Wilks USA TX850 Owner's Manual

TX850

GASOLINE PRESSURE WASHER

OWNERS MANUAL

.....GENERAL SAFTEY INSTRUCTION

MAINTENANCE AND STORAGE

.....GETTING TO KNOW YOUR PRESSURE WASHER

ASSEMBLY

.....ASSEMBLY

.....OPERATION AND USE

.....MAINTENANCE

.....TROUBLESHOOTING

.....PUMP PARTS

.....DECLARATION OF CONFORMITY

1

2

3

4-8

9-11

12

13

14

CONTENTS

• Read instructions carefully before operating this product.

• This product is for outdoor use only.

• Keep bystanders away.

• Ensure the engine is stopped before carrying out adjustments,

cleaning or maintenance.

• Always turn off the engine and water supply when finished.

• Do not use the product if found to be damaged.

• Only use with detergents specified by the manufacturer. Other chemicals may compromise

the safety of the product.

• Do not direct the pressure jet towards mechanical parts containing lubricant grease.

• Clean vehicle tyres from a minimum of 50cm to avoid damage by the high pressure jet.

• Do not point high pressure jets at people, animals, live electrical parts or the product itself.

• Do not use accessories such as hoses and connections that are not advised by the manufacturer.

• Engage the high pressure safety catch located on the gun when not in use.

• Do not step/stand on the high pressure hose.

• Ensure the nozzle is securely attached before using the Product. High pressure can cause it to

be fired from the lance with considerable force, and could cause injury damage.

• Be ready for the kick-back force and the sudden torque on the spray assembly

when operating the trigger.

• A high pressure jet can remove paint and other surface finish. It can also damage

tarmac and grouting.

• Switch off completely when not attended.

• The hose is designed specifically for operation with high pressures. Take care to avoid damage

that may prevent correct operation of the product.

• This product is not to be used by children or anyone with reduced capabilities.

• Always completely unwind the high pressure hose prior to operation.

• Make sure that the machine is switched off before unwinding the high pressure hose,

and take care not to pull the machine over.

• Do not let the high pressure hose contact the hot engine exhaust.

• Do not use this product indoors.

• Keep exhaust emissions away from air intakes.

• Do not attempt to modify the product in any way.

• To ensure good operating condition arrange regular servicing from an authorising agent.

• Only use replacement parts supplied by the manufacturer

• Only use fresh,clean and good quality fuel in the engine.

• Never operate the engine without oil.

• Never refuel in close proximity to naked flames, sparks or other sources of ignition e.g. cigarettes.

• Do not refuel when the engine is hot.

• Wipe up and correctly dispose of any fuel spillage immediately with a suitable medium.

• Move away from the refuelling areas before restarting the engine. Store fuel for short periods

only in a suitable container away from heat and direct sunlight.

• Clean the pressure washer thoroughly after each use.

• Regularly check external nuts and fixings to ensure vibration caused by normal use has not

begun loosen them. Remove the spark plug ignition lead from the back of the spark plug and

position the lead to avoid accidental reconnection.

• Store the machine in a secure dry location out of reach of children.

• Empty the fuel tank before storage.

• Make sure to empty the product of any excess water from your hose or gun.

• Do not leave product in freezing conditions as this will cause damage the product.

GENERAL SAFETY INSTRUCTIONS

MAINTENANCE AND STORAGE

1

GETTING TO KNOW YOUR PETROL PRESSURE WASHER

ASSEMBLY

• 7. Lower Frame

• 8. Engine Recoil Starter

• 9.Exhaust Silencer

(HOT do not touch)

• 1. Engine

• 2. Pump

• 3. Upper Frame

NOTE: Every machine is tested during the production, so there may be a few

drops of water inside the pump assembly.

FIG. 1

(FIGS. 1 - 3)

FIG. 2

FIG. 3

Push bar A down, Lift

handle B.

Then Lift bar A back up.

