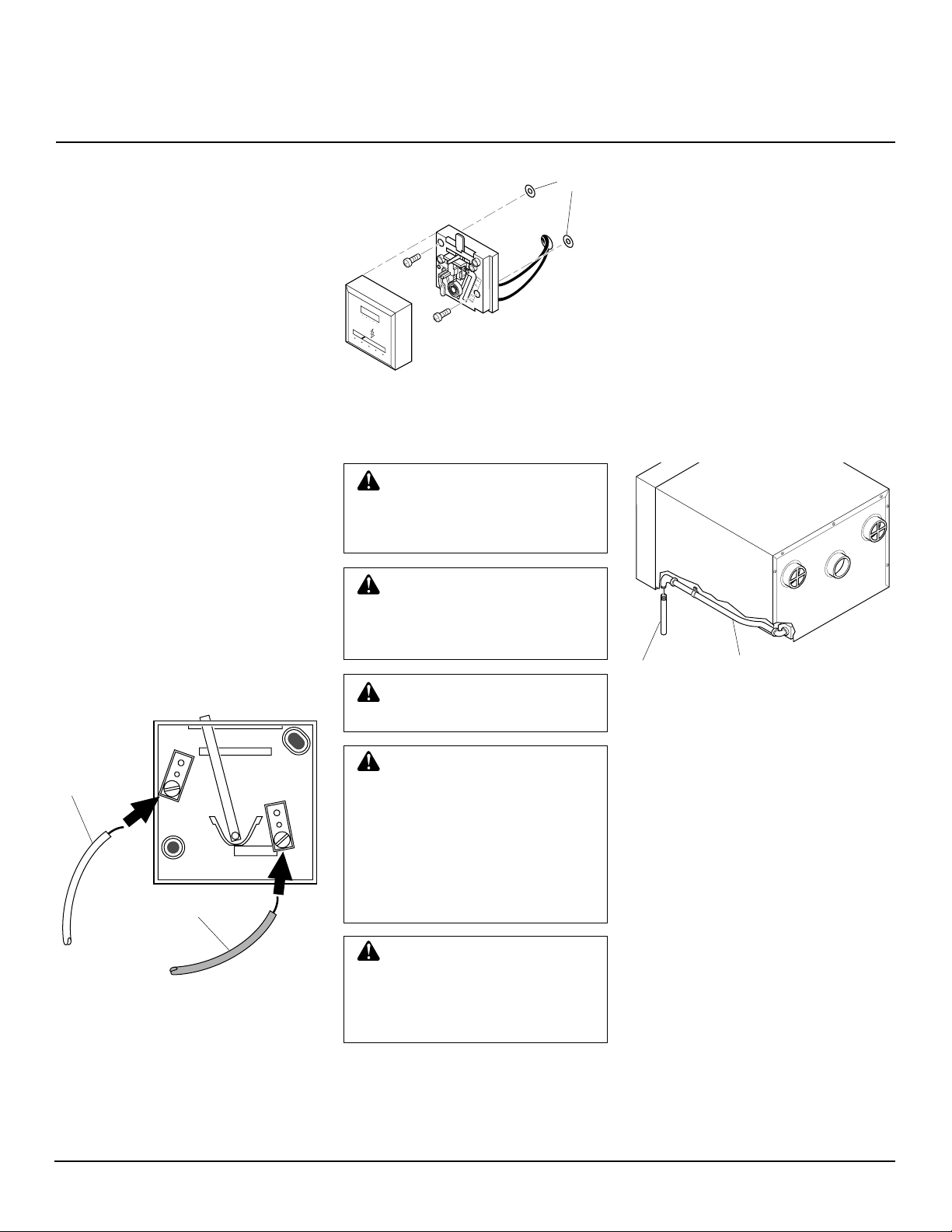

Mounting the Thermostat to Wall

1. Connect thermostat wires to the two

terminal screws on back of thermostat

(see Figure 6). Connect red wire to “R”

terminal. Connect white wire to “W”

terminal.

2. Push any excess wire back through hole

in wall and plug hole with insulation

to prevent drafts. Drafts affect the thermostat operation.

3. Use thermostat base to mark mounting

screw locations.

4. Drill proper-sized holes for wall anchors.

5. Attach thermostat to wall using screws

provided (see Figure 7).

IMPORTANT:

Make sure

Wall

Anchors

.2

.3

.4

OFF

.5

.7

1.0

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

Figure 7 - Mounting Thermostat to Wall

CONNECTING TO GAS

SUPPLY

WARNING: A qualified service person must connect furnace to gas supply. Follow all

local codes.

WARNING: Never connect

furnace to private (non-utility) gas

wells. This gas is commonly

known as wellhead gas.

WARNING: Unplug furnace

before connecting to gas supply.

All piping must comply with local codes

and ordinances or with the National Fuel

Gas Code (ANS Z223.1 NFPA No. 54),

whichever applies.

You can connect furnace to gas supply at

front of furnace (inside) or at rear of furnace

(outside).

Connecting Furnace to Gas

Supply at Front of Furnace

1. Locate gas inlet pipe on lower, right

front of furnace (see Figure 8).

2. Connect 3/8" NPT pipe or nipple to gas

inlet pipe (see Figure 8). See Provid-

ing Gas Piping to Furnace, pages 9 and

10, for correct gas pipe installation.

3/8" NPT

Pipe or

Nipple

Figure 8 - Connecting Gas from Inside of

Room

Gas Inlet Pipe

White Wire

W

R

Red Wire

Figure 6 - Connecting Thermostat Wires

to Thermostat

201842

CAUTION: Use only new,

black iron or steel pipe. Copper

tubing may be acceptable in certain areas. Check local codes.

Use pipe large enough in diameter to allow proper gas volume

to furnace. If pipe is too small,

undue loss of pressure will occur. Refer to chart on page 9.

CAUTION: Lightly apply pipe

joint sealant to male threads before connecting. Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Continued

7

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

(Continued)

