Page 1

B

C

G

B

G

!

!

Richland, MI 49083 Tel: (269) 629-5000

WARNING

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is present,

or the product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

Introduction:

Follow these instructions when installing, operating, or servicing

the product.

Application Limits

These products are intended for use in general purpose

compressed air systems only.

Operating Pressure: kPa PSIG bar

Maximum Inlet Pressure:

Metal Bowl 1734 250 17.3

Poly Bowl 1024 150 10.2

Operating Temperature:

Maximum Temperature 80°C (175°F)

Minimum Temperature 0°C (32°F)

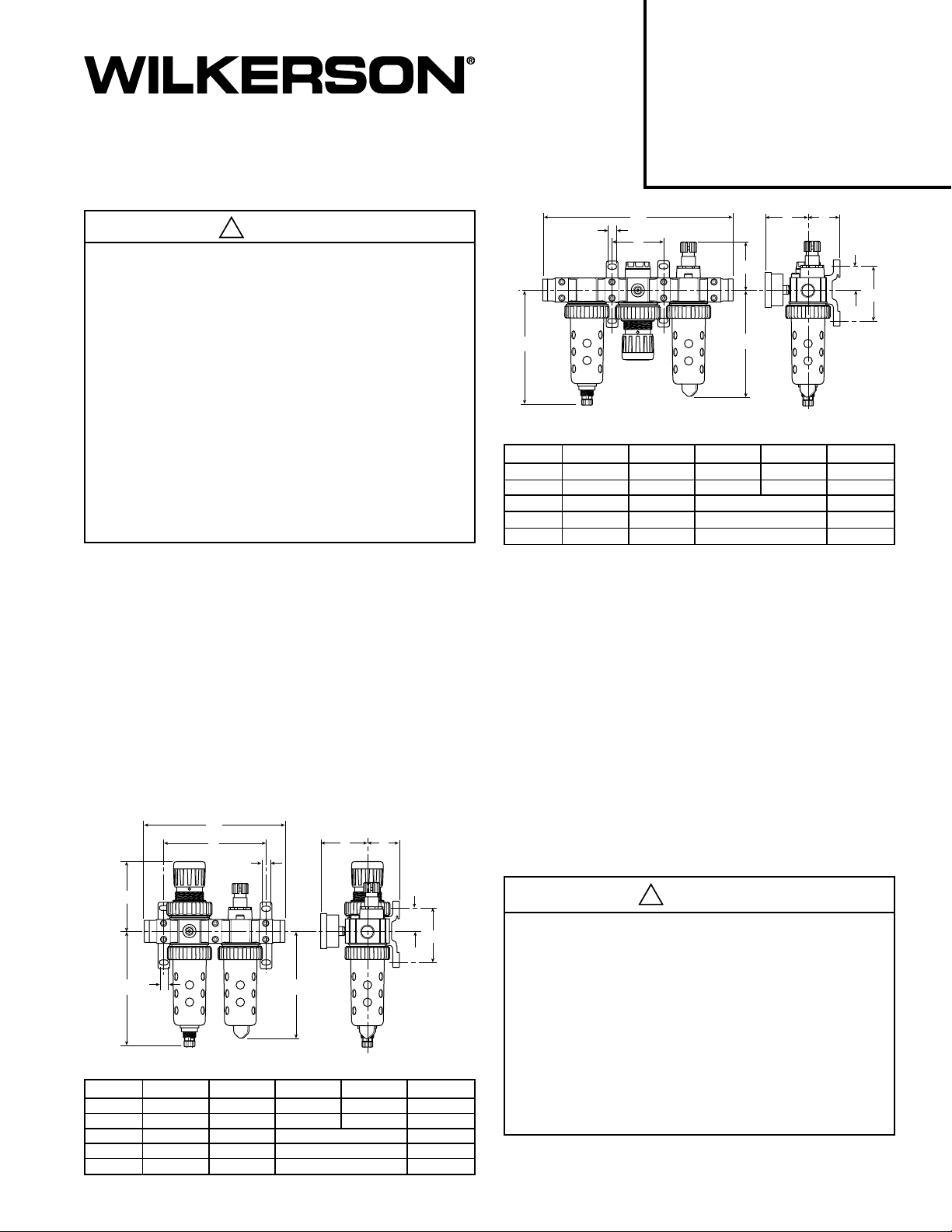

A

D

F

J

E

Installation and Service Instructions

83-960-000

12 Series Modular Kits

ISSUED: May, 2005

Supersedes: November, 2001

Doc.# 83960000, ECN# 050500, Rev. 2

D

A

J

F

C

B

1

E

H

3-Unit Modular Combo:

