WILLETT 430 Service Manual

430 Ink Jet Printer

Service Manual

THE WORLD'S CODING AND LABELLING COMPANY

Contents

Issue 2

i

Part No. 306-0430-102

C

ONTENTS

PREFACE............................................................................................................................................................. VII

Introduction......................................................................................................................................................... vii

Conventions ....................................................................................................................................................... vii

Positional References..................................................................................................................................... vii

Units of Measurement .................................................................................................................................... vii

Typography..................................................................................................................................................... vii

Applicable Standards ......................................................................................................................................... vii

Installation and Inspection................................................................................................................................. viii

Mains Power Supply...................................................................................................................................... viii

Grounding...................................................................................................................................................... viii

Restrictions.......................................................................................................................................................... ix

Acknowledgements ............................................................................................................................................. ix

Associated Publications ......................................................................................................................................ix

Contact Information ............................................................................................................................................. ix

Labelling ............................................................................................................................................................... x

Hazard Information..............................................................................................................................................xi

Warning Notices ..............................................................................................................................................xi

Caution Notices ............................................................................................................................................. xiii

INSTALLATION.......................................................................................................................................................1

Introduction...........................................................................................................................................................1

Unpacking ............................................................................................................................................................2

Commissioning.....................................................................................................................................................3

Access ..............................................................................................................................................................3

Preparation for Use ..........................................................................................................................................4

Passwords ........................................................................................................................................................9

Setting up Shifts ...................................................................................................................................................9

Production Line Setup........................................................................................................................................10

Typical Installation ..........................................................................................................................................10

Throw Distance ..................................................................................................................................................11

Shaft Encoder.....................................................................................................................................................11

Internal Source ...............................................................................................................................................11

External Source ..............................................................................................................................................11

Product Sensors.................................................................................................................................................13

CONSUMABLES...................................................................................................................................................15

Ink and Solvent Storage.....................................................................................................................................15

FIRMWARE DOWNLOAD ....................................................................................................................................17

Introduction.........................................................................................................................................................17

Requirements .....................................................................................................................................................17

Windows 3.xx Procedure ...................................................................................................................................17

Checking the Communications Link ...............................................................................................................17

Windows 95/98 Procedure .................................................................................................................................18

Checking the Communications Link ...............................................................................................................18

Using Microsoft Windows 3.xx to Download Firmware ..................................................................................20

Using Microsoft Windows 95 or 98 to Download Firmware............................................................................21

Boot Monitor Recovery Procedure .................................................................................................................23

SYSTEM CALIBRATION AND TEST ...................................................................................................................25

Introduction.........................................................................................................................................................25

Earth Continuity Test..........................................................................................................................................25

Machine Power-Up.............................................................................................................................................26

Pump Zero Offset Calibration.............................................................................................................................26

Cooling Fan Check.............................................................................................................................................26

430 Ink Jet Printer Service and Maintenance Manual

ii

Issue 2

Part No. 306-0430-102

I/O Board LED Check ........................................................................................................................................ 27

Voltage Checks.................................................................................................................................................. 28

Reset Run Hours ............................................................................................................................................... 28

Gutter Fault and Charge Error Disable.............................................................................................................. 29

Set EHT Range (preliminary settings for printhead and EHT table setup)........................................................ 29

Set EHT Trip Level (for printhead setup only) ................................................................................................... 29

Filling the Ink System......................................................................................................................................... 30

Fluid Identification Number (FIN)....................................................................................................................... 31

Fill Mixer Tank ................................................................................................................................................... 31

Calibrate 285 V Rail........................................................................................................................................... 32

VMS Calibration................................................................................................................................................. 32

Nozzle Flush ...................................................................................................................................................... 33

Strobe LED Check ............................................................................................................................................. 33

Ink Jet Alignment ............................................................................................................................................... 33

Head Heater Temperature and Ink Pressure .................................................................................................... 34

Modulation Calibration (Manual)........................................................................................................................ 35

Phase Profile Adjustment ..................................................................................................................................37

Phase Offset Calibration.................................................................................................................................... 37

Print Charge Value Calibration .......................................................................................................................... 37

Setting EHT Tables for Printing ......................................................................................................................... 38

Clean Shutdown Check ..................................................................................................................................... 38

Set EHT Trip Level (Normal Operation) ............................................................................................................ 39

EHT Trip Test .................................................................................................................................................... 39

Print Height Test ................................................................................................................................................ 39

Restore Calibration Parameters ........................................................................................................................40

Enable Gutter Detect and Charge Check .......................................................................................................... 40

Ink Viscosity Measurement................................................................................................................................ 41

Temperature/Viscosity Graphs ...................................................................................................................... 41

CIJ MK 390ID Black....................................................................................................................................... 41

CIJ MK 3903F Red ........................................................................................................................................ 42

CIJ MK 3930F Black ......................................................................................................................................42

CIJ EA 3969H Black ...................................................................................................................................... 43

TECHNICAL DESCRIPTION................................................................................................................................ 45

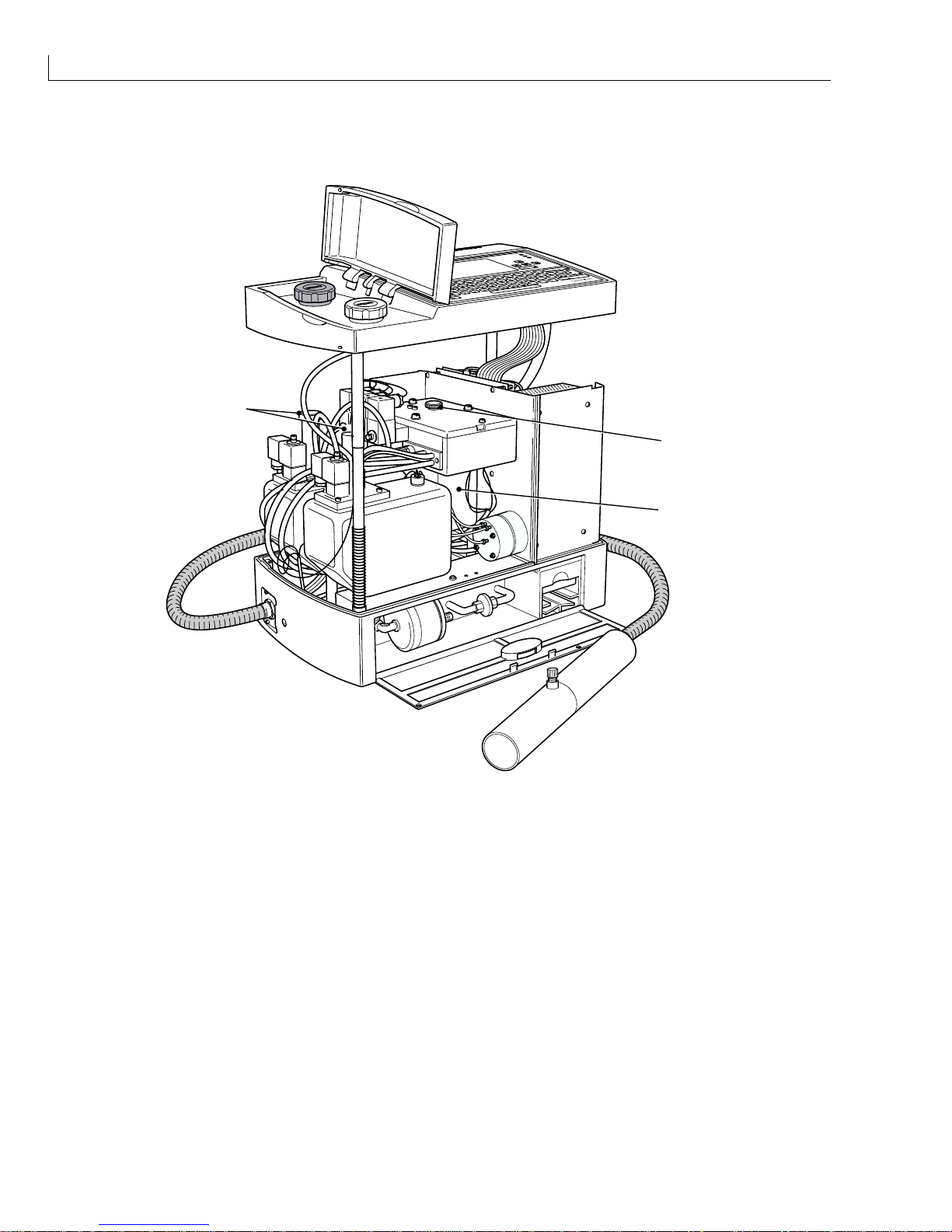

Main Assemblies................................................................................................................................................ 46

Cabinet .............................................................................................................................................................. 46

Top Cover ...................................................................................................................................................... 46

Side Covers.................................................................................................................................................... 47

Base ............................................................................................................................................................... 47

Printhead ........................................................................................................................................................... 48

Construction ................................................................................................................................................... 49

Electronics System ............................................................................................................................................ 51

Control Panel .................................................................................................................................................51

Connector Panel ............................................................................................................................................ 53

Control Electronics............................................................................................................................................. 55

General .......................................................................................................................................................... 55

CPU Board ..................................................................................................................................................... 56

I/O Board........................................................................................................................................................ 62

Ink Pump Motor Driver Board ........................................................................................................................ 74

PSU Board......................................................................................................................................................... 77

General Specification..................................................................................................................................... 77

Output Specification....................................................................................................................................... 77

Electronics Modules........................................................................................................................................... 78

EHT Module ................................................................................................................................................... 78

