WILKINS 350, 350ADA, 350DA, 350A Installation And Testing Instructions

a company

®

®

Model 350, 350A, 350ADA & 350DA

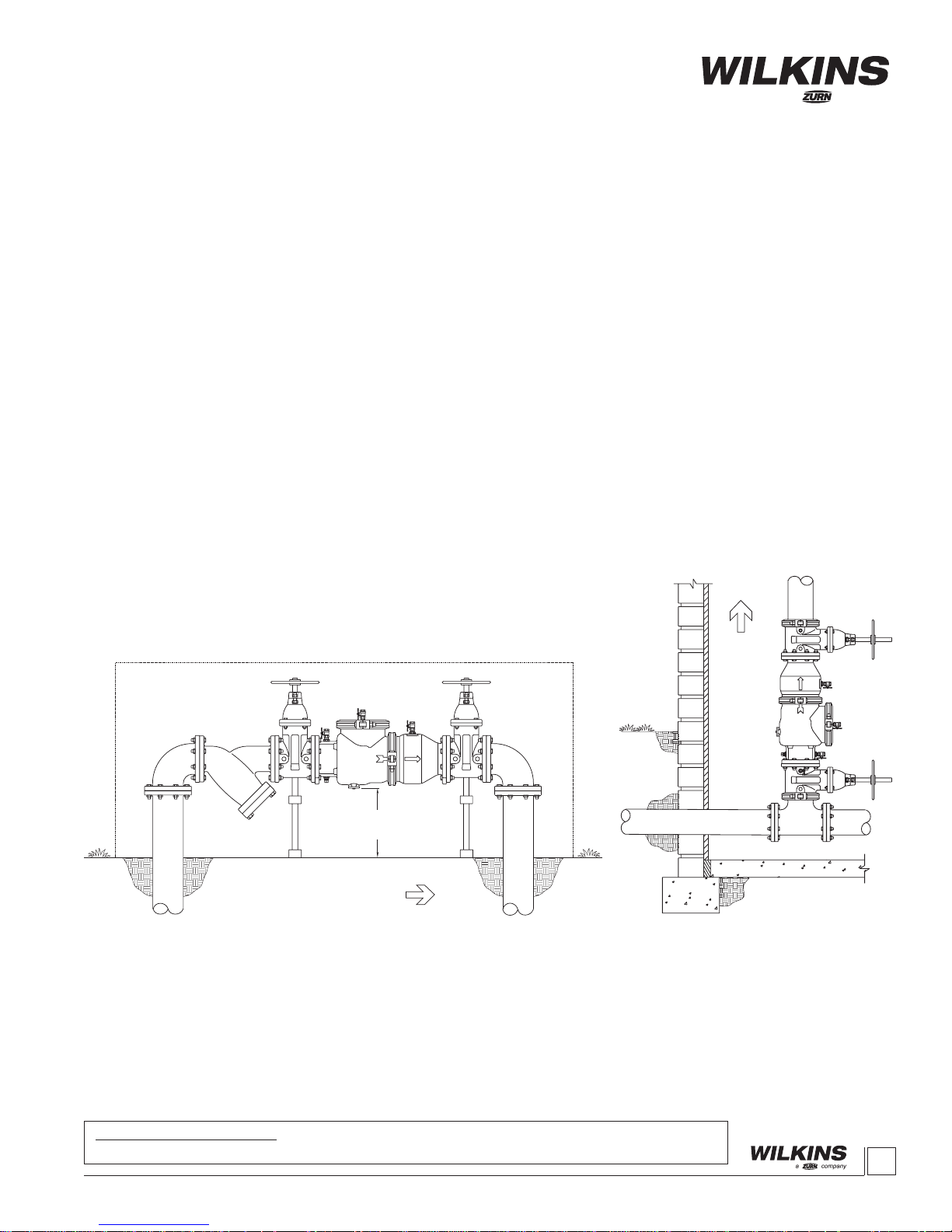

DIRECTION OF FLOW

12" MIN.

30" MAX.

DIRECTION OF FLOW

Double Check Valve Assembly (8”, 10” & 12”) and

Double Check Valve Detector Assembly (8”, 10” & 12”)

Installation Testing Maintenance Instructions

(Patent No. 5,913,331)

INSTALLATION INSTRUCTIONS

CAUTION: Installation of Backow Preventers must be performed by qualied, licensed

personnel. The installer should be sure the proper device has been selected for the

particular installation. Faulty installation could result in an improperly functioning device.

