Page 1

83-300-000 REV REL 8/95

Printed in the U.S.A.

NNR=NOT NORMALLY REPLACED

WARNING

DO NOT PLACE PLASTIC BOWL UNIT IN SERVICE

WITHOUT METAL BOWL GUARD INSTALLED

Plastic bowl units are sold only with metal bowl guards. To minimize the danger of flying fragments in

the event of plastic bowl failure, the metal bowl guards should not be removed. If the unit is in service

without the metal bowl guard installed, manufacturer's warranties are void, and the manufacturer

assumes no responsibility for any resulting loss.

IF UNIT HAS BEEN IN SERVICE AND DOES NOT HAVE A METAL BOWL GUARD, ORDER ONE

AND INSTALL BEFORE PLACING BACK IN SERVICE..

CAUTION

Certain compressor oils, chemicals, household cleaners, solvents, paints and fumes will attack plastic

bowls and can cause bowl failure. Do not use near these materials. When bowl becomes dirty replace

bowl or wipe only with clean, dry cloth. Reinstall metal bowl guard or buy and install a metal bowl guard.

Immediately replace any crazed, cracked, damaged or deteriorated plastic bowl with a metal bowl or a

new plastic bowl and metal bowl guard.

SOME OF THE MATERIALS THAT WILL ATTACK

POLYCARBONATE PLASTIC BOWLS.

Acetaldehyde Chlorobenzene Methylene chloride

Acetic acid (conc.) Chloroform Methylene salicylate

Acetone Cresol Milk of lime (CaOH)

Acrylonitrile Cyclohexanol Nitric acid (conc.)

Ammonia Cyclohexanone Nitrobenzene

Ammonium flouride Cyclohexene Nitrocellulose lacquer

Ammonium hydroxide Dimethyl formamide Phenol

Ammonium sulfide Diozane Phosphorous hydroxy

Anaerobic adhesives Ethane tetrachloride chloride

and sealants Ethyl acetate Phosphorous trichloride

Antifreeze Ethyl ether Propionic acid

Benzene Ethylamine Pyridine

Benzoic acid Ethylene chlorohydrin Sodium hydroxide

Benzyl alcohol Ethylene dichloride Sodium sulfide

Brake fluids Ethylene glycol Styrene

Bromobenzene Formic acid (conc.) Sulfuric acid (conc.)

Butyric acid Freon (refrig. & propell.) Sulphural chloride

Carbolic acid Gasoline (high aromatic) Tetrahydronaphthalene

Carbon disulfide Hydrazine Tiophene

Carbon tetrachloride Hydrochloric acid (conc.) Toluene

Caustic potash solution Lacquer thinner Turpentine

Caustic soda solution Methyl alcohol Xylene

Perchlorethylene

and others

TRADE NAMES OF SOME COMPRESSOR OILS, RUBBER COMPOUNDS AND

OTHER MATERIALS THAT WILL ATTACK POLYCARBONATE PLASTIC BOWLS.

Atlas "Perma-Guard" National Compound #N11

Buna N "Nylock" VC-3

Cellulube #150 and #220 Parco #1306 Neoprene

Crylex #5 cement *Permabond #910

*Eastman 910 Petron PD287

Garlock #98403 (polyurethane) Prestone

Haskel #568-023 Pydraul AC

Hilgard Co.'s hil phene Sears Regular Motor Oil

Houghton & Co. oil #1120. #1130 & #1055 Sinclair oil "Lily White"

Houtosafe 1000 Stauffer Chemical FYRQUEL #150

Kano Kroil Stillman #SR 269-75 (polyurethane)

Keystone penetrating oil #2 Stillman #SR 513-70 (neoprene)

*Loctite 271 Tannergas

*Locite 290 Telar

*Loctite 601 Tenneco anderol #495 & #500 oils

Loctite Teflon-Sealant Titon

Marvel Mystery Oil *Vibra-tite

Minn. Rubber 366Y Zerex

*When in raw liquid form.

WE CANNOT POSSIBLY LIST ALL HARMFUL SUBSTANCES, SO CHECK WITH MOBAY

CHEMICAL OR THE GENERAL ELECTRIC OFFICE FOR FURTHER INFORMATION ON POLY-

CARBONATE PLASTIC.

