Page 1

Richland, MI 49083 Tel: (269) 629-5000

WARNING

!

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

INSTALLATION

Install the Filter/Regulator as close as possible to the application. The

inlet port is marked with an arrow cast into the body to indicate the

direction of flow. Gauge ports (1/4") are provided in either side of the

body for installation of a gauge or use as an additional outlet port.

Plug unused port(s). System piping should be same size as regulator

porting. In systems with a cyclic demand, the regulator should be

located upstream of cycling device.

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

OPERATION

Maximum pressure rating is 150 psig (10 bar) for transparent

plastic bowls, and 200 psig (14 bar) for metal bowls.

Temperature range is 32°F to 125°F (0°C to 52°C) for transparent

plastic bowls, and 32°F to 150°F (0°C to 65.5°C) for metal bowls.

Before turning on the supply air pressure, turn the adjusting knob

counterclockwise until there is no load on the regulating spring. Turn

on the supply air pressure and then turn the adjusting knob clockwise

until the desired secondary pressure is reached. To avoid minor

readjustment after making a change in pressure setting, always

approach the desired pressure form a lower pressure. When reducing

from a higher to a lower setting, first reduce to some pressure less

than that desired and then increase to the desired pressure.

SEE REVERSE SIDE FOR LIST OF MATERIALS

UNSUITABLE FOR USE WITH POLYCARBONATE BOWLS

MAINTENANCE

1. The regulator can be disassembled for servicing without removal

from line.

2. DEPRESSURIZE UNIT BEFORE REMOVING GUARD AND/OR

BOWL.

3. TO DISASSEMBLE: shut off air to the filter/regulator and vent air

line on both sides of unit. Turn adjusting screw counterclockwise

to relieve spring compression. Remove knob, cover cap, screw

cover, and spring. Diaphragm assembly can now be removed.

4. To remove valve from bottom of unit, remove bowl. Remove baffle

and filter element exposing hex nut on adapter assembly.

Remove adapter assembly, valve and spring.

(continued on reverse side)

