Page 1

Pneumatic Division

3

2

1

4

!

!

!

Richland, Michigan 49083

269-629-5000

Installation & Service Instructions

2R210

40mm & 60mm

Proportional Regulator

ISSUED: September, 2008

Supersedes: May, 2005

Doc. # 2R210, EN #080690, Rev 2

WARNING

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnectairsupplyanddepressurizeallairlinesconnectedtothis

product before installation, servicing, or conversion.

• Operate within the manufacturer’sspecied pressure,temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Serviceaccordingtoprocedureslistedintheseinstructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• Afterinstallation,servicing,orconversion,airandelectricalsupplies

(when necessary) should beconnected andthe producttested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warningsandspecicationsontheproductshouldnotbecoveredby

paint, etc. If masking is not possible, contact your local representative

for replacement labels.

WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

at all times (parameter 14).

Mounting Position: Preferably vertical, with the cable gland on

top.

Electronics

Supply Voltage: ................................................24 VDC +/- 10%

Power Consumption: .......................................................1.1 W

Current Consumption: .................... Max. 200 mA with no load

Control Signals: The electronic pressure regulator can be

externally controlled through an analog control signal of 0-10 V,

adjustable to 4-20 mA via parameter 4.

Connections: .............................. Central M12 connector 4-pole

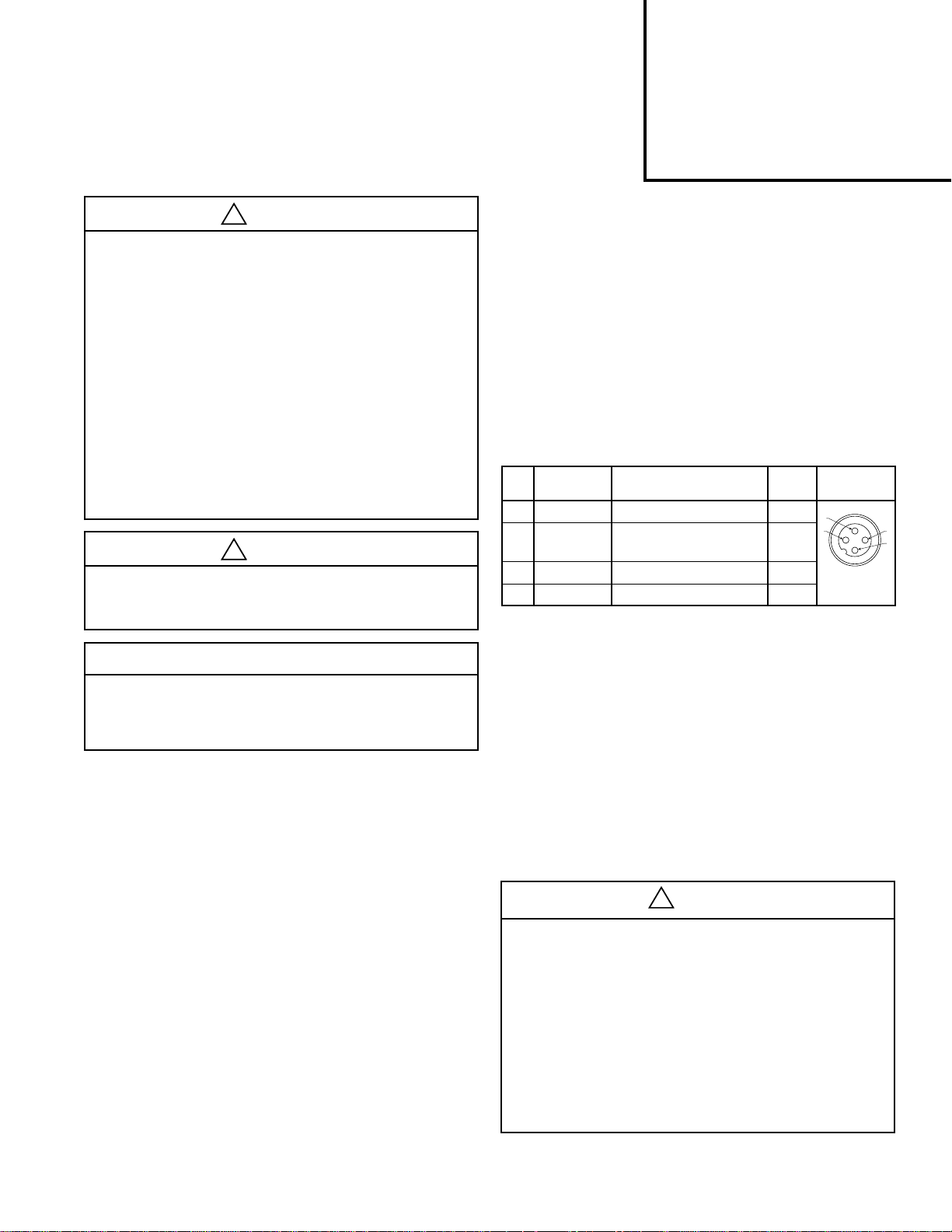

The electrical connections are as follows:

Pin

Function Description Color

No.

1 24 V Supply Brown

0 to 10 V or

2

4 to 20mA

3 0 V (GND) Supply Blue

4 24 V Alarm Output Signal Black

Control Signal Ri = 100k

W White

Do not exceed maximum primary pressure rating.

Dead Band: The dead band is preset at 1.3% F.S.*, adjustable

via parameter 13.

as indicated on the label, can be changed through the software

Safety Guide

For more complete information on recommended application

guidelines, see the Safety Guide section of Pneumatic Division

catalogs or you can download the Pneumatic Division Safety

Guide at: www.parker.com/safety

Introduction

Follow these instructions when installing, operating, or servicing

the product.

Technical Information

These products are intended for use in general purpose

Accuracy: .............................................Linearity: = < 0.3% F.S.*

Proportional Band: The proportional band is preset at 10% F.S.*