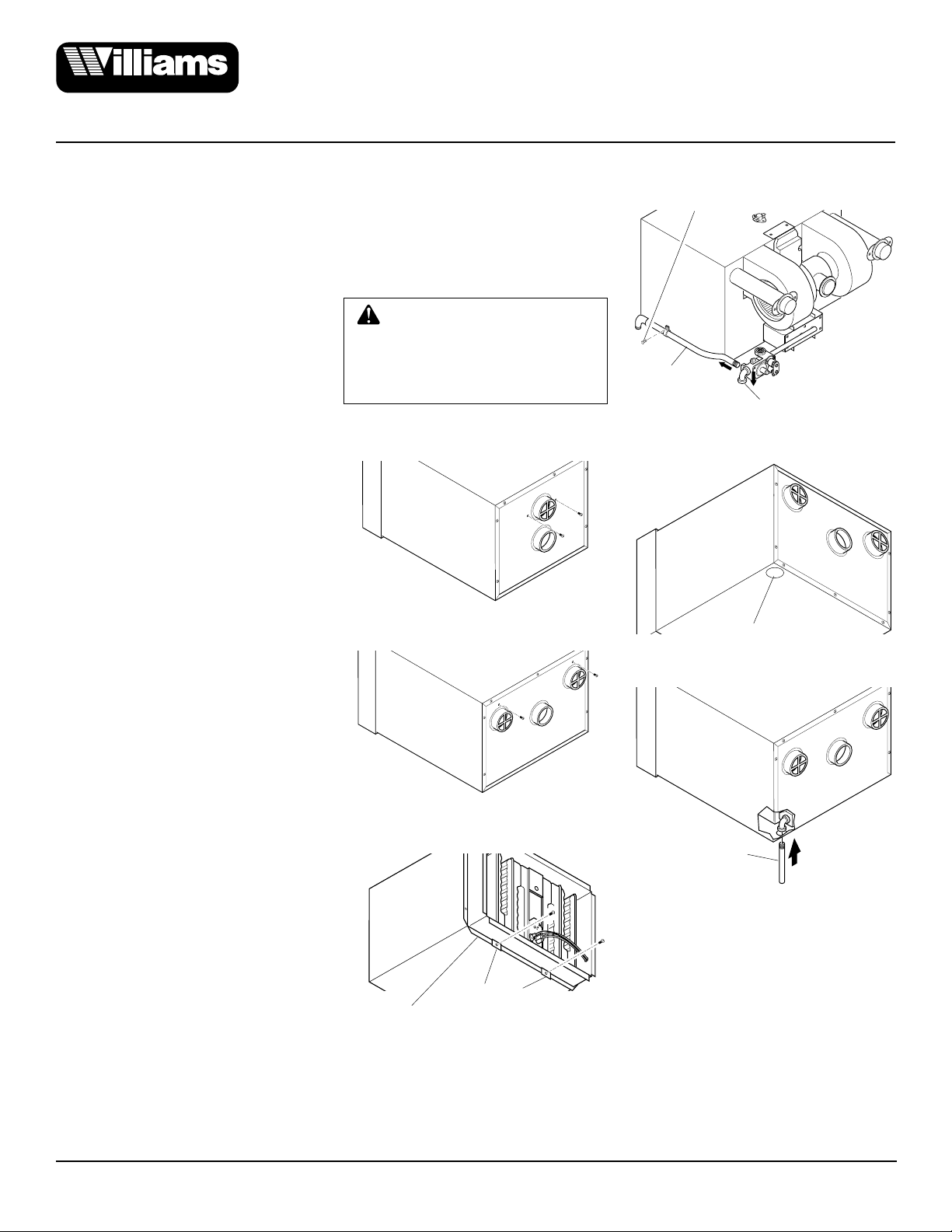

Connecting Furnace to Gas

Supply at Rear of Furnace

1. Remove the two screws in back of furnace cabinet located by the exhaust

vent(s) (see Figures 9 and 10).

2. Remove two screws on front lower

flange that attach furnace flange to furnace cabinet flange (see Figure 11).

Note:

40,000 BTU/Hr model has a bottom shield (see parts list, page 22, for

location). Removing two screws will

detach bottom shield.

3. Slide furnace out of furnace cabinet.

4. Locate gas inlet pipe on lower, right

front of furnace.

5. 40,000 BTU/Hr Model Only: Remove

screw holding gas inlet pipe clamp to

furnace.

6. Disconnect gas inlet pipe from 3/8"

manifold elbow. Turn gas inlet pipe

counterclockwise to disconnect (see

Figure 12).

7. Rotate the 3/8" manifold elbow 90° so

the opening is pointing downward (see

Figure 12).

8. Locate knockout plug in furnace cabinet. Knockout plug is in lower left rear

of furnace cabinet (as viewed from rear,

see Figure 13). Remove knockout plug.

9. Slide furnace back into furnace cabinet. Make sure exhaust tube gaskets are

in place. Make sure exhaust and intake

vent tubes extend into vent caps on

back of cabinet. Replace two screws by

exhaust vent(s) removed in step 1.

10. 25,000 BTU/Hr Model: Replace two

screws removed in step 2. Attach furnace flange and furnace cabinet lower

flange together.

40,000 BTU/Hr Model: Place bottom

shield back in place. Replace two

screws removed in step 2. Attach bottom shield, furnace flange, and furnace

cabinet lower flange together.

11. Run 3/8" pipe or nipple through knockout hole. Connect 3/8" pipe or nipple

to manifold elbow (see Figure 14). See

Providing Gas Piping to Furnace,

pages 9 and 10 for correct gas pipe installation.

12. Check connections for gas leak.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

13. Caulk around pipe or nipple. This prevents cold air entering knockout hole.

Figure 9 - Locations of Screws in Back of

Furnace Cabinet (25,000 BTU/Hr Model)

Figure 10 - Locations of Screws in Back

of Furnace Cabinet (40,000 BTU/Hr Model)

Furnace

Furnace

Cabinet

Flange

Figure 11 - Removing Screws on Lower

Flange (40,000 BTU/Hr Model Shown)

Flange

Remove Screw,

40,000 BTU/Hr

Model Only

Gas Inlet

Pipe

Manifold Elbow

Figure 12 - Disconnecting Gas Inlet Pipe

(40,000 BTU/Hr Model Shown)

Knockout Plug

Figure 13 - Location of Knockout Plug

3/8" NPT

Figure 14 - Inserting Pipe through

Knockout Hole

8

201842

OWNER’S MANUAL

INSTALLATION

(Continued)

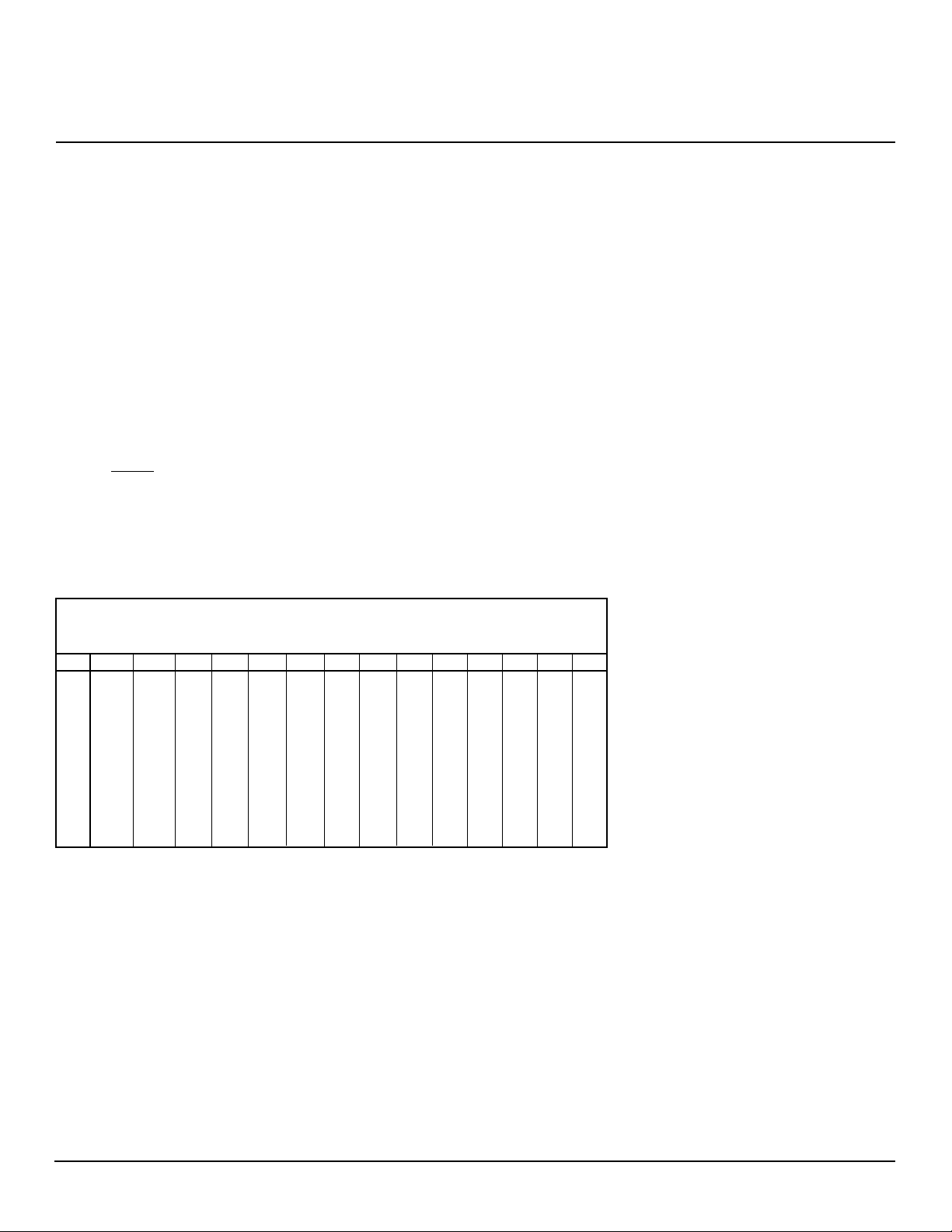

Providing Gas Piping to Furnace

You must provide gas piping from gas source to furnace. The gas piping must be in a vertical

position where it connects to the furnace. This prevents interference with front cover

installation.

