Page 1

Richland, Michigan 49083

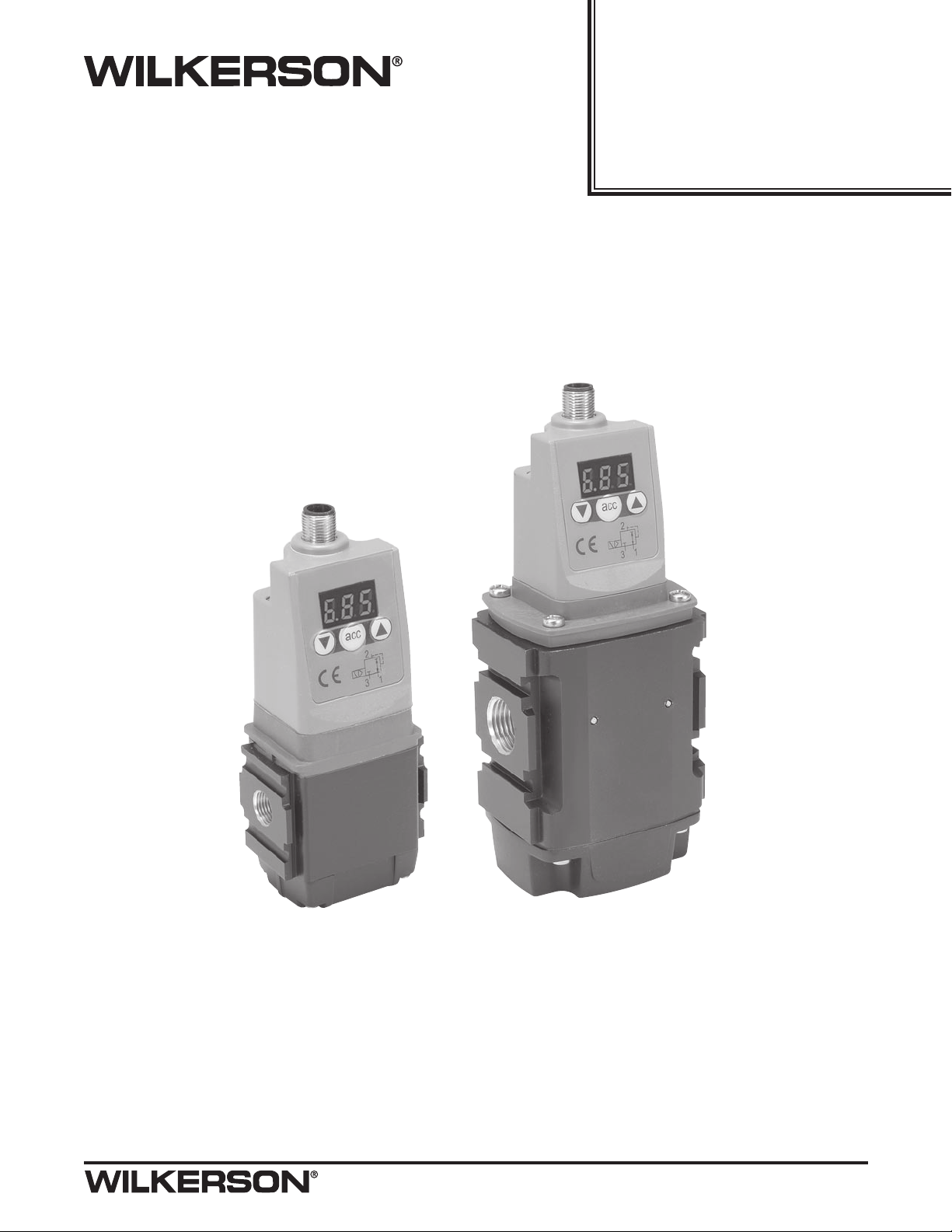

ER09 / ER19 Series

Electronic Proportional Regulator

0 to 10 volt, 4 to 20 mA

FRL-SIF-621

ER09 / ER19

Electronic Proportional Regulators

ISSUED: March, 2010

Supersedes: None

Proportional Regulator Applications .........................2-3

Why Proportional Technology? ....................................4

Numbering System (Ordering Information) ................. 5

Options ........................................................................6

