Page 1

!

!

Richland, MI 49083 Tel: (269) 629-5000

Installation & Service Instructions

83-956-000

1/4" and 3/8" R12 Regulator, and

1/4" and 3/8" P12 Precision Regulator

ISSUED: May, 2005

Supersedes: September, 2002

Doc.# 83956000, ECN# 050500, Rev. 4

WARNING

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before

installation, servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected

to this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure,

temperature, and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is

present, or the product does not operate properly, do not put

into use.

• Warnings and specifications on the product should not be

covered by paint, etc. If masking is not possible, contact your

local representative for replacement labels.

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

Introduction:

Follow these instructions when installing, operating, or servicing

the product.

Installation

1. The regulator should be installed with reasonable

accessibility for service whenever possible - repair service

kits are availab le. K eep pipe and tubing lengths to a minimum

with inside clean and free of dirt and chips. Pipe joint

compound should be used sparingly and applied only to

the male pipe - never into the female port. Do not use

PTFE tape to seal pipe joints - pieces have a tendency to

break off and lodge inside unit, possibly causing malfunction.

2. Install regulator so that air flow is in the direction of arrow.

Installation must be upstream (high pressure) side and as

close to the devices it is to service (valve, cylinder, tool,

etc.). Mounting may be in any position.

3. Gauge ports are located on both sides of the regulator

body for your con v enience. It is necessary to install a gauge

or pipe plugs into each port during installation.

4. For protection against rust, pipe scale, and other foreign

matter, install a filter on the upstream (high pressure) side

as close to the regulator as possible.

Operation

1. Before turning on the air supply, turn the adjusting knob

counterclockwise until compression is released from the

control spring. Then turn on air supply and adjust regulator

to desired secondary pressure by turning adjusting knob

clockwise. This permits pressure to build up slowly,

preventing an y une xpected operation of the v alv e , cylinders,

tools, etc., attached to the line. Adjustment to desired

secondary pressure can be made only with primary pressure

applied to the regulator.

2. To decrease regulator pressure setting, always reset from a

pressure lower than the final setting desired. For example,

lowering the secondary pressure from 550 to 410 kPa (80

to 60 psig) is best accomplished by dropping the secondary

pressure to 350 kPa (50 psig), then adjusting upward to

410 kPa (60 psig). Push the adjusting knob down to lock

the pressure setting.

Application Limits

WARNING

These products are intended for use in general purpose

compressed air systems only.

kPa PSIG bar

Maximum Inlet Pressure 1734 250 17.3

Ambient Temperature Range: 0°C to 80°C (32°F to 175°F)

ANSI Symbols

Relieving Regulator

Adjustable

Non-Relieving Regulator

Adjustable

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELA TED

ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for

further investigation by users having technical expertise. It is important

that you analyze all aspects of your application, including consequences

of any failure and review the information concerning the product or

systems in the current product catalog. Due to the variety of operating

conditions and applications for these products or systems, the user,

through its own analysis and testing, is solely responsible for making

the final selection of the products and systems and assuring that all

performance, safety and warning requirements of the application are

met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject to

change by The Company and its subsidiaries at any time without notice .

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

!

1/4" and 3/8" R12 Regulator, and 1/4" and 3/8" P12 Precision Regulator 83-956-000

!

Service

CAUTION:

SHUT OFF AIR SUPPLY and exhaust the primary and

secondary pressure before disassembling regulator unit.

(Turning the knob counterclockwise reduces regulator’s

setting, but does not vent downstream pressure on nonrelieving regulators.)

CAUTION:

Lubricate parts with a mineral based oil / grease or silicone free

grease. DO NOT use synthetic oils / greases such as esters.

A. Use the following procedure to service Diaphragm and

/ or Control Spring:

1. Disengage the adjusting knob by pulling upward. Turn

adjusting knob counterclockwise until the compression is

released from the pressure control spring.

2. Unscrew the threaded collar and remove the bonnet

assembly. Next, disassemble, clean, and carefully inspect

parts for wear and/or damage. If replacement is necessary,

use parts from service kits.

3.

Lubricate o-ring and lip seals with grease (supplied with kits).