Consult your local gas company for proper routing of the gas lines.

Pipe size is determined by the length of pipe from the gas source to the furnace and the total

BTU load on the gas source.

Add the total BTUs required for all appliances connected to the gas source including this furnace.

Divide this number by 1030. This will give you the approximate cubic feet per hour needed.

Example:

40,000 BTU/Hr

+ 15,000 BTU/Hr for other gas appliances

55,000 BTU/Hr total

55,000 ÷ 1030 = 53.4

Locate 53.4 or higher on chart below.

According to the chart below, you should use 50 feet or less of 1/2" pipe, 200 feet

or less of 3/4" pipe, etc...

MINIMUM

IRON PIPE

SIZE LENGTH OF PIPE (FEET)

10 20 30 40 50 60 70 80 90 100 125 150 175 200

3/8" 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2" 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4" 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1" 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1

/4" 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1

11/2" 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2" 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

21/2" 4800 3300 2700 2300 2000 1850 1700 1600 1500 1400 1250 1130 1050 980

3" 8500 5900 4700 4100 3600 3250 3000 2800 2600 2500 2200 2000 1850 1700

4" 17500 12000 9700 8300 7400 6800 6200 5800 5400 5100 4500 4100 3800 3500

IMPORTANT:

Check gas line pressure at gas meter before connecting furnace to gas line. Gas

line pressure must be no less than 5 inches of water and no greater than 7 inches of water. Gas

pressures and input to the burners must not exceed the rated input and pressure shown on the

rating plate. For natural gas, manifold pressure should be 3.5 inches of water. For elevations

above 2000 feet, reduce rating 4% for each 1000 feet above sea level (U.S.A. only).

201842

Continued

9

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

(Continued)

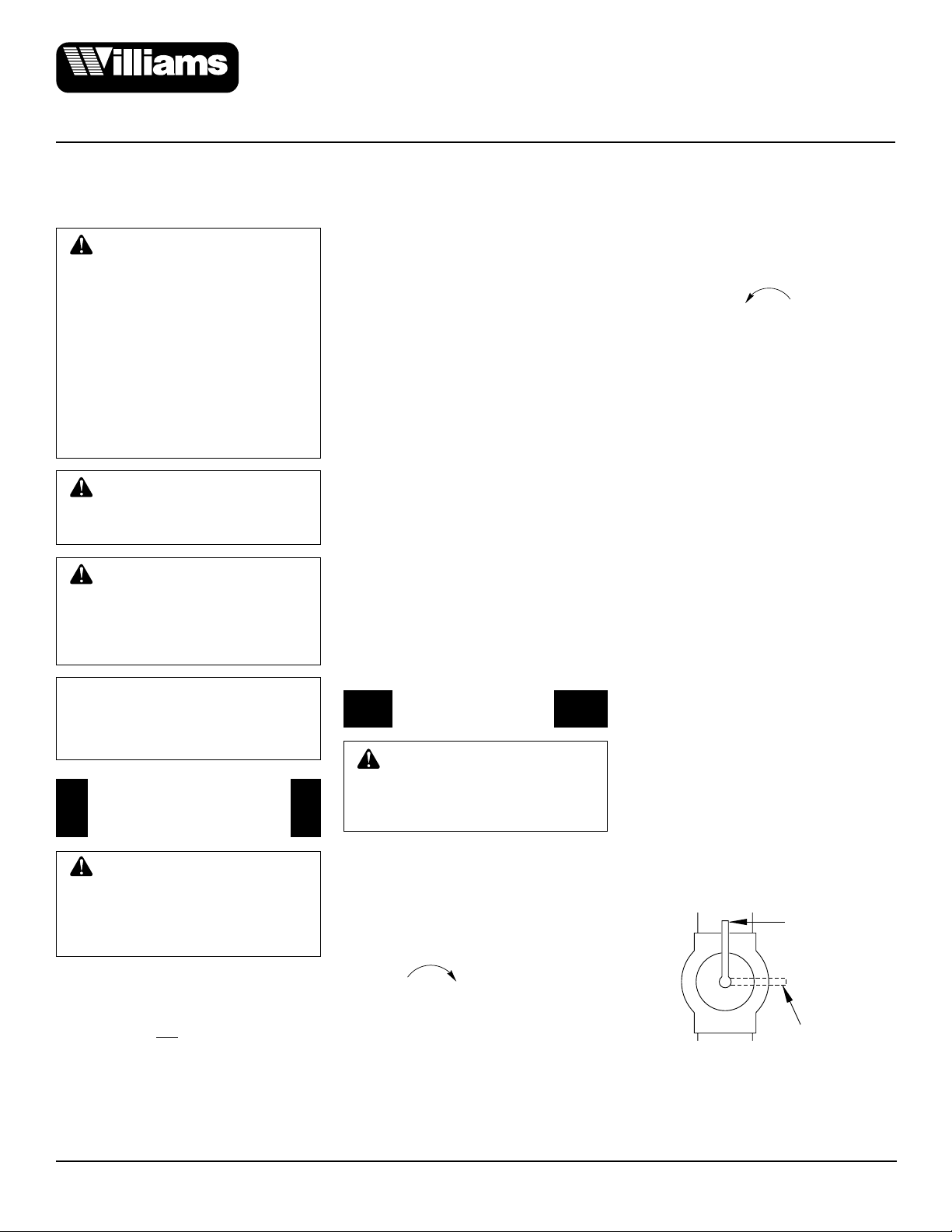

Installation must include an equipment

shutoff valve (supplied), ground joint union,

plugged 1/8" NPT tap, and a sediment trap.

Locate NPT tap within reach for test gauge

hook up. NPT tap must be upstream from

furnace (see Figure 15).

Install an equipment shutoff valve in an

accessible location. The equipment shutoff

valve is for turning on or shutting off the gas

to the appliance.

Apply pipe joint sealant lightly to male

threads. Prevent excess sealant from going

into pipe. Excess sealant in pipe could result

in clogged furnace valves.

Equipment

Shutoff Valve

Test Gauge

Connection

To Gas Supply

3" Min.

Sediment

Trap

To Gas Supply

CAUTION: Use pipe joint sealant that is resistant to liquid petroleum (LP) gas.

Install sediment trap in supply line as shown

in Figure 15. Locate sediment trap where it

is within reach for cleaning. A sediment trap

traps moisture and contaminants. This keeps

them from going into furnace controls. If

sediment trap is not installed or is installed

wrong, furnace may not run properly.

IMPORTANT:

Locate sediment trap where

trapped matter will not freeze. Install sediment trap in a vertical run of pipe. If gas

piping enters furnace from rear (outside),

you must locate sediment trap in crawl space

(see Figure 15). If you install furnace in

structure with slab foundation, you must

install gas piping to front of furnace (inside)

(see Figure 15).