CAUTION

EXCEPT as otherwise specified by the manufacturer, this product is specifically designed for com-

pressed air service, and use with any other fluid (liquid or gas) is a misapplication. For example, use

with or injection of certain hazardous liquids or gases in the system (such as alcohol or liquid petroleum gas) could be harmful to the unit or result in a combustible condition or hazardous external

leakage. Manufacturer's warranties are void in the event of misapplication, and manufacturer

assumes no responsibility for any resulting loss. Before using with fluids other than air, or for nonindustrial applications, or for life support systems consult manufacturer for written approval.

(see reverse side for Installation and Maintenance Instructions)

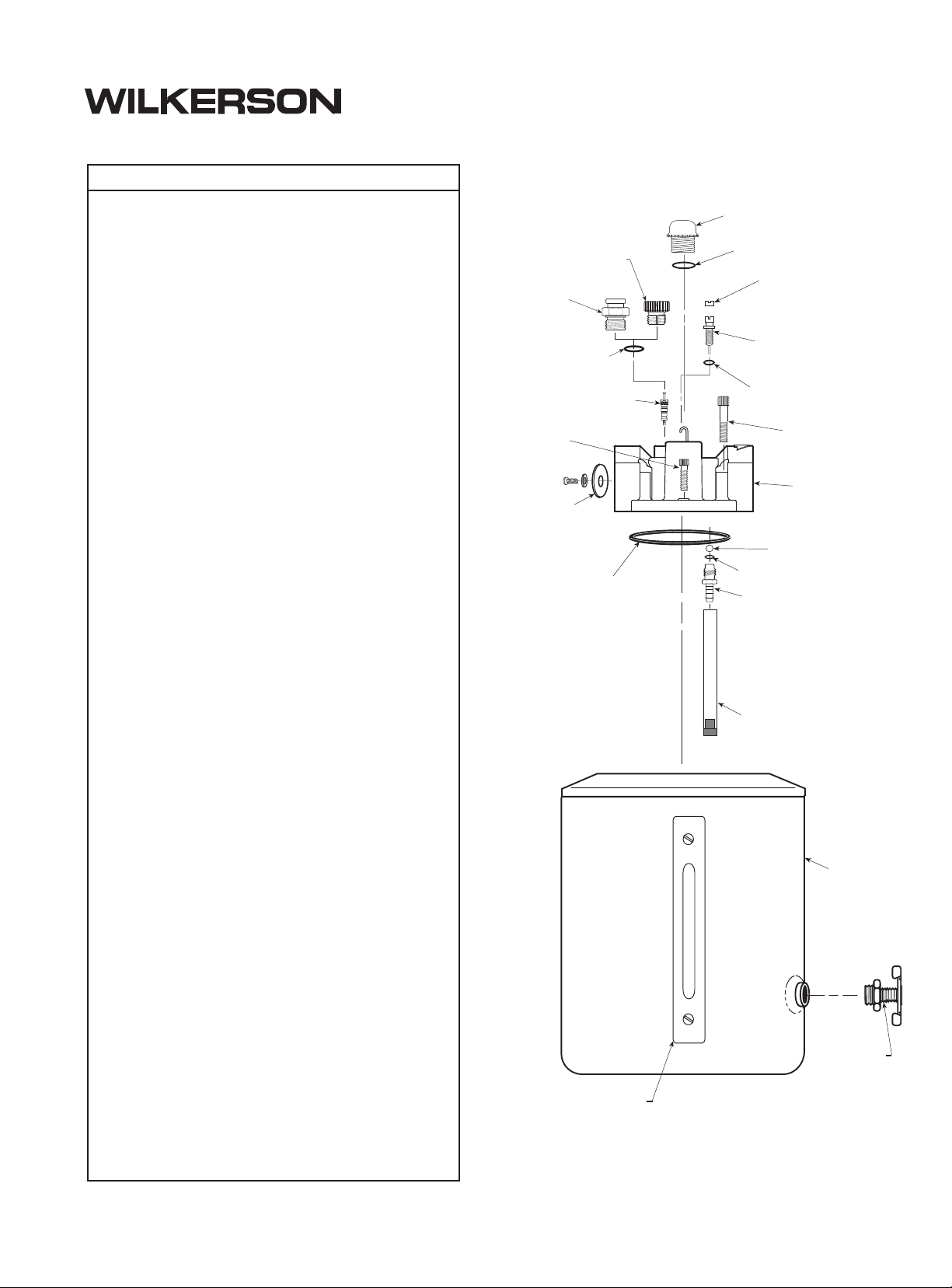

BODY

NNR

CHECK

VALVE

ADJUSTING

SCREW

O-RING

FORCE-FILL

ADAPTER KIT

FILL PLUG

SIGHT DOME

O-RING

O-RING

TAMPER-RESISTANT

KIT (Optional)

FLOW-GUIDE®

VARIABLE

ORIFICE

SCREW

(4 Required)

SCREW

(2 Required)

SIPHON TUBE

ADAPTER

O-RING

BALL

GASKET

TANK

NNR

PETCOCK

SIGHT GAUGE

(See Reverse Side

for Part Numbers

and Breakdown)

INSTALLATION AND

MAINTENANCE SHEET

Lubricator Model L41/L42

with Variations and Accessories

®

OPERATIONS

Page 2

INSTALLATION

1.Refer to the warning on front page.

2.Install as close as possible to the equipment requiring lubrication.

3.Install the unit with the air moving through the body in the direction indicated by the arrow.

4.Install a unit with the same pipe size as the line in use. Avoid using

fittings, couplings, etc., that restrict the airflow or baffle the oil out of the

air at the lubricator outlet.

5.The unit may be filled under pressure by removing the fill plug and

pouring the oil into a bowl through the fill port. The bowl may be taken off

after the fill plug is removed if a more rapid fill is required.

DO NOT

replace the fill plug until the bowl and bowl guard are in position and the

clamp ring is locked in place.

NOTE: As the fill plug is removed, the air

pressure in the bowl will be released.

6.Use only clean nondetergent oil. SAE 10 or lighter is usually best.

7.The rate of oil delivery may be controlled by turning the adjusting screw

