Wilks USA TX750, TX750i User Manual

1

© Wilks-USA

TX750 / TX750i

1

READ THIS MANUAL CAREFULLY BEFORE USE – FAILURE TO DO SO MAY RESULT IN INJURY, PROPERTY

DAMAGE AND MAY VOID WARRANTY. • KEEP THIS MANUAL FOR FUTURE REFERENCE. • Products covered by

this manual may vary in appearance, assembly, inclusions, specifications, description and packaging.

V 1.0

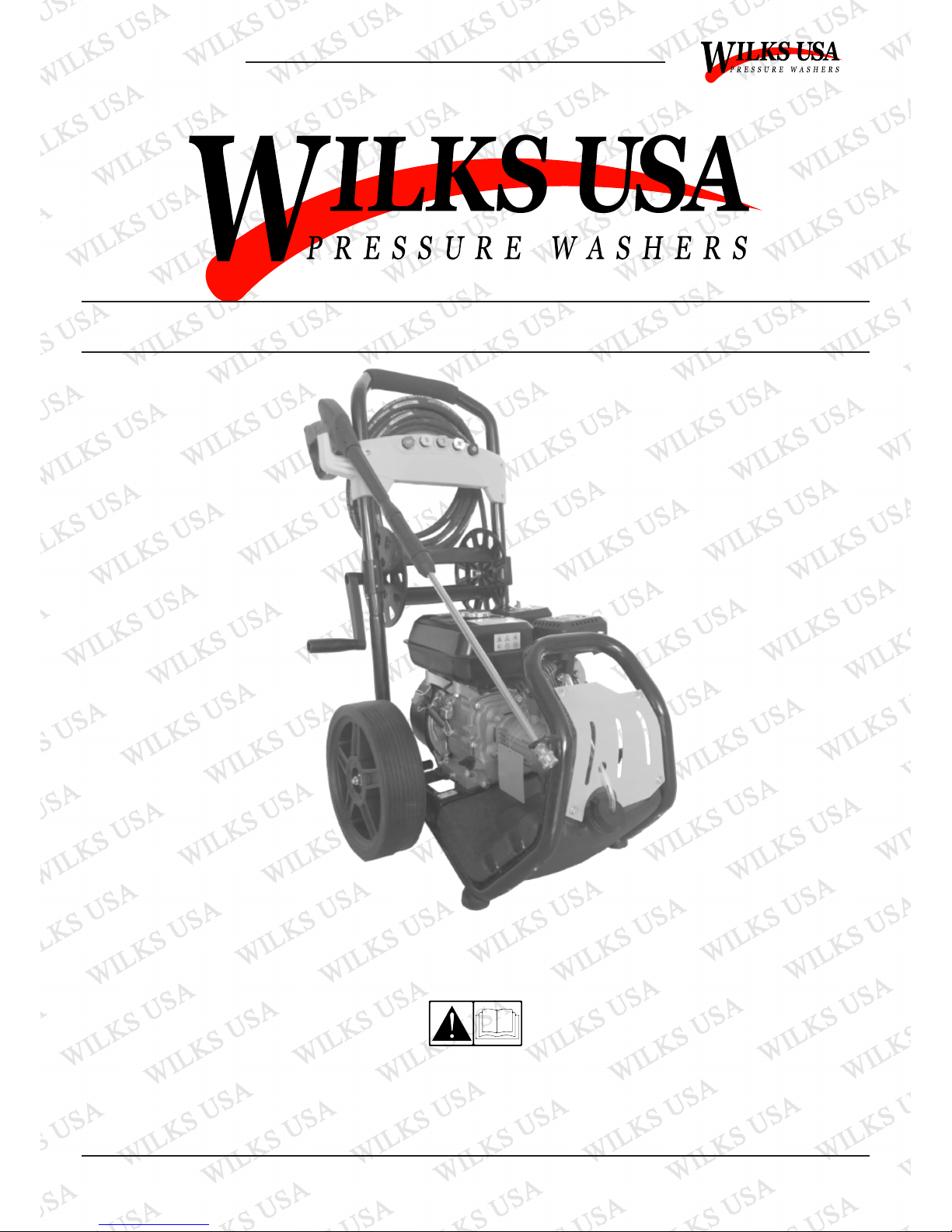

Gasoline Pressure Washer

TX750 . TX750i

2

© Wilks-USA

TX750 / TX750i

Contents

02 - Contents

03 - General Safety Instructions

04 - Explanation of the symbols used in this Manual

05 - Maintenance and Storage

Getting to know your petrol washer

06 - Assembly

07 - Operation and Use

08 - Water Supply from the Water Mains

09 - Adjusting the Spray Pattern

10 - Using the Detergent Facility

Clearing a Blockage

Safety Instructions for the Engine

11 - Pre-Operation Inspection

12 - Fuel and Fuel Tank

Fuel Tank Filter

Oil Level Switch

Air Filter

13 - Storage

Winter and Long Term Storage

14 - Maintenance

Exhaust Control System

Maintenance

Replacement of Parts

Modifying

Problems Affecting Exhaust Emissions

Water Suction Filter Checking

15 - Spark Plug Maintenance

Carburettor Idling Adjustment

16 - Transport

Storage

Prepare for Storage

17 - Removal Fom Storage

Service Schedule

Engine Oil Replacement

18 - Service Schedule Table

19 - Troubleshooting

20 - Troubleshooting

21 - Pump Parts Diagram

22 - CE Declaration of Conformity

3

© Wilks-USA

TX750 / TX750i

General Safety Instructions

• GENERAL SAFETY INSTRUCTIONS

• Read instructions carefully before operating this product.

• Keep bystanders away.

• This product is for outdoor use only.

• Ensure the engine is stopped before carrying out adjustments, cleaning or maintenance.