Locate the hose and

the lance onto the

upper frame and secure

using the nuts and bolts

provided.

• 4. High Pressure Hose

• 5. Hook

• 6. Wheel

1.

6.

8.

7.

3.

5.

4.

2.

9.

2

ASSEMBLY

WARNING:

The engine is not provided with oil. It’s necessary to fill the unit before starting the engine.

FIG. 4

FIG. 6

FIG. 9

FIG. 5

FIG. 7

FIG. 10

FIG. 8

FIG. 11

TO ASSEMBLE THE WHEELS

(FIGS. 4 - 5)

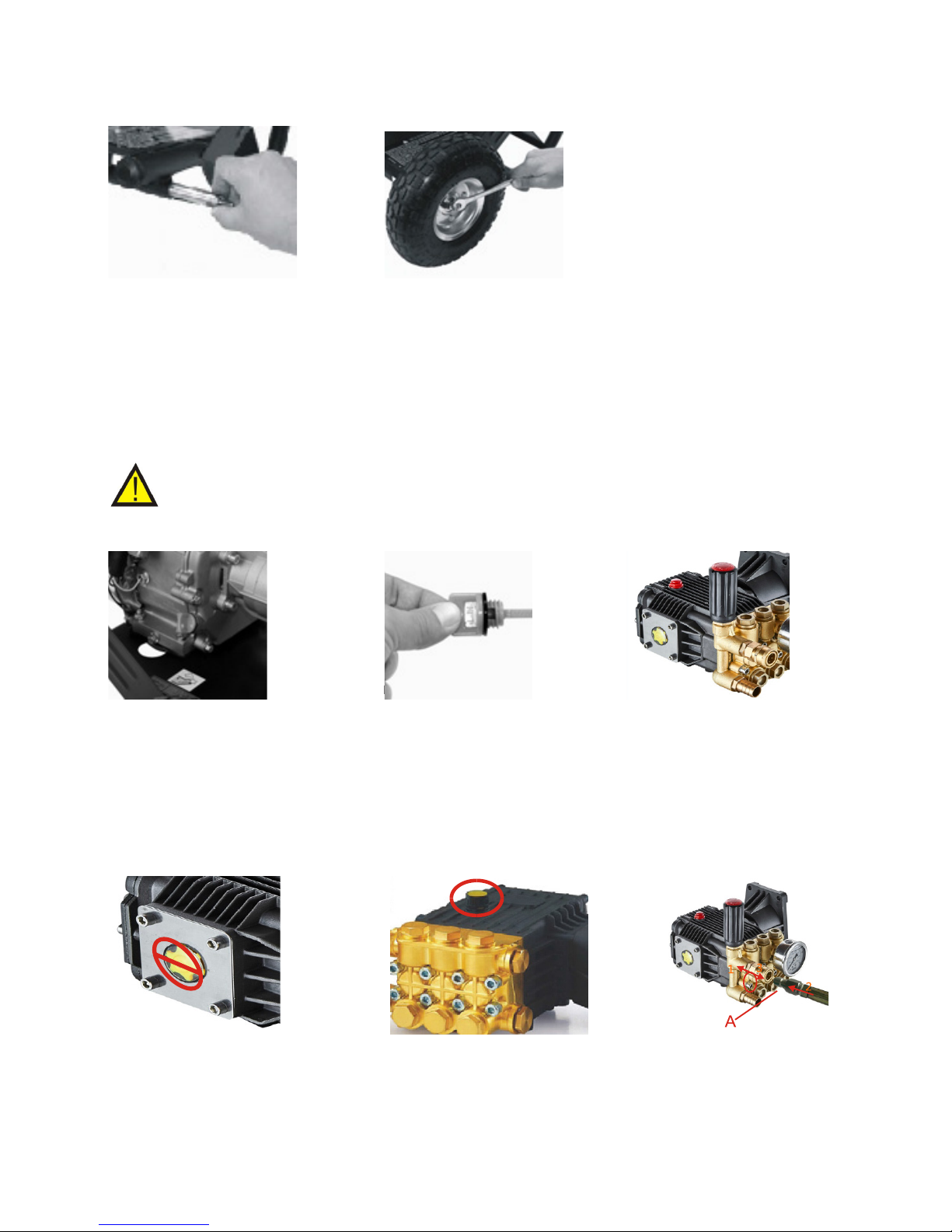

ENGINE OIL

(FIGS. 6 - 7)