WILKINS Model 350 Double Check Valve assemblies are for use on potable water lines

where a health hazard does not exist in the event of a backow situation.

Damage to the device could result wherever water hammer and/or water thermal expansion could create excessive line pressure. Where this could occur, shock arrestors, check

valves and/or pressure relief valves should be installed downstream of the device.

If installation is in a pit or vault, the Backow Preventer must never be submerged in

water because this could cause a cross-connection. Make sure that the pit or vault always

remains dry by providing ample drainage.

1. Before installing a Model 350 Backow Preventer, ush the line thoroughly to

remove all debris, chips and other foreign matter. If required, a strainer should be

placed upstream of the Backow Preventer. CAUTION: Do not use a strainer in

seldom used emergency waterlines such as re lines.

2. Provide adequate space around the installed unit so that the test cocks will be

accessible for testing and servicing.

3. Install valve at least 12 inches above surrounding ood level.

PLACING THE DEVICE IN SERVICE

1. Start with both shut-off valves closed.

Slowly open the inlet shut-off valve until the

backow preventer is completely pressurized.

2. When the unit has been pressurized,

vent any trapped air by slightly opening

each of the four test cocks.

3. Slowly open the downstream shut-off

valve. The Model 350 Double Check Valve

assembly is now in service.

4. After the Model 350 has been properly

installed, test the device (see “TEST PROCEDURES”). If the device fails the test,

remove the rst and second check valves

and thoroughly ush the device. Clean rubber and seats of all debris and place unit

back in service.

4. Always consult local codes for installation methods, approvals and guidance.

OUTDOOR INSTALLATION

The Model 350 Backow Preventer may

be installed outdoors only if the device

is protected against freezing conditions.

Exposure to freezing conditions will result

in improper function or damage to the

device. The installation location must be

kept above 32°F. All the basic installation

instructions apply.

INDOOR INSTALLATION

Indoor installation is preferred in areas that

are subject to freezing conditions. All the

basic installation instructions apply to such

installations.

VERTICAL INSTALLATION

Vertical installation is acceptable in applications where inlet and outlet piping

are flowing vertically upwards. All the

basic installation instructions apply to such

installations. Consult factory for approval

status.

Proposition 65 Warning This product contains chemicals known to the State of

California to cause cancer or birth defects or other reproductive harm.