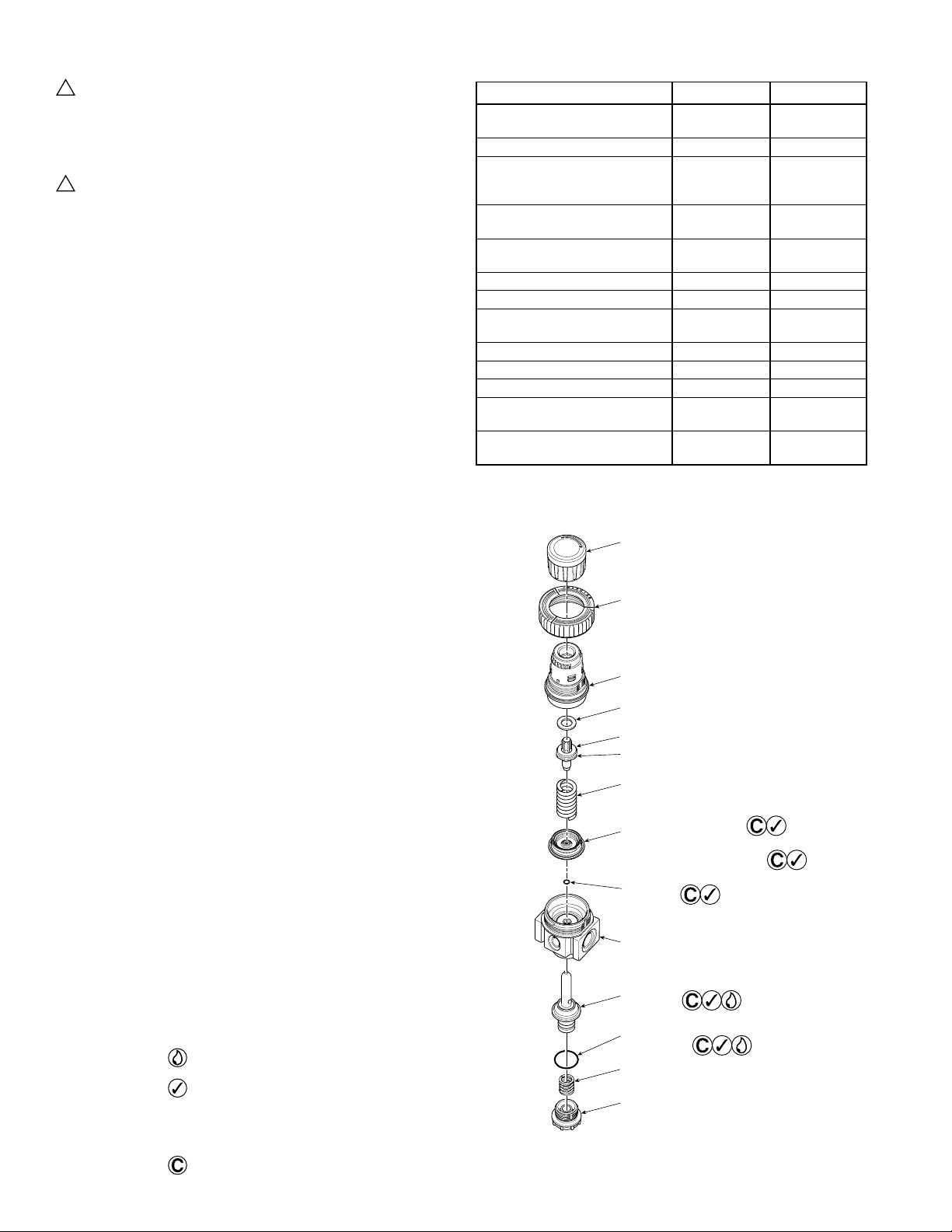

4. Install diaphragm assembly into bonnet. Then install bonnet

assembly to body and tighten threaded collar per Figure 1.

B. Servicing the Valve Assembly-

1. Exhaust system air pressure as previously described. Then

remove bottom cap by unscre wing it from body. Next, remov e

valve assembly, o-ring, cap o-ring and valve return spring.

2. Next, disassemble, clean, and carefully inspect parts for

wear and/or damage. If replacement is necessary, use parts

from service kits.

3. Lubricate o-ring and sliding surfaces using grease supplied

with service kit.