ABB1CDE

8.72 5.35 5.12 2.24 2.05 1.45

222mm 136mm 130mm 57mm 52mm 37mm

F G H J (Slot)

2.35 2.6 1.46 0.280 x 0.430

60mm 66mm 37mm 7mm x 11mm

Note: All Dimensions Nominal.

Installation

Attach inner clamp to wall bracket using the screw provided.

See Figure 1 for screw torque values. Mount wall bracket to

wall using spacing shown in Figure 2. The wall brackets are

designed to use 1/4 inch screws. Attach the port blocks to pipe

threads using a small amount of thread sealant. The unit will

leak if the port blocks are not positioned properly. Assemble

each inner and outer clamp with the tube seal and spacer

installed as shown. The inner and outer clamp must be installed

with proper orientation as shown in Figure 1. Install the clamp

screws with one thread of engagement. Position the filter,

regulator, or lubricator with the angled surface of body ears

engaged with the angled surface of the inner and outer clamp.

The regulator must be installed with knob pointing down. The

filter / regulator must be installed with the knob pointing up.

WARNING

H

J

2-Unit Modular Combo:

ABB1CDE

6.38 5.35 5.12 3.19 2.05 1.45

162mm 136mm 130mm 81mm 52mm 37mm

F G H J (Slot)

4.72 2.6 1.46 0.280 x 0.430

120mm 66mm 37mm 7mm x 11mm

Note: All Dimensions Nominal.

B

1

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED

ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for further

investigation by users having technical expertise. It is important that you

analyze all aspects of your application, including consequences of any

failure and review the information concerning the product or systems in the

current product catalog. Due to the variety of operating conditions and

applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product features,

specifications, designs, availability and pricing, are subject to change by

The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

12 Series Modular Kits 83-960-000

!

B

T

4

(

d;

