Wilkerson WRA-0250-2, WRA-0250-3, WRA-0250-4, WRA-0300-2, WRA-0300-3 Owner's/operator's Manual

...Page 1

READ ALL INFORMATION IN THIS MANUAL BEFORE BEGINNING

INSTALLATION OR OPERATION OF THE DRYER. BEFORE STARTING

INSTALLATION AND/OR MAINTENANCE PROCEDURES, TURN OFF

THE MAIN POWER TO THE DRYER AND COMPLETELY

DEPRESSURIZE THE UNIT TO PREVENT PERSONAL INJURY.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER

WHILE IT IS UNDER PRESSURE.

THIS DRYER USES REFRIGERANT R-22. COMPLY WITH ALL LOCAL,

STATE, AND FEDERAL REGULATIONS CONCERNING REFRIGERANT

WHEN PERFORMING ANY MAINTENANCE OR SERVICE ON THE

REFRIGERATION SYSTEM. ALL REFRIGERATION SYSTEM REPAIRS

OR MAINTENANCE NOT DETAILED IN THIS MANUAL SHOULD BE

DONE BY A QUALIFIED REPAIR PERSON.

NEVER OPERATE THIS DRYER ABOVE THE RATED OPERATING

CONDITIONS. OPERATION ABOVE SPECIFIED CONDITIONS WILL

RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO

THE UNIT AND/OR PERSONAL INJURY.

®

OWNER/OPERATOR MANUAL

COMPONENTS, INSTALLATION, OPERATION

AND SERVICE INSTRUCTIONS

REFRIGERATED COMPRESSED AIR DRYER

WRA 0250-WRA 0500

WRW 0250-WRW 0500

WARNING

83-030-000-FL • Rev. A • 9/95

Printed in the U.S.A.

REFRIGERATED AIR DRYER

SYSTEM MONITOR

POWER ON

HIGH TEMP

OUTLET

ORESSYRE

OUTLET

ORESSYRE

®

OPERATIONS

For further assistance contact:

P.O. Box 1237

1201 W. Mansfield Ave.

Englewood, CO 80150

Phone (269) 629-2550

FAX (269) 629-2475

Certificate No

BSI

R

E

G

I

S

T

E

R

E

D

F

I

R

M

NATIONAL

ACCREDITATION

OF CERTIFICATION

BODIES

®

R

E

G

I

S

T

E

R

E

D

F

I

R

M

WILKERSON OPERATIONS

REGISTERED TO ISO 9001

CERTIFICATE NO. A2192

FM21121

Page 2

WILKERSON OPERATIONS Page 1

Table of Contents

Why you need a Wilkerson Dryer and recommended Typical Installation..................Page 2

Components of a Refrigerated Dryer Compressed Air System....................................Page 3

Dryer Performance Specifications...................................................................................Page 4

Installation Instructions and Start-up Procedure...........................................................Page 5

Preventive Maintenance, Dryer Dimensions and

Recommended Wilkerson Air Accessories ....................................................................Page 6

Compressed Air Circuit ....................................................................................................Page 7

Refrigeration Circuit..........................................................................................................Page 8

Control Panel Components..............................................................................................Page 9

Electrical Box Components ...........................................................................................Page 10

Refrigeration Components ............................................................................................Page 11

Cabinet Components ......................................................................................................Page 12

Wiring Diagrams.........................................................................................................Page 13-14

Trouble Shooting Guide..................................................................................................Page 15

Dryer Warranty ................................................................................................................Page 16

Service Information.........................................................................................................Page 17

Page 3

Page 2 WILKERSON OPERATIONS

WHY YOU NEED A WILKERSON

REFRIGERATED AIR DRYER

Untreated compressed air will contain contaminants

such as water, compressor oil, rust, chemical contaminants, and bacterial growth.

All of these contaminants will cause corrosion and

product contamination.

With proper filtration and a Wilkerson refrigerated air

dryer in use, contaminants will be reduced to a harmless level.

The end result will be that the equipment which comes

in contact with dry, treated, compressed air will stay

cleaner, will not corrode, and will last longer.

Rejection rates of your end products will drastically

reduce when using dry, treated air in your plant

manufacturing operation.