4. Install parts as shown in Figure 1.

5. Lubricate cap o-ring and install it in o-ring groove on cap.

Then screw cap into body until the cap bottoms out in body

(See Figure 1).

6. Turn on air supply and adjust to desired secondary pressure

as described in the Operation section.

Turn on air pressure and check regulator for leakage. If leakage

occurs, DO NOT OPERATE — conduct repairs again.

If you have questions concerning how to service this unit, contact

your local authorized dealer or your customer service representative.

Service Kits Available

Description R12 P12

Air Pilot Conversion

(Relieving)

Bonnet Assembly RRP-96-308 —

Gauges:

Low Pressure RRP-96-664 RRP-96-664

0 to 414 kPa (0 to 60 PSIG)

Low Pressure

0 to 207 kPa (0 to 30 PSIG)

Standard Pressure

0 to 1103 kPa (0 to 160 PSIG)

Mounting Bracket Kit GPA-96-313 GPA-96-313

Regulator Control Knob RRP-96-300 —

Springs:

862 kPa (125 PSIG) RRP-96-301 RRP-96-301

414 kPa (60 PSIG) RRP-96-302 RRP-96-302

206 kPa (30 PSIG) RRP-96-303 RRP-96-303

1379 kPa (200 PSIG) RRP-96-304 RRP-96-304

Non-Relieving

Regulator Repair Kit*

Relieving Regulator

Repair Kit*

*Grease in kit is silicone free

Knob

Collar

(Hand tight

plus 1/4 turn)

Bonnet

Washer

Adjusting Screw

Drive Nut

GRP-96-350 —

RRP-96-663 RRP-96-663

RRP-96-665 RRP-96-665

RRP-96-307 —

RRP-96-306 RRP-96-305

Control Spring

Diaphragm Assembly

(Includes Upper Diaphragm Plate

& Lower Diaphragm Plate)

O-Ring,

Vent Seal

(Not used on 27RC)

Body

Valve

Assembly

O-Ring,

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface

imperfections. If present, reduced service

life is probable and future replacement

should be planned.

Clean with lint-free cloth.

Figure 1:

Bottom Cap

Spring,

Valve Return

Bottom Cap

Torque:

2.3 to 2.8 Nm

(20 to 25 in. lb.)

R12 and P12

Regulators

Page 3

Richland, MI 49083 Tel: (269) 629-5000

!

!

!

Instructions d’installation et d’entretien

83-956-000 (French)

Régulateur R12 de 1/4 in et 3/8 in et

régulateur de précision P12 de 1/4 in

et 3/8 in

PUBLICATION: mai, 2005

Remplace: septembre, 2002

Doc.# 83956000, ECN# 050500, Rev. 4

AVERTISSEMENT

Afin d’éviter un fonctionnement imprévu du système pouvant

occasionner des blessures aux personnes et des dommages matériels :

• Débrancher l’alimentation électrique (si nécessaire) avant toute

installation, entretien ou conversion.

• Débrancher l’alimentation en air et dépressuriser toutes les

canalisations d’air connectées à cet appareil avant installation,

entretien ou conversion.

• Utiliser l’appareil conformément aux normes de pression,

température, et autres conditions spécifiées par le fabricant dans

ces instructions.

• Le médium doit être exempt d’humidité si la température descend

en dessous de 0°C.

• L’entretien doit se faire conformément aux pr océdures décrites ici.

• L’installation, l’entretien, et la conversion de ces appareils doivent

être effectués par des personnels qualifiés, au fait des techniques

pneumatiques.

• Après installation, entretien, ou conversion, les alimentations en

air et en électricité (si nécessaire) seront connectées et l’appareil

testé pour vérifier son fonctionnement correct et l’absence de

fuites. Si l’appareil présente une fuite audible ou ne fonctionne

pas correctement, ne pas l’utiliser.

• Les inscriptions concernant les avertissements et spécifications

sur l’appareil ne devront pas être recouvertes de peinture, etc. Si

le masquage est impossible, contactez votre représentant local

pour des étiquettes de remplacement.

AVERTISSEMENT

Une rupture de l’appareil peut occasionner des blessures graves.

Ne pas utiliser ce régulateur pour du gaz en bouteille.