Technical Information................................................7-8

Programming Information .......................................9-17

Dimensions ................................................................18

Troubleshooting .........................................................19

Glossary ....................................................................20

1

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 2

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Energy Saving

Low Watt Power Consumption

Man-Machine Interface

High Visibility LED Display

No Unnecessary Loss of Air in

Steady State

Easy to Read Characters

All Controls on the Same Face

Total Flexibility

User Friendly and Easily

Accessible Software Controls

One Basic Unit Suits All

Customer Requirements -

0-10V Control Signal Standard

4-20mA Control Signal Software

Selectable

Modular Mounting

10 bar & 2 bar Version

Special Applications

Clean Line Design

Suitable for Washdown: IP65

Forced Exhaust Option Available

4 Output Signal Versions Available

Compact and Light Weight

40 & 60 mm Body Sizes

Light Weight Aluminum Bodies

Flexible Mounting Options

Stand-alone or Modular Mounting

Foot Bracket Mounting

DIN-Rail Mounting

Outstanding Performance

Very Fast Response Times

Full Flow Exhaust

Excellent Linearity

High Flow

2

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 3

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Generic Industries

The new Proportional Regulator is designed to quickly and accurately

adjust and maintain a set output pressure.

The unit will operate regardless of flow, in response to an electronic

control signal. The media can be compressed air or an inert gas.

Applications for this technology are virtually unlimited; from paint spray

control, paper manufacturing and printing to weaving and laser cutting

control; in fact anywhere that requires accurate remote pressure control.

Automation

In the field of general automation, the need to control processes or

movement via electronic signals is of paramount importance. The

Proportional Regulator unit provides the facility to incorporate pressure

control into a fully integrated control system.

Packaging and Food

The Packaging and Food industry provides another ideal area for

application of the Electronic Proportional Regulator, where fine control

of tension on wrapping foils and paper is required. The degree of control

and the ability to manually change parameters makes this unit ideally

suited to the varying requirements of this industry.

Automotive

Applications for this innovative product in the Automotive industry can

be seen in major manufacturers’ “body-in-white” lines.

The control of clamping and welding forces during panel assembly is

an ideal application, also accurate control in paint dipping and spraying

can be achieved.

3

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 4

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Why Proportional Technology ?

The Difference Between Open or

Closed Circuit Control

Standard pressure regulators go a long way towards

meeting customers needs. In most cases these

regulators work well in general pneumatic and

automation applications. However, sometimes the

application calls for more precise pressure control.

The effects of time, cycling, input, back pressure or

pressure and flow variation can all cause inconsistencies

in pneumatic systems. Proportional Regulators are

designed to eliminate those inconsistencies.

Open Control Circuit

In a normal pressure regulated control system, the inlet

pressure (p1) is converted into the output pressure

(p2) by the regulator. The set pressure (set value) is

usually manually set by adjusting the control knob and

in normal circumstances the regulator maintains the

output pressure (actual value).

No facility for monitoring the output pressure is

provided and there is consequently no way of checking

that the set value and the actual value are the same.

Also, no account is taken of external influences such as

air consumption by the system, which can drastically

alter the actual value.

Closed Loop Control Circuit

The input signal (Electronic Control Signal) is

converted into the output value (P2 Output Pressure).

This output value is continuously measured and

compared with the input signal. If they are different, the

unit adjusts the output value to correspond to the set

value, to close the loop.

Proportional Pressure Regulators

The Proportional Regulators provide all the advantages

of a closed circuit regulated system. When a set value

is defined via the input signal (e.g. 0-10 V), the pressure

regulator sets the corresponding output pressure (e.g.

0-150 PSI/0-10 bar). At the same time the integrated

pressure sensor measures the actual pressure at the

unit’s outlet (actual value).

If the electronic regulation system finds that the actual

value has deviated from the set value, it immediately

corrects the actual value. This is a continuous process

ensuring fast, accurate pressure regulation.

Typical Application in Automotive Body in

White Welding Pressure Control

4

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 5

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Electronic Proportional Regulator

= “Most Popular”

Numbering System

Unit Thread Port Power Control Signal Pressure

Function Family Type Size Supply / Feedback Range Version

E R 0 9 - 0 2 - 0 0 0 0

Unit Function

ER Electronic

Proportional

Regulator

Family

09 Miniature (40mm)

19 Compact (60mm)

Thread Type

0 NPT

C BSPP

Port or Tube Size

2 1/4" (ER09 Only)

4 1/2" (ER19 Only)

Power Supply

0 24 VDC

0-10V Control Signal † / Feedback

0 Digital, PNP

P Digital PNP or Analog 0-10V*

N Digital NPN or Analog 0-10V*

M 4-20mA Fixed

† All products have a 0-10V control

signal, this is switchable to 4-20mA by

means of parameter 4.

* Selectable by means of Parameter 6

1

0) Digital PNP output only, no analog

output selectable

P) Digital PNP and analog 0-10V

outputs slectable by means of

parameter 6 (factory defaults 0-10V)

N) Digital NPN and analog 0-10V

outputs slectable by means of

parameter 6 (factory defaults 0-10V)

M) Analog 4-20mA output only

Pressure Range

0 0-145 PSIG

(0 to 10 bar)

C 0-29 PSIG

(0 to 2 bar)

0 Bottom Exhaust

A Side Exhaust

E‡ Forced Exhaust

1

‡

When the supply

voltage is lost, the

unit will automatically

exhaust the regulated

pressure to 0 bar

(atmosphere).