Installation & Service Instructions

83-861-000

Precision Air Pressure Regulator

Type PC6B Filter / Regulator

ISSUED: April, 2006

Supersedes: July, 2004

Doc.# 83861000, ECN# 060299, Rev. 4

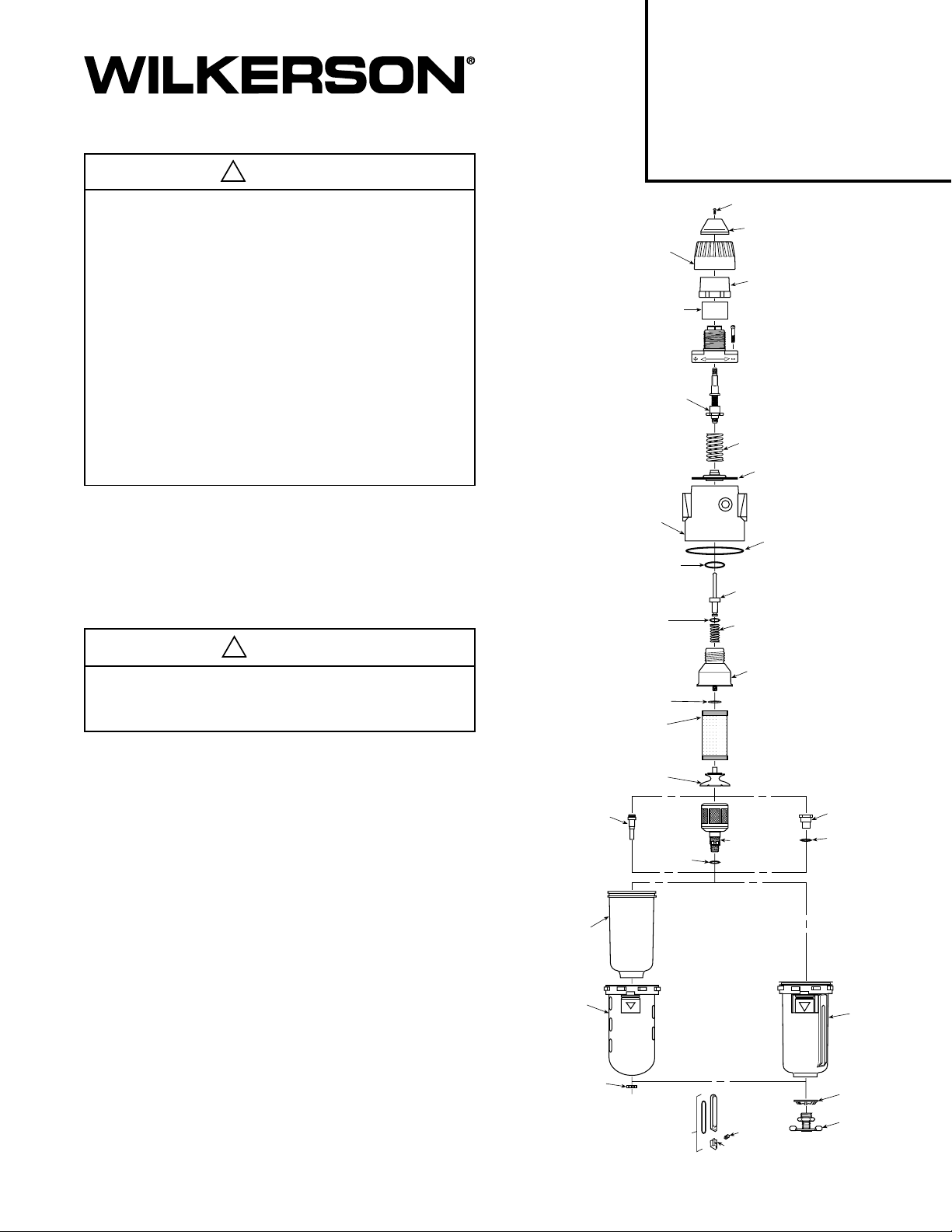

ADJUSTING

KNOB

ASSEMBLY

TAMPER

RESISTANT

KIT (optional)

ADJUSTING

STEM

ASSEMBLY

BODY

NNR

O-RING

O-RING

GASKET

FILTER

ELEMENT

BAFFLE

NNR

FLEX-DRAIN™

(plastic bowls only)

O-RING

TRANSPARENT

BOWL

BOWL

GUARD

NUT

(for use with

Auto. Mechanical

NNR = NOT NORMALLY REPLACED

Drain)

SIGHT GAUGE

KIT

SCREW

LOCK KNOB

PANEL

MOUNT

NUT

REGULATING

SPRING

DIAPHRAGM

ASSEMBLY

BOWL

O-RING

VALVE STEM

VALVE SPRING

ADAPTER

NNR

AUTOMATIC

MECHANICAL

DRAIN

SCREW

RETAINER

BOWL

INSERT

O-RING

METAL

BOWL

INSERT

RETAINER

PETCOCK

(for metal

bowls only

)

Page 2

5. If unit is equipped with plastic bowl, inspect daily to detect

crazing, cracking, damage, or other deterioration. Immediately

replace any crazed, cracked, damaged, or deteriorated bowl with

a metal bowl or a new plastic bowl and metal bowl guard.

6. Replace or clean the filter element periodically by removing from

filter, tapping on surface, and blowing off with air blow gun.

7. If unit is equipped with a manual petcock, drain bowl at least once

per work shift.

8. If unit is equipped with a float, clean the bowl each time the

element is cleaned or changed by turning the bowl upside down

and tapping onto tabletop. Blow clean with blow gun.

9. If unit will not regulate to required pressure, or if pressure

becomes excessive, follow instructions (see step 4) for removal of

valve. Remove valve and spring (Clean and check valve stem

and valve seat for wear or damage and replace if required.)