Gas Piping

Entering

Furnace

Front

(Inside)

Gas Piping

Entering

Furnace

Rear

(Inside)

Equipment

Shutoff

Valve

CHECKING GAS

CONNECTIONS

WARNING: Test all gas piping and connections for leaks

after installation or servicing.

Correct all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

Pressure Testing Gas Supply

Piping System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance

main gas valve (control valve) and

equipment shutoff valve from gas

supply piping system. Pressures in

excess of 1/2 psig (3.5 kPa) will

damage heater regulator.

2. Cap off open end of gas pipe where

equipment shutoff valve was connected.

3. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4. Check all joints of gas supply piping

system. Apply mixture of liquid soap

and water to gas joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect furnace and equipment

shutoff valve to gas supply. Check reconnected fittings for leaks.

Slab Floor Installation

Figure 15 - Gas Connection

3" Min.

Test Gauge

Connection

Crawl Space Installation

Sediment

Trap

10

201842

OWNER’S MANUAL

O

INSTALLATION

(Continued)

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

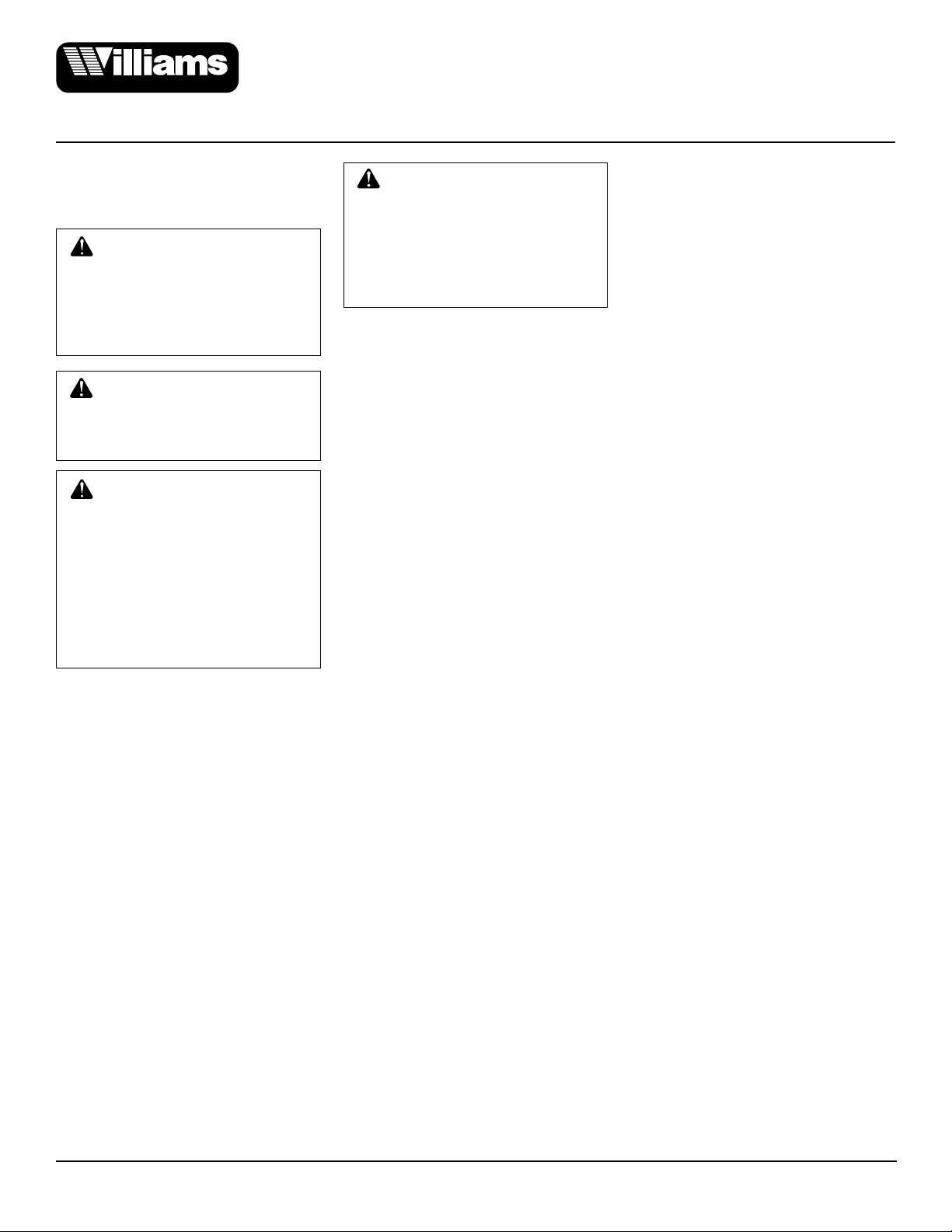

1. Close

2. Pressurize supply piping system by either

3. Check all joints from gas meter to

4. Correct all leaks at once.

Pressure Testing Furnace Gas

Connections

1. Open

2. Open main gas valve located on or near

3. Make sure control knob of furnace is

4. Check all joints from

5. Correct all leaks at once.

6. Turn on furnace (see Operating Fur-

7. Turn off furnace (see To Turn Off Gas

equipment

shutoff valve (see Fig-

ure 16).

using compressed air or opening main gas

valve located on or near gas meter.

equipment shutoff valve. Apply mixture of liquid soap and water to gas

joints. Bubbles forming show a leak.

equipment

shutoff valve (see Fig-

ure 16).

gas meter.

in the OFF position.

equipment

shutoff

valve to gas inlet pipe. Apply mixture

of liquid soap and water to gas joints.

Bubbles forming show a leak.

nace, pages 12 and 13). Check the rest

of the internal joints for leaks.

to Furnace, page 13).

O

On Position

POSI

CONNECTING TO

ELECTRICAL SUPPLY

IMPORTANT:

connecting electricity to furnace. In the absence of local codes, refer to the latest edition of the National Electrical Code ANS/

NFPA No. 70. If you are not familiar with

wiring codes, have a qualified electrician do

the wiring.

It is best to plug furnace into a separate and

permanent electrical line circuit.

1. Supply a 120-volt, 60-cycle, grounded

outlet at furnace location.

2. The furnace has a three-pronged

(grounded) plug. Use only a grounded,

three-prong outlet.

IMPORTANT:

rigid or semi-rigid conduit or metallic

sheathe cable. When using a semi-rigid or

metallic sheathe cable, the installer must

terminate the supply wire in the terminal

box opening.

Performance Check

Plug furnace into three-pronged outlet. If

ignitor remains on after main burner ignition or if the valve chatters, you may have

reversed polarity.

1. Unplug furnace.

2. Turn off electricity to outlet.

3. Reverse 120-volt connections inside

outlet.

4. Turn on electricity to outlet.

5. Plug in furnace. Ignitor should turn off

after main burner ignites. If ignitor does

not turn off, or if valve continues to

chatter, turn off furnace and unplug.

Call a qualified service person.

Follow all local codes when

Some local codes require

ATTACHING CABINET

FRONT COVER

CAUTION: Do not operate furnace with front cover removed or

mounted wrong. If front cover is

mounted wrong, you cannot secure it to cabinet with screws.

1. Hook top of front cover over top cabinet flange.

2. Secure the sides of front cover to lower

sides of furnace cabinet with two

screws provided (see Figure 17).

IMPORTANT:

nace from furnace cabinet during installation. You must correctly install furnace

within cabinet. If not, front cover will not

properly attach to cabinet. Make sure gaskets for intake and exhaust tubes are in

place. Make sure intake and exhaust tubes

extend into vent caps on cabinet back and

are secured with screws. Make sure you

secured flange on bottom of furnace to flange

on bottom front of cabinet.