Version

ER09 / ER19 Kits

Seal Kit (Valve Seat, Cover Seal) ..............................3538200

Valve Kit (2 Valves, Screws, Cover Seal) ..................3538100

Cable (M12, 4-Pin Female Connection

with 2m Cable) ..............................................CB-M12-4P-2M

5

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 6

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Ordering Code

Port Size Order Code Control Signal Output Signal Output Pressure

1/4 ER09-02-00C0 0 - 10 V Digital PNP Only 0-29 PSIG (0 -2 bar)

1/4 ER09-02-0000 0 - 10 V Digital PNP Only 0-145 PSIG (0 -10 bar)

1/4 ER09-02-0PC0 0 - 10 V Digital PNP or 0-10V 0-29 PSIG (0 -2 bar)

1/4 ER09-02-0P00 0 - 10 V Digital PNP or 0-10V 0-145 PSIG (0 -10 bar)

1/4 ER09-02-0NC0 0 - 10 V Digital NPN or 0-10V 0-29 PSIG (0 -2 bar)

1/4 ER09-02-0N00 0 - 10 V Digital NPN or 0-10V 0-145 PSIG (0 -10 bar)

1/4 ER09-02-0MC0 0 - 10 V 4-20mA Analog Only 0-29 PSIG (0 -2 bar)

1/4 ER09-02-0M00 0 - 10 V 4-20mA Analog Only 0-145 PSIG (0 -10 bar)

1/2 ER19-04-00C0 0 - 10 V Digital PNP Only 0-29 PSIG (0 -2 bar)

1/2 ER19-04-0000 0 - 10 V Digital PNP Only 0-145 PSIG (0 -10 bar)

1/2 ER19-04-0PC0 0 - 10 V Digital PNP or 0-10V 0-29 PSIG (0 -2 bar)

1/2 ER19-04-0P00 0 - 10 V Digital PNP or 0-10V 0-145 PSIG (0 -10 bar)

1/2 ER19-04-0NC0 0 - 10 V Digital NPN or 0-10V 0-29 PSIG (0 -2 bar)

1/2 ER19-04-0N00 0 - 10 V Digital NPN or 0-10V 0-145 PSIG (0 -10 bar)

1/2 ER19-04-0MC0 0 - 10 V 4-20mA Analog Only 0-29 PSIG (0 -2 bar)

1/2 ER19-04-0M00 0 - 10 V 4-20mA Analog Only 0-145 PSIG (0 -10 bar)