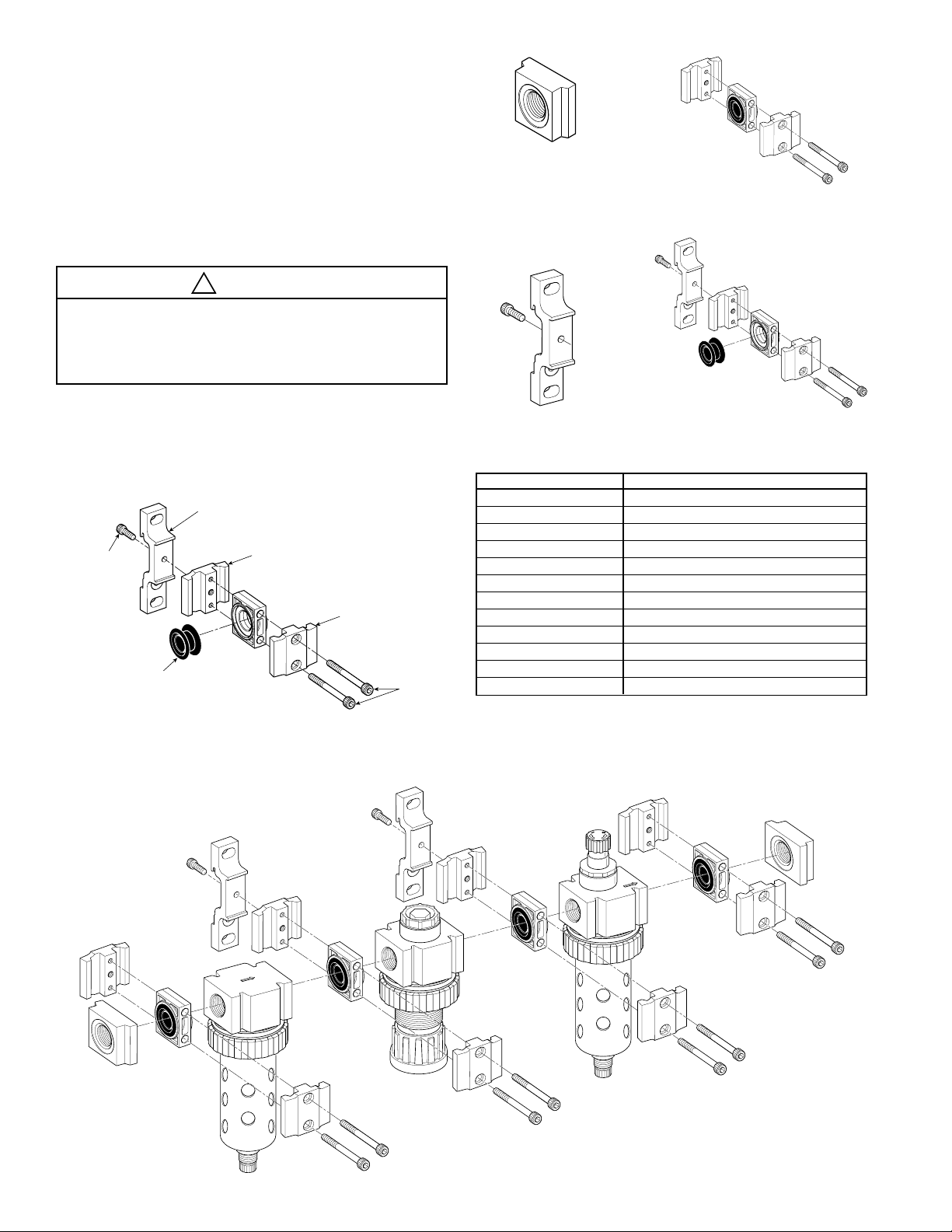

Tighten the clamp screws alternating between the two screws

per connector until both screws are snug. Check the alignment

of each body to verify fit between body and clamp. The bottom

flange of the inner and outer clamp must be positioned below

the bottom edge of the body. Pressurize the assembly and

check for air leaks. If air leaks are found, depressurize the unit.

Loosen the outer clamp and check fit between the body and

clamps. Retighten the screws and check for air leaks.

GPA-96-301

thru

GPA-96-309 GPA-96-310

Removal

Disconnect air supply and depressurize all air lines before

removing any modular units.

WARNING

Loosening the outer clamp screws may cause the

filter, regulator, lubricator, or accessory to dislodge

and fall. It is important to take necessary precautions

when loosening the outer clamp screws to prevent

the unit from falling and causing injury.

Loosen the outer clamp screws 8-9 turns. It is not necessary to

completely remove the screws. Slide the unit down until it

disconnects from the clamps. It may be necessary to pull the

outer clamp out when removing one of the units from the assembly.

Wall Bracket

racket Screw

orque T o

.5 - 5.1Nm

40 - 45 In. Lbs.)

Tube Seal (Assemble

Through Spacer)

Inner Clamp

Outer Clamp

Clamp

Screw

Start Screws Approximately 1 Turn By Han

Assemble To Bodies Or Port Blocks And

Torque To 3.4 - 4.5 Nm (30 - 40 In. Lbs.)

Figure 1

GPA-96-311

Service Kits Available

Description Kit Number

1/8" NPT Port Block GPA-96-301

1/4" NPT Port Block GPA-96-302

3/8" NPT Port Block GPA-96-303

1/8" BSPP Port Block GPA-96-304

1/4" BSPP Port Block GPA-96-305

3/8" BSPP Port Block GPA-96-306

1/8" BSPT Port Block GPA-96-307

1/4" BSPT Port Block GPA-96-308

3/8" BSPT Port Block GPA-96-309

Modular Connector Kit GPA-96-310

Wall Bracket Kit GPA-96-311

1/4" Lock Ball Kit GPA-96-312

GPA-96-312

Figure 2

Page 3

B

C

G

B

G

Richland, MI 49083 Tel: (269) 629-5000

!

!

AVERTISSEMENT

Afin d’éviter un fonctionnement imprévu du système pouvant

occasionner des blessures aux personnes et des dommages matériels :

• Débrancher l’alimentation électrique (si nécessaire) avant toute

installation, entretien ou conversion.

• Débrancher l’alimentation en air et dépressuriser toutes les

canalisations d’air connectées à cet appareil avant installation,

entretien ou conversion.