Electronics Compartment Cooling Fan .......................................................................................................... 78

Ink System Pump........................................................................................................................................... 78

Mains Input Circuit ......................................................................................................................................... 79

Contents

Issue 2

iii

Part No. 306-0430-102

Ink System..........................................................................................................................................................80

General ...........................................................................................................................................................80

Solenoid Valves..............................................................................................................................................81

V1 Solvent Top-up Valve (located at the solvent top-up reservoir) ............................................................81

V2 Ink Top-up Valve (located at the ink reservoir)......................................................................................81

V3 VMS Diverter Valve (located on the FMS ink system) ..........................................................................81

V6 Feed Valve (located on the FMS ink system)........................................................................................81

V7 Flush Valve (located on the FMS ink system) .......................................................................................81

V8 Gutter Valve (located on the FMS ink system)......................................................................................82

V11 Jet Valve (located in the printhead).....................................................................................................82

V12 Bleed Valve (located in the printhead) ................................................................................................82

Top Up and Ink Reservoirs.............................................................................................................................82

Ink System Filters ...........................................................................................................................................82

Main System Filter (located inside the filter compartment).........................................................................82

Pre Pump Filter (located inside the filter compartment) .............................................................................83

Pre Head Filter (located below the FMS printhead connection manifold) ..................................................83

Nozzle Filter (located behind the nozzle in the printhead)..........................................................................83

Flush Filter (located near flush pump) ........................................................................................................83

VMS Filter (located inside FMS top box) ....................................................................................................83

Fluid Management System (FMS)..................................................................................................................84

Viscosity Monitoring System (VMS) Chamber (located inside the FMS top box).......................................84

Venturi (Jet Pump) (located inside the FMS top box) .................................................................................85

Pressure Transducer (located on the FMS connect manifold) ...................................................................85

Ink System Pump (located in the base of the machine) .............................................................................85

Flush Pump (located close to the FMS)......................................................................................................85

Printhead Operation ...........................................................................................................................................86

Ink Jet Information ..........................................................................................................................................86

Droplet Charging ............................................................................................................................................86

Droplet Deflection ...........................................................................................................................................87

Ink System Operation.........................................................................................................................................88

Function ..........................................................................................................................................................88

Operation........................................................................................................................................................88

Viscosity Monitoring System Sequence .........................................................................................................89

Clean Start Jet Sequence...............................................................................................................................91

Quick Start Jet Sequence...............................................................................................................................93

Clean Stop Jet Sequence...............................................................................................................................94

Quick Stop Jet Sequence ...............................................................................................................................96

Nozzle Flush ...................................................................................................................................................96

Ink Addition to Mixer Tank ..............................................................................................................................97

Top Up Addition to Mixer Tank .......................................................................................................................98

SYSTEM SOFTWARE...........................................................................................................................................99

Introduction.........................................................................................................................................................99

Using the Menus.............................................................................................................................................99

Messages Menu ...............................................................................................................................................100

Editor Menu ......................................................................................................................................................101

User Fields Menu .............................................................................................................................................101

Print Menu ........................................................................................................................................................102

Password Menu................................................................................................................................................102

System Menu ...................................................................................................................................................103

Configure Menu................................................................................................................................................105

Calibrate Menu .................................................................................................................................................106

Data Logging Menu ..........................................................................................................................................108

DISASSEMBLY AND ASSEMBLY.....................................................................................................................109

Introduction.......................................................................................................................................................109

430 Ink Jet Printer Service and Maintenance Manual

iv

Issue 2

Part No. 306-0430-102

I/O Board ......................................................................................................................................................... 110

Removal ....................................................................................................................................................... 110

Installation .................................................................................................................................................... 111

Calibration .................................................................................................................................................... 111

CPU Board....................................................................................................................................................... 112

Removal ....................................................................................................................................................... 112

Installation .................................................................................................................................................... 112

Power Supply Unit ........................................................................................................................................... 113

Removal ....................................................................................................................................................... 113

Installation .................................................................................................................................................... 113

PSU Module Fuse Replacement.................................................................................................................. 114

LCD and Backlight ........................................................................................................................................... 115

Removal ....................................................................................................................................................... 115

Installation .................................................................................................................................................... 116

Keypad............................................................................................................................................................. 116

Removal ....................................................................................................................................................... 116

Installation .................................................................................................................................................... 116

Ink and Top Up Reservoir Sensor ................................................................................................................... 117

Removal ....................................................................................................................................................... 117

Installation .................................................................................................................................................... 117

Exchanging the Sensor and LED................................................................................................................. 117

Mains Inlet Connector...................................................................................................................................... 119

Removal ....................................................................................................................................................... 119

Installation .................................................................................................................................................... 120

Mains Switch.................................................................................................................................................... 120

Removal ....................................................................................................................................................... 120

Installation .................................................................................................................................................... 120

Fluid Management System (FMS)................................................................................................................... 121

Removal ....................................................................................................................................................... 121

Installation .................................................................................................................................................... 122

Ink System Pump............................................................................................................................................. 123

Removal ....................................................................................................................................................... 123

Installation .................................................................................................................................................... 124

Main Filter ........................................................................................................................................................ 125

Removal ....................................................................................................................................................... 125

Installation .................................................................................................................................................... 125

Flush Pump...................................................................................................................................................... 126

Removal ....................................................................................................................................................... 126

Installation .................................................................................................................................................... 126

Solenoid Valves ............................................................................................................................................... 127

Removal ....................................................................................................................................................... 127

Installation .................................................................................................................................................... 127

Fan................................................................................................................................................................... 128

Removal ....................................................................................................................................................... 128

Installation .................................................................................................................................................... 128

Fan Failure Card.............................................................................................................................................. 129

Removal ....................................................................................................................................................... 129

Installation .................................................................................................................................................... 129

EHT Module..................................................................................................................................................... 130

Removal ....................................................................................................................................................... 130

Installation .................................................................................................................................................... 130

Head Manifold.................................................................................................................................................. 131

Removal ....................................................................................................................................................... 131

Installation .................................................................................................................................................... 132

Phase Detector ................................................................................................................................................ 133

Removal ....................................................................................................................................................... 133

Installation .................................................................................................................................................... 134

Contents

Issue 2

v

Part No. 306-0430-102

EHT Block ........................................................................................................................................................135

Removal........................................................................................................................................................135

Installation.....................................................................................................................................................136

Nozzle Assembly..............................................................................................................................................137

Removal........................................................................................................................................................137

Installation.....................................................................................................................................................138

RS232 Jumper .................................................................................................................................................139

Installation.....................................................................................................................................................139

Removal........................................................................................................................................................139

Umbilical...........................................................................................................................................................141

PREVENTATIVE MAINTENANCE SCHEDULE.................................................................................................143

TROUBLESHOOTING ........................................................................................................................................145

Introduction.......................................................................................................................................................145

Fault Finding.....................................................................................................................................................146

Printer Fails to Initialise ................................................................................................................................146

Display Faults...................................................................................................................................................149

Backlight .......................................................................................................................................................149

Display ..........................................................................................................................................................150

Keypad Faults...............................................................................................................................................150

Display Icons ....................................................................................................................................................151

Mixer Tank Level High..................................................................................................................................155

CLEANING AND ADJUSTMENT........................................................................................................................157

Valve Cleaning .................................................................................................................................................157

VMS Inlet Restrictor Cleaning ..........................................................................................................................158

VMS Outlet Cleaning........................................................................................................................................159

Umbilical Purge ................................................................................................................................................160

Printhead Alignment.........................................................................................................................................161

ILLUSTRATED PARTS LIST..............................................................................................................................165

How to Use This Parts List ...............................................................................................................................165

Optional Parts and Accessories .......................................................................................................................165

430 Ink Jet Printer ............................................................................................................................................166

Stand and Traffic Light System ........................................................................................................................167

Options and Accessories .................................................................................................................................168

General Spare Parts and Tools........................................................................................................................169

Documentation .................................................................................................................................................169

Major Sub-Assemblies .....................................................................................................................................170

Top Moulding Ink System Components ...........................................................................................................171

Top Moulding, Keypad and LCD ......................................................................................................................172

Baffle Plate Assembly ......................................................................................................................................174

Printhead Assembly .........................................................................................................................................175

Base Moulding and Cabinet .............................................................................................................................177

Mains Plate Assembly ......................................................................................................................................179

Ink System........................................................................................................................................................181

APPENDIX B ...........................................................................................................................................................1

Earlier 430 Model .................................................................................................................................................1

Ink System............................................................................................................................................................1

General .............................................................................................................................................................1

Flush Tank............................................................................................................................................................2

Removal............................................................................................................................................................2

Installation.........................................................................................................................................................2

Earlier 430 Illustrated Parts List ...........................................................................................................................3

Ink System ........................................................................................................................................................3

430 Ink Jet Printer Service and Maintenance Manual

vi

Issue 2

Part No. 306-0430-102

Preface

Issue 2

vii

Part No. 306-0430-102

P

REFACE

Introduction

Welcome to the Service Manual for the Willett 430 Inkjet printer.

This manual is intended as a reference guide for trained service personnel and contains the following

information:

•

installation and calibration instructions;

•

disassembly and reassembly instructions for field-replaceable components;

•

a technical description of the principles of operation of the printer;

•

a troubleshooting guide;

•

a quick reference guide to the control software which describes the function of each menu item.

Conventions

Positional References

Unless stated to the contrary, positions and directions such as left, right, front, rear, clockwise and anticlockwise

are given with respect to the printer when viewed from the front.

Units of Measurement

This handbook uses SI units of measurement and their imperial equivalents.