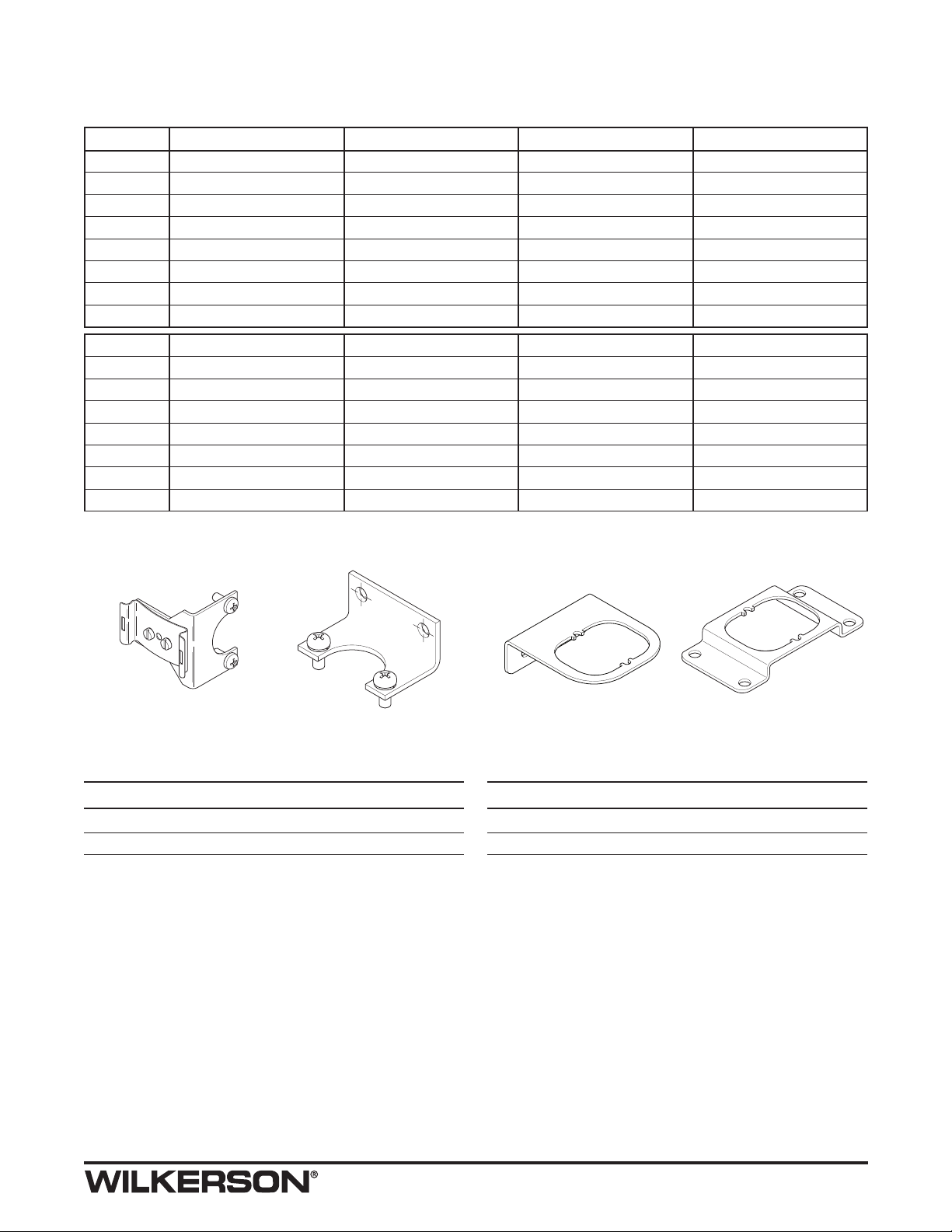

DIN Rail

Foot Bracket

ER09 Mounting Brackets

Order Code Description

P3HKA00MK

P3HKA00MF Foot Bracket Mounting Kit

DIN Rail Mounting Kit

L-Bracket

Foot Bracket

ER19 Mounting Brackets

Order Code Description

P3KKA00ML

P3KKA00MC Foot Bracket Mounting Kit

L-Bracket Mounting Kit

6

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 7

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

1

24 VDC

Control

Signal

3

2

U

O

P

+

2

4-PIN MICRO

(TOP COVER)

WHT

BRN

BLUE

BLK

ISO 20401

134

Pneumatics

Working Media

Compressed air or inert gasses, filtered to 40µ.

Operating Pressure

Max. Operating Pressure

2 bar unit ...............................................3 bar (43.5 PSI)

10 bar unit ........................................10.5 bar (152 PSI)

Min. Operating Pressure ............P2 Pressure + 0.5 bar

(7.3 PSI)

Pressure Control Range

Available in two pressure ranges, 0-2 bar (0-29 PSI) or

0-10 bar (0-145 PSI). Pressure range can be changed

through the software at all times. (parameter 19)

Temperature Range

32°F to 122°F (0°C to 50°C)

Weight

ER09 0.64 lbs (.291 kg)

ER19 1.42 lbs (.645 kg)

Electronics

Supply Voltage

24 VDC +/- 10%

Power Consumption

1.1 W with unloaded signal outputs

Current Consumption

Max. 200 mA with no load

Control Signals

The electronic pressure regulator can be externally

controlled through an analog control signal of 0-10 V,

adjustable to 4-20 mA via parameter 4.

Connections

Central M12 male connector 4-pole.

Air Consumption

No consumption in stable regulated situation.

Display

The regulator is provided with a digital display, indicating

the output pressure, either in PSI or bar.

The factory setting is as indicated on the label, can be

changed through the software at all times (parameter 14).

Schematic

The electrical connections are as follows:

Pin No. Function Color

1 24 V Supply Brown

0 to 10 V or

2

4 to 20mA

3 0 V (GND) Supply Blue

4 24 V Alarm Output Signal Black

In the case of 4 to 20mA the Ri will be 500 Ohm

Control Signal

Ri = 100k W

White

7

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 8

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Technical Information

Dead Band

The dead band is preset at 1.3% of Full Scale*,

adjustable via parameter 13.

Accuracy

Linearity: = < 0.3% of Full Scale.*

Proportional Band

The proportional band is preset at 10% of Full Scale.*

Fail Safe Operation

• IftheER09/ER19unithasan“0”or“A”inthe12th

digit of the model number

o When the supply voltage drops, the electronic

control reverts to the fail safe mode. The last

known output pressure is maintained at

approximately the same level depending upon

air consumption. The digital display indicates

the last known pressure setting.

o When the supply voltage is reinstated to the

correct level, the valve moves from the fail safe

mode and the output pressure immediately

follows the control signal requirement. The

display indicates the actual output pressure.

o Note: In the event of loss of both power and

inlet pressure the unit will exhaust downstream

pressure.