• Always turn off the engine and water supply when finished.

• Do not use the product if found to be damaged.

• Only use with detergents specified by the manufacturer. Other chemicals may compromise the safety of the product.

• Do not direct the pressure jet towards mechanical parts containing lubricant grease. ■

• Clean vehicle tyres from a minimum of 50cm to avoid damage by the high pressure jet. ■

• Do not point high pressure jets at people, animals, live electrical parts or the product itself. ■

• Do not use accessories such as hoses and connections that are not advised by the manufacturer.

• Engage the high pressure safety catch located on the gun when not in use. ■

• Do not step/stand on the high pressure hose.

• Ensure the nozzle is securely attached before using the Product. High pressure can cause it to be fired from the lance

with considerable force, and could cause injury damage. ■

• Be ready for the kick-back force and the sudden torque on the spray assembly when operating the trigger.

• A high pressure jet can remove paint and other surface finish. It can also damage tarmac and grouting.

• Switch off completely when not attended.

• The hose is designed specifically for operation with high pressures. Take care to avoid damage that may prevent

correct operation of the product.

• This product is not to be used by children or anyone with reduced capabilities.

• Always completely unwind the high pressure hose prior to operation.

• Make sure that the machine is switched off before unwinding the high pressure hose, and take care not to pull the

machine over.

• Do not let the high pressure hose contact the hot engine exhaust.

• Do not use this product indoors.

• Keep exhaust emissions away from air intakes.