• Utiliser l’appareil conformément aux normes de pression,

température, et autres conditions spécifiées par le fabricant dans

ces instructions.

• Le médium doit être exempt d’humidité si la température descend

en dessous de 0°C.

• L’entretien doit se faire conformément aux procédures décrites ici.

• L’installation, l’entretien, et la conversion de ces appareils doivent

être effectués par des personnels qualifiés, au fait des techniques

pneumatiques.

• Après installation, entretien, ou conversion, les alimentations en air

et en électricité (si nécessaire) seront connectées et l’appareil testé

pour vérifier son fonctionnement correct et l’absence de fuites. Si

l’appareil présente une fuite audible ou ne fonctionne pas

correctement, ne pas l’utiliser.

• Les inscriptions concernant les avertissements et spécifications sur

l’appareil ne devront pas être recouvertes de peinture, etc. Si le

masquage est impossible, contactez votre représentant local pour

des étiquettes de remplacement.

Introduction

Suivre ces instructions pendant l’installation, l’utilisation ou

l’entretien du produit.

Limites d’utilisation

Ces produits sont construits pour utilisation uniquement dans

les systèmes d’air comprimé pour service général.

Pression de fonctionnement kPa psi bar

Pression d’admission maximale

Cuve métallique 1734 250 17,3

Cuve en polycarbonate 1024 150 10,2

Température de fonctionnement

Température maximale 80 °C (175 °F)

Température minimale 0 °C (32 °F)

A

D

F

J

E

Instructions d’installation et d’entretien

83-960-000 (French)

Kits modulaires de la série 12

PUBLICATION: mai, 2005

Remplace: novembre, 2001

Doc.# 83960000, ECN# 050500, Rev. 2

D

A

J

F

C

B

1

E

H

Combinaison modulaire à trois appareils

ABB1CDE

8,72 5,35 5,12 2,24 2,05 1,45

222mm 136mm 130mm 57mm 52mm 37mm

F G H J (fente)

2,35 2,6 1,46 0,280 x 0,430

60mm 66mm 37mm 7mm x 11mm

REMARQUE – Toutes les dimensions sont nominales.

Installation

Attacher l’étrier interne à la patte murale, en utilisant la vis

fournie. Consulter les valeurs de serrage des vis à la figure 1.

Monter la patte murale sur le mur en utilisant la cale montrée à

la figure 2. Les pattes m urales sont conçues pour utiliser des vis

de 1/4 in. Monter les b locs à orifices sur les filets des tuyaux, en

utilisant une petite quantité de pâte à joint. L’appareil fuit si les

blocs à orifices ne sont pas correctement en position. Assemb ler

chaque étrier interne et externe, avec le joint de tube et la cale

installés, comme montré. L’étrier interne et l’étrier externe doivent

être installés, orientés correctement, comme montré à la figure

1. Installer les vis d’étrier, en engageant un filet. Mettre en

position le filtre, le régulateur ou le lubrificateur, avec la surface

inclinée des oreilles du corps engagée sur la surface inclinée

de l’étrier interne et de l’étrier externe. Le régulateur doit être

installé, le bouton vers le haut. Le filtre et régulateur doit être

installé, le bouton vers le haut.

AVERTISSEMENT

H

J

Combinaison modulaire à deux appareils

ABB1CDE

6,38 5,35 5,12 3,19 2,05 1,45

162mm 136mm 130mm 81mm 52mm 37mm

F G H J (fente)

4,72 2,6 1,46 0,280 x 0,430

120mm 66mm 37mm 7mm x 11mm

REMARQUE – Toutes les dimensions sont nominales.

B

1

LA DEFAILLANCE, LE CHOIX ERRONE OU L’USAGE NON CONFORME

DES PRODUITS ET/OU SYSTEMES ICI DECRITS, OU PRODUITS Y

AFFERANT, PEUVENT ENTRAINER LA MORT, DES BLESSURES AUX

PERSONNES ET DES DOMMAGES MATERIELS.