• IftheER09/ER19unithasan“E”inthe12thdigit

of the model number

o When the supply voltage drops, the electronic

control reverts to “Forced Exhaust Mode” and will

automatically exhaust the downstream (regulated)

pressure.

o When the supply voltage is reinstated to the

correct level the unit will return to normal

operation and follows the control signal

requirement. The display indicates the actual

pressure.

• Iftheunithasbeenprogrammedinmanualmode

(not with a control signal) the unit will EXHAUST

and the regulator will need to be reset when power

is applied.

Degree of Protection

IP65

EU Conformity

CE: standard

EMC: according to directive 89/336/EEC

The new pressure regulator is in accordance with:

EN 61000-6-1:2001

EN 61000-6-2:2001

EN 61000-6-3:2001

EN 61000-6-4:2001

These standards ensure that this unit meets the

highest level of EMC protection.

Mounting Position

Preferably vertical, with the cable gland on top.

Materials

Magnet Core ........................................................Steel

Solenoid Valve Poppet ....................................... FPM

Solenoid Valve Housing ................... Techno Polymer

Regulator Body (ER09 / ER19) ...................Aluminum

Regulator Top Housing ......................................Nylon

Valve Head ..............................................Brass & NBR

Remaining Seals ................................................. NBR

Full Exhaust

Complete exhaust of the regulator is defined as

P2 ≤ 1% Full Scale

* Full Scale (F.S.)

For 2 bar versions this will be 2 bar, for the 10 bar

version full scale will be 10 bar.

8

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 9

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Advanced Functionality

Pilot Valve Protection

When the required output pressure can not be

achieved due to lack of input pressure, the unit will

open fully and will display “NoP”. Approximately every

10 seconds the unit will retry. The output pressure will

then be approximately equal to the inlet pressure. As

soon as the input pressure is back on the required

level, the normal control function follows.

Safety Exhaust

Should the control signal fall below 0.1 volts, the

valve will automatically dump downstream system

pressure.

Input Protection

The unit has built-in protection against failure and

burnout resulting from incorrect input value, typically:

The 24v DC supply is incorrectly connected to the

setpoint input, the display will show ‘OL’, as an

overload indication. The unit will need to be rewired

and when correctly connected will operate normally.

The overload indicator ‘OL’ will also appear should the

wrong input value be applied or the wrong input value

be programmed: 4 - 20m instead of 0 - 10V. To correct

this a different set point value should be input or the

unit reprogrammed to correct the set point value

acceptance. (via parameter 4).

Response Times

Response time ER09 ER19

2 to 4 bar 25 msecs 35 msecs

1 to 6 bar 55 msecs 135 msecs

4 to 2 bar 70 msecs 85 msecs

6 to 1 bar 80 msecs 225 msecs

To fill volume of:

100cm3 - ER09

330cm3 - ER19

connected to the outlet of the regulator.

Settings

The regulator is pre-set at the factory. If required,

adjustments can be made.

9

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 10

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

7

8

9

10

00

14.5

29

43.5

58

72.5

87

101.5

116

130.5

145

010203040506070

1

2

3

4

5

6

Pressure Drop (bar)

Pressure Drop (PSIG)

Flow (SCFM)

0510 15 20 25 30

Flow (dm3/s)

P2 = 14.5 PSIG Pressure Drop @ 14.5 PSIG= N/A SCFM

P2 = 43.5 PSIG Pressure Drop @ 14.5 PSIG = 67.54 SCFM

P2 = 72.5 PSIG Pressure Drop @ 14.5 PSIG = 64.65 SCFM

P2 = 91.4 PSIG Pressure Drop @ 14.5 PSIG = 60.68 SCFM

P2 = 116 PSIG Pressure Drop @ 14.5 PSIG = 53.67 SCFM

ER09 Regulator 1/4" Ports

0102030405060708090 100 110120 130 140 150 160170 180 190 200 210

0510 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

ER19 Regulator 1/2" Ports

P2 = 116 PSIG Pressure Drop @ 14.5 PSIG = 147.8 SCFM

P2 = 14.5 PSIG Pressure Drop @ 14.5 PSIG = N/A SCFM

P2 = 43.5 PSIG Pressure Drop @ 14.5 PSIG = 203.6 SCFM

7

8

9

10

00

14.5

29

43.5

58

72.5

87

101.5

116

130.5

145

1

2

3

4

5

6

Pressure Drop (bar)

Pressure Drop (PSIG)

Flow (SCFM)

Flow (dm3/s)

P2 = 91.4 PSIG Pressure Drop @ 14.5 PSIG = 176.1 SCFM

P2 = 72.5 PSIG Pressure Drop @ 14.5 PSIG = 191.8 SCFM

Flow Characteristics

10

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 11

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

How to change parameters

Pressing the Accept key “acc” for more than 3 seconds, will

activate parameter change mode. The user can then select

the parameters by pressing up or down key. (display will

show Pxx). When parameter number is correct, pressing

accept again will enter parameter number.(display will show

parameter value).