counterclockwise for more and clockwise for less oil delivery. This

lubricator delivers all the oil downstream which passes through the sight

dome. The oil delivery rate will change automatically to deliver more oil

during higher airflows and less oil for airflows lower than that at which

the original setting was made.

8.Maximum pressure and temperature ratings for metal tanks

are 200 psig (14 bar) and 175°F (79°C).

MAINTENANCE

1.Given clean operating conditions, this unit will be trouble-free.

Contaminants from dirty oil may collect on the siphon tube inlet filter,

requiring the filter to be cleaned by tapping on a hard surface and

blowing off with an air blow gun.

2.If the oil delivery rate drops, the lubricator should be cleaned. Shut off air

supply and reduce pressure in unit to zero. Remove the Flow-Guide®

variable orifice screw and clean its air passage with a small wire. Check

the bore that the screw fits into for contaminants and clean, if necessary.

Be sure that the passageway from the sight dome cavity into the FlowGuide® variable orifice post is open. Remove the adjusting screw and

clean the needle and the seat in the body. Inspect and clean the

passage from the needle seat down into the adapter.

3.Drain off any contaminants which collect in the bottom of the bowl.

4.Lubricate o-rings with Parker O-Lube before assembly.

5.Clean plastic bowl with a clean, dry cloth only.

KITS AND REPLACEMENT PARTS

Repair Kit -(O-Rings) (for L41 and L42).................................LRP-95-061

Siphon Tube Assembly Kit (for L41)......................................LRP-96-182

Siphon Tube Assembly Kit (for L42)......................................LRP-96-211

Fill Plug Kit (for L41 and L42)................................................LRP-95-250

Flow-Guide® Variable Orifice Kit (for L41 and L42) ..............LRP-95-251

Sight Dome Kit (for L41 and L42)..........................................LRP-95-249

Sight Gauge Kit (for L41).......................................................LRP-95-771

Sight Gauge Kit (for L42).......................................................LRP-95-716

Tamper Resistant Kit ...........................................................LRP-95-587