3

4

© Wilks-USA

TX750 / TX750i

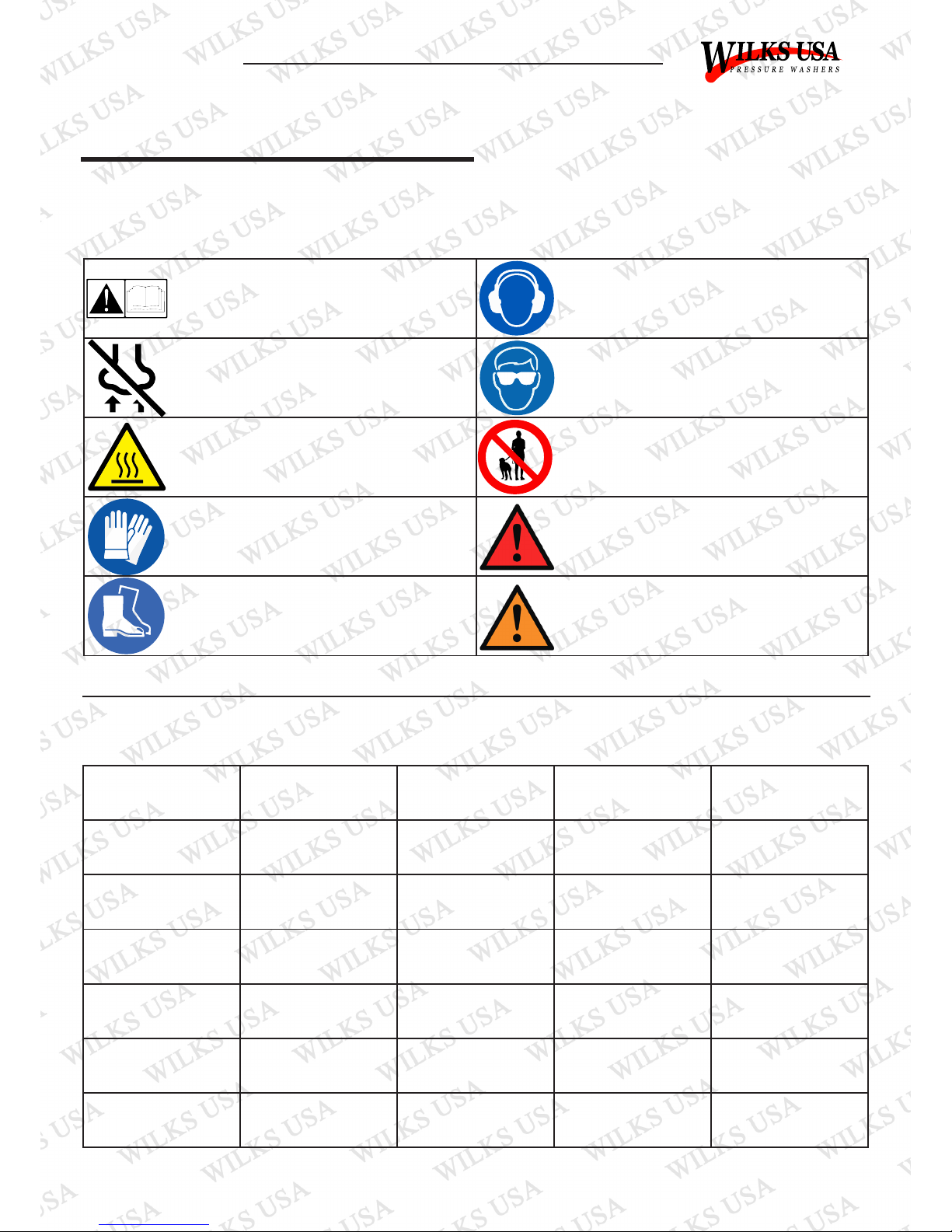

Explanation of the symbols used in this Manual

Technical Paramaters

Warning! Read the operating

Instructions before use!

Wear hearing protection!

Warning! Do not inhale exhaust fumes Wear safety goggles!

Attention! Hot surfaces! Risk of burns!

High-pressure jets can be dangerous

if misused. Do not aim at animals,

electrical appliances or the machine itself.

