Page 1

Particulate FilterLubricator

Pneumatic Division

Richland, Michigan 49083

269-629-5000

Installation & Service Instructions:

1M301

Miniature Series Mist Lubricators

& Particulate Filters

ISSUED: April, 2013

Supersedes: November, 2003

Doc# 1M301, EN# 130068, Rev. 3

!

WARNING

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Di sco nnect el ectri cal supp ly (w hen n ece ssary ) before

installation, servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected

to this product before installation, servicing, or conversion.

• Op era te withi n t he manufact ure r’s speci fie d press ure ,

temperature, and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is

present, or the product does not operate properly, do not put

into use.

• Warnings and specifications on the product should not be

covered by paint, etc. If masking is not possible, contact your

local representative for replacement labels.

Introduction

Follow these instructions when installing, operating, or servicing the

product.

Application Limits

These products are intended for use in general purpose compressed

air systems only.

Operating Inlet Pressure:

kPa PSIG bar

with Polycarbonate Bowl 1000 150 10.3

with Metal Bowl 1700 250 17.0

NOTE: The maximum recommended pressure drop for a particulate

filter is 70 kPa (10 psig, 0.7 bar)

Ambient Temperature Range:

with Polycarbonate Bowl 0°C to 52°C (32°F to 125°F)

with Metal Bowl 0°C to 80°C (32°F to 175°F)

Symbols

2. Install lubricator so that air flow is in the direction of arrow on body.

3. Installation should be upstream from, and as close as possible, to

the device it is to lubricate (valve, cylinder, tool, etc.). Whenever

possible, avoid locations that require air-borne oil to move in an

upward direction to reach the device to be lubricated.

4. The installation of an individual lubricator for each air consuming

device provides best assurances of proper lubrication.

5. In new installations, it is good practice to “wet down” the inside

diameter of piping and/hose with oil before making final connections.

Although your lubricator delivers oil to the line, pre-coating the inside

diameter with oil helps insure that proper amounts of oil are delivered

to the point of application.

Operation & Service of Lubricator

Warning: Before filling, inlet pressure must be eliminated

!

and then de-pressurize system pressure.

1. FILLING - After de-pressurizing system, remove bowl to refill

lubricator. Fill bowl to fill line indicated on the bowl with oil of 150 to

200 SSU at 100°F viscosity - same as SAE No. 10 (petroleum based

hydraulic oils or spindle oils are good examples). DO NOT USE

OILS WITH TACKY ADDITIVES, COMPOUND OILS CONTAINING

SOLVENTS, GRAPHITE, SOAPS OR DETERGENTS. (Automotive

oils generally contain detergents and are not recommended.

2. Replace the bowl and seat firmly. Excessive torque is not necessary.

The lubricator is now ready for setting.

3. OIL DELIVERY ADJUSTMENT - To adjust oil delivery, turn the

adjusting needle on top of the lubricator.

Leaner - Clockwise Richer - Counterclockwise

By counting the number of drops per minute in the sight dome, you can

adjust lubricator to your required setting.

Generally, one drop per minute downstream for every 10-15 SCFM flow

is satisfactory. 25 drops per minute equals one ounce per hour - volume

of oil passing through the sight dome.

NOTE: This is a constant density type lubricator which delivers a

constant ratio of oil to air flow. Therefore, if air flow increases

or decreases, oil delivery will be effected propor tionately.

ONLY IF DIFFERENT RATIO IS DESIRED SHOULD YOUR

ADJUSTMENT KNOB SETTING BE CHANGED AFTER YOUR

INITIAL SETTING.