Ne pas dépasser la norme de pression primaire maximum.

Introduction

Suivre ces instructions pendant l’installation, l’utilisation ou

l’entretien du produit.

Limites d’utilisation

Ces produits sont construits pour utilisation uniquement dans

les systèmes d’air comprimé pour service général.

kPa psi bar

Pression d’admission maximale 1734 250 17,3

Plage de température ambiante 0 °C à 80 °C (32 °F à 175 °F)

Symboles ANSI

Régulateur à

décharge réglable

Régulateur à décharge

non réglable

Installation

1. Il faut installer le régulateur dans un endroit raisonnablement

accessible pour faciliter l’entretien. Un kit de réparation est

offert. Les tuyaux et tubes doivent être aussi courts que

possible et ils doivent être propres et sans saleté ni copeaux

à l’intérieur. Il faut utiliser modérément la pâte à joint et

l’appliquer uniquement sur le tuyau, jamais dans l’orifice. Il

ne faut pas utiliser de ruban de PTFE pour assurer

l’étanchéité des connexions de tuyaux. Les pièces ont

tendance à se fracturer et se loger à l’intérieur de l’appareil,

ce qui peut causer un mauvais fonctionnement.

2. Installer le régulateur pour que l’air circule dans la direction

de la flèche. L’installation doit être en amont (côté haute

pression) et aussi proche que possible de l’appareil qu’il

faut protéger (vanne, vérin, outil, etc.). Le régulateur peut

être monté dans n’importe quelle position.

3. Pour être plus pratique, un orifice de manomètre se trouvent

de chaque côté du corps du régulateur. P endant l’installation,

il est nécessaire d’installer un manomètre ou un bouchon

de tuyau dans chaque orifice.

4. Pour assurer la protection contre la rouille, la calamine et

autres matières étrangères, installer un filtre en amont du

régulateur, aussi proche que possible de celui-ci.

Fonctionnement

1. Avant de mettre le système sous pression, tourner le bouton

de réglage dans le sens inverse des aiguilles d’une montre

jusqu’à l’élimination de toute la compression du ressort de

commande de pression. Mettre le système sous pression

et tourner le bouton dans le sens des aiguilles d’une montre

pour régler le régulateur à la pression secondaire désirée.

Ceci permet à la pression de monter lentement, évitant le

fonctionnement inattendu de la vanne, des vérins, des outils ,

etc. montés sur la conduite. Il n’est possible de faire le

réglage de la pression secondaire que si le régulateur est

soumis à la pression primaire.

AVERTISSEMENT

LA DEFAILLANCE, LE CHOIX ERRONE OU L’USAGE NON CONFORME

DES PRODUITS ET/OU SYSTEMES ICI DECRITS, OU PRODUITS Y

AFFERANT, PEUVENT ENTRAINER LA MORT, DES BLESSURES AUX

PERSONNES ET DES DOMMAGES MATERIELS.

Ce document et autres informations de « The Company », ses filiales et

distributeurs autorisés offre des options complémentaires d’utilisation du produit

et/ou système pour des utilisateurs ayant l’expertise technique requise. Il est

important que vous analysiez tous les aspects de l’usage prévu, y compris les

conséquences de toute défaillance, et que vous passiez en revue les inf ormations

concernant les produits et systèmes dans le catalogue actuel des produits. En

raison de la diversité des conditions de fonctionnement et d’utilisation de ces

produits ou systèmes, l’utilisateur, et lui seul, selon ses propres analyses et tests,

porte la responsabilité du choix final des produits et systèmes. Il est aussi de sa

responsabilité pleine et entière de s’assurer que les produits soient utilisés

conformément aux normes de sécurité et avertissements d’usage.

Les produits décrits ici, y compris, mais non exclusivement, les caractéristiques

des produits, spécifications, aspects, disponibilité et prix, sont susceptibles de

modification à tout moment et sans préavis par « The Company » et ses filiales.

DES EXEMPLAIRES SUPPLEMENTAIRES DE CES INSTRUCTIONS SONT

DISPONIBLES POUR ACCOMPAGNER LES APPAREILS/MANUELS D’

ENTRETIEN CORRESPONDANT A CES PRODUITS. CONTACTEZ VOTRE

REPRESENTANT LOCAL.