HIGH PRESSURE

CONNECTION

(FIGS. 11 - 14)

PUMP OIL

(FIGS. 8 - 10)

Ensure the appliance

is kept in the upright

postion. Insert the axle

bar into the axle support

tube on the lower frame,

tighten the bolt to

secure in place.

The engine is not provided with oil. It is necessary to fill

the oil before starting the engine. The engine has two oil

fill points at the front and back of the engine. Remove the

desired cap and fill with the engine oil specified to the

upper level mark. Install the oil filler cap.

Remove the desired

cap and fill with the

engine oil specified

to the upper level

mark. Replace the

oil filler caps.

Connect the high

pressure hose to the

the unit’s high pressure

outlet.

Fit a wheel to the axle

and secure using the

locking nut provided.

Repeat this process

for each wheel.

WARNING:

Must take off this red

plastic part of the pump.

WARNING:

Check the capacity of the

pump oil and see if it’s

reached ½.

WARNING:

Install the yellow plastic

breather plug in place of

the black shipping plug.

3

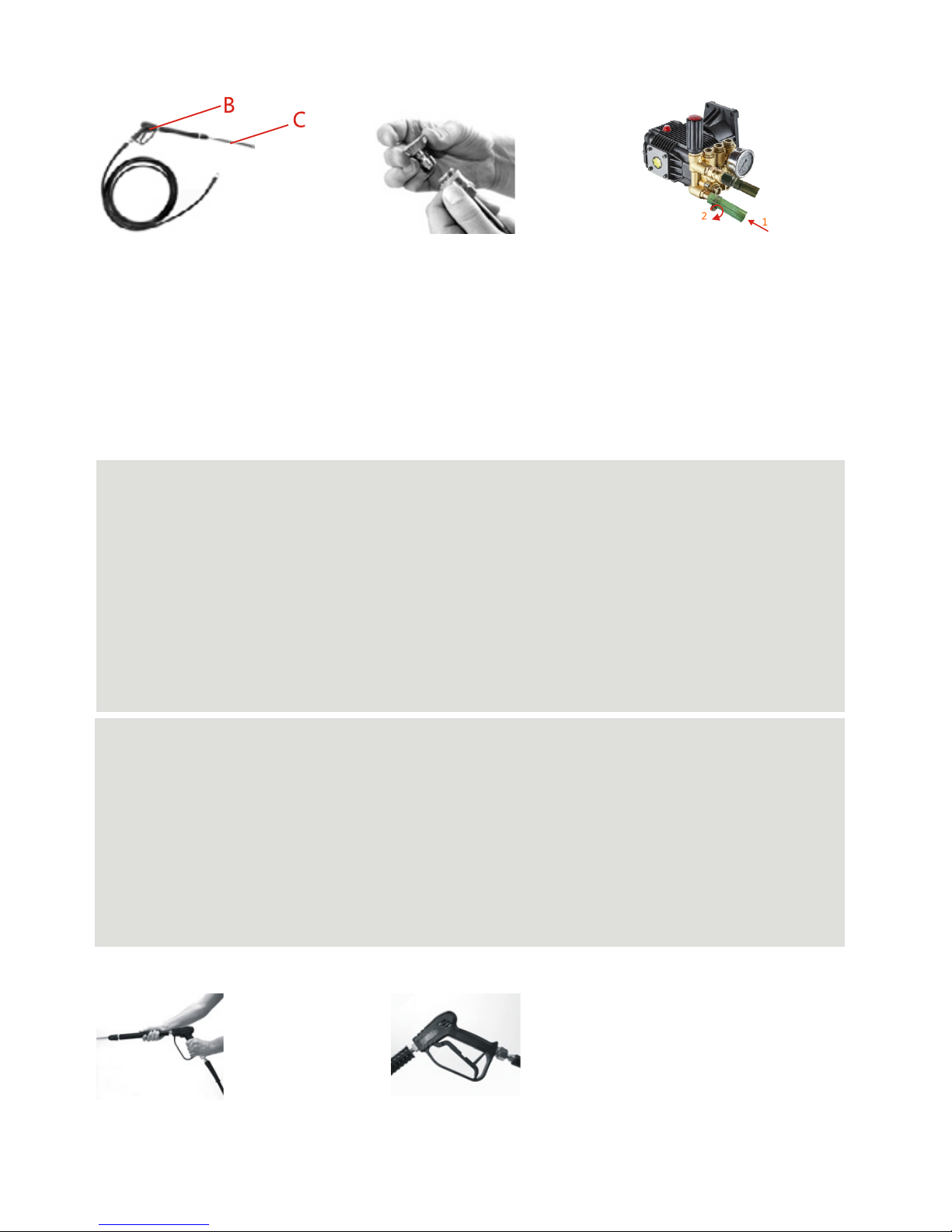

FIG. 12

FIG. 15

FIG. 13

FIG. 16

FIG. 14

Connect the high pressure

hose to the trigger B. Insert

the lance C into the trigger.

Press firmly against the spring

tension and twist the coupling

into the locked position.

Insert the required nozzle by

retracting the coupling at the

end of the lance, ensure the

nozzle is inserted securely

Pull the trigger to eliminate

trapped air and wait for a

steady flow of water to emerge

from the spray nozzle.

NOTE:

In order to assist the first

startup it is recommended to

press the trigger during the

pulling of the starter handle.

To prevent accidental

operation the trigger is fitted

with a locking facility.

To insert a nozzle, pull back

the locking collar at the end of

the lance, insert nozzle and

release the collar. This will lock