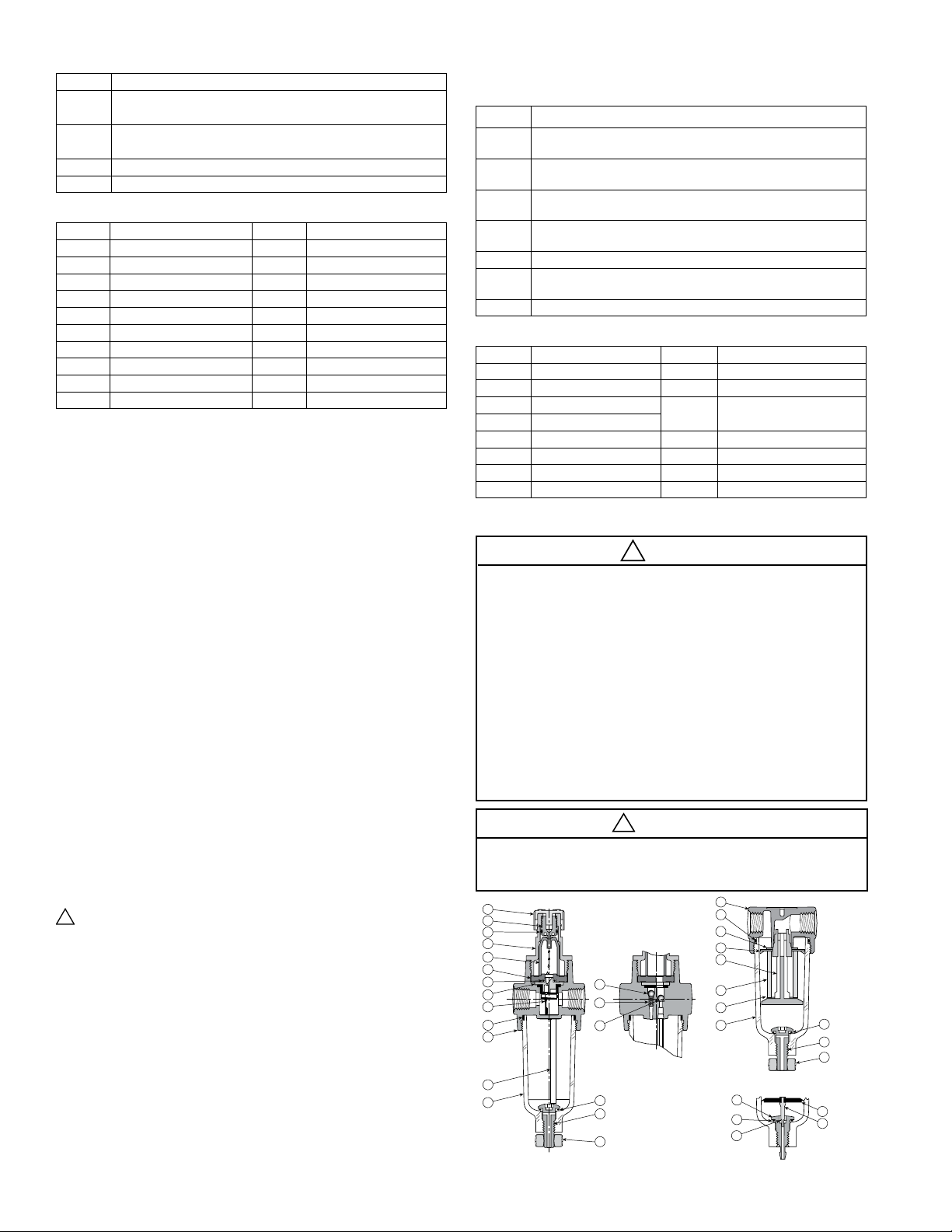

Mist Lubricators (Figure 1)

Description

These mist lubricators are designed to deliver an atomized oil mist to

air operated tools, motors, and other pneumatic equipment. Units are

equipped with full-view sight glass for visual indication of oil drop rate,

needle valve feed adjustment to regulate oil drop rate, and a venturi

bypass disc to compensate for changes in air flow demands.

Installation of Lubricator

1. Lubricator should be installed with reasonable accessibility for

service whenever possible - repair service kits are available. Keep

pipe and tubing lengths to a minimum with inside clean and free of

dirt and chips. Pipe joint compounds should be used sparingly and

applied only to the male pipe – never into the female port. Do not

use PTFE tape to seal pipe joints - pieces have a tendency to break

off and lodge inside the unit, possibly causing malfunction.

WARNING

!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF

THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for

further investigation by users having technical expertise. It is important

that you analyze all aspects of your application, including consequences

of any failure and review the information concerning the product or

systems in the current product catalog. Due to the variety of operating

conditions and applications for these products or systems, the user,

through its own analysis and testing, is solely responsible for making

the final selection of the products and systems and assuring that all

performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject to

change by The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

Mist Lubricator & Particulate Filters Series 1M301

!

Service Kits - Lubricator

Kit# Description

PS420

PS421

Polycarbonate Bowl with Manual Drain - consists of items:

18 (open bottom), 15, 16, 17 & 32

Polycarbonate Bowl without Drain - consists of items:

18 (closed bottom) & 15

PS740 Drip Control (Polycarbonate)

PS740N Drip Control (Nylon)

Parts Identification List - Lubricator

Item# Description Item# Description

1 Knob 11 Spring

2 Drip Control Body 12 Ball, Check

3 Needle 13 Body

4 O-ring 14 Tube

5 Drip Tube 15 O-ring (Body to Bowl)

6 Seal Plate 16 Twist Drain

7 O-ring 17 O-ring (Drain)

8 By-pass Plate 18 Bowl

9 By-pass 32

Twist Drain Knob

10 Ball, Check

Particulate Filter (Figure 2)

Description

These air line filters are heavy-duty units used to remove airborne

impurities from air supply lines by means of centrifugal force and

filter element. Units are equipped with vane-type deflectors and drain

valves. Deflector plate creates swirling action to the air stream assuring

entrainments separation at all flow rates. Filter element with extra large

surface assures fine filtration with low pressure drop. Turn manual drain

clockwise to open and counterclockwise to close.

Installation of Filter

1. Filter should be installed with reasonable accessibility for service

whenever possible - repair service kits are available. Keep pipe and

tubing lengths to a minimum with inside clean and free of dirt and

chips. Pipe joint compounds should be used sparingly and applied

only to the male pipe - never into the female port. Do not use PTFE

tape to seal pipe joints - pieces have a tendency to break off and

lodge inside the unit, possibly causing malfunction.