Page 4

Régulateur R12 de 1/4 in et 3/8 in et régulateur P12 de 1/4 in et 3/8 in 83-956-000

!

!

2.

Pour réduire la pression du système, il faut toujours faire le

réglage à partir d’une pression plus basse que la valeur

désirée. Par exemple, pour abaisser la pression secondaire

de 5,5 à 4,1 bar (550 à 410 kPa ; 80 à 60 psi), il est préférab le

de faire tomber la pression secondaire à 3,5 bar (350 kPa ; 50

psi) et de la régler, en montant à 4,1 bar (410 kPa ; 60 psi).

Enfoncer le bouton de réglage pour bloquer la valeur.

Entretien

ATTENTION :

COUPER L’ALIMENTATION D’AIR et évacuer la pression

primaire et secondaire avant de démonter le régulateur.

Tour ner le bouton dans le sens inverse des aiguilles d’une

montre réduit le réglage du régulateur, mais n’évacue pas

la pression en aval des régulateurs sans décharge.

ATTENTION :

Lubrifier les pièces avec de l’huile à base minérale ou de la

graisse sans silicones. NE PAS utiliser d’huile ni de graisse

synthétique, des éthers par exemple.

A. Suivre la procédure suivante pour remplacer le

diaphragme ou le ressort de commande.

1. Tirer vers le haut le bouton de réglage pour le libérer.

Tour ner ensuite le bouton de réglage dans le sens inverse

des aiguilles d’une montre jusqu’à l’élimination de la

compression du ressort de commande de pression.

2. Dévisser le collier fileté et déposer le chapeau. Ensuite,

démonter, nettoy er et vérifier soigneusement que les pièces

Kits d’intervention offerts

Description R12 P12

Conversion d’air de pilote

(décharge)

Chapeau RRP-96-308 —

Manomètres

Basse pression RRP-96-664 RRP-96-664

0 à 414 kPa (0 à 60 psi)

Basse pression

0 à 207 kPa (0 à 30 psi)

Pression standard

0 à 1103 kPa (0 à 160 psi)

Kit de patte de montage GPA-96-313 GPA-96-313

Bouton de commande

du régulateur

Ressorts

862 kPa (125 psi) RRP-96-301 RRP-96-301

414 kPa (60 psi) RRP-96-302 RRP-96-302

206 kPa (30 psi) RRP-96-303 RRP-96-303

1379 kPa (200 psi) RRP-96-304 RRP-96-304

Kit de réparation

du régulateur sans décharge*

Kit de réparation

du régulateur sans décharge*

*La graisse dans le kit ne contient pas de silicones.

GRP-96-350 —

RRP-96-663 RRP-96-663

RRP-96-665 RRP-96-665

RRP-96-300 —

RRP-96-307 —

RRP-96-306 RRP-96-305

ne sont pas usées ni endommagées. S’il faut en remplacer,

utiliser des pièces des kits de réparation.

3. Lubrifier le joint torique et les joints à lèvre avec de la

Bouton

graisse (fournie avec les kits).

4. Installer le diaphragme dans le chapeau. Monter ensuite le

chapeau sur le corps et serrer le collier fileté, comme montré

à la figure 1.

B. Intervention sur la vanne

Evacuer la pression d’air du système, comme indiqué

1.

précédemment. Dévisser ensuite le capuchon inférieur pour

l’enlever du corps. Déposer ensuite la vanne, le joint torique,

le joint torique du capuchon et le ressort du clapet de retour.

2. Ensuite, démonter, nettoyer et vérifier soigneusement que

les pièces ne sont pas usées ni endommagées. S’il faut en

remplacer, utiliser des pièces des kits de réparation.

Collier

(serré à la main,

plus un quart de tour)

Chapeau

Rondelle

Vis de réglage

Ecrou d'entraînement

3. Lubrifier le joint torique est les surfaces coulissantes avec

la graisse fournie dans le kit de réparation.

Ressort de commande

4. Monter les pièces, comme indiqué à la figure 1.

5. Lubrifier le joint torique du capuchon et installer le joint

torique dans la gorge du capuchon. Visser ensuite le

capuchon à fond dans le corps (figure 1).