Fail-safe Operation: After interrupting the power supply voltage,

the present output pressure is maintained at approximately

the same level. After switching the power supply on again, the

pressure can be adjusted immediately by giving a new control

signal.

Full Exhaust:

Complete exhaust of the regulator is defined as

P2 ≤ 1% F.S.*

Degree of Protection: .........................................................IP65

* Full Scale

compressed air systems only.

Pneumatics

Working Media: Compressed air or inert gasses, filtered to 40µ.

Operating Pressure:

Max. Operating Pressure ...... 2 bar unit ............. 3 bar (43.5 PSI)

10 bar unit ...... 10.5 bar (152 PSI)

Min. Operating Pressure .......... P2 Pressure + 0.5 bar (7.3 PSI)

Pressure Control Range: Available in two pressure ranges,

0-2 bar (0-29 PSI) or 0-10 bar (0-145 PSI). Pressure range can be

changed through the software at all times. (parameter 19)

Temperature Range: .....................32°F to 122°F (0°C to 50°C)

Weight: ............................................................................10 oz.

Air Consumption: No consumption in stable regulated situation.

Display: The regulator is provided with a digital display, indicating

the output pressure, either in PSI or bar. The factory setting is

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS

CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its

subsidiaries and authorized distributors provide product and/or system options

for further investigation by users having technical expertise. It is important

that you analyze all aspects of your application, including consequences of

any failure and review the information concerning the product or systems

in the current product catalog. Due to the variety of operating conditions

and applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance, safety and warning

requirements of the application are met.

The products described herein, including without limitation, product features,

specifications, designs, availability and pricing, are subject to change by Parker

Hannifin Corporation and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR INCLUSION

IN EQUIPMENT / MAINTENA NCE MANUALS THAT UTILIZE THESE PRODUCTS.

CONTACT YOUR LOCAL REPRESENTATIVE.

WARNING

Page 2

40mm & 60mm Proportional Regulator 2R210

or

or

or

or

Installation

1. Place muffler in Port 3

2. Connect the device to the Air Supply Port 1 and 2.

3. Connect Female M12 Connector on the Male Connector of

the device.

4. Apply 24V = (10 second time delay for initialization of

unit).