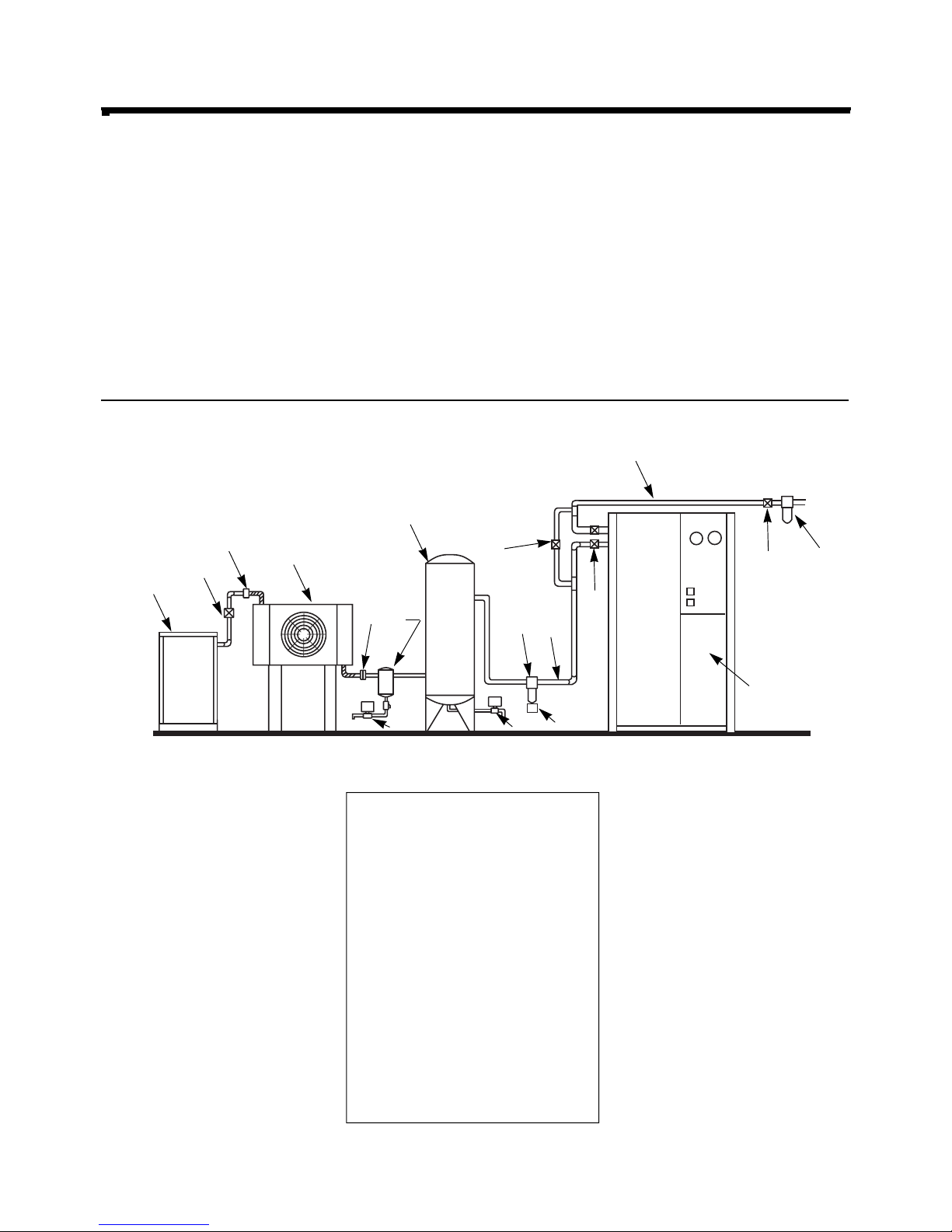

FIGURE 1: TYPICAL COMPRESSOR ROOM LAYOUT:

1 Air Compressor

2 Shut-off Valve

3 Flex Connector

4 Compressed Air Aftercooler

5 Flex Connector

6 Liquid Separator with

Electric Drain

7 Storage Tank

8 Prefilter

9 Electric Drain Valve

10 Flex Connector

11 Shut-off Valve

12 By-pass Valve

13 Flex Connector

14 Shut-off Valve

15 Afterfilter

16 Refrigerated Air Dryer

1

2

3

4

7

13

11

14

15

16

12

5

6

9

9

9

8

10

Page 4

WILKERSON OPERATIONS Page 3

The Air Compressor 1

Although there are many types of compressors, all have

some type of inlet filtration. If this filtration is not maintained

or is not properly designed for ambient conditions (ie. large

amounts of coal dust, road dust, fly ash, etc.) the result will

be increased compressor maintenance and an additional

contamination load on downstream equipment.

Shut-Off Valve 2, 11, 14

Sized in accordance with air flow capacities, to provide the

minimum pressure drop.

Flexible Connections 3, 5, 10, 13

Flexible piping between a compressed air system and the air

dryer or aftercooler is recommended to eliminate any

possible vibration induced damage.

The Aftercooler 4

As the name implies, the aftercooler cools the hot air after

compression. This not only reduces the temperature of the

air to within acceptable values for downstream equipment,

but also condenses out a very large amount of water. This is

very important because for approximately every 20°F (11°C)

reduction in compressed air temperature, one half of the

water is condensed. A separator must be used to actually

remove the water from the system.