Diaphragme

(comprend la plaque supérieure

et la plaque inférieure du diaphragme)

6. Mettre le système sous pression et régler la pression

secondaire comme indiqué dans la section

Fonctionnement.

Mettre en marche l’alimentation d’air et vérifier que le régulateur

ne fuit pas. S’il y a des fuites, NE PAS FAIRE FONCTIONNER,

refaire l’intervention.

Joint torique,

Joint d'évent

(pas utilisé sur le 27RC)

Corps

En cas de question sur l’intervention de l’appareil, contacter le

distributeur local agrée ou le représentant technique.

Vanne

Joint torique,

Appliquer un peu de la graisse fournie.

Vérifier qu’il n’y a pas d’entailles, de rayures

ni d’imperfections superficielles. S’il y en

a, la longévité est probablement réduite et

il faut prévoir un remplacement à l’av enir.

Nettoyer avec un chiffon sans peluche.

Figure 1: Régulateurs

Capuchon inférieur

Ressort,

Clapet de retour

Capuchon inférieur

Couple

2,3 à 2,8 Nm

(20 à 25 in-lb)

R12 et P12

Page 5

Richland, MI 49083 Tel: (269) 629-5000

!

!

!

Instrucciones para instalación y servicio

83-956-000 (Spanish)

Reguladores R12 de 1/4 y 3/8 de pulgada

y reguladores de precisión P12 de 1/4 y

3/8 de pulgada

EMITIDO: Mayo de 2005

Sustituye a: Septiembre de 2002

Doc.# 83956000, ECN# 050500, Rev. 4

ADVERTENCIA

Para evitar un comportamiento impredecible del sistema que pueda

ocasionar lesiones personales y daños a la propiedad:

• Antes de instalar, reparar o convertir, desconecte el suministro

eléctrico (cuando sea necesario).

• Antes de instalar, reparar o convertir, desconecte el suministro de

aire y despresurice todas las líneas de aire que están conectadas

a este producto.

• Haga funcionar dentro de la presión, temperatura y demás

condiciones especificadas por el fabricante y que se incluyen en

estas instrucciones.

• El medio debe estar libre de humedad si la temperatura ambiente

se encuentra por debajo del punto de congelación.

• Repare de acuerdo con los procedimientos que se incluyen en

estas instrucciones.

• La instalación, reparación y conversión de estos productos debe

ser realizada por personal competente que entienda la manera en

que se deben aplicar los productos neumáticos.

• Después de la instalación, reparación y conversión, se debe

conectar los suministros eléctricos y de aire (cuando sea

necesario), y el producto se debe poner a prueba para determinar

que funciona correctamente y no tiene pérdidas. Si se detecta una

pérdida audible, o si el producto no funciona correctamente, no lo

ponga en funcionamiento.

• Las advertencias y especificaciones que aparecen en el producto

no deben estar cubiertas por pintura, etc. Si no resulta posible

colocarlo con cinta adhesiva, póngase en contacto con su

representante local para obtener etiquetas de repuesto.

ADVERTENCIA

La ruptura del producto puede ocasionar lesiones graves.

No conecte el regulador al gas embotellado.

No exceda la clasificación de presión primaria máxima.

Introducción:

Observe las siguientes instrucciones al instalar, operar o dar

servicio al producto.

Límites de aplicación

Estos productos han sido diseñados para usarse solamente en

sistemas de aire comprimido para propósitos generales.

kPa PSIG barras

Presión de entrada máxima 1734 250 17,3

Rango de temperatura ambiental: 0°C a 80°C (32°F a 175°F)

Símbolos de ANSI

Regulador ajustable

con descarga

Regulador ajustable

sin descarga

Instalación

1. Siempre que sea posible, al instalar los reguladores se les

debe colocar en lugares de fácil acceso, para poder darles

servicio. Hay disponib les juegos de servicio para reparación.

Se deben usar tuberías y conductos tan cortos como sea

posible, manteniendo su interior limpio y sin desechos o

astillas. Los compuestos para unir tuberías deben usarse

moderadamente y se les debe aplicar a las tuberías macho

solamente, nunca a los puertos hembra. No use cinta PTFE

para sellar las junturas de tuberías ya que algunas veces

pedazos de cinta tienden a separarse y fijarse dentro de

las unidades provocando posiblemente mal funcionamiento .

