Page 1

Richland, MI 49083 Tel: (269) 629-5000

Installation & Service Instructions

83-181-000

Regulator Model R26

With Variations and Accessories

ISSUED: April, 2006

Supersedes: August, 1995

Doc.# 83181000, ECN# 060135, Rev. 1

WARNING

!

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

INSTALLATION

1. Install as close as possible to where regulated air is needed.

2. Install the unit with the air flowing through the body in the direction

indicated by the arrow.

3. Install the same pipe size unit as the pipe line in use. Avoid using fittings,

couplings etc. that restrict the airflow, unless maximum flow is not

needed.

4. Regulator may be installed with the adjusting knob in any position. Attach

gauge to one 1/4" female gauge port and plug the other 1/4" female

port, or use it as a regulated outlet port.

5. Turning the adjusting screw clockwise increases the regulated pressure

and turning it counterclockwise decreases the regulated pressure.

6. Panel mount regulators require a 17/8" diameter hole and are mountable

on panels from 1/8" to 1/2" thick.

MAINTENANCE

1. The regulator can be disassembled for servicing without removal from

line.

2. Occasionally remove bottom plug and clean plug, body and valve seat

(vent air line on both sides of regulator).

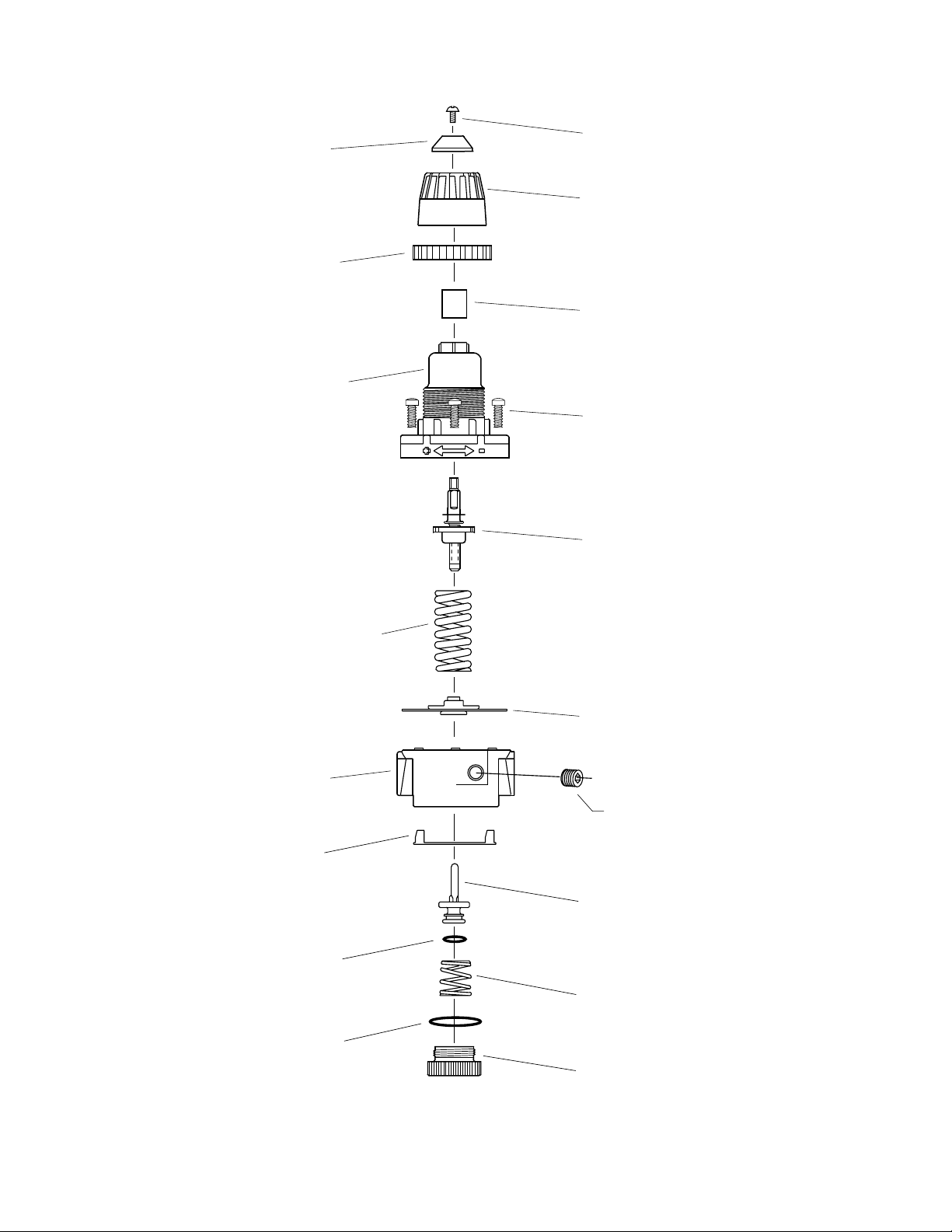

3. TO DISASSEMBLE-shut off air to regulator and vent air line on both

sides of regulator. Turn adjusting screw counterclockwise to relieve

adjusting knob (panel mount nut, if used), tamper-resistant kit (on

tamper-resistant models) and cover cap. Remove the six screws, cover

and regulating spring. Diaphragm assembly can now be removed. By

removing bottom plug and spring the valve stem can be removed from

the bottom of the regulator

4. IF UNIT WILL NOT REGULATE TO DESIRED PRESSURE OR IF

PRESSURE BECOMES EXCESSIVE remove bottom plug, spring, and

valve assembly. Clean and check o-ring, valve stem and valve seat for

water damage. Replace worn or damaged parts. Install Repair Kit No.

RRP-95-951 for self-relieving models and Repair Kit No. RRP-95-950

for nonrelieving models for complete overhaul.

5. IF UNIT LEAKS AT RELIEF PORT, install proper repair kit as listed

under Repair Kits and Replacement Parts.

6. TO REPLACE BODY O-RING-This o-ring is located above a metal

washer through which the valve stem passes and which cannot be

removed. Using a pointed probe of some kind, pull o-ring out. Force

new o-ring through washer hole into o-ring cavity.

REPAIR KITS AND REPLACEMENT PARTS

SELF-RELIEVING REPAIR KIT

(includes self-relieving diaphragm assembly,