Typography

The names of menu options are presented in

bold

typeface. Cross-references are presented on

bold, italic

typeface.

Applicable Standards

Willett Limited is a BS5750/ISO9000 approved company (certification number FM14003 dated 9 December

1991).

The 400 Series Continuous Ink Jet (CIJ) printers conform to the following legislation:

EN55022: 1987 - Emissions.

IEC801: parts 2 to 6 inclusive - Immunity standards.

Machinery directive 89/392/EEC - Essential health and safety.

BS5304 - Machinery design.

EN60204 (BS2771) - Electrical safety in machinery.

EN292: 1991 - Safety of machinery.

EN60950 - Safety standards of Information Technology (IT) equipment.

430 Ink Jet Printer Service and Maintenance Manual

viii

Issue 2

Part No. 306-0430-102

Installation and Inspection

The equipment described in this handbook must be installed and subsequently inspected at the recommended

intervals by qualified service and maintenance personnel.

Mains Power Supply

Ensure that the mains electrical supply is within the range indicated by the label adjacent to the mains inlet on

the printer. If the voltage ratings differ, do not use the printer until you have consulted your local supplier.

Use only the mains power cable supplied with the printer. This cable must terminate in an approved, three-pole,

mains plug which has a protective ground conductor.

Keep electrical power cables, sockets and plugs clean and dry at all times.

Grounding

The equipment must be connected only to an a.c. power supply, which has a protective ground conductor in

accordance with IEC requirements or applicable local regulations. Any interruption of the protective ground

conductor or disconnection of the protective ground terminal may render the apparatus dangerous.

Preface

Issue 2

ix

Part No. 306-0430-102

Restrictions

The information contained herein shall not be reproduced in whole or part without the manufacturer’s prior

written approval.

The manufacturer reserves the right to make changes in specifications and other information contained in this

document without prior notice. The reader should in all cases consult the manufacturer to determine whether

any such changes have been made.

Copyright © Willett Limited 2001.

Printed in the UK. March 2001.

Acknowledgements

The Willett name and Willett logo are trademarks of Willett Limited.

Associated Publications

Willett 430 Ink Jet Printer Instructions for Use

Part Number 306-0430-101.

Contact Information

Willett Limited

Cronin Road

Corby

Northamptonshire

NN18 8AQ

England

Phone +(44) 1536 400777

Fax +(44) 1536 400888

http://www.willett.com

430 Ink Jet Printer Service and Maintenance Manual

x

Issue 2

Part No. 306-0430-102

Labelling

The following labels appear on the 430 Ink Jet printer:

PRINT TRIGGER 1 SHAFT ENCODER

PRINT TRIGGER 2 STATUS O/P RID

I/O A I/O A COMM2

COMM 1

No smoking

or naked lights

Highly

flammable

SERIAL No.

DESIGNED AND MANUFACTURED BY

WILLETT SYSTEMS LTD. CORBY ENGLAND TEL: 01536 400777

WHOSE QUALITY SYSTEM IS REGISTERED BY BSI

TO ISO 9001 CERT No FM 14003

geprüfte

Sicherheit

TÜV

Rheinland

Product safety

UNDER CERTAIN OPERATING CONDITIONS

THERE COULD BE SOLVENT EMISSIONS

FROM THIS MACHINE.

ENSURE THAT THE MACHINE IS OPERATED

IN A WELL VENTILATED AREA AND IF

NECESSARY MONITOR CONCENTRATIONS

INTHE IMMEDIATE VICINITY.

W A R N I N G

OPERATING VOLTAGE

TENSION SECTEUR

BETRIEBSSPANNUNG

FREQUENCY

FREQUENCE

FREQUENZ

CURRENT

COURANT ASSIGNÉ

NENNSTROM

POWER

CONSOMMATION

NENNLEISTUNG

FUSES

FUSIBLES

SICHERUNG

110/230 Vac 1

50/60Hz

2A

160W

T5A/T3.15A

CAUTION : DOUBLE POLE/NEUTRAL FUSING

ATTENTION : PROTECTION BIPOLAIRE

ACHTUNG : 2-POLIG ABGESICHERT

ISOLATE THIS UNIT BEFORE MAKING

ANY INTERNAL ADJUSTMENTS

DEBRANCHER L'APPAREIL AVANT

TOUT INTERVENTION INTERNE

VOR ÖFFNEN DES GEHÄUSES

NETZSTECKER ZIEHEN

Ø

Preface

Issue 2

xi

Part No. 306-0430-102

Hazard Information

This section contains important hazard notices. You must read these notices before using the printer.

The hazard information is prioritised into typographically distinct warning and caution notices as follows:

WARNING NOTICES

Warning notices denote a potential hazard to the health and safety of users. These

notices clearly state the nature of the respective hazard and the means by

which it can be avoided.

Warning notices, together with the warning symbol shown on the left, appear in full in the

preliminary pages and at their points of application in the manual. They are presented in

the typographical style of this notice.

Caution Notices

Cautionary notices denote a potential hazard to the physical integrity of equipment/software but not a

danger to personnel. These notices clearly state the nature of the hazard and the means by

which it can be avoided.

Cautionary notices appear in full in the preliminary pages and at their points of application in the

manual. They are presented in the typographical style of this notice.

Warning Notices

WARNING - LETHAL VOLTAGES

Lethal voltages are present within this equipment when it is connected to the mains

electrical supply. Only trained and authorised personnel may carry out maintenance work.

Observe all statutory electrical safety codes and practices. Unless it is necessary to run

the printer, disconnect the printer from the mains electrical supply before removing the

covers or attempting any service or repair activity, otherwise death or

personal injury may result.

WARNING - HANDLING INK, SOLVENT AND TOP-UP

The ink, solvent and top-up are irritating to the eyes and respiratory system. To prevent

personal injury when handling these substances:

Always wear protective clothing and rubber gloves.

Always wear goggles with side-shields or a face mask. It is also advisable to wear safety

glasses when carrying out maintenance.

Apply barrier hand cream before handling ink.

If ink or top-up contaminates the skin, wash immediately with soapy water. DO NOT use

washdown or solvent to clean ink stains from the skin.

430 Ink Jet Printer Service and Maintenance Manual

xii

Issue 2

Part No. 306-0430-102

WARNING - RISK OF PERSONAL INJURY

To avoid spillage of ink or top-up, do not remove the foil seal from the bottle prior to

replenishing the ink or top-up reservoir.

WARNING - FIRE AND HEALTH HAZARD

The ink, solvent and top-up are volatile and flammable. They must be stored and handled

in accordance with local regulations.

Do not smoke or use a naked flame in the vicinity of these substances.

Immediately after use remove any tissue or cloths that become saturated with these

substances. Dispose of all such items in accordance with local regulations.

In the event that any ink, solvent or top-up container is not completely empty after use, it

should be resealed. Only full bottles are recommended for use when replenishing ink or

top ups; partially filled bottles should be disposed of in accordance with local regulations.

WARNING - WASTE INK

When setting up the nozzle, direct the ink stream into a beaker or suitable container. To

avoid contamination of the ink supply in the printer, do not re-use any ink collected in this

way. Dispose of all waste ink in accordance with local regulations.

WARNING - VAPOUR HAZARD

Prolonged breathing of top-up or cleaning fluid vapour may cause drowsiness and/or

effects similar to alcoholic intoxication. Use only in open, well-ventilated areas.

WARNING - FUSES FIRE HAZARD

To ensure continued protection against the risk of fire, replace fuses only with the

specified type and rating.

WARNING - TOXIC HAZARD

The cleaning agent is poisonous if taken internally. Do not drink. Seek medical attention

immediately if ingested.

WARNING - HANDLING CLEANING AGENT

The cleaning agent is irritating to the eyes and respiratory system. To prevent personal

injury when handling this substance:

Always wear protective rubber gloves and clothing.

Always wear goggles with side-shields or a face mask. It is also advisable to wear safety

glasses when carrying out maintenance.

Apply barrier hand cream before handling ink.

If cleaning agent contaminates the skin, rinse off with running water for

at least 15 minutes.

Preface

Issue 2

xiii

Part No. 306-0430-102

WARNING - FIRE AND HEALTH HAZARD

The cleaning agent is volatile and flammable. It must be stored and handled in accordance

with local regulations.

Do not smoke or use a naked flame in the vicinity of the cleaning agent.

Immediately after use remove any tissue or cloths that become saturated with cleaning

agent. Dispose of all such items in accordance with local regulations.

WARNING - PERSONAL INJURY

Airborne particles and substances are a health hazard. Do not use high pressure

compressed air for cleaning purposes.

WARNING - EARTH CONTINUITY

To ensure safe earthing the resistance between the mains lead earth wire and the test

points must be less than 1 Ω.

WARNING - INK/SOLVENT SPILLAGE HAZARD

Ensure that the top cover of the machine is lowered fully into the correct working position

and the filler tubes are correctly located in the ink/top up reservoir before continuing,

otherwise there is a risk of ink spillage.

WARNING - HANDLING INK, SOLVENT AND TOP-UP

A high ac voltage is present at the inverter and backlight.

Extreme caution is required when diagnosing failure in these areas.

Caution Notices

Caution - Equipment Damage

Only Willett trained personnel my carry out installation and maintenance work. Any such work

undertaken by unauthorised personnel may damage the printer and will invalidate the warranty.

Caution - Equipment Damage

Take care not to damage the printer base, internal components or wiring when removing or

refitting the side covers

Caution - Equipment Failure

Ensure that the top cover is lowered to the correct working position and that the filler tubes are correctly

located in the ink and solvent top-up reservoirs before proceeding.