Ce document et autres informations de « The Company », ses filiales et

distributeurs autorisés offre des options complémentaires d’utilisation du produit

et/ou système pour des utilisateurs ayant l’expertise technique requise. Il est

important que vous analysiez tous les aspects de l’usage prévu, y compris les

conséquences de toute défaillance, et que vous passiez en revue les inf ormations

concernant les produits et systèmes dans le catalogue actuel des produits. En

raison de la diversité des conditions de fonctionnement et d’utilisation de ces

produits ou systèmes, l’utilisateur, et lui seul, selon ses propres analyses et tests,

porte la responsabilité du choix final des produits et systèmes. Il est aussi de sa

responsabilité pleine et entière de s’assurer que les produits soient utilisés

conformément aux normes de sécurité et avertissements d’usage.

Les produits décrits ici, y compris, mais non exclusivement, les caractéristiques

des produits, spécifications, aspects, disponibilité et prix, sont susceptibles de

modification à tout moment et sans préavis par « The Company » et ses filiales.

DES EXEMPLAIRES SUPPLEMENTAIRES DE CES INSTRUCTIONS SONT

DISPONIBLES POUR ACCOMPAGNER LES APPAREILS/MANUELS D’

ENTRETIEN CORRESPONDANT A CES PRODUITS. CONTACTEZ VOTRE

REPRESENTANT LOCAL.

Page 4

Kits modulaires de la série 12 83-960-000

!

V

S

c

4

(

lb)

Serrer alternativement les vis d’étrier, jusqu’à ce les deux vis

soient serrées. Vérifier l’alignement de chaque corps et l’écart

entre le corps et l’étrier. La bride inférieure de l’étrier interne et

de l’étrier externe doit être en position sous le bord inférieur du

corps. Mettre le système sous pression et vérifier qu’il n’y a pas

de fuite. S’il y a des fuites, faire tomber la pression du système.

Desserrer l’étrier extérieur et vérifier l’écart entre le corps et les

étriers. Resserrer les vis et vérifier qu’il n’y a pas de fuite.

GPA-96-301

à

GPA-96-309 GPA-96-310

Dépose

Débrancher l’alimentation d’air et faire tomber la pression de

toutes les conduites avant de déposer tout dispositif modulaire.

ATTENTION

Desserrer les vis de l’étrier externe peut permettre au

filtre, régulateur , lubrificateur ou accessoire de se déloger

et tomber. Il est important de prendre des précautions

pendant le desserrage des vis de l’étrier externe pour

empêcher la chute de l’appareil et des blessures.

Desserrer de 8 à 9 tours les vis de l’étrier externe. Il n’est pas

nécessaire d’enlever complètement les vis. Glisser l’appareil vers le

bas, complètement hors des étriers. Il peut être nécessaire de tirer

l’étrier externe pendant la dépose d’un des appareils de l’ensemble.

Patte murale

is de patte

errer à un

ouple de

,5 à 5,1 Nm

40 à 45 in-lb)

Joint de tube

(assemblé dans la cale)

Visser à la main les vis d'environ un tour.

Monter sur les corps ou les blocs d'orifice et

serrer à un couple de 3,4 à 4,5 Nm (30 à 40 in-

Etrier interne

Etrier externe

Etrier

Vis

Figure 1

GPA-96-311

Kits d’intervention offerts

Description Numéro du kit

Bloc d’orifices de 1/8 in NPT GPA-96-301

Bloc d’orifices de 1/4 in NPT GPA-96-302

Bloc d’orifices de 3/8 in NPT GPA-96-303

Bloc d’orifices de 1/8 in BSPP GPA-96-304

Bloc d’orifices de 1/4 in BSPP GPA-96-305

Bloc d’orifices de 3/8 in BSPP GPA-96-306

Bloc d’orifices de 1/8 in BSPT GPA-96-307

Bloc d’orifices de 1/4 in BSPT GPA-96-308

Bloc d’orifices de 3/8 in BSPT GPA-96-309

Kit de connecteur modulaire GPA-96-310

Kit de patte murale GPA-96-311

Kit de bille de verrouillage de 1/4 in GPA-96-312

GPA-96-312

Figure 2

Page 5

!

B

C

G

B

G

Instrucciones para instalación y servicio

!

83-960-000 (Spanish)

Juegos modulares serie 12

Richland, MI 49083 Tel: (269) 629-5000

EMITIDO: Mayo de 2005

Sustituye a: Noviembre de 2001

Doc.# 83960000, ECN# 050500, Rev. 2

E

ADVERTENCIA

Para evitar un comportamiento impredecible del sistema que pueda

ocasionar lesiones personales y daños a la propiedad:

• Antes de instalar, reparar o convertir, desconecte el suministro

eléctrico (cuando sea necesario).

