Page 1

Richland, MI 49083 Tel: (269) 629-5000

Installation & Service Instructions

83-130-000

Electronic Regulator

Model ER1 / ER2

ISSUED: February, 2005

Supersedes: July, 2004

Doc. #83-130-000, ECN # 050149, Rev. 4

WARNING

!

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

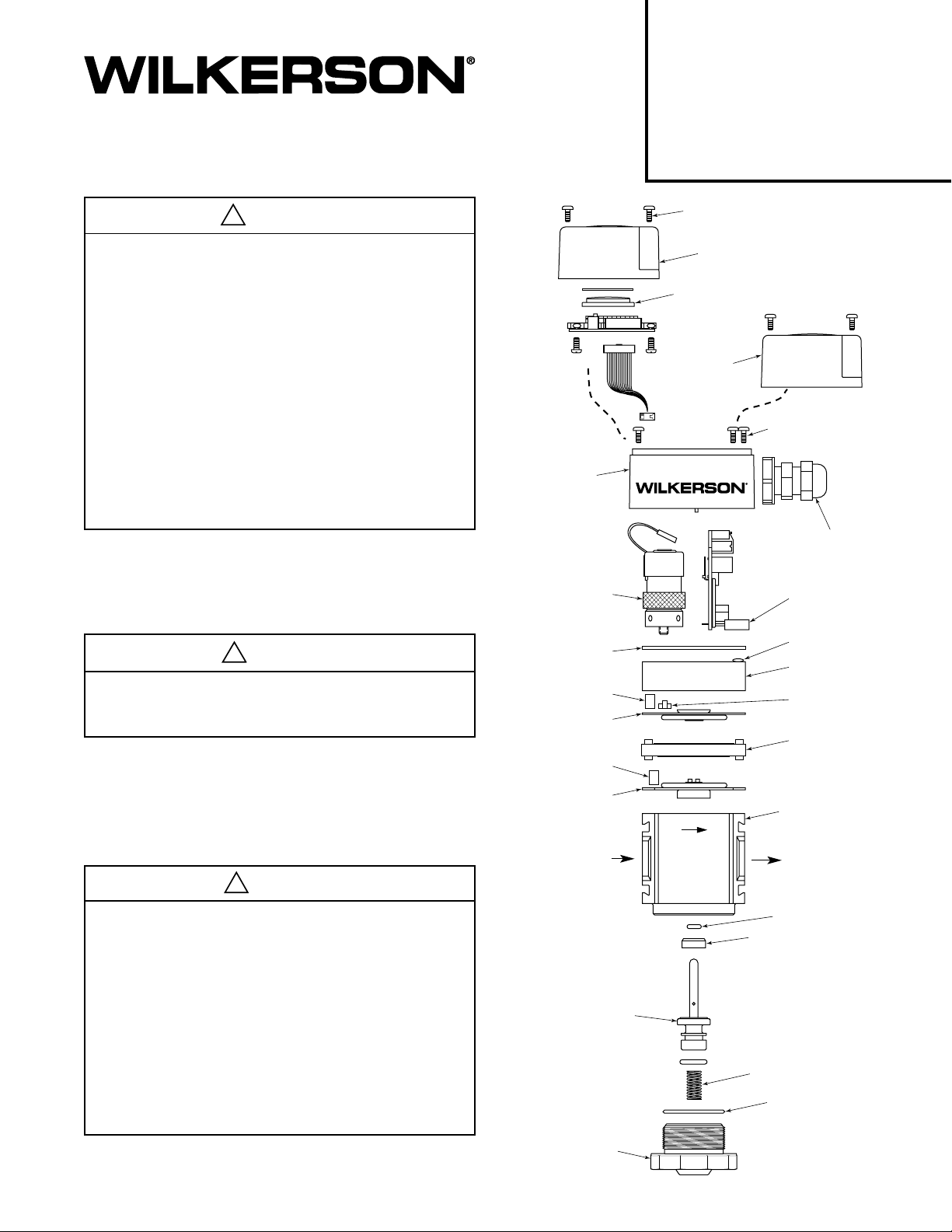

Control

Board

Housing

Intake / Exhaust

Valve

(2 Required)

Housing

Gasket

Filter

Upper

Diaphragm

Filter

Screw (2 Required)

For LCD Housing

LCD Housing

LCD Cover

Standard

Housing

Screw (3 Required)

