Page 1

WARNING

DO NOT PLACE PLASTIC BOWL UNIT IN SERVICE

WITHOUT METAL BOWL GUARD INSTALLED

Plastic bowl units are sold only with metal bowl guards. To minimize the danger of flying fragments in the

event of plastic bowl failure, the metal bowl guards should not be removed. If the unit is in service without

the metal bowl guard installed, manufacturer's warranties are void, and the manufacturer assumes no

responsibility for any resulting loss.

IF UNIT HAS BEEN IN SERVICE AND DOES NOT HAVE A METAL BOWL GUARD, ORDER ONE AND

INSTALL BEFORE PLACING BACK IN SERVICE..

For information on materials harmful to plastic bowls, contact a Mobay Chemical or General Electric office for

information regarding materials that will attack polycarbonate plastic.

CAUTION

Certain compressor oils, chemicals, household cleaners, solvents, paints and fumes will attack plastic

bowls and can cause bowl failure. Do not use near these materials. When bowl becomes dirty replace bowl

or wipe only with clean, dry cloth. Reinstall metal bowl guard or buy and install a metal bowl guard.

Immediately replace any crazed, cracked, damaged or deteriorated plastic bowl with a metal bowl or a new

plastic bowl and metal bowl guard.

EXCEPT as otherwise specified by the manufacturer, this product is specifically designed for

compressed air service, and use with any other fluid (liquid or gas) is a misapplication. For example,

use with or injection of certain hazardous liquids or gases in the system (such as alcohol or liquid

petroleum gas) could be harmful to the unit or result in a combustible condition or hazardous external

leakage. Manufacturer's warranties are void in the event of misapplication, and manufacturer assumes

no responsibility for any resulting loss. Before using with fluids other than air, or for non-industrial

applications,or for life support systems consult manufacturer for written approval.

INSTALLATION

1.Refer to the above warning before installing filter.

2.Install as close as possible to the point where air is being used.

3.Install unit with air flowing through the body in the direction indicated by

arrow.

4.Install the same size unit as the pipe line in use. Avoid using fittings,

couplings, etc. that restrict the airflow.

5.DO NOT install filter where pressure drop could exceed 20 psi. Downstream

from a quick-opening valve, for example, could cause a momentary pressure

drop in excess of 20 psi.

6.A drain line with 1/8"-inch NPT connect may be attached to drain port if

desired. Drain line should be 1/4-inch tubing or larger; as short as possible;

and crimp free.

7.Maximum pressure and temperature ratings are: transparent plastic bowls,

150 psig (10,3 bar) and 125°F (52°C); metal bowls, 200 psig (14 bar) and

175°F (79,4°C).

8.Mount unit in vertical position.

MAINTENANCE

1.EACH TIME BOWL IS CLEANED OR THE FILTER ELEMENT REPLACED:

a. Depressurize unit.

b. Inspect seals and replace crazed, cracked, damaged or deteriorated seals

with original manufacturer's approved seals only.

2.FILTER ELEMENT-Clean periodically by removing filter, tapping on hard

surface and blowing off with an air blow gun. When cleaning or replacing

element, blow off louvers with an air blow gun.

3.Before placing the unit in service be sure that the bowl and bowl guard are

reinstalled and the4e clamp ring is securely locked in position.

4.If automatic bowl drain fails to function properly refer to Service Manual Sheet

9SM-96-487.

REPAIR KITS AND REPLACEMENT PARTS

Repair Kit (Type A Element).............................................................FRP-95-209

Float Drain Assembly .......................................................................FRP-96-487

Metal Bowl w/Drain Seat..................................................................GRP-95-903

Plastic Bowl w/Drain Seat & Bowl Guard.........................................GRP-95-902

Bowl Guard ......................................................................................DRP-95-810

83-281-000 REV REL 8/95

Printed in the U.S.A.