Wear protective gloves Warning! Risk of injury. Pay special attention

Wear safety shoes Caution! Be aware of potential risks/hazards

Model TX675 TX700 TX725 TX750

Max Pressure 13Mpa (1885 PSI) 17Mpa (2465 PSI) 18Mpa (2610 PSI) 27Mpa (3950 PSI)

Continuous

Pressure

10Mpa (1450 PSI) 15Mpa (2175 PSI) 16Mpa (2320 PSI) 22Mpa (3200PSI)

Max Flow Rate 9.2L/min 9.2L/min 9.2L/min 10L/min

Engine 2.5-4 HP 5.5 HP 6.5 HP 8 HP

Rated Rotation

Speed

3400 RPM 3400 RPM 3400 RPM 3400 RPM

Allowable

Temperature

0-60ºC 0-60ºC 0-60ºC 0-60ºC

5

© Wilks-USA

TX750 / TX750i

• Do not attempt to modify the product In any way.

• To ensure good operating conditions, range regular service from an authorized agent.

• Only use replacement parts supplied by the manufacturer.

• Only use fresh, clean and good quality fuel in the engine.

• Never operate the engine without oil.

• Never refuel in close proximity to naked flames, sparks or other sources of ignition e.g. cigarettes.

• Do not refuel when the engine it hot.

• Wipe up and correctly dispose of any fuel spillage immediately within public guidelines.

• Move away from the refuelling areas before restarting the engine. Store fuel for short periods only in a suitable

container away from heat and direct sunlight.

• Clean the pressure washer thoroughly after each use.

• Regularly check external nuts and fixings to ensure vibration caused by normal caused y normal use has not loosened

them. Remove the spark plug ignition lead (HT Lead) from the back of the spark plug and position the lead to avoid

accidental reconnection.

• Store the machine in a secure dry location out of reach of children.

• Empty the fuel lank before storage.