For Control

Board Housing

Strain Relief

Standard

or LCD

Control

Board

O-Ring

Body Cap

Restrictor

Mid-Plate

WARNING

!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED

ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for further

investigation by users having technical expertise. It is important that you

analyze all aspects of your application, including consequences of any

failure and review the information concerning the product or systems in the

current product catalog. Due to the variety of operating conditions and

applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product features,

specifications, designs, availability and pricing, are subject to change by

The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Lower

Diaphragm

Inlet Port

Valve Stem

and Base

Bottom

Plug

Body

Outlet

Port

O-Ring

Insert

Spring

O-Ring

Page 2

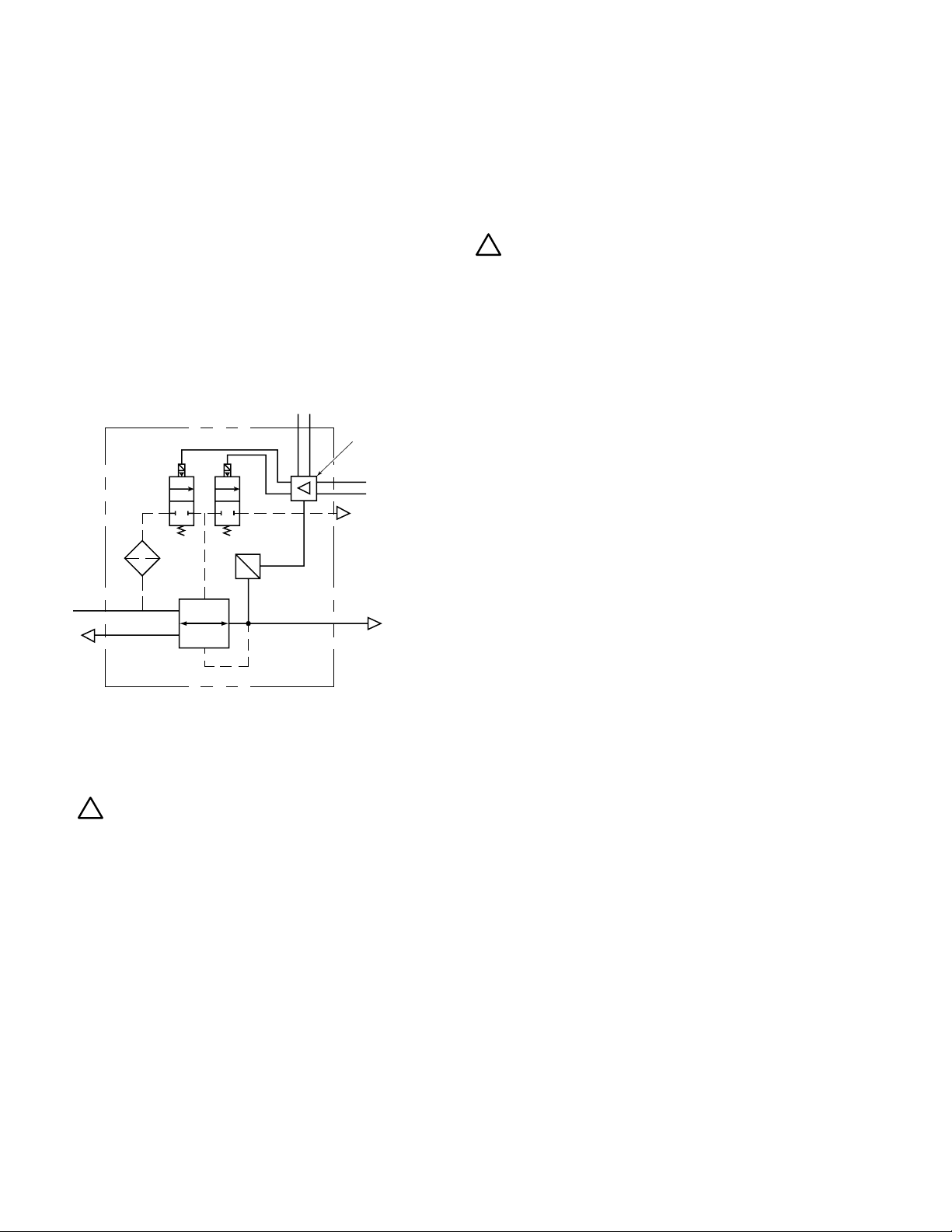

Description

The ERl and ER2 are high flow electro-pneumatic regulators

capable of delivering accurate pressures over a wide range of

flows. The units have a variety of port sizes, ranging from 1/4

inch to 3/4 inch NPT and “G” series threads and use the

convenient Wilkerson 18/28 series modular mounting. The ER

series consists of an integral system of two control valves and

feedback transducer to provide closed-loop control. In addition

the units come with an optional LCD display that displays the

outlet pressure in psig or bar.