• Antes de instalar, reparar o conver tir, desconecte el suministro de

aire y despresurice todas las líneas de aire que están conectadas a

este producto.

• Haga funcionar dentro de la presión, temperatura y demás

condiciones especificadas por el fabricante y que se incluyen en

estas instrucciones.

• El medio debe estar libre de humedad si la temperatura ambiente se

encuentra por debajo del punto de congelación.

• Repare de acuerdo con los procedimientos que se incluyen en estas

instrucciones.

• La instalación, reparación y conversión de estos productos debe

ser realizada por personal competente que entienda la manera en

que se deben aplicar los productos neumáticos.

• Después de la instalación, reparación y conversión, se debe

conectar los suministros eléctricos y de aire (cuando sea

necesario), y el producto se debe poner a prueba para determinar

que funciona correctamente y no tiene pérdidas. Si se detecta una

pérdida audible, o si el producto no funciona correctamente, no lo

ponga en funcionamiento.

• Las advertencias y especificaciones que aparecen en el producto

no deben estar cubiertas por pintura, etc. Si no resulta posible

colocarlo con cinta adhesiva, póngase en contacto con su

representante local para obtener etiquetas de repuesto.

Introducción:

Observe las siguientes instrucciones al instalar, operar o dar

servicio al producto.

Límites de aplicación

Estos productos han sido diseñados para usarse solamente en

sistemas de aire comprimido para propósitos generales.

Presión de operación: kPa PSIG barras

Presión de entrada máxima:

Tazón de metal 1734 250 17,3

Tazones de poli 1024 150 10,2

Temperatura de operación:

Temperatura máxima 80°C (175°F)

Temperatura mínima 0°C (32°F)

A

J

F

Combinación modular de 3 unidades:

ABB1CDE

8,72 5,35 5,12 2,24 2,05 1,45

222mm 136mm 130mm 57mm 52mm 37mm

F G H J (ranura)

2,35 2,6 1,46 0,280 x 0,430

60mm 66mm 37mm 7mm x 11mm

Nota: Todas las dimensiones son nominales.

Instalación

Utilizando el tornillo suministrado, coloque el sujetador interno

en el soporte de pared. Para averiguar el valor de la torsión

para el tornillo, vea la Figura 1. Monte el soporte de pared en la

pared utilizando los espaciadores que se muestran en la Figura

2. Los soportes de pared están diseñados para usar tornillos de

1/4 de pulgada. Coloque los bloqueos de los puertos en las

roscas de las tuberías utilizando una cantidad pequeña de

sellador. Si no se colocan adecuadamente los bloqueos de los

puertos la unidad tendrá fugas. Ensamble cada sujetador interno y externo colocando los selladores para tubería y los

espaciadores como se muestra. Se deben instalar los

sujetadores internos y externos orientándolos adecuadamente

como se muestra en la Figura 1. Coloque los tornillos de los

sujetadores girándolos una revolución. Ubique el filtro, regulador o lubricador manteniendo la superficie angulada de las

orejeras del cuerpo haciendo contacto con la superficie angulada

D

C

B

1

H

de los sujetadores internos y externos. Se debe instalar el

A

D

F

J

E

regulador con la perilla apuntando hacia abajo. Se debe instalar

el filtro / regulador con la perilla apuntando hacia arriba.

ADVERTENCIA

EL FALLO O LA SELECCIÓN INCORRECTA O EL USO INCORRECTO

H

J

Combinación modular de 2 unidades:

ABB1CDE

6,38 5,35 5,12 3,19 2,05 1,45

162mm 136mm 130mm 81mm 52mm 37mm

F G H J (ranura)

4,72 2,6 1,46 0,280 x 0,430

120mm 66mm 37mm 7mm x 11mm

Nota: Todas las dimensiones son nominales.

B

1

DE LOS PRODUCTOS Y/O SISTEMAS AQUÍ DESCRITOS U OTROS

ARTÍCULOS RELACIONADOS PUEDE RESULTAR EN MUERTE,

LESIONES PERSONALES Y DAÑO A LA PROPIEDAD.