Caution - Degraded Performance

Machine functions that only Willett trained personnel can access are set at Password Level 3

(MASTER password), these functions must not be given as customer options.

430 Ink Jet Printer Service and Maintenance Manual

xiv

Issue 2

Part No. 306-0430-102

Caution - Electrostatic Sensitive Devices

The printed circuit boards contain static sensitive devices. A suitably grounded, antistatic wrist strap

must be worn when working on or handling printed circuit boards.

Caution - False Readings

To avoid the risk of false readings, the pump zero offset should only be calibrated when there is no ink

in the system and the pump is off.

Caution - Print Quality

To ensure high print quality, ink viscosity must be checked and must be correct prior to attempting

modulation calibration.

Caution – Incorrect Measurement

If the temperature compensation factor is not used, the end result could be incorrect

by as much as 40%.

Caution - Equipment Damage

Never attempt to bend the gutter. Its position is fixed.

Caution - Damage to Charge Electrode

Take care not to deform the charge electrode slot when rotating the charge electrode.

Caution - Charge Cable

Ensure that the charge cable is not pulled out of its position in the rear face of the

deflector block assembly.

Caution - Equipment Damage

Never attempt to bend the gutter. It is in a fixed position.

Caution - Equipment Damage

The I/O Board LEDS connector must not be used to drive anything other than LEDs as specified

otherwise damage may occur.

Caution - Excessive Use of Top-Up or Solvent

As solvent is used during the stop cycle, repeatedly stopping and starting the printer can lead to

excessive use of top-up or solvent and may lead to a Mixer Tank High error.

Caution - Quick Stop

After a Quick Stop machine should not be left in this state for any length of time as drying ink may

make restarting difficult

Preface

Issue 2

xv

Part No. 306-0430-102

Caution - Equipment Damage

To avoid the risk of overfilling or spillage, never replenish ink or top-up unless the relevant

low icon is shown.

Ensure that ink bottle is completely empty before removing.

Caution - Equipment Damage

Do not fit or remove any connector on the printer whilst power is on, otherwise the printer

may be damaged.

Caution - Cleaning Materials

To avoid damage to the printer components use only soft brushes and lint free cloths for cleaning. Do

not use high pressure air, cotton waste or abrasive materials.

Caution - Equipment Damage

Ensure that the cleaning agent is compatible with the ink used before carrying out printhead cleaning

otherwise the printhead may be damaged.

Caution - Equipment Damage

The printhead must be completely dry before attempting to start the printer otherwise the printhead

may be damaged.

Caution - Printer Overheating

Report all overheating incidents to a maintenance engineer.

Caution - Risk of Data Loss

Ensure the correct message name is selected for message deletion as no message selection

confirmation prompt is given.

Caution - Risk of Data Loss

All messages apart from the TEST MESSAGE will be deleted.

Caution - Risk of Data Loss

The Clear Message option, when selected, does not ask for confirmation to

clear the message.

Caution - Risk of Data Loss

The Delete user field option does not ask for confirmation to delete a User Field.

430 Ink Jet Printer Service and Maintenance Manual

xvi

Issue 2

Part No. 306-0430-102

Installation: Introduction

Issue 2

1

Part No. 306-0430-102

I

NSTALLATION

Introduction

The printer is tested and commissioned prior to despatch to the customer. If further on-site commissioning is

required, refer to the

Troubleshooting

section of this manual.

Each installation must be approached on an individual basis due to variations in production line build

specifications. Supposedly identical production lines can vary significantly due to customer requirements or

modifications.

Each installation must be preceded by a site survey to establish the necessary information relevant to the

production line and printer. In some cases it may be impossible to install a printer; it is therefore of vital

importance that all the installation criteria are met before attempting installation. The site survey form must be

completed as fully as possible by the sales engineer.

Missing or ambiguous information should be clarified by telephone or fax prior to the installation procedure.

WARNING - LETHAL VOLTAGES

Lethal voltages are present within this equipment when it is connected to the mains

electrical supply. Only trained and authorised personnel may carry out maintenance work.

Observe all statutory electrical safety codes and practices. Unless it is necessary to run

the printer, disconnect the printer from the mains electrical supply before removing the

covers or attempting any service or repair activity, otherwise death or

personal injury may result.

Caution - Equipment Damage

Only Willett trained personnel may carry out installation and maintenance work. Any such work

undertaken by unauthorised personnel may damage the printer and will invalidate the warranty.

430 Ink Jet Printer Service and Maintenance Manual

2

Issue 2

Part No. 306-0430-102

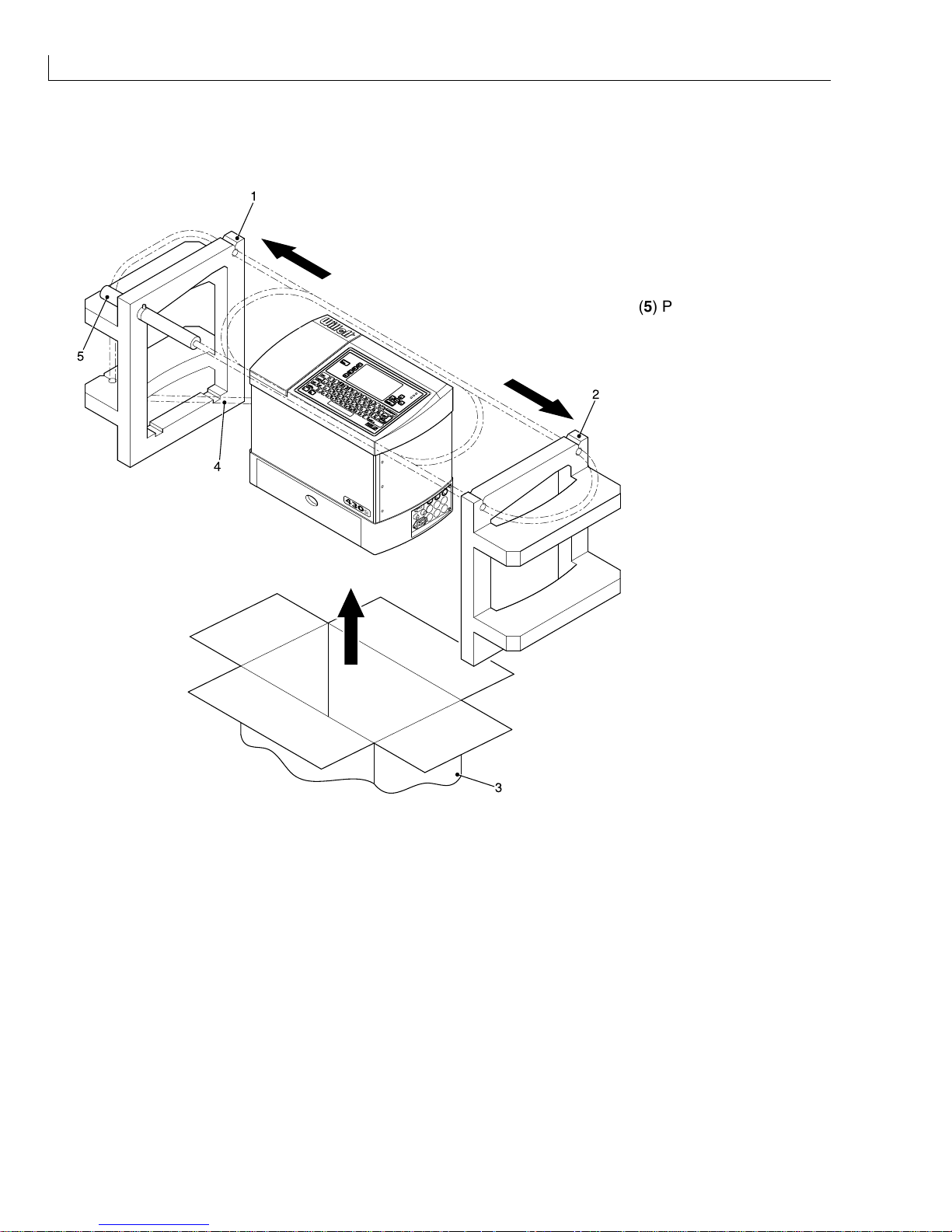

Unpacking

(1) Left-hand Insert

(2) Right-hand Insert

(3) Carton

(4) Umbilical

1

2

3

4

5

(5) Printhead

Figure 1 Unpacking the Printer

1

Open the top flaps of the carton and gently pull the complete machine and inserts (1 and 2) upwards from

the carton.

2

Place the printer and inserts on a clean level surface.

3

Remove the printhead (5) from the left-hand insert (1).

4

Remove the umbilical (4) from its transit routeing.

5

Remove the left-hand insert and right-hand insert (2).

6

Place the printer on a clean level surface for commissioning.