The Separator 6

The separator removes the large droplets of oil and water

from the compressed air stream which condense in the

aftercooler, subsequently improving the dryer capacity.

Though one of the least expensive components of the

compressed air system, the separator is one of the most

critical. A difference of only a few percent efficiency in a

separator can allow substantial amounts of additional water

to pass downstream, both overloading a dryer and causing

potential maintenance problems. A properly sized electronic

drain should be installed to drain away accumulated liquids.

Storage Tank 7

This acts as a storage vessel which will also remove liquids.

Therefore, an electric drain valve should be installed. (Note:

Where possible the receiver should be installed with the

inlet near the bottom and the outlet near the top.)

Prefiltration 8

Wilkerson refrigerated air dryers will operate efficiently and

reliably without filtration. But if your system also requires dirt

and oil free air, then appropriate particulate or coalescing

filtration is required.

Electric Drains 9

Proper drainage of accumulated liquids is essential to proper

system operation. Should liquids be allowed to build up in

receivers and filters, liquid “slugging” can occur causing loss

of performance to downstream components.

Automatic electric drain valves provided on the dryers

automatically drain liquid water from the dryer evaporator and

separator. They feature full adjustment of drain cycles from 1

to 45 minutes, and valve opening durations from 1 to 15

seconds. Two indicator lights for indicating “power on” and

“valve open” status allow for easy visual inspection. Electric

drains are also recommended for all other drain points in the

compressed air system including separators, filters,

receivers, and drip legs.

By-pass Valve System 12

It is strongly recommended that a by-pass valve system be

utilized to provide for convenient maintenance and service.

Applications which require a continuous supply of dry air

should consider installing two dryer systems. This will assure

a steady supply of dry air under any conditions.

Afterfiltration 15

For critical applications, to obtain a maximum downstream oil

content of .01 ppm/wt and .003 ppm/wt respectively. See the

chart below for recommended afterfilters.

The Refrigerated Air Dryer 16

The Wilkerson Refrigerated Air Dryer is the result of

unprecedented research and testing. It is subjected to

simulated no load, partial load and full load performance

examinations to meet our quality standards. As such, it will

provide years of reliable service if properly installed and

operated within its design specifications. The dryer should be

installed in a well ventilated area.

Components Of A Refrigerated Dryer Compressed Air System

Recommended Filtration

Recommended Coalescing Prefilters/Afterfilters

Dryer Dryer/Filter

Model Pipe Type A Type B1 Type C

Number Size 5.0 Micron 1.0 Micron (.01 ppm downstream

Inlet/Outlet Particulate Coalescing remaining oil content)

WR( )-0250 2" NPT F35-0

C-0

00 M35-0C-S00 M35-0C-000

WR( )-0300 2" NPT F35-0

C-0

00 M35-0C-S00 M35-0C-000

WR( )-0400 2" NPT F35-0

C

-000 M36-0C-S00 M36-0C-000

WR( )-0500 2" NPT F35-0

C

-000 M36-0C-S00 M36-0C-000

NOTE: Recommended filters were selected on the basis of flow capacity—not pipe size.

Page 5

Page 4 WILKERSON OPERATIONS

Water-Cooled Performance Specifications (60 Hz)

Performance Specifications: Flow Capacity (dm

3

/s) (50Hz)

Air-Cooled Performance Specifications (60 Hz)

Flows* at 37.7° C Comp Full

Model Inlet Air Temperature Rating Load Shipping

Number 2-4°C Dew Point** Voltage (HP) Amps Weight

(dm3/s/hr)

WRA-0250-4 99 380/50/3 2.0 4.4 660

WRA-0300-4 118 380/50/3 2.5 5.2 675

WRA-0400-4 158 380/50/3 3.2 6.4 690

WRA-0500-4 197 380/50/3 3.8 7.7 700

All inlet and outlet air connections are: 2" NPT.

Specifications apply to air-cooled, water-cooled and 50 hertz.

Air flow rates are based on 100 psig (7 bar) inlet pressure and 100°F inlet air temperature.