Pressing the up or down key will change the parameter

itself. (display will flash indicating parameter editing mode).

Pressing the accept key will accept the new parameter value.

(all digits will flash whilst being accepted).

After releasing all keys , the next parameter number will

be presented on the display. (you may step to the next

parameter). When no key is pressed, after 3 seconds the

display will show the actual output pressure.

Back to Factory Setting

After start up. (Power is on)

Parameter 0 = 3

Entering this value in parameter 0 will store the calibrated

factory data into the working parameters. (Default calibration

data is used)

When the unit is initially powered up allow approximately 10

seconds for the unit to “boot-up” before changing parameter

settings.

Only parameter numbers 0, 4, 6, 8, 9, 14, 18, 19, 20, 12, 13

and 21 are accessible to edit. All other parameters are fixed.

Manual mode

When keys DOWN and UP are pressed during startup,

(connecting to the 24V power supply) manual mode is

activated. This means that the user is able to in/decrease

the output pressure of the regulator, by pressing the UP or

DOWN key. During this action the display will blink, indicating

that the manual mode is activated. After powering up again,

the unit will revert back to normal mode.

Parameter Number 0 – Reset Back to Factory Settings

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Flashing Decimal Flashing Decimal Flashing

Description

Accesses

changeable

parameters.

Accesses

parameter no. 0.

Displays current

parameter value.

Edits parameter.

3 = standard

factory settings.

If other than 3,

use Up or Down

Arrow and

accept 3

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

11

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 12

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

or

Set Control Signal

The unit is factory set for 0-10 V control signal. If 4-20 mA

control signal is required, change parameter 4.

Parameter Number 4 – Set Control Signal in Volts or Milliamps

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Flashing Decimal Flashing Decimal Flashing

Description

Accesses

changeable

parameters.

Accesses

parameter no. 4.

Displays current

parameter value.

1 = V

0 = mA

Edits parameter.

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Set Output Signal

Parameter 6 is used to set the type of out put signal to your PLC.

This parameter is used as follows:

Output Signal option “0” = Digital Output – PNP

• Factorysetat“0”NonAdjustable

Output Signal option “P” = Digital PNP or Analog 1-10V

• Factorysetat“1”forAnalogSignal

• ConverttoDigitalPNPbychangingparameterto“0”setting

Output Signal option “N” = Digital NPN or Analog 1-10V

• Factorysetat“1”forAnalogSignal

• ConverttoDigitalNPNbychangingparameterto“0”

Output Signal option “M” = Analog 4-20 mA

• FactorySetat“2”NonAdjustable

Parameter Number 6 – Set Output Signal

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 6.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

1 = m factory

default for ER

with analog

options

(Value 0, 1 or 2)

Edits parameter.

0 = digital

(NPN or PNP)

1 = analog 0..10V

2 = analog 4..20 mA

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

12

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 13

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

or

Adjust Span Analog Output Signal

Parameter 8 is used to adjust the Analog output range.

• Setvalueisa%ofFullAnalogrange.Asanexamplefora0-10Voutputsignal

the original factory setting of 100% will give you an adjustment of 0-10V. If you

reset Parameter 8 to 50% the new output range would be 0-5 V or 50% of the full

range.

• Intheeventthattheoutputsignalistolow,inacertainapplication,youcan

adjust it by increasing Parameter 8 to a maximum value of 130% of scale.

• Notethatallvaluesarenominalandthatanactualmeasurementmaybe

required to ensure signal strength.

Parameter Number 8 – Adjust Span Analog Output Signal

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 8.

Flashing Decimal Flashing Decimal

(Value between

0 and 130)

Displays current

parameter value. Edits parameter.

Flashing

Accepts and saves

new parameter

setting and

implements the

new analog signal

span.

Sequences to

next parameter.

Adjust Digital Display

If necessary, adjustments can be made to the digital display

when using an external pressure sensor.

Parameter Number 9 – Adjust Digital Display Value (Pressure Calibration)

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Flashing Decimal Flashing Decimal Flashing

Use up or down

arrows and

accept to adjust

Description

Accesses

changeable

parameters.

Accesses

parameter no. 9.

Displays current

digital display

13

the display

value if using an

external pressure

sensor.

Accepts and

saves new

parameter

setting.

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Sequences to

next parameter.