valve assembly and o-rings) ............................................ RRP-95-951

NONRELIEVING REPAIR KIT

(includes nonrelieving diaphragm assembly,

valve assembly and o-rings) ............................................ RRP-95-950

Self-Relieving Diaphragm Kit ............................................. RRP-96-238

Nonrelieving Diaphragm Kit ............................................... RRP-96-332

Valve Assembly (valve stem, valve spring) ........................ RRP-96-294

Regulating Springs:

0-60 psi ............................................................................ RRP-95-962

0-125 psi .......................................................................... GRP-95-225

0-250 psi .......................................................................... RRP-95-219

Adjusting Knob Assembly .................................................. RRP-95-023

ACCESSORIES

Panel Mount Nut ................................................................ RRP-95-954

Wall Mounting Bracket ........................................................ RPA-95-947

Wall Mounting Bracket (for 26 Series Combo’s) ................ GRA-95-956

Tamper Resistant Kit ........................................................... RPA-95-006

Gauges:

0-60 psig ....................................................................... K4520N14060

0-160 psig ..................................................................... K4520N14160

0-300 psig ..................................................................... K4520N14300

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

WARNING

!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS

CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for further

investigation by users having technical expertise. It is important that you

analyze all aspects of your application, including consequences of any

failure and review the information concerning the product or systems in the

current product catalog. Due to the variety of operating conditions and

applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product features,

specifications, designs, availability and pricing, are subject to change by

The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

83-181-000

LOCK

KNOB

PANEL

MOUNT

NUT

BONNET

NNR

SCREW

ADJUSTING

KNOB

ASSEMBLY

TAMPERRESISTANT

KIT (Optional)

SCREW

ADJUSTING

SCREW

ASSEMBLY

REGULATING

SPRING

BODY

NNR

CAP

NNR

O-RING

O-RING

DIAPHRAGM

ASSEMBLY

PIPE PORT

PLUG

NNR

VALVE

ASSEMBLY

VALVE

SPRING

BOTTOM PLUG

NNR

NNR=NOT NORMALLY REPLACED

Loading...

Loading...