Installation: Commissioning

Issue 2

3

Part No. 306-0430-102

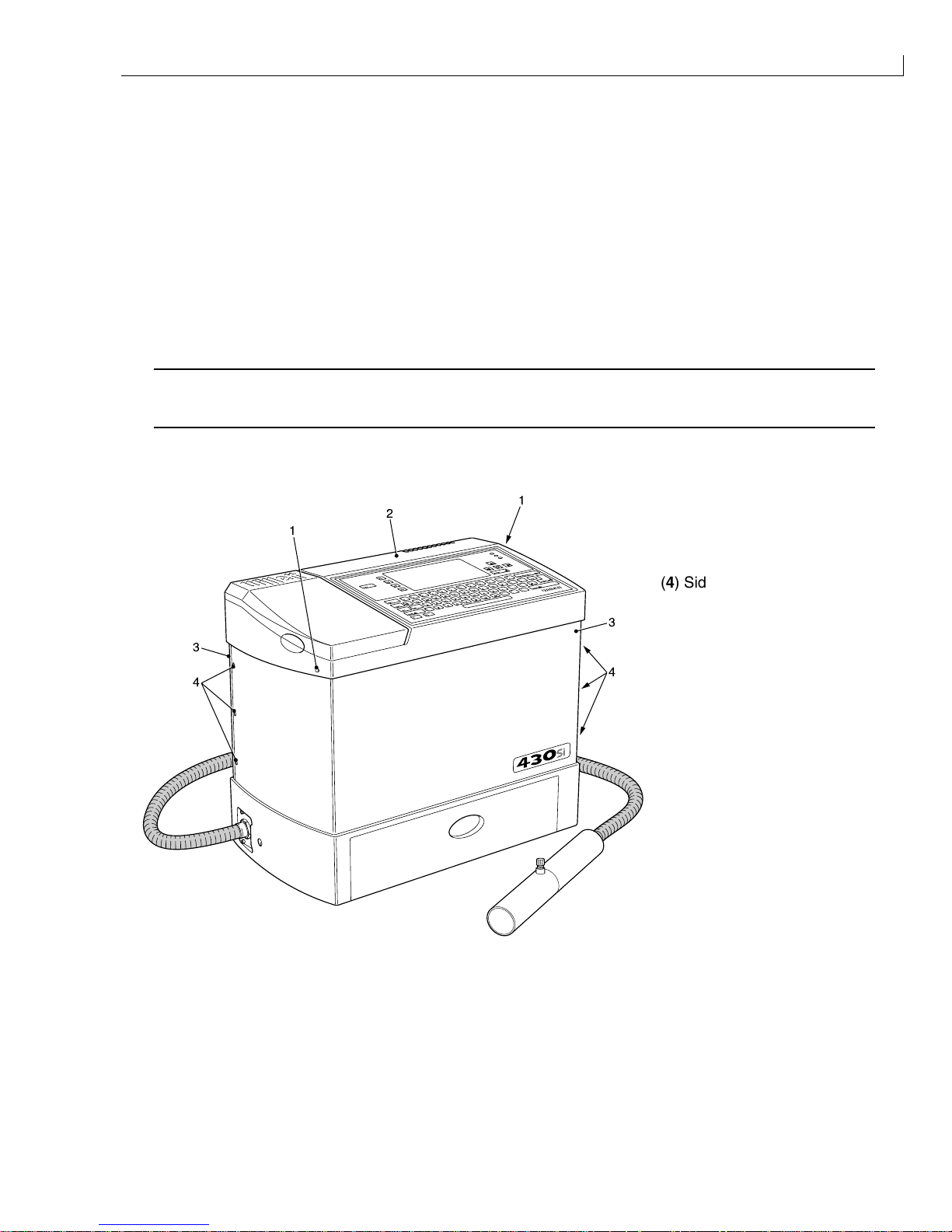

Commissioning

Access

1

Tighten the two top cover fasteners (1) until they release the top cover catches (the top cover (2) will raise

slightly).

2

Unscrew both top cover fasteners, leaving them captive.

3

Raise the top cover until the spring loaded locating pins on the extender legs slot into their respective

locating holes.

4

Turn the six side cover fasteners (4) one quarter turn counter-clockwise. These fasteners are captive in their

respective side covers (3).

Caution - Equipment Damage

Take care not to damage the printer base, internal components or wiring when removing or refitting the

side covers

5

Remove the side covers, noting their orientation for refitting.

(1) Top Cover Fasteners

(2) Top Cover

(3) Side Cover

1

2

1

3

4

3

4

(4) Side Cover Fasteners

Figure 2 Cover Fastener Location

430 Ink Jet Printer Service and Maintenance Manual

4

Issue 2

Part No. 306-0430-102

Preparation for Use

(1) Filler Plug

(2) Ink Mixer Bowl

3

2

1

(3) Filler Tubes

Figure 3 Ink Mixer Bowl Filler Plug Location

1

Remove and retain the black rubber shipping cap from the breather tube.

2

Fit the breather tube to the blue fitting located on the underside of the top cover.

3

Ensure that the correct fuses (Figure 4 (2)) are fitted for the local mains electrical supply as shown in the

table below.

Installation: Commissioning

Issue 2

5

Part No. 306-0430-102

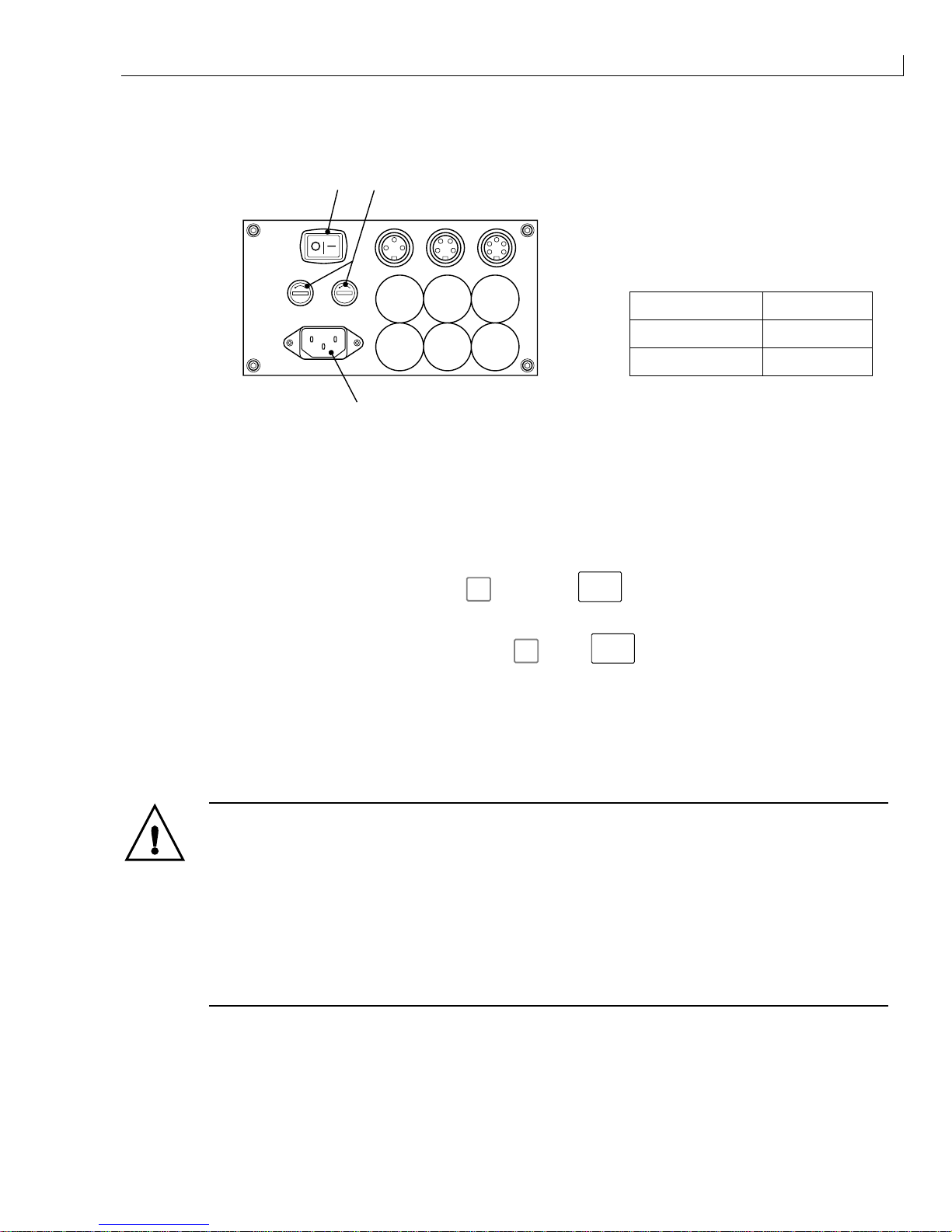

(1) On/Off switch

(2) Supply fuse holder

(3) Mains inlet socket

Mains Voltage Fuse Rating

110 V AC 5 A

230 V AC 3.15 A

3

21

PRINT TRIGGER 1 SHAFT ENCODER COMM 1

Figure 4 Connector Panel and Fuse Ratings

4

Connect the mains electrical supply to the mains inlet socket (3) and set the On/Off switch (1) to I (On). The

printer PSU will automatically detect and adjust to the mains voltage.

The printer remains uninitialised and the quick screen is displayed on the LCD panel.

5

If

nothing is visible on the LCD display, press f3, then press

ctrl

and L. Press any key to set the

contrast when the LCD is visible.

6

If the menu system cannot be accessed by pressing

f3

, press

ctrl

and Z, then P, enter the MASTER

password and repeat step 6.

7

Access the

Password

menu and enter the MASTER password.

8

Remove the filler plug (Figure 3 (1)) and prime the mixer bowl (2) with approximately 250 ml of the correct

ink using a syringe and a length of 40 mm x 6 mm tube. The Ink Out icon will cease to be displayed when

approximately 250 ml is added to the mixer bowl.

WARNING - HANDLING INK, SOLVENT AND TOP-UP

The ink, solvent and top-up are irritating to the eyes and respiratory system. To prevent

personal injury when handling these substances:

Always wear protective clothing and rubber gloves.

Always wear goggles with side-shields or a face mask. It is also advisable to wear safety

glasses when carrying out maintenance.