Page 14

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

or

Set Pressure Scale

Units with NPT port threads are supplied with a factory set

PSI pressure scale. Use parameter 14 to change scale to bar.

Parameter Number 14 – Set Pressure Scale in PSI or bar

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Flashing Decimal Flashing Decimal Flashing

Displays current

Description

Accesses

changeable

parameters.

Accesses

parameter no. 14.

parameter value.

1 = PSI

0 = bar

2 = MPA

Edits parameter.

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Preset Minimum Pressure

If there is a need for a pre-set minimum pressure, use

parameter 18. (Note: preset pressure is affected by % P19.)

Parameter Number 18 – Set Minimum Preset Pressure

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 18.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

Incremental

value is:

2 bar unit:

x 2 mbar x % P19

10 bar unit:

x 10 mbar x % P19

(value between

0 and 200)

Edits parameter.

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

14

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 15

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

or

Set Pressure Correction

Pressure correction allows the user to set a maximum

pressure as a percentage of secondary pressure F.S.

Example: If F.S. is 10 bar, set parameter 19 to 50 for

maximum preset pressure of 5 bar.

Pressure correction also affects the minimum preset

pressure in parameter 18.

Example: If F.S. is 10 bar and parameter 18 is set to a value

of 100 (1 bar), and parameter 19 is set to 50%, then the

actual minimum preset pressure seen is 0.5 bar.

Parameter Number 19 – Set Maximum Preset Pressure

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 19.

Flashing Decimal Flashing Decimal

(value between

0 and 100)

Displays current

parameter value.

Incremental

value is:

% of F.S. Edits parameter.

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Behavior Control

The regulation speed of the pressure regulator can be

modified by means of one parameter. (P 20)

The value in this parameter has a range from 0-5. A higher

value indicates slower regulation speed, but will be more

stable.

Parameter Number 20 – Set Behavior Control

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 20.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

(value between

0 and 5)

Edits parameter

0 = custom set*

1 = fastest (narrow

proportional band)

2 = fast

3 = normal

4 = slow

5 = slowest

(proportional

band is broad)

Accepts and

Flashing

saves new

parameter

setting.

Sequences to

next parameter.

* When the value 0 is entered, you are able to create your own custom settings true parameters 12, 13 and 21.

15

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 16

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

or

Fine Settings

Set Proportional Band

Proportional band is used for setting the reaction sensitivity

of the regulator. The displayed value is X 10 mbar and has a

range between 50 (0.5 bar) and 250 (2.5 bar).

Parameter Number 12 – Set Proportional Band (P20 Must be Set to 0)

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 12.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

Incremental

value is:

x 10 mbar

Edits parameter.

(value between

50 and 250)

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Set Deadband

Deadband is the minimum limit of accuracy at which the regulator

is set for normal operation. The displayed value is X 10 mbar and

has a range between 4 (40 mbar) and 40 (400 mbar).

Parameter Number 13 – Set Deadband (P20 Must be Set to 0)

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 13.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

Incremental

value is

x 10 mbar

Edits parameter.

(value between

4 and 40)

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

16

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 17

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

or

or

or

Proportional Effect

Sets the speed at which the regulator adjusts either filling or

exhausting. The displayed value has a range between 5

(fastest regulation) and 100 (slowest regulation).

Parameter Number 21 – Set Proportional Effect (P20 Must be Set to 0)

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 21.

Flashing Decimal Flashing Decimal

Displays current

parameter value.

(value between

5 and 100)

Edits parameter.

5 = fastest

regulation

100 = slowest

regulation.

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Parameter Number 39 – Displays Current Software Version

Step 1 2 3

Press

3-6 seconds

Until Display

Reads

Flashing Decimal

Displays current

parameter value.

XXX = current

software version

Description

Accesses

changeable

parameters.

Accesses

parameter no. 39.

17

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 18

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

ER09 ER19

0.56

(14.3)

4 Pin M12

Connector

0.56

(14.3)

6.94

(175.7)

1.13

(28.6)

4.99

(126.25)

0.79

(20)

1.12

(28.5)

2.25

(57)

0.79

(20)

1.58

(40)

3.51

(89)

1.47

(37.25)

1.48

(37.5)

4 Pin M12

Connector

2.96

(75)

1.13

(28.6)

2.26

(57.2)

4.16

(105.3)

2.54

(64.4)

0.28

(7)

0.28

(7)

L-Bracket L-Bracket

0.59

(15)

0.98

(25)

1.18

(30)

1.42

(36)

0.28

(7)

Foot Bracket

1.02

(26)

2.05

(52)

2.05

(52)

1.57

(40)

2.20

(56)

1.18

(30)

0.47

(12)

0.39

(10)

Ø 0.28 (7)

4 holes

2.05

(52)

0.59

(15)

1.57

(40)

1.18

(30)