The ER series regulators are controlled by either a 0–10 VDC

or 4–20 mA external input signal, or by internal adjustment for

stand- alone operation. The control signal is compared to the

output signal of the internal pressure sensor and the regulator

adjusts the pressure accordingly. The pressure sensor signal

is also an output of 0–10 VDC for external monitoring.

Powe r

Supply

12–28 VDC

+–

Comparator /

Controller

Command

Signal

0–10 VDC

4–20 mA

E

P

Sensor

IN

OUT

Installation

Mechanical Installation

!

1. Refer to the WARNING above.

2. Do not install until you have read the entire product

information sheet.

3. Minimum inlet pressure ............................. 20 psig (1.4 bar)

Maximum inlet pressure ........................ 150 psig (10.3 bar)

Minimum temperature ..................................... 40°F (4.4°C)

Maximum temperature ................................ 125°F (51.6°C)

4. Prior to installation, ensure that the pressure in the line

where this product is to be connected is at atmospheric

pressure 0 psig (0 bar).

5. Install a quality Wilkerson filter upstream of the unit for

maximum trouble free operation.

6. Install with the air flow in the same direction as the arrow on

the unit. DO NOT restrict the air flow with undersize piping

or fittings, unless maximum flow is not required.

Electrical Connection

Since the same control board is used for all control signal options

(Figure 3A)

board must be configured for each particular application by

positioning the jumpers correctly and wiring correctly. This is a

very important step to ensure optimum performance.

Determine what signal you will be using to control the regulator

and follow the instructions for that application. The control

board must be configured and wired accordingly.

to provide maximum flexibility at minimum cost, the

!

Caution: Improper wiring may result in damage to the unit.

To configure the unit for the desired option, and to connect the

external wires to unit, remove the housing by removing the two

screws on top of the unit

off and lay it to one side, making sure not to damage the ribbon

cable that connects the control board to the LCD board.

The jumpers should be configured correctly from the

factory for the configuration ordered and will only need to be

changed if once the unit is received, the user decides on

different control signal, pressure display or pressure range.

(Refer to Figure 2)

Option #1 Sensor feedback signal

Internal sensor ................................. Jumper on position #5

Option #2 LCD display mode

a. psig............................................... Jumper on position #4

b. bar ................................................ Jumper off position #4

NOTE: If using bar option, be careful not to lose jumper.

Option #3 Control signal

a. 0–10 VDC .................................... Jumper on position #1

b. Internal control ............................. Jumper on position #2

c. 4–20 mA ....................................... Jumper on position #3

NOTE: Only one control signal at a time can be used.

Option #4 Pressure Range

Each control board has two pressure ranges available and

can be selected by the Jumper on position #7

The high range board can be configured for either:

a. 0–90 psig (0–6 bar) .....................Jumper on position #7

b. 0–125 psig (0–8,6 bar) ................Jumper off position #7

The low range board can be configured for either:

a. 0–30 psig (0–2 bar) .....................Jumper on position #7

b. 0–60 psig (0–4 bar) .....................Jumper off position #7

First feed the cable through the strain relief provided and remove

the retaining nut for the strain relief. Now feed the wires through

the hole in the control board housing, slide the retaining nut over

the wires and secure the strain relief to the housing making sure

to have the required amount of wire to connect them to the

terminal block. Once this is completed you can connect the wires

to the terminal block as the following describes.

Now, with the unit configured to the desired options, the

external electrical connection of the unit can be done. This is

accomplished by securing the wires directly to the control

board terminal block on the upper right hand side of the unit

(Figure 3)

required number of wires for your application be used to

connect the unit if using an external control and monitor signal.

The shield should be connected to the supply ground and not

to the unit. If using the internal control, only a supply voltage

will be required, although the monitor signal can be used.

. It is recommended that a shielded cable with the

(Figure 4)

. Carefully lift the housing

or

or

or

or

Page 3

ON PSIG / OFF Bar

Position #4

(For LCD Units Only)

Position #5

Internal Sensor

Position #6

(Not Used)

Position #7

Range Selection

Position #3

4–20 mA Control

Position #2

INTERNAL Control

Position #1

0–10 VDC Control

Position #5

0–10 VDC

Control Signal

Position #6

4–20 mA

Control Signal

Position #4

Not Used

Position #3

0–10 VDC

Monitor Signal

Position #2

Common

Ground (-)

Position #1

VDC Supply (+)

Positive Pole

Figure 3 – Terminal Block

Figure 2 – Jumper Connections

If using an external control circuit, connect the wires to

the appropriate terminals as follows:

(Refer to Figure 3)

Control signal:

- If using a 0–10 VDC control signal, connect the control wire

to position #5.