Apply barrier hand cream before handling ink.

If ink or top-up contaminates the skin, wash immediately with soapy water. DO NOT use

washdown or solvent to clean ink stains from the skin.

9

Ensure that the complete 250 ml is added before proceeding.

10

Refit the filler plug (1) to the top of the FMS.

11

Refit the side covers, ensure that the orientation is correct as noted, secure the side cover fasteners

(Figure 3 (4)).

430 Ink Jet Printer Service and Maintenance Manual

6

Issue 2

Part No. 306-0430-102

12

Push in the locating pins on each of the extender legs and lower the top cover (Figure 2 (2)) into position. It

will be necessary to exert a small amount of pressure to locate the cover properly.

Caution - Equipment Failure

Ensure that the top cover is lowered to the correct working position and that the filler tubes are correctly

located in the ink and solvent top-up reservoirs before proceeding.

13

Pour the remaining ink into the ink reservoir (4-slot spider with black cap).

14

Fill the top-up reservoir (3-slot spider with white cap) with 1 litre of the appropriate top-up solvent.

15

From the

System

menu, select

Fill Mixer Tank

and press

enter

. The pump will start and the mixer tank

will fill. The pump will stop automatically when the ink level is satisfactory.

16

Remove the printhead cover, nozzle seal and gutter plug (retain the seal and plug for refitting if the machine

has to be transported).

17

Mount the printhead to a suitable support.

18

Disable Gutter Detect as follows:

a

Access the

System

menu.

b

Select

Gutter Fault Shutdown Disable

.

c

In the

Machine Control

sub-menu set

Gutter Fault

to

Disable

and press

enter

.

19

Disable Charge Check as follows:

a

Access the

System

menu.

b

Select Charge Error Shutdown Disable.

c

In the

Machine Control

sub-menu set

Charge

Error to

Disable

and press

enter

.

20

Press

f1

to start the jet.

21

Ensure that the printhead alignment is correct. If adjustment is required then refer to

Printhead

Alignment,

page 161.

22

From the

Machine Control

sub-menu:

a

Select

Gutter fault

to enable Gutter Detect.

b

Select

Charge Error

to enable Charge Check.

23

Fit the printhead cover.

24

Input a message. The message must contain a six-digit incrementing counter.

25

Place an earthed print collector dish under the printhead.

26

Select the created message for printing.

27

Select Continuous Print mode:

a

From the

Print

menu, select

Continuous Print

.

b

From the Continuous print sub-menu set

Continuous mode

to Time Mode and Time Mode Delay to 50.

Installation: Commissioning

Issue 2

7

Part No. 306-0430-102

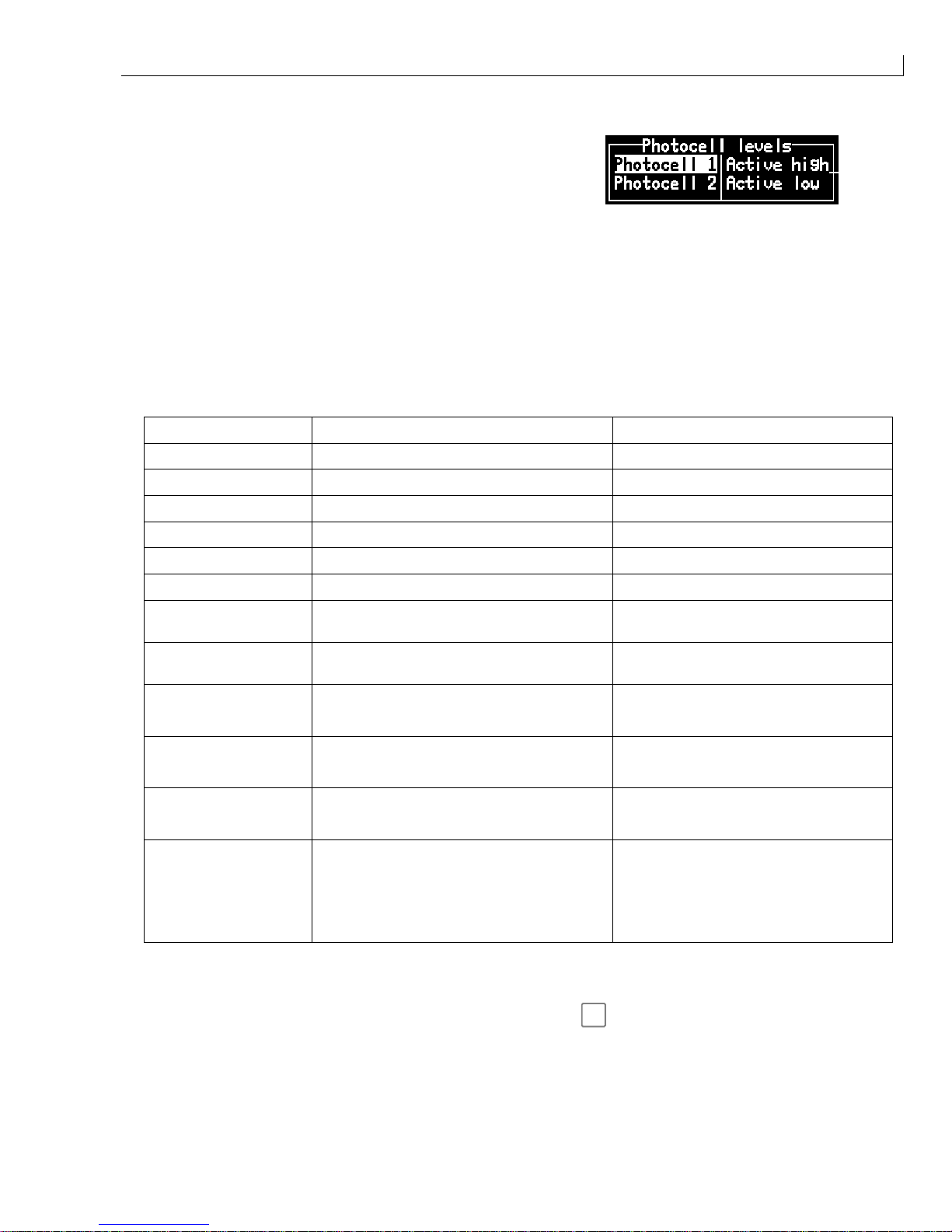

28

From the

Configure

menu, select

Photocell Levels

and set

the state of the

photocell 1 level

to

Active high

or

Active Low

as required.

29

The printer should now be printing continuously. Let the printer complete a minimum of 250 000 prints. Use

the counter to monitor the number of messages printed. Monitor the printer to ensure that the system

functions correctly.

30

At regular intervals access the

Calibrate

menu and select the Diagnostics Screen. Monitor the machine

parameters and check that they remain stable. Typical Diagnostics Screen values are shown in the table

below.

Note: The values provided are typical. The exact figures will vary slightly for each machine depending

on the model, ink type and ambient conditions.

Machine Parameter Typical Value (see Note above) Dependancy

Ink Pressure 32 Ink type, Pressure set value.

Cabinet Temperature 35 Ambient temperature.

Viscosity Set Point 29 Ink type, Ambient temperature.

Phase Angle Any value (must be stable) Correct Jet Break-up.

Ink Temperature 25 Ambient temperature

Head Temperature 25-35 Ink type, heater set point.

Viscosity Actual 29 Indicated value ±1 compared to Viscosity

Set Point = correct viscosity.

Phase Profile 08-09 (Ideal) Phase charge, charge value,

Phase pick-up position

Ink (Reservoir Tank)

J

Covered

F

Low

Level Detect covered – OK

Level Detect uncovered – LOW

Sol (Top-up Reservoir)

J

Covered

F

Low

Level Detect covered – OK

Level Detect uncovered – LOW or EMPTY

VMS

F

J Full F

F

J

Filling J J Emptying F Empty

VMS chamber Sequence

Mix

F

F F J High

F

F J On

J

F

Empty J Low J

J

MIXER TANK CONDITION

High – Tank level too High

On – Tank level OK

Low – Tank level too Low

31

After 250 000 prints have been satisfactorily completed, press

f1

and ensure that the printer performs a

clean shutdown.

Note: If the machine does not provide an adequate clean start-up or shutdown during these

procedures, it is possible that air may have become trapped in the flush pump and flush

pipework.

430 Ink Jet Printer Service and Maintenance Manual

8

Issue 2

Part No. 306-0430-102

To remove trapped air, proceed as follows:

a

Remove the front and rear covers from the printhead.

b

Slacken the jet valve (V11) screws.

c

Place tissue paper around the printhead and jet valve to absorb solvent when the priming procedure

commences.

WARNING - HANDLING CLEANING AGENT

The cleaning agent is irritating to the eyes and respiratory system. To prevent personal

injury when handling this substance:

Always wear protective rubber gloves and clothing.

Always wear goggles with side-shields or a face mask. It is also advisable to wear safety

glasses when carrying out maintenance.

Apply barrier hand cream before handling ink.

If cleaning agent contaminates the skin, rinse off with running water for at least

15 minutes.