Maintenance and Storage

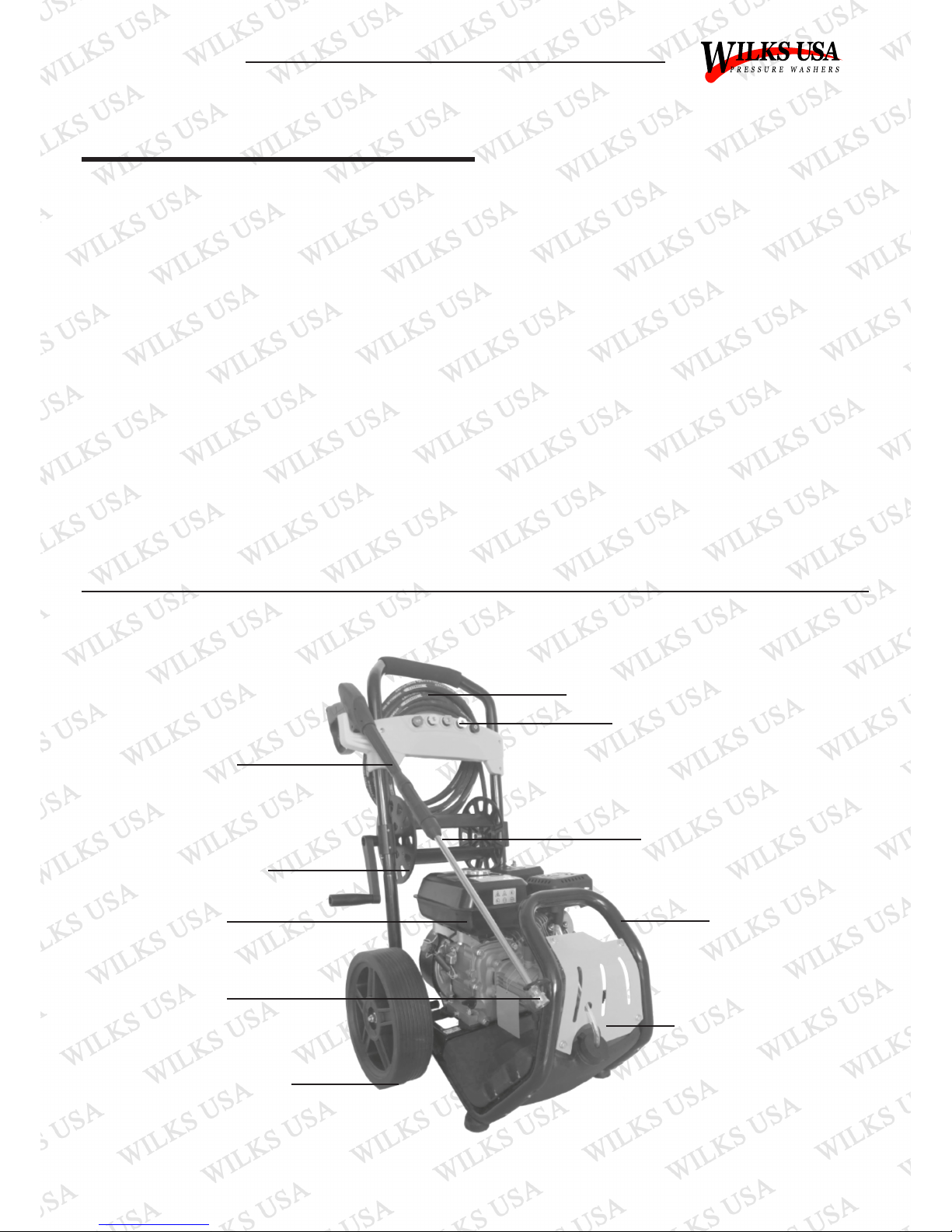

Getting to Know Your Petrol Washer

Fuel Tank

Lance Nozzle End

Wheels

Hose Reel (TX750i)

Gun/Lance

Spare Hose

Nozzle Storage

Lance Extension

Lower Frame

Detergent Tank

6

© Wilks-USA

TX750 / TX750i

Note: Every Machine is tested during production, so there may be a few drops of water inside the pump