5. Air Supply to Port 1.

6. Give desired Set Point Signal.

7. Secondary Pressure will now be displayed.

How to Change Parameters

Pressing the Accept key for 3 to 6 seconds, will activate parameter

change mode. The user can then select the parameters by pressing

up or down key (display will show Pxx). When parameter number is

correct, pressing accept again will enter parameter number (display

will show parameter value).

Pressing the up or down key will change the parameter itself

(display will flash indicating parameter editing mode). Pressing

the accept key will accept the new parameter value (all digits will

flash while being accepted).

After releasing all keys, the next parameter number will be

presented on the display (you may step to the next parameter).

When no key is pressed, after 3 seconds the display will show

the actual output pressure.

Only parameter numbers 0, 4, 9, 14, 18, 19, 20, 12, 13, and 21

are accessible to edit. All other parameters are fixed.

Manual Mode

When keys DOWN and UP are pressed during startup,

(connecting to the 24 V pow er supply) man ual mode is activated.

This means that the user is able to in/decrease the output

pressure of the regulator, by pressing the UP or DOWN key.

During this action the display will blink, indicating that the manual

mode is activated.

Back to Factory Setting

After start up. (Power is on)

Parameter 0 = 3

Entering this value in parameter 0 will store the calibrated factory data into the working parameters. (Default calibration data is

used)