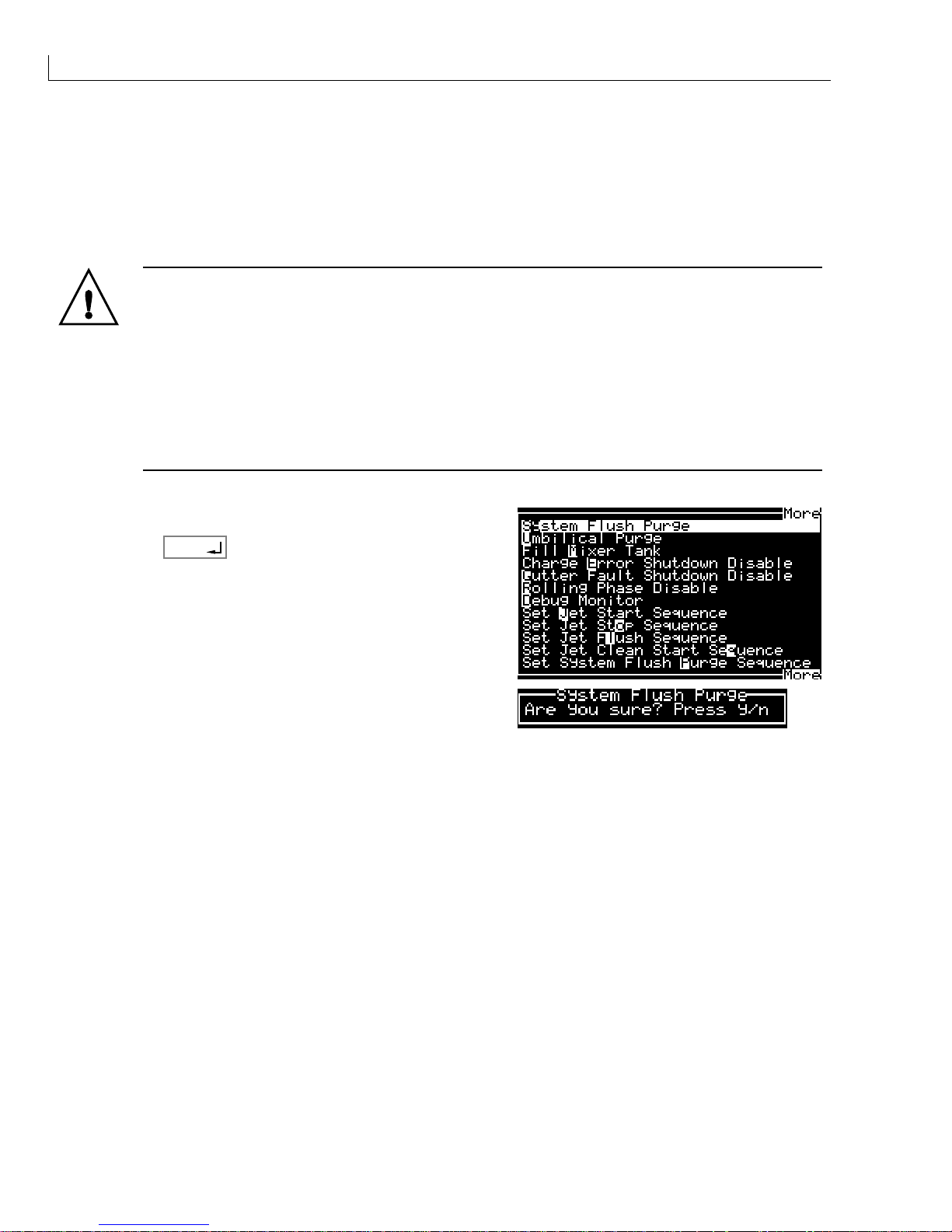

d

From the

System

menu, select

System Flush Purge

.

e

Press

enter

.

f

Press Y to confirm or N to cancel the operation.

The machine starts and the flush pump is actuated. During the actuation of the flush pump, solvent is ejected

from beneath the jet valve.

g

Allow the machine to run for approximately 30 seconds before switching off the mains electrical supply

to the machine to stop the flushing sequence.

h

Tighten the jet valve (V11) screws and dry the printhead.

i

Switch on the mains electrical supply to the machine and perform a clean start and clean stop.

j

Evaluate the clean start/clean stop performance. Repeat the procedure if necessary.

Installation: Setting up Shifts

Issue 2

9

Part No. 306-0430-102

Passwords

Liase with the customer and find out which machine functions they want available to relevant personnel and

which passwords they want to use. Set the Passwords for Levels 1 and 2.

Caution - Degraded Performance

Machine functions that only Willett trained personnel can access are set at Password Level 3 (MASTER

password), these functions must not be given as customer options.

Notes: You must be at Password Level 3 to set Password Levels.

Do not divulge the master password to the customer.

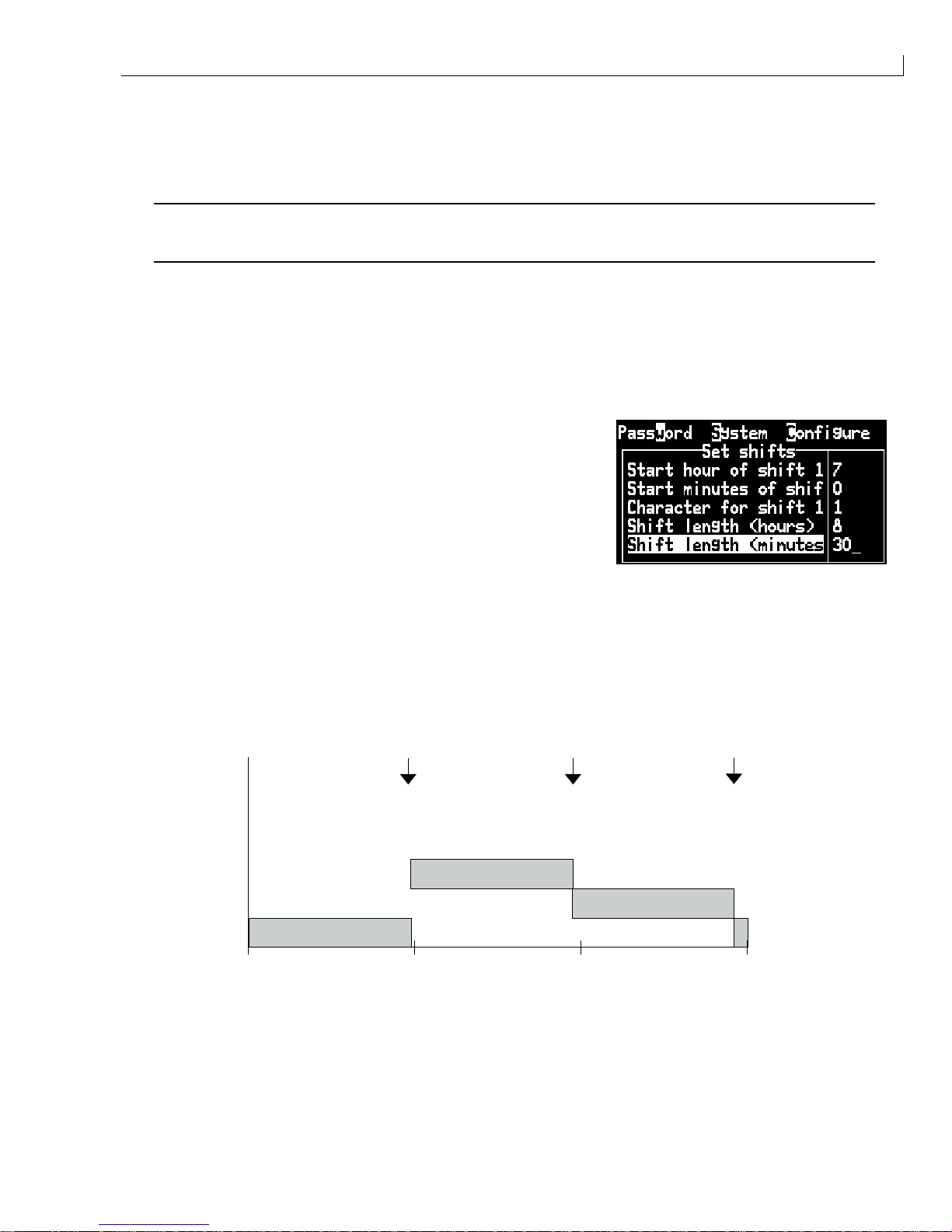

Setting up Shifts

Liase with the customer to confirm shift requirements (if any). The example below show how to set a shift

system where the day is split into three shifts with each shift numbered from 1 and shift 1 starting at 0700.

1

From the

Configure

menu, select

Set Shifts

. The Set Shifts

sub-menu is displayed.

2

Set the shift parameters as follows:

Start hour of shift 1 = 7

Start minutes of shift 1 = 00

Character for shift 1 = 1

Shift length (hours) = 8

Shift length (minutes) = 00

Notes: You must delete the Character for shift 1 using the

backspace

or

del

key before entering a new

value.

Once you enter a start time and length, the other shifts are calculated automatically.

3

Using the Shift criteria defined above, the insertion of a shift at approximately 0330 would provide a shift

number of 2.