assembly

Assembly

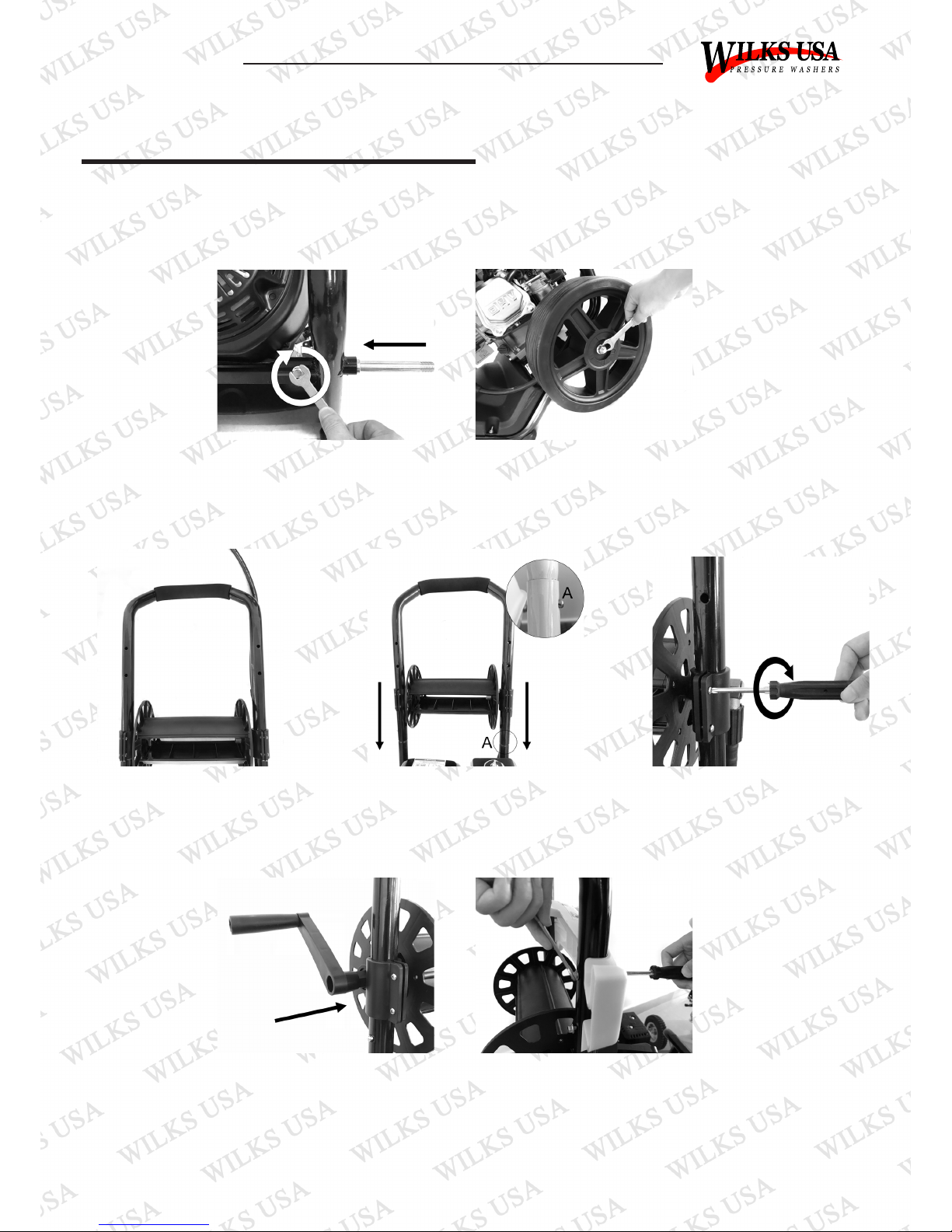

To assemble the wheels (figs 1-2)

Insert the axle in to the axle tube

at the bottom of the frame, then

fix with M6 screws.

Fig.01 Fig.02

Assemble the wheel on the axle

and fix it with a nut.

In the direction of the arrow, fix

the hose reel on the frame (TX750i

only)

Fig.03 Fig.04 Fig.05

Fig.06 Fig.07

In the direction of the arrow, insert

the handle of the frame into the

frame, lock it by lock catch A.

In order to avoid the hose reel

moving, fix it with screw and nut

In the direction of the arrow, insert

the handle into the mounting hole

of the hose reel.

Assemble the panel as shown.