10. Before placing unit in service, make sure that bowl and bowl

guard are reinstalled and securely locked in place.

REPAIR KITS AND REPLACEMENT PARTS

SELF-RELIEVING REPAIR KIT (includes self-relieving

diaphragm assembly, valve stem, valve spring,

filter element, and bowl o-ring) ................................................ PRP-95-025

Regulating Springs:

0-30 psi ..................................................................................... RRP-95-916

0-50 psi ..................................................................................... RRP-95-222

0-125 psi ................................................................................... RRP-95-224

Self-Relieving Diaphragm Kit ...................................................... PRP-95-960

Valve Assembly (valve stem, valve spring) ................................ PRP-95-959

Filter Element Assembly (includes

element and bowl o-ring) ......................................................... FRP-95-160

Transparent Plastic Bowl Assemblies:

with Flex-Drain™ ...................................................................... FRP-95-017

with bowl guard, Automatic Mechanical Drain ........................ FRP-95-015

with bowl guard, Flex-Drain™ ................................................. GRP-95-014

Bowl O-Ring Kit (10 per kit) ........................................................ GRP-95-009

Bowl Guard Kit ............................................................................. GRP-95-013

Metal Bowl Assemblies:

with metal petcock ................................................................... PRP-95-070

with Sight Gauge, metal petcock (for units

with “G” in model no) ................................................................ PRP-95-071

with Automatic Mechanical

Drain and Viton® seals ............................................................ PRP-96-006

Drains:

Automatic Drain Kit (includes

o-ring, nut) ................................................................................ GRP-95-973

Automatic Mechanical Drain with Viton® seals ...................... GRP-95-981

Brass Petcock (for metal bowls) ................................................. GRP-95-182

Flex-Drain™ Kit (for plastic bowls) ............................................. FRP-95-610

Adjusting Knob Kit ....................................................................... RRP-95-023

NOTE: All bowl kits include bowl o-ring

ACCESSORIES

Wall Mounting Bracket with Panel Mount Nut ............................ GRP-95-011

Wall Mounting Bracket ................................................................ GRP-95-012

Panel Mount Nut .......................................................................... GPA-95-032

Tamper Resistant Kit ................................................................... RPA-95-006

Viton Valve Assembly .................................................................. PPA-95-067

Gauges:

0-30 psig ................................................................................ K4520N18030

0-60 psig ................................................................................ K4520N14060

0-120 psig .............................................................................. K4520N14160

WARNING: IF YOUR UNIT HAS A PLASTIC BOWL

1.

DO NOT use plastic bowl units without a metal bowl guard installed.

Plastic bowl units are sold only with metal bowl guards to minimize

the danger of flying fragments in the event of bowl failure.

2. DO NOT install the unit where it will be subjected to temperatures

higher than 125°F (52°C).

3. DO NOT install the unit where it will be subjected to pressure

higher than 150 psig (10 bar).

4. CAUTION: Certain compressor oils, household cleaners,

chemicals, solvents, paints and fumes will attack plastic bowls

and can cause plastic-bowl failure. See manufacturer's list below.

Do not use near these materials.

83-861-000

!

CAUTION

Polycarbonate bowls, being transparent and tough, are ideal for use with

Filters and Lubricators. They are suitable for use in normal industrial

environments, but should not be located in areas where they could be

subjected to direct sunlight, an impact blow, nor temperatures outside of the

rated range. As with most plastics, some chemicals can cause damage.

Polycarbonate bowls should not be exposed to chlorinated hydrocarbons,

ketones, esters and certain alcohols. They should not be used in air systems

where compressors are lubricated with fire-resistant fluids such as phosphate

ester and di-ester types.

Metal bowls are recommended where ambient and/or media conditions are

not compatible with polycarbonate bowls. Metal bowls resist the action of

most such solvents, but should not be used where strong acids or bases are

present or in salt laden atmospheres. Consult the factory for specific

recommendations where these conditions exist.