Este documento y demás información de la compañía, sus subsidiarias y

distribuidores autorizados ofrecen opciones de productos y sistemas para

mayor investigación por parte de los usuarios que cuentan con conocimientos

técnicos. Es importante que analice todos los aspectos de su aplicación,

incluyendo las consecuencias de cualquier fallo y que revise la información

concerniente al producto o los sistemas que se encuentran en el catálogo

actual de productos. Debido a la variedad de condiciones de funcionamiento

y aplicaciones para estos productos o sistemas, el usuario, mediante su

propio análisis y pruebas, es únicamente responsable por la selección final

de los productos y sistemas, y por garantizar que se cumpla con todos los

requisitos de funcionamiento, seguridad y advertencia de la aplicación.

Los productos aquí descritos, incluyendo pero sin limitarse, a las

características del producto, las especificaciones, los diseños, la

disponibilidad y los precios, están sujetos a cambios por parte de la

compañía y de sus subsidiarias en cualquier momento sin aviso.

SE PUEDE OBTENER COPIAS ADICIONALES DE ESTAS INSTRUCCIONES

PARA INCLUIR CON EL EQUIPO / LOS MANUALES DE MANTENIMIENTO

QUE UTILIZAN ESTOS PRODUCTOS. COMUNIQUESE CON SU

REPRESENTANTE LOCAL.

Page 6

!

Juegos modulares serie 12 83-960-000

or

T

p

A

d

(

l

na

s

s)

Al apretar los tornillos de los sujetadores alterne entre los dos

tornillos por conectador hasta que ambos queden ajustados.

Verifique el alineamiento de cada uno de los cuerpos para

comprobar que el cuerpo y el sujetador estén acoplados. Los

bordes inferiores de los sujetadores superior e inferior deben

colocarse por debajo del borde inferior del cuerpo. Presurice el

conjunto y verifique que no hay fugas de aire. Si hay fugas,

saque la presión de la unidad. Afloje el sujetador externo y

compruebe el acoplamiento entre el cuerpo y los sujetadores.

Vuelva a apretar los tornillos y verifique que no hay fugas de aire.

GPA-96-301

a

GPA-96-309 GPA-96-310

Cómo quitarla

Antes de quitar cualquier unidad modular, desconecte el

suministro de aire y saque la presión de todas las líneas de aire.

ADVERTENCIA

El aflojar los tornillos de los sujetadores externos

puede hacer que el filtro, regulador, lubricador u otro

accesorio se destrabe y caiga. Al aflojar los tornillos

de los sujetadores externos es importante tomar las

precauciones necesarias para evitar que la unidad se

caiga y provoque lesiones.

Gire los tornillos de los sujetadores externos 8 o 9 revoluciones.

No es necesario sacar completamente los tornillos. Mueva la

unidad hacia abajo hasta que se separe de los sujetadores. Al

quitar una de las unidades del conjunto, podría ser necesario

sacar el otro sujetador.

Soporte de pared

ornillo

ara soporte

plicar torsión

e 4,5 a 5,1 Nm

40 a 45

ibras pulgadas)

Sello de tubería (colóquelo

a través del espaciador)

Comience a apretar los tornillos a mano aproximadamente u

revolución. Colóquelo en el cuerpo o bloqueos de los puerto

y aplique una torsión de 3,4 a 4,5 Nm (30 - 40 libras pulgada

Sujetador interno

Sujetador externo

Tornillo

del sujetad

Figura 1

GPA-96-311

GPA-96-312

Juegos para servicio disponibles

Descripción Número del juego

Bloqueo para puerto NPT 1/8 pulg. GPA-96-301

Bloqueo para puerto NPT 1/4 pulg. GPA-96-302

Bloqueo para puerto NPT 3/8 pulg. GPA-96-303

Bloqueo para puerto BSPP 1/8 pulg. GPA-96-304

Bloqueo para puerto BSPP 1/4 pulg. GPA-96-305

Bloqueo para puerto BSPP 3/8 pulg. GPA-96-306

Bloqueo para puerto BSPT 1/8 pulg. GPA-96-307

Bloqueo para puerto BSPT 1/4 pulg. GPA-96-308

Bloqueo para puerto BSPT 3/8 pulg. GPA-96-309

Juego de conector modular GPA-96-310

Juego de soporte de pared GPA-96-311

Juego esférico de bloqueo de 1/4 pulg. GPA-96-312

Figura 2

Loading...

Loading...