System

COMPRESSOR DATA Full

Model SCFM Load Fan

Number Flow Voltage HP Full Load Amps LRA Amps CFM Shipping

WRA-0250-2 250 230/60/1 2.0 9.9 53 12.1 1700 660

WRA-0250-3 250 230/60/3 2.0 6.6 49 8.8 1700 660

WRA-0250-4 250 460/60/3 2.0 3.3 24 4.4 1700 660

WRA-0300-2 300 230/60/1 2.5 12.7 64 14.9 1700 675

WRA-0300-3 300 230/60/3 2.5 7.7 49 9.9 1700 675

WRA-0300-4 300 460/60/3 2.5 3.9 24 5.0 1700 675

WRA-0400-2 400 230/60/1 3.2 17.2 95 19.4 1870 690

WRA-0400-3 400 440/60/3 3.2 10.8 65 13.0 1870 690

WRA-0400-4 400 460/60/3 3.2 5.3 27 6.4 1870 690

WRA-0500-2 500 230/60/1 3.8 21.5 46 23.7 1870 700

WRA-0500-3 500 230/60/3 3.8 13.3 92 15.5 1870 700

WRA-0500-4 500 460/60/3 3.8 6.6 116 7.7 1870 700

System

COMPRESSOR DATA Full

Model SCFM Load

Number Flow Voltage HP Full Load Amps LRA Amps Shipping

WRA-0250-2 250 230/60/1 2.0 9.9 53 9.9 660

WRA-0250-3 250 230/60/3 2.0 6.6 49 6.6 660

WRA-0250-4 250 460/60/3 2.0 3.3 24 3.3 660

WRA-0300-2 300 230/60/1 2.5 12.7 64 12.7 675

WRA-0300-3 300 230/60/3 2.5 7.7 49 7.7 675

WRA-0300-4 300 460/60/3 2.5 3.9 24 3.9 675

WRA-0400-2 400 230/60/1 3.2 17.2 95 17.2 690

WRA-0400-3 400 440/60/3 3.2 10.8 65 10.8 690

WRA-0400-4 400 460/60/3 3.2 5.3 27 5.3 690

WRA-0500-2 500 230/60/1 3.8 21.5 46 21.5 700

WRA-0500-3 500 230/60/3 3.8 13.3 92 13.3 700

WRA-0500-4 500 460/60/3 3.8 6.6 116 6.6 700

Page 6

Installation Instructions

NOTE: ALL ELECTRICAL AND MECHANICAL

CONNECTIONS MUST BE MADE BY A

QUALIFIED PERSON.

1. The dryer needs to be installed in a well ventilated area.

There needs to be 12" (30 cm) clearance for the

condenser air inlet of the dryer.

2. In the location the dryer is installed the ambient

temperature should not exceed 110°F (43°C) or fall

below 40°F (4.4°C).

3. The inlet compressed air should not exceed 120°F

(49°C). NOTE: EXCESSIVE AMBIENT OR INLET AIR

TEMPERATURE WILL RESULT IN UNSATISFACTORY

PERFORMANCE AND IF NOT REMEDIED CAN

RESULT IN PERMANENT DAMAGE TO THE DRYER.

4. The dryer must be mounted on a suitable structure,

on an elevated, or flat and level floor.

5. It is recommended, that the air system be installed

similar to the layout shown in Fig.1 Page 2. Using shutoff valves and by-pass valves will allow for servicing of

the filters, drain valves, and dryer removal without

shutting down the compressed air system.

6. Electric drain connections must be made in manner that it

will not interfere with the flow. The discharge needs to be

treated in accordance with local and national EPA

code/regulations.

7. Verify that the “service voltage” is correct and that the

dryer is not wired to cycle with the air compressor, the

power to the dryer must be continuous.

8. Pressurize the air system, check for leaks and correct.

9. For “water cooled condensers” the water flow rate must

not be lower than what is specified on page 4, and the

incoming water temperature must not exceed 80°F.

WARNING: NEVER REMOVE THE ELECTRICAL

CONTROL PANEL WITHOUT TURNING OFF

ELECTRICAL SERVICE DISCONNECT TO THE DRYER

Start-up Procedure

NOTE: THE DRYER HAS A REFRIGERANT CRANKCASE

HEATER. PRIOR TO INITIAL START-UP THE

CRANKCASE HEATER SHOULD BE ENERGIZED FOR 24

HOURS BEFORE TURNING ON THE DRYER.

POWER TO THE CRANKCASE HEATER IS SUPPLIED

WHEN THE MAIN ELECTRICAL SERVICE DISCONNECT

IS TURNED ON. THE POWER ON/OFF SWITCH OF THE

DRYER HAS NO CONTROL OF THE CRANKCASE

HEATER.

LEAVE THE POWER ON/OFF SWITCH OFF

FOR THE FIRST 24 HOURS.

Do not start the dryer with an air load, bypass the airflow

before turning on the dryer.

By pushing the power switch to the on position the green light

will illuminate, the red high temperature light will come on

briefly and then go off. If the red light remains on for over 3

minutes thru the dryer off and refer to the trouble-shooting

guide.

The fan will not come on immediately, it will cycle in

accordance with the head pressure. Without any air load

through the dryer, the fan may stay off up to 5 minutes before

coming on; this is normal.