- If using a 4–20mA control signal, connect control wire to

position #6.

Monitor signal: (If used)

- Connect the external monitor feedback to position #3, this

outputs a 0–10 VDC that corresponds to a 1 VDC per 10%

of range.

Supply voltage and common ground:

- Connect the supply voltage positive pole (+) to position #1.

- Connect the common ground (–) for supply, control and

monitor signals to position #2.

If using the internal resistor control, wire the unit as follows:

Monitor signal: If monitor signal is not required, no

connection is required.

- Connect the external monitor feedback to position #3, this

outputs a 0–10 VDC that corresponds to a 1 VDC per 10%

of range.

Supply voltage and common ground:

- Connect the supply voltage positive pole (+) to position #1.

- Connect the common ground (–) for supply, and monitor

signals to position #2.

!

CAUTION: Reversing the polarity of the supply signal my

result in damage to the board.

Once the wires are properly located, secure the wires in the

terminal block and tighten the strain relief to secure the wires

and provide protection from the environment.

PLC Control with 0 – 10 VDC

PLC

Power Supply (+)

12 – 28 VDC

Monitor Signal (+)

0 – 10 VDC (–)

Control Signal (+)

0 – 10 VDC (–)

PLC Control with 4 – 20 mA

(–)

PLC

Power Supply (+)

12 – 28 VDC

Monitor Signal (+)

0 – 10 VDC (–)

Control Signal (+)

4 – 20 mA (–)

Internal Potentiometer

Power Supply (+)

12 – 28 VDC

Monitor Signal (+)

0 – 10 VDC (–)

(–)

(–)

Figure 3A – Control Options

Pressure Display

Internal Pressure Control

Internal Pressure Control

Internal Pressure Control

and

1

2

E

3

4

5

6

Pressure Display

1

2

3

4

5

6

Pressure Display

1

2

3

4

5

6

P

and

I

P

and

E

P

Page 4

Zero and Span Adjustment

The zero and span adjustment was set at the factory and should

not require any further adjustment. If the zero and span do need

to be adjusted, energize the unit. Input 0 VDC to the control

signal and using a volt meter, measure the output on the

position #3 of the terminal block. The output should be -0.01 to 0

VDC. If not turn the zero potentiometer

output is correct. To adjust the span, attach an external

pressure gauge and apply 8 VDC to the control signal. Then

adjust the span potentiometer

(Figure 4)

80% of the range selected [i.e. 24 psig (1,6 bar) for 0–30 psig

(0–2 bar), 48 psig (3,3 bar) for 0–60 psig (0–4 bar), 72 psig (4,9

bar) for 0–90 psig (0–6 bar), 100 psig (6,8 bar) for 0–125 psig

(0–8,6 bar)]. This completes the zero and span adjustments.

Now carefully replace the cover. It can be installed in two

positions, 180 degrees apart from each other. Then replace

the two securing screws.

The unit is now ready for operation. Supply pressure and

power to the unit can be turned on.

(Figure 4)

until the

until the P2 pressure is

Exhaust

Valve

Connector

Zero

Adjustment

Potentiometer

Jumpers

Cover

Intake Valve

Connector

Span

Adjustment

Potentiometer

Terminal

Block

LCD Board

Ribbon Cable

Connector

Control

Board

Housing

Body Cap

Mid Plate

Body

Bottom Plug

Figure 4

If Internally Controlled (On LCD Units Only)

To adjust the pressure, pry the internal adjustment cap off.

With power and pressure to the unit turn the adjustment screw

(Figure 5)

the cap.

until the desired pressure is achieved then replace

Internal

Pressure

Adjustment

Screw

Figure 5

Page 5

Maintenance

1.

DEPRESSURIZE THE AIR LINE PRIOR TO ATTEMPTING ANY

!

SERVICE TO THE UNIT! IT IS ALSO RECOMMENDED THAT

POWER TO THE UNIT BE DISCONNECTED PRIOR TO SERVICING.

2. Main Valve: Remove bottom plug, valve assembly and valve spring.

Inspect all the seals and components for damage and replace as

required. Clean all seals and components with soft cloth and lightly

lubricate the valve O-ring, bottom plug O-ring and valve stem with

MAGNALUBE-G lubricant and reassemble in reverse order.

3. LCD Display: Remove the two screws from the LCD cover and

carefully remove the cover. Turning the cover over, remove the two

screws inside that retain the LCD board to the cover and lift out the

LCD board. Unplug the display board from the ribbon cable. If

defective replace with a new LCD board and re-connect the ribbon

cable. Making sure the LCD lens and seal are in place, replace the

LCD board in the cap and secure with the two screws. Replace the

cover back on the unit and secure with the two screws.