1.42

(36)

0.59

(15)

0.98

(25)

0.59

(15)

Foot Bracket

2.20

(56)

0.47

(12)

1.02

(26)

Ø 0.28 (7)

4 holes

1.77

(45)

2.05

(52)

Dimensions are in inches (mm)

3.31

(84)

3.94

(100)

18

3.31

(84)

3.94

(100)

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 19

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Troubleshooting Guide

Problem Possible Reason Solution

Display will not light up No 24 volts power supply Check if the wiring is connected according to

Unit will not, or not correctly respond to

given setpoint

Display shows NoP. Unit detects that required output pressure is

Unit behavior is not considered normal Faulty settings made in the parameters Reset the unit to factory settings by using the

Desired pressure can not be reached Setpoint value to low

Wrong current applied ( I.e. Volt instead of

mA or mA instead of Volt

Setpoint signal is not stable enough Stabilize setpoint signal input

higher than the supplied pressure

No inlet pressure at all Connect port 1 to the supply pressure

the schematic wiring diagram

Change setpoint current or re configure the

setpoint current through the software by

changing parameter 4

Check wiring if the setpoint signal lead is

connected to the right pin within the male

M12 connector ( should be pin 2)

Adjust the inlet pressure to a higher value,

preferably 0,5 bar higher than requested

output pressure

Give lower setpoint value which corresponds

to a output pressure lower than the inlet

pressure

green key function under parameter 0

Increase setpoint value

Pre-set pressure limit has been changed to a

lower max. outlet pressure

Supply pressure is to low Increase supply pressure

Secondary side stays pressurized Setpoint value is higher than 0,1 Volt

Pre-set pressure has been enabled to a

certain pressure

Display shows unrealistic value Display maybe configured in the wrong value

( bar instead of psi)

Unit response time too slow or too quick Volume behind the unit is either too big or

too small

Unit gives too much overshoot Relation between volume and response me

is out of balance

Unit is adjusting/regulating constantly Air leakage in the system behind the unit

Constant changing volume behind the unit

“Deadband “area is set too small

Can not enter software through touchpad Unit is currently working/processing Make sure that the unit is in steady state

Activating time is too short Hold the accept button for at least 3 seconds

Display indicates ‘OL’ Wiring not according to diagram (24 volt con-

nected on the setpoint connection pin)

Wrong setpoint value given in relation to

programmed setpoint value acceptance

Any other problem Please consult factory

Change max. outlet pressure back to required pressure by changing parameter 19

Lower your setpoint value, preferably to 0

Volts

Reset parameter 18 to 0

Check through parameter 14, if the display

value is set on either psi or bar, if necessary

change it to the required setting

Adjust the regulating speed of the unit

through parameter 20

Adjust response time to a higher value

through parameter 20, to achieve more accurate behavior

Resolve leakage

Unit needs to regulate to keep required pres-

sure at the same level

Try to minimize the volume changes

Enlarge deadband setting through parameter

13 in the software ( parameter 20 has to be

set to 0 before changing parameter 13)

while activating the software

Rewire so that on the setpoint connection pin

will be either 0-10v or 4-20mA

Change over setpoint value to either V or mA

or Reprogram the unit to the correct setpoint

value via parameter 4

19

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Page 20

ER09 / ER19 Electronic Proportional Regulators FRL-SIF-621

Glossary

Hysteresis – The mechanical limits of accuracy of

the unit. The regulator cannot be adjusted within the

inherent mechanical limits of the design.

Dead Band – The minimum limit of accuracy at which

the regulator is set for normal operation. This band

must be equal to, or exceed, the inherent design limits

of the regulator or the hysteresis band.

Proportional Band – The band used for setting

reaction sensitivity of the regulator. The regulator

senses the excursion from the set pressure and adjusts

response in relation to the degree of excursion beyond

the dead band. This band must exceed the dead band

of the unit.

Proportional Effect – The speed at which the unit

approaches P2 (secondary pressure).

Sensitivity –

The smallest change in the control signal,

or feedback signal, to cause a change in regulated

output pressure.

Repeatability –

a measurement of how consistently

the unit can reproduce an output pressure in relation

to a specific set pressure.

Linearity –

A measure of how closely the relationship

of output pressure vs. the control signal deviates from

a straight line function.

PNP Output –

Referred to as a “Sourcing” open

collector transistor output where the voltage sources

towards 24VDC when activated.

NPN Output –

Referred to as a “Sinking” open

collector transistor output. The output sinks towards

0VDC when activated.

Safety Guide

For more complete information on recommended application

guidelines, see the Safety Guide section of Pneumatic Division

catalogs or you can download the Pneumatic Division Safety

Guide at: www.wilkersoncorp.com

20

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Loading...

Loading...