Figure 17 - Attaching Front Cover to

Cabinet

You may have removed fur-

P

Off Position

Figure 16 - Equipment Shutoff Valve

201842

11

THE COMFORT PRODUCTS PEOPLE

O

DIRECT-VENT NATURAL GAS HEATER

OPERATING

FURNACE

WARNING: Furnace burner,

combustion chamber, and exhaust port are very hot during

operation. Keep children and

adults away from hot surfaces to

avoid burns and clothing ignition. Carefully supervise young

children when they are in the

same room as furnace. Furnace

will remain hot for a time after

shutdown. Let surface cool before touching.

WARNING: Do not operate

furnace with front cover removed.

Unsafe operation could result.

CAUTION: Do not block circulating air openings in the louver of the front cover. This is

necessary for furnace to operate

properly.

NOTICE: If operating furnace for

the first time, a slight odor will

occur. This odor will go away

after a few hours of operation.

FOR YOUR SAFETY

READ BEFORE

LIGHTING

WARNING: If you do not follow these instructions exactly, a

fire or explosion may result causing property damage, personal

injury, or loss of life.

A. This appliance does not have a pilot.

It is equipped with an ignition device

which automatically lights the

burner . Do not try to light the burner

by hand.

B. BEFORE OPERATING smell all

around the appliance area for gas. Be

sure to smell next to the floor because

some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to turn the

handle on the equipment shutoff

valve. Never use tools. If the handle

will not turn by hand, don’t try to

repair it. Call a qualified service technician. Force or attempted repair

may result in a fire or explosion.

D. Do not use this appliance if any part

has been under water. Immediately

call a qualified service technician to

inspect the appliance and to replace

any part of the control system and

any gas control which has been under water.

OPERATING

INSTRUCTIONS

WARNING: Always follow

lighting instructions. Never attempt to light burner with a match

or butane torch.

1. STOP! Read the safety information,

column 1.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the

furnace.

4. T urn equipment shutoff valv e clockwise to OFF position (see

Figure 18).

5. Wait f ive (5) minutes to clear out any

gas. Then smell for gas, including

near the floor. If you smell gas,

STOP! Follow “B” in the safety information, column 1. If you don’t

smell gas, go to next step.

6. Turn equipment shutoff valve counterclockwise to ON position

(see Figure 18).

7. This furnace is equipped with an ignition device which automatically

lights the burner. Do not try to light

the burner by hand.

8. Plug in furnace.

9. Set thermostat to desired setting. If

thermostat is set above room temperature, the blower will come on.

10. Allow approximately 45 seconds for

ignition to occur. When ignition occurs, the glo-bar will stay on for a

short period of time. The flame sensing probe will sense the burner flame

and shut off glo-bar.

If ignition does not occur within 22

seconds, the ignition control will attempt to light burner three times.

This will take about two minutes. If

ignition does not occur, the ignition

control will lock out the glo-bar and

valve circuit. Air in the gas line or a

short gas interruption will prevent

furnace from igniting. If this happens, turn thermostat off and wait 5

minutes. Turn the thermostat back

on. The furnace will try to ignite

again.

11. If the furnace still does not ignite, follow instructions To Turn Off Gas to

Furnace, page 13. Call a qualified

service person. Do not attempt to restart furnace.

O

On Position

POSI

P

Off Position

Figure 18 - Equipment Shutoff Valve

12

201842

OWNER’S MANUAL

OPERATING

FURNACE

(Continued)

TO TURN OFF GAS

TO FURNACE

1. Set thermostat to lowest setting

2. Turn equipment gas valve clockwise

to OFF position. Do not

force equipment gas valve.

3. Unplug furnace if service is to be per-

formed.

To Shut Down Furnace for an

Extended Period of Time

1. Turn equipment gas valve clockwise

to OFF position. Do not

force equipment gas valve.

2. Set thermostat on OFF.

CAUTION: Do not try to adjust

heating levels by using the equipment shutoff valve.

THERMOSTAT

CONTROL

OPERATION

The thermostat responds to the room temperature. When the room temperature drops

below the thermostat setting, the thermostat

turns the furnace burner and blower on.

When the room temperature goes above the

thermostat setting, the thermostat turns the

furnace burner off. The blower will continue to blow about two to three minutes

after the burner goes out. The thermostat

keeps the room at a constant temperature.

INSPECTING

BURNER FLAME

To observe burner flame, remove furnace

front cover. Remove the two screws at the

lower edges of front cover. Lift front cover

away. Locate viewing window on front of

combustion chamber. You can see burner

flame through this window.

Correct Burner Flame: Blue flame with

well-defined burner ports.

Incorrect Burner Flame: Yellow or lazy

flame without well-defined burner ports.

If burner flame is incorrect, shut off furnace

and contact a qualified service person.

Correct Flame

Pattern

Figure 19 - Burner Flame Patterns

Incorrect Flame

Pattern

NORMAL

OPERATING

SEQUENCE

1. When the room temperature drops below

the thermostat setting, the thermostat calls

for heat. A 24-volt circuit is completed

through the time delay relay coil. After

three to five seconds, the contacts in the

relay close. The blowers come on.

2. One motor drives both the combustion

air blower and the circulating room air

blower. The combustion air blower

draws air from outside through the intake air vent. This air discharges into

the combustion chamber. The combustion air blower then forces the combustion products out of the exhaust tube(s).

The Combustion air blower is sealed

so that air does not pass between it and

the circulating room air blower.

3. When the blower motor reaches 75% of

normal r.p.m. (three to five seconds), air

from the blower turns on the

microswitch. When the microswitch

activates, the electrical circuit is completed through the limit switch to the

control module. The glo bar begins to

glow. In about 15 seconds, the glo bar

becomes hot enough to ignite the burner.

4. Another 24-volt circuit is completed

through the module to the main gas

valve. The valve opens. Gas passes

through the valve to the main burner.

The gas is ignited by the glo bar.

5. After the main burner ignites, the flame

detector senses the presence of flame.

This opens the circuit to the glo bar.

The glo bar shuts down.

6. The circulating room air blower pulls

return air in from the living area. This

air is heated as it flows past the combustion chamber. The heated air is then

blown out into the room.

7. When the room temperature rises above

the thermostat setting, the circuit to the

valve opens and the burner shuts off.

8. The blower continues to run about two to

three minutes until the time delay relay

coil cools. When the coil cools, the circuit

to the motor opens. The blower shuts off.

LIMIT SWITCH

WARNING: Do not operate

furnace without a properly-working limit switch.

The limit switch will turn off the gas to the

main burner if the furnace becomes too hot.

When this happens, the main burner will go

out and the blower will continue to run for

two to three minutes. This usually happens

when circulating air is partially or completely blocked.

Occasional cycling of the limit switch is not

bad. This indicates safe operation. Limit

switch cycling will most likely occur on

warm days. If this happens too often or for

a long period of time, the circulating air

system should be thoroughly cleaned by a

qualified service person.

If the circulating air system is cleaned and

the limit switch continues to shut down the

furnace, the limit switch is defective. A

defective limit switch cannot be repaired. It

must be replaced. For safety reasons, never

operate the furnace without a limit switch.

201842

13

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

CLEANING AND

MAINTENANCE

WARNING: Turn off and unplug furnace and let cool before

cleaning. Turn equipment shutoff

valve to OFF position. Only a

qualified service person should

service and repair furnace.

WARNING: Keep furnace clear

and free from combustible materials, gasoline, and other flammable vapors and liquids.

CAUTION: You must keep

control areas, burner, and circulating air passageways of furnace

clean. Inspect these areas of furnace before each use. Have furnace inspected yearly by a qualified service person. Furnace may

need more frequent cleaning due

to excessive lint from carpeting,

bedding material, pet hair, etc.