4. Control Board: If unit is an LCD type, remove the LCD display

board from the cap as described in step #3 and unplug the ribbon

cable from the LCD board. Now unscrew the three screws that retain

the control board housing and unplug the valves from the back of the

control board. Carefully lift the housing with the control board still

inside. Remove the control board from the bottom of the housing and

replace with the new control board. Reassemble in reverse order.

5.

Valve Replacement: The electronic valves cannot be serviced

internally. If failure occurs, replace the valve. To replace the valves,

remove the housing as described in step #4 above. Once the housing

is removed, unscrew the defective valve from the cap. Making sure to

replace with correct valve [3 position connector for intake valve and 2

position connector for the exhaust valve

down until it seals on the base of the valve seal. Reassemble the

control board and cap as described in steps #3 and #4.

6. Diaphragm, Mid-plate and Regulator Cap: Remove the control

board and housing as described in step #4 and remove the exhaust

valve. Now remove the two screws that secure the cap to the

regulator body. Lift the cap from the body. Remove the upper and

lower diaphragms, noting which one is upper and lower, from the

mid-plate. Examine the diaphragms and relief seat in the lower

diaphragm for wear and tears and replace as required. Replace the

filter in the mid plate. Clean all surfaces and components with a soft

cloth and reassemble in reverse order.

(Figure 6)

], screw the valve

NOTE:

Intake Valve

Exhaust Valve

Any time the mid-plate is removed, replace the internal

filters (see exploded view for locations). One is in the cap

for the exhaust, one is in the mid-plate for the intake.

Figure 6

Page 6

Inches

G

millimeters

Dimensions

Models A B C D E F G

A

B

E

DC

Front View Side View

F

Repair Kits and Replacement Parts

Control Board LCD 30/60 psig (2.0/4.0 bar) ..... ERP-95-786

Control Board LCD 90/125 psig (6.0/8.6 bar) ... ERP-95-788

Control Board, STD, 30/60 psig (2.0/4.0 bar) ... ERP-95-798

Control Board, STD, 90/125 psig (6.0/8.6 bar) . ERP-95-799

LCD Board and Ribbon ..................................... ERP-95-787

Intake Valve ....................................................... ERP-95-790

Exhaust Valve .................................................... ERP-95-791

Diaphragm Kit, ER1 ........................................... ERP-95-792

Diaphragm Kit, ER2 ........................................... ERP-95-793

Bottom Valve and Valve Spring ........................ ERP-95-794

ER1 6.31 4.71 2.35 .79 1.79 2.35 1.20

160 120 60 20 45 60 30

ER2 6.31 4.71 2.88 .79 1.79 2.88 1.20

160 120 73 20 45 73 30

Troubleshooting

Unit Fails to Operate

1) Verify supply voltage

2) Verify control voltage

3) Intake valve or controller failure

4) Apply 12 VDC to valve and listen for slight

click indicating valve is working

5) Replace control board

Specifications

Min Max Nom Units

Supply Voltage 12 28 — VDC

Supply Current — 250 80 mA

Control Signal

Voltage 0 10 — VDC

Impedance — 200 KOHM

Current 4 20 — mA

Impedance — 600 OHM

Internal — — — —

Monitor Output 0 10 — VDC

Overall Accuracy — — 1.5% SCALE

Supply Pressure 20 150 — psig

(1.4) (10.3) — (bar)

Output Pressure 0 30/60/90/125 psig

(0.0) (2/4/6/8.6) (bar)

Temperature 40 125 — °F

(4.4) (51.6) — (°C)

Flow Rate [150 psig (10 bar) inlet and 90 psig (6 bar)

outlet with a 5 psid (0.3 bar)]

ER1 ................................................................ 200 SCFM (94.3 dm3/s)

ER2 ................................................................ 200 SCFM (94.3 dm3/s)

Note: For optimum operation, inlet pressure should be a minimum

of 15 psig (1.0 bar) above the controlled pressure.

Unit Remains Pressurized

1) Verify control voltage

2) Exhaust valve or controller failure

3) Apply 12 VDC to valve and listen for

slight click indicating valve is working

4) Replace control board

LCD Fails to Display Pressure

1) Verify supply voltage

2) Verify that ribbon cable is secure on both ends

3)

Have dealer check LCD board and replace if necessary

4) Replace control board

Unit Has Constant Leak or is Unstable

1) Inspect and clean bottom valve seals and

lubricate bottom valve

2) Inspect and clean diaphragms

Loading...

Loading...