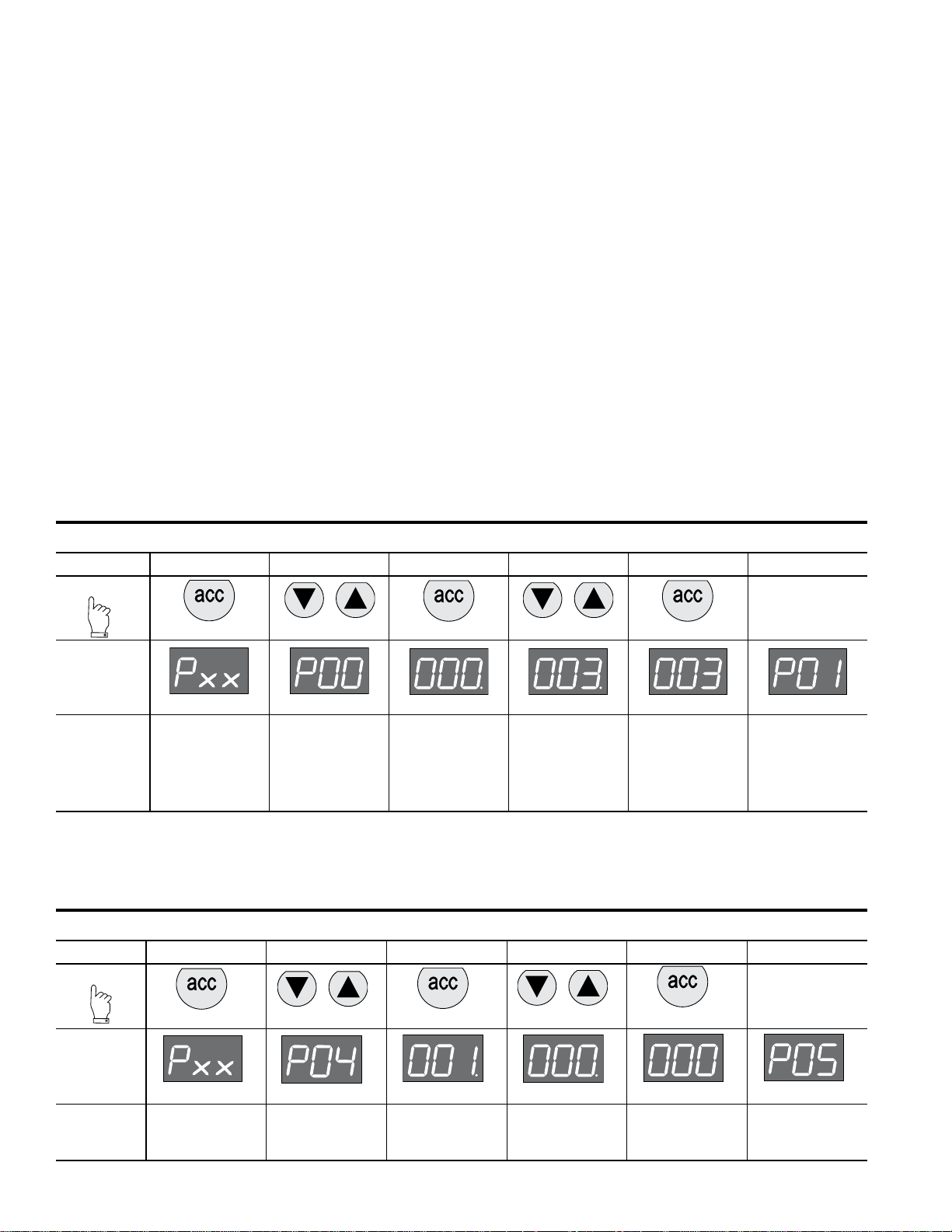

Parameter Number 0 – Reset Back to Factory Settings

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Flashing Decimal Flashing Decimal Flashing

Description

Accesses

changeable

parameters.

Accesses

parameter no. 0.

Displays current

parameter value.

Edits parameter.

3 = standard

factory settings. If

other than 3, use

Up or Down

Arrow and accept 3

Accepts and saves

new parameter

setting.

Set Control Signal

The unit is factory set for 0-10 V control signal. If 4-20 mA control signal is required, change parameter 4.

Parameter Number 4 – Set Control Signal in Volts or Milliamps

Step 1 2 3 4 5

Press

Sequences to next

parameter.

Until

Display

Reads

Description

3-6 seconds

Accesses

changeable

parameters.

Accesses

parameter no. 4.

Flashing Decimal Flashing Decimal Flashing

Displays current

parameter value.

1 = V, 0 = mA

Edits parameter.

Accepts and saves

new parameter

setting.

2

Sequences to next

parameter.