1

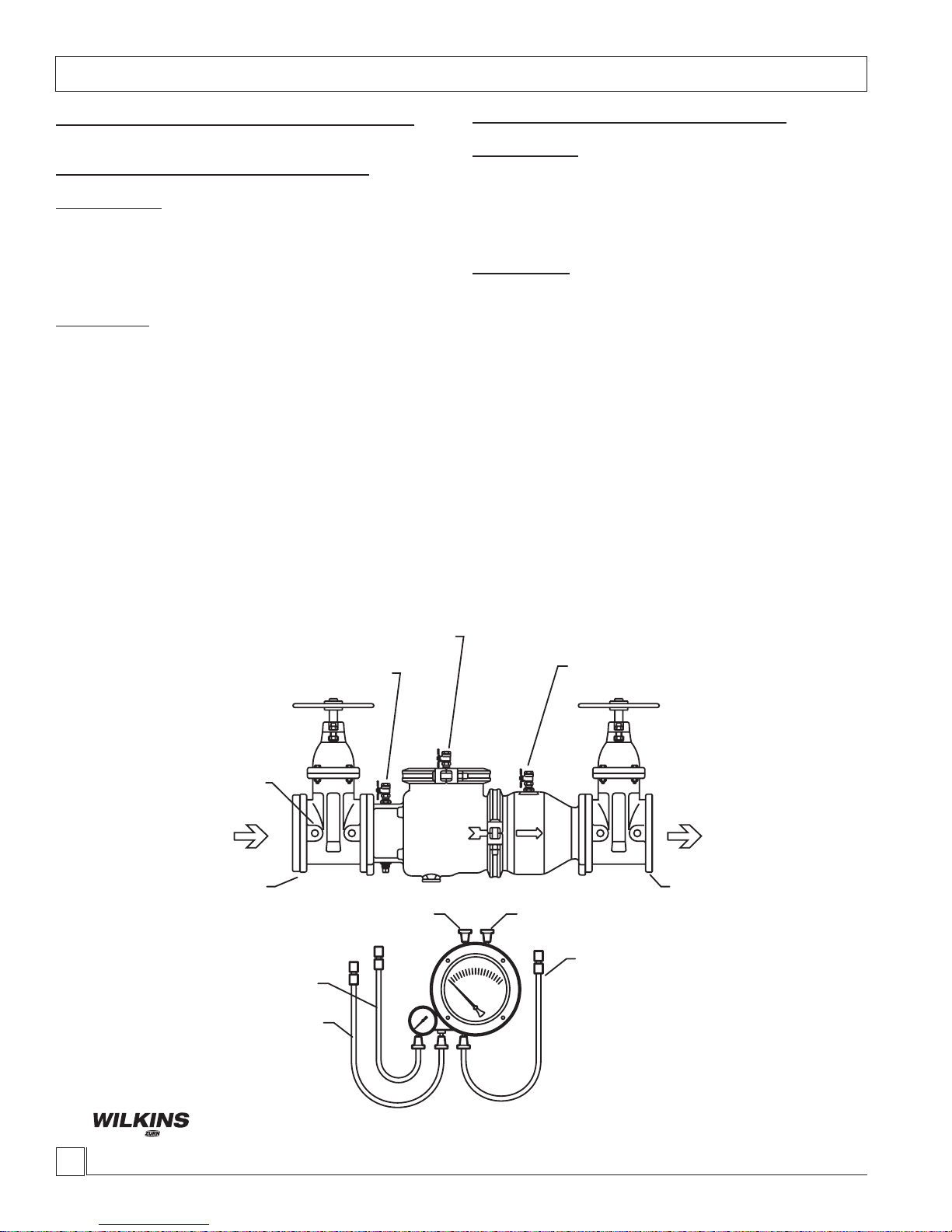

VENT HOSE

LOW SIDE HOSE

HIGH SIDE HOSE

LOW SIDE BLEED

NEEDLE VALVE

#1 TEST COCK

#4 TEST COCK

#3 TEST COCK

#2 TEST COCK

#2 SHUT-OFF

VALVE

#1 SHUT-OFF

VALVE

HIGH SIDE BLEED

NEEDLE VALVE

Testing Procedures

a company

®

®

MODEL 350 DOUBLE CHECK VALVE ASSEMBLY

Equipment Required: Differential pressure gauge test kit.

TEST NO. 1 - TIGHTNESS OF #1 CHECK VALVE

REQUIREMENT:

The static pressure drop across check valve #1 shall be at least

1.0 psid. If test cock #3 is not at the highest point of the check

valve body, then a vertical tube must be installed on test cock #3

so that it rises to the top of the check valve body.

PROCEDURE:

1. Slowly open all 4 test cocks to remove any foreign material

and attach ttings.

2. Attach hose from the high side of the test kit to the #2 test cock.

3. Open test cock #2 and bleed all air from the hose and gauge

by opening the high side bleed needle valve. Close high side

bleed needle valve. If a tube is attached to test cock #3, open

test cock #3 to ll the tube. Close test cock #3. Close #2

shut-off valve then close the #1 shut-off valve.

4. Hold gauge at same level as test cock #3 or water level in tube.

Slowly open test cock #3. Record the static pressure drop

across check valve #1 after gauge reading stabilizes and

water stops running out of test cock #3.

5. Close all test cocks, open shut-off valve #1 and remove test

equipment.

TEST NO. 2 - TIGHTNESS OF #2 CHECK VALVE

REQUIREMENT:

The static pressure drop across check valve #2 shall be at least

1.0 psid. If test cock #4 is not at the highest point of the check

valve body, then a vertical tube must be installed on test cock #4

so that it rises to the top of the check valve body.

PROCEDURE:

1. Attach hose from the high side of the test kit to the #3 test cock.

2. Open test cock #3 and bleed all air from the hose and gauge

by opening the high side bleed needle valve. Close high

side bleed needle valve. If a tube is attached to test cock

#4, open test cock #4 to ll the tube. Close test cock #4.

Close #1 shut-off valve.

3. Hold gauge at same level as test cock #4 or water level in

tube. Slowly open test cock #4. Record the static pressure

drop across check valve #2 after gauge reading stabilizes and

water stops running out of test cock #4.

4. Close all test cocks, slowly open shut-off valve #1 & #2 and

remove test equipment.

WILKINS, a ZURN company

2

1747 Commerce Way, Paso Robles, CA 93446 Phone:805/238-7100 Fax:805/238-5766

Loading...

Loading...