Instale el regulador de manera que el flujo de aire ocurra en

2.

la dirección de la flecha. La instalación se debe hacer en el

lado flujo arriba (alta presión) y cerca de los dispositivos

que ha de servir (válvulas, cilindros, herramientas, etc.). Se

le puede montar en cualquier posición.

3. Para su conveniencia, hay puertos para medidores en

ambos lados del cuerpo del regulador. Al hacer la

instalación, es necesario colocar un medidor o un tapón de

casquillo en cada uno de esos puertos.

4.

Instale un filtro en el lado flujo arriba (alta presión) tan cerca

al regulador como sea posible para protegerlo contra el moho,

las escamas de las tuberías y otros materiales extraños.

Funcionamiento

1.

Antes de activar el suministro de aire, gire la perilla para

ajuste en contra de las agujas del reloj hasta liberar la

compresión del muelle para control de la presión. Luego

active el suministro de aire y ajuste el regulador a la presión

secundaria deseada girando la perilla en el sentido de las

agujas del reloj. Con esto se permite que la presión se

acumule lentamente, evitando todo funcionamiento

inesperado de las válvulas, cilindros, herramientas, etc.

unidas a la línea. Sólo se puede ajustar la presión secundaria

deseada cuando hay presión principal aplicada al regulador.

ADVERTENCIA

EL FALLO O LA SELECCIÓN INCORRECTA O EL USO INCORRECTO

DE LOS PRODUCTOS Y/O SISTEMAS AQUÍ DESCRITOS U OTROS

ARTÍCULOS RELACIONADOS PUEDE RESULTAR EN MUERTE,

LESIONES PERSONALES Y DAÑO A LA PROPIEDAD.

Este documento y demás información de la compañía, sus subsidiarias y

distribuidores autorizados ofrecen opciones de productos y sistemas para

mayor investigación por parte de los usuarios que cuentan con conocimientos

técnicos. Es importante que analice todos los aspectos de su aplicación,

incluyendo las consecuencias de cualquier fallo y que revise la información

concerniente al producto o los sistemas que se encuentran en el catálogo

actual de productos. Debido a la variedad de condiciones de funcionamiento

y aplicaciones para estos productos o sistemas, el usuario, mediante su

propio análisis y pruebas, es únicamente responsable por la selección final

de los productos y sistemas, y por garantizar que se cumpla con todos los

requisitos de funcionamiento, seguridad y advertencia de la aplicación.

Los productos aquí descritos, incluyendo pero sin limitarse, a las

características del producto, las especificaciones, los diseños, la

disponibilidad y los precios, están sujetos a cambios por parte de la

compañía y de sus subsidiarias en cualquier momento sin aviso.

SE PUEDE OBTENER COPIAS ADICIONALES DE ESTAS INSTRUCCIONES

PARA INCLUIR CON EL EQUIPO / LOS MANUALES DE MANTENIMIENTO

QUE UTILIZAN ESTOS PRODUCTOS. COMUNIQUESE CON SU

REPRESENTANTE LOCAL.

Page 6

Reguladores R12 de 1/4 y 3/8 de pulgada y reguladores de precisión P12 de 1/4 y 3/8 de pulgada 83-956-000

!

!

2. Para disminuir la graduación de la presión del regulador,

comience siempre con una presión menor que la graduación

final deseada. Por ejemplo, para reducir la presión

secundaria de 550 a 410 kPa (80 a 60 psig) lo mejor es

reducir la presión secundaria a 350 kPa (50 psig), y luego

aumentarla a 410 kPa (60 psig). Presione la perilla de

ajuste para fijar la graduación de la presión.

Servicio

PRECAUCIÓN:

Antes de desarmar la unidad reguladora, DESACTIVE EL

SUMINISTRO DE AIRE y elimine la presión principal y

secundaria. (El sólo girar la perilla en contra de las agujas

del reloj reduce la calibración del regulador, pero no v entea

la presión flujo abajo de los reguladores sin descarga).

PRECAUCIÓN:

Lubrique las piezas con aceite o grasa a base de minerales

o con grasa sin silicona. NO USE aceites o grasas sintéticos

tales como esteres.