Force-Fill Adapter (for L41 and L42)......................................LRP-96-420

Check Ball and O-Ring Kit.....................................................LRP-95-310

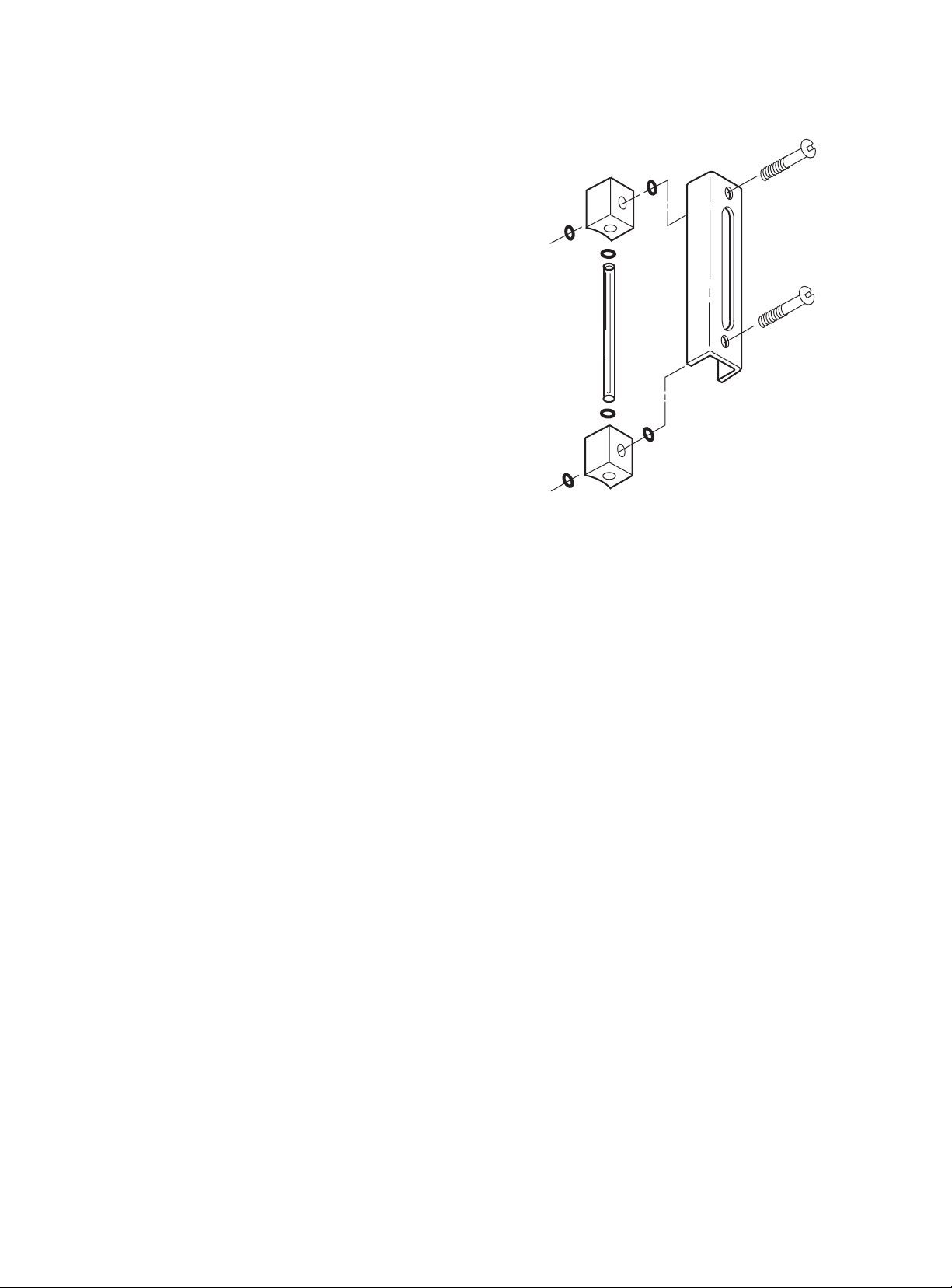

SIGHT GAUGE KIT

Loading...

Loading...