CAUTION: Label all wiring

prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous

operation.

Verify proper operation after servicing.

CABINET

Air Passageways

• Use a vacuum cleaner or pressurized air

to clean.

Exterior

• Use a soft cloth dampened with a mild

soap and water mixture. Wipe cabinet

and front cover to remove dust.

• Use a vacuum cleaner to remove dust

from front cover louvers.

EXHAUST AND INTAKE VENTS

Make sure the exhaust and intake vents are

not blocked. The intake combustion air and

the exhaust gases must be expelled to the

outside. Have a qualified service person clean

dirt and loose debris from vents annually.

GASKETS

Inspect all gaskets. If any gaskets show

signs of leakage or damage, replace them.

Safe operation of furnace depends on all

gaskets being tight.

FRONT COVER

Remove anything that may be blocking the

air to the louvers of the front cover.

COMBUSTION CHAMBER

AND MAIN BURNER

Check flame pattern of main burner often

(see Inspecting Burner Flame, page 13).

Have combustion chamber and main burner

cleaned if you have run the furnace with a

high yellow flame. Incomplete combustion

from lack of air causes the yellow flame.

This deposits soot inside the combustion

chamber and on the burner. Contact a qualified service person to clean combustion

chamber and main burner.

OUTSIDE VENT CAPS

Inspect outside vent caps for obstructions or

soot. If soot is found, do not use furnace.

Contact a qualified service person to clean

furnace.

14

201842

OWNER’S MANUAL

TROUBLESHOOTING

Note:

All troubleshooting items are listed in

order of operation.

OBSERVED PROBLEM

No heat

POSSIBLE CAUSE

1. Thermostat off

2. Gas supply

3. Electrical connections and power

4. Motor

5. Malfunctioning microswitch

6. Gas valve

WARNING: Turn off and unplug furnace and let cool before servicing. Unless you need gas supply for testing, shut off equipment shutoff

valve before servicing. Only a qualified service person should service

and repair furnace.

REMEDY

1. Check to be sure thermostat is calling for heat.

Wire to thermostat could be off terminal

2. Be sure equipment gas valve is in the open position (level or parallel to gas line)

3. Be sure all electrical connections are secure

4. Motor must be operating at top speed before

burner will come on. If blower is not operating

at top speed, check voltage supply (minimum

100 volts A.C.). If voltage supply is okay, check

for defective motor

5. Be sure the microswitch is sailing in far enough

to open the solenoid valve and to energize the

ignition control. If the switch is not sailing in,

clean any dust or dirt from the actuator pin. Other

reasons for the switch not sailing in are

A.Insufficient blower speed - Slow motor due to

faulty motor or lint and dust accumulation on

the blower wheels or restriction of return air to

the furnace

B. Faulty microswitch - Replace switch if cir-

cuit to ignition control is not completed when

switch is manually engaged. Switch should

also be replaced if blower motor running at

top speed fails to engage switch within six or

seven seconds.

bustion chamber must be pulled out. Follow

steps 1, 2, 3, 9 and 10 on page 8 to remove

combustion chamber

6. Within 20 seconds after motor reaches 75% of

its r.p.m. and microswitch engages, check the

following:

A. Voltage at valve - If current is present but

valve is not opening, check wire connections

B. If wire connections okay - Replace valve

C. No voltage at valve - Check circuit completion

through microswitch and limit switch as well

as wiring and wire connections. If no defects

are found, see Ignition Failures, page 16

Note:

T o service switch, com-

201842

Continued

15

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

TROUBLESHOOTING

Continued

OBSERVED PROBLEM

No heat (continued)

POSSIBLE CAUSE

7. Blower not operating

8. Short cycling (motor goes on and off)

REMEDY

7. A. Check power supply to furnace

B. Check electrical connections at furnace

C. W ith thermostat points closed, check for cir-

cuit completion at motor. If voltage is present,

replace motor. If no voltage is present at motor, check for:

• 24 volts on secondary coil or transformer. If

no voltage, replace transformer.

• If 24 volt transformer okay, check for circuit

completion across contacts on time delay

relay. Allow three to five seconds for contact to close

• If circuit across contacts okay, check conti-

nuity of wiring in motor circuit

8. A. Check thermostat. Contacts should remain

closed. If contacts are breaking:

• Check thermostat anticipator setting. It

should be between .75 and 1.0

• If anticipator setting okay, check amp draw

across thermostat. If amp draw exceeds .65,

check amp draw across coil of valve and time

delay relay.

bar, there is a momentary surge of approximately 4.0 amps

• If amp draw is within limits, check for shorts

in thermostat wiring

• If wiring is okay, replace thermostat

Note:

On initial operation of glo

IGNITION FAILURES

WARNINGS:

• Never connect unit or ignition

circuit to 230 volts.

• Never operate unit with glo bar

touching burner or any other

ground. Damage to ignition

control will occur.

• Be sure sensor probe never

touches glo bar. This will damage ignition control.

• If the ignition control is defective, it must be replaced. It is

not field-repairable.

CAUTION: Do not attempt to

repair the ignition control. This

may alter it and cause it to operate incorrectly.

The electronic system is made up of two

parts: the ignition control and the glo bar.

The ignition control is the brain of the electronic system. It has several functions:

1. When the blower reaches full r.p.m., a

24-volt circuit is completed to the ignition control. (Check across yellow

and orange wires.)

2. The red and blue wires at the ignition

control are the 120-volt input for the

glo-bar circuit. When the 24-volt circuit is completed, the ignition control

will complete the 120-volt circuit to the

glo bar and it begins to glow. (Check

this circuit across the two white wires

at the ignition control.)

3. After approximately 20 seconds, a 24volt circuit is completed through the ignition control to the gas valve. (This circuit is checked from brown wire at ig-

16

nition control to a neutral ground.) This

circuit opens the valve, gas flows to the

burner and is ignited by the heat from

the glo bar.

4. When the burner flame is established,

the sensing probe will sense the presence of burner flame and open the globar circuit. The glo bar will then stop

glowing.

It is important to determine the type of

problem being experienced. Then the proper

checkout procedure can be made. The following is a list of problems, how to identify

in which area the problem is located, and

how to correct it.

Note:

Glo bar remains on.

201842

TROUBLESHOOTING

Continued

OBSERVED PROBLEM

Ignition failures

POSSIBLE CAUSE

1. Glo bar will not glow - with blower running and microswitch engaged

2. Glo bar glows but burner will not

come on

3. Glo bar operating and gas valve opening but burner will not light

4. If the ignitor remains on after main

burner ignition or the valve chatters, reverse the 120-volt A.C. connections at

the wall receptacle

OWNER’S MANUAL

REMEDY

1. Check the following:

A. Check for 24 volts A.C. across yellow and

orange wires at ignition control. If no voltage, check microswitch and limit switch for

circuit completion as well as wiring and wiring connections

B. V oltage present across yellow and orange wires,

check for 120-volt input to ignition control

across red and blue wires. If no voltage, check

wiring all the way back to power supply

C. 120 volts present across red and blue wires,

check for 120 volts across the two white wires

at ignition control. If no voltage, replace ignition control

D. Voltage present across the two white wires,

check wiring and wire connections to glo bar

E. If wiring and wire connections okay, replace

glo bar. (Glo bar broken)