Page 3

40mm & 60mm Proportional Regulator 2R210

or

or

or

or

or

or

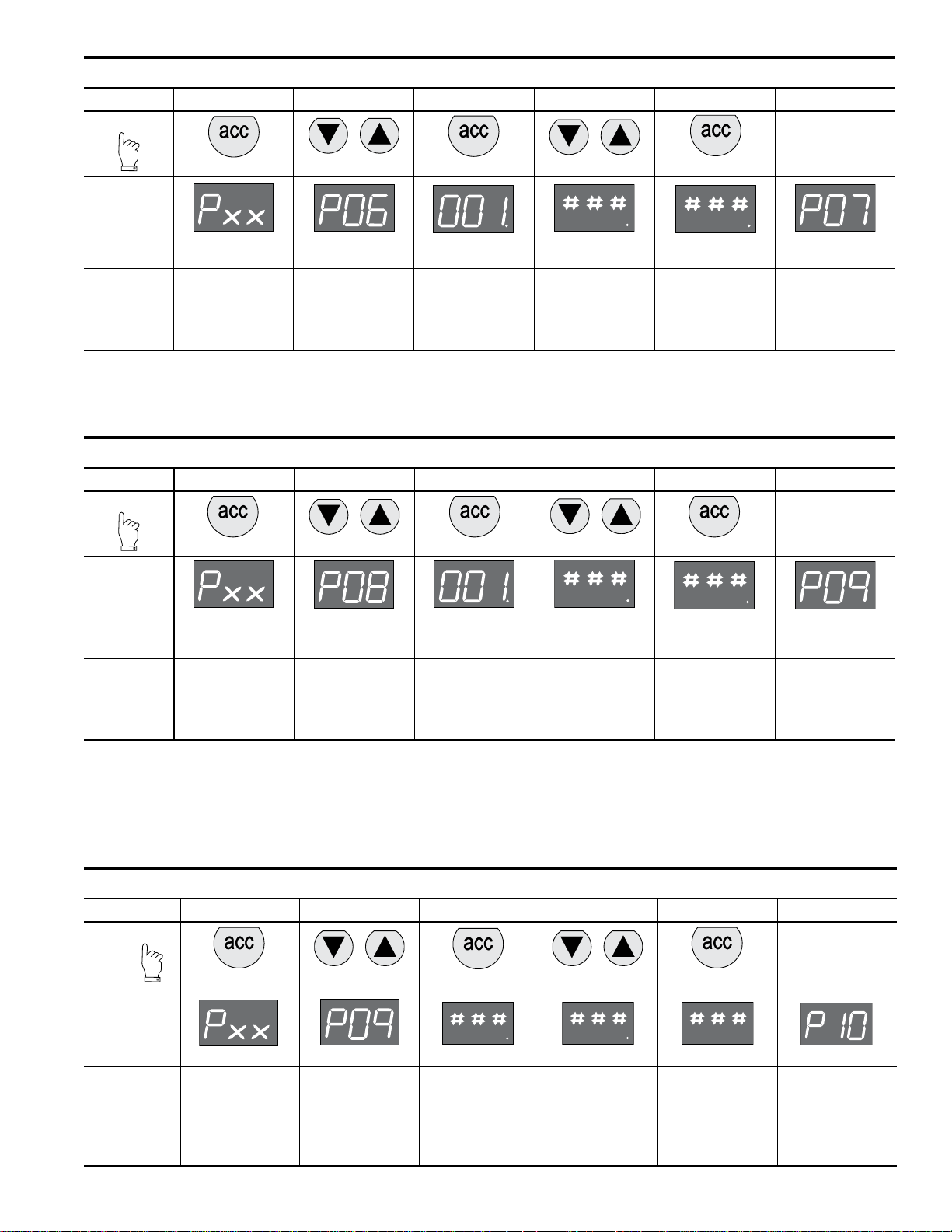

Parameter Number 6 – Set Output Signal

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 6.

Flashing Decimal

Displays current

parameter value.

1 = m factory

default for P3H with

analog options

Flashing Decimal

(Value 0, 1 or 2) Flashing

Edits parameter.

0 = digital

(NPN or PNP)

1 = analog 0..10V

2 = analog 4..20 mA

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Parameter Number 8 – Adjust Span Analog Output Signal

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 8.

Flashing Decimal

(For 2 bar versions

value = 92)

Displays current

parameter value. Edits parameter.

Flashing Decimal

(Value between

0 and 130) Flashing

Accepts and saves

new parameter

setting and

implements the new

analog signal span.

Sequences to next

parameter.

Adjust Digital Display

If necessary, adjustments can be made to the digital display when using an external pressure sensor.

ParameterNumber9–AdjustDigitalDisplayValue(PressureCalibration)

Step 1 2 3 4 5

Press

3-6 seconds

Until Display

Description

Reads

Accesses

changeable

parameters.

Accesses

parameter no. 9.

Flashing Decimal Flashing Decimal Flashing

Use up or down

arrows and accept

to adjust the

Displays current

digital display

display value if

using an external

pressure sensor.

Accepts and saves

new parameter

setting.

3

Sequences to next

parameter.

Page 4

40mm & 60mm Proportional Regulator 2R210

or

or

or

or

or

or

Set Pressure Scale

Units with NPT port threads are supplied with a factory set PSI pressure scale. Use parameter 14 to change scale to bar.

Parameter Number 14 – Set Pressure Scale in PSI or bar

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Flashing Decimal Flashing Decimal Flashing

Description

Accesses

changeable

parameters.

Accesses

parameter no. 14.

Displays current

parameter value.

1 = PSI, 0 = bar

Edits parameter.

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Preset Minimum Pressure

If there is a need for a pre-set minimum pressure, use parameter 18. (Note: preset pressure is affected by % P19.)

Parameter Number 18 – Set Minimum Preset Pressure

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no.

18.

Flashing Decimal

Displays current

Incremental value is:

2 bar unit: x 2 mbar x % P19

10 bar unit: x 10 mbar x % P19

parameter value.

Flashing Decimal

(value between

0 and 200)

Edits parameter.

Flashing

Accepts and

saves new

parameter

setting.