07:00

00h

SHIFT 3

SHIFT 1

SHIFT 2

08:00 16:00 23:59

07:00+8=15:00 07:00+8+8=23:00

Figure 5 Shift Setting Diagram

430 Ink Jet Printer Service and Maintenance Manual

10

Issue 2

Part No. 306-0430-102

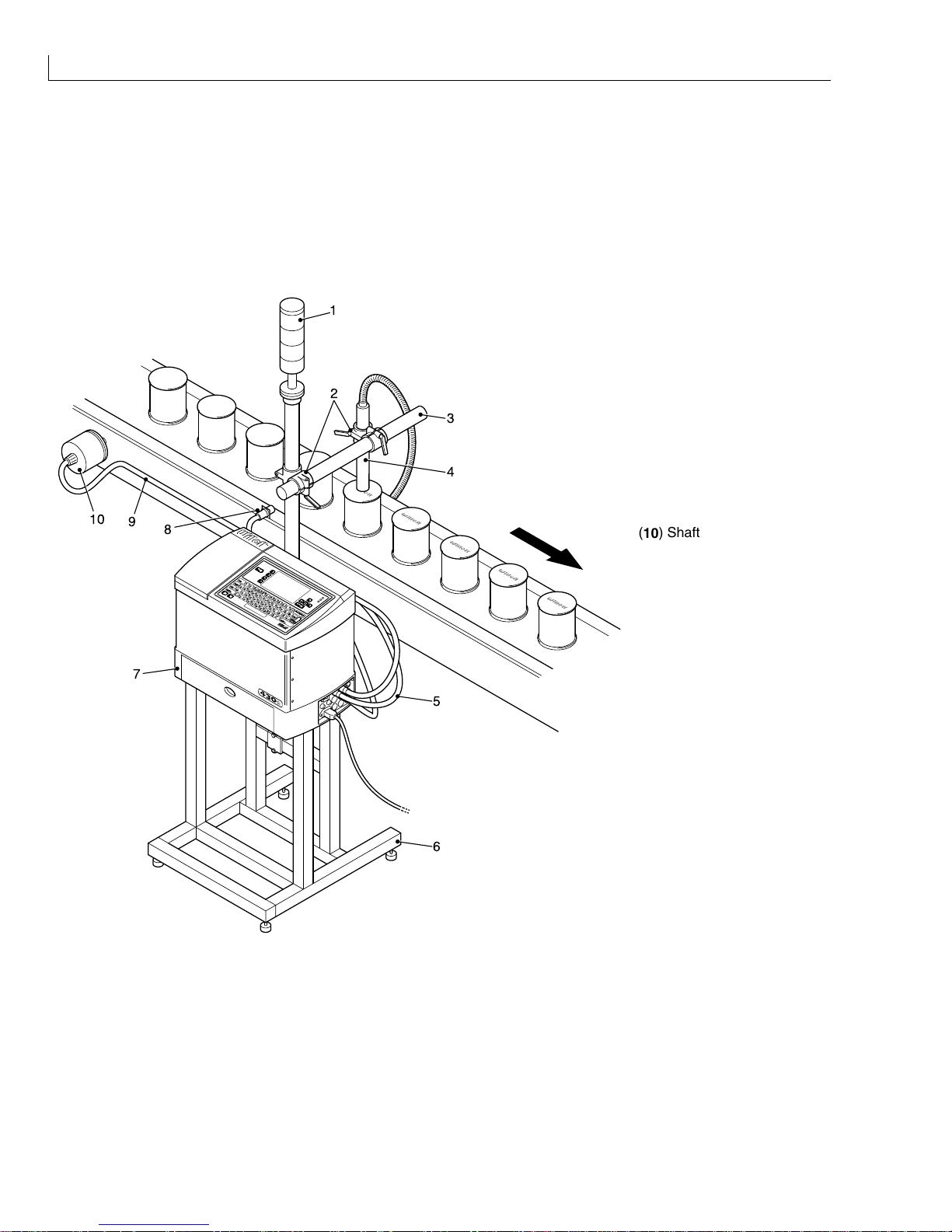

Production Line Setup

Typical Installation

A typical installation is shown in Figure 6, where the printer (7) is mounted on a printer stand (6). The printhead

(4) is configured to print vertically via a clamp (2) and bracket (3) assembly. A lamp stack (1) is fitted to the

printer stand.

(1) Lamp stack

(2) Clamp

(3) Bracket

(4) Printhead

(5) Photocell cable

(6) Printer stand

(7) Printer

(8) Photocell

(9) Shaft encoder cable

1

2

3

4

5

7

9

10

6

8

(10) Shaft encoder

Figure 6 Typical Production Line Installation

Installation: Throw Distance

Issue 2

11

Part No. 306-0430-102

Throw Distance

The optimum throw distance from the printhead to the product is 8 mm.

Shaft Encoder

Internal Source

If no external shaft encoder is to be fitted then set the

Shaft Encoder Source

to

Internal

, via the

Configure

menu. However, if the line speed varies then a shaft encoder

must

be fitted in order to maintain constant

message width.

A Width (Message Parameters) of 1 will provide the fastest print that the printer can achieve in each font using

the Internal Shaft Encoder option. The message width is increased by approximately 3% for each increment.

External Source

If an external shaft encoder is fitted then set the

Shaft Encoder Source

to

External

, via the

Configure

menu.

Figure 6 shows an external shaft encoder (10) connected via a cable (9) to the SHAFT ENCODER connector on

the connector panel.

The printer can be configured to accept two shaft encoder (quadrature) outputs. This allows the printer to

compensate for changes in direction of the production line.

Caution - Electrostatic Sensitive Devices

The printed circuit boards contain static sensitive devices. A suitably grounded, antistatic wrist strap

must be worn when working on or handling printed circuit boards.

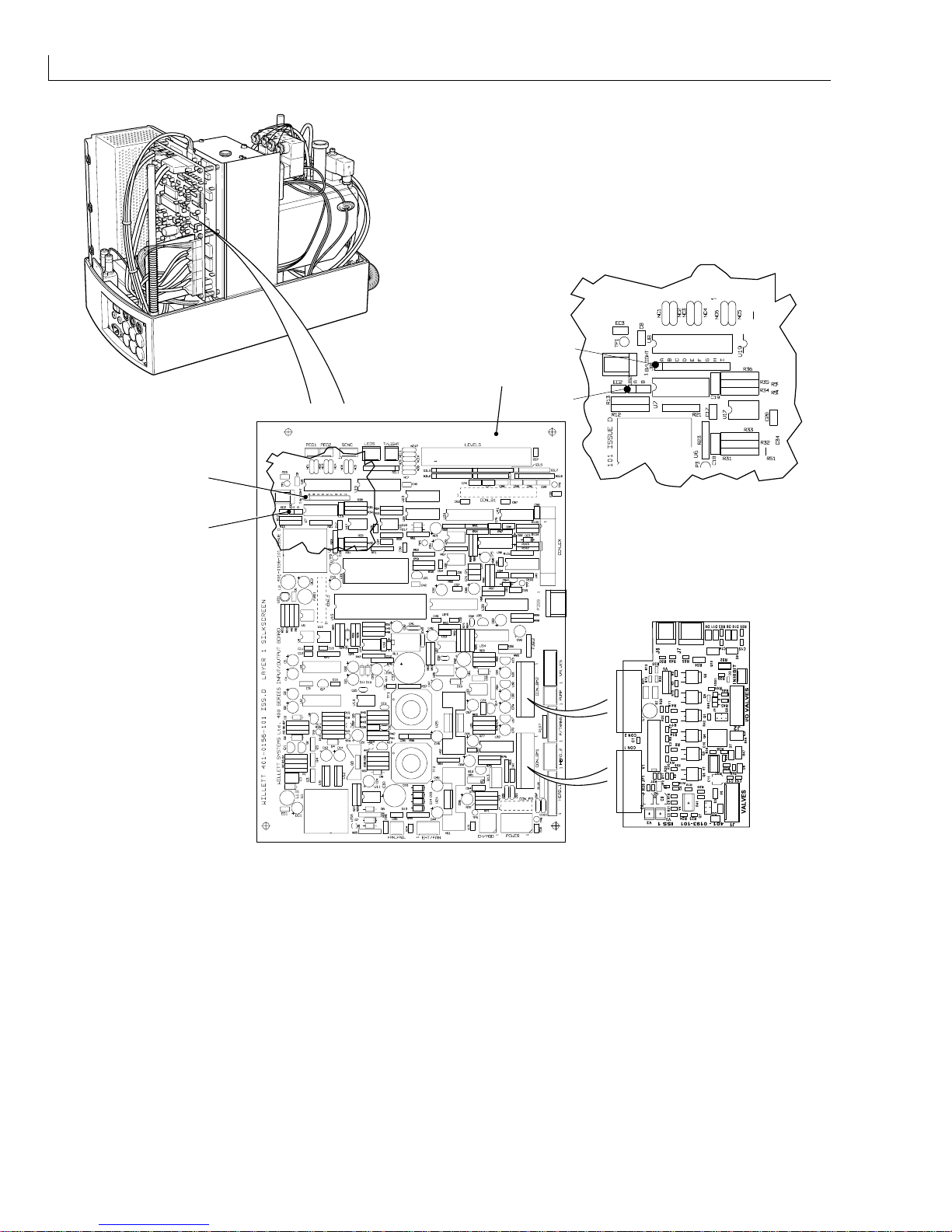

If a quadrature shaft encoder is to be used you must do the following:

1

Set jumper JB2 (Figure 7 (2)) to position B.

2

Download the appropriate special software to the printer.

3

Set the Width Value to 1.

4

Disable Print Trigger 2.

Note: Using quadrature shaft encoders to determine changes of direction disables the width function

(ie it must be set to 1). If width control is required, an external divider box must be provided.

430 Ink Jet Printer Service and Maintenance Manual

12

Issue 2

Part No. 306-0430-102

1

3

2

3

2

(1) Input/Output board (2) Sensor 2/Quadrature shaft encoder jumper JB2 (3) Print trigger 1 and 2 jumper JB1

Figure 7 Input/Output Board Product Sensor and Shaft Encoder Jumper Location

Installation: Product Sensors

Issue 2

13

Part No. 306-0430-102

Product Sensors

Figure 6 shows a photocell (8) connected via a cable (5) to PRINT TRIGGER 1 on the connector panel.