2. A. Check for voltage (24 volts A.C.) at valve

40 seconds after glo bar begins to glow. If

voltage present but valve not opening, replace

valve

B. If no voltage at valve, check brown wire at

ignition control for continuity and good connection

C. If wire and wire connections okay, replace

ignition control

3. A. Check gas flow through burner. If no gas is

coming through burner, check for obstruction in gas line, main burner orifice, or main

burner

B. If thermostat okay, check for 24 volt A.C.

circuit completion across yellow and orange

wires at ignition control. If no voltage, check

for circuit completion through limit switch

and microswitch

C. If voltage is present at ignition control across

yellow and orange wires yet burner continues to go off, replace ignition control

4. A. If polarity is okay yet burner continues to go

off, check thermostat to be sure it is still completing the valve circuit. If not, check for

excessive amp draw in valve circuit

B. If thermostat okay, check for 24 volt A.C.

circuit completion across yellow and orange

wires at ignition control. If no voltage, check

for circuit completion through limit switch

and microswitch

C. Voltage present at ignition control across

yellow and orange wires yet burner continues to go off, replace ignition control

Continued

201842

17

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

TROUBLESHOOTING

Continued

OBSERVED PROBLEM

Ignition failures

Excessive noise

Main burner will not cycle off

Furnace will not operate

POSSIBLE CAUSE

5. Burner cycles off and glo bar comes on

immediately, check the following:

1. Blower out of balance

2. Motor hums

1. Thermostat setting

2. Gas valve stuck open

1. Wiring connections or shorts

REMEDY

5. A. Check flame sensing probe. Be sure

probe is positioned in the burner

flame and glowing cherry red. Check

wire and wire connections at probe

and ignition control

B. If wire and wire connections okay,

check for voltage across brown and

orange wires at ignition control. If

no voltage, replace ignition control

C. If voltage present, check wiring and

wire connections at valve

D. If wire and wire connections okay,

replace valve

1. Replace blower

2. Replace motor

1. Check thermostat

2. Check gas valve. If stuck open, replace.

Do not attempt to repair valve!

1. Check all wiring to assure proper con-

nection or detect possible shorts

18

201842

OWNER’S MANUAL

WIRING DIAGRAMS

Limit

Switch

Orange

Blue

Yellow

Brown

Gas Valve

Yellow

White

Limit

Switch

★★

Brown

Brown

Gas Valve

Brown

White

Black

Green

115 V.A.C.

▲White

Transformer

White

Junction

Box

Black

White

Black

Thermostat

Red

White

Brown

Motor

White

Terminal Block

370 V.A.C.

Capacitor

5 MFD

Brown

Brown

Green

Black

Note:

Black

▲

♦

Time Delay

Relay

Red Black

Figure 20 - Wiring Diagram (25,000 BTU/Hr Model)

Black

Green

115 V.A.C.

▲White

Transformer

Junction

Box

Black

White

Red

Thermostat

White

White

Brown

Motor

White

Terminal Block

Black

370 V.A.C.

White

White

Green

Black

Capacitor

5 MFD

Brown

Note:

Red Black

Time Delay

Relay

Black

Blue

Sail Switch

Sail Switch

Orange

Green

Brown

Yellow

White

Green

Brown

Yellow

White

Black

♦Black

White

White

Black

♦Black

White

White

1

2

3

4

5

6

7

Probe

1

2

3

4

5

6

7

Probe

Ignition

Control

Board

(Open)

Glo-Bar

Ignition

Control

Board

(Open)

Glo-Bar

REPLACEMENT

PARTS

Note:

Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

All parts listed herein may be ordered from

your equipment supplier.

When ordering repair parts, always give the

following information:

• model number of your furnace

• type of gas, natural or propane/LP

• the replacement part number and de-

scription

SERVICE HINTS

When Gas Pressure Is Too Low

• glo-bar glows, but burner will not ignite

When Gas Quality Is Bad

• burner will not stay lit

• burner will produce flames and soot

You may feel your gas pressure is too low or

gas quality is bad. If so, contact your local

gas supplier.

TECHNICAL

SERVICE

You may have further questions about installation, operation, or troubleshooting. If

so, contact your installer, a qualified service

person, or Williams Technical Help Line at

1-800-266-0993.

★

▲

♦

Figure 21 - Wiring Diagram (40,000 BTU/Hr Model)

201842

19

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

ILLUSTRATED

PARTS LIST

CABINET ASSEMBLY

25,000 BTU/HR MODEL

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

8

5

SOLID STATE IGNITION

50 60 70 80 90

6

7

4

50 60 70 80 90

1

2

3

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 030643 Front Cover Assembly 1

2 121520 Screw, #8 x 3/8" ** 2

3 191240 Front Cover Trim* 1

4 160912 Thermostat 1

5 100892 Cabinet Assembly 1

6 070509 Cabinet Insulation (right and left sides) 1

7 121224 Screw, #10 x 3/4" ** 4

8 062242 Thermostat Mounting Plate 1

∆ 070542 Cabinet Insulation (back) 1

∆ 070508 Cabinet Insulation (top) 1

∆ 191244 Operating Instructions Decal (English) 1

∆ 191246 Operating Instructions Decal (French) 1

∆ 531010 Warning Decal 1

∆ 191293 Nameplate 1

∆ Parts available, not shown.

* You must order nameplate and operating instructions decal separately.

** Standard hardware, can be picked up at local hardware store.

20

201842

OWNER’S MANUAL

ILLUSTRATED

PARTS LIST

CABINET ASSEMBLY

40,000 BTU/HR MODEL

10

8

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

5

9

6

4

1

7

2

3

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 280498 Bottom Shield 1

2 121520 Screw, #8 x 3/8" ** 2

3 191241 Front Cover Trim* 1

4 030642 Front Cover Assembly 1

5 100896 Cabinet Assembly 1

6 070511 Cabinet Insulation (right and left sides) 1

7 120158 Screw, #8 x 3/8" ** 2

8 160912 Thermostat (includes 2 screws) 1

9 121224 Screw, #10 x 3/4" ** 4

10 062242 Thermostat Mounting Plate 1

∆ 070541 Cabinet Insulation (back) 1

∆ 070510 Cabinet Insulation (top) 1

∆ 191245 Operating Instructions Decal (English) 1

∆ 191247 Operating Instructions Decal (French) 1

∆ 531010 Warning Decal 1

∆ 191293 Nameplate 1

∆ Parts available, not shown.

* You must order nameplate and operating instructions decal separately.

** Standard hardware, available at local hardware store.

201842

21

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

ILLUSTRATED

PARTS LIST

COMBUSTION CHAMBER

ASSEMBLY

25,000 BTU/HR MODEL

24

21

22

26

19

7

27

25

22

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

11

15

16

18

17

14

7

3

1

2

4

12

13

23

6

5

13

8

20

13

10

9

1

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 121357 Screw, #6 x 5/8" ** 4

2 231955 Wire Harness and

Ignition Control 1

3 062461 Ignition Control Mounting

Bracket 1

4 121372 Screw, #6 x 1/2" ** 2

5 230625 Time Delay Relay 1

6 230218 Bushing 1

7 120158 Screw, #8 x 3/8" ** 4

8 230825 Limit Switch 1

9 231144 Terminal Block 1

10 121224 Screw, #10 x 3/4" ** 2

11 070487 Gasket 1

12 231143 Transformer Assembly 1

13 121252 Screw, #10 x 3/8" ** 6

** Standard hardware, available at your local hardware store.

KEY PART

NO. NUMBER DESCRIPTION QTY.