If the dryer is equipped with a refrigerant suction pressure

gauge, it should be indicating between 57-65 psig without any

air load.

Open the air by-pass valve and allow full air flow thru the

dryer.

Various dryer functions and conditions can be monitored.

Temperature at the probe locations will be displayed on

digital display (optional) by rotating the selector knob.

Simultaneously, pressure, air and refrigerant, can be

monitored on the analog gauges.

MAXIMUM INLET AIR TEMPERATURE: 120° F

MAXIMUM INLET AIR PRESSURES: 200 PSIG

MAXIMUM AMBIENT AIR TEMPERATURE: 110° F

MAXIMUM INLET WATER COOLED CONDENSER TEMPERATURE: 80° F

Water Flow Requirements at Various Water

Temperatures

Gallons per hour at the following temperatures

60°F 70°F 80°F

WRW-0250 80 100 132

WRW-0300 100 125 165

WRW-0400 120 150 198

WRW-0500 140 175 231

WILKERSON OPERATIONS Page 5

Page 7

Page 6 WILKERSON OPERATIONS

Preventive Maintenance Cont.

A. Weekly Checklist

1. Check Air-Cooled condenser coil for contaminants and

clean as required. Check Water-Cooled condenser coil for

proper water flow.

2. Inspect all electrical drains for operation. Turn off the shutoff valve and depress the manual override switch on the

electrical valve, this will depressurize the discharge line,

and clean the “Y” strainers.

3. Assure dryer inlet temperature does not exceed 120°F

(48°C).

4. Assure dryer ambient temperature does not exceed

110°F (43°C) and there are no ventilation obstructions

around the dryer. Ventilate the area and remove

obstructions as required.

5. Check separator, receiver, filter drains and strainers.

Check filter high differential pressure indicators, and

replace fouled elements as needed.

B. Semi-Annual Checklist

1. Remove and inspect all air system filters for excessive

particulate loading and physical damage. Replace the

filters that show any sign of damage, or if pressure drop

exceeds 7 psid (0,5 bar).

2. Shut off drain shut-off valves and clean “Y” strainers.

Disassemble solenoid valves if necessary and check for

contaminants. Clean as required.

10.38

9.36

7.88

6.50

.50

67.88

60.75

54.75

35.42

6.75

5.06

1/4" NPT DRAIN

LOCATIONS

POWER CORD

ACCESS

AIR INLET

AIR OUTLET

7.56

10.25

12.87

25.25

29.62

1

/2 NPT (FEMALE)

WATER OUTLET

1

/2 NPT (FEMALE)

WATER INLET

(WATER

CONNECTIONS

FOR WRW ONLY)

Air-Cooled and Water-Cooled Dryers

Dimensions

Page 8

WILKERSON OPERATIONS Page 7

The Compressed Air Circuit

Hot, saturated, compressed air first enters the air-to-air heat

exchanger “A”, where it is precooled by the exiting dry outlet

air. By precooling the incoming air, energy is saved by

reducing the heat load imposed on the refrigeration system.

As soon as the incoming air comes in contact with the cooler

air, condensation begins.

The saturated air then enters the evaporator (section “B”)

where the air temperature is reduced to 35°F to 39°F

(1.6° to 3.8°C). The water vapor is condensed and drained

off. The cold air then flows through the separator “C” where,

by gravity and vortex action the condensed water and

contaminants are collected in a “quiet zone” at the bottom of

the separator and are discharged through an automatic drain

valve. Our unique and highly efficient separator design

combines centrifugal action, directional flow change,

impingement, and velocity reduction to achieve superior

performance.

The dry chilled air then reenters the air-to-air exchanger

where it precools the incoming air and in turn is reheated.

Reheating of the air does not affect its dew point. The chilled

air flows in a counter flow thereby assuring high temperature

differential throughout the heat exchanger. The reheating

of the air prevents moisture condensation on the air

system piping.

AIR TO AIR AND EVAPORATOR

FLOW SCHEMATIC

REFRIGERANT IN

REFRIGERANT OUT

X17 Drain

Air Outlet

Air Inlet

EVAPORATOR

“B”

AIR TO AIR HEAT EXCHANGER

“A”

WATER

SEPARATOR

“C”

REFRIGERATION

EVAPORATOR

COIL

Page 9

Page 8 WILKERSON OPERATIONS

The refrigerant compressor (“A”) increases the pressure and

the temperature of the returning suction vapor containing the

latent heat removed from the air by the evaporator (“B”). This

high pressure vapor is then condensed by being cooled in the

condenser (“C”). The condenser surrenders the heat to the

surrounding ambient.