Sequences to

next parameter.

Set Pressure Correction

Pressure correction allows the user to set a maximum pressure as a percentage of secondary pressure F.S.

Example: If F.S. is 10 bar, set parameter 19 to 50 for maximum preset pressure of 5 bar.

Pressure correction also affects the minimum preset pressure in parameter 18.

Example: If F.S. is 10 bar and parameter 18 is set to a value of 100 (1 bar), and parameter 19 is set to 50%, then the actual

minimum preset pressure seen is 0.5 bar.

Parameter Number 19 – Set Maximum Preset Pressure

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 19.

Flashing Decimal

Flashing Decimal

Displays current

parameter value.

Incremental

value is: % of F.S. Edits parameter.

(value between

0 and 100)

4

Flashing

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Page 5

40mm & 60mm Proportional Regulator 2R210

or

or

or

or

Behavior Control

The regulation speed of the pressure regulator can be modified by means of one parameter. (P 20)

The value in this parameter has a range from 0-5. A higher value indicates slower regulation speed, but will be more stable.

Parameter Number 20 – Set Behavior Control

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Flashing Decimal

Description

Accesses

changeable

parameters.

* When the value 0 is entered, you are able to create your own custom settings true parameters 12, 13 and 21.

Accesses

parameter

no. 20.

Displays current

parameter value.

Flashing Decimal

(value between 0

and 5)

Edits parameter

0 = custom set*

1 = fastest (narrow

proportional band)

2 = fast,

3 = normal,

4 = slow,

5 = slowest

(proportional band

is broad)

Flashing

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Fine Settings

Set Proportional Band

Proportional band is used for setting the reaction sensitivity of the regulator. The displayed value is X 10 mbar and has a range

between 50 (0.5 bar) and 250 (2.5 bar).

ParameterNumber12–SetProportionalBand(P20MustbeSetto0)

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 12.

Flashing Decimal

Displays current

parameter value.

Incremental

value is:

x 10 mbar

5

Flashing Decimal

(value between

50 and 250)

Edits parameter.

Flashing

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Page 6

40mm & 60mm Proportional Regulator 2R210

or

or

or

or

or

Set Deadband

Deadband is the minimum limit of accuracy at which the regulator is set for normal operation. The displayed value is X 10 mbar

and has a range between 4 (40 mbar) and 40 (400 mbar).

ParameterNumber13–SetDeadband(P20MustbeSetto0)

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 13.

Flashing Decimal

Displays current

parameter value.

Incremental

value is

x 10 mbar

Flashing Decimal

(value between

4 and 40)

Edits parameter.

Flashing

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Proportional Effect

Sets the speed at which the regulator adjusts either filling or exhausting. The displayed value has a range between 5 (fastest

regulation) and 100 (slowest regulation).

ParameterNumber21–SetProportionalEffect(P20MustbeSetto0)

Step 1 2 3 4 5

Press

3-6 seconds

Until

Display

Reads

Description

Accesses

changeable

parameters.

Accesses

parameter no. 21.

Flashing Decimal

Displays current

parameter value.

Flashing Decimal

(value between

5 and 100)

Edits parameter.

5 = fastest

regulation

100 = slowest

regulation.

Flashing

Accepts and saves

new parameter

setting.

Sequences to next

parameter.

Parameter Number 39 – Displays Current Software Version

Step 1 2 3

Press

3-6 seconds

Until

Display

Reads

Flashing Decimal

Displays current

parameter value.

XXX = current

software version

Description

Accesses

changeable

parameters.

Accesses

parameter no. 39.