TO CLEAN POLYCARBONATE BOWLS USE MILD SOAP AND WATER

ONLY! DO NOT use cleansing agents such as acetone, benzene, carbon

tetrachloride, gasoline, toluene, etc., which are damaging to this plastic.

Bowl guards are recommended for added protection of polycarbonate bowls

where chemical attack may occur.

SOME OF THE MATERIALS THAT WILL ATTACK POLYCARBONATE

Acetaldehyde

Acetic acid (conc.)

Acetone

Acrylonitrile

Ammonia

Ammonium fluoride

Ammonium hydroxide

Ammonium sulfide

Anaerobic adhesives

& sealants

Antifreeze

Benzene

Benzoic acid

Benzyl alcohol

Brake fluids

Bromobenzene

Butryic acid

Carbolic acid

Carbon disulfide

Carbon tetrachloride

Caustic potash solution

Caustic soda solution

TRADE NAMES OF SOME COMPRESSOR OILS, RUBBER

COMPOUNDS AND OTHER MATERIAL THAT WILL

ATTACK POLYCARBONATE PLASTIC BOWLS.

Atlas Perma Guard

Buna N

Cellulube #150 and #220

Crylex #5 cement

*Eastman 910

Garlock #98403 (polyurethane)

Haskel #568-023

Hilgard Co’s hil-phene

Houghton & Co oil #1120 #1130 and #1055

Houtosafe 1000

Kano Kroil

Keystone penetrating oil #2

* Loctite 271

* Loctite 290

* Loctite 601

* Loctite Teflon-Sealant

Marvel Mystery Oil

Minn Rubber 366Y

National Compound #N11

“Nylock” VC 3

* When in raw liquid form

WE CANNOT POSSIBLY LIST ALL HARMFUL SUBSTANCES,

CHECK WITH A MOBAY CHEMICAL OR

GENERAL ELECTRIC OFFICE FOR FURTHER

INFORMATION ON POLYCARBONATE PLASTIC.

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED

ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for further

investigation by users having technical expertise. It is important that you

analyze all aspects of your application, including consequences of any

failure and review the information concer ning the product or systems in the

current product catalog. Due to the variety of operating conditions and

applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product features,

specifications, designs, availability and pricing, are subject to change by

The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

PLASTIC BOWLS

Chlorobenzene

Chloroform

Cresol

Cyclohexanol

Cyciohexanone

Cyclohexene

Dimethyl formamide

Dioxane

Ethane tetrachloride

Ethyl acetate

Ethyl ether

Ethylamine

Ethlene chlorohydrin

Ethlene dichloride

Ethlene glycol

Formic acid (conc.)

Freon (refrigerant & propellant)

Gasoline (high aromatic)

Hydrazine

Hydrochloride acid (conc.)

Lacquer thinner

Methyl alcohol

Parco #1306 Neoprene

* Permabond 910

Petron PD287

Prestone

Pydraul AC

Sears Regular Motor Oil

Sinclair oil “Lily White”

Some Loctite Compounds

Stauffer Chemical FYRQUEL #150

Stillman #269-75 (polyurethane)

Stillman #SR-513-70 (neoprene)

Tannergas

Telar

Tenneco anderol #495 & #500 oils

Titon

* Vivra-tite

Zerex

WARNING

!

Methylene cholride

Methylene salicylate

Milk of lime (CaOH)

Nitric acid (conc.)

Nitrobenzene

Nitriocellulose lacquer

Phenol

Phosphorous hydroxy chloride

Phosphorous trichloride

Propionic acid

Pyridine

Sodium hydroxide

Sodium sulfide

Styrene

Sulfuric acid (conc.)

Sulphural chloride

Tetrahydronaphthalene

Thiophene

Toluene

Turpentine

Perchlorethylene and others

Loading...

Loading...