The liquid refrigerant flows from the receiver through a liquid

line heat exchanger located in the suction line (“H”), through

the filter/dryer (“E”), and the the thermostatic expansion valve

(“F”), which regulate the flow of refrigerant into the evaporator

(“B”). The liquid refrigerant removes the heat from the

compressed air by evaporation. The hot-gas bypass valve

(“G”) controls the temperature of the evaporator by sensing

low evaporator pressure and injecting hot discharge gas to be

mixed with the liquid refrigerant entering the evaporator,

creating an artificial load during low load operation to prevent

ice from forming in the evaporator.

The refrigerant now flows to the suction accumulator (“D”),

where any liquid refrigerant is intercepted allowing only vapor

to return to the compressor completing the refrigeration cycle.

Refrigeration Circuit

SUCTION

ACCUMULATOR

(D)

EXPANSION

VALVE

(F)

HOT GAS

BY-PASS VALVE

(G)

TXV

BULB

EXTERNAL

EQUALIZER

LINE

FILTER

DRYER

(E)

EVAPORATOR

(B)

LIQUID

LINE HEAT

EXCHANGER

(H)

COMPRESSOR

(A)

CONDENSER

(C)

AIR FLOW

DISCHARGE

SUCTION

Page 10

WILKERSON OPERATIONS Page 9

CONTROL PANEL COMPONENTS

Item Description Part Number

1 On/Off Switch 87-379-000

2 High Temperature Light 87-382-000

3 Air Pressure Gauge 49-111-000

4 Refrigerant Pressure Gauge 49-093-000

5 Digital Display 87-508-000

6 Selector Knob 87-470-000

Check air compressor aftercooler system. Clogged or fouled heat exchanger surfaces in the aftercooler (water or air cooled) are

the principal cause of high inlet air temperatures to dryer.

Check air compressor as well. Lack of lubrication, excessive wear, compressor undersized (i.e. substantial increase in air

consumption without adding to compressor capacity: oil cooler malfunction, etc.)

If high ambient temperature is the problem, immediately begin to cool dryer area with ventilating fans, open windows, louvers,

etc. Sustained high temperatures will damage dryer.

Dryer Indicates “High Inlet Temperature”

Page 11

Page 10 WILKERSON OPERATIONS

ELECTRICAL COMPONENTS:

Item Description Voltage Model Number Part Number

1 Transformer ALL ALL 87-044-000

2 Contactor ALL ALL 87-063-000

3 Fuse Holder ALL ALL 87-209-000

4 Fuse 1.0 AMP ALL ALL 87-210-000

5 Electrical Outlet ALL ALL 87-246-000

6 Electrical Enclosure ALL ALL 87-685-000

7 Cover ALL ALL 63-685-000

8 Start Relay 230/60/1 WR ( )-0250/0300-2 87-040-000

(Single Phase Units Only) 230/60/1 WR ( )-0400/0500-2 87-041-000

9 Start Capacitor 230/60/1 WR ( )-0250-2 87-056-000

(Single Phase Units Only) 230/60/1 WR ( )-0300-2 87-056-000

230/60/1 WR ( )-0400-2 87-036-000

230/60/1 WR ( )-0500-2 87-036-000

10 Run Capacitor 230/60/1 WR ( )-0250-2 87-039-000

(Single Phase Units Only) 230/60/1 WR ( )-0300-2 87-614-000

230/60/1 WR ( )-0400-2 87-039-000

230/60/1 WR ( )-0500-2 87-074-000

Electrical Box Components

Page 12

WILKERSON OPERATIONS Page 11

REFRIGERATION COMPONENTS:

Item Description Voltage Model Number Part Number

1 Compressor 230/60/1 WR ( )-0250-2 51-045-000

230/60/3 WR ( )-0250-3 51-046-000

460/60/3 WR ( )-0250-4 51-047-000

230/60/1 WR ( )-0300-2 51-048-000

230/60/3 WR ( )-0300-3 51-049-000

460/60/3 WR ( )-0300-4 51-050-000

230/60/1 WR ( )-0400-2 51-051-000

230/60/3 WR ( )-0400-3 51-052-000

460/60/3 WR ( )-0400-4 51-053-000

230/60/1 WR ( )-0500-2 51-000-000

230/60/3 WR ( )-0500-3 51-001-000

460/60/3 WR ( )-0500-4 51-002-000

2 Expansion Valve ALL WR ( )-0250 52-097-000

ALL WR ( )-0300 52-098-000

ALL WR ( )-0400 52-099-000

ALL WR ( )-0500 52-099-000

3 Hot Gas By-Pass Valve ALL WR ( )-0250 52-021-000

ALL WR ( )-0300 52-021-000

ALL WR ( )-0400 52-024-000

ALL WR ( )-0500 52-024-000

REFRIGERATION COMPONENTS:

Item Description Voltage Model Number Part Number

4 Filter Dryer — ALL 54-072-000

5 Suction Accumulator — ALL 54-000-000

6 Fan Motor ALL ALL 51-040-000

7 Fan Blade — ALL 51-102-000

8 Fan Guard — ALL 51-030-000

9 Fan Cycle Control — WRA-0250-0400 87-121-000

WRA-0500 87-092-000

10 High Pressure Control — ALL 87-120-000

11 High Temperature Control — ALL 87-116-000

12 Condenser (Air-cooled) — WRA-0250/0300 59-094-000

WRA-0400 59-095-000

WRA-0500 59-092-000

13 Condenser (Water-cooled) — WRW-0250/0300 59-099-000

WRW-0400 59-100-000

WRW-0500 59-101-000

14 Water Control Valve — ALL WRW 52-060-000

15 Refrigerant Service Valve — ALL 52-090-000

Refrigeration Components

Page 13

Page 12 WILKERSON OPERATIONS

CABINET COMPONENTS

Item Description Model Number Part Number

1 Frame Assembly ALL 14-138-000

2 Panel, Back ALL 63-673-000

3 Panel, Exhaust ALL 63-674-000

ALL WATER-COOLED 63-091-000

4 Panel, Inlet

ALL AIR-COOLED 63-672-000

5 Panel, Front Left ALL 63-774-000

6 Panel, Front, Lower Right ALL 63-709-000

7 Panel, Front, Top Right ALL 63-050-000

8 Lid ALL 63-669-000

Cabinet Components

Page 14

WILKERSON OPERATIONS Page 13

Wiring Diagram-Air

Page 15

Page 14 WILKERSON OPERATIONS

Wiring Diagram-Air

Page 16

WILKERSON OPERATIONS Page 15

TROUBLE SHOOTING GUIDE

Problem, Caused By: Corrective Action

I. Dryer will not run, caused by:

1. No power A. Have qualified technician

check main disconnect

fuses and wiring (see

wiring diagram page

13 & 14).

2. Wrong voltage B. Voltage should be within

+/- 10% of rating on

nameplate. Have

qualified electrician

correct it.

3. Defective “ON/OFF” switch C. Have qualified technician

replace.

4. Compressor overload E. Allow time to cool (2 to 20

(protector) open minutes); switch will

automatically reset. Check

for high or low electrical

voltage. See I., 2 (B).

Have qualified technician

check for poor electrical

connections. Dryer may

be overloaded.

5. Refrigerant compressor motor F. Have qualified technician

failure check if winding is open or

shut.

6. Low refrigerant charge G Check for and repair

refrigerant leaks. Replace

filter-dryer, evacuate and

charge with recommended

type and amount of

refrigerant.

7. Dirty condenser H. Blow out condenser, install

furnace filter and clean

periodically.

8. Fan motor failure, head pressure J. Replace defective

control failure components.

II. Compressed air leaks, caused by:

1. Poor connections A. Check all connections

and tighten.

2. Automatic drain malfunctioning B. Check for constant air leak

from drain discharge. Shut

off air pressure, remove

drain, clean or replace

drain and/or drain valve

seat.

III. Liquid water in compressed air system, caused by:

1. Incorrect dryer installation A. Check for proper

inlet/outlet compressed air

connections.

2. Compressed air bypass line open B. Close dryer by-pass valve.

3. Dryer not running C. See section I. above.

4. Residual liquid water in piping D. Drain all drop legs and

system points and allow time for

dry air to purge system.

Problem, Caused By: Corrective Action

III. Liquid water in compressed air system, caused by cont.:

5. Automatic drain on dryer not E. 1. Check “Power On”

working (electric) light on drains to

verify they have power.

2. Check drain shut-off

valve to assure it is

open.

3. Clean Y-strainer (be

sure shut-off valve is

closed before servicing

Y-strainer.)

4. Verify that the drain

solenoid valves are

opening.

5. Adjust cycle time and

duration to assure

complete draining.

6. Excessive compressed air flow or F. Check flow and

temperature temperature inlet against

dryer ratings.

7. Compressed air aftercooler G.Check separator; drain,

separator malfunction replace or repair.

8. Low ambient temperature H. Check if compressed air

outlet piping is routed

through an area where

ambient temperatures are

below the dryer dew point

rating.

IV. Excessive noise and vibration, caused by:

1. Broken or bent condenser fan A. Check and straighten fan

blades striking housing mounting bracket or

blades. Replace

damaged fan.

2. Damaged parts in air circuits B. Replace damaged

components. Check the air

system for “quick” or rapid

opening valves that can

cause an abrupt traveling

pressure front (hammer

effect) in the system.