7

© Wilks-USA

TX750 / TX750i

Operation and Use

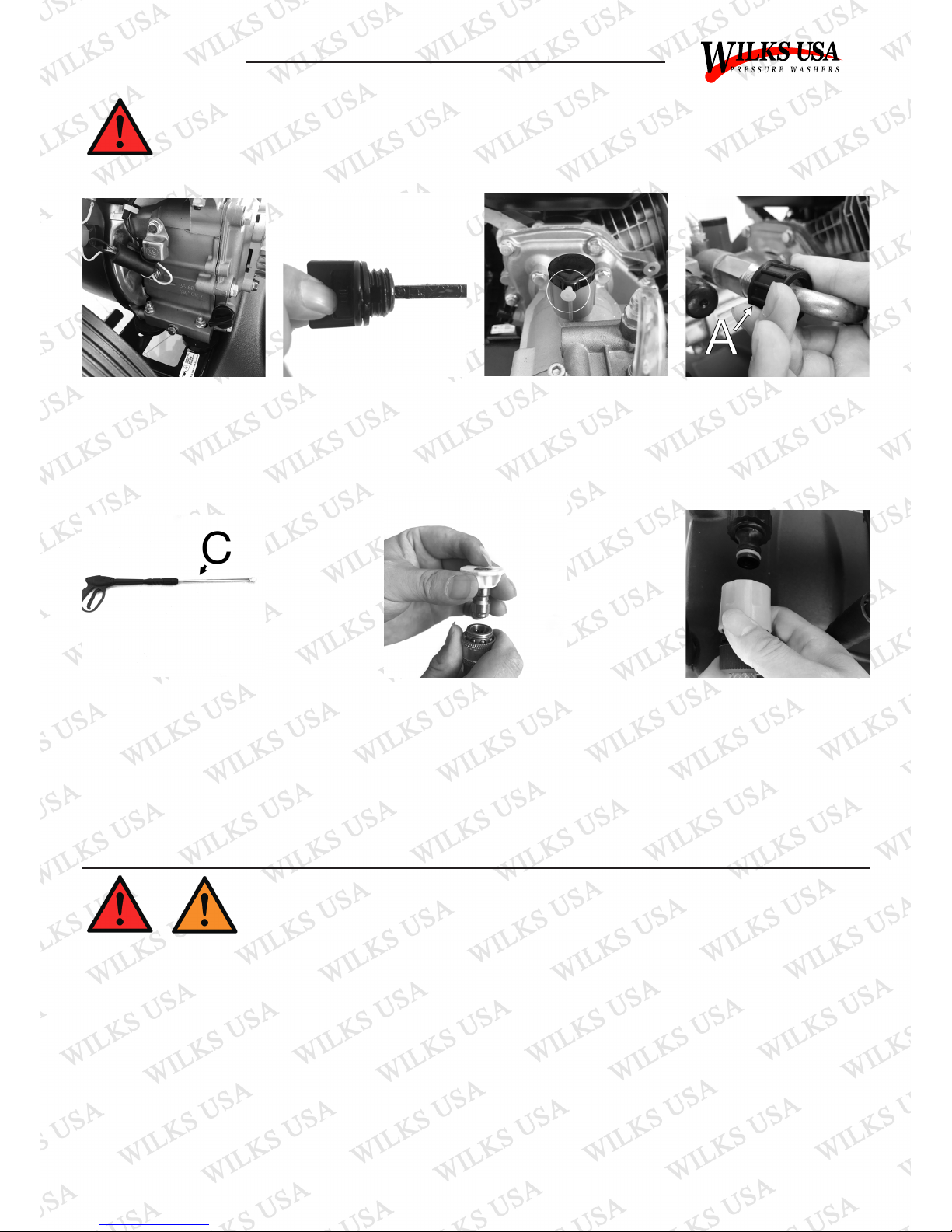

Warning: The engine is not filled with oil. It is necessary to fill the unit before starting the engine. The engine

will not product a spark unless sufficient oil is inside.

Caution: Do not run the engine with high or low oil level as this can cause engine damage.

Caution: Only use unleaded gasoline.

Caution: Avoid damaging your hose by ensuring it does not touch the hot exhaust during or after use.

Caution: Avoid damaging your pump by ensuring the water supply is clean and free of any foreign objects

Caution: Inlet water temperature must not exceed 40ºC and 20 PSI

Caution: Never let the appliance operate for more than 2 minutes with the spray gun in the closed position

Caution: Never operate the pressure washer with repeated and rapid on/off movements of the trigger

WARNING: The engine is not provided with oil. It is necessary to fill the unit before starting the

engine.

Fig.08

Engine Oil. (g.08-09) Warning: The engine is not provided

with oil. It is necessary to fill the unit before starting the engine.

The engine has two oil fill points at the front and back of the

engine. Remove the desired cap and fill with the engine oil

specified to the upper level mark or base of threads.

Fig.09

Pump Oil. (g.10) Warning:

The YELLOW pin must be

removed from the RED

breather plug before use.

High Pressure Connection

(g.11-14): Connect the

high pressure hose A to the

units high pressure outlet.

Fig.10 Fig.11

Connect the High Pressure

Hose to the Trigger B: Insert

the lance C into the gun

end. Press firmly and twist

the coupling into the locked

position.

Fig.12

Connecting the Hose:

Connect the hose to the

water inlet connector (MAX.

20PSI, MAX 40°C Temp)

and turn the water on

completely.

Fig.14

Inserting a Nozzle (g.13):

To insert a nozzle, pull back

the locking collar at the end

of the lance, insert nozzle

and release the collar. This

will lock the nozzle in place.

Ensure the nozzle is inserted

correctly. If not it can fly

out and injure personnel or

damage property.

Fig.13

Loading...

Loading...