2. Install unit so that air flow is in the direction of arrow. Installation must

be upstream of and close to devices it is to service (valve, cylinder,

tool, etc.). Position unit vertically with the bowl drain mechanism at

the bottom. Free moisture will thus drain into the sump (“quiet zone”)

at the bottom of the bowl.

Operation of the Filter

1. Both free moisture and solids are removed automatically by

the filter.

2. Manual drain filters must be drained regularly before the separated

moisture and oil reaches the bottom of the element holder. Automatic

drain models (pulse drain) will collect and dump liquids automatically.

They are actuated when a pressure drop occurs within the filter.

3. The filter element should be removed and replaced when the

pressure differential across the filter exceeds 70 kPa (10 psig, 0.7

bar).

Service

Caution: SHUT OFF AIR SUPPLY and exhaust the primary and

!

secondary pressure before dis-assembling unit. (Units may be

serviced without removing them from the air line.)

Servicing Filter Element

1. Unscrew threaded bowl and element holder. Then remove filter

element, deflector, and gaskets.

2. Clean all internal parts, bowl, and body before re-assembling unit.

See Polycarbonate bowl cleaning section.

3. Install deflector, filter element, and gaskets.

4. Attach element holder. Torque from 0.9 to 1.4 Nm (8 to 12 in-lbs).

5. To assist with retaining bowl’s o-ring while installing bowl, lubricate

the o-ring (with a mineral based oil or grease). Then place on

the bowl.

6. Screw bowl into the body until it is stopped by body; then back off

bowl 1/8 turn.

7. Apply pressure to the system and check for leaks. If leaks occur, shut

off the air supply, de-pressurize the system and make necessary

adjustments to eliminate leakage.

If you have questions concerning how to service this unit, contact your

local dealer or your customer service representative.

Service Kits- Filter

Kit# Description

PS404

PS408

PS447B

PS451

Polycarbonate Bowl with Manual Drain - consists of items:

19, 24, 26 & 27

Polycarbonate Bowl with Automatic Drain - consists of items:

19, 24, 26, 28, 29, 30 & 31

Metal Bowl with Manual Drain - consists of items:

19, 24, 26 & 27

Metal Bowl with Automatic Drain - consists of items:

19, 24, 26, 28, 29, 30 & 31

PS403 5 Micrometer Element Kit - consists of items: 20, 21 & 24

PS407

5 Micrometer Element Car tridge Kit - consists of items:

20, 21, 22, 23 & 24

PS401 40 Micrometer Element Kit - consists of items: 20, 21 & 24

Parts Identification List - Filter Units

Item# Description Item# Description

19 Bowl 27 Manual Drain (twist style)

20 Gasket 28 O-ring - pulse drain

21 Filter Element

22 Filter Holder

Drain (body of pulse

29

drain shown)

23 Deflector 30 Diaphragm

24 O-ring (body to bowl) 31 Pin

25 Body 32 Twist Drain Knob

26 O-ring (drain to bowl)

Safety: Transparent Bowls

CAUTION

!

Polycarbonate bowls, being transparent and tough, are ideal for use with

Filters and Lubricators. They are suitable for use in normal industrial

environments, but should not be located in areas where they could be

subjected to direct sunlight, an impact blow, nor temperatures outside of

the rated range. As with most plastics, some chemicals can cause damage.

Polycarbonate bowls should not be exposed to chlorinated hydrocarbons,

ketones, esters and certain alcohols. They should not be used in air systems

where compressors are lubricated with fire-resistant fluids such as phosphate

ester and diester types.

Metal bowls are recommended where ambient and/or media conditions are

not compatible with polycarbonate bowls. Metal bowls resist the action of

most such solvents, but should not be used where strong acids or bases

are present or in salt laden atmospheres. Consult the factory for specific

recommendations where these conditions exist.

TO CLEAN POLYCARBONATE BOWLS USE MILD SOAP AND WATER

ONLY! DO NOT use cleansing agents such as acetone, benzene, carbon

tetrachloride, gasoline, toluene, etc., which are damaging to this plastic.

WARNING

To avoid polycarbonate bowl rupture that can cause personal injury or

property damage, do not exceed bowl pressure or temperature ratings.

Polycarbonate bowls have a 150 PSIG pressure rating and a maximum

temperature rating of 125°F.

1

3

4

2

5

6

7

8

9

15

13

14

18

Torque Bowl

to bottom stop,

then back off

Bowl 22 to 45

Figure 1: Mist Lubricator Figure 2: Particulate Filter

10

11

12

17

16

TORQUE:

finger tight

32

25

24

20

23

22

TORQUE:

8 - 12 in-lbs

21

20

19

Torque bowl to

bottom stop,

then back off

bowl 22 to 45

TORQUE:

1 - 3 in-lbs

26

TORQUE:

27

finger tight

32

29

26

28

30

31

Loading...

Loading...