NNR=NOT NORMALLY REPLACED

INSTALLATION AND

MAINTENANCE SHEET

Filter Model F34

with Variations and Accessories

®

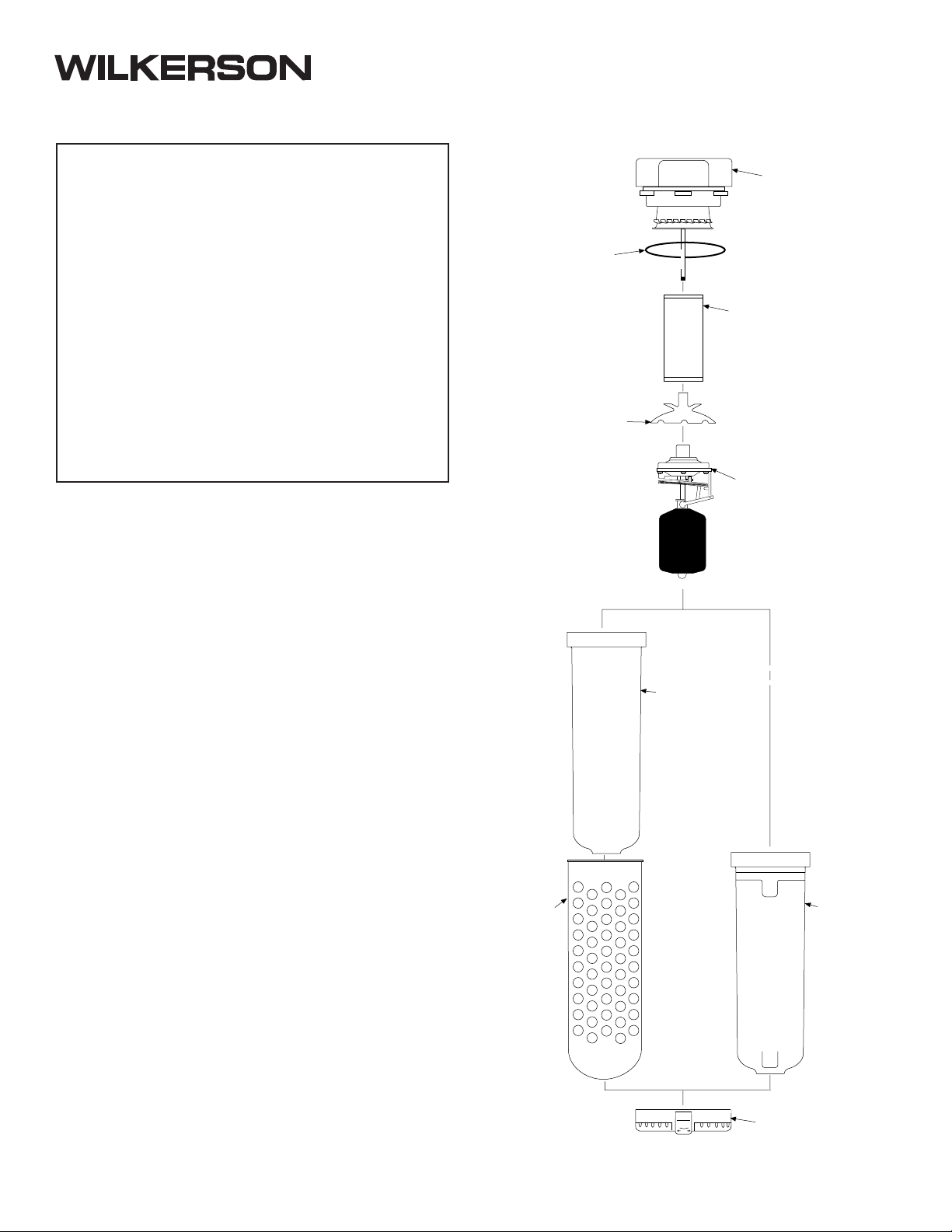

BOWL GUARD

COVER

ASSEMBLY

NNR

O-RING

FILTER KIT

(includes O-Ring)

BAFFLE

NNR

DRAIN ASSEMBLY

(see 9SM-96-487

for parts detail)

TRANSPARENT

PLASTIC BOWL

METAL BOWL

ASSEMBLY

PRESS

TURN

METAL BOWL

ASSEMBLY

Loading...

Loading...