6

Page 7

40mm & 60mm Proportional Regulator 2R210

Problem Possible Reason Solution

Display will not light up No 24 volts power supply Check if the wiring is connected according to

the schematic wiring diagram

Unit will not, or not correctly respond to

given setpoint

Display shows NoP. Unit detects that required output pressure

Unit behavior is not considered normal Faulty settings made in the parameters Reset the unit to factory settings by using the

Desired pressure can not be reached Setpoint value to low

Wrong current applied ( I.e. Volt instead of

mA or mA instead of Volt

Setpoint signal is not stable enough Stabilize setpoint signal input

is higher than the supplied pressure

No inlet pressure at all Connect port 1 to the supply pressure

Change setpoint current or re configure the

setpoint current through the software by

changing parameter 4

Check wiring if the setpoint signal lead is

connected to the right pin within the male M12

connector ( should be pin 2)

Adjust the inlet pressure to a higher value,

preferably 0,5 bar higher than requested output

pressure

Give lower setpoint value which corresponds to

a output pressure lower than the inlet pressure

green key function under parameter 0

Increase setpoint value

Pre-set pressure limit has been changed

to a lower max. outlet pressure

Supply pressure is to low Increase supply pressure

Secondary side stays pressurized Setpoint value is higher than 0,1 Volt

Pre-set pressure has been enabled to a

certain pressure

Display shows unrealistic value Display maybe configured in the wrong

value ( bar instead of psi)

Unit response time too slow or too quick Volume behind the unit is either too big or

too small

Unit gives too much overshoot Relation between volume and response

me is out of balance

Unit is adjusting/regulating constantly Air leakage in the system behind the unit

Constant changing volume behind the unit

“Deadband “area is set too small

Can not enter software through touchpad Unit is currently working/processing Make sure that the unit is in steady state while

Activating time is too short Hold the accept button for at least 3 seconds

Display indicates ‘OL’ Wiring not according to diagram (24 volt

connected on the setpoint connection pin)

Wrong setpoint value given in relation to

programmed setpoint value acceptance

Any other problem Please consult factory

Change max. outlet pressure back to required

pressure by changing parameter 19

Lower your setpoint value, preferably to 0 Volts

Reset parameter 18 to 0

Check through parameter 14, if the display

value is set on either psi or bar, if necessary

change it to the required setting

Adjust the regulating speed of the unit through

parameter 20

Adjust response time to a higher value through

parameter 20, to achieve more accurate

behavior

Resolve leakage

Unit needs to regulate to keep required pres-

sure at the same level

Try to minimize the volume changes

Enlarge deadband setting through parameter

13 in the software ( parameter 20 has to be set

to 0 before changing parameter 13)

activating the software

Rewire so that on the setpoint connection pin

will be either 0-10v or 4-20mA

Change over setpoint value to either V or mA

or Reprogram the unit to the correct setpoint

value via parameter 4

7

Page 8

40mm & 60mm Proportional Regulator 2R210

0.55

(14)

4.49

(114)

1.85

(47)

1.18

(30)

1/4 1/4

1/4

Ø 0.87

(22)

0.85

(21.5)

0.08

(2)

0.35

(9)

0.83

(21)

0.83

(21)

Ø 0.22

(5.5)

4 Pin M12 Connector

0.53

(13.5)

0.35

(9)

2.19

(55.5)

80°

4.49

(114)

1.85

(47)

1/4

1/4

1/4

0.59

(15)

1.65

(42)

Ø 0.87

(22)

0.83

(21)

1.83

(46.6)

1/4(3x)

1.65

(42)

21

(0.83)

0.09

(2.3)

DIN-Rail

Clamp

4.49

(114)

Ø 0.87

(22)

0.35

(9)

4 Pin M12 Connector

0.56

(14.3)

6.62

(168.1)

2.46

(62.6)

4.12

(104.6)

2.50

(63.5)

1.18

(30)

2.95

(75)

1.48

(37.5)

1/2” Port

1.18

(30)

2.36

(60)

.59

(15)

.59

(15)

.59

(15)

.98

(25)

1.18

(30)

1.42

(36)

1.77

(45)

.47

(12)

2.20

(56)

1.02

(26)

2.05

(52)

1.57

(40)

2.05

(52)

3.31

(84)

3.94

(100)

Ø .28

(7)

4 Holes

Dimensions

40mm Bottom Exhaust Version

60mm Bottom Exhaust Version

Dimensionsareinmm(Inches)

Dimensionsareinmm(Inches)

Foot Bracket

DIN Rail Bracket

L Bracket

Foot Bracket

8

Loading...

Loading...