the nozzle in place. Ensure the

nozzle is inserted correctly.

If not it can fly out and injure

personnel or damage property.

Connect the hose to the

unit’ s water inlet connector

(Max. 10 bar, max.

tempreture 40°C) and turn

the water on completely.

INSERTING A

NOZZLE

(FIG. 13)

CONNECTING THE

HOSE

(FIG. 14)

OPERATION AND USE

WARNING: The engine is not filled with oil. It is necessary to fill the unit before starting the engine.

The engine will not produce a spark unless sufficient oil is inside.

CAUTION: Do not run the engine with high or low oil level as this can cause engine damage.

CAUTION: Only use unleaded gasoline.

CAUTION: Avoid damaging your hose by ensuring it does not touch the hot exhaust during and

after use.

CAUTION: Avoid damaging your pump by ensuring the water supply is clean and free of any

foreign objects.

CAUTION: Inlet water temperature must not exceed 40°C and 1Mpa

CAUTION: Never let the appliance operate for more than 2 minutes with the spray gun in theclosed

position.

CAUTION: Never operate the pressure washer with repeated and rapid on and off movements of

the trigger

WATER SUPPLY FROM THE WATER MAIN

• Connect a water supply hose (not supplied) to the water inlet connection of the pressure

washer.

• Turn on the water supply and pull the trigger until water is continually flowing out of the nozzle.

WATER SUPPLIER FROM A CONTAINER

• Unscrew the coupling part for the water inlet.

• Screw the suction hose with filter (not included) onto the water connection of the unit.

• Hang the filter in the container.

• Vent the unit before operation.

• Unscrew the high pressure line at the high pressure outlet of the unit.

• Switch on the unit and let it run until water is free of bubbles at the high pressure outlet.

• Switch off the unit and screw on the high pressure hose again.

4

Loading...

Loading...