V. Digital Temperature Indicator:

1. No display A. Check fuse on the back side

of the board, replace if

necessary

2. Erroneous reading on some B. Check for constant air leak

positions from drain discharge. Shut

off air pressure, remove

drain, clean or replace

drain and/or drain valve

seat.

C. Verify the temperature

probe making good

contact on the surface.

D. Plug in another probe

knowing to be giving

available if the on/off switch

is off.

3. Erroneous reading all channels E. Replace display board.

Page 17

Page 16 WILKERSON OPERATIONS

In an effort to maximize warranty support and minimize confusion concerning the Wilkerson Refrigerated Air Dryer warranty policy,

the following is presented as a supplement to the standard Wilkerson warranty policy.

First, please note that Wilkerson is not necessarily responsible for labor costs associated with a warranted part. It has been

incorrectly assumed by many customers that Wilkerson would accept labor charges regardless of the claim submitted. This is not the

case as indicated by the following clarifications.

Problems such as plugged drains, burned out light bulbs, simple electrical trouble shooting, and minor adjustments will not be

covered under warranty. It is our intent to work with the customer over the phone to correct such minor problems.

For example:

It is not uncommon for a hot-gas bypass valve to drift slightly out of calibration over a period of time. This simple

adjustment can be performed by the customer under most circumstances. It requires no knowledge of refrigeration systems and will

be supported by telephone and written documentation. This not only saves the customer time but also educates them on this

common procedure so that it can be performed again when the dryer is

not

under warranty.

Naturally, customers will not be expected to perform major repairs such as replacing a compressor or installing a heat exchanger.

These tasks must be performed by a qualified technician. Along these lines, a customer may be asked to take ohm or amp readings

to determine if a compressor needs to be replaced. At this point, it is not necessary to write down every task a customer may be

asked to perform. These issues are better addressed on a case-by-case basis.

Now that the written warranty policy has been reviewed and some examples given, the next step is to review the correct way to file

a warranty claim. The following

“Warranty Procedure”

clearly outlines the obligations of Wilkerson Corporation and the procedure to

be followed when processing a warranty claim.

WILKERSON REFRIGERATED AIR DRYER WARRANTY

Wilkerson products are warranted to be free from defects in material and workmanship, under proper use, installation, application and

maintenance in accordance with Wilkerson's written recommendations and specification for a period of one year from the date of shipment

from the factory (refrigerated dryers are warranted for 2 years). Wilkerson's obligation under this warrant is limited to, and the sole remedy

for any such defect shall be, the repair or replacement (at Wilkerson's option) of unaltered products returned to Wilkerson and proven to

have such defect, provided such defect is promptly reported to Wilkerson within said one-year period.

This is the only authorized Wilkerson warranty and is in lieu of all other express or implied warranties or representation, including any

implied warranties of merchantability or fitness, or of any other obligations on the part of Wilkerson.

Warranty claims must be submitted and shall be processed in accordance with Wilkerson's established warranty claim procedure. In no

event will Wilkerson be liable for business interruptions, loss of profits, personal injury, costs of delay or for any other special, indirect,

incidental or consequential losses, cost or damages.

NOTE: Routine maintenance and minor adjustments to Wilkerson refrigerated compressed air dryers are not covered under

this warranty. Prior to performing any possible warranty service or replacing a possible warranted part, Wilkerson must be

notified at (303) 761-7601. Failure to comply with this procedure will result in denial of warranty claim. Please fill in the Service

Information Sheet prior to calling Wilkerson.

Service Information Sheet

1. Dryer Model No.

2. Dryer Serial No.

3. Date Installed and Started Up

4. Prefilter Model No(s). (if no prefilters are present, so indicate)

5. Nature Of Problem

Page 18

SERVICE INFORMATION

We will be glad to assist with any service problems you may have. However, before contacting us, please have the

following information available.

1. MODEL NUMBER 2. SERIAL NUMBER

3. What is the nature of the problem?

4. What is the Refrigerant Suction Pressure Gauge reading?

OTHER INFORMATION NEEDED:

A. AIR TEMPERATURES AND PRESSURES

Inlet air temperature ___________________°F (°C) Outlet air temperature _____________________°F (°C)

Inlet air pressure___________________psig (bar) Outlet air pressure _____________________psig (bar)

B. AIR FLOW

What is H.P. of compressor? __________________ What is the air flow? _______________scfm (Nm3/h)

C. AMBIENT CONDITIONS AT DRYER INSTALLATION

What is the ambient air temperature? _____________°F (°C)

Is ambient air at dryer installation dusty? ____________ Has condenser been cleaned recently? ___________

WILKERSON OPERATIONS Page 17

Loading...

Loading...