A. Utilice el siguiente procedimiento para dar servicio al

diafragma y/o al muelle para control:

esengrane la perilla de ajuste tirando de ella hacia arriba.

1. D

Gire la perilla de ajuste en contra de las agujas del reloj hasta

liberar la compresión del muelle para control de la presión.

2. Desenrosque el collarín y quite el conjunto del bonete. A

continuación, desarme y limpie las piezas y verifique

Juegos para servicio disponibles

Descripción R12 P12

Conversión para piloto de aire

(con descarga)

Conjunto de bonet RRP-96-308 —

Medidores:

Presión baja RRP-96-664 RRP-96-664

de 0 a 414 kPa (0 a 60 PSIG)

Presión baja

0 a 207 kPa (0 a 30 PSIG)

Presión normal

0 a 1103 kPa (0 a 160 PSIG)

Juego de soporte para montaje GPA-96-313 GPA-96-313

Perilla para control del regulador RRP-96-300 —

Muelles:

862 kPa (125 PSIG) RRP-96-301 RRP-96-301

414 kPa (60 PSIG) RRP-96-302 RRP-96-302

206 kPa (30 PSIG) RRP-96-303 RRP-96-303

1379 kPa (200 PSIG) RRP-96-304 RRP-96-304

Juego para reparación

de reguladores sin descarga*

Juego para reparación

de reguladores con descarga*

* La grasa que viene con los juegos no contiene silicona

GRP-96-350 —

RRP-96-663 RRP-96-663

RRP-96-665 RRP-96-665

RRP-96-307 —

RRP-96-306 RRP-96-305

cuidadosamente que no presenten desgaste o daños. Si

es necesario remplazarlas, use las piezas que se

encuentran en los juegos de servicio.

3. Lubrique los aros tóricos y los sellos con labios con la

grasa (que se suministra con los juegos).

Perilla

4. Coloque el conjunto del diafragma en el bonete. Luego

coloque el conjunto del bonete en el cuerpo y apriete el

collarín roscado de acuerdo a la Figura 1.

B. Cómo dar servicio al conjunto de la válvula.

Collarín

(apriételo a mano,

más 1/4 de revolución)

1. Desaloje la presión de aire del sistema tal y como se

explicó anteriormente. Después quite la tapa inferior

desenroscándola del cuerpo. A continuación, quite el

conjunto de la válvula, el aro tórico, aro tórico de la tapa y

el muelle para retorno de la válvula.

2. A continuación, desarme y limpie las piezas y verifique

cuidadosamente que no presenten desgaste o daños. Si

es necesario remplazarlas, use las piezas que se

encuentran en los juegos de servicio.

3. Lubrique los aros tóricos y las superficies deslizantes con

Bonete

Arandela

Tornillo para ajuste

Tuerca para impulsión

Muelle para control

la grasa que se suministra con los juegos para servicio.

4. Instale las piezas tal y como se muestra en la Figura 1.

5. Lubrique el aro tórico de la tapa y colóquelo en su ranura

en la tapa. Después enrosque la tapa en el cuerpo hasta

que se asiente en él (vea la figura 1).

6. Active el suministro de aire y ajuste la presión secundaria

tal y como se explica en la sección de Funcionamiento.

Active la presión de aire y verifique que el regulador no tenga

fugas. Si hay fugas, NO OPERE EL SISTEMA. Efectúe

reparaciones nuev amente.

Conjunto del diafragma

(incluye la placa superior del diafragma

y la placa inferior del diafragma)

Aro tórico,

sello para venteo

(No se usan en 27RC)

Cuerpo

Si tiene alguna pregunta acerca de cómo dar servicio a esta

unidad, póngase en contacto con el concesionario autorizado

de su localidad o con el representante de servicio al cliente.

Conjunto

de la válvula

Engráselo ligeramente con el lubricante

suministrado.

Verifique que no existen mellas, rasguños ni imperfecciones en la superficie. Si

existen, es posible una menor vida útil y

se debe planificar su futuro reemplazo.

Límpielo con un paño sin hilas.

Figura 1: Reguladores

Aro tórico,

Tapa inferior

Muelle,

regreso de la válvula

Torsión

de la tapa inferior

2,3 a 2,8 Nm

(20 a 25 in. lb.)

R12 y P12

Loading...

Loading...