14 020983 Combustion Chamber/

Heat Shield Assembly 1

15 070606 Heat Shield Gasket 1

16 070398 Burner Access Door Gasket 1

17 290141 Cover Plate 1

18 310026 Glass Disc 1

19 030893 Burner Access Door 1

20 230844 Bushing with Terminals 1

21 231950 Flame Sensing Probe 1

22 121502 Screw, #6 x 3/8" ** 2

23 090211 Junction Box Cover 1

24 121388 Screw, #10 x 1/2" ** 4

25 063018 Glo-Bar Retainer 1

26 100980-01 Glo-Bar 1

27 070909 Glo-Bar Gasket 1

22

201842

OWNER’S MANUAL

ILLUSTRATED

PARTS LIST

COMBUSTION CHAMBER

ASSEMBLY

40,000 BTU/HR MODEL

22

21

20

23

16

26

25

4

27

20

16

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

21

22

19

4

31

14

13

12

6

4

8

9

7

5

11

3

1

2

1

24

28

16

16

30

29

18

17

16

29

15

16

10

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 121502 Screw, #6 x 3/8" ** 2

2 231950 Flame Sensing Probe 1

3 063018 Glo-Bar Retainer 1

4 120158 Screw, #8 x 3/8" ** 6

5 030891 Burner Access Door 1

6 121388 Screw, #10 x 1/2" 4

7 310026 Glass Disc 1

8 290141 Cover Plate 1

9 070398 Burner Access Door Gasket 1

10 100980-01 Glo-Bar 1

11 070909 Glo-Bar Gasket 1

12 230844 Bushing with Terminals 1

13 070607 Heat Shield Gasket 1

14 020982 Combustion Chamber/Heat

Shield Assembly 1

15 061663 Wire Clamp 2

16 121252 Screw, #10 x 3/8" ** 12

17 230560 Limit Switch 1

** Standard hardware, available at your local hardware store.

201842

23

KEY PART

NO. NUMBER DESCRIPTION QTY.

18 062563 Ignition Control Mounting

Bracket 1

19 231954 Wire Harness and

Ignition Control 1

20 121357 Screw, #6 x 5/8" ** 4

21 121224 Screw, #10 x 3/4" ** 4

22 070487 Gasket 2

23 121372 Screw, #6 x 1/2" ** 2

24 231144 Terminal Block 1

25 230625 Time Delay Relay 1

26 231164 Transformer Assembly 1

27 062837 Transformer and Relay

Mounting Bracket 1

28 062694 Wire Clamp, 5/8" Diameter 5

29 230555 Strain Relief Bushing 2

30 090211 Junction Box Cover 1

31 121577 Screw, #10 x 1/4" ** 2

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

ILLUSTRATED

PARTS LIST

BURNER ASSEMBLY

25,000 BTU/HR MODEL

2

1

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

4

5

3

6

12

7

9

8

10

11

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 120717 Hex Nut, #10-24 ** 2

2 121459 Screw, #10-24 x 1/2" ** 2

3 010701 Burner Assembly 1

4 180220 Main Burner Orifice 1

5 121388 Screw, #10 x 1/2" ** 4

6 070408 Manifold Gasket 1

7 171174 Manifold Assembly 1

8 170545 Reducer Fitting, 3/8" NPT to 1/8" NPT ** 1

9 160968 Valve 1

10 170012 90° Street Elbow ** 1

11 171170 Gas Inlet Pipe 1

12 170082 90° Elbow ** 1

** Standard hardware, available at your local hardware store.

24

201842

OWNER’S MANUAL

ILLUSTRATED

PARTS LIST

BURNER ASSEMBLY

40,000 BTU/HR MODEL

2

1

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

5

4

6

6

3

12

13

7

8

9

10

11

201842

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 120717 Hex Nut, #10-24 ** 4

2 010621 Left Burner Assembly 1

3 010623 Right Burner Assembly 1

4 070591 Manifold Gasket 1

5 171167 Manifold Assembly 1

6 180189 Main Burner Orifice 2

7 121388 Screw, #10 x 1/2" ** 6

8 160968 Valve 1

9 170012 90° Street Elbow ** 1

10 171170 Gas Inlet Pipe 1

11 121388 Screw, #10 x 1/2" ** 1

12 062694 Gas Inlet Pipe Clamp 1

13 170082 90° Elbow ** 1

** Standard hardware, available at your local hardware store.

25

THE COMFORT PRODUCTS PEOPLE

DIRECT-VENT NATURAL GAS HEATER

ILLUSTRATED

PARTS LIST

BLOWER ASSEMBLY

25,000 BTU/HR MODEL

3

2

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

23

21

25

24

14

17

16

4

6

8

15

5

7

23

17

17

12

13

11

19

18

22

20

1

9

10

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 350086 Room Air Wheel 1

2 121252 Screw, #10 x 3/8" ** 5

3 121247 Screw, #2-56 x 5/8" ** 2

4 230510 Microswitch Assembly 1

5 070537 Intake Tube Gasket 1

6 121661 Tinnerman Nut 2

7 390260 Blower Housing (room air) 1

8 121421 Hex Lock Nut, #10-24 ** 3

9 050751 Crossover Tube 1

10 121388 Screw, #10 x 1/2" ** 4

11 070385 Crossover Tube Gasket 2

12 121227 Screw, #10-24 x 1/2" ** 2

13 070362 Universal Bushing 1

14 231231 Capacitor Boot 1

15 390296 Combustion Air and Motor

Cover Assy. Housing 1

∆ Part available, not shown.

** Standard hardware, available at your local hardware store.

KEY PART

NO. NUMBER DESCRIPTION QTY.

16 070386 Combustion Air Housing

Gasket 1

17 231389 Motor with Bushings 1

18 062307 Motor Support Bracket 1

19 120717 Hex Nut, #10-24 (keps) ** 2

20 121712 Tinnerman 1

21 350117 Combustion Air Wheel 1

22 390240 Combustion Air Housing

(outside) 1

23 120615 Screw, #8 x 1/2" ** 10

24 231036 Capacitor 1

25 062633 Capacitor Clamp 1

∆ 161093 Equipment Shutoff Valve 1

26

201842

OWNER’S MANUAL

ILLUSTRATED

PARTS LIST

BLOWER ASSEMBLY

40,000 BTU/HR MODEL

2

5

3

This list contains replaceable parts used in your furnace. When ordering parts, follow the

instructions listed under Replacement Parts on page 19 of this manual.

2

20

10

21

6

2

11

22

7

8

4

1

14

9

13

15

19

18

12

25

24

17

16

27

24

26

5

23

28

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 070570 Combustion Air Cover

Gasket 1

2 121252 Screw, #10 x 3/8" ** 8

3 350088 Room Air Wheel

(CW Rotation) 1

4 390328 Room Air Blower Housing

(left side) 1

5 120717 Hex Nut, #10-24 (keps) ** 5

6 121661 Tinnerman Nut 2

7 230681 Microswitch Assembly 1

8 121247 Screw, #2-56 x 5/8" ** 2

9 070537 Intake Tube Gasket 1

10 120615 Screw, #8 x 1/2" ** 1

11 390205 Combustion Air Cover Assy. 1

12 121388 Screw, #10 x 1/2" ** 3

13 070420 Combustion Air Crossover

Gasket 1

14 390318 Combustion Air and Motor

Cover Assembly 1

KEY PART

NO. NUMBER DESCRIPTION QTY.

15 121227 Screw, #10-24 x 1/2" ** 2

16 070362 Universal Bushing 1

17 070406 Combustion Air Housing

Gasket 1

18 120158 Screw, #8 x 3/8" ** 10

19 061663 Wire Clamp 1

20 231036 Capacitor 1

21 062691 Capacitor Clamp 1

22 231231 Capacitor Boot 1

23 350087 Room Air Wheel

(CCW Rotation) 1

24 231136 Motor with Bushings 1

25 062307 Motor Support Bracket 1

26 070165 Motor Gasket 1

27 350085 Combustion Air Wheel 1

28 390201 Room Air Blower Housing

(right side) 1

∆ 161093 Equipment Shutoff Valve 1

∆ Part available, not shown.

** Standard hardware, available at your local hardware store.

201842

27

WARRANTY INFORMATION